Page 1

PNEG-318

Concrete Foundation

Recommendations for

GSI Grain Bins

Instructions Manual

PNEG-318

Date: 06-27-13

Page 2

• “FCDL” Series bins

• 4.00" (“W”) Series farm bins

• 2.66" (“N”) Series farm bins

• Inside stiffened commercial tanks

• Outside stiffened commercial tanks

• Commercial hopper tanks

2PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................5

Chapter 2 General Foundation Requirements for GSI Bins ...............................................................................8

Requirements ................................... ............................................. ........................................................ 8

Selecting the Proper Site ...................................................................................................................... 8

Scribe the Diameter ............................................................................................................................... 8

Prepare the Foundation Forms ............................................................................................................. 9

Vane Axial Fan Pad ............................................................................................................................ 11

Centrifugal Fan Pad ............................................... ... .......................................................................... 12

Anchor Bolt Placement ........................................................................................................................ 13

FCDL Anchor Bolt Detail ..................................................................................................................... 14

Commercial Tank Anchor Bolt Detail .................................................................................................. 14

Outside Bin Hold-Down Details (Unstiffened 2.66" Corrugation) ........................................................ 15

Outside Bin Hold-Down Details (Unstiffened 4.00" Corrugation) ........................................................ 16

Chapter 3 FCDL Series Anchor Bolt Charts ......................................................................................................18

Chapter 4 Monolithic Pad FCDL .............................................. .... ... ... ... ..............................................................22

Floating Monolithic Pad for GSI FCDL Bins up to 5 Rings ......... ................................................ ......... 22

Chapter 5 Frost Free Pad FCDL ..........................................................................................................................24

Anchor Bolt Placement ........................................................................................................................ 24

Frost Free Pad (FCDL Bins) .................. ... ... .... ... ... ... .... ... ................................................................... 26

Chapter 6 Inverted “T” FCDL ..............................................................................................................................30

3000 PSF Soil Bearing Capacity ......................................................................................................... 30

Chapter 7 Monolithic Pad 4.00" Farm Bin ................................................ ... ... ... ... .... ... ... ... .... ... ... .......................34

Floating Monolithic Pad for Unstiffened GSI Bins up to 5 Rings (4.00" Corrugation) ....... .......... ......... 34

Chapter 8 Frost Free Pad Unstiffened 4.00" Farm Bin . ... ... ... .... .......................................................................36

Outside Bin Hold-Down Charts (4.00" Corrugation) ............................................................................ 36

Chapter 9 Monolithic Pad 2.66" Farm Bin ................................................ ... ... ... ... .... ... ... ... .... ... ... .......................42

Floating Monolithic Pad for Unstiffened GSI Bins up to 7 Rings (2.66" Corrugation) ....... .......... ......... 42

Chapter 10 Frost Free Pad Unstiffened 2.66" Farm Bin ...................................................................................44

Outside Bin Hold-Down Chart (2.66" Corrugation) ......................... ... ... .... ... ... ................................... 44

Chapter 11 Frost Free Pad Commercial Tank ...................................................................................................50

Chapter 12 Inverted “T” Foundation 2.66" Outside Stiffened Commercial Tanks .................................. ....... 56

3000 PSF Soil Bearing Capacity .......................................... .... ... ... ... ... .... ... ... ... .... ... ......................... 56

3500 PSF Soil Bearing Capacity .......................................... .... ... ... ... ... .... ... ... ... .... ... ......................... 65

4000 PSF Soil Bearing Capacity .......................................... .... ... ... ... ... .... ... ... ... .... ... ......................... 74

Chapter 13 T-Cap Foundation 2.66" Outside Stiffened Commercial Tanks ...................................................84

Chapter 14 Outside Universal Stiffened Anchor Bolt Charts ..........................................................................90

Outside Universal Stiffened Anchor Bolt Charts 2.66" Corrugation Commercial Tanks .................... 90

Chapter 15 Inverted “T” Foundation 4" Outside Stiffened (WCL Series) Commercial Tanks ......................98

3000 PSF Soil Bearing Capacity .......................................... .... ... ... ... ... .... ... ... ... .... ... ......................... 98

3500 PSF Soil Bearing Capacity .......................................... .... ... ... ... ... .... ... ... ... .... ... ....................... 103

4000 PSF Soil Bearing Capacity .......................................... .... ... ... ... ... .... ... ... ... .... ... ....................... 108

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 3

Page 4

Table of Contents

Chapter 16 WC Series Outside Universal Stiffened Anchor Bolt Charts ......................................................114

WC Series Outside Universal Stiffened Anchor Bolt Charts 4" Corrugation Commercial Tanks ..... 114

Chapter 17 Concrete Foundation Commercial Hopper Tanks .......................................................................124

12' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 124

12' Diameter Commercial Hopper Tank Foundation for 13-17 Rings .............................................. 125

15' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 126

15' Diameter Commercial Hopper Tank Foundation for 13-17 Rings .............................................. 127

18' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 128

18' Diameter Commercial Hopper Tank Foundation for 13-19 Rings .............................................. 129

21' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 130

21' Diameter Commercial Hopper Tank Foundation for 13-19 Rings .............................................. 131

24' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 132

24' Diameter Commercial Hopper Tank Foundation for 13-19 Rings .............................................. 133

27' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 134

27' Diameter Commercial Hopper Tank Foundation for 13-19 Rings .............................................. 135

30' Diameter Commercial Hopper Tank Foundation up to 12 Rings ............................................... 136

30' Diameter Commercial Hopper Tank Foundation for 13-19 Rings .............................................. 137

36' Diameter Commercial Hopper Tank Foundation up to 18 Rings ............................................... 138

36' Diameter Commercial Hopper Tank Foundation for 19-22 Rings .............................................. 140

Chapter 18 Frost Free Foundation 4.00" FCHT Hopper Tanks ......................................................................144

18' Diameter FCHT Hopper Tank Foundation .................................... ............................................. 144

21' Diameter FCHT Hopper Tank Foundation .................................... ............................................. 145

24' Diameter FCHT Hopper Tank Foundation .................................... ............................................. 146

Chapter 19 Commercial Tank Foundation Tunnels ........................................................................................148

4 x 4 Tunnels ................................................................................................................................... 148

6' Wide Tunnels ............................................................................................................................... 155

Chapter 20 Foundation Recommendations BFT/GHT Series ........................................................................160

Chapter 21 Warranty ..........................................................................................................................................179

4 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 5

1. Introduction

ATTENTION: READ BEFORE USING THIS MANUAL

All instructions should be construed as recommendations only. Because actual installation will vary

according to local conditions, The GSI Group, Inc. assumes no liability for the results arising from the use

of such recommendations.

Always make sure to use the correct tables and charts for the bin and soil conditions at building site.

Determine the following before using this manual:

Bin Style

1. FCDL Series

2. “W” Series farm bin (4.00" corrugation)

3. “N” Series farm bin (2.66" corrugation)

4. NCL Inside stiffened commercial tanks

5. NCL Outside stiffened commercial tanks

6. WCL Outside stiffened commercial tanks

7. Commercial hopper tanks

8. BFT/GHT Unstiffened hopper tanks

Foundation Style

1. Floating monolithic pad

2. Frost free pad

3. Inverted “T” foundation or T-Cap

In-Foundation Aeration Systems

1. Tunnel sizing and forming

2. Transition opening requirements

If a foundation for the bin height is not provided, always use the foundation for the next taller tank.

NOTE: A “frost free” pad does not mean the foundation will not shift or be damaged by freezing and

thawing. It is only a term used by GSI to describe that foundation. Always use the inverted

“T” foundation for frost-susceptible soils.

GSI Engineering also has recommendations available for the following foundation options:

1. Hopper cones

2. Tunnels

3. Seismic specifications

4. In-foundation aeration system

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 5

Page 6

1. Introduction

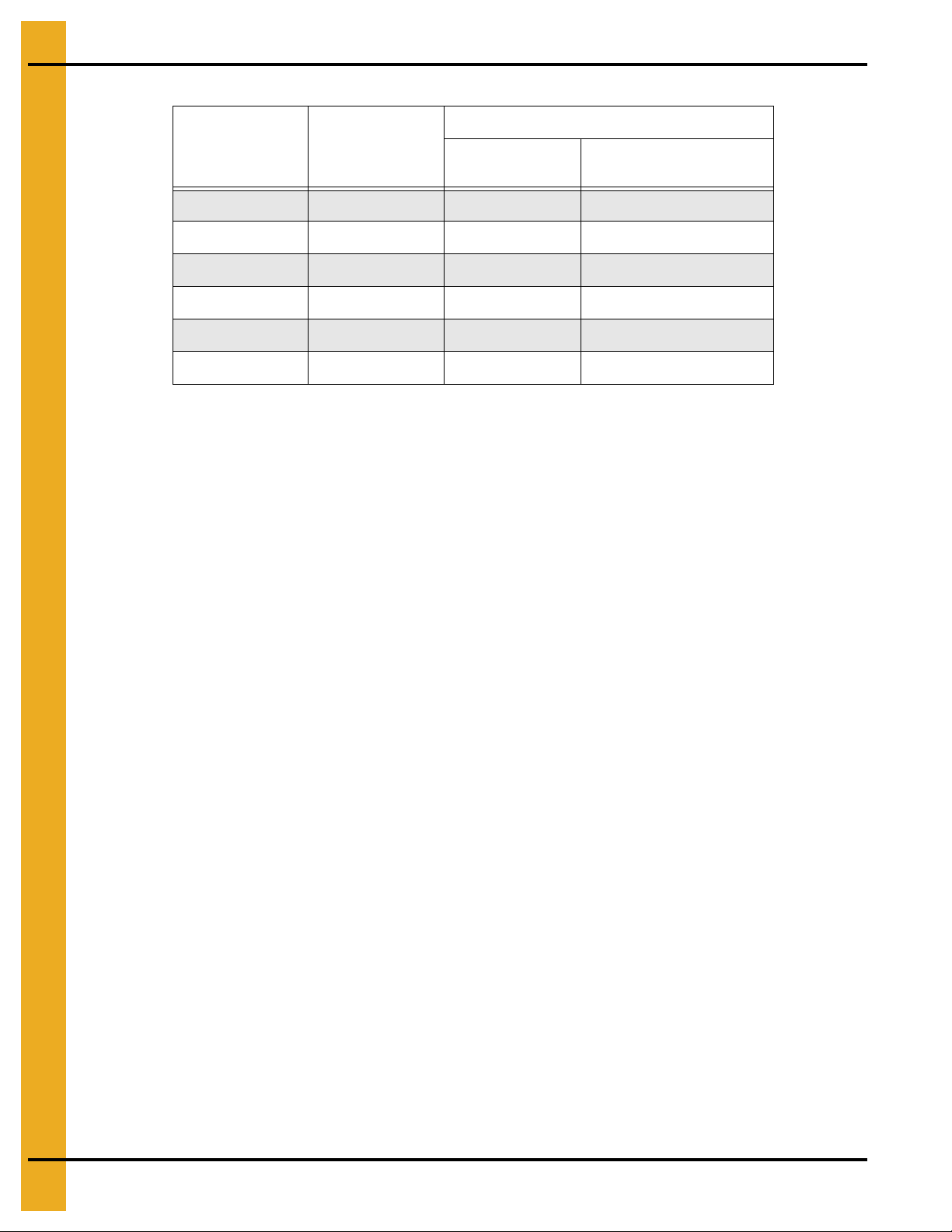

Reinforcement Bar Properties

Standard Nominal Dimensions

Bar Designation

Number

3 0.367 3/8" (9) 0.110

4 0.668 1/2" (13) 0.200

5 1.043 1-5/8" (16) 0.310

6 1.502 3/4" (19) 0.440

7 2.044 7/8" (22) 0.600

8 2.670 1" (25) 0.790

NOTES: Lap all circumferential bars 35 diameters and stagger all laps in plan 3' 0".

All reinforcement bar estimates do not include end laps.

Weight

per Foot (lb.)

Diameter

in. (mm.)

Cross Sectional

Area (sq. in.)

6PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 7

General Foundation

Requirements for GSI Bins

®

Section 02

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 7

Page 8

2. General Foundation Requirements for GSI Bins

Requirements

The following construction related notes pertain to the installation of farm bin foundations.

Selecting the Proper Site

The selected site should be level, firm and free from underlying debris. The bin can be installed

satisfactorily on slopes, but as the slope increases, additional labor and materials are required for the

foundation. The concrete foundation surface must be level. If some fill is required, it should be watered

and tamped thoroughly to prevent uneven settling from the weight of the bin. Naturally, the site must allo w

convenient access for easy loading and unloading, plus provide additional space for future units. Also

consider the positioning of handling equipment, availability of electricity and placement of fans, heaters

and gas tanks.

All foundation specifications should be construed as recommendations only. Because of the many

variable conditions in actual installation, GSI assumes no liability for results arising from the use of

such recommendations.

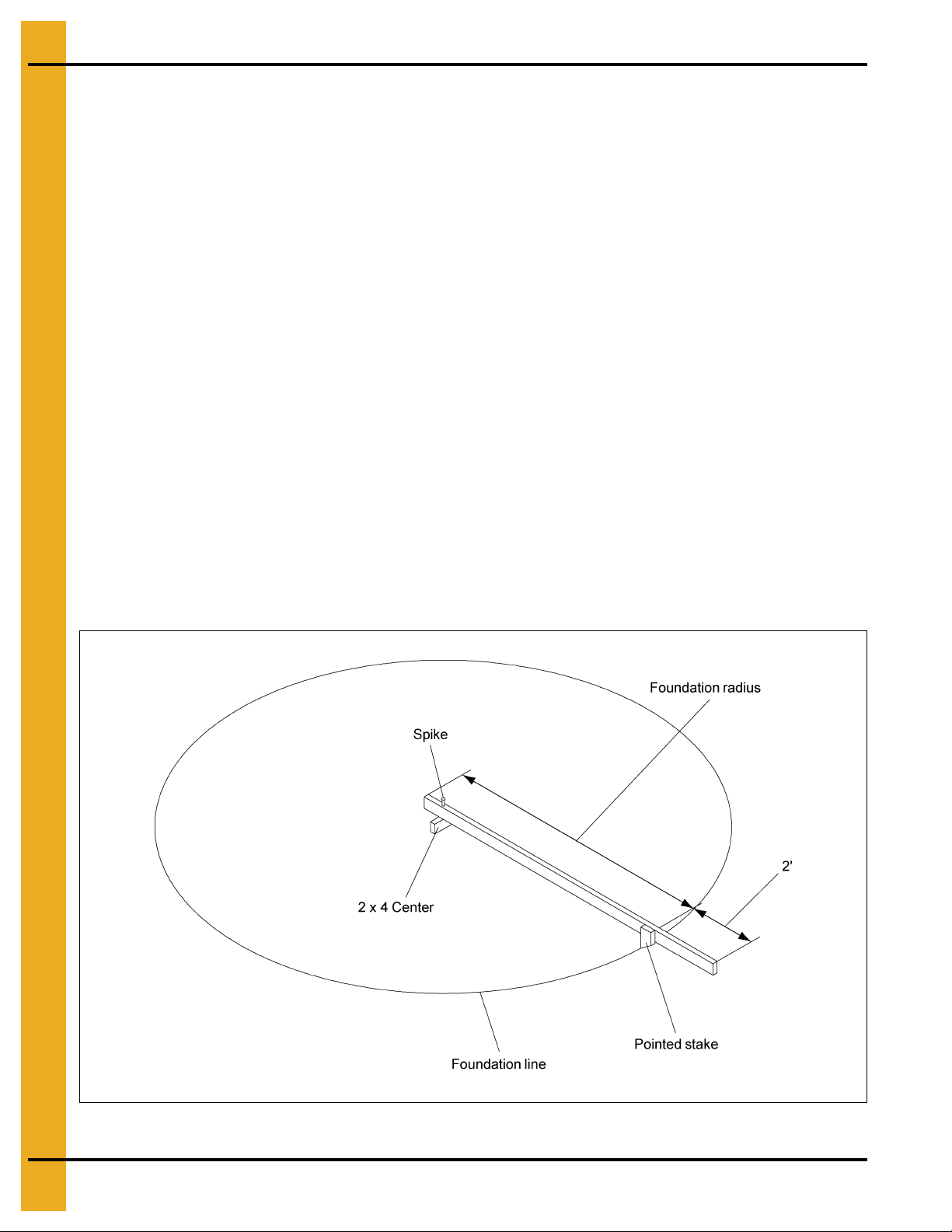

Scribe the Diameter (See Figure 2A.)

After determining the center of the site, drive a small 2 x 4 in the ground to mark the center point of the

foundation. The top of the stake should be the same height as the finished foundation will be. Using one

large spike, nail a straight 2 x 4 (approximately 2' longer than the radius of the bin) to the top of the center

stake. The swiveling 2 x 4 will act as a compass, enabling you to scribe the correct diameter of the

foundation and later locate the anchor and stiffener bolt locations. (NOTE: Making the 2 x 4 two feet (2')

longer than the radius will allow the 2 x 4 to also be used as a leveling device and for pulling concrete.)

Figure 2A Scribe the Diameter

8PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 9

2. General Foundation Requirements for GSI Bins

Carpenter’s level

Footing trench

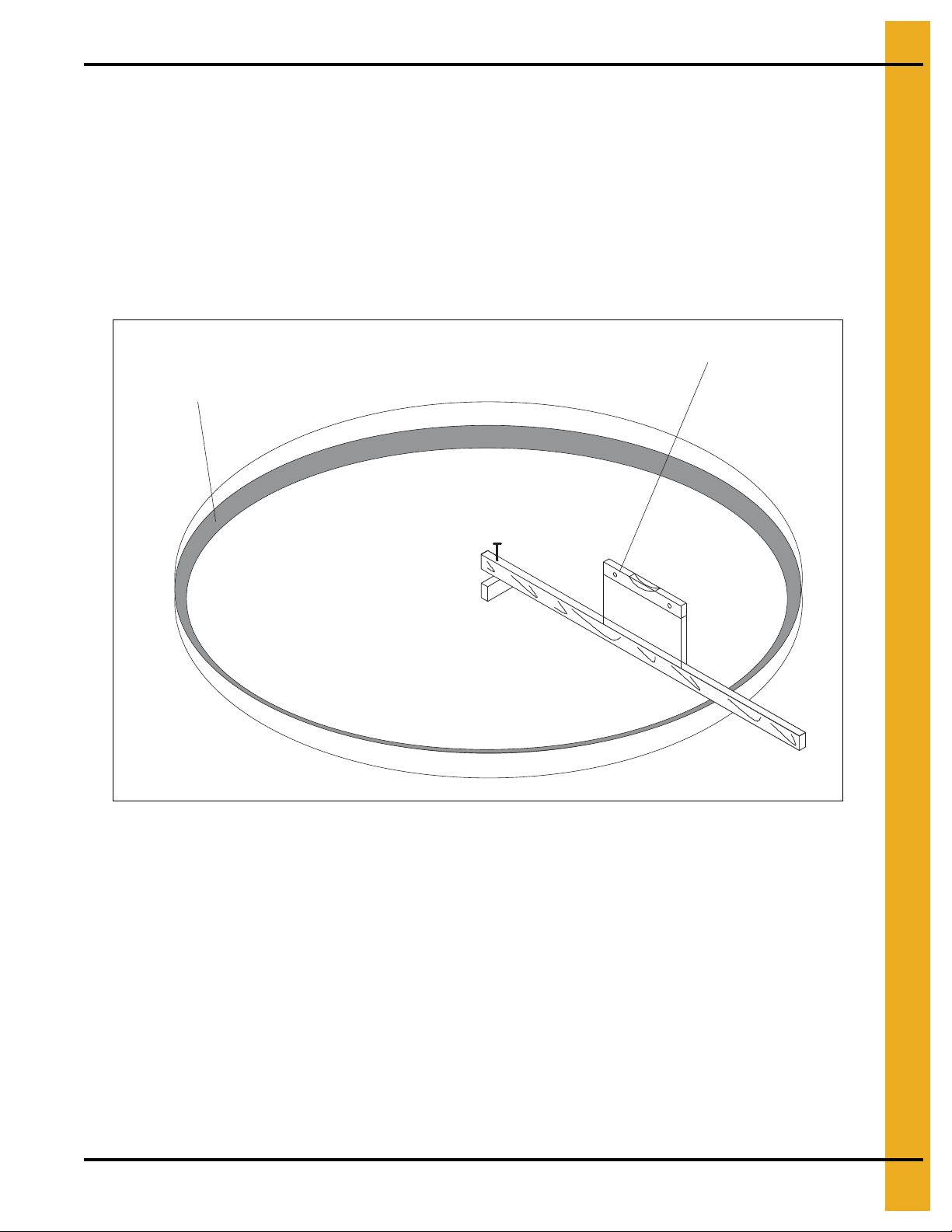

Prepare the Foundation Forms

After scribing the diameter of the foundation, proceed by digging the foundation’s footing. This consists of

a large circular trench dug just inside the foundation line. (Refer to foundation details (frost free pad,

inverted “T” and T-Cap) of corresponding bins and tanks in this manual for necessary information.) Once

the footing has been dug, you are ready to build the forms. It is most important that the form be rigid enough

to hold its shape against the poured concrete. Also, the foundation must be flat. Sloped floors cannot be

used in drying bins. A carpenter’s level placed atop the compass 2 x 4 will enable you to set the top of the

forms to match the top of the center stake.

a uniform elevation for the entire foundation. The foundation should be level within 1/8" on non-stiffened

tanks and 1/4" on stiffened tanks at bin wall perimeter. Stiffened tanks must be shimmed level.

(See Figure 2B.)

Check the form work with a transit to ensure

Figure 2B Level the Forms

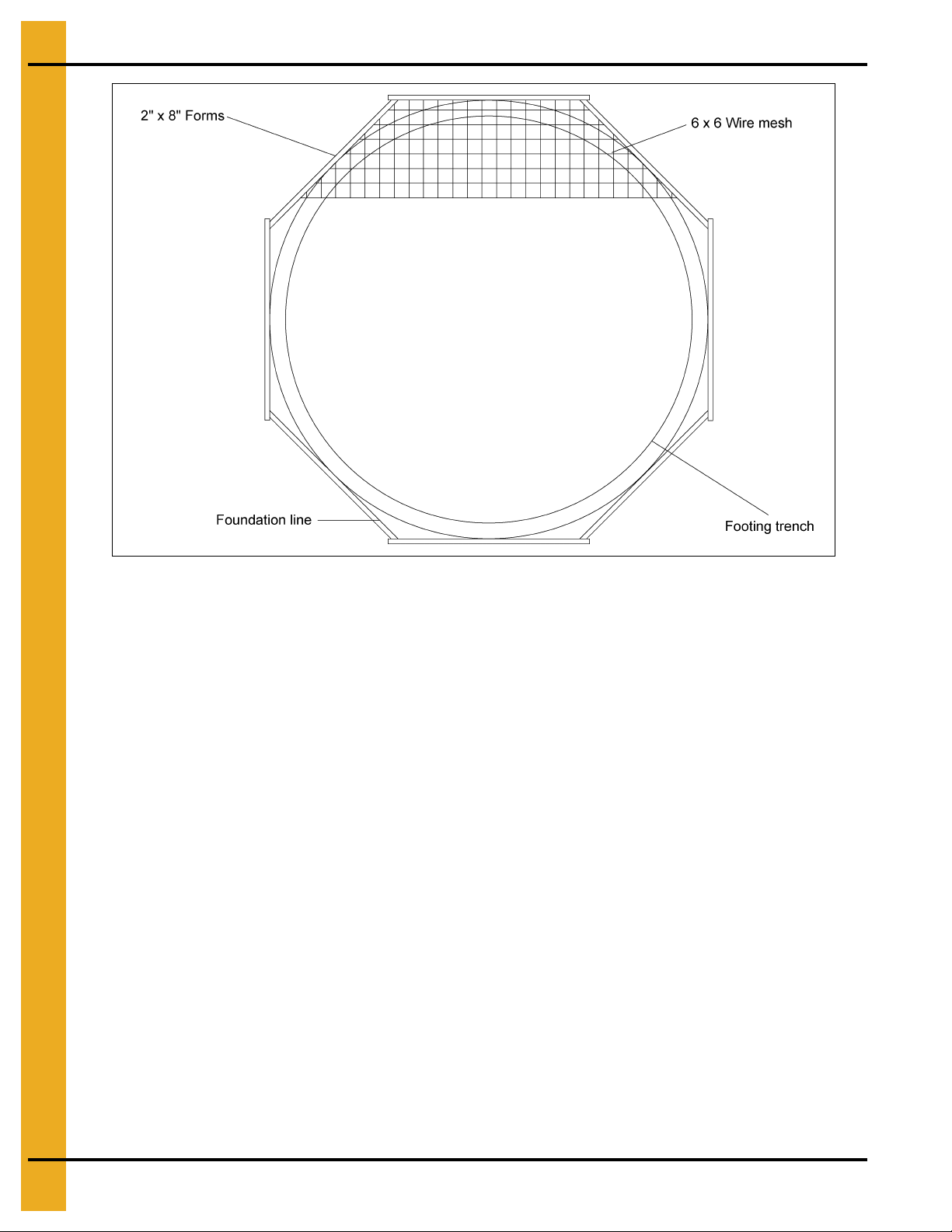

Alternate Foundation Forms

There are two (2) styles of foundation forms commonly used. The first is the circular form shown in

Figure 2B. The second style of foundation can be made of 2" x 8" boards set into a square with the corners

blocked off to form an octagon. (See Figure 2C on Page 10.) This eight (8) sided form will approximate a

circle and can also be constructed easily.

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 9

Page 10

2. General Foundation Requirements for GSI Bins

Figure 2C Alternate Foundation Form

Place the Reinforcement

Once the forms and trench have been prepared, begin the placement of reinforcement rods at various

levels in the foundation’s footing. See the appropriate charts and drawings in this manual for the bin to

determine requirements and positions of the reinforcement. The reinforcement rods offer their greatest

strength when lapped properly and connected by wiring or welding. Next, place a minimum of 2" of

compacted sand on the inside section of the foundation to provide a good base for the concrete and

protect against rodents. The sand should then be covered with 4 mil polyethylene plastic, which will act as

a moisture barrier. Two (2) layers of 6 x 6 wire mesh should then be added to the entire area of the

foundation to complete the preparation of the bin’s foundation.

10 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 11

2. General Foundation Requirements for GSI Bins

TR-4734

A = 20" for fans without heaters

A = 44" for fans with heaters

TR-6918 and TR-6919

A = 32" for fans without heaters

A = 56" for fans with heaters

TR-7048

A = 45" for fans without heaters

A = 69" for fans with heaters

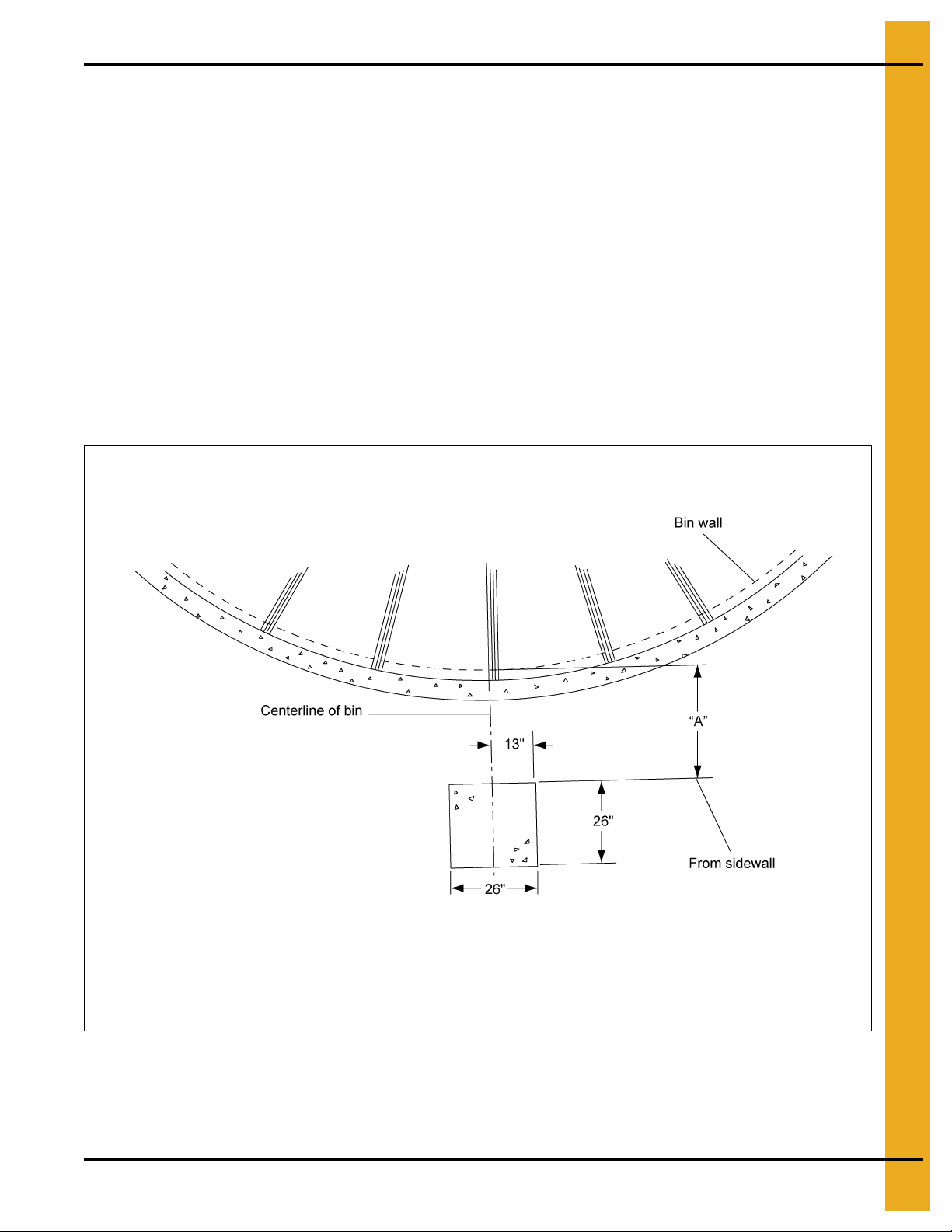

Vane Axial Fan Pad

Placement of the Fan Pad: Transitions/Fans/Heaters Only.

If a fan or fan and heater will be installed, refer to Figure 2D to determine the concrete pad size.

1. The top of this pad should be level with the top of the bin’s foundation.

2. Recommended pad thickness is 4" minimum.

3. Front of pad should be perpendicular to bin wall.

4. Pad for heater not required, but if it is to added, pour the pad to cover both locations.

For fans and transitions used in aeration duct system applications, refer the transition and aeration

installation instructions.

IMPORTANT: Fan pad and fan must be level and smooth for proper operation. Vibration problems can

result from improper fan leveling.

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 11

Figure 2D

Page 12

2. General Foundation Requirements for GSI Bins

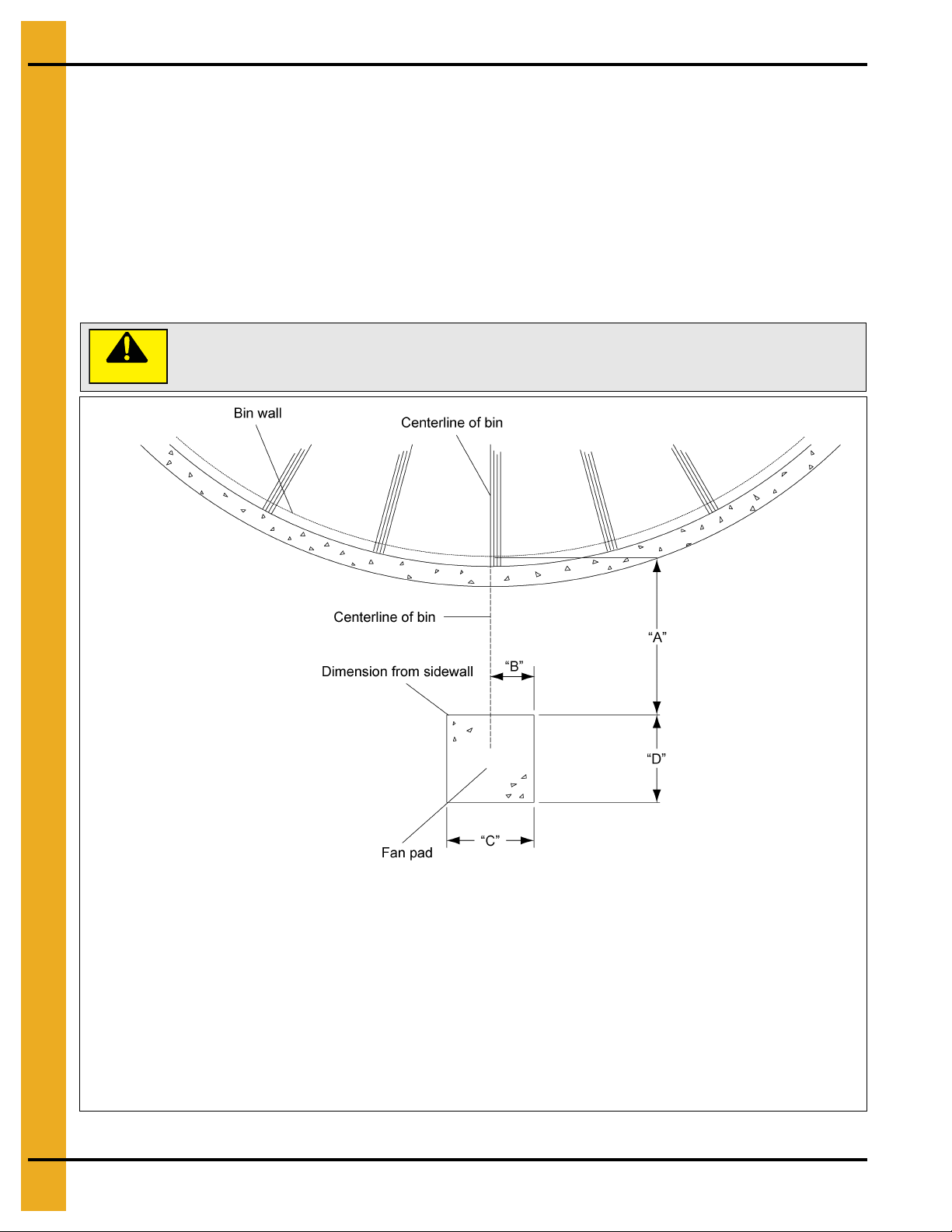

CAUTION

Fan pad and fan must be level and smooth for proper operation. Vibration

problems can result from improper fan leveling.

Front of pad should be perpendicular to bin wall. Recommended thickness for fan pad is

4" minimum. Surface of pad should be 2" below the bin foundation. Pad for heater not required.

TR-4734

A = 20" without heater

A = 44" with heater

B = 10"

C = 40"

D = 40"

TR-7048

A = 45" without heater

A = 69" with heater

B = 10"

C = 40"

D = 48"

TR-6918 and

TR-6919

A = 32" without heater

A = 65" with heater

B = 13"

C = 48"

D = 52"

TR-7049

A = 45" without heater

A = 78" with heater

B = 13"

C = 48"

D = 52"

TR-6207

A = 42" without heater

A = 78" with heater

B = 13"

C = 48"

D = 60"

TR-6958

A = 55" without heater

A = 85" with heater

B = 13"

C = 48"

D = 60"

TR-6853 (Double inlet)

A = 54" without heater

A = 88" with heater

B = 28"

C = 100"

D = 60"

TR-4013

A = 36" without heater

B = 13"

C = 48"

D = 60"

TR-6944

A = 48" without heater

B = 13"

C = 48"

D = 60"

Centrifugal Fan Pad

1. Fan pad should be poured 2" below the top of the bin foundation for all centrifugal fans.

2. A pad for heaters is not required, but is recommended.

3. Recommended pad thickness is 4".

4. If a downwind heater pad is to be installed, the pad width (“C”) should be 48" and extended toward

the bin by 33".

5. Fan discharge should be centered on centerline of bin.

6. The fan pad should be perpendicular to bin wall.

12 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Figure 2E Centrifugal Fan Pad

Page 13

2. General Foundation Requirements for GSI Bins

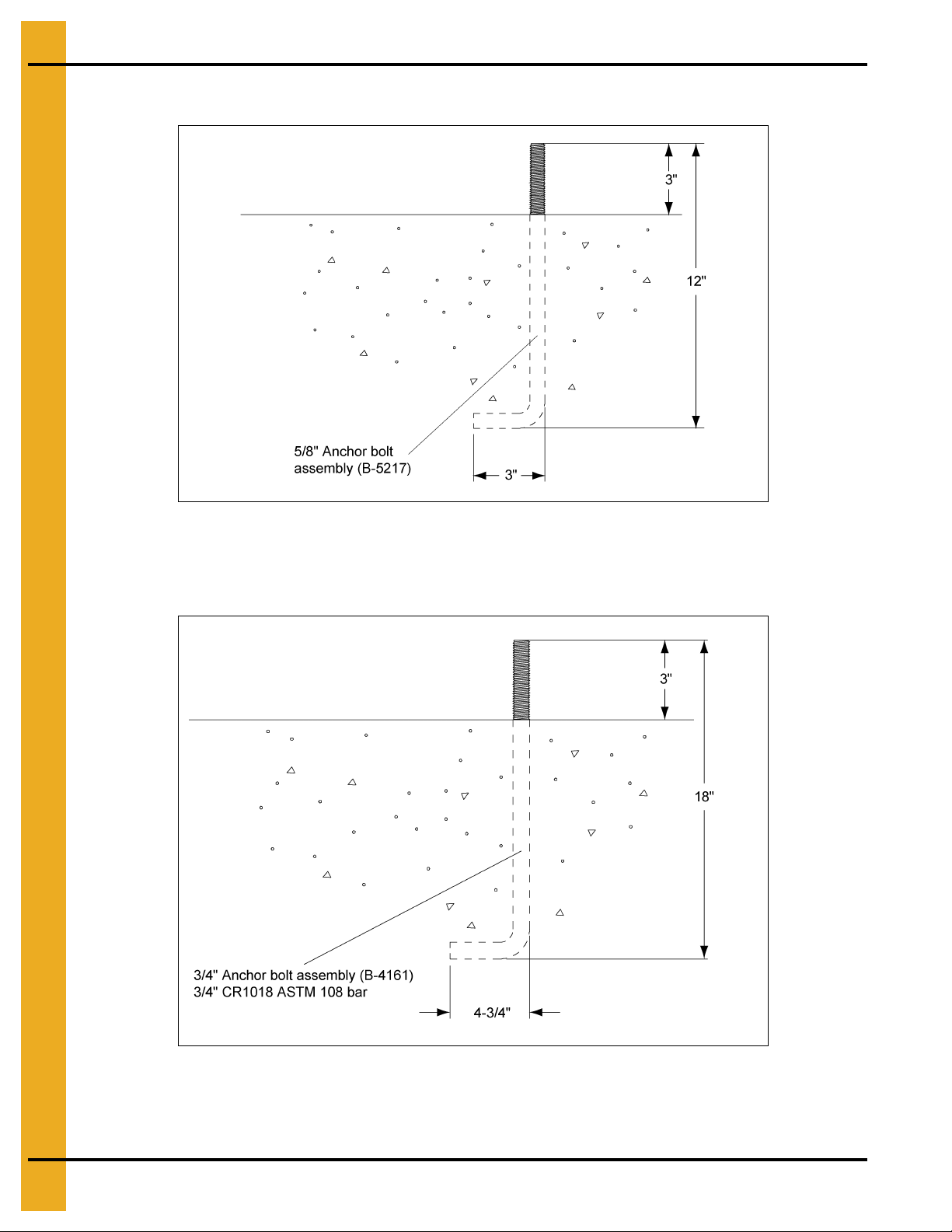

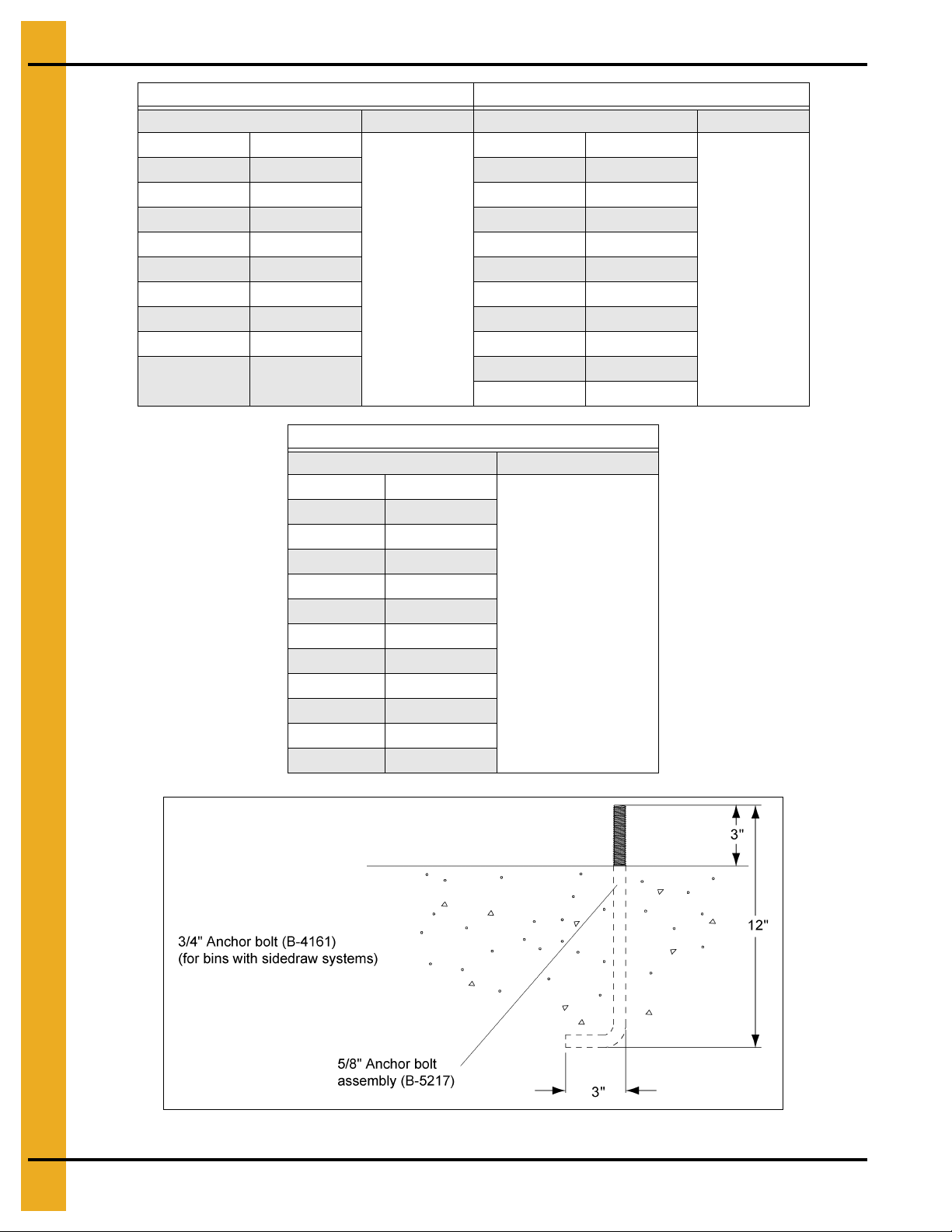

Anchor Bolt Placement

Having poured and leveled the concrete, use the center stake and straight 2 x 4 again to find the bolt circle

radius for the outside hold-down brackets. Select a starting point and stretch a pre-measured chord along

the imaginary circle formed by the bolt circle radius. Take into consideration the placement of these bolts

so as not to interfere with the positions of bin doors and transitions. (Refer to charts on Pages 18-20 for

necessary radii and chord lengths.) Take the time and work carefully: ACCURACY IS IMPORTANT.

FOR STIFFENER ANCHOR BOLT LOCATIONS ON COMMERCIAL TANKS, REFER TO COMMERCIAL

TANK SECTION IN THIS MANUAL OR CALL THE GSI ENGINEERING DEPARTMENT.

NOTE: Top edge of slab where the bin wall sets must be held to within 1/8" of level.

Figure 2F Anchor Bolt Placement

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 13

Page 14

2. General Foundation Requirements for GSI Bins

FCDL Anchor Bolt Detail

Figure 2G FCDL Anchor Bolt Detail

Commercial Tank Anchor Bolt Detail

Figure 2H Commercial Tank Anchor Bolt Detail

NOTE: This is a general case anchor b olt detail. Some situations, conditions and storage tanks may have

different anchor bolt or anchoring requirements.

14 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 15

2. General Foundation Requirements for GSI Bins

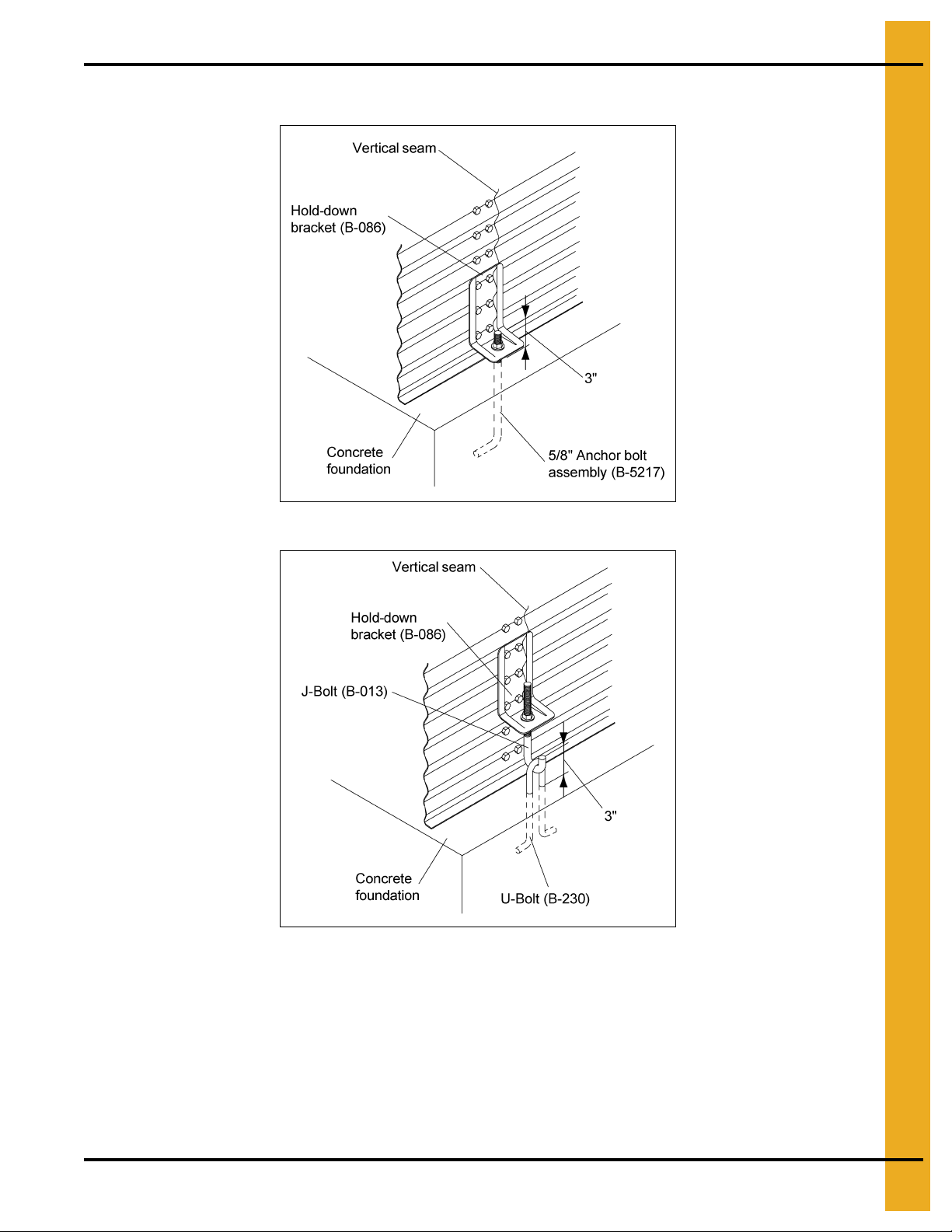

Outside Bin Hold-Down Details (Unstiffened 2.66" Corrugation)

Figure 2I Single Anchor Bolt

Figure 2J U-Bolt/J-Bolt Combination

Outside bin hold-downs should be used on all non-stiffened bins/silos. When anchoring the bin, be sure

the vertical seams of the bin/silo align with the U-bolts or single anchor bolts in the foundation. Bin/silos

up to 36' diameter and 12 rings tall or shorter may be anchored using either the U-bolt/J-bolt combina tion

or the single anchor bolt. Bin/silos 42' and greater in diameter and all 13 rings or taller sh ould be anchored

using the single anchor bolt. Bins/silos 13 rings and taller require double hold-downs. The sidewall must

be field drilled to attach the hold-down bracket located between the horizontal seams. For the case of 42'

and larger bin/silo, no greater than 12 rings tall, double U-bolt/J-bolt combination anchors may be used as

an option to the single anchors bolt. Additional hold-downs are required with this option.

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 15

Page 16

2. General Foundation Requirements for GSI Bins

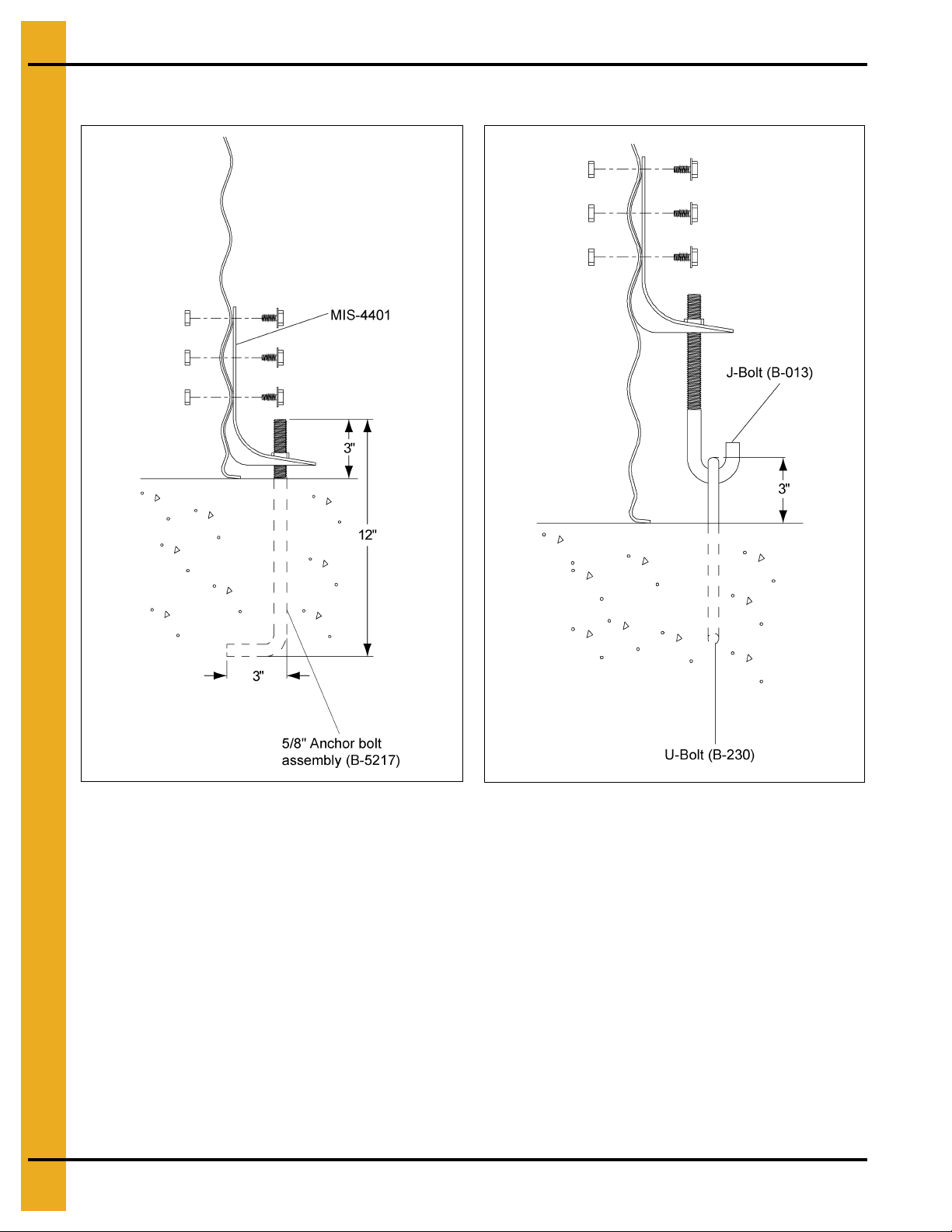

Outside Bin Hold-Down Details (Unstiffened 4.00" Corrugation)

Figure 2K Single Anchor Bolt

Outside bin hold-downs should be used on all non-stiffened GSI bins. When anchoring the bin, be sure

the vertical seams of the bin align with the U-bolts in the foundation. They may be anchored to the

foundation using either the U-bolt and J-bolt combination or the single anchor bolt, except on 42' diameter

and larger bins and bins 10 rings tall.

NOTE: All non-stiffened 42' and larger bins and bins 10 rings tall should use single anchor bolts, not the

U-bolt/J-bolt combination. (Double U-bolt/J-bolt may be used on non-stiffened 42' and larger bins,

no greater than 9 rings tall as an option.)

16 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Figure 2L U-Bolt/J-Bolt Combination

Page 17

FCDL Series

Anchor Bolt Charts

®

Section 03

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 17

Page 18

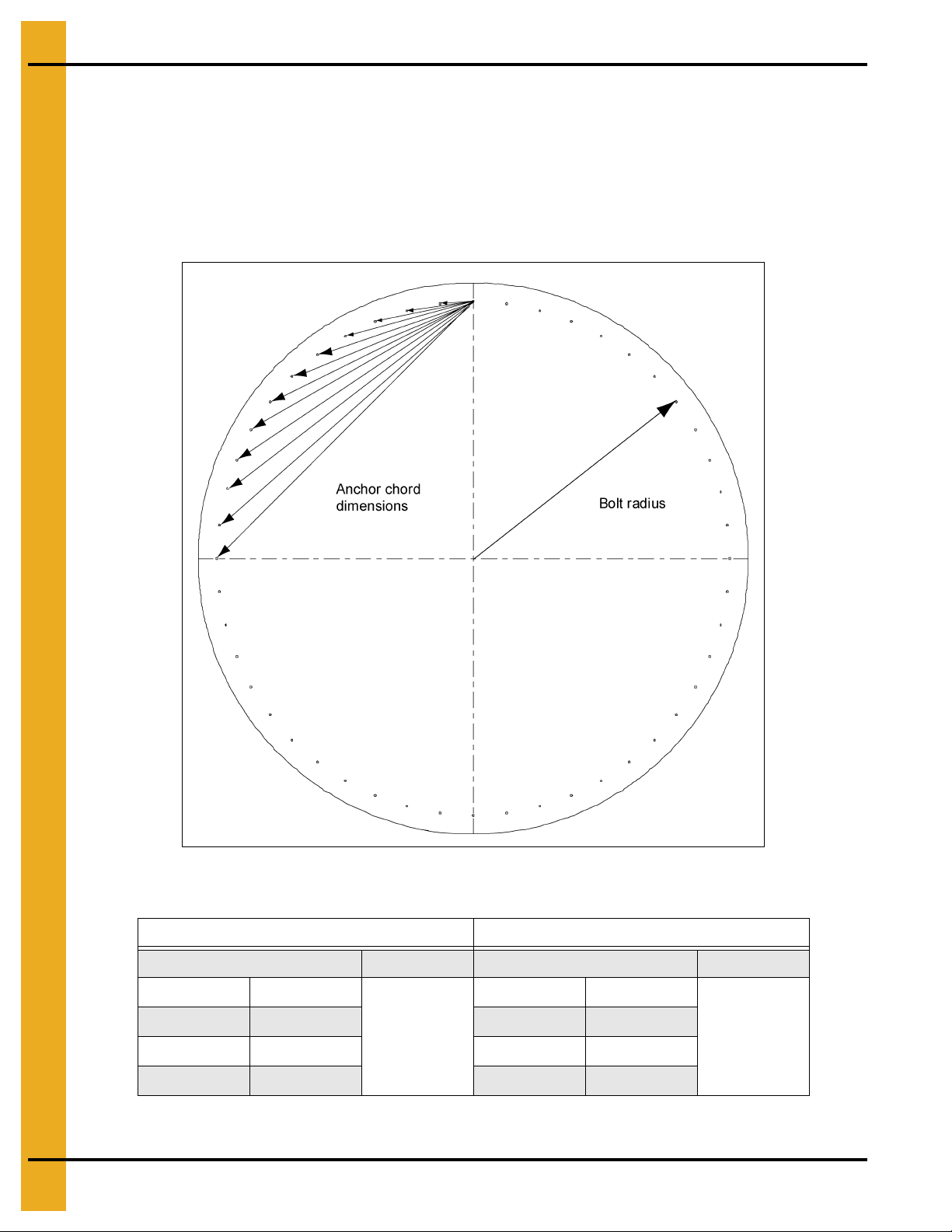

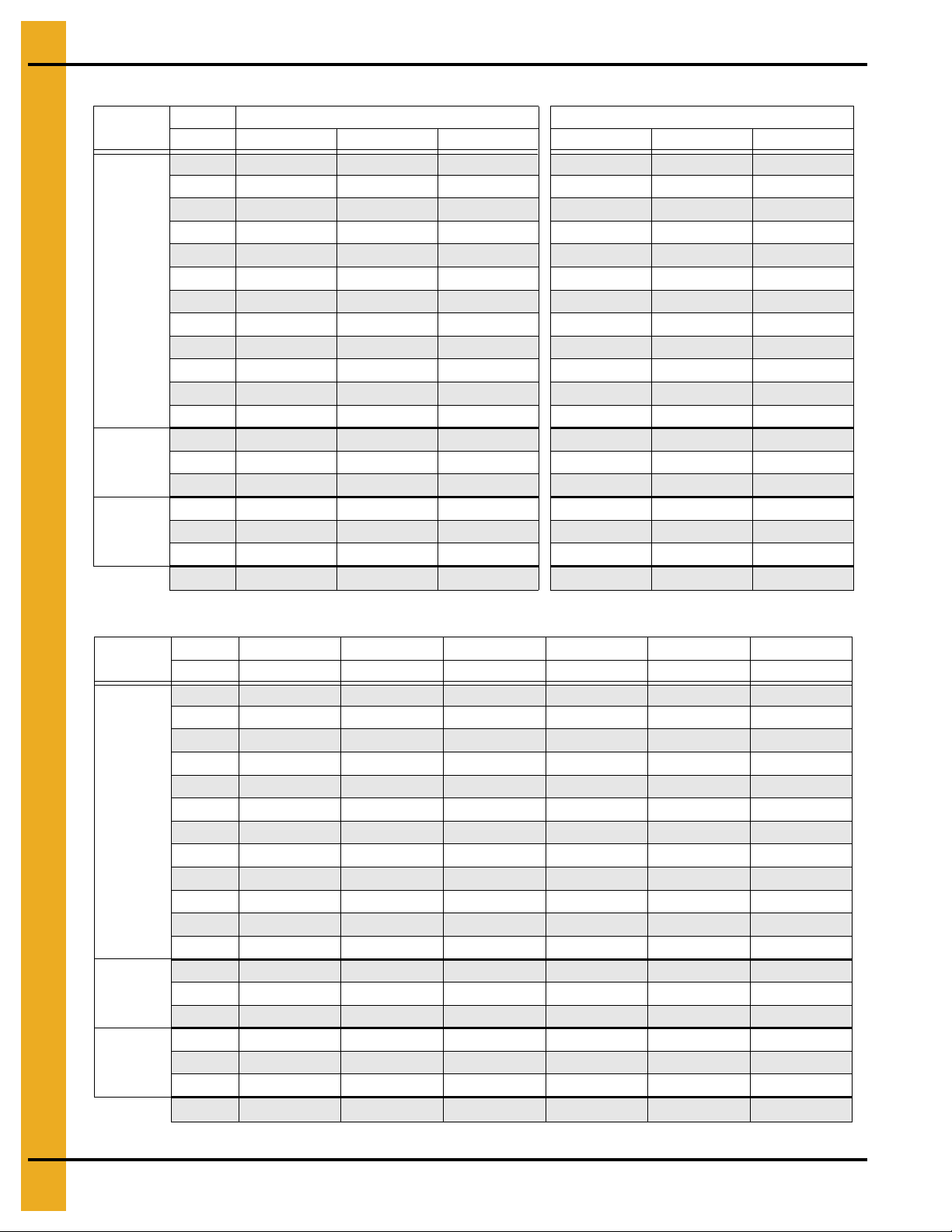

3. FCDL Series Anchor Bolt Charts

The dimensions in this chart on Pages 18-20 apply only to the FCDL series. For WC or NC series

commercial tanks, refer the appropriate section of PNEG-318.

Refer to proper chart on Pages 18-20 to find the anchor chord that corresponds to the bin that is going to

be built.

Start with one anchor bolt and work from it to the left to locate one qua rter of the anchor bolts, then to the

right to locate another quarter of the bolts. Now work off of the last anchor bolt s in each quarter t o lo cate

remaining anchor bolts in the last two (2) quarters.

Figure 3A

Anchor Bolt Charts

12' Diameter Bin 15' Diameter Bin

Bolt Radius 6' - 3-1/4'' Bolt Qty. 8 Bolt Radius 7' - 9-1/8'' Bolt Qty. 10

Chord # Chord Dist. Chord # Chord Dist.

1 4' - 9-5/8'' 1 4' - 9-9/16''

2 8' - 10-7/16'' 2 9' - 1-1/2''

3 11' - 7-1/16" 3 12' - 6-11/16''

18 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 19

3. FCDL Series Anchor Bolt Charts

18' Diameter Bin 21' Diameter Bin

Bolt Radius 9' - 3-1/16'' Bolt Qty. 12 Bolt Radius 10' - 8-15/16" Bolt Qty. 14

Chord # Chord Dist. Chord # Chord Dist.

1 4' - 9-1/2" 1 4' - 9-3/8"

2 9' - 3-1/16" 2 9' - 3-7/8"

3 13' - 1-1/16" 3 13' - 4-13/16"

4 16' - 0-3/8" 4 16' - 9-5/8"

24' Diameter Bin 27' Diameter Bin

Bolt Radius 12' - 2-7/8'' Bolt Qty. 16 Bolt Radius 13' - 8-3/4" Bolt Qty. 18

Chord # Chord Dist. Chord # Chord Dist.

1 4' - 9-5/16" 1 4' - 9-3/16"

2 9' - 4-7/16" 2 9' - 4-11/16"

3 13' - 7-3/16" 3 13' - 8-3/4"

4 17' - 3-11/16" 4 17' - 7-13/16"

5 20' - 4-1/4" 5 21'-7/16"

30' Diameter Bin 33' Diameter Bin

Bolt Radius 15' - 2-11/16'' Bolt Qty. 20 Bolt Radius 16' - 8-9/16" Bolt Qty. 22

Chord # Chord Dist. Chord # Chord Dist.

1 4' - 9-3/16" 1 4' - 9-1/16"

2 9' - 4-15/16" 2 9'-5"

3 13' - 9-7/8" 3 13' - 10-5/8"

4 17' - 10-3/4" 4 18'-7/8"

5 21' - 6-3/8" 5 21' - 10-11/16"

6 24' - 7-5/8" 6 25' - 3-1/8"

36' Diameter Bin 42' Diameter Bin

Bolt Radius 18' - 2-1/2'' Bolt Qty. 24 Bolt Radius 21' - 2-5/16'' Bolt Qty. 28

Chord # Chord Dist. Chord # Chord Dist.

1 4' - 9-1/16" 1 4 ' - 8-15/16"

2 9' - 5-1/8" 2 9' - 5-3/16"

3 13' - 11-1/4" 3 14'-0"

4 18' - 2-1/2" 4 1 8' - 4-11/16"

5 22'-2" 5 22' - 6-5/8"

6 25'-9" 6 26' - 5-1/8"

7 28' - 10-11/16" 7 29' - 11-5/8"

8 31' - 6-7/16" 8 33' - 1-11/16"

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 19

Page 20

3. FCDL Series Anchor Bolt Charts

48' Diameter Bin 54' Diameter Bin

Bolt Radius 24' - 2-1/8'' Bolt Qty. 32 Bolt Radius 27' - 1-15/16'' Bolt Qty. 36

Chord # Chord Dist. Chord # Chord Dist.

1 4' - 8-7/8" 1 4' - 8-13/16"

2 9' - 5-3/16" 2 9' - 5-3/16"

3 14' - 7/16" 3 14' - 11/16"

4 18' - 6-1/16" 4 18' - 6-15/16"

5 22' - 9-1/2" 5 22' - 11-1/2"

6 26' - 10-3/8" 6 27' - 1-15/16"

7 30' - 8-1/8" 7 31' - 1-7/8"

8 34' - 2-5/16" 8 34'-11"

9 37' - 4-9/16"

Bolt Radius 30' - 1-3/4" Bolt Qty. 40

Chord # Chord Dist.

1 4' - 8-3/4"

2 9' - 5-3/16"

3 14'-7/8"

4 18' - 7-9/16"

5 23'-7/8"

6 27' - 4-7/16"

7 31'-6"

8 35' - 5-1/4"

9 39' - 1-7/8"

10 42' - 7-9/16"

11 45' - 10-1/8"

9 38' - 4-15/16"

10 41' - 7-3/8"

60' Diameter Bin

Figure 3B Anchor Bolt Detail (Typical)

20 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 21

Floating Monolithic Pad Recommendations

for FCDL and FCRL Series Bins

®

Section 04

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 21

Page 22

4. Monolithic Pad FCDL

All foundation specifications shall be

construed as recommendations only. Because

of the many variable conditions in actual

installation, GSI assumes no liability for results

arising from the use of such recommendations.

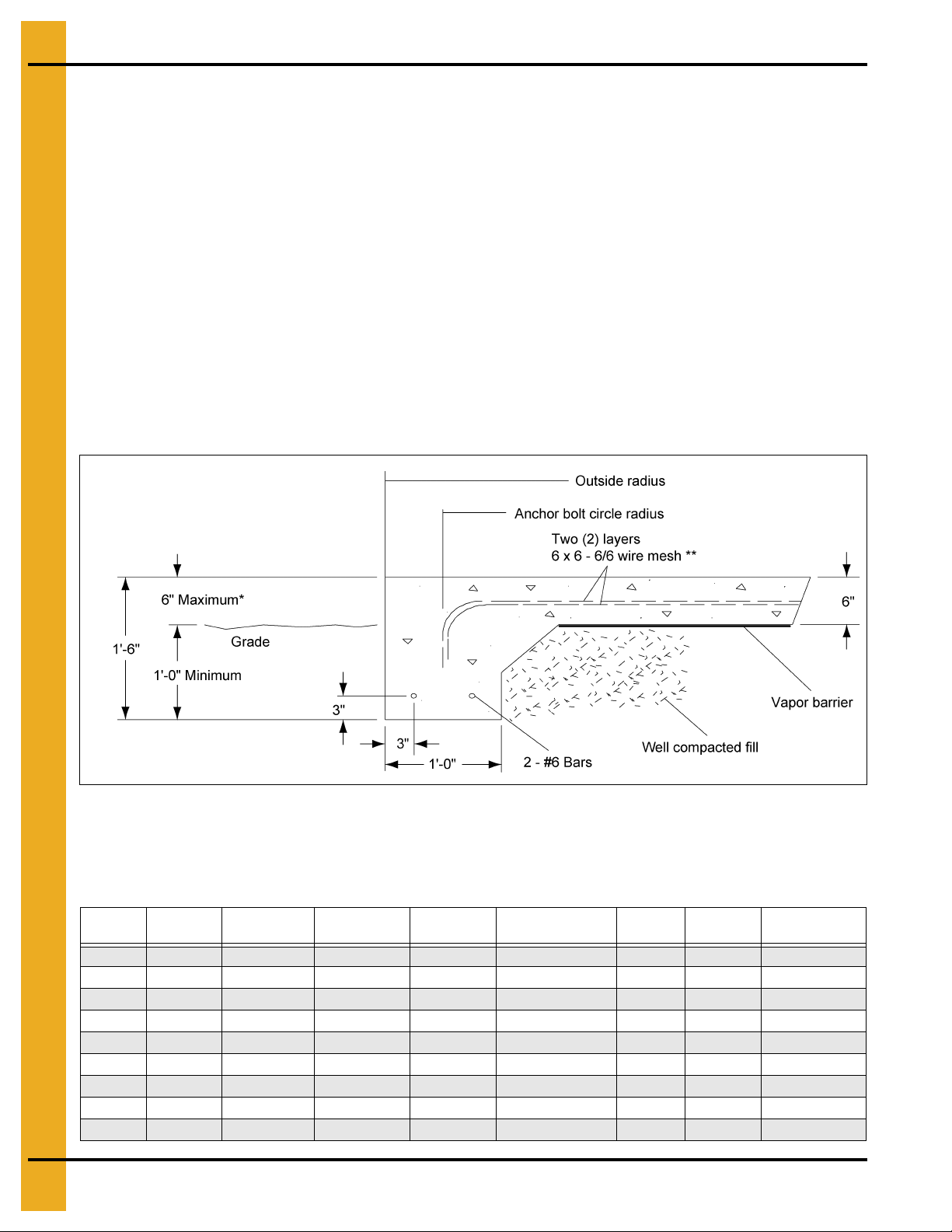

Floating Monolithic Pad for GSI FCDL Bins up to 5 Rings

Monolithic Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 4A

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most cases. Place the #4 bars

in the pad at 18" c/c each way.

Bin

Diameter

12' 6'-9'' 6' - 3-1/4'' 4' - 9-5/8'' 8 4.5 300 100 200

15' 8'-3'' 7' - 9-1/8'' 4' - 9-9/16'' 10 6 500 100 300

18' 9'-9'' 9' - 3-1/16'' 4' - 9-1/2'' 12 8 700 200 400

21' 11'-3'' 10' - 8-15/16'' 4' - 9-3/8'' 14 10 900 200 600

24' 12'-9" 12' - 2-7/8'' 4' - 9-5/16'' 16 12-1/2 1100 200 700

27' 14'-3" 13' - 8-3/4'' 4' - 9-3/16'' 18 15 1200 200 900

30' 15'-9'' 15' - 2-11/16'' 4' - 9-3/16'' 20 18 1600 200 1100

33' 17'-3'' 16' - 8-9/16'' 4' - 9-1/16'' 22 21-1/2 1800 300 1300

36' 18'-9'' 18' - 2-1/2'' 4' - 9-1/16'' 24 25 2300 300 1500

22 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Outside

Radius

Single Bolt

Radius

Anchor Chord # of Anchors

Total Cu. Yds.

Concrete

Sq. Ft.

Mesh

Length #6

Bar

Optional #4

Grid (ft.)

Page 23

Frost Free Pad Recommendations

for FCDL and FCRL Series Bin

®

Section 05

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 23

Page 24

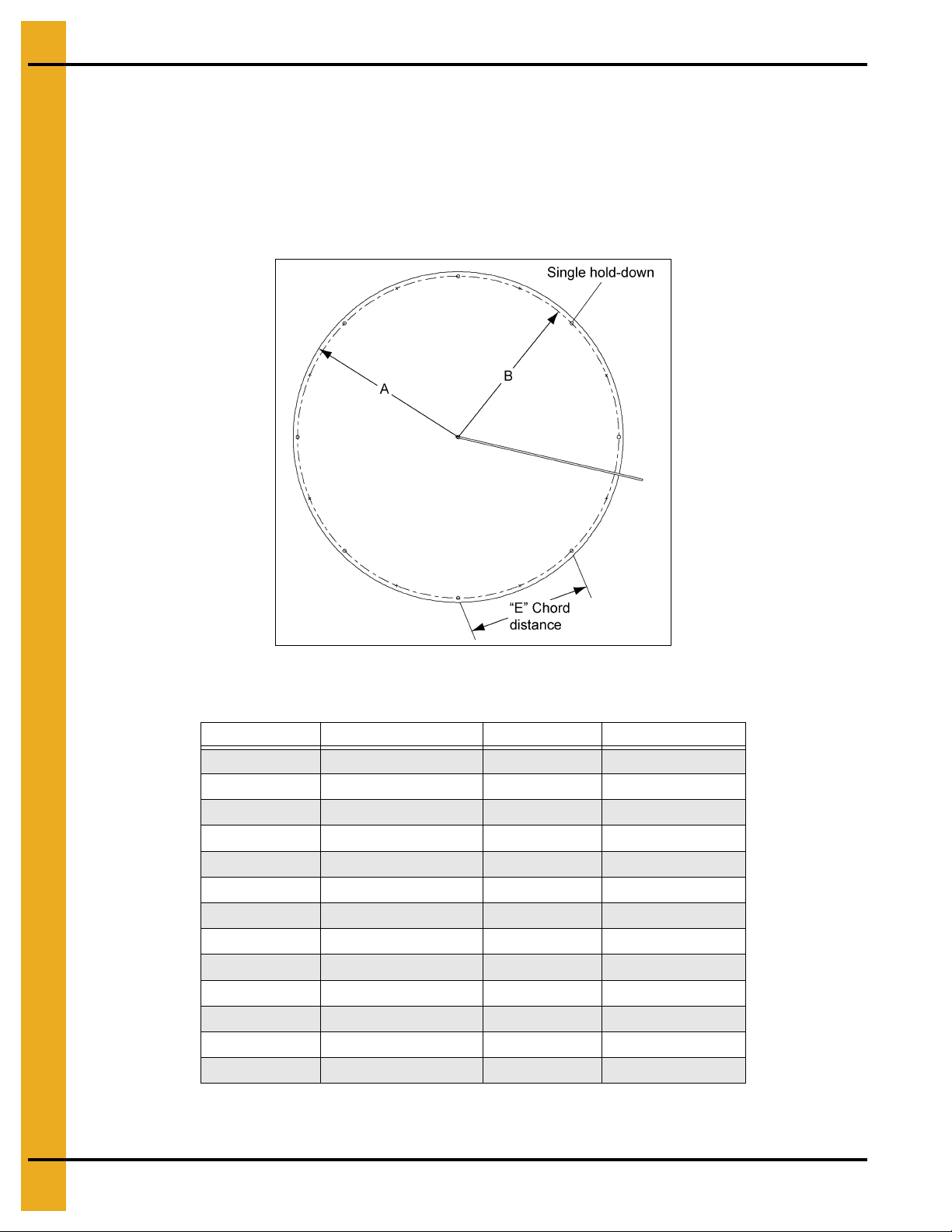

5. Frost Free Pad FCDL

Anchor Bolt Placement

Having poured and leveled the concrete, use the center stake and straight 2 x 4 again to find the bolt circle

radius for the outside hold-down brackets. Select a starting point and stretch a pre-measure d chord along

the imaginary circle formed by the bolt circle radius. Take into consideration the placement of these bolts

so as not to interfere with the positions of bin doors and transitions. (Refer to following chart below for

necessary radii and chord lengths.) Take the time and work carefully since accuracy is important.

NOTE: Top edge of slab where the bin wall sets must be held to within 1/8" of level.

Figure 5A

NOTE: Refer to chapter 4 on Page 21 for additional anchor details.

Bin Diameter “B” Bolt Circle Radius # of Anchors “E” Chord Distance

12' 6' - 3-1/4" 8 4' - 9-5/8"

15' 7' - 9-1/8" 10 4' - 9-9/16"

18' 9' - 3-1/16" 12 4' - 9-1/2"

21' 10' - 8-15/16" 14 4' - 9-3/8"

24' 12' - 2-7/8" 16 4' - 9-5/16"

27' 13' - 8-3/4" 18 4' - 9-3/16"

30' 15' - 2-11/16" 20 4' - 9-3/16"

33' 16' - 8-9/16" 22 4' - 9-1/16"

36' 18' - 2-1/2" 24 4' - 9-1/16"

42' 21' - 2-5/16" 28 4' - 8-15/16"

48' 24' - 2-1/8" 32 4' - 8-7/8"

54' 27' - 1-15/16" 36 4' - 8-3/16"

60' 30' - 1-3/4" 40 4' - 8-3/4"

For stiffener anchor bolt locations on commercial tanks, refer to commercial tank section found later in this

manual or call the GSI engineering department.

24 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 25

5. Frost Free Pad FCDL

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising from the

use of such recommendations.

Frost Free Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most ca ses. Place the #4 bars

in the pad at 18" c/c each way.

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 25

Figure 5B

Page 26

5. Frost Free Pad FCDL

Frost Free Pad (FCDL Bins)

(Refer to Figure 5A on Page 24.)

Diameter of Bin: 12'

Corrugation: 4.00"

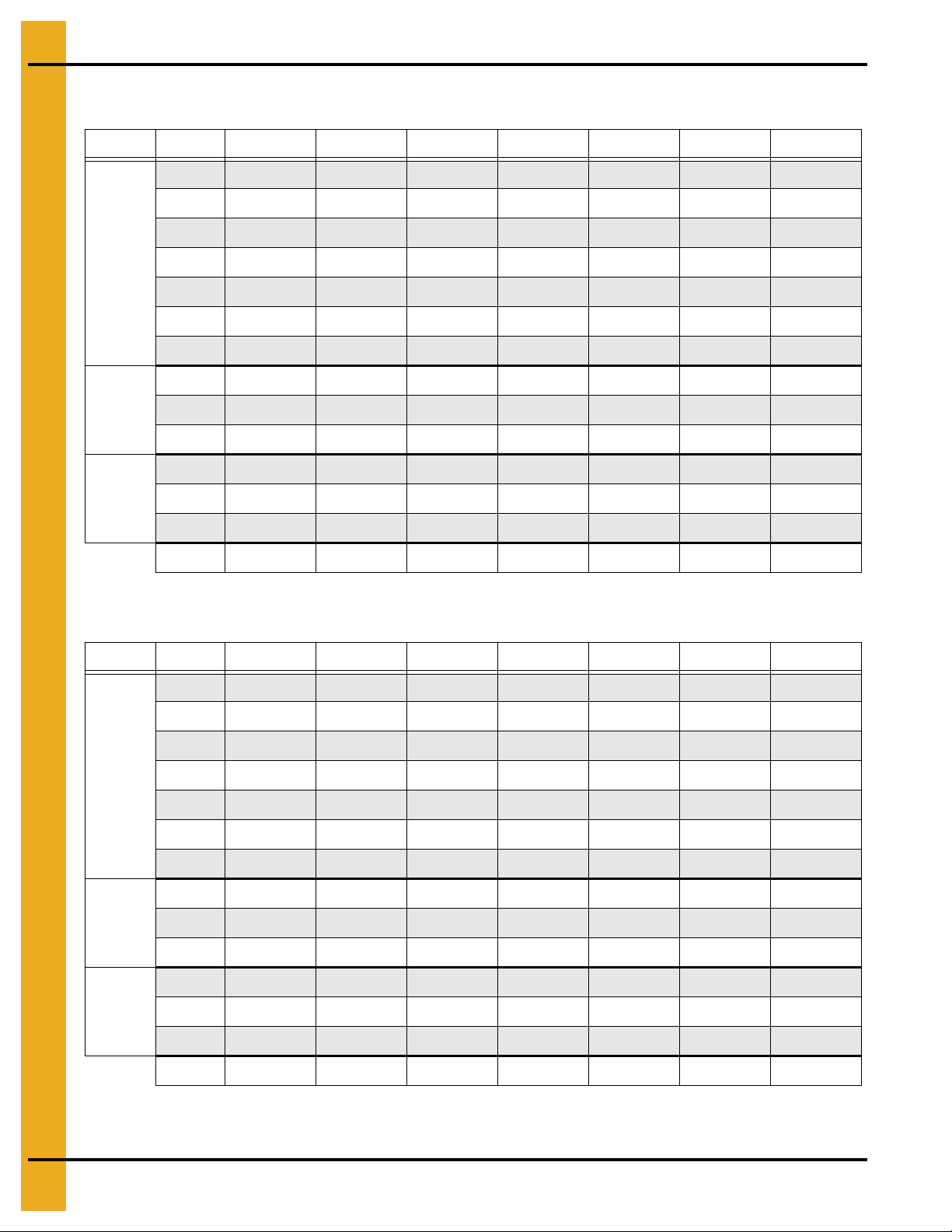

Ring # B N

6 1 ft. 0 in. 2 6 f t. 9 in. 300 200 100 5

7, 8 1 ft. 7 in. 2 6 ft. 9 in. 300 200 100 5

9, 10 2 ft. 0 in. 2 7 ft. 0 in. 300 200 200 6

1 1, 12 2 ft. 10 in. 3 7 ft. 6 in. 300 200 300 8

Diameter of Bin: 15'

Corrugation: 4.00''

Ring # B N

6 1 ft. 0 in. 2 8 ft. 3 in. 400 300 100 6

7, 8 1 ft. 7 in. 2 8 ft. 3 in. 400 300 100 7

9, 10 2 ft. 0 in. 2 8 ft. 7 in. 400 300 200 8

11, 12 2 ft. 0 in. 2 8 ft. 7 in. 400 300 200 8

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Diameter of Bin: 18'

Corrugation: 4.00''

Ring # B N

6 1 ft. 0 in. 2 9 ft. 9 in. 500 400 200 8

7, 8 1 ft. 7 in. 2 9 ft. 9 in. 500 400 200 9

9 2 ft. 0 in. 2 10 ft. 1 in. 500 400 200 11

11, 12 2 ft. 6 in. 3 10 ft. 6 in. 5 00 400 300 12

Diameter of Bin: 21'

Corrugation: 4.00''

Ring # B N

6 1 ft. 1 in. 2 11 ft. 3 in. 700 500 200 11

7, 8 1 ft. 7 in. 2 11 ft. 3 in. 700 500 200 12

9, 10 2 ft. 0 in. 2 11 ft. 6 in. 700 500 300 13

1 1 , 12 2 ft. 6 in. 3 11 ft. 9 in. 700 500 400 15

Diameter of Bin: 24'

Corrugation: 4.00''

Ring # B N

6 1 ft. 1 in. 2 12 ft. 9 in. 900 600 200 13

7, 8 1 ft. 9 in. 2 12 ft. 9 in. 900 600 200 15

Outside

Radius

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Total Cu. Yds.

Concrete

To tal Cu. Yds.

Concrete

Concrete

9, 10 2 ft. 6 in. 3 13 ft. 2 in. 900 600 400 18

11, 12 2 ft. 9 in. 3 13 ft. 4 in. 900 600 500 18

26 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 27

5. Frost Free Pad FCDL

Frost Free Pad (FCDL Bins) (Continued)

(Refer to Figure 5A on Page 24.)

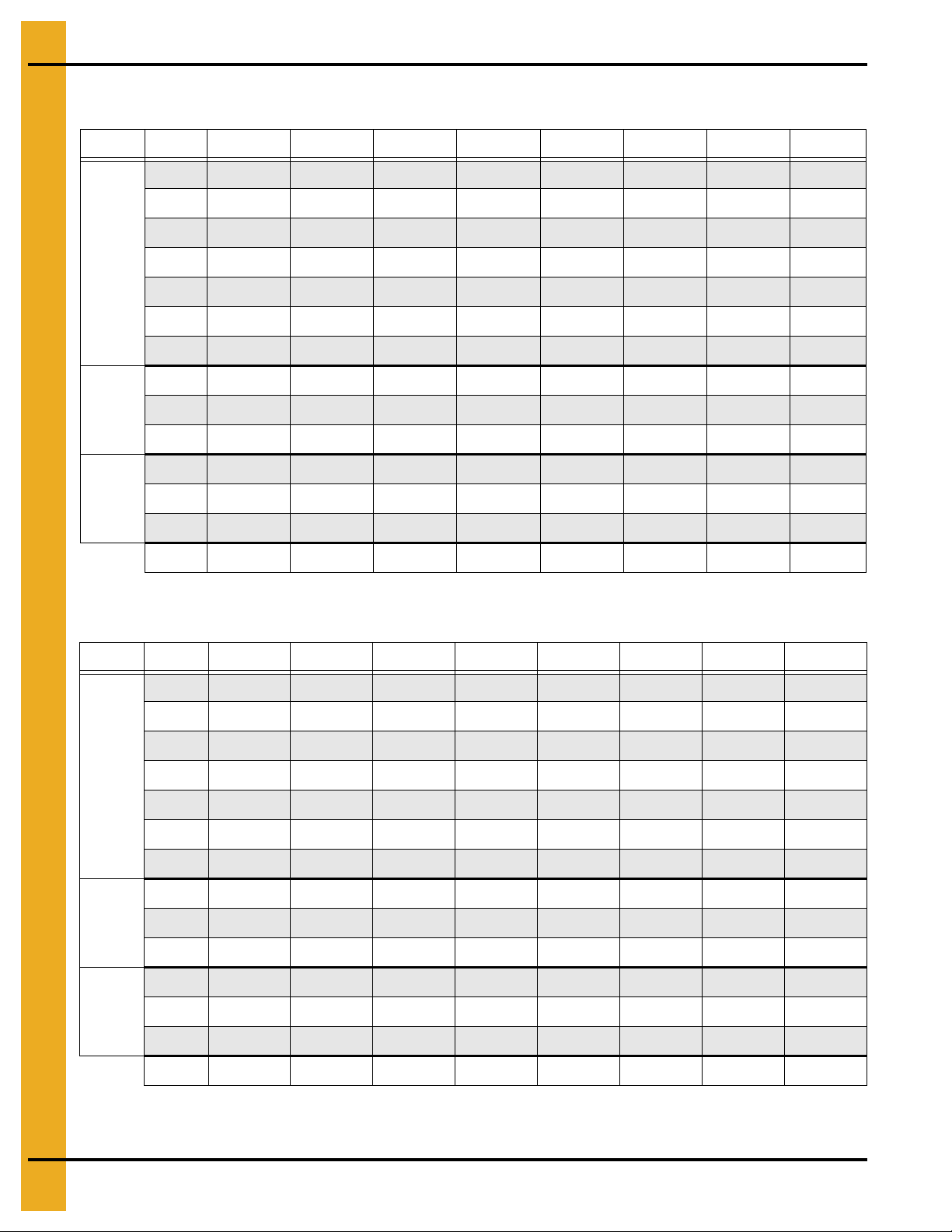

Diameter of Bin: 27'

Corrugation: 4.00''

Ring # B N

6 1 ft. 2 in. 2 14 ft. 3 in. 1100 800 200 16

7, 8 1 ft. 10 in. 2 14 ft. 4 in. 1100 800 200 18

9, 10 2 ft. 7 in. 3 14 ft. 7 in. 1100 800 500 21

Diameter of Bin: 30'

Corrugation: 4.00"

Ring # B N

6 1 ft. 2 in. 2 15 ft. 9 in. 1400 900 200 19

7, 8 1 ft. 10 in. 2 15 ft. 10 in. 1400 900 200 21

9, 10 2 ft. 8 in. 3 16 ft. 1 in. 1400 900 500 25

11, 12 3 ft. 8 in. 4 16 ft. 5 in. 1400 900 700 29

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

T otal Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Diameter of Bin: 33'

Corrugation: 4.00"

Ring # B N

6 1 ft. 3 in. 2 17 ft. 3 in. 1700 1100 300 23

7, 8 1 ft. 11 in. 2 17 ft. 4 in. 1700 1100 300 25

9, 10 2 ft. 9 in. 3 17 ft. 6 in. 1700 1100 600 29

11, 12 3 ft. 10 in. 4 18 ft. 0 in. 1700 1100 800 34

Diameter of Bin: 36'

Corrugation: 4.00"

Ring # B N

6 1 ft. 3 in. 2 18 ft. 9 in. 2000 1300 300 26

7, 8 2 ft. 0 in. 2 18 ft. 11 in. 2000 1300 400 30

9, 10 2 ft. 10 in. 3 19 ft. 0 in. 2000 1300 600 33

11, 12 3 ft. 11 in. 4 19 ft. 6 in. 2000 1300 900 39

13 4 ft. 10 in. 5 19 ft. 9 in. 2000 1300 1100 43

Diameter of Bin: 42'

Corrugation: 4.00"

Ring # B N

6 1 ft. 4 in. 2 21 ft. 8 in. 2600 1800 300 34

7, 8 2 ft. 1 in. 3 21 ft. 11 in. 2600 1 800 700 39

9 3 ft. 1 in. 4 22 ft. 2 in. 2600 1800 900 44

10, 11 4 ft. 2 in. 5 22 ft. 7 in. 2600 1800 1200 50

12, 13 4 ft. 10 in. 5 22 ft. 11 in. 2600 1800 1300 54

14 5 ft. 6 in. 6 23 ft. 2 in. 2600 1800 1500 66

Outside

Radius

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 27

Page 28

5. Frost Free Pad FCDL

Frost Free Pad (FCDL Bins) (Continued)

(Refer to Figure 5A on Page 24.)

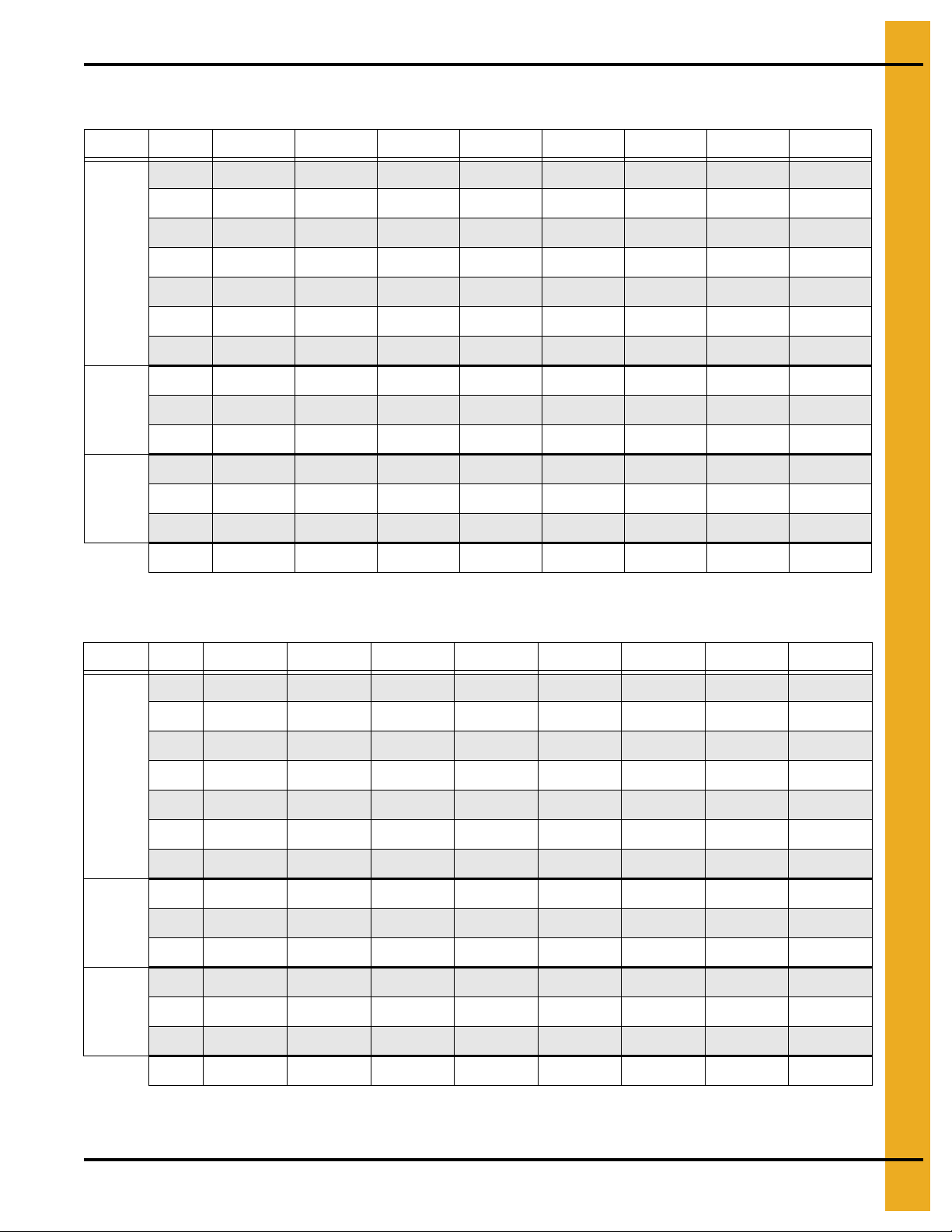

Diameter of Bin: 48'

Corrugation: 4.00"

Ring # B N

6 1 ft. 5 in. 2 24 ft. 8 in. 3400 2300 400 44

7, 8 2 ft. 3 in. 3 24 ft. 11 in. 3400 2300 800 49

9 3 ft. 3 in. 4 25 ft. 2 in. 3400 2300 1100 55

10, 11 4 ft. 5 in. 5 25 ft. 8 in. 3400 2300 1400 63

12, 13 5 ft. 1 in. 5 25 ft. 11 in. 3400 2300 1500 67

14 5 ft. 8 in. 6 26 ft. 2 in. 5400 2300 1700 72

Diameter of Bin: 54'

Corrugation: 4.00"

Ring # B N

6 1 ft. 5 in. 2 27 ft. 9 in. 4800 3300 400 56

7, 8 2 ft. 3 in. 3 28 ft. 1 in. 4800 3300 600 63

9, 10 3 ft. 3 in. 4 28 ft. 4 in. 4800 3300 700 69

11, 12 4 ft. 5 in. 4 28 ft. 7 in. 4800 3300 1400 75

13, 14 6 ft. 0 in. 6 29 ft. 2 in. 4800 3300 1900 87

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Y ds.

Concrete

Total Cu. Yds.

Concrete

Diameter of Bin: 60'

Corrugation: 4.00"

Ring # B N

6 1 ft. 6 in. 2 30 ft. 7 in. 5400 3600 400 65

7, 8 2 ft. 10 in. 3 31 ft. 3 in. 5400 3600 1100 77

9, 10 3 ft. 8 in. 4 31 ft. 7 in. 5400 3600 1400 82

11, 12 4 ft. 7 in. 5 31 ft. 9 in. 5400 3600 1700 91

13 6 ft. 1 in. 6 32 ft. 4 in. 5400 3600 2200 103

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

28 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 29

Inverted “T” Foundation

Recommendations for

FCDL and FCRL Series Bin

®

Section 06

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 29

Page 30

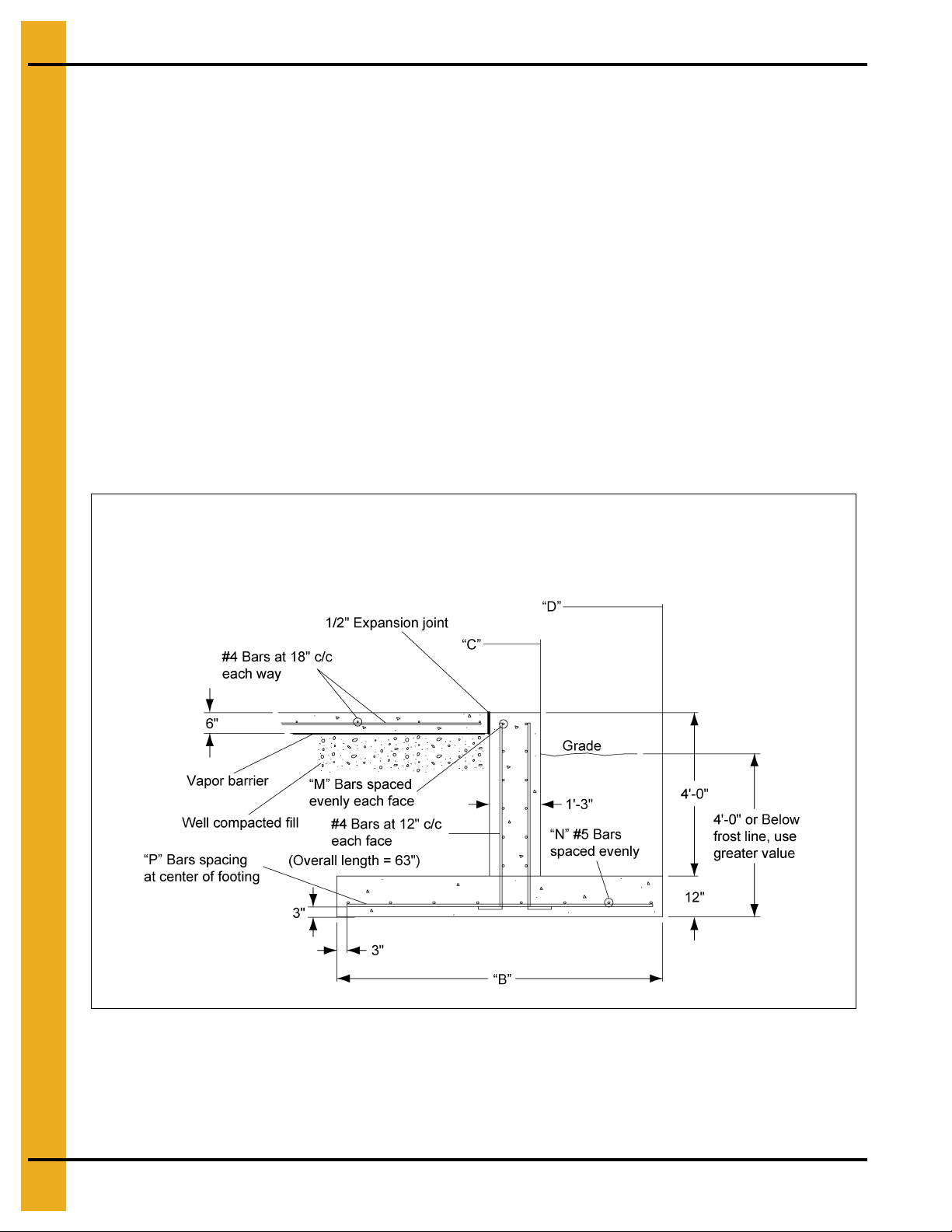

6. Inverted “T” FCDL

All foundation shall be construed as recommendations

only. Because of the many variable conditions in

actual installation, GSI assumes no liability for results

arising from the use of such recommendations.

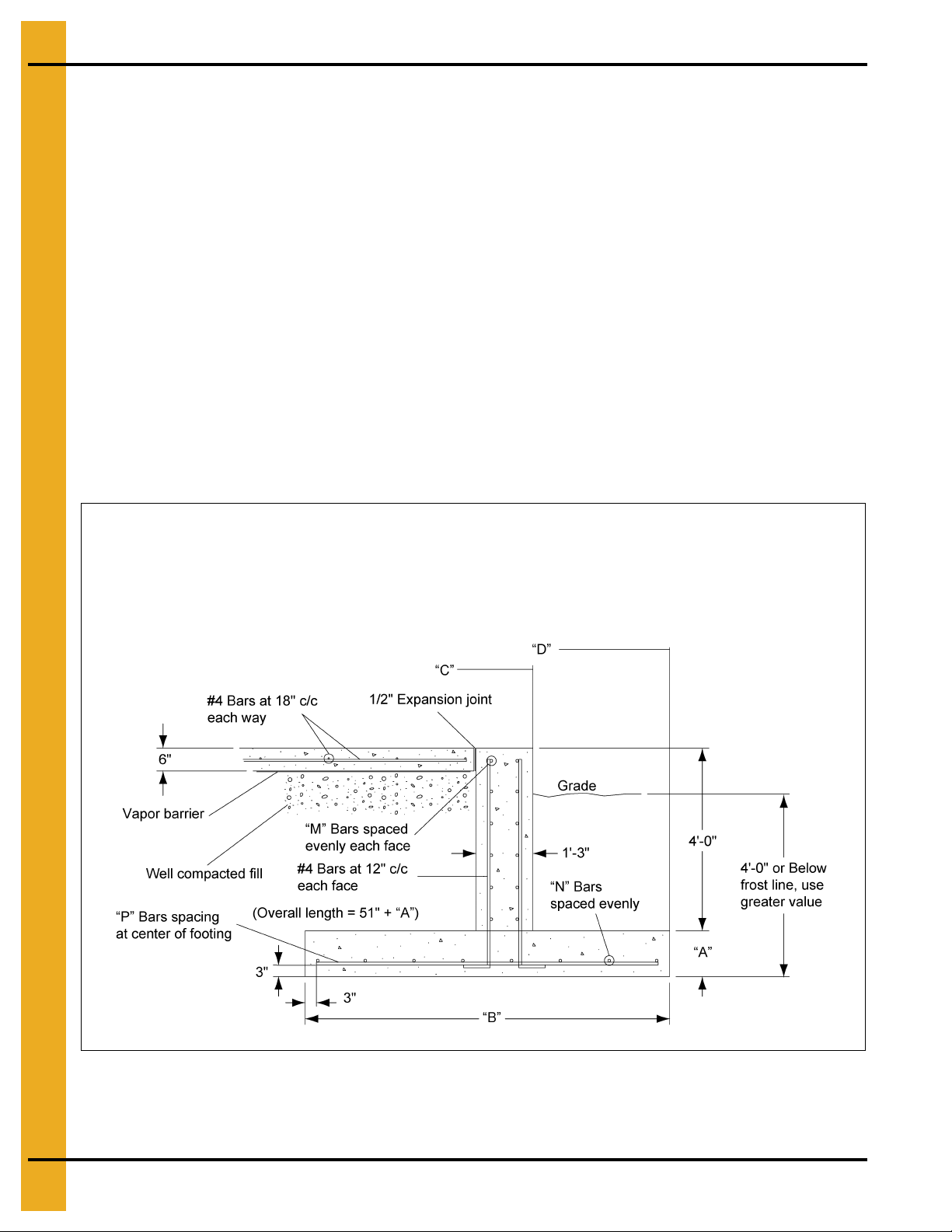

3000 PSF Soil Bearing Capacity

Inverted “T” Foundation Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

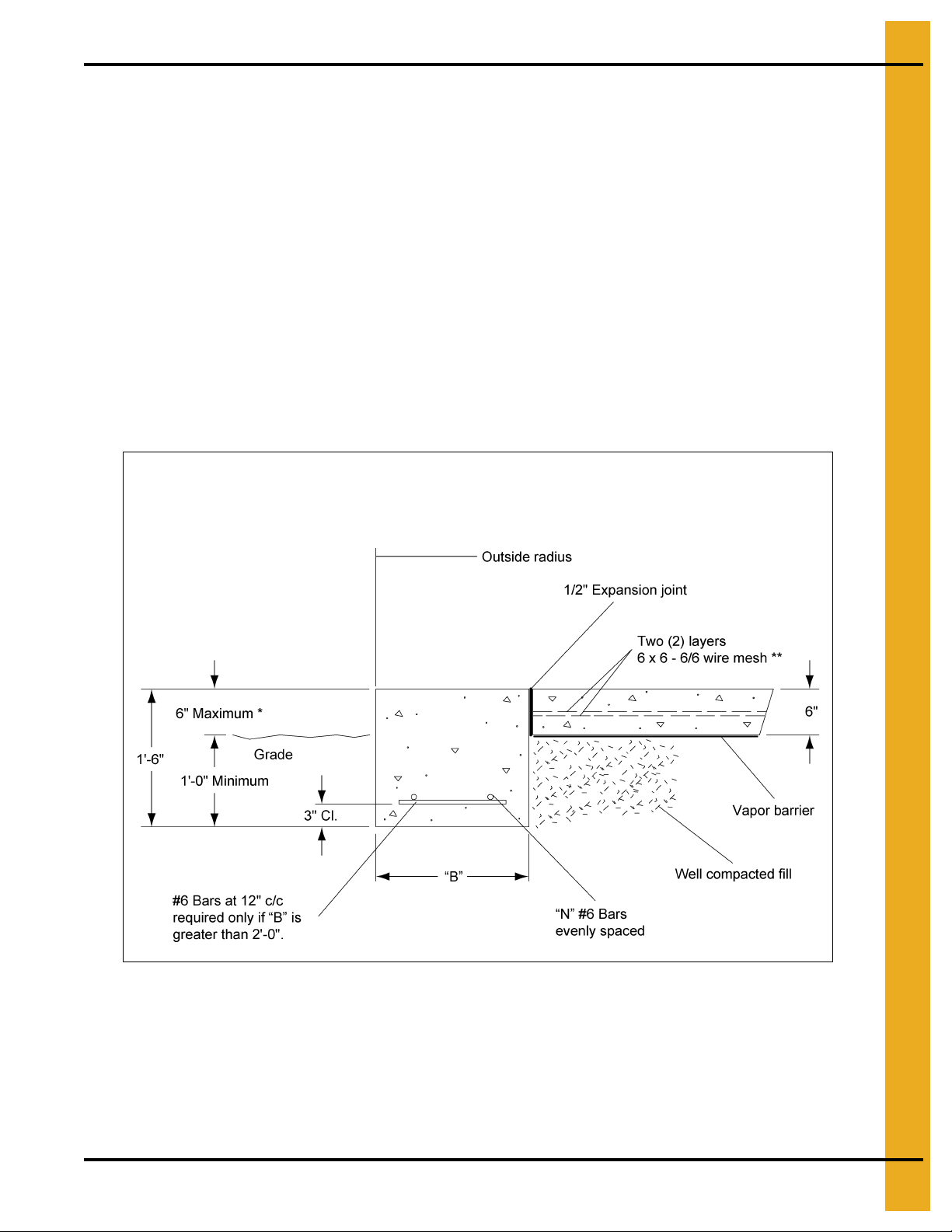

Figure 6A Inverted “T” Foundation

30 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 31

6. Inverted “T” FCDL

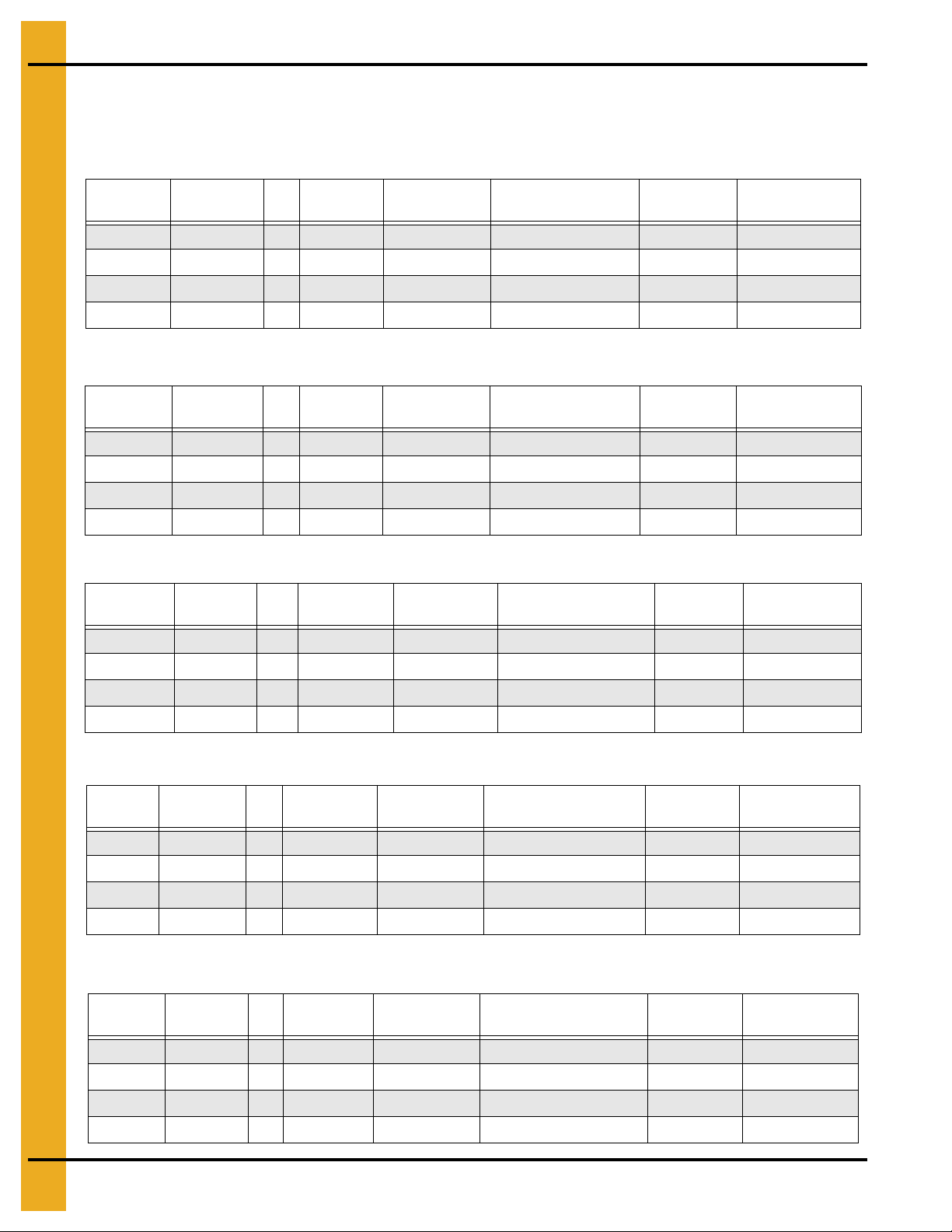

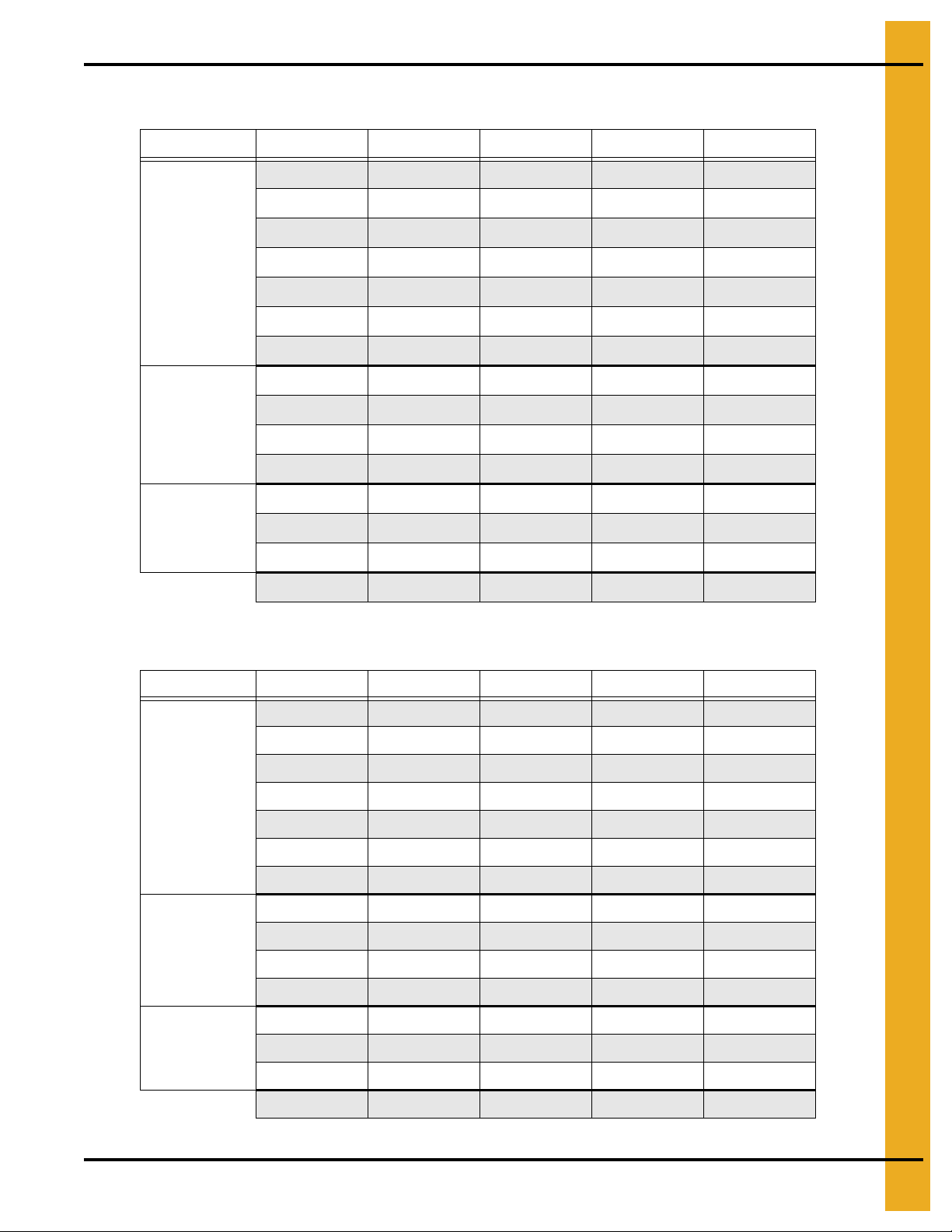

Inverted “T” Foundations

(Refer to Figure 6A on Page 30.)

Diameter of Bin: 18'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-3" 9'-8" 9'-8" 5 #4's 2 #5's #5 @ 14" c/c 1600 300 18

7, 8 1'-7" 9'-8" 9'-10" 5 #4's 2 #5's #5 @ 14" c/c 1600 300 19

9, 10 2'-2" 9'-8" 10'-1" 5 #4's 3 #5's #5 @ 14" c/c 1600 300 20

11, 12 2'-4" 9'-8" 10'-2" 5 #4's 3 #5's #5 @ 14" c/c 1600 300 21

Diameter of Bin: 21'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-3" 11'-2" 11'-2" 5 #4's 2 #5's #5 @ 14" c/c 2000 300 22

7, 8 1'-8" 11'-2" 11'-4" 5 #4's 2 #5's #5 @ 14" c/c 2000 300 23

9, 10 2'-3" 11'-2" 11'-7" 5 #4's 3 #5's #5 @ 14" c/c 2000 400 25

11, 12 2'-6" 11'-2" 11'-8" 5 #4's 3 #5's #5 @ 14" c/c 2000 400 27

Diameter of Bin: 24'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-3" 12'-8" 12'-8" 5 #4's 2 #5's #5 @ 14" c/c 2300 300 26

7, 8 1'-9" 12'-8" 13'-1" 5 #4's 2 #5's #5 @ 14" c/c 2300 300 27

9 2'-5" 12'-8" 13'-2" 5 #4's 3 #5's #5 @ 14" c/c 2300 500 29

10, 11 2'-8" 12'-8" 13'-4" 5 #4's 3 #5's #5 @ 14" c/c 2300 500 31

Cu. Yds.

Concrete

Cu. Yds.

Concrete

Cu. Yds.

Concrete

Diameter of Bin: 27'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-3" 14'-2" 14'-2" 5 #4's 2 #5's #5 @ 14" c/c 2600 300 31

7, 8 1'-10" 14'-2" 14'-5" 5 #4's 2 #5's #5 @ 14" c/c 2600 400 33

9 2'-6" 14'-2" 14'-8" 5 #4's 3 #5's #5 @ 14" c/c 2600 500 35

10, 11 3'-4" 14'-2" 15'-1" 5 #4's 4 #5's #5 @ 14" c/c 2600 700 37

Diameter of Bin: 30'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-3" 15'-8" 15'-8" 5 #4's 2 #5's #5 @ 14" c/c 3000 300 36

7, 8 1'-11" 15'-8" 16'-0" 5 #4's 2 #5's #5 @ 14" c/c 3000 400 39

9, 10 2'-7" 15'-8" 16'-3" 5 #4's 3 #5's #5 @ 14" c/c 3000 500 42

11, 12 3'-6" 15'-8" 16'-10" 5 #4's 4 #5's #5 @ 14" c/c 3000 700 44

13 3'-11" 15'-8" 17'-0" 5 #4's 4 #5's #5 @ 14" c/c 3000 700 46

Diameter of Bin: 33'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-4" 17'-1" 17'-1" 5 #4's 2 #5's #5 @ 14" c/c 3400 400 40

7, 8 1'-11" 17'-1" 17'-4" 5 #4's 2 #5's #5 @ 14" c/c 3400 500 42

9, 10 2'-8" 17'-1" 17'-8" 5 #4's 3 #5's #5 @ 14" c/c 3400 600 45

11, 12 3'-8" 17'-1" 18'-2" 5 #4's 4 #5's #5 @ 14" c/c 3400 800 48

13 4'-2" 17'-1" 18'-7" 5 #4's 4 #5's #5 @ 14" c/c 3400 900 51

Cu. Yds.

Concrete

Cu. Yds.

Concrete

Cu. Yds.

Concrete

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 31

Page 32

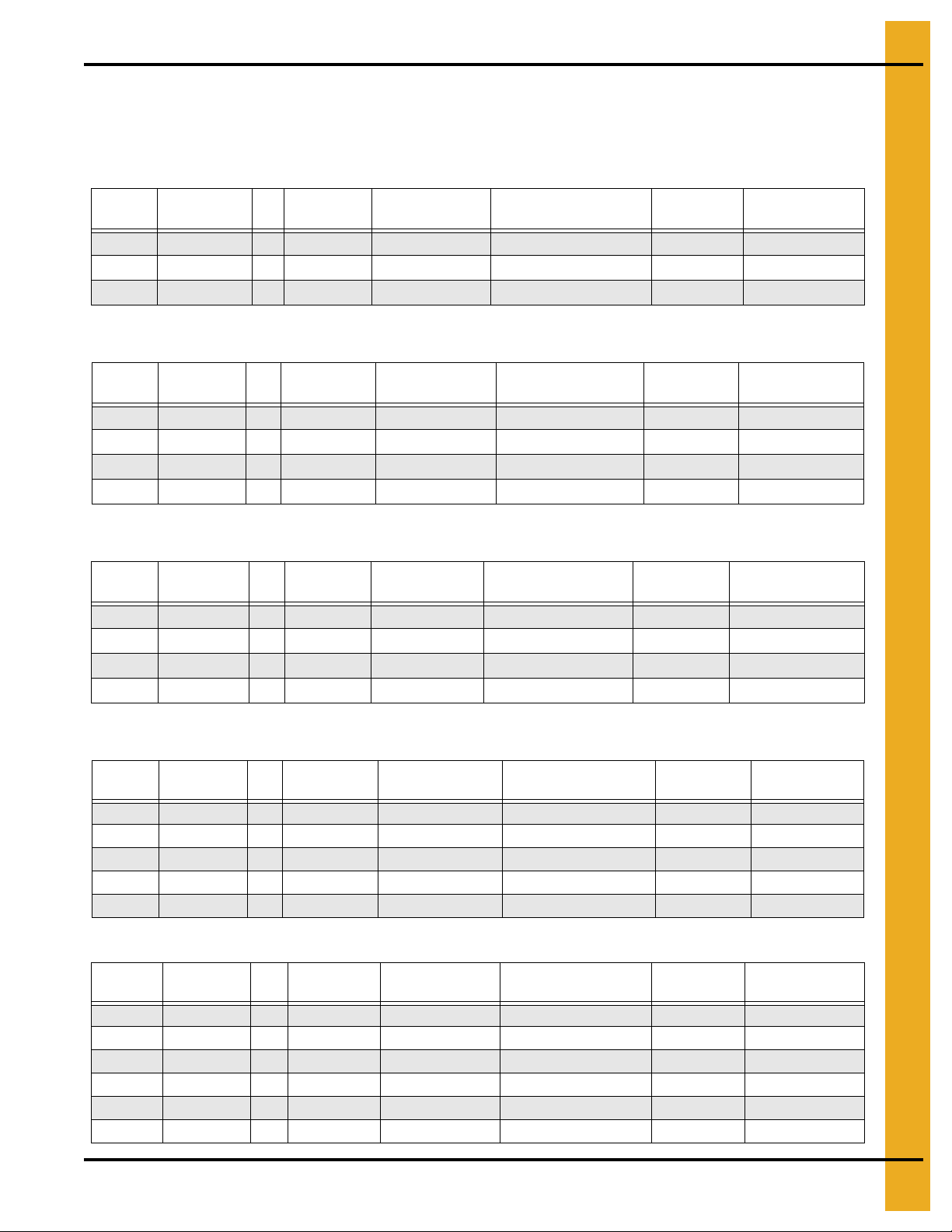

6. Inverted “T” FCDL

Inverted “T” Foundations (Continued)

(Refer to Figure 6A on Page 30.)

Diameter of Bin: 36'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-4" 18'-7" 18'-7" 5 #4's 2 #5's #5 @ 14" c/c 3800 400 44

7, 8 2'-0" 18'-7" 18'-11" 5 #4's 2 #5's #5 @ 14" c/c 3800 500 47

9, 10 2'-10" 18'-7" 19'-3" 5 #4's 3 #5's #5 @ 14" c/c 3800 700 50

11, 12 3'-9" 18'-7" 19'-8" 5 #4's 4 #5's #5 @ 14" c/c 3800 1000 55

13 4'-4" 18'-7" 20'-3" 5 #4's 4 #5's #5 @ 14" c/c 3800 1200 58

Diameter of Bin: 42'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-5" 21'-7" 21'-8" 5 #4's 2 #5's #5 @ 14" c/c 4700 500 56

7, 8 2'-2" 21'-7" 22'-0" 5 #4's 3 #5's #5 @ 14" c/c 4700 600 60

9 3'-0" 21'-7" 22'-4" 5 #4's 3 #5's #5 @ 14" c/c 4700 700 64

10, 11 4'-0" 21'-7" 22'-9" 5 #4's 4 #5's #5 @ 14" c/c 4700 1000 69

12, 13 4'-6" 21'-7" 23'-3" 5 #4's 4 #5's #5 @ 14" c/c 4700 1200 71

Cu. Yds.

Concrete

Cu. Yds.

Concrete

Diameter of Bin: 48'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 1'-6" 24'-7" 24'-8" 5 #4's 2 #5's #5 @ 14" c/c 5600 600 68

7, 8 2'-3" 24'-7" 25'-0" 5 #4's 3 #5's #5 @ 14" c/c 5600 800 72

9 3'-2" 24'-7" 25'-5" 6 #4's 3 #5's #5 @ 14" c/c 5800 900 77

10, 11 4'-2" 24'-7" 25'-10" 6 #4's 4 #5's #5 @ 14" c/c 5800 1200 84

12, 13 4'-10" 24'-7" 26'-5" 6 #4's 4 #5's #5 @ 14" c/c 6300 1300 87

Diameter of Bin: 54'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 2'-0" 27'-7" 28'-1" 5 #4's 3 #5's #5 @ 14" c/c 6600 900 85

7, 8 2'-9" 27'-7" 28'-4" 5 #4's 3 #5's #5 @ 14" c/c 6600 1000 90

9, 10 3'-6" 27'-7" 28'-7" 5 #4's 4 #5's #5 @ 14" c/c 6600 1200 94

11, 12 4'-3" 27'-7" 28'-10" 6 #4's 4 #5's #5 @ 14" c/c 6900 1300 103

Diameter of Bin: 60'

Ring # B C D M N P #4 Bar (ft.) #5 Bar (ft.)

6 2'-0" 30'-9" 31'-3" 5 #4's 3 #5's #5 @ 14" c/c 7700 900 101

7, 8 2'-10" 30'-9" 31'-6" 5 #4's 3 #5's #5 @ 14" c/c 7700 1000 106

9, 10 3'-6" 30'-9" 31'-9" 5 #4's 4 #5's #5 @ 14" c/c 7700 1300 111

11, 12 4'-5" 30'-9" 32'-2" 7 #4's 5 #5's #5 @ 14" c/c 8500 1700 117

Cu. Yds.

Concrete

Cu. Yds.

Concrete

Cu. Yds.

Concrete

32 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 33

Floating Monolithic Pad

Recommendations for

4.00" Corrugation “W” Series,

Unstiffened Farm Bins

®

Section 07

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 33

Page 34

7. Monolithic Pad 4.00" Farm Bin

All foundation specifications shall be construed

as recommendations only. Because of t he many

variable conditions in actual installation, GSI

assumes no liability for results arising from the

use of such recommendations.

Floating Monolithic Pad for Unstiffened GSI Bins up to 5 Rings

(4.00" Corrugation)

Monolithic Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 7A

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most cases. Place the #4 bars

in the pad at 18" c/c each way.

Bin

Diameter

12' 6'-6'' 6' - 3-1/4'' 8' - 10-7/16'' 4 4.0 300 100 200

15' 8'-0'' 7' - 9-1/4'' 9' - 1-1/2'' 5 5.5 500 100 300

18' 9'-6'' 9' - 3-1/16'' 9' - 3-1/16'' 6 7.5 700 200 400

21' 11'-2'' 10' - 8-15/16'' 9' - 3-15/16'' 7 9.5 900 200 600

24' 12'-6" 12' - 2-7/8'' 9' - 4-3/8'' 8 12.0 1100 200 700

27' 14'-0" 13' - 8-3/4'' 9' - 4-11/16'' 9 14.5 1200 200 900

30' 15'-7'' 15' - 2-11/16'' 9' - 4-7/8'' 10 17.5 1600 200 1100

33' 17'-0'' 16' - 8-9/16'' 9'-5'' 11 20.5 1800 300 1300

36' 18'-8'' 18' - 2-7/16'' 9' - 5-1/16'' 12 24.0 2300 300 1500

34 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Outside

Radius

U/J Anchor

Bolt Radius

Anchor Chord # of Anchors

Total Cu. Yds.

Concrete

Sq. Ft.

Mesh

Length

#6 Bar

Optional #4

Grid (ft.)

Page 35

Frost Free Pad Recommendations

for 4.00" Corrugation “W” Series,

Unstiffened Farm Bins

®

Section 08

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 35

Page 36

8. Frost Free Pad Unstiffened 4.00" Farm Bin

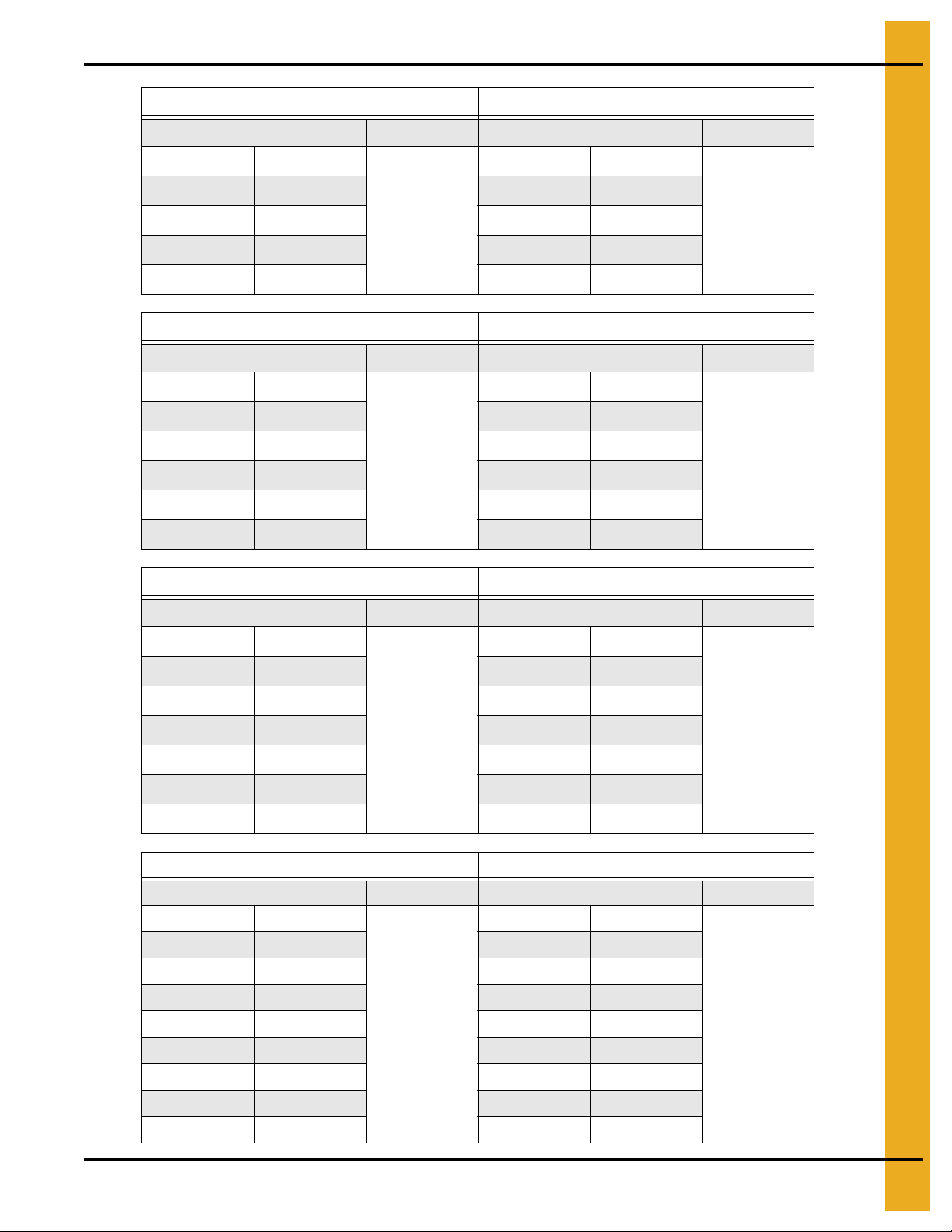

Outside Bin Hold-Down Charts (4.00" Corrugation)

Outside bin hold-down should be used on all non-stiffened bins. When anchoring the bin, be sure the

vertical seams of the bin align with the U-bolts in the foundation. They may be anchored to the foundation

using either the U-bolt and J-bolt combination or the single anchor bolt except on the 42' and larger bins

and bins 10 rings tall.

NOTE: All non-stiffened 42' and larger bins and bins 10 rings tall should use single anchor bolts not

the U-bolt/J-bolt combination. 10 Ring bins require double hold-downs. (Double U-bolt/J-bolt may

be used on non-stiffened 42' and larger bins no greater than 9 rings tall, as an option. Extra

hold-downs required with this option.)

Single Anchor Bolt Chart

3-9 Rings Except on

Bin Diameter

12' 6' - 2-7/16" 4 8' - 9-1/4" 8 4'-9"

15' 7' - 8-5/16" 5 9' - 0-9/16" 10 4' - 9-1/16"

18' 9' - 2-1/4" 6 9' - 2-1/4" 12 4' - 9-1/16"

21' 10' - 8-1/8" 7 9' - 3-3/16" 14 4'-9"

24' 12' - 2-1/16" 8 9' - 3-13/16" 16 4'-9"

27' 13' - 7-15/16" 9 9' - 4-1/8" 18 4' - 8-15/16"

30' 15' - 1-7/8" 10 9' - 4-3/8" 20 4' - 8-7/8"

33' 16' - 7-3/4" 11 9' - 4-9/16" 22 4' - 8-7/8"

36' 18' - 1-11/16" 12 9' - 4-11/16" 24 4' - 8-13/16"

42' 21' - 1-1/2" 14 9' - 4-13/16" 28 4' - 8-3/4"

48' 24' - 1-5/16" 16 9' - 4-7/8" 32 4' - 8-11/16"

“B” Bolt

Circle Radius

42', 48' and 60' Diameter

# of

Anchors

“E” Chord

Distance

10 Rings or Optional

Double Hold-Down

Anchors

# of

Anchors

U-Bolt/J-Bolt Combination Chart

Bin Diameter

“B” Bolt

Circle Radius

3-9 Rings Except on

42', 48' and 60' Diameter

# of

Anchors

“E” Chord

Distance

Optional Double

Hold-Down Anchors

# of

Anchors

“F” Chord

Distance

“F” Chord

Distance

12' 6' - 3-1/4" 4 8' - 10-7/16" 8 4' - 9-5/8"

15' 7' - 9-1/4" 5 9' - 1-1/2" 10 4' - 9-9/16"

18' 9' - 3-1/16" 6 9' - 3-1/16" 12 4' - 9-1/2"

21' 10' - 8-15/16" 7 9' - 3-15/16" 14 4' - 9-3/8"

24' 12' - 2-7/8" 8 9' - 4-3/8" 16 4' - 9-5/16"

27' 13' - 8-3/4" 9 9' - 4-11/16" 18 4' - 9-1/4"

30' 15' - 2-11/16" 10 9' - 4-7/8" 20 4' - 9-3/16"

33' 16' - 8-9/16" 11 9'-5" 22 4' - 9-1/16"

36' 18' - 2-7/16" 12 9' - 5-1/16" 24 4' - 9-1/16"

42' 21' - 2-5/16" 28 4' - 8-15/16"

48' 24' - 2-1/8" 32 4' - 8-7/8"

36 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 37

8. Frost Free Pad Unstiffened 4.00" Farm Bin

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising from the

use of such recommendations.

Frost Free Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF. Bearing

capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most ca ses. Place the #4 bars

in the pad at 18" c/c each way.

Figure 8A

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 37

Page 38

8. Frost Free Pad Unstiffened 4.00" Farm Bin

Frost Free Pads Unstiffened 4.00" Farm Bin

(Refer to Figure 8A on Page 37.)

Diameter of Bin: 18'

Corrugation: 4.00"

Ring # B N

6 1 ft. 0 in. 2 9 ft. 6 in. 600 400 200 8

8 1 ft. 7 in. 2 9 ft. 9 in. 600 400 200 9

Diameter of Bin: 21'

Corrugation: 4.00''

Ring # B N

6 1 ft. 1 in. 2 10 ft. 11 in. 800 500 200 10

8 1 ft. 8 in. 2 11 ft. 3 in. 800 500 200 12

Diameter of Bin: 24'

Corrugation: 4.00''

Ring # B N

6 1 ft. 1 in. 2 12 ft. 5 in. 1000 600 200 12

8 1 ft. 9 in. 2 12 ft. 9 in. 1000 600 200 15

Outside

Radius

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

9 2 ft. 6 in. 3 13 ft. 2 in. 1000 600 400 18

Diameter of Bin: 27'

Corrugation: 4.00''

Ring # B N

6 1 ft. 2 in. 2 14 ft. 0 in. 1200 700 200 16

8 1 ft. 10 in. 2 14 ft. 4 in. 1200 700 200 18

9 2 ft. 7 in. 3 14 ft. 7 in. 1200 700 500 21

Diameter of Bin: 30'

Corrugation: 4.00''

Ring # B N

6 1 ft. 2 in. 2 15 ft. 6 in. 1400 900 200 19

8 1 ft. 10 in. 2 15 ft. 10 in. 1400 900 200 21

9 2 ft. 8 in. 3 16 ft. 1 in. 1400 900 500 25

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

38 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 39

8. Frost Free Pad Unstiffened 4.00" Farm Bin

Frost Free Pads Unstiffened 4.00" Farm Bin (Continued)

(Refer to Figure 8A on Page 37.)

Diameter of Bin: 33'

Corrugation: 4.00''

Ring # B N

6 1 ft. 3 in. 2 17 ft. 0 in. 1700 1100 300 22

8 1 ft. 11 in. 2 17 ft. 4 in. 1700 1100 300 25

9 2 ft. 9 in. 3 17 ft. 6 in. 1700 1100 600 29

Diameter of Bin: 36'

Corrugation: 4.00"

Ring # B N

6 1 ft. 3 in. 2 18 ft. 6 in. 2000 1300 300 26

8 2 ft. 0 in. 2 18 ft. 11 in. 2000 1300 400 30

9, 10 2 ft. 10 in. 3 19 ft. 0 in. 2000 1300 600 33

Diameter of Bin: 42'

Corrugation: 4.00"

Ring # B N

Outside

Radius

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

T otal Cu. Yds.

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Concrete

6 1 ft. 4 in. 2 21 ft. 7 in. 2700 1800 300 34

8 2 ft. 1 in. 3 21 ft. 11 in. 2700 1800 700 39

9, 10 3 ft. 1 in. 4 22 ft. 2 in. 2700 1800 900 44

Diameter of Bin: 48'

Corrugation: 4.00"

Ring # B N

6 1 ft. 5 in. 2 24 ft. 6 in. 3500 2300 400 43

8 2 ft. 3 in. 3 24 ft. 11 in. 3500 2300 800 49

9, 10 3 ft. 3 in. 4 25 ft. 2 in. 3500 2300 1100 55

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 39

Page 40

NOTES

40 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 41

Floating Monolithic Pad

Recommendations for

2.66" Corrugation “N” Series,

Unstiffened Farm Bins

®

Section 09

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 41

Page 42

9. Monolithic Pad 2.66" Farm Bin

All foundation specifications shall be construed as

recommendations only. Because of the many variable

conditions in actual installation, GSI assumes

no liability for results arising from the use of

such recommendations.

Floating Monolithic Pad for Unstiffened GSI Bins up to 7 Rings

(2.66" Corrugation)

Monolithic Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

Figure 9A

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most cases. Place the #4 bars

in the pad at 18" c/c each way.

Bin

Diameter

12' 6'-6'' 6' - 2-3/16'' 8' - 8-7/8'' 4 4.0 300 100 200

15' 8'-0'' 7' - 8-1/16'' 9' - 0-1/4'' 5 5.5 500 100 300

18' 9'-6'' 9'-2'' 9'-2'' 6 7.5 700 200 400

21' 11'-2'' 10' - 7-7/8'' 9'-3'' 7 9.5 900 200 600

24' 12'-6" 12' - 1-13/16'' 9' - 3-5/8'' 8 12.0 1100 200 700

27' 14'-0" 13' - 7-11/16'' 9'-4'' 9 14.5 1200 200 900

30' 15'-7'' 15' - 1-5/8'' 9' - 4-1/4'' 10 17.5 1600 200 1100

33' 17'-0'' 16' - 7-1/2'' 9' - 4-3/8'' 11 20.5 1800 300 1300

36' 18'-8'' 18' - 1-3/8'' 9' - 4-1/2'' 12 24.0 2300 300 1500

42 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Outside

Radius

U/J Anchor

Bolt Radius

Anchor Chord # of Anchors

Total Cu. Yds.

Concrete

Sq. Ft.

Mesh

Length

#6 Bar

Optional #4

Grid (ft.)

Page 43

Frost Free Pad Recommendations

for 2.66" Corrugation “N” Series,

Unstiffened Farm Bins

®

Section 10

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 43

Page 44

10. Frost Free Pad Unstiffened 2.66" Farm Bin

Outside Bin Hold-Down Chart (2.66" Corrugation)

Outside bin hold-downs should be used on all non-stiffened bins/silos. When anchoring the bin, be sure

the vertical seams of the bin/silo align with the U-bolts or single anchor bolts in the foundation. Bin/silos

up to 36' diameter and 12 rings tall or shorter may be anchored using either the U-bolt/J-bolt combination

or the single anchor bolt. Bin/silos 42' and greater in diameter and all 13 rings o r taller should be anchored

using the single anchor bolt. Bins/silos 13 rings and taller require double hold-downs. The sidewall must

be field drilled to attach the hold-down bracket located between the horizontal seams. For the case of 42'

and larger bin/silo, no greater than 12 rings tall, double U-bolt/J-bolt combination anchors may be used as

an option to the single anchors bolt. Additional hold-downs are required with this option. Refer to Page 15

for outside hold-down bracket details.

Single Anchor Bolt Chart

Bin Diameter

12' 6' - 1-3/8" 4 8' - 7-3/4" 8 4' - 8-3/16"

15' 7' - 7-1/4" 5 8' - 11-5/16" 10 4' - 8-3/8"

18' 9' - 1-3/16" 6 9' - 1-3/16" 12 4' - 8-1/2"

21' 10' - 7-1/16" 7 9' - 2-1/4" 14 4' - 8-9/16"

24' 12'-1" 8 9' - 2-15/16" 16 4' - 8-9/16"

27' 13' - 6-7/8" 9 9' - 3-7/16" 18 4' - 8-9/16"

30' 15' - 0-13/16" 10 9' - 3-3/4" 20 4' - 8-9/16"

33' 16' - 6-11/16" 11 9' - 3-15/16" 22 4' - 8-9/16"

36' 18' - 0-9/16" 12 9' - 4-1/8" 24 4' - 8-9/16"

42' 21' - 0-7/16" 14 9' - 4-3/8" 28 4' - 8-1/2"

48' 24' - 0-1/4" 16 9' - 4-1/2" 32 4' - 8-1/2"

60' 29' - 11-7/8" 20 9' - 4-9/16" 40 4' - 8-1/2"

“B” Bolt

Circle Radius

For 3-12 Rings

# of

Anchors

“E” Chord

Distance

Double Hold-Down Anchors

Required for 13-15 Rings

# of

Anchors

U-Bolt/J-Bolt Combination Chart

Bin Diameter

12' 6' - 2-3/16" 4 8' - 8-7/8" 8 4' - 8-3/4"

15' 7' - 8-1/16" 5 9' - 0-1/4" 10 4' - 8-15/16"

18' 9'-2" 6 9'-2" 12 4' - 8-15/16"

21' 10' - 7-7/8" 7 9'-3" 14 4' - 8-15/16"

24' 12' - 1-13/16" 8 9' - 3-5/8" 16 4' - 8-7/8"

27' 13' - 7-11/16" 9 9'-4" 18 4' - 8-7/8"

30' 15' - 1-5/8" 10 9' - 4-1/4" 20 4' - 8-13/16"

33' 16' - 7-1/2" 11 9' - 4-3/8" 22 4' - 8-13/16"

36' 18' - 1-3/8" 12 9' - 4-1/2" 24 4' - 8-3/4"

42' 21' - 1-1/4" 28 4' - 8-11/16"

48' 24' - 1-1/16" 32 4' - 8-11/16"

60' 30' - 0-11/16" 40 4' - 8-5/8"

“B” Bolt

Circle Radius

For 3-12 Rings

# of

Anchors

“E” Chord

Distance

Optional Double Hold-Down

Anchors

# of

Anchors

“F” Chord

Distance

“F” Chord

Distance

44 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 45

10. Frost Free Pad Unstiffened 2.66" Farm Bin

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising

from the use of such recommendations.

Frost Free Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most ca ses. Place the #4 bars

in the pad at 18" c/c each way.

Figure 10A

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 45

Page 46

10. Frost Free Pad Unstiffened 2.66" Farm Bin

Frost Free Pads Unstiffened 2.66" Farm Bin

(Refer to Figure 10A on Page 45.)

Diameter of Bin: 18'

Corrugation: 2.66"

Ring # B N

8 1 ft. 0 in. 2 9 ft. 6 in. 600 400 200 8

10 1 ft. 4 in. 2 9 ft. 8 in. 600 400 200 9

12 1 ft. 10 in. 2 9 ft. 10 in. 600 400 200 10

Diameter of Bin: 21'

Corrugation: 2.66''

Ring # B N

8 1 ft. 0 in. 2 10 ft. 11 in. 800 500 200 10

10 1 ft. 5 in. 2 11 ft. 1 in. 800 500 200 11

12 1 ft. 11 in. 2 11 ft. 4 in. 800 500 200 13

Diameter of Bin: 24'

Corrugation: 2.66''

Ring # B N

8 1 ft. 1 in. 2 12 ft. 5 in. 1000 600 200 12

Outside

Radius

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

10 1 ft. 6 in. 2 12 ft. 8 in. 1000 600 200 14

12 2 ft. 0 in. 2 12 ft. 11 in. 1000 600 300 16

Diameter of Bin: 27'

Corrugation: 2.66''

Ring # B N

8 1 ft. 1 in. 2 13 ft. 11 in. 1200 700 200 15

10 1 ft. 6 in. 2 14 ft. 2 in. 1200 700 200 17

12 2 ft. 1 in. 3 14 ft. 5 in. 1200 700 400 19

Diameter of Bin: 30'

Corrugation: 2.66''

Ring # B N

8 1 ft. 2 in. 2 15 ft. 6 in. 1400 900 200 19

10 1 ft. 7 in. 2 15 ft. 8 in. 1400 900 200 20

12 2 ft. 2 in. 3 16 ft. 0 in. 1400 900 500 23

14 2 ft. 9 in. 3 16 ft. 0 in. 1400 900 500 25

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

15 3 ft. 6 in. 4 16 ft. 4 in. 1400 900 700 28

46 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 47

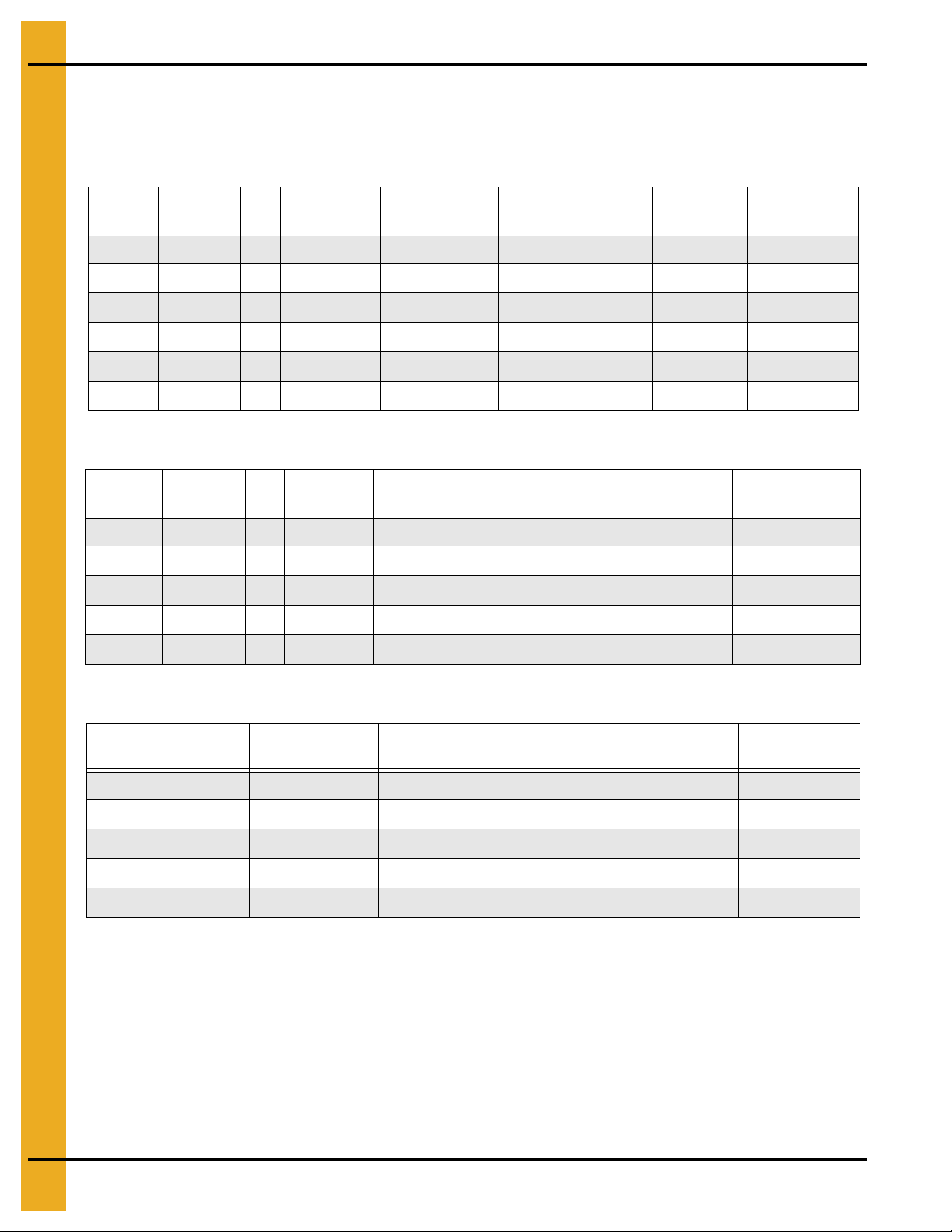

10. Frost Free Pad Unstiffened 2.66" Farm Bin

Frost Free Pads Unstiffened 2.66" Farm Bin (Continued)

(Refer to Figure 10A on Page 45.)

Diameter of Bin: 33'

Corrugation: 2.66''

Ring # B N

8 1 ft. 2 in. 2 17 ft. 0 in. 1700 1100 300 22

10 1 ft. 8 in. 2 17 ft. 3 in. 1700 1100 300 24

12 2 ft. 3 in. 3 17 ft. 6 in. 1700 1100 500 27

14 2 f t. 10 in. 3 17 ft. 6 in. 1700 1100 600 29

15 3 ft. 7 in. 4 17 ft. 10 in. 1700 1100 800 32

Diameter of Bin: 36'

Corrugation: 2.66"

Ring # B N

8 1 ft. 2 in. 2 18 ft. 6 in. 2000 1300 300 25

10 1 ft. 8 in. 2 18 ft. 9 in. 2000 1300 300 28

12 2 ft. 3 in. 3 19 ft. 0 in. 2000 1300 600 31

14 3 ft. 2 in. 3 19 ft. 1 in. 2000 1300 700 35

15 3 ft. 11 in. 4 19 ft. 5 in. 2000 1300 900 38

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

T otal Cu. Yds.

Total Cu. Yds.

Concrete

Concrete

Diameter of Bin: 42'

Corrugation: 2.66"

Ring # B N

8 1 ft. 4 in. 2 21 ft. 7 in. 2700 1800 300 34

10 1 ft. 10 in. 2 21 ft. 10 in. 2700 1800 300 37

12 2 ft. 5 in. 3 22 ft. 1 in. 2700 1800 700 41

14 3 ft. 2 in. 4 22 ft. 2 in. 2700 1800 900 44

15 3 ft. 11 in. 4 22 ft. 6 in. 2700 1800 100 49

Diameter of Bin: 48'

Corrugation: 2.66"

Ring # B N

8 1 ft. 4 in. 2 24 ft. 6 in. 3500 2300 400 43

10 1 ft. 11 in. 2 24 ft. 9 in. 3500 2300 400 47

12 2 ft. 7 in. 3 25 ft. 1 in. 3500 2300 800 51

14 3 ft. 4 in. 4 25 ft. 2 in. 3500 2300 1100 56

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Total Cu. Yds.

Concrete

Concrete

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 47

Page 48

10. Frost Free Pad Unstiffened 2.66" Farm Bin

Frost Free Pads Unstiffened 2.66" Farm Bin (Continued)

(Refer to Figure 10A on Page 45.)

Diameter of Bin: 54'

Corrugation: 2.66"

Ring # B N

8 1 ft. 5 in. 2 27 ft. 6 in. 4300 2900 400 53

10 2 ft. 1 in. 2 27 ft. 9 in. 4300 2900 700 58

12 2 ft. 9 in. 3 28 ft. 1 in. 4300 2900 900 63

14 3 ft. 6 in. 4 28 ft. 2 in. 4300 2900 1200 68

Diameter of Bin: 60'

Corrugation: 2.66"

Ring # B N

8 1 ft. 6 in. 2 30 ft. 7 in. 5400 3600 400 65

10 2 ft. 2 in. 3 30 ft. 11 in. 5400 3600 900 71

12 2 ft. 10 in. 3 31 ft. 3 in. 5400 3600 1100 77

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Total Cu. Yds.

Concrete

Concrete

48 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 49

Frost Free Pad Recommendations for

2.66" Corrugation Commercial Tanks

®

Section 11

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 49

Page 50

11. Frost Free Pad Commercial Tank

All foundation specifications shall be construed as

recommendations only. Because of the many

variable conditions in actual installation, GSI

assumes no liability for results arising

from the use of such recommendations.

Frost Free Pad Notes:

1. The foundation design is based on a minimum allowable soil bearing capacity of 3000 PSF.

Bearing capacity of the soils should be determined by geotechnical investigation and be of uniform

bearing capacity.

2. The foundation site must be free of vegetation and debris and well drained.

3. The foundation must be founded below the frost line or constructed on non-expansive frost free fill.

4. All material used for backfill inside the ring wall should be clean, well graded, crushed rock or a

sand-gravel mixture. Backfill should be placed in 6" lifts, 95% compaction.

5. All reinforcement must meet the requirements of ASTM A615 grade 60 deformed bars.

6. Lap all circumferential bars 35 bar diameters and stagger all laps in plans 3'-0". Estimates do not

include end laps.

7. Concrete must have a minimum compressive strength of 3000 PSI at 28 days, 6%-8% air

entrainment, 4" slump.

* Contact GSI Engineering for heights greater than 6".

** The optional #4 rebar grid can be substituted for the wire mesh in most cases. Place the #4 bars

in the pad at 18" c/c each way.

Figure 11A

50 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 51

11. Frost Free Pad Commercial Tank

Frost Free Pad Commercial Tank

(Refer to Figure 11A on Page 50.)

Diameter of Bin: 18'

Corrugation: 2.66"

Ring # B N

8 1 ft. 0 in. 2 9 ft. 6 in. 500 400 200 8

10 1 ft. 4 in. 2 9 ft. 8 in. 500 400 200 9

12 1 ft. 10 in. 2 9 ft. 10 in. 500 400 200 10

Diameter of Bin: 21'

Corrugation: 2.66''

Ring # B N

8 1 ft. 0 in. 2 10 ft. 11 in. 700 500 200 10

10 1 ft. 5 in. 2 11 ft. 1 in. 700 500 200 11

12 1 ft. 11 in. 2 11 ft. 4 in. 700 500 200 13

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

Diameter of Bin: 24'

Corrugation: 2.66''

Ring # B N

8 1 ft. 1 in. 2 12 ft. 5 in. 900 600 200 12

10 1 ft. 6 in. 2 1 2 ft. 8 in. 900 600 200 14

12 2 ft. 0 in. 2 12 ft. 11 in. 900 600 300 16

14 2 ft. 7 in. 3 1 2 ft. 2 in. 900 600 400 18

Diameter of Bin: 27'

Corrugation: 2.66''

Ring # B N

8 1 ft. 1 in. 2 13 ft. 11 in. 1100 700 200 15

10 1 ft. 6 in. 2 14 ft. 2 in. 1100 700 200 17

12 2 ft. 1 in. 3 14 ft. 5 in. 1100 700 400 19

14 2 ft. 8 in. 3 14 ft. 5 in. 1100 700 500 21

Diameter of Bin: 30'

Corrugation: 2.66''

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

To tal Cu. Yds.

Concrete

Ring # B N

8 1 ft. 2 in. 2 15 ft. 6 in. 1300 900 200 19

10 1 ft. 7 in. 2 15 ft. 8 in. 1300 900 200 20

12 2 ft. 2 in. 3 16 ft. 0 in. 1300 900 500 23

14 2 ft. 9 in. 3 16 ft. 0 in. 1300 900 500 25

16 3 ft. 6 in. 4 16 ft. 4 in. 1300 900 700 28

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Length #6

Bar (ft.)

To tal Cu. Yds.

Concrete

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins 51

Page 52

11. Frost Free Pad Commercial Tank

Frost Free Pad Commercial Tank (Continued)

(Refer to Figure 11A on Page 50.)

Diameter of Bin: 33'

Corrugation: 2.66''

Ring # B N

8 1 ft. 2 in. 2 17 ft. 0 in. 1600 1100 300 22

10 1 ft. 8 in. 2 17 ft. 3 in. 1600 1100 300 24

12 2 ft. 3 in. 3 17 ft. 6 in. 1600 1100 500 27

14 2 ft. 10 in. 3 17 ft. 6 in. 1600 1100 600 29

16 3 ft. 7 in. 4 17 ft. 10 in. 1600 1100 800 32

Diameter of Bin: 36'

Corrugation: 2.66"

Ring # B N

8 1 ft. 2 in. 2 18 ft. 6 in. 1900 1300 300 25

10 1 ft. 8 in. 2 18 ft. 9 in. 1900 1300 300 28

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18'' x 18'' Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

12 2 ft. 3 in. 3 19 ft. 0 in. 1900 1300 600 31

14 3 ft. 2 in. 3 19 ft. 1 in. 1900 1300 700 35

16 3 ft. 11 in. 4 19 ft. 5 in. 1900 1300 900 38

18 4 ft. 10 in. 5 19 ft. 9 in. 1900 1300 1100 43

Diameter of Bin: 39'

Corrugation: 2.66"

Ring # B N

8 1 ft. 3 in. 2 20 ft. 0 in. 2300 1500 300 29

10 1 ft. 9 in. 2 20 ft. 3 in. 2300 1500 300 32

12 2 ft. 4 in. 3 20 ft. 6 in. 2300 1500 600 35

14 3 ft. 2 in. 3 20 ft. 10 in. 2300 1500 700 40

16 3 ft. 11 in. 4 21 ft. 2 in. 2300 1500 1000 44

18 4 ft. 10 in. 5 21 ft. 6 in. 2300 1500 1200 49

Diameter of Bin: 42'

Corrugation: 2.66"

Ring # B N

Outside

Radius

Outside

Radius

Sq. Ft. Mesh

6 x 6 - 6/6

Sq. Ft. Mesh

6 x 6 - 6/6

Optional #4

18" x 18" Grid (ft.)

Optional #4

18" x 18" Grid (ft.)

Length #6

Bar (ft.)

Length #6

Bar (ft.)

Total Cu. Yds.

Concrete

Total Cu. Yds.

Concrete

8 1 ft. 4 in. 2 21 ft. 7 in. 2600 1800 300 34

10 1 ft. 10 in. 2 21 ft. 10 in. 2600 1800 300 37

12 2 ft. 5 in. 3 22 ft. 1 in. 2600 1800 700 41

14 3 ft. 2 in. 4 22 ft. 2 in. 2600 1800 900 44

16 3 ft. 11 in. 4 22 ft. 6 in. 2600 1800 1000 49

18 4 ft. 10 in. 5 22 ft. 11 in. 2600 1800 1300 54

52 PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

Page 53

11. Frost Free Pad Commercial Tank

Frost Free Pad Commercial Tank (Continued)

(Refer to Figure 11A on Page 50.)

Diameter of Bin: 45'

Corrugation: 2.66"

Ring # B N

8 1 ft. 4 in. 2 23 ft. 0 in. 3000 2000 300 38

10 1 ft. 10 in. 2 23 ft. 3 in. 3000 2000 300 41

12 2 ft. 6 in. 3 23 ft. 6 in. 3000 2000 800 46