Page 1

Instructions

PNEG-300

1004 East Illinois Street • Assumption, IL 62510 • 1-217-226-4421

Rotary Switch Instructions

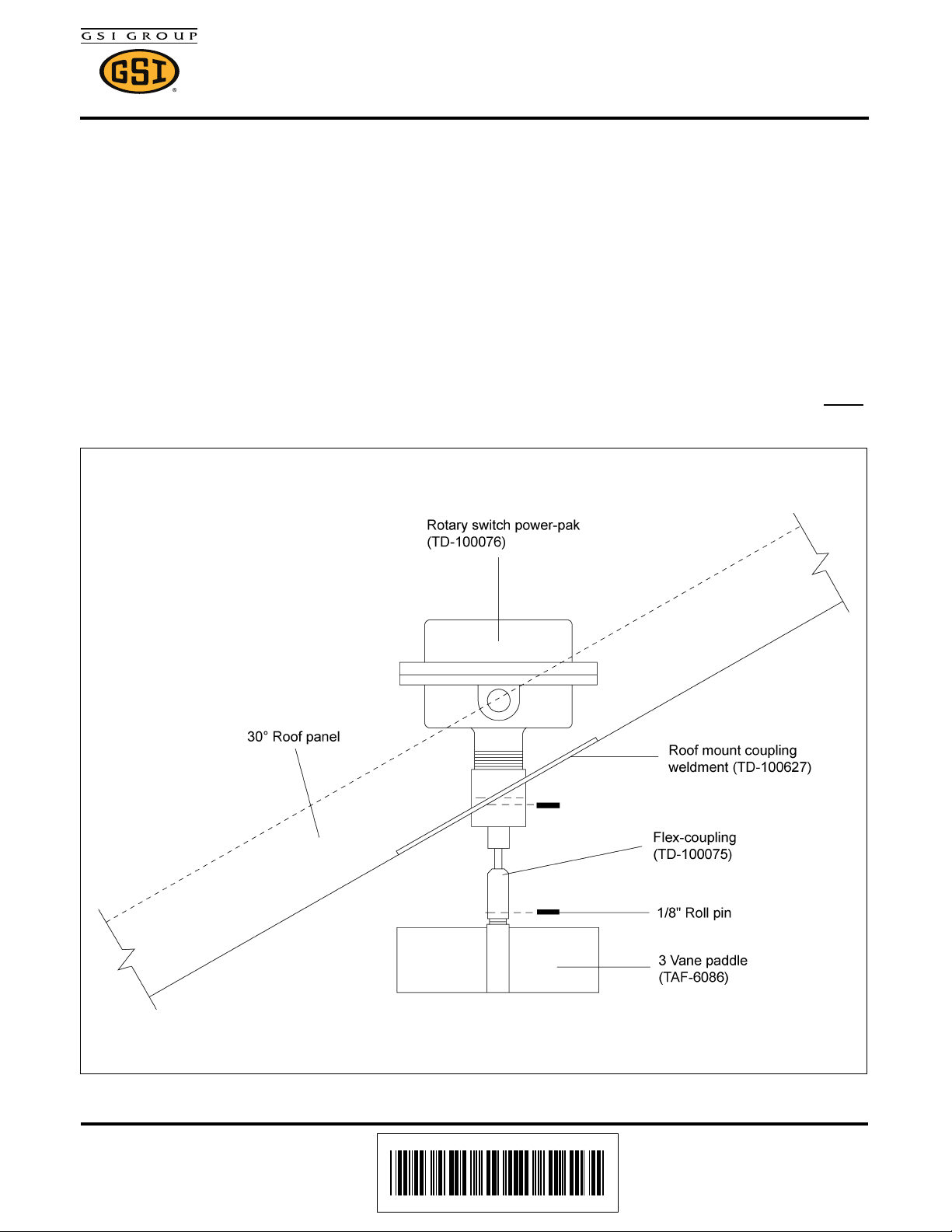

Installation of Roof Mounted Level Switches

Drill 2" diameter holes through roof panels at locations shown on Page 3. Use a mounting plate as a

pattern and drill four (4) 3/8" holes through roof panels at each switch location so the plate can be bolted to

the roof.

Attach flex-coupling to the power-pak. Apply teflon tape or pipe sealant (not included) to power-pak pipe

threads and thread power-pak into mounting plate coupling. Conduit opening in power-pak should be at

right angles to roof rib or face toward eave.

Caulk underside of mounting plate above and both sides of 2" hole. Bolt to roof panel.

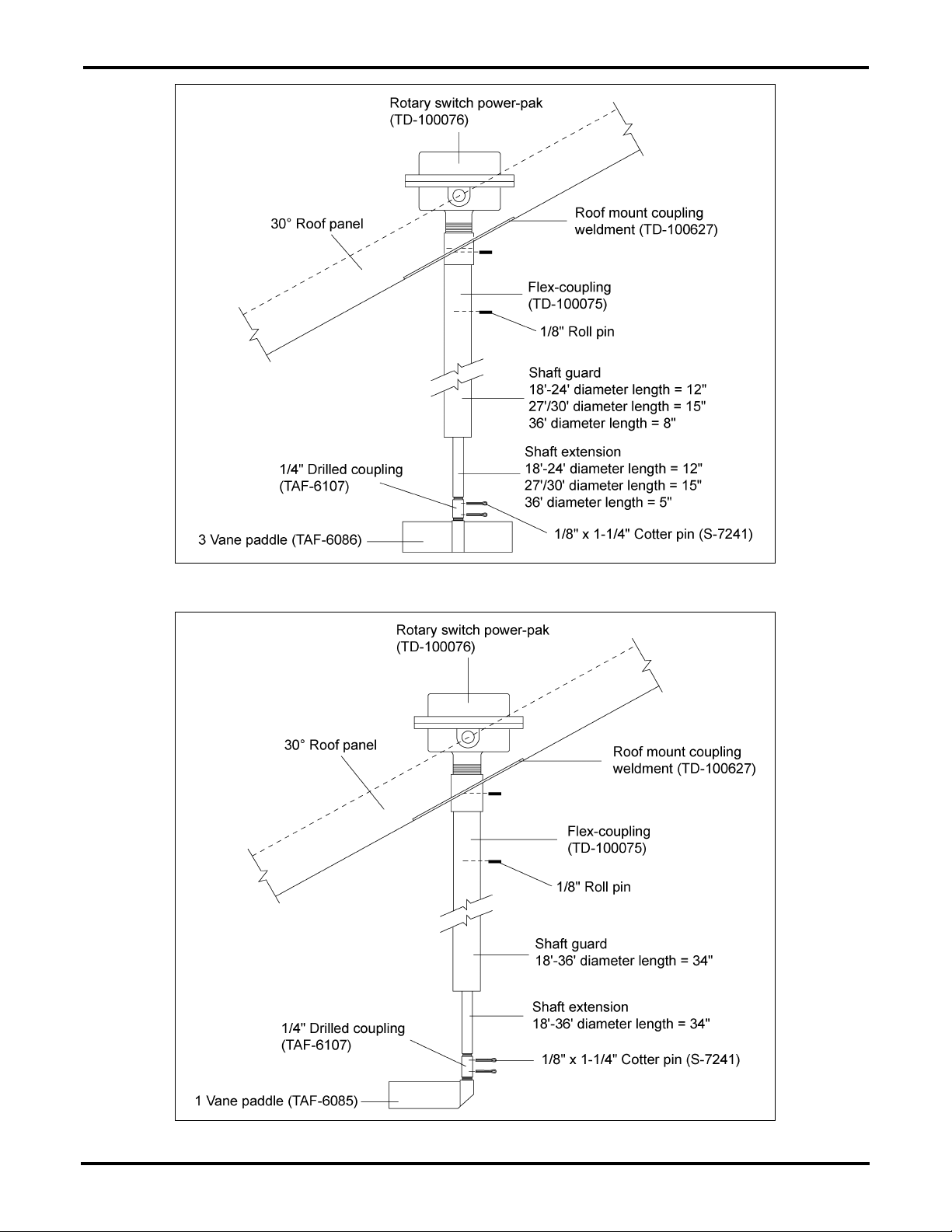

Attach shaft extension according to Figure 2 and Figure 3 on Page 2. Use teflon tape or pipe sealant

(not included) on shaft guard (see Figure 2 and Figure 3 on Page 2 for lengths) and thread to underside

of mount plate coupling. Add 1/4" drilled coupling and paddle. (NOTE: Single vane paddle is used on LOW

level switch.)

Date: 12-16-10

Printed in the U.S.A.

Copyright © 2010 by GSI Group

www.gsiag.com

Figure 1 Overflow Rotary Switch Assembly

PNEG-300

Page 1 of 4

Page 2

Rotary Switch Instructions

Figure 2 High-Limit Rotary Switch Assembly

Figure 3 Low-Limit Rotary Switch Assembly

Page 2 of 4 PNEG-300

Page 3

Rotary Switch Instructions

NOTE: Attach the flex-coupling to the rotary switch

power-pak, then thread the power-pak into the roof mount

coupling before bolting the roof mount to the roof sheet.

Top Dry Bin

Diameter

“A”

18'-24' 23-1/2"

27'/30' 19"

36' 31"

PNEG-300 Page 3 of 4

Figure 4

Page 4

Rotary Switch Instructions

Installation of Wall Mounted Level Switch

Drill 2" hole through wall at desired location. If bin is 2.66" corrugation, hole should be centered on outside

hill. If bin is 4.00" corrugation, hole should be centered on outside valley.

Position mount plate as desired (from inside), mark and drill 3/8" holes. Caulk coupling abundantly where

it passes through wall. Add foam weather strip around top and sides of plate then bolt to bin wall. Caulk

coupling to wall seam from outside.

Attach flex coupling to power-pak. Add teflon tape or pipe sealant (not provided) to power-pak pipe

threads and thread into coupling. Conduit opening should be horizontal or down. Add 1 vane paddle.

(Paddle may be added to flex coupling before power-pak is threaded into coupling if desired.)

Figure 5

Page 4 of 4 PNEG-300

Loading...

Loading...