Page 1

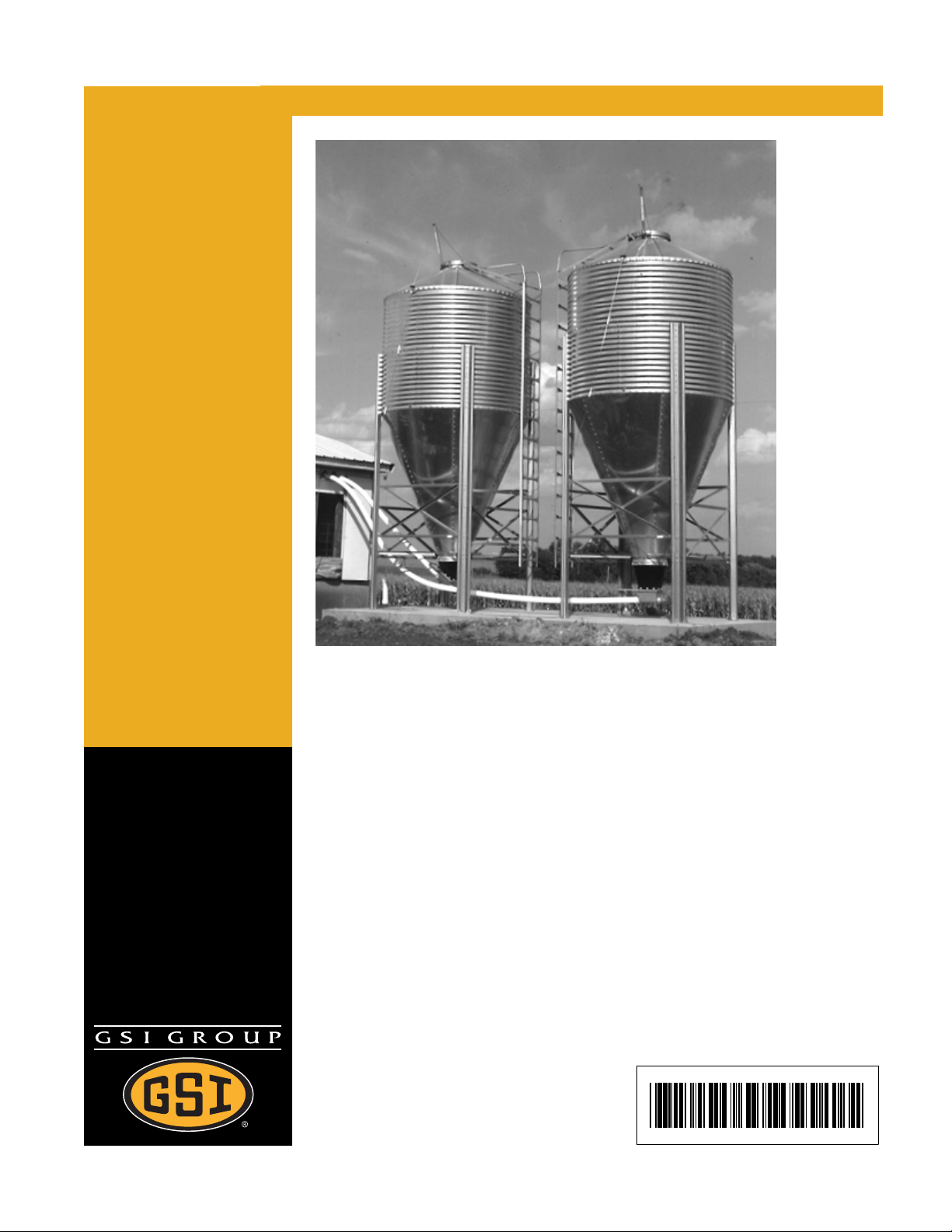

6', 7' & 9' Bulk Feed Tanks

Assembly Manual

PNEG-256

Date: 03-29-07

PNEG-256

Page 2

All information, illustrations, photos, and specifications in this manual are based on

the latest information available at the time of publication. The right is reserved to

make changes at any time without notice.

2 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 3

Table of Contents

Contents

Chapter 1 Introduction ....................................................................................................................... 4

Chapter 2 Safety ................................................................................................................................. 5

Safety Guidelines ................................................................................................................ 5

General Safety Statement ................................................................................................... 6

Safety Instructions ............................................................................................................... 7

Prevent Wet Storage Stain .................................................................................................. 9

Chapter 3 Decals ............................................................................................................................... 10

Chapter 4 General Information ........................................................................................................ 13

Bulk Feed Tank Assembly Manual General Instructions .................................................. 13

Chapter 5 Foundation ....................................................................................................................... 15

Chapter 6 Sidewall Assembly .......................................................................................................... 21

Tank Side Walls ................................................................................................................21

Sidewall Sheet Orientation ................................................................................................ 23

Chapter 7 Roof .................................................................................................................................. 26

Sealed Roof Panels Installation ........................................................................................ 26

Peak Ring .......................................................................................................................... 27

Eave Safety Rail (6') ..........................................................................................................28

Eave Ladder ...................................................................................................................... 29

Peak Ring-Ladder ............................................................................................................. 30

Cap .................................................................................................................................... 32

Peak Ring .......................................................................................................................... 36

Chapter 8 Hopper Assembly ............................................................................................................ 37

Hopper Sheets ..................................................................................................................37

Chapter 9 Legs and Leg Braces ...................................................................................................... 44

Tank Legs and Leg Braces ............................................................................................... 44

Chapter 10 Ladder ............................................................................................................................ 52

Optional Sidewall Ladder ................................................................................................. 52

Safety Cage ..................................................................................................................... 54

Chapter 11 Raising Bin ..................................................................................................................... 56

Raising Bin to set on Foundation ..................................................................................... 56

Chapter 12 Grounding ...................................................................................................................... 58

Bin Grounding Instructions ............................................................................................... 58

Chapter 13 Pneumatic Fill Kit Assembly ........................................................................................59

Roof Panel ....................................................................................................................... 59

Chapter 14 Parts Section ................................................................................................................. 61

6' Diameter 60° Hopper Bin Specifications ...................................................................... 62

6' Diameter 60° Hopper Bin Specifications ...................................................................... 64

7' Diameter 67° Hopper Bin Specifications ...................................................................... 66

7' Diameter 67° Hopper Bin Specifications ...................................................................... 68

7' Diameter 45° Hopper Bin Specifications ...................................................................... 70

7' Diameter 45° Hopper Bin Specifications ...................................................................... 72

9' Diameter 60° Hopper Bin Specifications ...................................................................... 74

9' Diameter 60° Hopper Tank Specifications ................................................................... 76

9' Diameter 45° Hopper Bin Specifications ...................................................................... 78

9' Diameter 45° Hopper Bin Specifications ...................................................................... 80

Chapter 15 Warranty ......................................................................................................................... 83

PNEG-256 6', 7' & 9' Bulk Feed Tanks 3

Page 4

1. INTRODUCTION

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do

so could result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The Customer is responsible for ensuring that

all quantities are correct. Report any damage or shortages by recording a detailed description

on the Bill of Lading to justify the Customer’s claim from the Transport Firm. Our responsibility

for damage to the equipment ends with acceptance by the delivering carrier. Save all paperwork

and documentation furnished with any of the equipment/components.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be

easily accessible when needed.

WARRANTY is provided as part of the company’s support program for customers who use and

maintain their equipment as described in the manual. The warranty is explained on the warranty

page located on the inside of the back cover of this manual.

This warranty provides you the assurance that the company will back its products where defects

appear within the warranty period. In some circumstances, the company also provides field

improvements, often without charge to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to change its performance beyond the factory

specifications, the warranty will become void and field improvements may be denied.

4 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 5

E

T

A

2

.

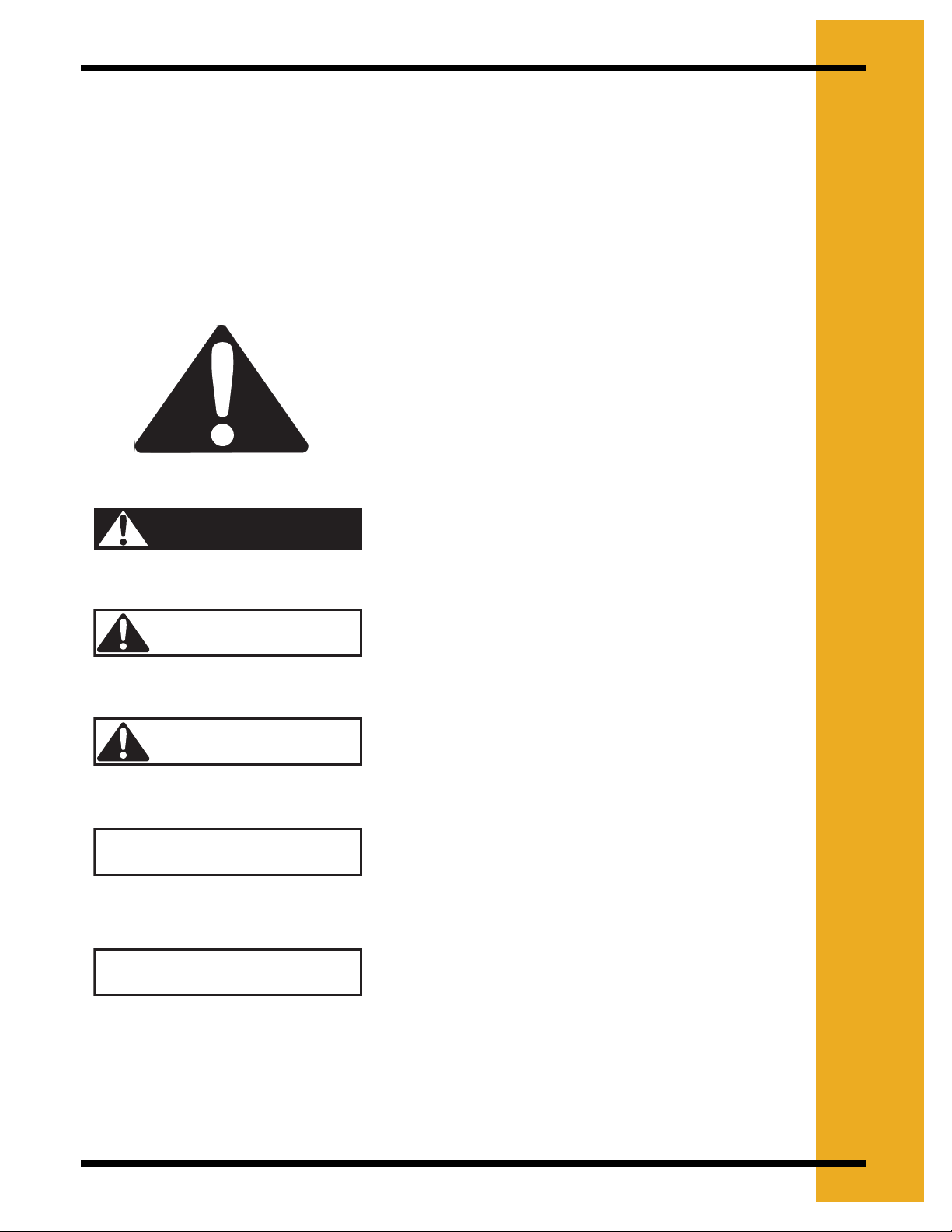

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing equipment

problems. It is the responsibility of the owner/operator to inform anyone operating or working in

the area of this equipment of these safety guidelines. To help you recognize this information, we

use the symbols that are defined below. Please read the manual and pay attention to these

sections. Failure to read this manual and it’s safety instructions is a misuse of the equipment and

may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

F

S

Y

DANGER

WARNING

CAUTION

CAUTION

NOTE

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTE indicates information about the equipment that

you should pay special attention to.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 5

Page 6

2. SAFETY

General Safety Statement

Our principle concern is your safety and the safety of others associated with grain handling

equipment. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and

precautions exist, and to inform all personnel associated with the equipment or in the area.

Safety precautions may be required from the personnel. Avoid any alterations to the equipment.

Such alterations may produce a very dangerous situation, where serious injury or death may

occur.

You should consider the location of the bin site relative to power line locations or electrical

transmission equipment. We recommend you contact your local power company to review your

installation plan or for information concerning required equipment clearance. Clearance of

portable equipment that may be taken to the bin site should be reviewed and considered as well.

Any electrical control equipment in contact with the bin should be properly grounded and

installed in accordance with National Electric Code provisions and other local or national codes.

This product is intended for the use of grain storage only. Any other use is a misuse of the

product!

This product has sharp edges! These sharp edges may cause serious

injury. To avoid injury, handle sharp edges with caution and use proper

protective clothing and equipment at all times.

Sidewall bundles or sheets must be stored in a safe manner. The safest method of storing

sidewall bundles is laying horizontally with the arch of the sheet upward or over like a dome.

Sidewall sheets stored on edge must be secured in a way that they cannot fall over and cause

injury. Care should be taken in the handling and movement of sidewall bundles.

Personnel operating or working around equipment should read this manual. This manual must

be delivered with equipment to its owner. Failure to read this manual and its safety instructions

is a misuse of the equipment.

6 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 7

Safety Instructions

Follow Safety Instructions

Carefully read all safety messages in this manual and

on your machine safety signs. Keep signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts

include the current safety signs. Replacement safety

signs are available from the manufacturer.

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may

impair the function and/or safety and affect machine

life.

2. SAFETY

Read and Understand Manual

If you do not understand any part of this manual and

need assistance, contact your dealer.

Practice Safe Maintenance

Understand service procedures before doing work.

Keep area clean and dry.

Never lubricate, service, or adjust machine while it is

in operation. Keep hands, feet, and clothing from all

rotating parts.

Keep all parts in good condition and properly

installed. Fix damage immediately. Replace worn or

broken parts. Remove any build up grease, oil, or

debris.

Maintain Equipment and Work Area

PNEG-256 6', 7' & 9' Bulk Feed Tanks 7

Page 8

2. SAFETY

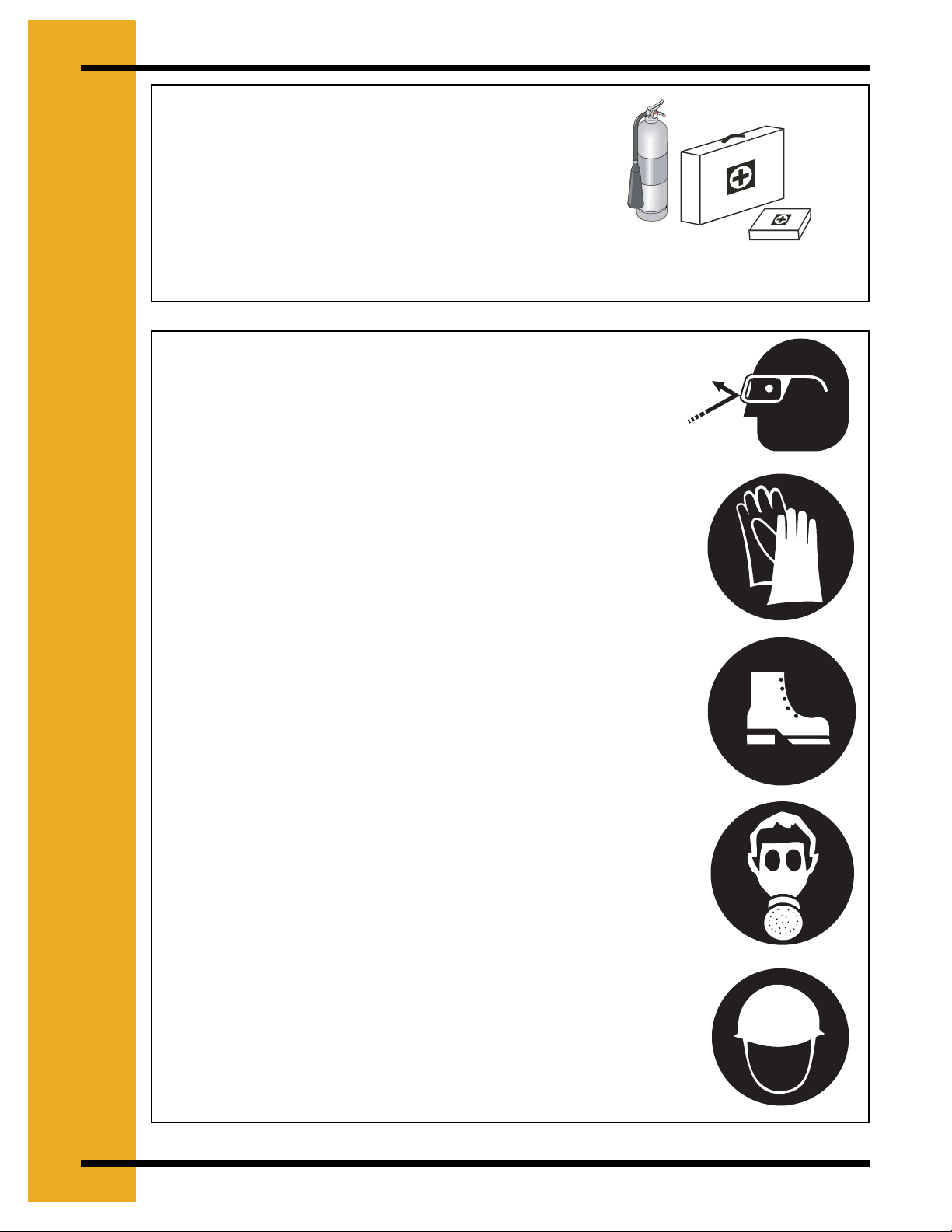

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher

handy.

Keep emergency numbers for doctors,

ambulance service, hospital, and fire

department near your telephone.

Wear Protective Clothing

Wear close fitting clothing and safety

equipment appropriate to the job.

Safety glasses should be worn at all times

to protect eyes from debris.

Keep Emergency Equipment Quickly

Accessible

Eye Protection

Wear gloves to protect your hands from

sharp edges on plastic or steel parts.

Wear steel toe boots to help protect your

toes from falling debris.

A respirator may be needed if a hog house

has poor ventilation. Waste fumes can be

toxic.

Remove all jewelry.

Tuck in any loose or dangling shoe strings.

Gloves

Steel Toe Boots

Respirator

Long hair should be tied up and back.

Wear hard hat to help protect your head.

Hard Hat

8 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 9

2. SAFETY

Prevent Wet Storage Stain

Properly Store Grain Bin/Silo Materials Prior to Construction to Prevent Wet Storage

Strain:

Wet storage stain (rust) will develop when closely packed bundles of galvanized material such

as sidewall and roof sheets have moisture present from any source. Roof and sidewall bundles

should be inspected on arrival for the presence of moisture. If moisture is present, moisture must

not be permitted to remain between the sheets. In the case of moisture presence, sheets or

panels should be separated immediately, wiped down, dried and sprayed with a light oil or diesel

fuel.

Where possible, sidewall bundles, roof sheets and other closely packed materials should be

stored in a dry, climate controlled building. Storage inside a dry building should be done if at all

possible. Where outdoor storage is unavoidable, the materials should be raised out of contact

from the ground or vegetation. Stacking and spacing materials should not be corrosive or wet.

Materials must be protected from the weather. Weather protection that permits more air

movement around the bundles is best.

The storage method of the roof bundles and sidewall sheets may also help minimize moisture

presence. Roof bundles should be stored inclined. The bundles should be stored and secured

in a safe & stable manner. Turning the bundles over and storing with the center of the dome “up”

like a arch is an option. Sidewall bundles may be stored on edge, however these bundles

should be secured in such as way as they cannot fall over and cause injury.

Should “white rust” or “wet storage stain” occur, contact the manufacturer immediately

concerning methods to minimize the adverse effect upon the galvanized coating.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 9

Page 10

3. DECALS

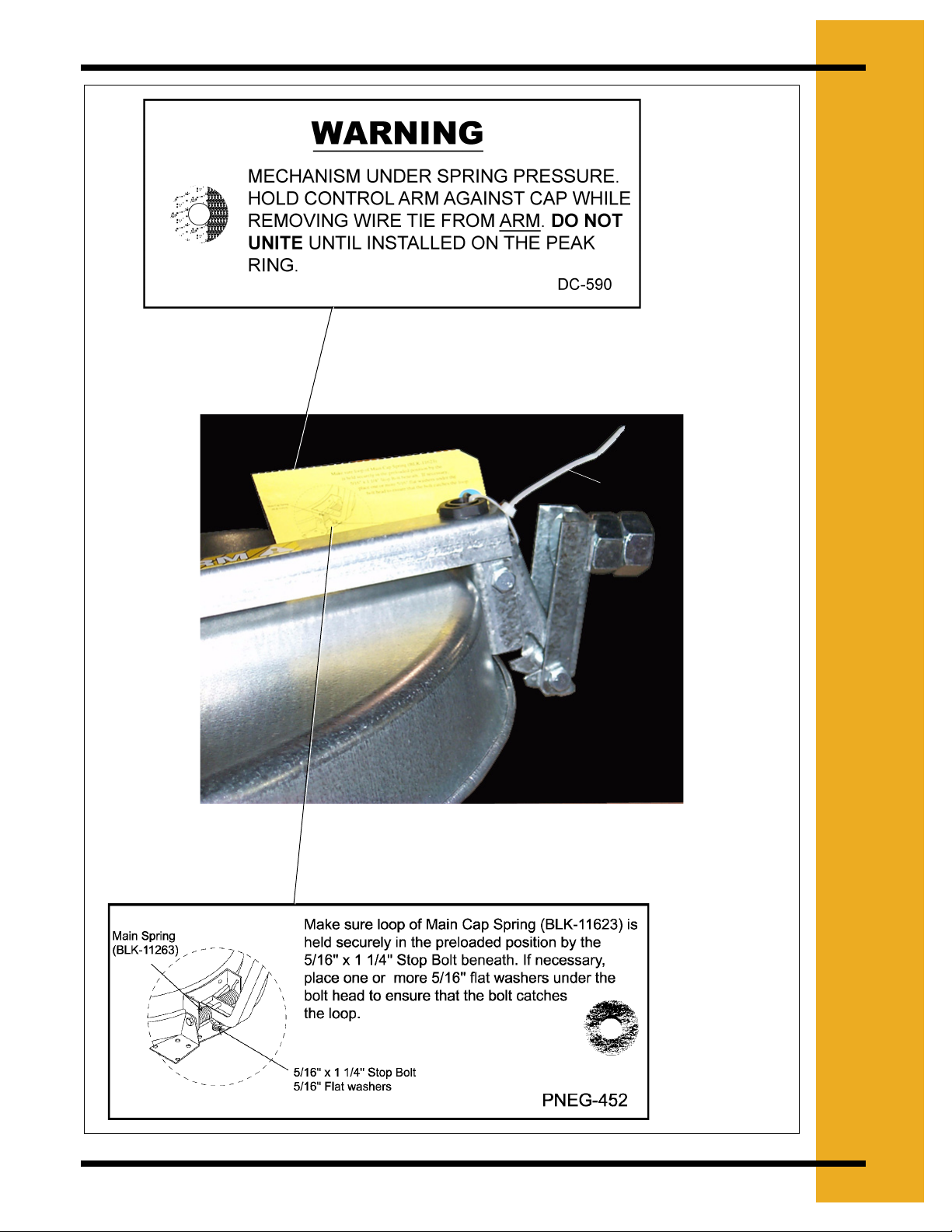

DC-604

DC-604 located on the Cap Latch Control Arm.

10 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 11

DC-590 located on the Cap

Latch Control Arm

Wire Tie

3. DECALS

PNEG-256 6', 7' & 9' Bulk Feed Tanks 11

Page 12

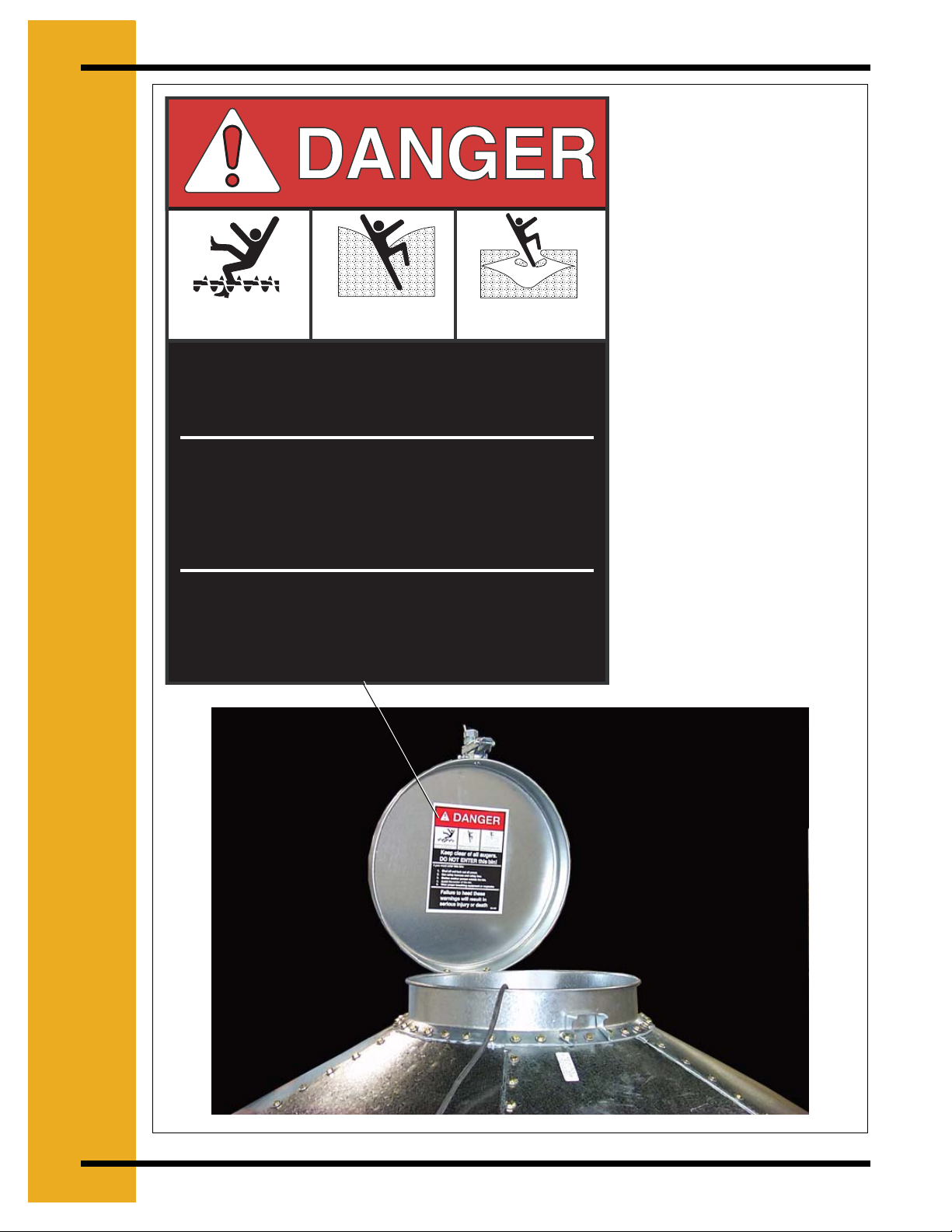

3. DECALS

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

If you must enter the bin:

1. Shut OFF and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

For Replacement Decals

Contact

P.O.Box 20

1004E. Illinois Street

Assumption IL, 62510-0020

Phone:1-217-226-4421

Failure to heed these

warnings will result in

serious injury or death.

DC-GBC-1A located on

Inside the Peak Cap

DC-GBC-1A

12 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 13

I

O

4

R

M

A

O

I

N

A

E

N

E

G

.

R

L

F

T

N

Bulk Feed Tank Assembly Manual General Instructions

This product is intended for the use of storing feed only. Any other use is a misuse of the product!

While every effort has been made to keep the edges from being sharp, please wear the proper

protective clothing while erecting the bulk feed tank.

Our company recommends that you contact your local power company and have a

representative review your installation so your wiring will be compatible with their system and so

that you will have adequate power supplied to your unit.

A bulk feed tank weighs a minimum of 444 lbs (201 kg). All precautions should be taken when

raising the tank to its feet. Follow the instructions given later in this manual.

The safety pages show you where you can find the safety decals. The photographs show exactly

where the decals should be. If a decal has been damaged or is missing contact our company for

a free replacement.

First, read the Assembly Manual completely before starting to assemble your Bulk Feed Tank.

Check your shipment with the packing list to be sure there are no shortages.

1. Decal protective mask must be removed when assembling tank. Mask may become difficult

to remove if left exposed to sunlight.

2. Vertical seams must be staggered on all sidewall rings.

3. When legs extend up two rings, the leg holes must be in alignment in the bottom two rings.

4. All hopper seams and the hopper collar use truss head bolts. The heads of the bolts must

be on the inside of the tank.

5. All bolts are to be tightened from the nut side only. Do not allow bolt heads to spin.

6. Hex head bin bolts are used on all sidewall and roof seams with the bolt heads on the

outside of the bin.

7. Hex head bolts are to be used on all leg to sidewall connections with the bolt heads on the

inside of the tank.

8. 7' diameter sidewall sheets must be bolted together so there is 65-5/8'' between leg holes.

(Refer to Page 66).

9. Drift punches can be used to align holes.

10. All vertical sidewall sheet seams must be overlapped in the same direction.

11. A hole spacing of 3-1/8'' is used at the top of all top sidewall sheets and at the bottom of

all bottom sidewall sheets.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 13

Page 14

4. GENERAL INFORMATION

Selecting the Proper Site

The selected site should be level, firm and free from underlying debris. The tank can be installed

satisfactorily on slopes, but as the slope increases, additional labor and materials are required

for the foundation. The concrete foundation surfaces must be level. If some fill is required, it

should be watered and tamped thoroughly to prevent uneven settling from the weight of the tank.

Good water drainage should be provided to prevent water collecting under or around the tank.

Naturally, the site must allow convenient access for easy loading and unloading, plus provide

additional space for future units. Also, consider the positioning of handling equipment, availability

of electricity, etc.

Tools

Tools recommended for assembly of Bulk Feed Tanks.

1. Assorted sizes of combination wrenches

2. Hammer

3. 3-12'' long drift punches

4. 1 Large Flathead Screwdriver

5. 1 Pair of slip joint pliers

6. 2 Adjustable wrenches

7. Ratchet and sockets

8. Impact wrenches and sockets (if available).

14 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 15

5

I

O

T

N

D

N

A

.

U

F

O

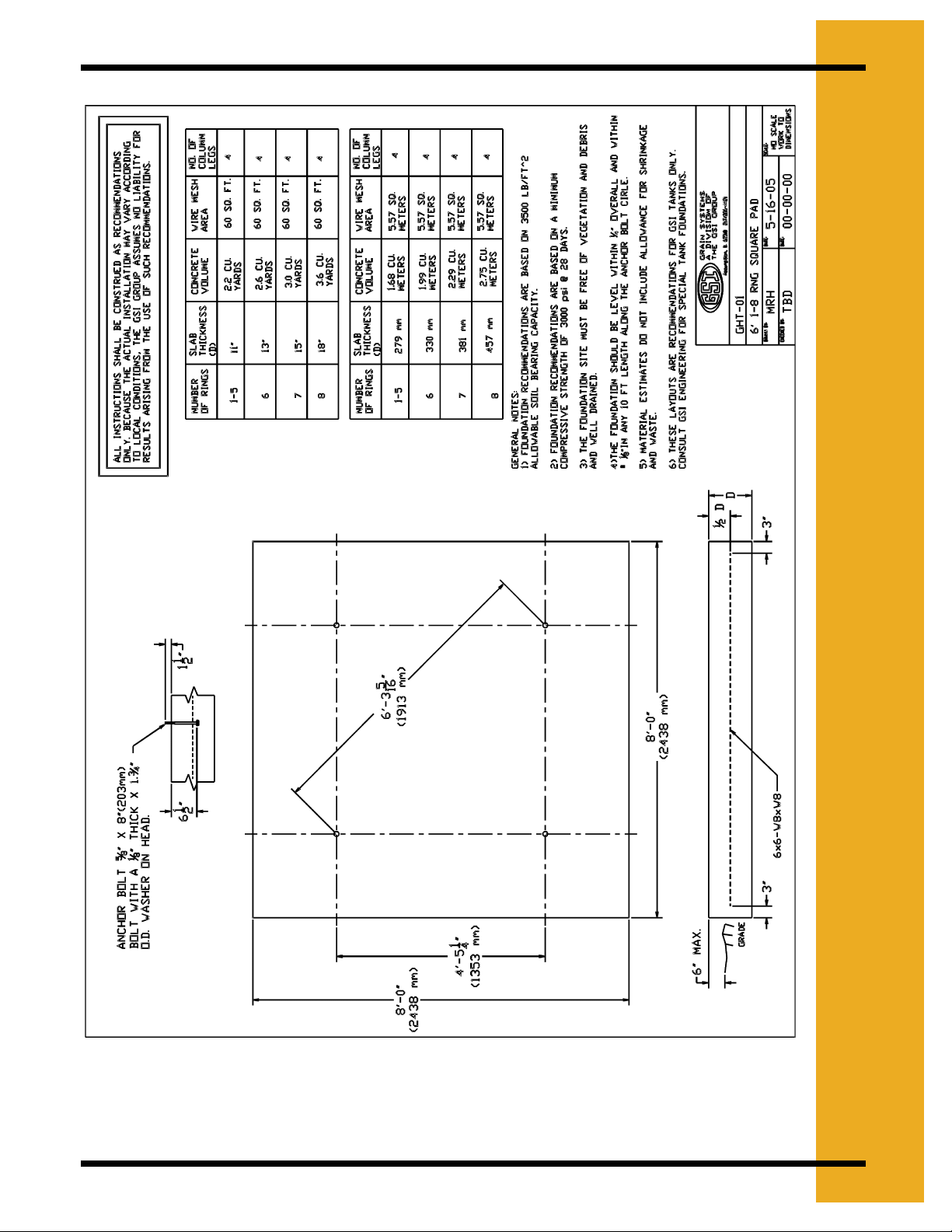

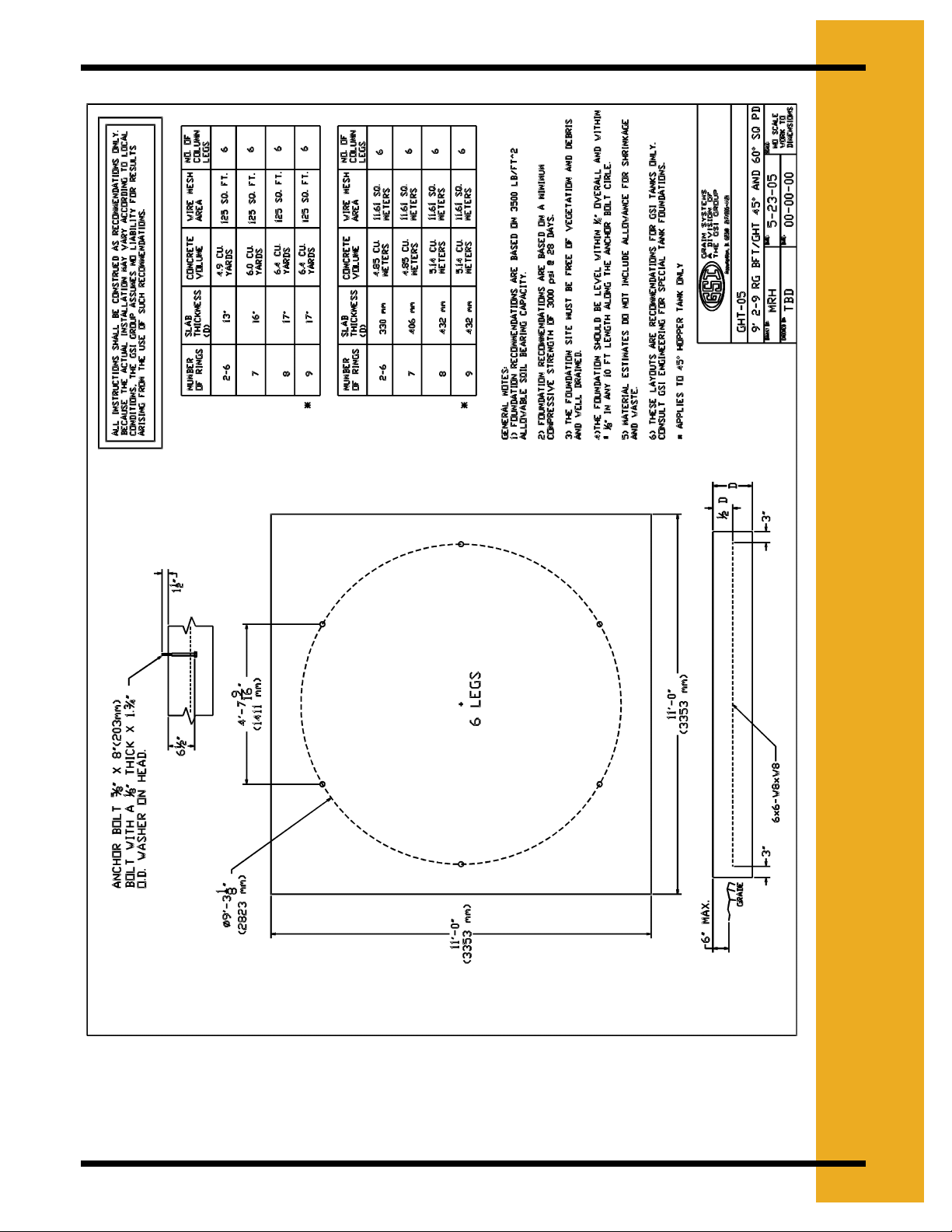

Figure 5A

PNEG-256 6', 7' & 9' Bulk Feed Tanks 15

Page 16

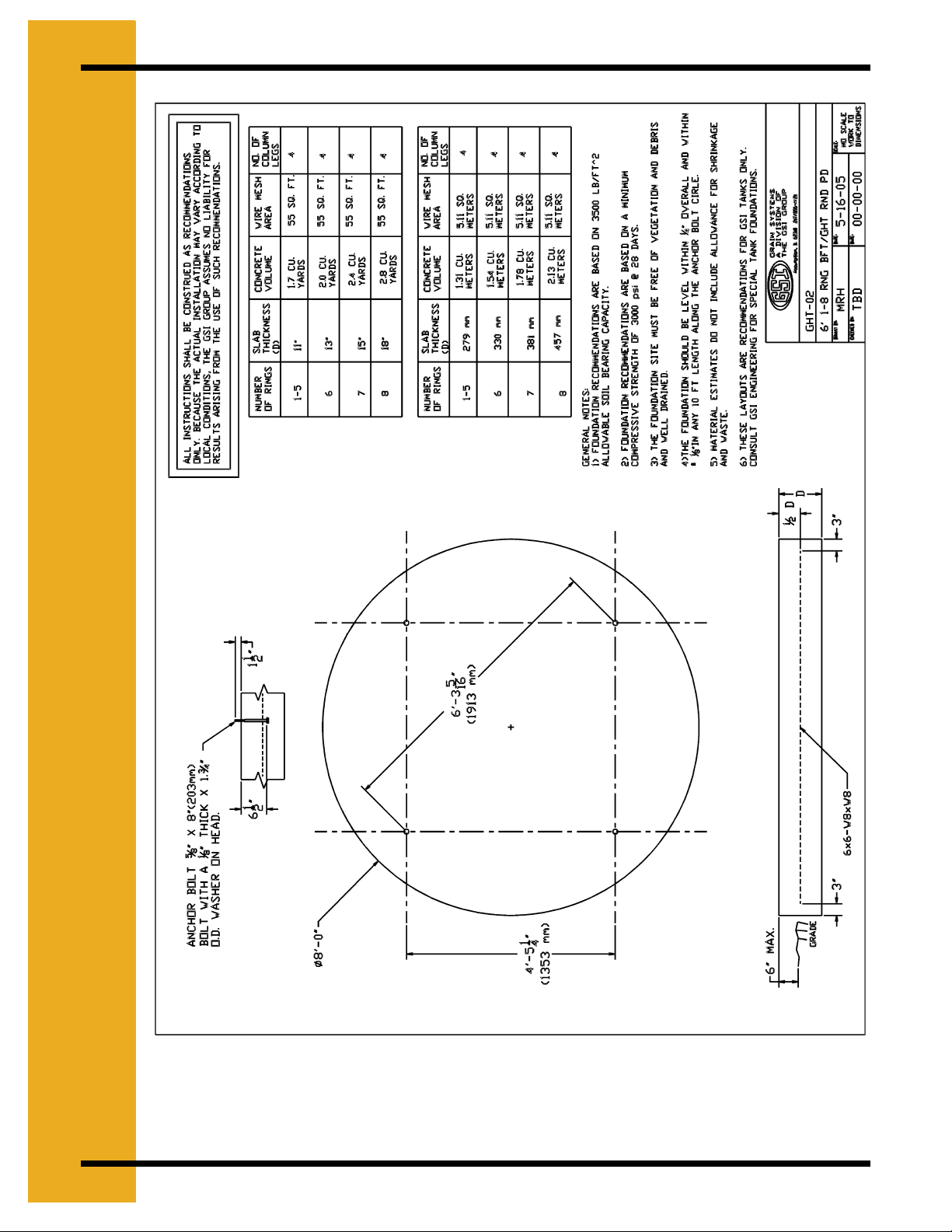

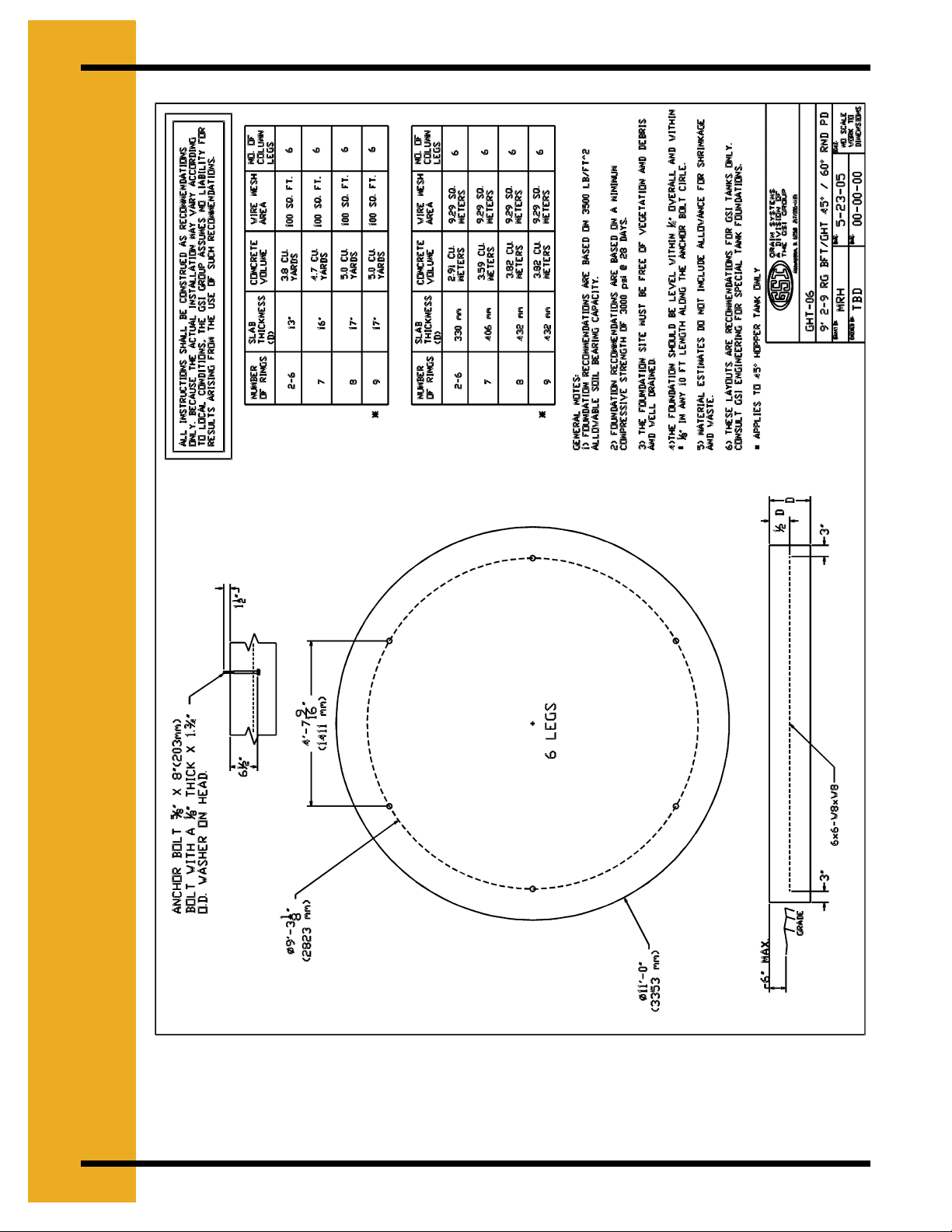

5. FOUNDATION

Figure 5B

16 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 17

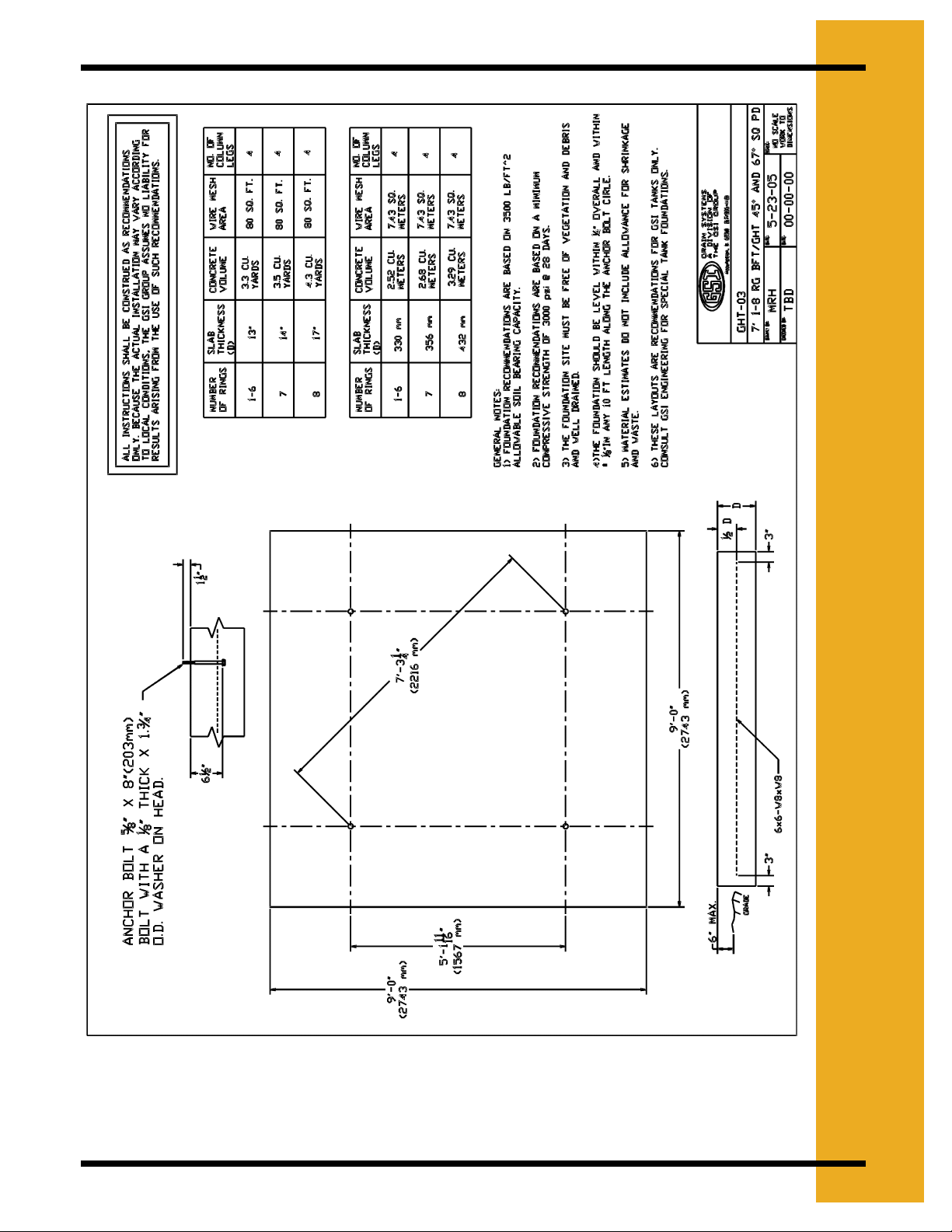

5. FOUNDATION

Figure 5C

PNEG-256 6', 7' & 9' Bulk Feed Tanks 17

Page 18

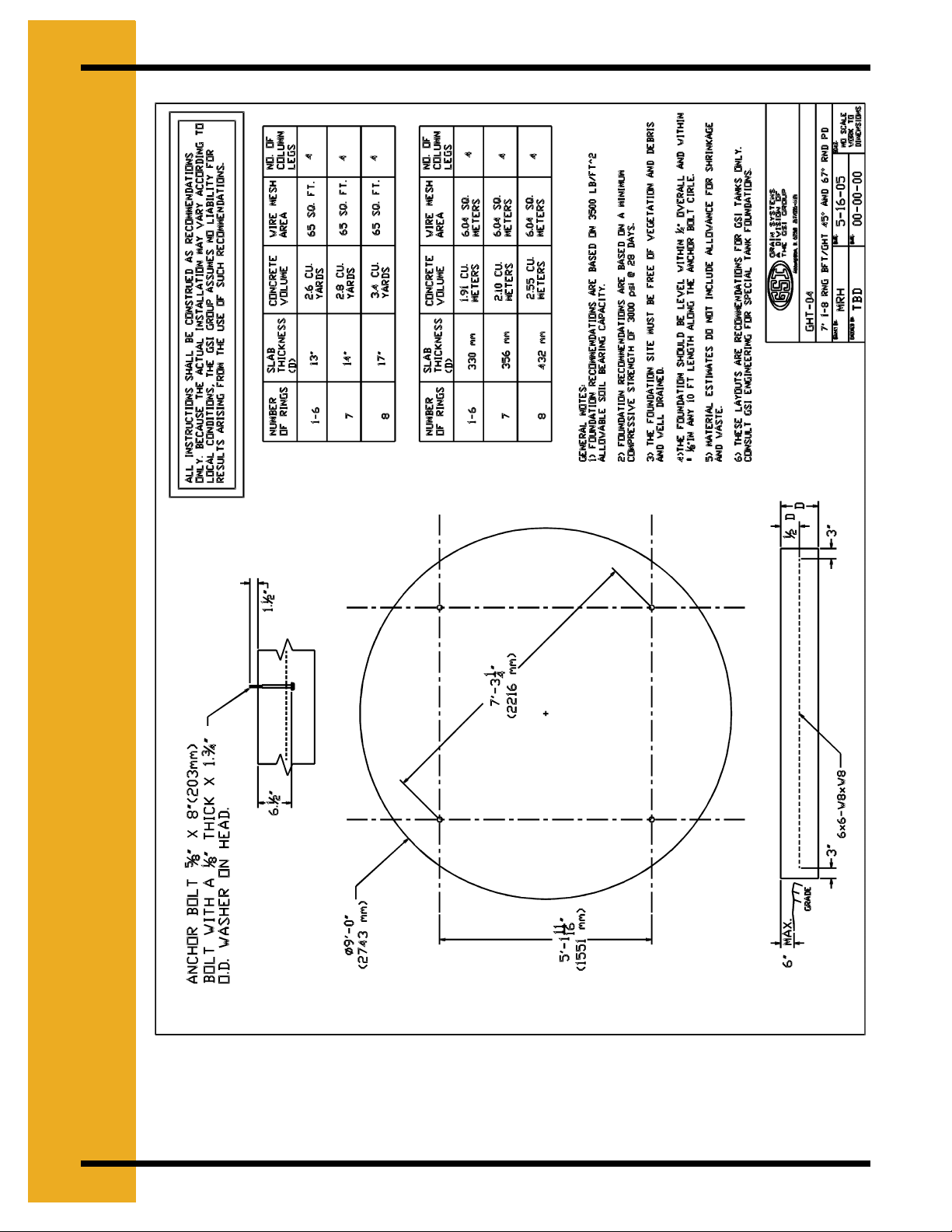

5. FOUNDATION

Figure 5D

18 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 19

5. FOUNDATION

Figure 5E

PNEG-256 6', 7' & 9' Bulk Feed Tanks 19

Page 20

5. FOUNDATION

Figure 5F

20 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 21

Tank Side Walls

I

6

Sidewall Sheet Gauge Chart

Model Gauge

BFT 6'-1 Ring 20

BFT 6'-2 Ring 20-20

BFT 6'-3 Ring 18-20-20

BFT 6'-4 Ring 18-20-20-20

BFT 7'-1 Ring 20

BFT 7'-2 Ring 18-20

BFT 7'-3 Ring 18-20-20

BFT 7'-4 Ring 18-18-20-20

BFT 7'-5 Ring 17-17-18-20-20

BFT 7'-6 Ring 15-15-17-18-20-20

BFT 9'-1 Ring 20

BFT 9'-2 Ring 20-20

BFT 9'-3 Ring 20-20-20

BFT 9'-4 Ring 18-18-20-20

BFT 9'-5 Ring 17-17-18-20-20

BFT 9'-6 Ring 15-15-17-18-20-20

D

.

S

E

W

A

L

L

B

L

E

S

M

A

S

Y

How to Use Chart on this Page

The chart labeled “Sidewall Sheet Gauge Chart” is for your reference when building the tank.

This chart tells you what gauges your rings of your specific tank must have. To read the chart

you look up the tank size you are building (a 7 foot diameter tank with 4 rings is referred to as

BFT 7'-4 Ring). The side labeled “Gauge” will indicate which sidewall sheets to use. The sheets

are color coded, all that needs to be done is to match the gauge number with the color

(use “Sheet Gauge Color Chart”).

Note: Sidewall sheets are color coded on edges for gauge identification.

Sheet Gauge Color Chart

Code # Color

20 Red

18 Orange

17 Pink/Light Blue

16 Blue

15 Brown/Red

14 Green

13 yellow/Blue

12 Black

11 Pink

10 Light Blue

PNEG-256 6', 7' & 9' Bulk Feed Tanks 21

Page 22

6. SIDEWALL ASSEMBLY

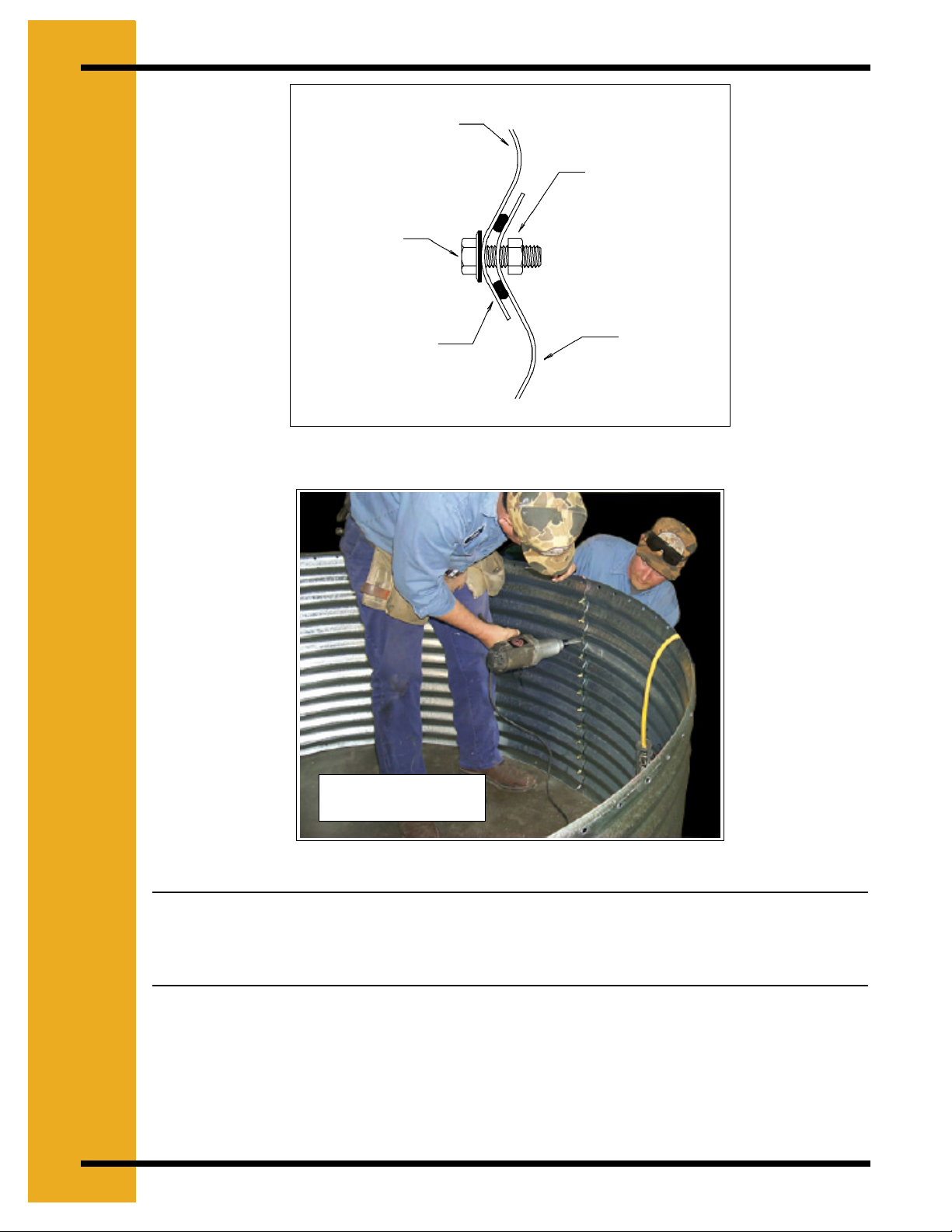

Caulking

Figure 6A Caulking Detail

Note: The rope caulking is installed before each sheet is assembled. Wipe sheet clean

where it is to be applied. Apply caulking on each side of the holes on the vertical

seams and also on each side of the horizontal row of holes.

Figure 6B

Caulking is to be

applied to all BFT

parts before

assembly.

22 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 23

6. SIDEWALL ASSEMBLY

Sidewall Sheet Orientation

Important: Please note the sheet orientation when assembling the bin sidewall. The

upper right corner will have a slot or identifying sticker. This corner should be

on the inside of the tank when assembled.

Figure 6C Viewed from inside

Sheet orientation will effect how the sheets lap together.

Sidewall Assembly

Start by assembling the top ring of the Bulk Feed Tank. The top row of bolt holes has 3-1/8"

spacing in the top ring. Before bolting the sidewall sheets together, check that you have the

proper gauge steel for the top ring. The higher gauge number denotes thinner material.

(Example, 20 gauge material is thinner than 14 gauge.) In assembling all bulk feed tanks the

thinnest material always go on top. The heaviest corrugated sidewall sheet will be located on the

bottom of the tank. Check the various gauges of your tank with the “Sheet Gauge Color Code

Chart” & “Sidewall Sheet Gauge Chart”, Page 21 and Page 21.) Begin by putting the rings

together on the edge of the sheets. On 7'-1 ring tanks ensure vertical leg seams are spaced

equally around tank. (Refer to Page 66.) After the first ring is complete the roof needs to be

assembled. The pages that follow give the proper instructions for this. After the roof is assembled

the tank can be rolled on its side for easier sidewall assembly. (See Figure 6D)

All bolts are to be tightened from the nut side only!

Continue to add rings with lighter gauges first, then heavier gauges. The next row of sidewall

sheets go to the inside of the previous row of sidewall panels. Do not forget to place the caulking

between every ring.

Be sure to stagger all vertical seams between rows.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 23

Page 24

6. SIDEWALL ASSEMBLY

Upper Ring

5/16'' x 3/4''

5/16'' Nut

Caulking

Figure 6D Ring Overlap Detail

Tighten bolts from the

nut side only.

Lower

First Ring Assembly

Figure 6E

Important: BOLTING PATTERN BEGINS IN THE CENTER OF THE SHEET! When starting

to assemble the sidewall rings to one another, be sure to start in the center of

the sheet and work to the outside edges (horizontal seams). This allows the

sidewall to draw up evenly.

24 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 25

6. SIDEWALL ASSEMBLY

Sidewall Assembly

Figure 6F

It is easier to put on more sidewall sheets with the tank on its side. It can be rolled easily from

side-to-side to allow the bolts and nuts to be put in the proper holes. (The roof is, however,

assembled on the first ring before rolling it over to its side.)

PNEG-256 6', 7' & 9' Bulk Feed Tanks 25

Page 26

7. ROOF

Sealed Roof Panels Installation

Note that the roof and sidewall ladders are centered on a roof seam. Take notice when placing

roof panel, that the outside edge is bent down. This edge is to be placed on the outside of other

roof panel to form a tight seal. Be sure to apply two strips of caulking on all seams. Assemble

roof panels in a counter clockwise manner.

Lining up holes and placing bolts

Figure 7A

Figure 7B

Assemble roof panels in a counter clockwise manner. On bins that will be equipped with a

pneumatic fill system (refer to Page 59), the two roof panels with fill hole and exhaust hole should

be located opposite each other on the bulk feed tank. The peak ring may now be installed.

5/16'' x 3/4'' Bin

Blot

Caulking

(2 Strips)

Inside of Tank

Figure 7C Roof Sheet Overlap Detail

26 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 27

7. ROOF

Caulki

Peak Ring

Peak Ring Collar to Roof Panels

Use two strips of caulking between peak ring and roof panels (See Figure 7E). Note that the peak

ring goes on the outside of the roof panels.

Peak Ring Collar

Inside of Tank

Roof Sheet

ng

(2 Strips)

5/16'' x 3/4'' Bin Blot

Caulking

Figure 7D Peak Ring Collar Detail

Peak Ring

5/16'' x 3/4''

Bin Bolt

Figure 7F

Figure 7E

PNEG-256 6', 7' & 9' Bulk Feed Tanks 27

Page 28

7. ROOF

Eave Safety Rail (6')

(See Figure 7H)

(See Figure 7I)

(See Figure 7J)

Figure 7G 6' Roof Eave Safety Rail Detail

6' Roof Safety Rail Detail

Ref # Part # Qty Description

1L BLK-11877L 1 6' BFT Left Hand Roof Eave Safety Rail

1R BLK-11877R 1 6' BFT Right Hand Roof Eave Safety Rail

3 S-275 6 5/16'' x 3/4'' Bin Bolt

5 S-396 6 5/16'' - 18 Hex Nut

6 BLK-11673 -- Lower Support Channel Bracket

7 LDR-4002 -- 44'' Sidewall Ladder Section

8 LS-121 -- Sidewall Ladder Standoff

Field drill two (2) 3/8'' Dia. holes in 6' roof for safety rail attachment. Use bin bolt sealing washer

between roof and rail. Note left and right positioning so it will fall between the legs when tank is

complete.

28 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 29

Figure 7H

7. ROOF

Figure 7I

Figure 7J

Eave Ladder

Note: Ladder is symmetrical about roof seam. One side shown for clarity.

Figure 7K 7' & 9' Roof Eave Ladder Detail

PNEG-256 6', 7' & 9' Bulk Feed Tanks 29

Page 30

7. ROOF

7' & 9' Roof Eave Ladder Detail

Ref # Part #

1 BLK-11680 2 2 Ladder Eave Safety Ring

2 BLK-11760 2 -- 7' BFT Roof Ladder Support Channel

BLK-11761 -- 2 9' BFT Roof Ladder Support Channel

3 S-275 16 18 5/16'' x 3/4'' Bin Bolt

4 BLK-11679 2 3 Roof Ladder Rung

5 S-396 16 18 5/16'' - 18 Hex Nut

6 BLK-11673 2 2 Lower Support Channel Bracket

7 LDR-4002 -- -- 44'' Sidewall Ladder Bracket

8 LS-121 -- -- Sidewall Ladder Standoff

Qty 7'

Dia

Qty 9'

Dia

Description

Peak Ring-Ladder

Bolt Spacing Used for Roof

Ladder Attachment

Figure 7L

*Possible Cap Latch

Locations

Roof Seam

Bolt Spacing Used for

Roof Ladder Attachment

Figure 7M 7'-9' Roof Ladder Peak Ring Detail

30 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 31

7. ROOF

Figure 7N

Note: Three (3) hole spaces on either side of center line of ladder. (Six (6) spaces

between brackets).

7' & 9' Roof Eave Ladder Detail

Ref # Part # Qty 7' Dia Qty 9' Dia Description

1 LS-147 2 2 Inside Ladder Standoff

2 BLK-11760 2 -- 7' BFT Roof Ladder Support Channel

2 BLK-11761 -- 2 9' BFT Roof Ladder Support Channel

3 S-275 16 18 5/16'' x 3/4'' Bin Bolt

4 BLK-11679 2 3 Roof Ladder Rung

5 S-396 16 18 5/16'' - 18 Hex Nut

Note that peak ring is mounted to the outside of the roof panels. 6' Bulk Feed Tank utilizes only

eave safety rail. See Page 29 for details.

Note: Center roof ladder over roof seam during assembly. Ladder is symmetrical about

roof seam. One side shown for clarity.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 31

Page 32

7. ROOF

Cap

Roof Cap Ground Control

See Figure 7P

Figure 7O

Ground control comes standard on 6'-60°, 7-67° and 9'-60° Bulk Feed Tanks. Ground Control is

optional on all 45° Bulk Feed Tanks. Ground control components come fully assembled for your

convenience. The ground control is shipped with the control arm secured for safety and shipping

purposes. The short chain and retaining tie are intended for shipping use only.

Important: Adjust Chain

in this Area as Explained

Below

See Figure 7Q

See Figure 7R

CAUTION

The control arm is spring loaded. Be careful when removing shipping retainers.

Chain Route

Cotter Pin

Figure 7P

32 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 33

7. ROOF

Refer to the Control Arm Detail and Cap Latch Detail on for component part assembly. The cap

latch hook, located opposite the cap hinge, latches over the BLK-11846 Hold Down Bracket

(Item 20, Cap Latch Detail on Page 19). One end of the ground control chain is secured at the

counterweight arm with a cotter pin (See Figure 7P). The chain is passed up and over the cap,

through the grommet on the pivot arm, and through the Roof Eave Bracket (BLK-11950), then

continues down the side of the tank.

After removing the slack from the ground control chain while in the fully closed and latched

position. Install the key ring clip 2'' below chain holder bracket (See Figure 7R). Ensure that the

key ring allows the cap to fully latch when the cap is in the closed position, yet will not allow the

chain enough slack on top of the cap to become wrapped around the pivot arm in a high wind

condition.

Roof Eave Bracket

BLK-11950

Figure 7Q

Make sure the loop of the Main Cap Spring (BLK-11623) is held securely in the preloaded

position by the head of the 5/16" Bolt beneath (Item 4, Control Arm Detail See Figure 7T). If

necessary, place one or more 5/16" flat washers under the bolt head to ensure that the bolt

catches the loop. See Stop Bolt Detail on Page 34.

Chain Holder

BLK-11949

Handle

Key Ring

Figure 7R

PNEG-256 6', 7' & 9' Bulk Feed Tanks 33

Page 34

7. ROOF

Bolt the Chain Holder (BLK-11949) to the bottom horizontal row of sidewall holes, or field drill

and bolt to the leg tie brace (See Figure 7R). Two (2) 4'' plastic handles and extra key ring clips

are provided for use at the hopper eave to be used as fully open and fully closed cap indicators.

Make sure the loop of the Main Cap Spring

(BLK-11623) is held securely in the preloaded

position by the head of the 5/16'' bolt beneath.

If necessary, place one or more 5/16'' flat

Washers under the bolt head to ensure

that the bolt catches the loop.

Figure 7S

WARNING

The control arm is spring loaded. It must be released while on the ground and before

attaching it to the peak ring. Failure to do so will result in serious injury.

Note: Use the chart on Page 19 for Control Arm and Ground Control details.

Right Hinge

Attachment Holes

Left Hinge

Attachment Holes

Figure 7T Control Arm Detail

Spring Stop Attachment Hole

34 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 35

7. ROOF

20

18

19

8

17

10

16

15

14

Figure 7U Ground Control Detail

Parts List for Control Arm and Ground Control

Ref # Part # Description

1 BLK-11735 Control Arm

2 BLK-11876 Nylon Grommet with Nut

3 BLK-11623 Flush Cap Main Spring

4 S-277 5/16'' - 18 x 1.25'' Bin Bolt (Grade 5)

5 S-845 5/16'' Wrought Iron Washer (Grade 2)

6 BLK-11842 Lower Cap Hinge

7 BLK-11734 Upper Cap Hinge

8 S-7329 5/16'' - 18 x 2'' Hex Head Bolt

9 BLK-10015 Bulk Tank Roof Cap

10 S-5220 5/16'' - 18 Hex Lock Nut (Grade 2)

11 BLK-11503 1.875'' Long Spring Spacer

12 BLK-11730 1 Piece Bulk Tank Peak Ring

13 S-7171 3/8'' - 16 x 6.5'' Hex Head Bolt (Grade 5)

14 S-3214 7/8'' - 9 Hex Nut (Grade 2)

15 BLK-11845 Latch Counterweight

16 S-7281 7/8'' - 9 x 1.5'' Hex Head Bolt

17 BLK-11844 Peak Cap Latch

18 BLK-11795 0.938'' x 0.750 Dia. Plastic Spacer

19 BLK-11843 Pivot Bracket

20 BLK-11846 Cap Hold Down Bracket

21 S-4663 3/8'' - 16 Hex Head Lock Nut

9

PNEG-256 6', 7' & 9' Bulk Feed Tanks 35

Page 36

7. ROOF

s

Peak Ring

BLK-10472 Bulb

Seal

S-7120 5/16''

3.1/2'' Bolt

CRP-4654

Cap Hold

Down

CRP-4639 Cap

Hold Down

Bracket

Figure 7V Bulb Seal Kit (Optional)

BLK-10022

Cap Latch

Left Hinge

Attachment Hole

Figure 7W Cap Hold Down Package

Right Hinge

Attachment

Holes

Note: Bulb seal kit is included with all pneumatic fill kits. When ordered as a separate

option, specify Part No. BLK-10472.

Cap Hold Down Package comes standard on all 45° hopper bulk tanks., Optional on all 60° and

67° hopper bulk tanks.

36 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 37

B

L

8

E

S

M

A

R

S

O

P

.

H

E

P

Y

Hopper Sheets

When starting to attach hopper sheets to sidewall it is recommend that the first hopper sheet

seam be positioned halfway between leg positions. Lap the hopper sheets as shown. Use two

(2) strips of caulking on all seams at sidewall to hopper and hopper sheet to hopper sheet. Be

sure to place the head of the truss bolt on the inside of hopper. Leave one hopper sheet out to

allow room to install hopper collar. Be sure to use two (2) strips of caulking between hopper collar

and hopper sheets, then put last hopper sheet in place.

CAUTION

All 9' diameter 60° 3-6 ring and 7' diameter 67° 5 & 6 ring tanks require hopper

reinforcement angles. Angle covers entire seam (including hopper collar).

Note: When used for 22" (559 mm)

hopper openings, field cut brace

below slot to fit properly.

Hopper Sheet to

Sidewall Sheet

Hopper Reinforcement

Angle

Figure 8A

Figure 8B

PNEG-256 6', 7' & 9' Bulk Feed Tanks 37

Page 38

8. HOPPER ASSEMBLY

Sidewall Sheet

Use two Strips of

Caulking

Use 5/16'' x 1-1/4'' Bin

Bolts

Inside of Tank

Hopper sheet

Figure 8C

9' 60° Leg Attachment (for 9' 60° Tanks Only)

Curved Washer are supplied in the hardware packages. These washers must be installed at the

Bottom Leg to Sidewall Bolt Connection, to the inside of the Hopper Panel as indicated in the

Illustration Below.

Apply caulking in between the hopper panel and the sidewall sheet.

Sidewall Sheet

5/16" Hex Nut (S-396)

10 Ga. Curved

Washer (Blk-12483)

5/16" x 1-1/4" Bin

Bolt (S-277)

Leg

Figure 8D

Hopper Panel

38 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 39

Inside of Tank

Hopper Panel

Figure 8E

8. HOPPER ASSEMBLY

Reinforcement

Angle

Inside of Tank

Hopper Sheet

Section “A” - “A”

Caulking (2 Strips)

Hopper Sheet

Reinforcement Angle

Figure 8F Hopper Overlap and Bolt Detail W/Reinforcement Angle

Bolt head to be on inside of

hopper.

Hopper Sheet

5/16" x 3/4" Truss

Head Bolts

Hopper Sheet

Inside of Tank

Flange Nut

Caulking (2 Strips)

Figure 8G Hopper Overlap and Bolt Detail for Tanks W/Out

Reinforcement Angle

PNEG-256 6', 7' & 9' Bulk Feed Tanks 39

Page 40

8. HOPPER ASSEMBLY

Reinforcement Angles

Note: Every hole in the hopper sheet will be utilized. Use 5/16" x 3/4" truss head bolt on

hopper seams. (Truss head goes on inside of hopper).

The 9' 3-6 ring, 60° & 7' 5-6 ring, 67° Ring tanks are the only once to use reinforcement

angles.

Note: Last (bottom) bolt in reinforcement angle goes through hopper collar also.

Hopper Collar

Before last hopper panel is attached, assemble the hopper extensions (if utilized) on the hopper

collar. Use 5/16'' truss head bolts, and caulk all joints on the assembly, attach to the hopper

panels, using 5/16'' truss head bolts. Be sure to caulk between hopper extensions and hopper

panels. (Refer to details on Figure 8I).

Figure 8H

40 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 41

Hopper Panel

8. HOPPER ASSEMBLY

5/16" x 3/4" Truss

Head Bolt

Caulking

Flange Nut

16" or 22" Hopper or Hopper

Extension (if used)

5/16" x 3/4" Truss

Head Bolt

Caulking

Hopper

Extension

Inside of Tank

Bolt Detail: Hopper

Extension (if used)

Flange Nut

16" or 22" Hopper

Collar

Bolt Detail: Hopper

Collar

Inside of Tank

Figure 8I

PNEG-256 6', 7' & 9' Bulk Feed Tanks 41

Page 42

8. HOPPER ASSEMBLY

Install hopper collar before all hopper panels are assembled. Use 5/16" truss head bolts, as

shown in the illustration, on all hopper seams. Be sure to caulk between the hopper collar and

hopper panels. See Figure 8J, Figure 8K, Figure 8L.

22" Hopper Collar

Figure 8J 22'' Hopper Collar

22'' Hopper Collar

BLK-10854 45 Degree 22" Hopper Collar

BLK-10342 60 Degree 22" Hopper Collar

BLK-10341 67 Degree 22" Hopper Collar

16" Hopper Collar

Part # Description

Figure 8K 16'' Hopper Collar

16'' Hopper Collar

Part # Description

BLK-10489 6' - 16" 60 Degree (24 Holes)

BLK-10488 7' - 16" 67 Degree (24 Holes)

BLK-11463 *9' - 16" 60 Degree (27 Holes)

42 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 43

8. HOPPER ASSEMBLY

Note: 9' 16" 60° Hopper Collar BLK-11463 is used with a 9' - 16" 60° tank only (27 Holes).

16" Hopper Collar

Figure 8L Hopper Extension Kit

22''-16" Hopper

Extension

Hopper Extension Kit

Part # Description

BLK-10847 16" 45° Hopper Extension & Collar (Standard on 7' & 9' 45 Degree)

BLK-10587 16" 60° Hopper Extension & Collar (Optional)

BLK-10591 16" 67° Hopper Extension & Collar (Optional)

PNEG-256 6', 7' & 9' Bulk Feed Tanks 43

Page 44

9. LEGS AND LEG BRACES

Tank Legs and Leg Braces

When installing legs to sidewall, reverse normal insertion procedure on bolts. Place hex head

and neoprene washer to inside of sidewall, leaving threaded portion of bolt protruding outward.

This provides for a weather tight seal at the leg attachment location. See on Page 44 to Page 46

for Leg Attachment to Sidewall Sheet details.

Figure 9A

Use 5/16" x 3/4" bin bolts and nuts when attaching the leg to base. Make sure the washer is used

on the slot side of the leg.

Leg

Back Leg Anchor Plate

BLK-10057 (1 Tab)

Front Leg Anchor Plate

BLK-10058 (2 Tab)

Figure 9B

44 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 45

9. LEGS AND LEG BRACES

Line up leg with these holes and bolt (refer to drawing below)

6' tank leg shown

Figure 9C

5/16'' x 3/4'' Bin Bolts

Inside of Tank

Leg

Insert bolts inside to outside on all leg to tank connections.

Figure 9D

Figure 9E

PNEG-256 6', 7' & 9' Bulk Feed Tanks 45

Page 46

9. LEGS AND LEG BRACES

Leg Size Chart

Tank Size Hopper Number of Rings Length Leg Coverage

6' Diameter 60 Degree 1-3 Rings 106-3/8'' 1-Ring

6' Diameter 60 Degree 4-Rings 106-3/8'' 1-Ring

7' Diameter 67 Degree 1-4 Rings 140-1/2'' 1-Ring

7' Diameter 67 Degree 5-6 Rings 164-1/2'' 1-3/4 Ring (56'')

7' Diameter 45 Degree 1-4 Rings 94-1/8'' 1-Ring

7' Diameter 45 Degree 5-6 Rings 120-3/4'' 1-3/4 Rings (56'')

9' Diameter 60 Degree 1-5 Rings 140-1/2'' 1-Ring

9' Diameter 60 Degree 6 Rings 164-1/2'' 1-3/4 Ring (56'')

9' Diameter 45 Degree 1-5 Rings 106-1/8'' 1-Ring

9' Diameter 45 Degree 6 Rings 132-3/4'' 1-3/4 Rings (56'')

One-Ring Leg 140-1/2'' (3569 mm)

13 Holes

Figure 9F Leg Adjustment (7' (1-4 ring) 67° & 9' (1-5 ring) 60° only)

10 Holes

Note: 9' 5 - Ring tanks must utilize two ring coverage legs if raising 8" (203.2 mm).

CAUTION

Failure to follow instructions may cause damage or failure of the equipment.

Depending on the size of the Bulk Feed Tank you are assembling, the leg will cover either the

bottom ring or 1-3/4 rings (56"). Refer to this chart to find the correct number of rings your legs

will cover. Put all legs on, but don't tighten bolts until all braces are in place. Be sure to put

leg braces on properly. (Refer to Page 47 to Page 51)

46 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 47

9. LEGS AND LEG BRACES

Extra Clearance Leg Adjustment

In cases where extra clearance is required (on 7' 67° & 9' 60° tanks only), you may raise the tank

up to 8" when installing the legs. See details for proper positioning. Call Company's engineering

for any other special requirements.

Note: 9' 5 - Ring tanks must utilize two ring coverage legs if raising 8" (203.2 mm).

CAUTION

Failure to follow instructions may cause damage or failure of the equipment.

Bracing Hole Layout (60° & 67° Legs)

For 7' 67° and 9' 60° Feed Tank bracing layout see Page 48 and Page 49.

22 Holes

Figure 9G Leg Adjustment (7' (5-6 ring) 67° & 9' (6 ring) 60° only)

Two-Ring Leg 164 1/2" (4178 mm)

19 Holes

Figure 9H

PNEG-256 6', 7' & 9' Bulk Feed Tanks 47

Page 48

9. LEGS AND LEG BRACES

67.766''

Ladder Standoff (All

.375'' Dia Hole

31.766''

Ladder Standoff 2-4-6

Rings .375'' Dia Hole

9.813''

29.938''

16'' Hopper Brace

.438'' Dia Hole

Cross Tie Brace

.438'' Dia Hole

37.928''

7' 67° 1-6 RING

16'' Hopper Brace

(Raising Tank 8'')

.438'' Dia Hole

Drawing below has been modified for clarity (not to Scale)

22'' Hopper Brace.438'' Dia Hole

38.438''

Between

Braces

25.328''

Cross Tie Brace

.438'' Dia Hole

36.438''

23.766''

Ladder Standoff 1-3-5

Rings .375'' Dia Hole

7' 67° 1-6 RING

7' & 9' BRACING NOTES (SEE Page 47)

DRAWING ABOVE HAS BEEN MODIFIED FOR CLARITY (NOT TO SCALE)

Dimensions shown are measured from center of attachment holes in legs to bottom of leg. Use 3/8" nuts and bolts to attach cross ties to each

other and to leg. Hopper braces are attached to legs with 3/8" nuts and bolts and to hopper collar with 5/16" hardware. Ladder standoffs are

attached to legs with 5/16" nuts and bolts. Do not tighten hardware until all bracing is in place.

Figure 9I

48 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 49

L

dd

S

d

ff

Ladder Standoff (All)

.375'' Dia Hole

9. LEGS AND LEG BRACES

67.766''

36.375''

16'' Hopper Brace (Raising

Tank 8'') .438'' Hole

33''

22'' Hopper

Brace .438''

31.766''

9' 60° 2 THRU 6 RING TANK

Drawing below has been modified for clarity (not to Scale)

Note: 9' 5-ring tanks must use 6-ring legs when raising 8" (203.2 mm)

Ladder Standoff

2-4-6 Rings .375''

28.375''

16'' Hopper

Brace 38''

25.328''

Cross Tie

Brace .438''

Cross Tie Brace .438'' Dia Hole

23.766''

opper

etween

8.438''

races

o

tan

er

a

1-3-5 Rings .375''

7' & 9' BRACING NOTES (SEE Page 47)

5/16" nuts and bolts. Do not tighten hardware until all bracing is in place.

Dimensions shown are measured from center of attachment holes in legs to bottom of leg. Use 3/8" nuts and bolts to attach cross ties to each other and

to leg. Hopper braces are attached to legs with 3/8" nuts and bolts and to hopper collar with 5/16" hardware. Ladder standoffs are attached to legs with

63.766''

Figure 9J

PNEG-256 6', 7' & 9' Bulk Feed Tanks 49

Page 50

9. LEGS AND LEG BRACES

Hopper to Leg Horizontal Bracing

Tank

Description

6' Dia 60° Hopper 4 0** 0**

7' Dia 67° Hopper 4 4 4

7' Dia 45° Hopper 4 0** 0**

9' Dia 60° Hopper 6 6 6

9' Dia 45° Hopper 6 0** 0**

Hopper

Brace

Inside Cross

Tie Brace

** 6' 60°, 7' 45° & 9' 45° tanks do not require cross tie braces.

Outside Cross

Tie Brace

All 6' 60°, all 7' 67° and all 9' 60° tanks utilize

hopper bracing. Braces attach horizontally to

the legs with 3/8" hardware and to the hopper

with 5/16" hardware.

Figure 9K

Leg

3/8'' x 1'' Bolt

Hopper

5/16'' x 3/4'' Truss Head Bolt

(Head to Inside)

Figure 9L

50 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 51

9. LEGS AND LEG BRACES

Hopper braces are to be spaced equally around tank. Hopper braces are required on all hopper

tanks. Refer to the chart below for the quantities required.

Tan k

6' 60° BLK-12146 4 BLK-12147 4

7' 67° BLK-12107 4 BLK-12108 4

7' 45° BLK-12105 4 BLK-12106 4

9' 60° BLK-12109 6 BLK-12110 6

9' 45° BLK-12111 6 BLK-12112 6

Brace Part Number

(16'' Hopper) (22'' Hopper)

Qty

Brace Part Number

Qty

Note: Hopper braces attach between the legs and the collar/hopper horizontal seam.

Never bolt the braces directly to the hopper seam above the collar. Use 16" braces

with 16" collar and 22" braces with 22" collars.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 51

Page 52

10. LADDER

6

Optional Sidewall Ladder

Instructions

To start sidewall ladder, places two outside standoffs spaces 18.3/4" (476 mm) apart. At the roof

eave, the ladder should be located on the standoffs. (Refer to drawing). Continue with standoff

located on every horizontal seam. Ladder support ring should be located between two legs as

shown. This will support the ladder at the bottom of bulk feed tank. When positioning the ladder

on the tank, be sure to attach ladder so the raised non-slip tread surface is to the top of the

ladder rungs.

Ladder Standoff Ring Qty

6' BLK-10147 1

7' BLK-10148 2

9' BLK-10149 3

Roof Eave

Safety Rail

Roof Panel

Ladder Standoff

.25" (159 mm)

Ladder Section

Sidewall

Figure 10A Sidewall Ladder Detail

52 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 53

Ladder Standoff

LS-121

Ladder Section

LDR-4002

Ladder Standoff

Ring

10. LADDER

Figure 10B Ladder Standoff Detail

Note: Locations of legs and other rings horizontal hole spacing when placing ladder.

Ladder Standoff

Lower Ladder Section will overlap

Upper Ladder Section's Offset. Each side

is to bolted together by (2) 5/16" x 3/4"

bolts and 5/16" nut.

Ladder Standoff

Ladder Standoff

Figure 10C

PNEG-256 6', 7' & 9' Bulk Feed Tanks 53

Page 54

10. LADDER

Safety Cage

Ladder and Safety Cage Usage Chart (Number in Chart Specifies Ring Size)

Ladder Safety

Package No Cage No

BLK-10824 N/A 1

BLK-10630 BLK-10831 1 2

BLK-10634 BLK-10832 2 1 2

BLK-10635 BLK-10833 3 2 2 3 3

BLK-10640 BLK-10835 4 3 3 4 4

BLK-10637 BLK-10836 4 4 5

BLK-10641 BLK-10837 6 5

BLK-10642 BLK-10838 5 5 6

BLK-10643 BLK-10839 6 6

6' 60° 7' 67° 9' 60° 7' 45° 9' 45°

Start attaching ladder at the eave (top) of the Bulk Feed Tank. After the first ladder section has

been attached to the sidewall of tank, attach ladder extension rails to the ladder as shown. Refer

to Page 52 for proper ladder placement in relation to the eave of the tank. Use 5/16" bin bolts

and nuts on all safety cage connections. Attach hoop brackets and adjustable safety cage

braces to the top of the extension rails. Now attach the opposite end of the adjustable brace to

the roof ladder rail. After completing this, drill two (2) 5/16" holes through the adjustable brace

and use 1/4" x 1.1/2" bolts and nuts to secure the two braces together.

Add the safety cage hoops to the brackets and attach vertical supports to the hoops. Continue

adding ladder sections and safety cage as sidewall rings are attached. Included in your safety

cage package are two (2) Bell hoop halves which should be located at the bottom of the safety

cage. Follow all drawings and details for proper placement of parts and proper location of safety

cage.

Note: Belled safety cage section parts are color code: RED.

Safety Cage Standard Bracket

Adjustable Bracket

Field Drill 5/16''

Holes (2)

LS-6616 End

Section

Side View

Figure 10D

Ladder

Extension

Rail LS-4355

Front View

54 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 55

10. LADDER

Safety Cage Half Hoop LS-4351

Head of the Bolt to be Placed to the

Inside of the Safety Cage.

Safety Cage Vertical Support LS-4353

5/16'' Hex

Bin Bolts

Inside of Safety Cage

Front View

Safety/Cage Standard Bracket LS-4349

Attach Hoop to Bracket on Ladder

Overlap Safety Cage Hoops 5" (127 mm)

Side View

Top Vi e w

Figure 10E Safety Cage Assembly

PNEG-256 6', 7' & 9' Bulk Feed Tanks 55

Page 56

11. RAISING BIN

Raising Bin to set on Foundation

Preparing Bin

Just before standing the bin upright, peel protective mask off the decal while it is easy to reach.

Mask may become difficult to remove if left exposed to sunlight.

Check for all possible overhead obstructions, power line, etc., BEFORE standing the bin

on the foundation.

To prevent damage to Legs when raising bin, brace them with 2" x 4 " (50 mm x 100 mm) pieces

of wood as shown in the illustration. See the chart for the correct length.

WARNING

Do not raise tank near power lines. Electrocution could occur if the tank came into contact

with live power lines.

Bin Size 2 x 4 Length

6' Dia. (1,829 mm) 51.3/8" (1,305 mm)

7' Dia. (2,134 mm) 59.7/8" (1,521 mm)

9' Dia. (2,743 mm) 52.1/8" (1,324 mm)

Bottom

End View

Location of Cable or Sling wrapped

around tank

2'' x 4''

Anchor or stabilize to prevent sliding

during raising

Figure 11A

Be sure that all bolts are tightened properly. Bulk feed tank can now be set up on foundation.

Small bulk feed tanks may be set up with manpower. As the tanks get taller and heavier, other

means must be used to raise the bulk feed tank. A small crane of adequate capacity attached to

a cable or sling secured around the bulk feed tank just above the legs will usually do the job.

Refer any questions to a qualified rigger.

56 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 57

11. RAISING BIN

Anchoring Tank

Check all legs to see if shims are necessary to level the tank properly. After bulk feed tank is

level and shimmed properly, anchor the tank down with 5/8" washers and nuts (See Figure 11B).

Standard Hopper Bin Anchoring

Measure between opposite Legs to be sure they are an equal distance apart before securing the

Bin with Anchor Bolts. Follow the chart shown below. Failure to do so may cause damage to the

bin.

Bin Size Distance Between Opposite Legs

6' Dia. (1,829 mm) 72.1/4" (1,835 mm)

7' Dia. (2,134 mm) 84.1/4" (2,140 mm)

9' Dia. (2,743 mm) 108.1/8" (2,746 mm)

5/8" Nut S-836

(not supplied)

Figure 11B

5/8" Washer

S-858 (not

supplied)

Figure 11C Leg Base Detail

Note: Leg shims are not standard equipment and must be obtained locally.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 57

Page 58

12. GROUNDING

Bin Grounding Instructions

Note: Parts not supplied by Manufacturer, they should be purchased Locally.

All bins shall have two (2) Ground connections. Ground clamps must be placed at equal

distances around the bin.

Alternate Installation: Cables may be placed in the foundation or through PVC Sleeve inserted

in the slab during construction.

Figure 12A

Key Description

1 Cable Clamp

2 5' (1524 mm) Copper Cable (Plain or Jacketed)

3 Ground Rod Clamp

4 Ground Rod 1/2" x 10' (3048 mm)

58 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 59

B

L

1

3

E

S

M

K

L

L

T

F

I

C

E

M

N

.

P

A

U

I

A

S

I

T

Y

Roof Panel

Identical pre-punched roof panels are available from Manufacturer for inlet and outlet sections

of Pneumatic fill systems. Extruded lip of the panels provide for weather tight installation.

Caulking placed between angle rings virtually eliminates all leakage problems. Rubber seal must

be utilized at roof cap area to prevent material “Blow By” from pressurized systems.

To install fill kits in roof panels not pre-punched, cut 5 5/8" (143 mm) diameter holes in opposing

roof panels as shown. Caulk sufficiently to provide weather tight seal.

Refer to “Peak Ring Seal Strip” installation procedure when installing pneumatic fill kits.

Abnormal pressure may require us of optional “Cap Hold Down Package” (BLK-10474).

Note: Inlet and exhaust parts from roof eave upward supplied with kit.

5/16'' Square Neck Bolt

Fill tube is 4" in Diameter

(available)

/16'' Hex Nut

S-396)

Cupped Washers

Exhaust Tube is 6" in

Diameter

Figure 13A

PNEG-256 6', 7' & 9' Bulk Feed Tanks 59

Page 60

13. PNEUMATIC FILL KIT ASSEMBLY

9-5/8"

Figure 13B

60 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 61

1. 6' Diameter 60° Hopper Bin Specifications

2. 6' Diameter 60° Hopper Bin Specifications

3. 7' Diameter 67° Hopper Bin Specifications

4. 7' Diameter 67° Hopper Bin Specifications

5. 7' Diameter 45° Hopper Bin Specifications

6. 7' Diameter 45° Hopper Bin Specifications

7. 9' Diameter 60° Hopper Bin Specifications

8. 9' Diameter 60° Hopper Tank Specifications

9. 9' Diameter 45° Hopper Bin Specifications

10. 9' Diameter 45° Hopper Bin Specifications

1

4

I

O

T

N

E

A

T

.

P

S

R

C

S

PNEG-256 6', 7' & 9' Bulk Feed Tanks 61

Page 62

14. PARTS SECTION

6' Diameter 60° Hopper Bin Specifications

Under Collar Clearance

16" Collar 28.5/16" (719 mm)

22" Collar 32.7/8" (837 mm)

Important: Bolt Heads are inside of bin at the Leg to Body attachment and on all Vertical

Seams on Hopper Panels. All bolts to be tightened from the nut side only.

Refer to Detail on Page 22 for location of caulking. No cross tie bracing

required.

62 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 63

14. PARTS SECTION

6' Diameter 60° Hopper Bin

Ref # Part # Qty Description

1 BLK-12254 6 6' 30° Roof Panel (20 Gauge) (Shown)

BLK-12257 6 6' 40° Roof Panel (20 Gauge)

2 6' Sidewall

Sheet

SS40682006 20 Gauge (Top Punched Sidewall Sheet)

SS41632006 20 Gauge (Top Punched Decal Sidewall Sheet)

SS40672006 20 Gauge (Bottom/Top Leg Sidewall Sheet)

SS40692006 20 Gauge (Middle Punched Sidewall Sheet)

SS41622006 20 Gauge (Bottom/Top Leg Decal Sidewall Sheet)

SS40712006 20 Gauge (Bottom Leg Sidewall Sheet)

SS40711806 18 Gauge (Bottom Leg Sidewall Sheet)

3 BLK-11475 6 6' 60° Offset Hopper Panel 16" Opening (20 Gauge) (Shown)

BLK-10358 6 6' 60° Hopper Panel 22" Opening (20 Gauge)

4 BLK-12716 4 6' 60° Leg 106 - 1/16" (14 Gauge) (1--3 Rings)

BLK-12222 4 6' 60° Leg 106 - 1/16" (12 Gauge) (4 Ring)

5 BLK-12146 4 Hopper Brace for 16" Collar (Shown)

BLK-12147 4 Hopper Brace for 22" Collar

6 BLK-10489 1 16" 60° Hopper Collar (24 Holes) (Shown)

BLK-10342 1 22" 60° Hopper Collar (36 Holes)

7 BLK-11730 1 30° Bulk Tank Peak Ring (Shown)

BLK-12534 1 40° Bulk Tank Peak Ring

2 Per

Ring

PNEG-256 6', 7' & 9' Bulk Feed Tanks 63

Page 64

14. PARTS SECTION

O

6' Diameter 60° Hopper Bin Specifications

Peak Ring Collar

Roof Sheet

Inside

4

Roof Sheet

utside

Inside

Body Sheet

Roof Sheet

2

Outside

Body

Sheet

Outside

Inside

1

Inside

3

Outside

Leg

Inside

5

Outside

6

Body Sheet

Body Sheet

Outside

Body

Sheet

Inside

Hopper Panel

Inside

8

Outside

Offset Hopper Panel

9

Inside

Outside

Hopper Collar

Leg

Hopper Brace

7

Outside

Body Sheet

Body

Sheet

Inside

Hopper

Sheet

10

64 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 65

14. PARTS SECTION

6' Diameter 60° Hopper Bin parts list

Ref # Part # Qty Description

1 S-275 36 Bulk Tank Peak Ring to Roof Panels (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 36

2 S-275 48 Roof Panel to Roof Panel (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16"

S-396 48

3 S-275 72 Roof Panels to Top Sidewall Sheets (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 72

4 S-275 Varies Vertical Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts and

S-396 Varies

5 S-275 Varies Horizontal Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 Varies

6 S-275 48 Leg to Sidewall Sheet (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16" Hex

S-396 48

7 S-277 72 Hopper Panels to Sidewall Sheet (Use 5/16" x 1-1/4" Hex Head Bin Bolts

S-396 72

8 S-4303 108 Vertical Hopper Seams (Use 5/16" x 3/4" Truss Head Bin Bolts and 5/16"

S-3611 108

9 S-4303 24 or 36Hopper Collar to Hopper Panel (Use 5/16" x 3/4" Truss Head Bin Bolts and

S-3611 24 or

10 S-7927 4 Hopper Brace to Leg (Use 3/8" x 1" Flange Head Bolts and 3/8" Hex Nuts.)

S-456 4

and 5/16" Hex Nuts.)

Hex Nuts.)

and 5/16" Hex Nuts.)

5/16" Hex Nuts.)

and 5/16" Hex Nuts.)

Nuts.) (Bolt Heads to Inside of Tank.)

and 5/16" Hex Nuts.) (Bolt Head to Inside at Leg to Hopper to Sidewall

Connection Only.)

Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.)

5/16" Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.) (16" Shown)

36

Note: Bolt listed first and nut second for each usage.

Hardware usage: Heads of Bolts are on the outside of tank unless otherwise noted.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 65

Page 66

14. PARTS SECTION

7' Diameter 67° Hopper Bin Specifications

Under Collar Clearance

16" Collar 30.3/8" (771 mm)

22" Collar 36.1/2" (927 mm)

65.5/8'' (1,667 mm)

37.1/2''28.1/8''

(714 mm)

(953 mm)

Important: Vertical seams of Body Sheets with leg holes MUST be bolted together to

provide 65.5/8" (1,667 mm) between Leg Holes.

Important: Bolt Heads are inside of bin at the Leg to Body attachment and on all Vertical

Seams on Hopper Panels. All bolts to be tightened from the nut side only.

Refer to Detail on Page 22 for location of caulking.

66 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 67

14. PARTS SECTION

7' Diameter 67° Hopper Bin Specifications

Ref # Part # Qty Description

1 BLK-12260 6 7' 30° Roof Panel (20 Gauge) (Shown)

BLK-12263 6 7' 40° Roof Panel (20 Gauge)

2 7' Sidewall

Sheet

SS40602007 20 Gauge (Bottom/Top Leg Punched Sidewall Sheet)

SS41642007 20 Gauge (Bottom/Top Leg Punched Decal Sidewall Sheet)

SS40612007 20 Gauge (Top Punched Sidewall Sheet)

SS41652007 20 Gauge (Top Punched Decal Sidewall Sheet)

SS40462007 20 Gauge (Middle Punched Sidewall Sheet)

SS40461807 18 Gauge (Middle Punched Sidewall Sheet)

SS40461707 17 Gauge (Middle Punched Sidewall Sheet)

SS40641707 17 Gauge (Middle Leg Punched Sidewall Sheet)

SS40641507 15 Gauge (Middle Leg Punched Sidewall Sheet)

SS40661807 18 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40661707 17 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40661507 15 Gauge (Bottom Leg Punched Sidewall Sheet)

3 BLK-11476 6 7' 67° Offset Hopper Panel 16" Opening (18 Gauge) (Shown)

BLK-10569 6 7' 67° Hopper Panel 22" Opening (18 Gauge)

4 BLK-12039 4 7' Leg 140 - 1/2" (12 Gauge) (1 -- 4 Rings) (Shown)

BLK-12040 4 7' Leg 164 - 1/2" (10 Gauge) (1 -- 4 Rings) (Shown)

5 BLK-12107 4 Hopper Brace for 16" Collar (Shown)

BLK-12108 4 Hopper Brace for 22" Collar

6 BLK-10488 1 16" 67° Hopper Collar (Shown)

BLK-10341 1 22" 67° Hopper Collar (36 Holes)

7 BLK-12056 4 7' Inside Cross Tie Brace (72.49'') (12 Gauge)

BLK-12057 4 7' Outside Cross Tie Brace (72.49'') (12 Gauge)

8 BLK-11730 1 30° Bulk Tank Peak Ring (Shown)

BLK-12534 1 40° Bulk Tank Peak Ring

9 BLK-12009 6 7' 67° Hopper Reinforcement Angle (5 -- 6 Ring Tanks Only)

2 Per

Ring

PNEG-256 6', 7' & 9' Bulk Feed Tanks 67

Page 68

14. PARTS SECTION

7' Diameter 67° Hopper Bin Specifications

Peak Ring Collar

Roof Sheet

Inside

Outside

Inside

Roof Sheet

Roof Sheet

Outside

Outside

Inside

Inside

Body Sheet

Roof Sheet

Body Sheet

Inside

1

2

2

3

Outside

Body Sheet

Inside

5

Leg

Outside

6

Outside

Body Sheet

Body Sheet

Inside

4

Hopper Panel

Inside

8

Outside

Hopper Reinforcement

Angle (5-6 Rings Only)

Offset Hopper Panel

Inside

9

Outside

Body

Sheet

38.438''

Leg

7

Outside

11

Leg Cross Tie

10

Body

Sheet

Inside

Hopper

Sheet

Leg

Outside

Hopper Brace

Hopper Collar

68 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 69

14. PARTS SECTION

7' Diameter 67° Hopper Bin Specifications

Ref # Part # Qty Description

1 S-275 36 Bulk Tank Peak Ring to Roof Panels (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 36

2 S-275 60 Roof Panel to Roof Panel (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16"

S-396 60

3 S-275 84 Roof Panels to Top Sidewall Sheets (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 84

4 S-275 Varies Vertical Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts and

S-396 Varies

5 S-275 Varies Horizontal Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 Varies

6 S-275 52 or 88 Leg to Sidewall Sheet (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16" Hex

S-396 52 or 88

7 S-277 84 Hopper Panels to Sidewall Sheet (Use 5/16" x 1-1/4" Hex Head Bin Bolts

S-396 84

8 S-4303 162 Vertical Hopper Seams (Use 5/16" x 3/4" Truss Head Bin Bolts and 5/16"

S-3611 162

9 S-4303 24 or 36 Hopper Collar to Hopper Panel (Use 5/16" x 3/4" Truss Head Bin Bolts and

S-3611 24 or 36

10 S-7927 4 Hopper Brace to Leg (Use 3/8" x 1" Flange Head Bolts and 3/8" Hex Nuts.)

S-456 4

11 S-7927 12 Cross Tie Brace (Use 3/8'' x 1'' Flange Head Bolts and 3/8'' Hex Nuts.)

S-456 12

and 5/16" Hex Nuts.)

Hex Nuts.)

and 5/16" Hex Nuts.)

5/16" Hex Nuts.)

and 5/16" Hex Nuts.)

Nuts.) (Bolt Heads to Inside of Tank.)

and 5/16" Hex Nuts.) (Bolt Head to Inside at Leg to Hopper to Sidewall

Connection Only.)

Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.)

5/16" Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.) (16" Shown)

Note: Bolt listed first, nut second for each usage.

Hardware usage: Heads of Bolts are on the outside of tank unless otherwise noted.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 69

Page 70

14. PARTS SECTION

7' Diameter 45° Hopper Bin Specifications

Under Collar Clearance

16" Collar 29.3/4" (756 mm)

22" Collar 32.5/16" (821 mm)

Important: Bolt Heads are inside of bin at the Leg to Body attachment and on all Vertical

Seams on Hopper Panels. All bolts to be tightened from the nut side only. Refer

to Detail on Page 22 for location of caulking. No cross tie bracing required

70 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 71

14. PARTS SECTION

7' Diameter 45° Hopper Bin

Ref # Part # Qty Description

1 BLK-12260 6 7' 30° Roof Panel (20 Gauge) (Shown)

BLK-12263 6 7' 40° Roof Panel (20 Gauge)

2 7' Sidewall

Sheet

SS40602007 20 Gauge (Bottom/Top Leg Punched Sidewall Sheet)

SS41642007 20 Gauge (Bottom/Top Leg Punched Decal Sidewall Sheet)

SS40612007 20 Gauge (Top Punched Sidewall Sheet)

SS41652007 20 Gauge (Top Punched Decal Sidewall Sheet)

SS40462007 20 Gauge (Middle Punched Sidewall Sheet)

SS40461807 18 Gauge (Middle Punched Sidewall Sheet)

SS40461707 17 Gauge (Middle Punched Sidewall Sheet)

SS40641707 17 Gauge (Middle Leg Punched Sidewall Sheet)

SS40641507 15 Gauge (Middle Leg Punched Sidewall Sheet)

SS40661807 18 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40661707 17 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40661507 15 Gauge (Bottom Leg Punched Sidewall Sheet)

3 BLK-10693 6 7' 45° Offset Hopper Panel 22" Opening (18 Gauge) (Shown)

4 BLK-12014 4 7' Leg 94-1/8" (12 Gauge) (1--4 Rings) (Shown)

BLK-12042 4 7' Leg 120-3/4" (10 Gauge) (5--6 Rings)

5 BLK-12105 4 Hopper Brace for 16" Collar (Shown)

BLK-12106 4 Hopper Brace for 22" Collar

6 BLK-10696 1 16" 45° Hopper Collar (24 Holes) (Shown)

BLK-10854 1 22" 45° Hopper Collar (36 Holes)

7 BLK-11730 1 30° Bulk Tank Peak Ring (Shown)

BLK-12534 1 40° Bulk Tank Peak Ring

2 Per

Ring

PNEG-256 6', 7' & 9' Bulk Feed Tanks 71

Page 72

14. PARTS SECTION

7' Diameter 45° Hopper Bin Specifications

Peak Ring Collar

Roof Sheet

Roof Sheet

Inside

4

Outside

Inside

Roof Sheet

2

Body Sheet

Outside

Inside

Inside

1

3

Outside

Body Sheet

Inside

5

Leg

Outside

Body Sheet

Outside

Body Sheet

Body Sheet

Outside

Hopper Panel

Inside

8

Outside

Offset Hopper Panel

9

Inside

Outside

Hopper Collar

Body

Sheet

Leg

Hopper Brace

6

7

Outside

10

Inside

Body

Sheet

Inside

Hopper

Sheet

72 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 73

14. PARTS SECTION

7' Diameter 45° Hopper Bin Specifications

Ref # Part # Qty Description

1 S-275 36 Bulk Tank Peak Ring to Roof Panels (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 36

2 S-275 60 Roof Panel to Roof Panel (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16"

S-396 60

3 S-275 84 Roof Panels to Top Sidewall Sheets (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 84

4 S-275 Varies Vertical Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts and

S-396 Varies

5 S-275 Varies Horizontal Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 Varies

6 S-275 48 or 88 Leg to Sidewall Sheet (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16" Hex

S-396 48 or 88

7 S-277 84 Hopper Panels to Sidewall Sheet (Use 5/16" x 1-1/4" Hex Head Bin Bolts

S-396 84

8 S-4303 102 Vertical Hopper Seams (Use 5/16" x 3/4" Truss Head Bin Bolts and 5/16"

S-3611 102

9 S-4303 24 or 36 Hopper Collar to Hopper Panel (Use 5/16" x 3/4" Truss Head Bin Bolts and

S-3611 24 or 36

10 S-7927 4 Hopper Brace to Leg (Use 3/8" x 1" Flange Head Bolts and 3/8" Hex Nuts.)

S-456 4

and 5/16" Hex Nuts.)

Hex Nuts.)

and 5/16" Hex Nuts.)

5/16" Hex Nuts.)

and 5/16" Hex Nuts.)

Nuts.) (Bolt Heads to Inside of Tank.)

and 5/16" Hex Nuts.) (Bolt Head to Inside at Leg to Hopper to Sidewall

Connection Only.)

Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.)

5/16" Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.) (16" Shown)

Note: Bolt listed first, nut second for each usage.

Hardware usage: Heads of Bolts are on the outside of tank unless otherwise noted.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 73

Page 74

14. PARTS SECTION

9' Diameter 60° Hopper Bin Specifications

Under Collar Clearance

16" Collar 28.1/16" (713 mm)

22" Collar 32.5/8" (829 mm)

Important: Bolt Heads are inside of bin at the Leg to Body attachment and on all Vertical

Seams on Hopper Panels. All bolts to be tightened from the nut side only.

Refer to Detail on Page 22 for location of caulking.

74 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 75

14. PARTS SECTION

9' Diameter 60° Hopper Bin Specifications

Ref # Part # Qty Description

1 BLK-12266 9 9' 30° Roof Panel (20 Gauge) (Shown)

BLK-12269 9 9' 40° Roof Panel (20 Gauge)

2 9' Sidewall

Sheet

SS40682009 20 Gauge (Top Punched Sidewall Sheet)

SS41662009 20 Gauge (Top Punched Decal Sidewall Sheet)

SS40692009 20 Gauge (Middle Punched Sidewall Sheet)

SS40691809 18 Gauge (Middle Punched Sidewall Sheet)

SS40691709 17 Gauge (Middle Punched Sidewall Sheet)

SS40701509 15 Gauge (Middle Leg Punched Sidewall Sheet)

SS40712009 20 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40711809 18 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40711709 17 Gauge (Bottom Leg Punched Sidewall Sheet)

SS40711509 15 Gauge (Bottom Leg Punched Sidewall Sheet)

3 BLK-12311 9 9' 60° Offset Hopper Panel 16" Opening (18 Gauge) (Shown)

BLK-12313 9 9' 60° Hopper Panel 22" Opening (18 Gauge)

4 BLK-12036 6 9' Leg 140-1/2" (12 Gauge) (2--5 Rings) (Shown))

BLK-12037 6 9' Leg 164-1/2" (10 Gauge) (6 Rings)

5 BLK-12109 6 Hopper Brace for 16" Collar (Shown)

BLK-12110 6 Hopper Brace for 22" Collar

6 BLK-12342 1 16" 60° Hopper Collar (18 Holes) (Shown)

BLK-10342 1 22" 60° Hopper Collar (36 Holes)

7 BLK-12058 6 9' Inside Cross Tie Brace (67.788") (12 Gauge)

BLK-12059 6 9' Outside Cross Tie Brace (67.788") (12 Gauge)

8 BLK-11730 1 30° Bulk Tank Peak Ring (Shown)

BLK-12534 1 40° Bulk Tank Peak Ring

9 BLK-12730 9 9' 60° Hopper Reinforcement Angle (3--6 Ring Tanks Only)

3 Per

Ring

PNEG-256 6', 7' & 9' Bulk Feed Tanks 75

Page 76

14. PARTS SECTION

9' Diameter 60° Hopper Tank Specifications

Peak Ring Collar

Roof

Panel

Leg

Outside

Hopper Panel

Outside

Inside

8

Inside

Hopper

Panel

Roof Panel

1

Sidewall

Washer

Outside

2

Inside

Roof Panel

Sidewall

Sheet

Inside

3

Roof Panel

Sidewall

Sheet

Outside

Sidewall

Sheet

4

Inside

Outside

Sidewall

Sheet

9

Leg

Cross Tie

Cross Tie

Inside

Outside

10

10

11

Hopper Brace

Offset Hopper Panel

12

Inside

Inside

Leg

5

Outside

6

Inside

7

Outside

Sidewal

Sheet

Inside

Sidewall

Sheet

Outside

Hopper

Panel

Leg

Hopper Collar

76 PNEG-256 6', 7' & 9' Bulk Feed Tanks

Page 77

14. PARTS SECTION

9' Diameter 60° Hopper Tank Specifications

Ref # Part # Qty Description

1 S-275 36 Bulk Tank Peak Ring to Roof Panels (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 36

2 S-275 108 Roof Panel to Roof Panel (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16"

S-396 108

3 S-275 108 Roof Panels to Top Sidewall Sheets (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 108

4 S-275 Varies Vertical Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts and

S-396 Varies

5 S-275 Varies Horizontal Sidewall Sheet Seams (Use 5/16" x 3/4" Hex Head Bin Bolts

S-396 Varies

6 S-275 78 or 132 Leg to Sidewall Sheet (Use 5/16" x 3/4" Hex Head Bin Bolts and 5/16" Hex

S-396 78 or 132

7 S-277 108 Hopper Panels to Sidewall Sheet (Use 5/16" x 1-1/4" Hex Head Bin Bolts

S-396 108

8 S-277 6 Leg to Body Sheet to Hopper Connection (Use 10 Gauge Washer under

S-396 6

BLK-12483 6

9 S-4303 216 Vertical Hopper Seams (Use 5/16" x 3/4" Truss Head Bin Bolts and 5/16"

S-3611 216

10 S-7927 18 Cross Tie Brace (Use 3/8" x 1" Flange Head Bolts and 3/8" Hex Nuts.)

S-456 18

11 S-7927 6 Hopper Brace to Leg (Use 3/8" x 1" Flange Head Bolts and 3/8" Hex Nuts.)

S-456 6

12 S-4303 27 or 36 Hopper Collar to Hopper Panel (Use 5/16" x 3/4" Truss Head Bin Bolts and

S-3611 27 or 36

and 5/16" Hex Nuts.)

Hex Nuts.)

and 5/16" Hex Nuts.)

5/16" Hex Nuts.)

and 5/16" Hex Nuts.)

Nuts.) (Bolt Heads to Inside of Tank.)

and 5/16" Hex Nuts.) (Bolt Head to Inside at Leg to Hopper to Sidewall

Connection Only.)

5/16" x 1-1/4" Hex Head Bin Bolts and 5/16" Hex Nuts.) (Bolt Head to

Inside at Leg to Hopper to Sidewall Connection Only.)

Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.)

5/16" Flanged Whiz Nuts.) (Bolt Heads to Inside of Tank.) (16" Shown)

Note: Bolts listed first, nut second for each usage.

Hardware Usage: Heads of Bolts are on the outside of tank unless otherwise noted.

PNEG-256 6', 7' & 9' Bulk Feed Tanks 77

Page 78