Page 1

Humidistat-Thermostat

Model # HF _-_ _-_ _-

Owner ’s Manual

PNEG-236

Date: 12-02-09

PNEG-236

Page 2

2 PNEG-236 Humidistat-Thermostat

Page 3

Table of Contents

Contents

Chapter 1 Safety .................................................................................................................................................. 4

Safety Guidelines ... ... ... ... ................................................................................................................... 4

Humidistat-Thermostat Operation ...................................................................................................... 5

Chapter 2 Safety Alert Decals ......................................... ... ... ............................................. ................................ 6

Chapter 3 General Installation ........................................................................................................................... 9

Installation Instructions ................. .... ... ... ... ... .......................................... .... ... ... ... .... ... ... .......... ... ........ 9

Chapter 4 Installation of Top Dry High-Low Thermostat .............................................................................. 10

Installation Instructions ................. .... ... ... ... ... .......................................... .... ... ... ... .... ... ... ................... 10

Chapter 5 Operation ......................................................................................................................................... 11

Temperature Control ........................................................................................................................ 11

Humidity Control ............................................................................................................................... 11

Chapter 6 Operation and Service .................................................................................................................... 12

High-Low Temperature Control ........................................................................................................ 12

Humidistat-Thermostat Service ........................................................................................................ 12

Chapter 7 Parts List .......................................................................................................................................... 13

Humidistat-Thermostat Parts ........................................................................................................... 13

Low-Temperature Humidistat-Thermostat Parts ........................................................... ... ... .... ... ... ... 14

High-Low Humidistat-Thermostat Parts ................................. .... ... ... ... ... .... ... ... ... .... ... ... ................... 15

Chapter 8 Wiring Diagrams .............................................................................................................................. 16

Humidistat-Thermostat Wiring .......................................................................................................... 16

Thermostat Wiring .................................. ... ... .... ... ... ... .... ... .......................................... ... ... ................ 17

Humidistat Wiring ............................................................................................................................. 18

High-Low Thermostat Wiring ..................... ... .... ... ... ... .... ... ... ... .......................................... ... .... ......... 19

Chapter 9 Mounting Template ......................................................................................................................... 20

Chapter 10 Warranty ......................................................................................................................................... 21

PNEG-236 Humidistat-Thermostat 3

Page 4

1. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

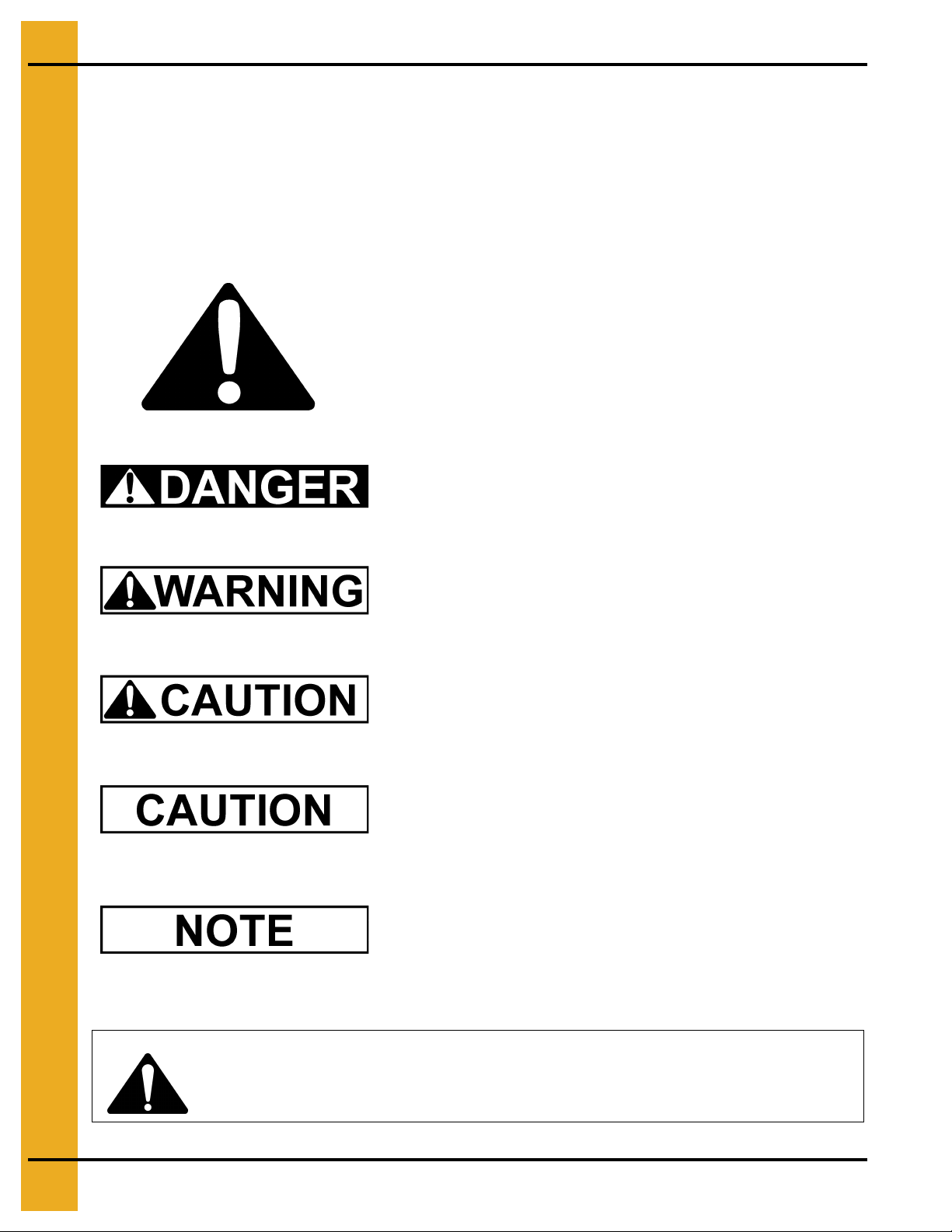

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

WARNING! BE ALERT!

Personnel operating or working around electric fans should read this manual. This

manual must be delivered with the equipment to its owner. Failure to read this manual

and its safety instructions is a misuse of the equipment.

4 PNEG-236 Humidistat-Thermostat

Page 5

1. Safety

Humidistat-Thermostat Operation

Thank you for choosing a GSI product. It is designed to give excellent performance and service for

many years.

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating p rocedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation where SERIOUS INJURY or DEATH may occur.

PNEG-236 Humidistat-Thermostat 5

Page 6

2. Safety Alert Decals

The GSI Group recommends contacting your local power company, and having a representative survey

the installation so the wiring is compatible with their system, and adequate power is supplied to the unit.

Safety decals should be read and understood by all people in the grain handling area. If a decal is

damaged or missing, contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

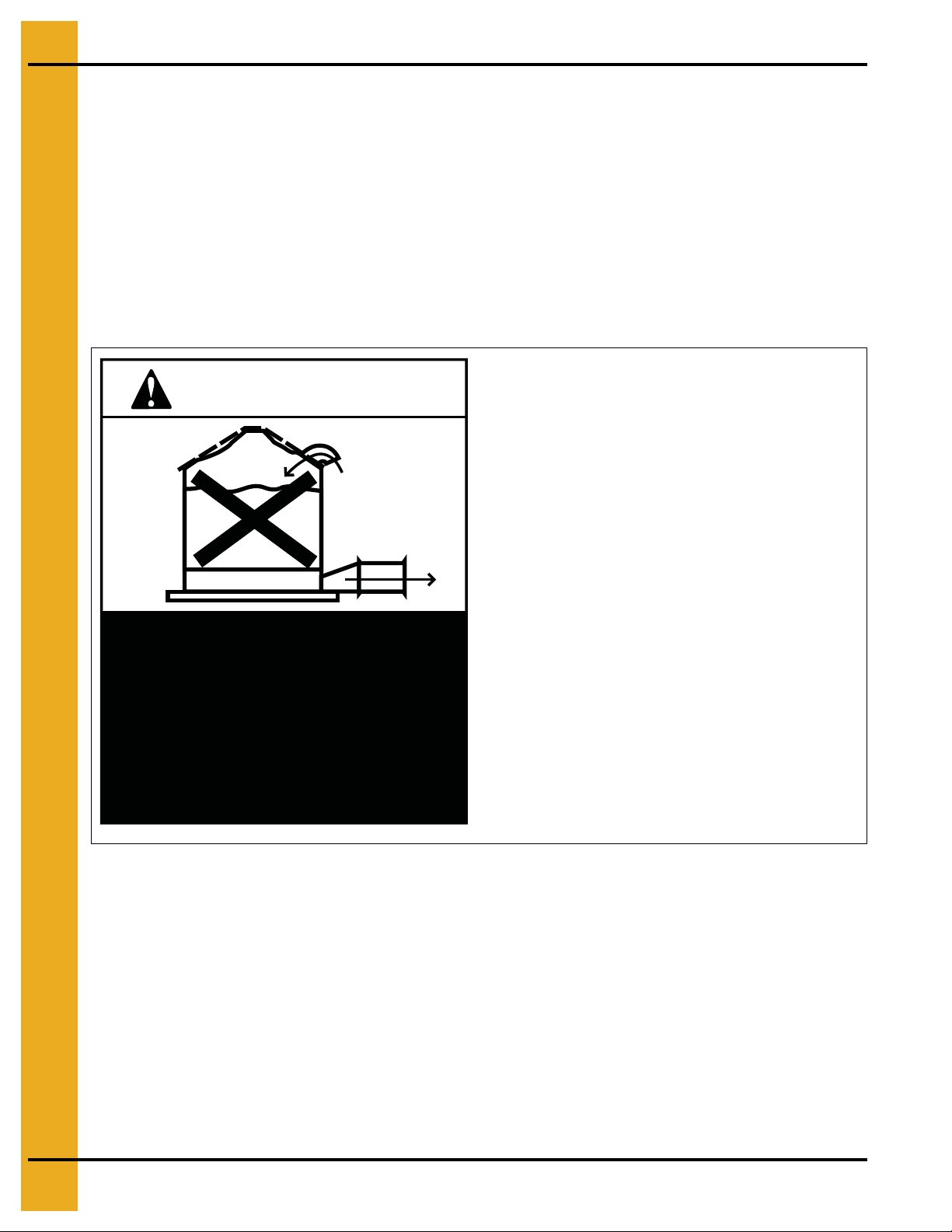

Roof Damage Warning and Disclaimer

GSI does not warrant any roof damage caused by

CAUTION!

excessive vacuum or internal pressure from fans

or other air moving systems. Adequate ventilation

and/or “Makeup Air” devices should be provided

for all powered air handling systems. GSI does not

recommend the use of downward flow systems

(suction). Severe roof damage can result from any

blockage of air passages. Running fans during

high humidity/cold weather conditions can cause

air exhaust or intake ports to freeze.

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

DC-969

6 PNEG-236 Humidistat-Thermostat

Page 7

2. Safety Alert Decals

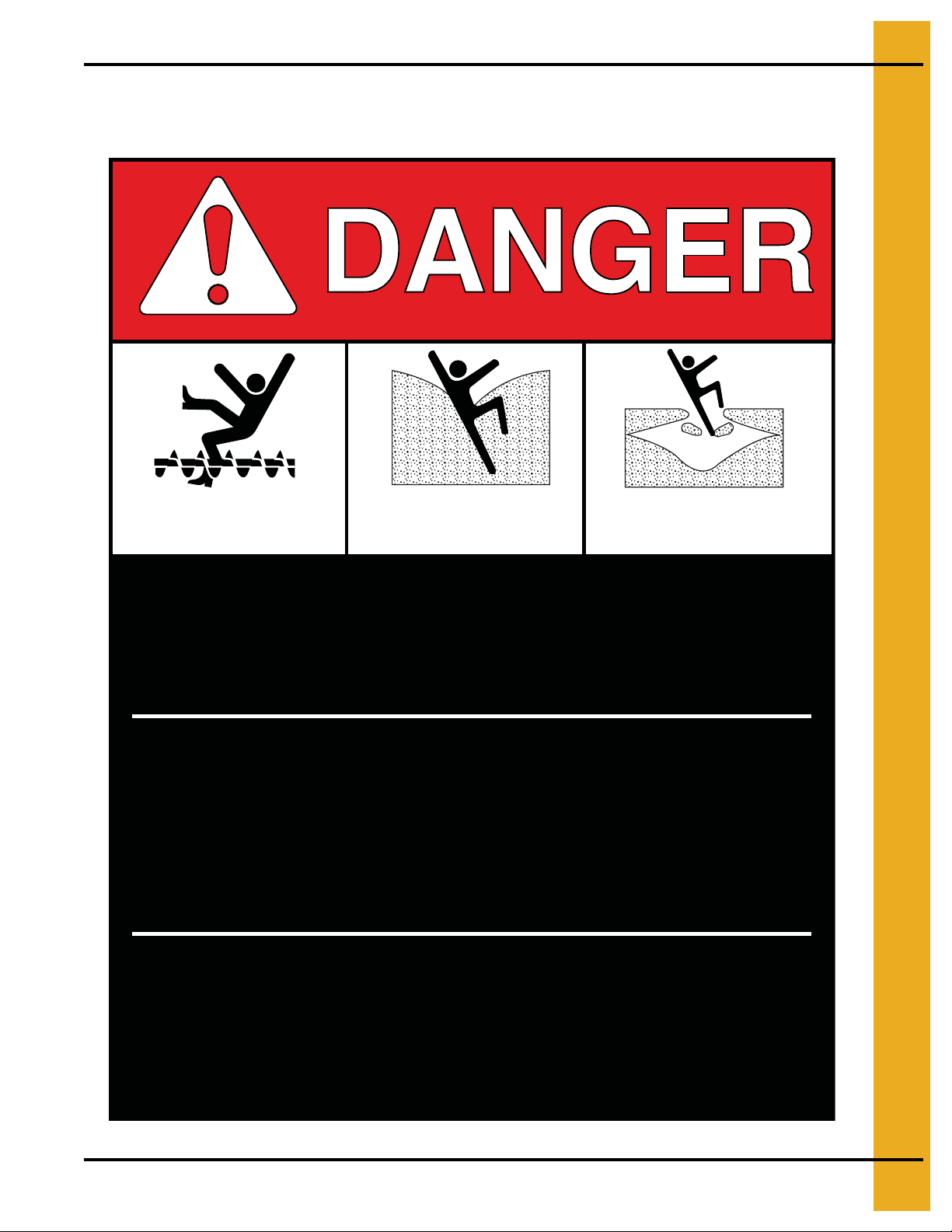

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring,

24" porthole door cover and the roof manway cover.

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

Failure to heed these

warnings will result in

serious injury or death.

DC-GBC-1A

PNEG-236 Humidistat-Thermostat 7

Page 8

2. Safety Alert Decals

HIGH VOLTAGE.

Will cause serious

injury or death.

Lockout power

before servicing.

DC-1224

WARNING

Flame and pressure beyond

door can cause serious

injury. Do not operate with

service door removed. Keep

head and hands clear.

WARNING

DC-1227

Stay clear of rotating

blade. Blade could start

automatically. Can cause

serious injury. Disconnect

power before servicing.

DC-1225

8 PNEG-236 Humidistat-Thermostat

Page 9

3. General Installation

Figure 3A 24" is the approximate distance from the edge of the transition to the edge

of the humidistat installation.

Installation Instructions

Standard electrical safety practices and codes should be used when installing the HumidistatThermostat. Refer to the National Electric Code Standard Handbook by the National Fire Protection

Association. A qualified electrician should make all wiring installations.

Always disconnect and lock out power before working on or around heater.

1. The Humidistat-Thermostat should be mounted on the side of the bin wall between the foundation

and the drying floor. It should be installed approximately 24" from the right side of the transition as

shown in

2. Use the template on Page 20. With these instructions, drill only the holes necessary for the

particular model. (NOTE: For humidistat to operate properly optional cutout must be used.)

3. Caulk the top and sides of the plastic housing using roll caulking supplied with the unit. Do not caulk

the bottom side of housing so moisture can escape.

4. Carefully insert sensing probes through bin wall and secure housing to wall using self-drilling

screws provided. Be careful not to overtighten screws. Damage to housing could result.

Figure 3A

.

5. Make wiring connections to heater as shown in heater Owner’s manual.

PNEG-236 Humidistat-Thermostat 9

Page 10

4. Installation of Top Dry High-Low Thermostat

The High-Low thermostat is designed for use with the GSI top dry crop dryer units. It comes with one

thermostat which is adjustable and cycles the heater from high to low flame. The High-Low thermostat

also comes with a thermometer for monitoring the plenum temperature.

Installation Instructions

1. Locate the mounting position of the thermostat as shown in Figure 4A.

2. Use the template on Page 20. With these instructions, drill only the holes necessary for the

particular model.

3. Apply rope caulk to sides and top of plastic housing. Leave bottom open to let moisture escape.

4. Secure housing to sidewall using self-drilling screws supplied. Be careful not to overtighten.

Overtightening may cause the housing to crack.

rd

5. Connect the black and white wires to the terminals marked bin High-Limit (3

bottom left hand terminal strip) on fan and heater safety circuit board.

th

6. Connect the green and red wires to the terminals marked cycle (8

and 6th terminal bottom left hand

terminal strip) on fan and heater safety circuit board.

and 4th terminal

Figure 4A Placement of the Top Dry High-Low Thermostat

10 PNEG-236 Humidistat-Thermostat

Page 11

5. Operation

Temperature Control

1. Turn the fan unit ON and let it run 3 to 5 minutes to equalize temperature under the bin.

2. Set bypass switch to the “HUMIDISTAT OFF” position. This setting allows the unit to run based on

temperature only.

3. Rotate the thermostat knob clockwise to the warmest position.

4. Open the gas valves to the heater and turn the heater ON. Set heater gas pressure to a moderately

high setting (5 to 10 PSI).

5. Monitor the thermometer on the thermostat housing. When the thermometer comes up to the desired

temperature, slowly turn the thermostat knob counterclockwise until the heater cycles OFF.

6. If the unit does not reach the desired temperature, gradually increase the gas pressure until the

temperature rises to the desired level.

7. Watch the unit run through several cycles and make any final adjustments. (NOTE: The unit should

be on approximately 80% of the time. If not adjust gas pressure.)

8. Significant changes in outside air temperature may require readjustment of gas pressure.

Humidity Control

1. Set bypass switch to the “HUMIDISTAT ON” position. This setting allows the unit to run based on

temperature and humidity.

2. Set the thermostat (Humidistat-Thermostat units only) to the maximum temperature desired. This

allows the thermostat to function as a High-Limit control only. See the above Temperature Control

for setting the thermostat.

3. Set the humidistat to the desired relative humidity level you want to maintain under the drying floor.

The heater will cycle on above this relative humidity, and OFF when this level is reached.

4. Use the equilibrium moisture chart below as a guide for setting the humidistat.

Equilibrium Moisture Chart (Shelled Corn)

Air

T emperature

(F)

20° 11.2 11.7 12.7 13.7 14.5 15.1 16.2 17.1 18.0 19.6 21.2 23.5 25.8 29.1

30° 10.8 11.3 12.2 13.1 13.9 14.6 15.5 16.4 17.4 18.7 20.2 22.5 25.0 28.3

40° 10.5 11.0 11.7 12.5 13.3 14.0 14.8 15.5 16.6 17.8 19.4 21.5 24.2 27.5

50° 10.1 10.6 11.3 12.0 12.7 13.3 14.1 14.8 15.8 16.9 18.6 20.5 23.4 26.7

35 40 45 50 55 60 65 70 75 80 85 90 95 100

Relative Humidity - Percentage (%)

60° 9.7 10.2 10.9 11.6 12.1 12.7 13.4 14.2 15.0 16.0 17.8 19.5 22.6 25.9

70° 9.0 9.7 10.4 11.1 11.5 12.0 12.8 13.5 14.5 15.4 16.8 18.5 21.3 24.5

80° 8.3 9.1 9.8 10.5 10.8 11.2 12.1 13.0 13.9 14.8 15.8 17.4 20.0 22.8

Boxed area indicates safe moisture for normal winter storage of shelled corn at 15%. Grain

to be stored through the summer or long term, needs to be 1 to 3 points dryer.

PNEG-236 Humidistat-Thermostat 11

Page 12

6. Operation and Service

High-Low Temperature Control

1. Turn fan unit ON and let it run 3 to 5 minutes to equalize temperature under the bin.

2. Rotate the thermostat knob clockwise to warmest position.

3. Open gas valves (including Low-Fire valve) to the heater and turn the heater ON. Set heater gas

pressure to a moderately high setting (5 to 10 PSI).

4. Monitor the thermometer on the thermostat housing. When the thermostat comes up to desired

temperature, slowly turn the most at knob counterclockwise until heater cycles to Low-Flame.

5. If the unit does not reach desired temperature, gradually increase the gas pressure until the

temperature rises to desired level.

6. Adjust the Low-Fire valve so that the temperature drops until the unit cycles back to High-Flame.

7. Watch the unit run through several cycles and make any final adjustments. (NOTE: The unit should

cycle approximately two (2) times per minute. If not adjust gas pressure.)

8. Significant changes in outside air temperature may require readjustment of gas pressure.

NOTE: If temperature of Low-Flame exceeds thermostat settings (above normal outside temperat ures)

unit will cycle from Low-Flame to OFF. (Top dry units will shut down completely.)

Humidistat-Thermostat Service

GSI thermostats are designed and built to withstand the harsh conditions usually found in drying bins. A

yearly preventative maintenance inspection may extend the life of the heating controls many years.

Always disconnect and lock out power before working on or around heater.

1. Remove mounting screws from the thermostat housing and remove the housing from the bin wall.

2. Carefully remove the back panel from the housing. (It may be necessary to cut caulking.)

3. Blow out any dust or dirt that may have collected inside the housing.

4. Inspect the wiring for any loose connections, or rodent and insect damage.

5. Replace the back panel and caulk the corners to help seal the unit.

6. Reinstall the unit on the bin wall.

The Airstream Humidistat-Thermostat is mounted

on the lower right side of the grain bin’s transition.

This allows for easy service and operation.

Figure 6A

12 PNEG-236 Humidistat-Thermostat

Page 13

Humidistat-Thermostat Parts

7. Parts List

Ref # Part # Description

1 HF-1431 2.66" Plastic Housing

1 HF-1446 4.00" Plastic Housing

2 HF-1432 Thermostat

3 HF-1433 Humidistat

4 HF-1434 Static Pressure Gauge

5 HH-1435 220° Thermometer

6 HH-1436 Screen Plug

7 HH-1970 Plastic Knob

8 HH-2089 Large Red Plastic Plug

9 HH-1442 Toggle Switch

10 HF-7108 Thermostat Cover

11 HH-7032 Rubber Grommet

12 HH-7029 Heat Shrink Tube 1/2"

13 HF-7110 Humidistat Cover

PNEG-236 Humidistat-Thermostat 13

Page 14

7. Parts List

Low-Temperature Humidistat-Thermostat Parts

Ref # Part # Description

1 HF-1431 2.66" Plastic Housing

1 HF-1446 4.00" Plastic Housing

2 HF-3974 Low-Temperature Thermostat

3 HF-1433 Humidistat

4 HF-1434 Static Pressure Gauge

5 HH-3973 140° Thermometer

6 HH-1436 Screen Plug

7 HH-1970 Plastic Knob

8 HH-2089 Large Red Plastic Plug

9 HH-1442 Toggle Switch

10 HF-7108 Thermostat Cover

11 HH-7032 Rubber Grommet

12 HF-7110 Humidistat Cover

14 PNEG-236 Humidistat-Thermostat

Page 15

High-Low Humidistat-Thermostat Parts

7. Parts List

Ref # Part # Description

1 HF-1431 2.66" Plastic Housing

1 HF-1446 4.00" Plastic Housing

2 HF-7028 Low-Temperature Thermostat

3 HF-1434 Static Pressure Gauge

4 HF-1435 220° Thermometer

5 HH-1436 Screen Plug

6 HH-1970 Plastic Knob

7 HH-2089 Large Red Plastic Plug

8 HH-7029 Heat Shrink Tube 1/2"

9 HH-7108 Thermostat Cover

10 HF-7032 Rubber Grommet

11 HF-7110 Humidistat Cover

PNEG-236 Humidistat-Thermostat 15

Page 16

8. Wiring Diagrams

Humidistat-Thermostat Wiring

16 PNEG-236 Humidistat-Thermostat

Page 17

Thermostat Wiring

8. Wiring Diagrams

PNEG-236 Humidistat-Thermostat 17

Page 18

8. Wiring Diagrams

Humidistat Wiring

18 PNEG-236 Humidistat-Thermostat

Page 19

High-Low Thermostat Wiring

8. Wiring Diagrams

PNEG-236 Humidistat-Thermostat 19

Page 20

9. Mounting Template

20 PNEG-236 Humidistat-Thermostat

Page 21

10. Warranty

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive

components, shall be free from defects in materials for a period of time beginning on the twelfth (12

the date of purchase and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period).

th

) month from

During the extended warranty period, GSI will replace the frame or basket components that prove to be defective

under normal conditions of use without charge, excluding the labor, transportation, and/or shipping costs incurred in

the performance of this extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE

OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT,

SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user.

GSI shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer,

agent or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment

at initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse,

alteration, accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to

products manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

9101239_1_CR_rev7.DOC (revised July 2009)

PNEG-236 Humidistat-Thermostat 21

Page 22

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2009 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...