Page 1

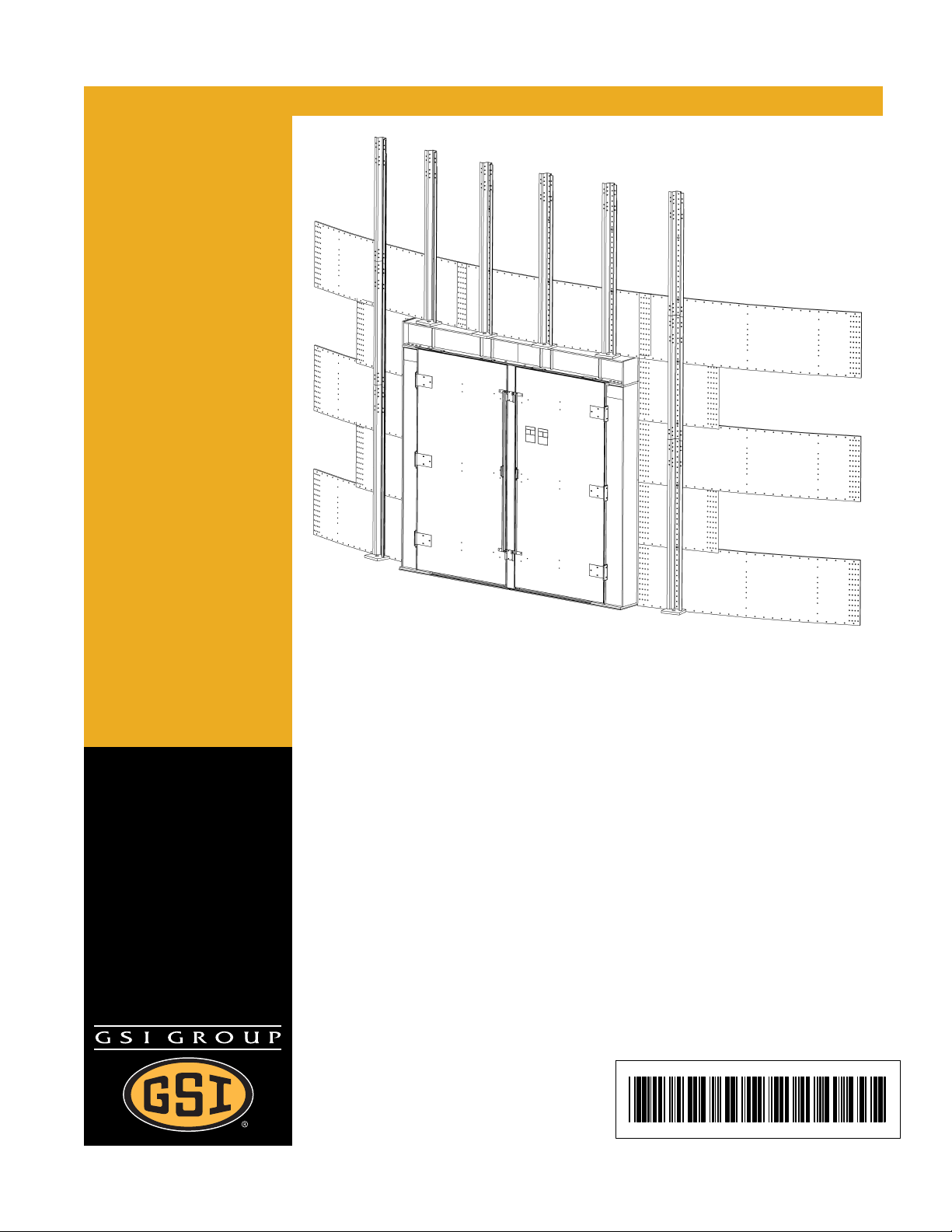

VTDL-72-8X9D - VTDL-78-8X9D

Door

Assembly Instructions

PNEG-1336D

Date: 05-14-08

PNEG-1336D

Page 2

2 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

Page 3

Table of Contents

Contents

Chapter 1 Introduction ........................................................................................................................................ 4

Chapter 2 Safety ..................................................................................................................................................5

Safety Guidelines ............................................................................................................................... 5

General Safety Statement ................................................................ ... ... .... ... ... ... ............................... 6

Safety Instructions .............................................................................................................................. 7

Safety Sign-Off Sheet ......................................................................................................................... 9

Proper Storage Grain Bin/Silo Materials Prior to Construction ......................................................... 10

Chapter 3 Safety Decals ...................................................................................................................................11

Chapter 4 Assembly Instructions ....................................................................................................................14

Chapter 5 Door Assembly ................................................................................................................................17

Sidewall and Stiffener Layout ........................................................................................................... 17

Door Assembly Exploded View ........................................................................................................ 18

Column Installation ........................................................................................................................... 19

Header Beam Installation ................................................................................................................. 20

Header Beam Connection Details .................................................................................................... 21

Center Column Installation ............................................................................................................... 22

Door Panel Assembly ....................................................................................................................... 23

Door Panel Assembly (2) ................................................................................................................. 24

Stiffener/SDW Attachment ............................................................................................................... 25

Weld Details ................................. .... ... ... ... .......................................... ... .......................................... 26

Outer Cover Assembly ..................................................................................................................... 27

VTDL Door Foundation Note ............................... ................................................ ............................. 29

Chapter 6 Warranty ...........................................................................................................................................33

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 3

Page 4

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of

lading to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provide s field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will be come void

and field improvements may be denied.

4 PNEG-1336D VTDL-72-8X9D - VTDL-7 8-8X9 D Door

Page 5

2. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 5

Page 6

2. Safety

General Safety Statement

Our foremost concern is your safety and the safety of others associated with grain handling equipment.

This manual is to help you understand safe operating procedures and some problems which may be

encountered by the operator and other personnel.

As owner and/or operator, you are responsible to know what requirements, hazards and precautions

exist and inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment, which may produce a very

dangerous situation, where serious injury or death may occur.

You should consider the location of the bin site relative to power line locations or electrical transmission

equipment. Contact your local power company to review your installation plan or for information

concerning required equipment clearance. Clearance of portable equip ment that may be taken to the bin

site should also be reviewed and considered. Any electrical control equipment in contact with the bin

should be properly grounded and installed in accordance with National Electric Code provisions and

other local or national codes.

This product is intended for the use of grain storage only. Any other use is a misuse of the product.

This product has sharp edges, which may cause serious injury. To avoid injury, handle

sharp edges with caution and always use proper protective clothing and equipment.

Sidewall bundles or sheets must be stored in a safe manner. The safest method of storing sidewall

bundles is laying horizontally with the arch of the sheet upward, like a dome. Sidewall sheets stored on

edge must be secured so that they cannot fall over and cause injury. Use care when handling and

moving sidewall bundles.

Personnel operating or working around equipment should read this manual. This manual must be

delivered with equipment to its owner. Failure to read this manual and its safety instructions is a misuse

of the equipment.

6 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

Page 7

2. Safety

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating proced ures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built up grease oil and debris.

Read and Understand Manual

Maintain Equipment

and Work Area

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 7

Page 8

2. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Keep Emergency Equipment

Quickly Accessible

Eye Protection

Long hair should be tied up and back.

Safety glasses should be worn at all times to protect eyes

from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel toe boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoe strings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear hard hat to help protect your head.

Gloves

Steel Toe Boots

Respirator

Hard Hat

8 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

Page 9

2. Safety

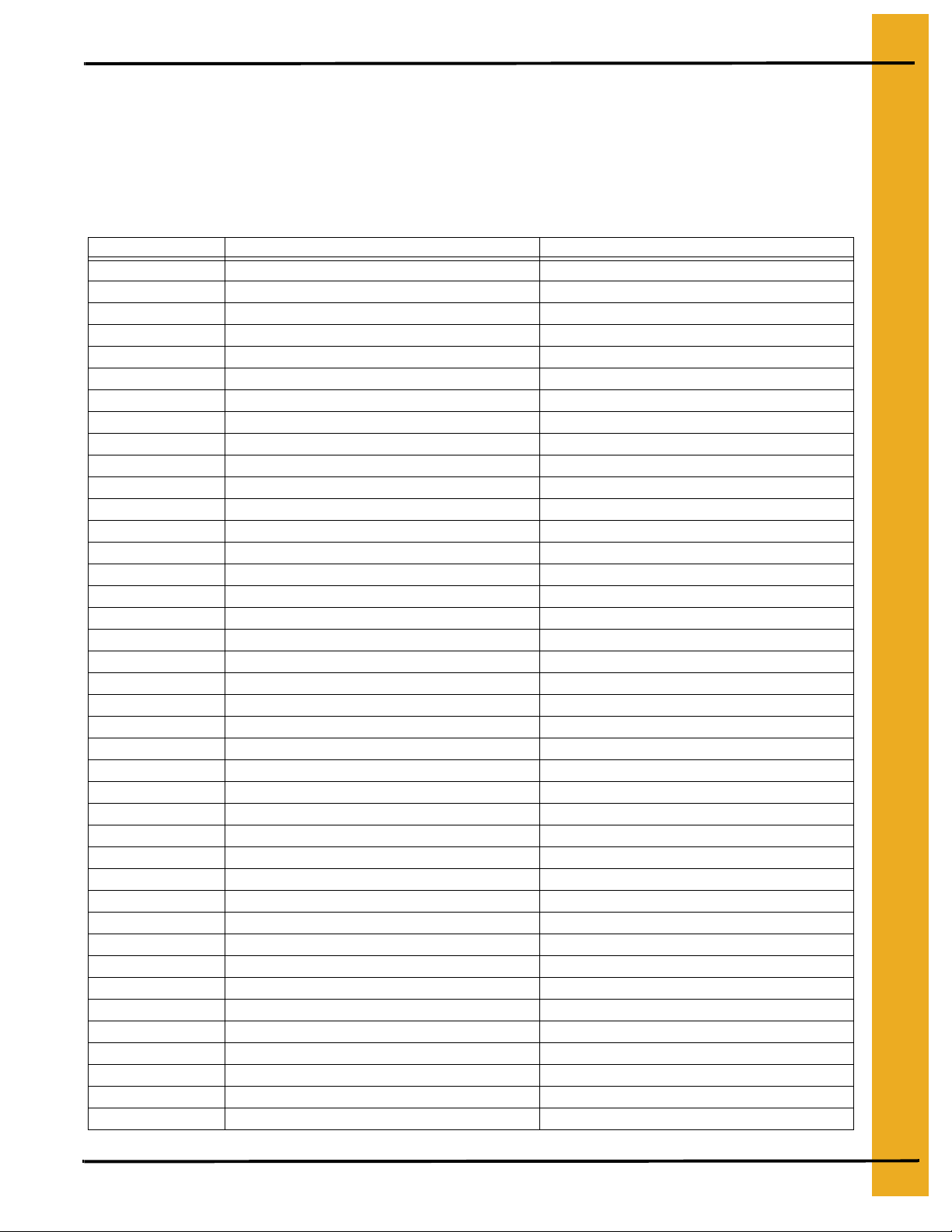

Safety Sign-Off Sheet

As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe operating

and safety procedures for this auger. This sign-off sheet is provided for your convenience and personal

record keeping. All unqualified persons are to stay out of the work area at all times. It is strongly

recommended that another qualified person who knows the shut down procedure be in the area in the

event of an emergency.

Date Employee Name Supervisor Name

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 9

Page 10

2. Safety

Proper Storage Grain Bin/Silo Materials Prior to Construction

Wet storage stain (rust) will develop when closely packed bundles of galvanized material, such as

sidewall and roof sheets, have moisture present. Inspect roof and sidewall bundles on arrival for any

moisture. If moisture is present, it must not be allowed to remain between the sheets. Separate the

sheets or panels immediately and wipe them down. Spray with a light oil or diesel fuel.

If possible, sidewall bundles, roof sheets and other closely packed galvanized materials should be stored

in a dry, climate controlled building. If outdoor storage is unavoidable, the materials should be stored so

that they are raised above the ground and vegetation. Any tacking and spacing materia ls should not be

corrosive or wet. Be sure to protect materials from the weather, but permit air movement around the

bundles if possible.

Storing roof bundles and sidewall sheets at a slight incline can also help minimize the presence of

moisture. Storing the bundles with the center of the dome up (like an arch) is one option for minimizing

moisture during storage. Sidewall bundles can also be stored on edge but must be secured so that they

do not fall over and cause injury.

If “white rust” or “wet storage stain” occurs, contact the manufacturer immediately about ways to

minimize the adverse effect upon the galvanized coating.

10 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

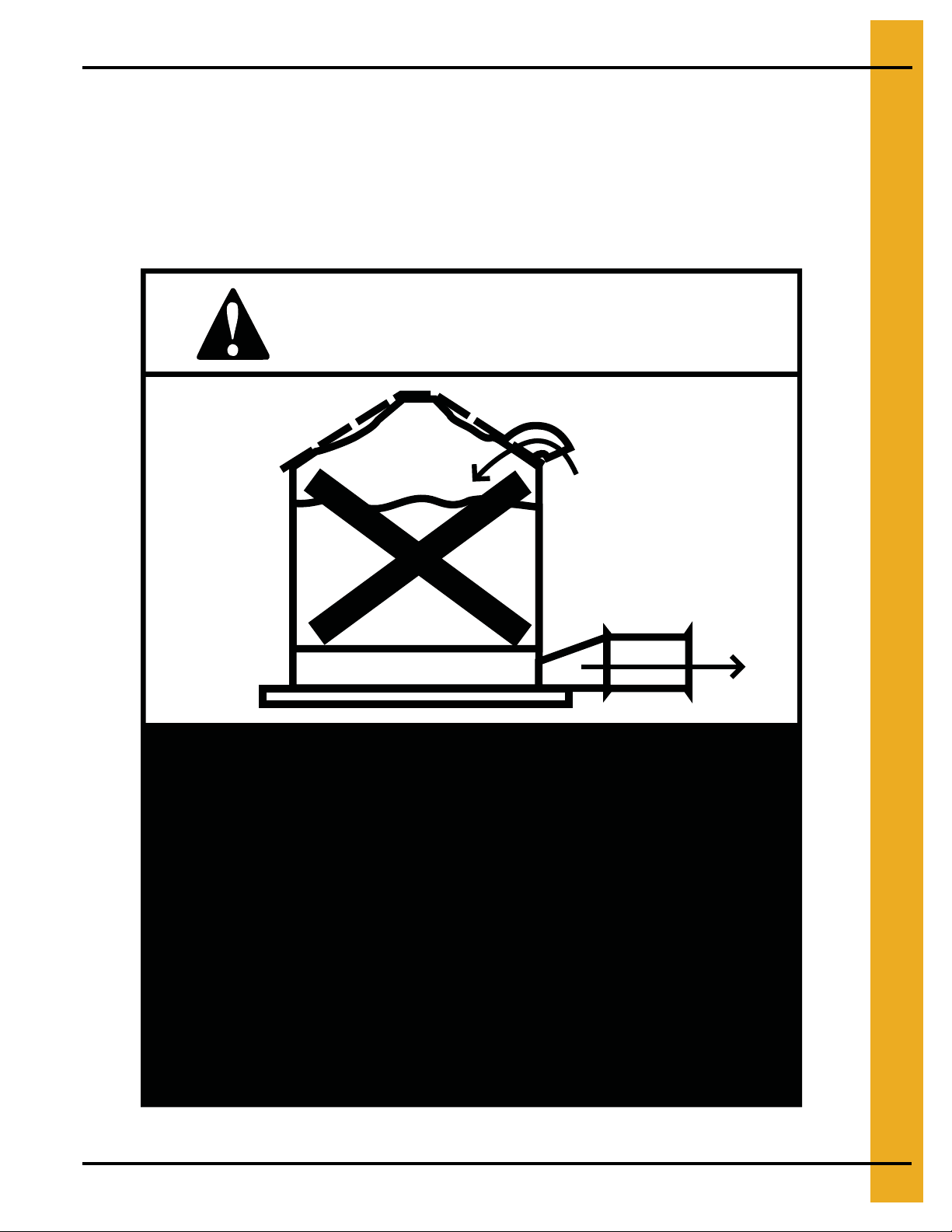

Page 11

3. Safety Decals

The manufacturer does not warrant any roof damage caused by excessive vacuum or internal

pressure from fans or other air moving systems. Adequate ventilation and/or “makeup air”

devices should be provided for all powered air handling systems. The manufacturer does not

recommend the use of downward flow systems (suction). Severe roof damage can result from

any blockage of air passages. Running fans during high humidity/cold weather conditions can

cause air exhaust or intake ports to freeze.

CAUTION!

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

DC-969

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 11

Page 12

3. Safety Decals

ATTENTION: The decal shown below should be present on the outside of the door cover of the

2 ring, 24" porthole door cover and the roof manway cover. If a decal has been damaged or is missing

in any of these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 217-226-4421

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

Failure to heed these

warnings will result in

serious injury or death.

DC-GBC-1A

12 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

Page 13

3. Safety Decals

ATTENTION: The decal shown below should be present on the outside of the door cover of the

2 ring, 24" porthole door cover and the roof manway cover. If a decal has been damaged or is missing

in any of these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 217-226-4421

WARNIN

DON’T

DO

UNLOADING INSTRUCTIONS:

1. Use CENTER FLOOR OUTLET ONLY until NO grain

remains above this outlet.

2. Side floor outlets to be used ONLY when above

condition is satisfied.

3. Lock all side floor outlets to avoid accidental

premature use.

4. See manufacturers instructions for proper use of

factory supplied sidedraw (wall) discharge systems.

Failure to heed these warnings

could result in serious injury, death,

structural damage or collapse of tank.

DC-GBC-2A

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 13

Page 14

4. Assembly Instructions

Written Instructions for Installation of a VTDL-72-8X9D - VTDL-78-8X9D

Large Vehicle Traffic Door in 72'-78' Diameter, Externally Stiffened Tanks

Prior to door installation, tank should be fully erected and anchored. The VTDL door is to be installed in

the bottom 4 rings of the tank. Adequate provisions should be made for door installation. A list of

necessary tools and equipment is attached. Also some field fabrication and welding will be necessary.

1. The VTDL door is to be installed in the bottom 4 rings of the tank.

2. The door must be placed near an intermediate discharge well such that grain will clear away from

the door panels when tank is emptied.

3. Tank erection will be done as normal until the fifth ring from the bottom is to be installed. The fifth

ring will be installed as normal except that the orientation of the sidewall sheets should match the

sidewall layout shown on Page 17. At door location, install special punched, special length door

sheets at the correct position as shown on Page 17. Use two (2) non-laminated sidewall sheets

(minimum 12 gauge) per ring without caulk to temporarily complete the ring. Use only horizontal

seam bolts to connect the filler sheets to the door sheets. Continue installing the sidewall as normal

except for installing the special door sheets and temporary sheets. These sheets are used as filler

sheets to keep the tank round until fully erected. They will be removed prior to door installation.

Also four (4) sets of stiffeners should be omitted at the door location. (See Page 17.) Stan dard base

stiffener weldments will be used in these locations after doorframe is completely installed. Anchor

tank securely before installing door.

4. When tank is properly anchored, remove filler sheets. Be sure the sidewall is installed as shown

on Page 17.

5. Review Pages 18 and 27 to identify doorframe and outer cover parts.

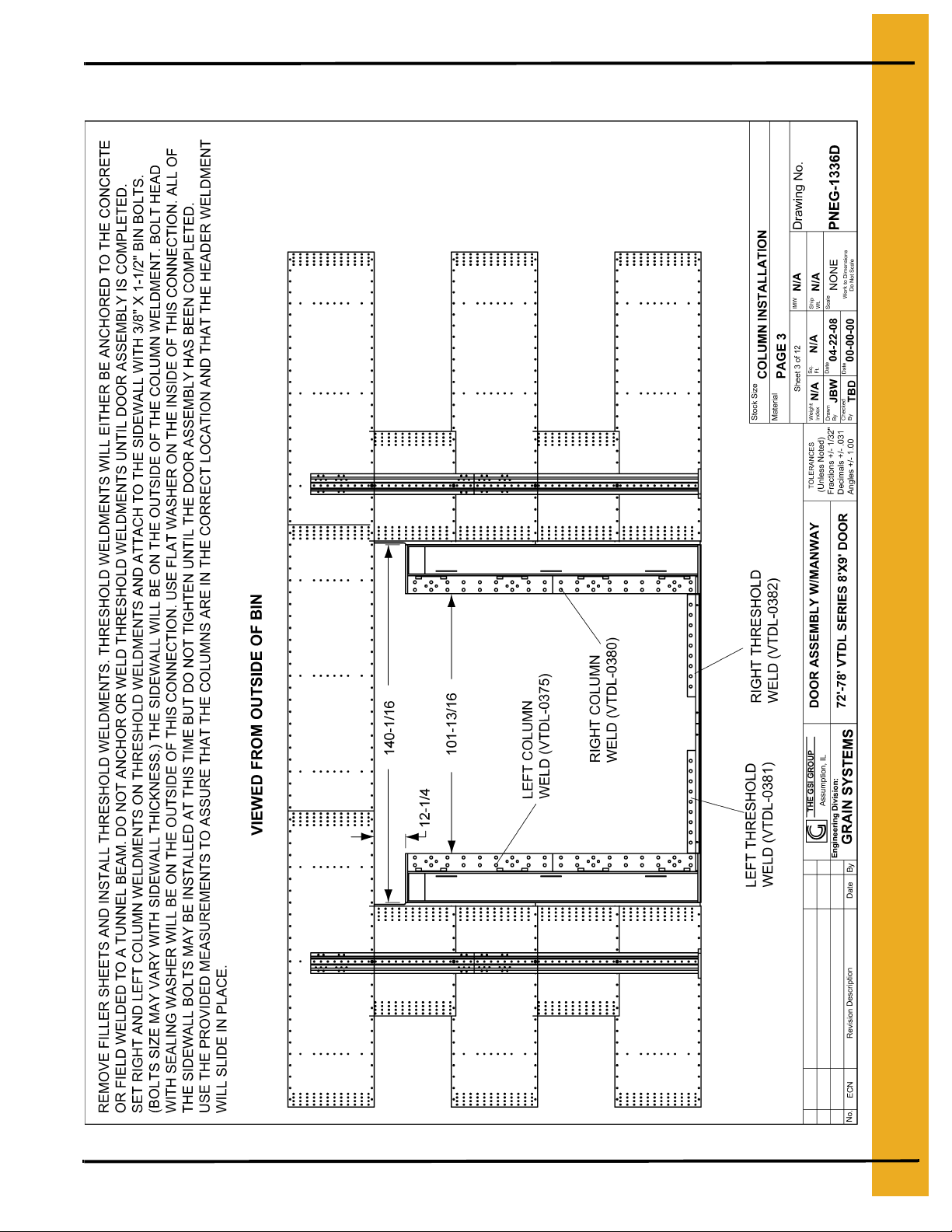

6. Place threshold weldments (VTDL-0381 and VTDL-0382) in door opening between sidewall sheets.

Install left and right column weldments (VTDL-0375 and VTDL-0380) as shown

column weldments to sidewall sheets with 3/8" x 1-1/2" bolts (S-5060) and 3/8" nuts (S-456).

NOTE:

(

corrugated sealing strips onto the outer edge of the sidewall sheets and the inner edge of the

sidewall attachment plates. Caulk around seal strip as well. Align edge of column base plate with

edge of threshold weldment. Also the door panel attachment strips of the columns and threshold

must be aligned.

anchored with 3/4" epoxy type anchors or by field welding to tunnel girder. The column weldments

must be field welded to the threshold weldme nts. Do no t anch or or weld until d oor is fully installe d.

7. Install header beam weldment (VTDL-0370 for 72' and VTDL-0530 for 78 ') on the top of the column

weldments. The header beam weldment will slide onto the top of the columns from the inside of the

tank. Fasten loosely with 1" x 3-1/2" Grade 8 bolts (S-7622), 1" washers (S-7623) and 1" nuts

(S-240). See detail A on Page 21. Be sure that the sidewall attachment plate holes of the header

and column are aligned. Attach the sidewall of the fifth ring to the header seal strip with

3/8" x 1-1/2" bolts. Do not tighten bolts until door panels are installed.

Bolt size may change slightly with gauge changes.) Do not tighten bolts at this time. Insert

(See Page 19 and Page 21.)

The columns and threshold weldments will be

on Page 19

. Fasten

14 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

Page 15

4. Assembly Instructions

8. The center column weldments (VTDL-0383) will be installed within the doorframe. The bottom of

the center column weldment will rest between the column outer cover strip on the threshold

weldment. The top of the center column weldment will bolt to the header beam weldment with

1" x 3-1/2" bolts. See details B and C

column and header beam and threshold weldment. Place one (1) shim plate on the threshold

weldment splice prior to the placement of the center column. The center column should be placed

inside of the tank with the base of the column near the threshold weldment splice. Tilt the column

upward into position and bolt it to the header beam. Install the top shim plate. The door panel

attachment plates of the column, header and threshold weldments sh o uld be align ed.

(See Page 22.)

center column. Do not tighten bolts until door panels are installed.

9. Verify that the doorframe is square and all door panel attachment plates are in alignment prior to

installing door panels.

10. Assemble door panels as shown on Page 23. Door panels must be installed in this manner to

maintain proper orientation of hinges. Door hinge plate weldments (VTDL-0391) are to be placed

as shown on Page 23 detail D. Use 3/8" x 1" bin bolts at door panel splices and 3/8" x 1-1/2" bolts

at hinge plate weldments. Bolt head with sealing washer should be on the outside for all splice

connections and on the inside for all hinge weldment connections. Follow installation details

on Page 24 for door panel placement. Use 1" x 2-1/2" Grade 8 bolts to attach door panels to the

doorframe. 1" x 3-1/2" Grade 8 bolts will be used at hinge location. Use only enough bolts to hold

panels in place and clamp the panels to the doorframe. Be sure that the panels are closed

completely and all holes are aligned. The door panels will be opened later to allow for field welding

and sealing. Caulk all along door panel splices.

The center column is to be removed when door is opened; do not field weld to

on Page 22

. Use VTDL-0338 shim plates between center

11. Insert hinge pins (VTDL-0244) through hinge plates on the door panels and column weldments.

See detail E on Page 25. Place 1/2" washer over top of the hinge pin and secure it with 1/8" cotter

pin (S-7241). Tighten all door panel bolts and doorframe connection bolts at this time.

12. Attach standard base stiffener weldments above header beam as shown on Page 25. Use

3/8" x 1" bin bolts for attaching to seal strip and 3/8" x 2" bolts for attaching to sidewall plates.

Tighten all sidewall and stiffener bolts at this time. Shim as necessary and field weld stiffeners to

header beam. Base plates may have to be trimmed to align with header beam. See Page 25.

13. Anchor threshold weldments to foundation or field weld to tunnel beam. Field weld columns to

threshold weldments. Open door panels and field weld door panel attachment plates of header and

threshold to left and right column weldments. Be sure that the door panels open and close

smoothly. Field weld threshold weldment splice and access cover plates on column weldments.

Welding should be done on both the inside and outside of the doorframe. Refer to Page 26 for

complete field welding details.

14. Clean, inspect, and paint all welds. Place foam seal strip all along the outer edge of the door panel

assembly to seal door panels. Close door panels and install all door panel bolts with washer on

each side. Tighten door panel bolts. Inspect all welds and door assembly bolts at this time. Place

decals DC-GBC-1A and DC-GBC-1S on the inside of the door panels. Caulk any gaps around the

center column weldment and threshold weldments.

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 15

Page 16

4. Assembly Instructions

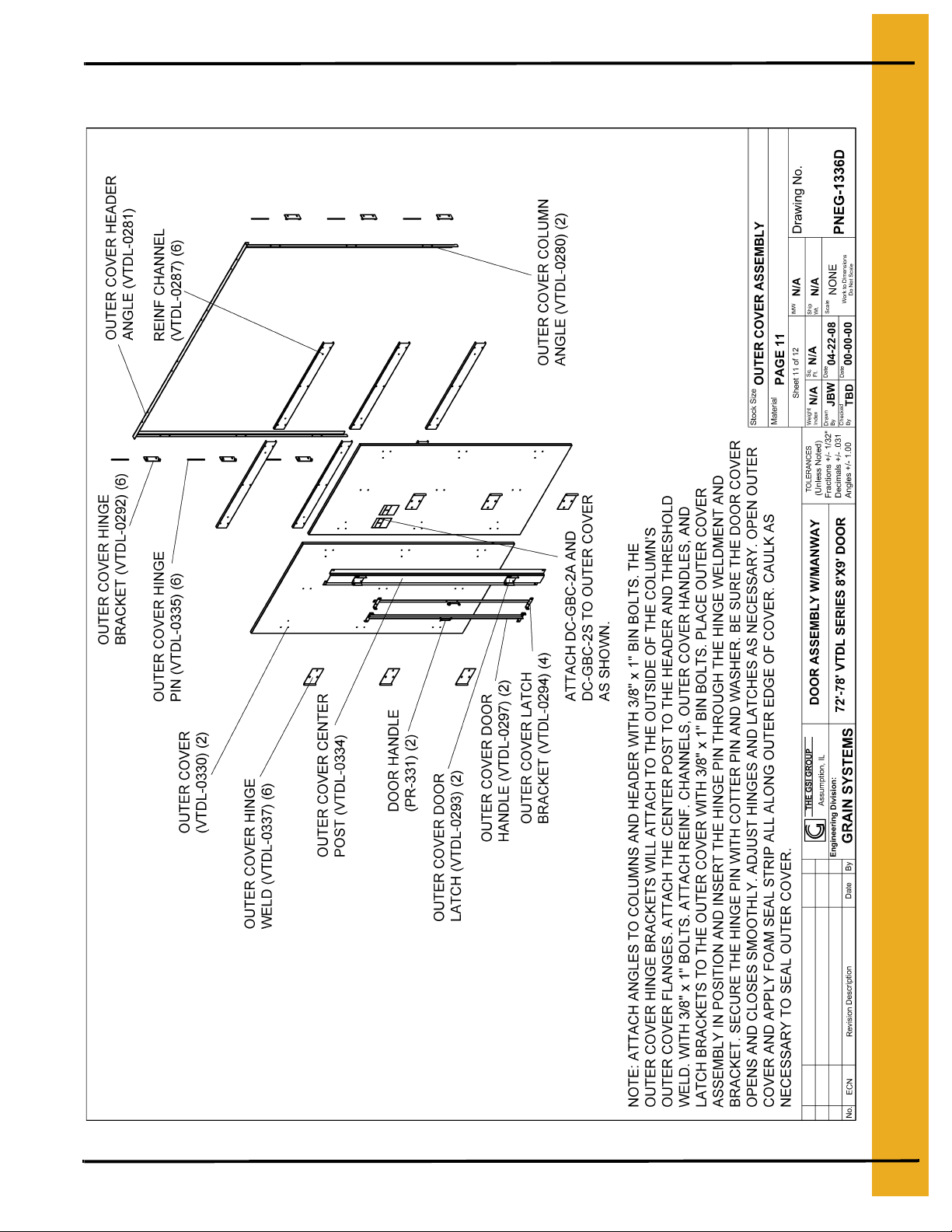

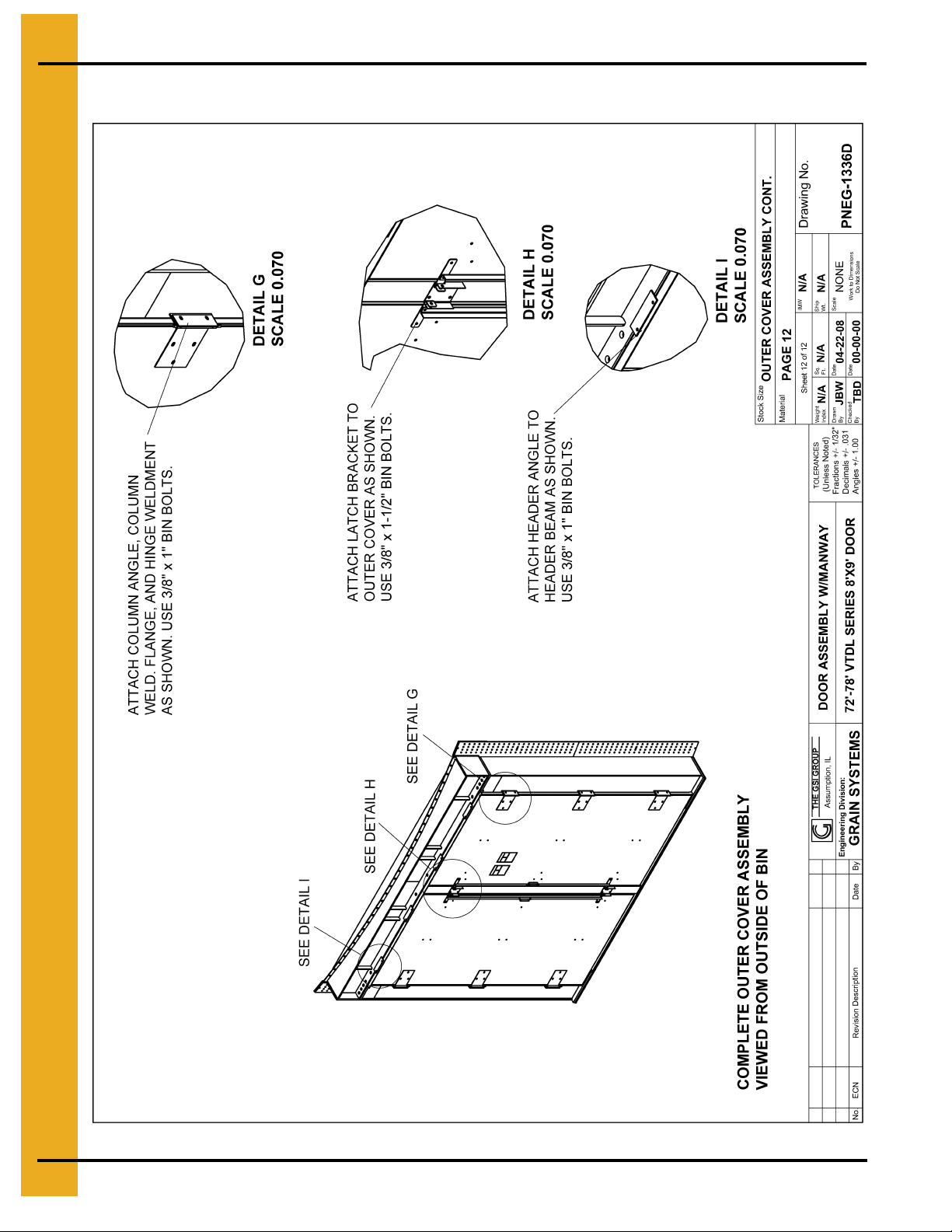

15. Assemble outer cover as shown on Page 27. Apply strip of caulk behind column and header angles

before attaching them to column and header beam clips. Attach center post and center door latch

(VTDL-0293) to header angle and threshold weldment. Apply caulking to the top and bottom of

center post. Assemble door outer cover, reinforcement channels, hinges, latch brackets and door

handles as shown on Page 27. 3/8" x 1" Bin bolts will be used for all connections. Use 3/8" nut and

sealing washer as spacer between latch bracket and outer cover. Place outer cover in doorframe

and align hinge weldment (VTDL-0337) with hinge bracket (VTDL-0292). Insert hinge pins

(VTDL-0335) through hinges and hold in place with washers and cotter pins. Review details

G-I on Page 28 for connection details. Adjust door hinges and latches as necessary until door

opens and closes smoothly. Apply foam seal strip around perimeter of outer cover and caulk as

necessary to seal outer cover. Place decals DC-GBC-2A and DC-GBC-2S on the outer cover as

shown on Page 28.

16. To open door, open outer cover and remove door cover or tie back to bin, remove center post,

unbolt door panels from doorframe. Do not remove hinges or unbolt door panels from one another.

Swing door panels open to remove center column. Provisions should be made to hold the door

panels open while center column is being removed and bin is being cleaned. Unbolt top of center

column from header beam and remove shim plate. Slide center column section inside off the

threshold weldment, tilt outward and remove. Caution center column is extremely heavy and proper

equipment should be used for removal. Temporary ramps should be made to avoid driving over the

door panel attachment plates of the threshold weldment. Once the bin is fully emptied, re-install the

center column section, close door panels, and bolt panels to doorframe. It may be necessary to

re-seal around door panels and column weldments. Close outer cover and re-seal as necessary.

Inspect all decals each time door is opened and replace if damaged or missing.

Recommended Tools for Installing VTDL-72-8X9 Door

1. Forklift or similar piece of equipment capable of lifting 1500 lbs. at heights above 10'.

2. Welder

3. Plasma cutter, torch, or similar tool for cutting base plates.

4. Concrete drill for installing 3/4" epoxy type anchors (if anchors are used).

5. 1/2" and 7/16" drill bits.

6. Sockets and wrenches including 9/16", 5/8", 1-1/8", and 1-1/2" sizes.

7. Drift pins and/or pry bars.

16 PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door

Page 17

Sidewall and Stiffener Layout

5. Door Assembly

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 17

Page 18

5. Door Assembly

Door Assembly Exploded View

MANWAY DOOR PANEL

ASSEMBLY REFER

PAGES 23-24

SEE PAGE

DOOR PA NEL ASSEMBLY

REFER P AGES 23-24

OUTER COVER

ASSEMBLY

REFER PAGE 27

18 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 19

Column Installation

5. Door Assembly

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 19

Page 20

5. Door Assembly

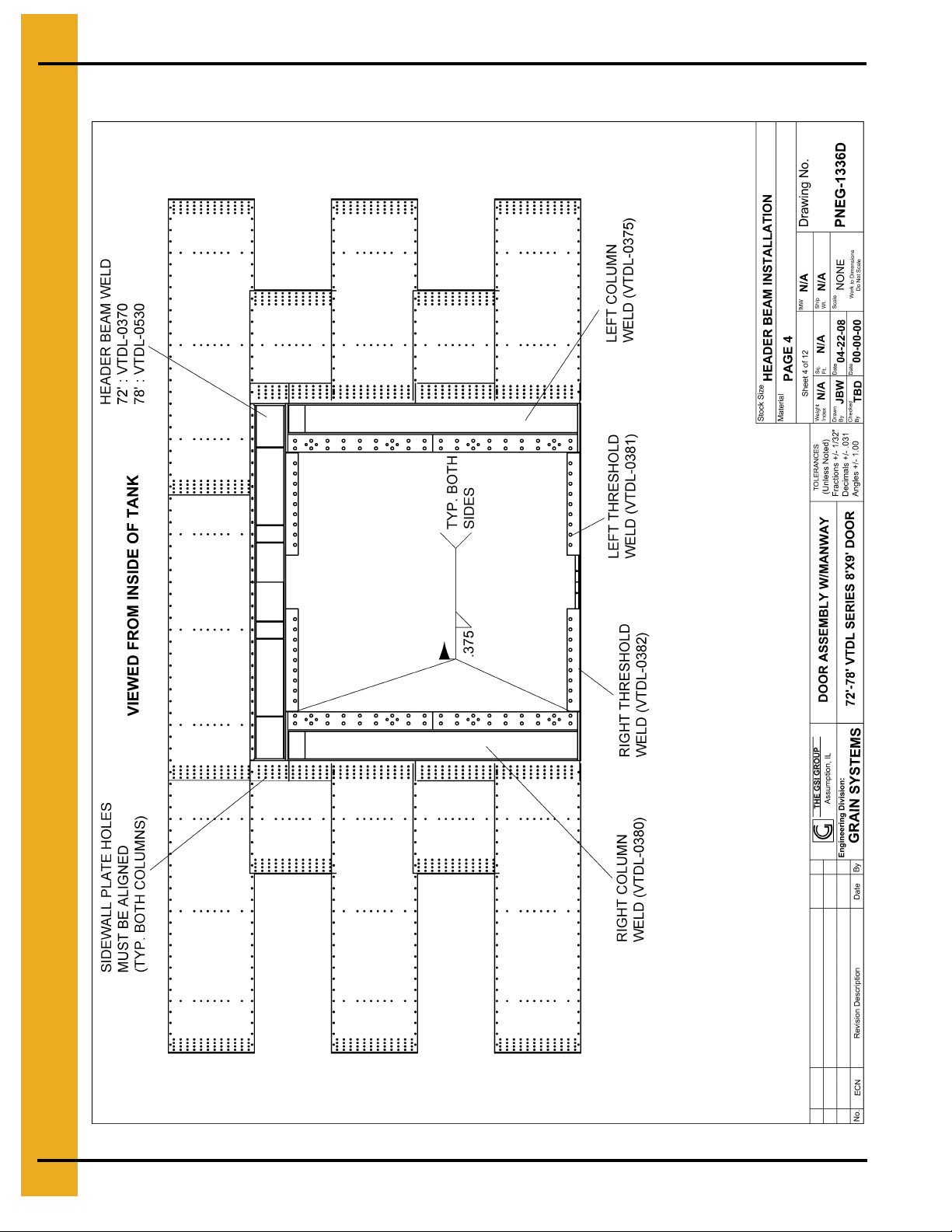

Header Beam Installation

THE HEADER BEAM MUST SLIDE ONTO THE COLUMNS FROM THE INSIDE OF THE TANK. THE SEAL

STRIP ATOP OF THE HEADER WILL BOLT TO THE FIFTH RING FROM THE INSIDE OF THE TANK.

ATTACH THE HEADER TO THE COLUMNS WITH 1" x 3-1/2" GRADE 8 BOLTS, NUTS AND WASHERS.

20 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

REFER PAGE 21 FOR HEADER TO COLUMN CONNECTION DETAILS. REQUIRED FIELD WELDING

DOOR A TTACHMENT PLATES AS SHOWN. REFE R PAGE 26 FOR COMPLETE WELD DETAILS. (VIEWED

FROM INSIDE OF TANK).

SHOULD BE DONE AFTER DOOR IS COMPLETELY INSTALLED. FIELD WELD SIDEWALL PLATES AND

Page 21

Header Beam Connection Details

5. Door Assembly

NOTE: INSTALL HEADER BEAM ONTO COLUMNS AS SHOWN ON PAGE 20. USE 1" x 3-1/2"

GRADE 8 BOL TS WITH WASHER ON EACH SIDE. INSER T BOL T FROM THE COLUMN SIDE AND

TIGHTEN. ACCESS COVER PLATES (VTDL-0246) WILL BE WELDED ONTO THE INSIDE AND

OUTSIDE OF THE COLUMNS A T THE ACCESS OPENING AFTER THE DOOR IS INSTALLED. BE

SURE THAT THE EDGE OF THE THRESHOLD PLATE IS ALIGNED WITH THE EDGE OF THE

COLUMNS. FIELD WELD THRESHOLD PLATES, SIDEWALL PLATES, AND DOOR PANEL

PLATES AFTER DOOR IS COMPLETELY INSTALLED.

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 21

Page 22

5. Door Assembly

Center Column Installation

22 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 23

Door Panel Assembly

5. Door Assembly

DOOR PANELS SHOULD BE ASSEMBLED AS SHOWN. ATTACH THE DOOR PANELS

TO THE COLUMNS, HEADER, AND THRESHOLD WITH 1" x 2-1/2" GRADE 8 BOLTS

WITH WASHERS ON EACH SIDE. BOLT HEAD SHOULD BE ON THE OUTSIDE OF

THE CONNECTION. USE 1" x 3-1/2" GRADE 8 BOLTS AT HINGE LOCATIONS. USE

FOAM SEAL STRIP ON BACK SIDE OF DOOR PANELS. APPLY CAULKING BETWEEN

ALL DOOR PANEL SPLICES. ATTACH HINGE WELDMENTS TO DOOR PANELS WITH

3/8" x 1-1/2" BIN BOLTS. BOLT HEAD WITH SEALING WASHER SHOULD BE ON

THE INSIDE FOR THESE CONNECTIONS. REFER PAGE 24 FOR DOOR PANEL TO

FRAME ASSEMBLY.

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 23

Page 24

5. Door Assembly

Door Panel Assembly (2)

24 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 25

Stiffener/SDW Attachment

5. Door Assembly

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 25

Page 26

5. Door Assembly

Weld Details

26 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 27

Outer Cover Assembly

5. Door Assembly

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 27

Page 28

5. Door Assembly

Outer Cover Assembly (Continued)

28 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 29

5. Door Assembly

VTDL Door Foundation Note

VTDL doors will require special foundation requirements and aeration floor systems. The following

pages (Pages 30, 31 and 32) contain foundation sp ecifica tions fo r the in stallation o f VTDL doors in 72 '

through 78' diameter externally stiffened tanks. These specifications are based on the Grain Systems

Concrete Manual PNEG-318. All foundation specifications shall be construed as recommendations only.

Because of the many variable conditions in actual installation, Grain Systems assumes no liability for

results arising from the use of such recommendations. Please contact the Grain Bin Engineering

Department if there are any specific questions about the concrete requirements for a VTDL door.

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 29

Page 30

5. Door Assembly

R417-3/4 STD INNER

WALL RADIUS

30 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 31

5. Door Assembly

3'-0"

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 31

Page 32

5. Door Assembly

R40' 7" OUTER WALL RADIUS

32 PNEG-1336D VTDL-7 2-8X9D - VTDL-78-8X9D Door

Page 33

6. Warranty

The GSI Group Limited Warranty

The GSI Group, Inc. (“GSI”) warrants products which it manufactures to be free of defects in materials

and workmanship under normal usage and conditions for a period of 12 months after sale to the orig inal

end-user or if a foreign sale, 14 months from arrival at port of discharge, whichever is earlier. The

end-user’s sole remedy (and GSI’s only obligation) is to repair or replace, at GSI’s option and expense,

products that in GSI’s judgment, contain a material defect in materials or workmanship. Expenses

incurred by or on behalf of the end-user without prior written authorization from the GSI Warranty Group

shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems

Performer Series Direct Drive Fan Motor 3 Years

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Apex Flooring 10 Years *

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1.75" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Grain Bin Structural Design 5 Years

Portable Dryers (Excluding Motors) 2 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION

SET FORTH ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION

WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE, INSTRUCTION,

RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION,

LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without

limitation, loss of anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited

Warranty, which shall not exceed the amount paid for the product purchased. This warranty is not

transferable and applies only to the original end-user. GSI shall have no obligation or responsibility for

any representations or warranties made by or on behalf of any dealer, agent or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized

modifications to products which it manufactured. Modifications to products not specifically delineated in

the manual accompanying the equipment at initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use,

misuse, alteration, accident or which have been improperly/inadequately maintained. This Limited

Warranty extends solely to products manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes

which apply to the location and installation of products manufactured or sold by GSI.

9101239_1_CR_rev3.DOC (rev ised February 2008)

PNEG-1336D VTDL-72-8X9D - VTDL-78-8X9D Door 33

Page 34

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2008 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...