PNEG-1070

15', 18', 21', 24', 27' and 30'

Diameter Commercial

Hopper Tanks

Installation Manual

PNEG-1070

Version: 2.0

Date: 11-29-11

All information, illustrations, photos and specifications in this manual are based on the latest

information available at the time of publication. The right is reserve d to make changes at any time

without notice.

2 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................5

Chapter 2 Safety .....................................................................................................................................................6

Safety Guidelines .................................................................................................................................. 6

General Safety Statement ..................................................................................................................... 7

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 8

Safety Sign-Off Sheet ......................................................................................................................... 10

Proper Storage of Grain Bin/Silo Materials Prior to Construction ....................................................... 11

Chapter 3 Decals ..................................................................................................................................................12

Chapter 4 Foundation ..........................................................................................................................................16

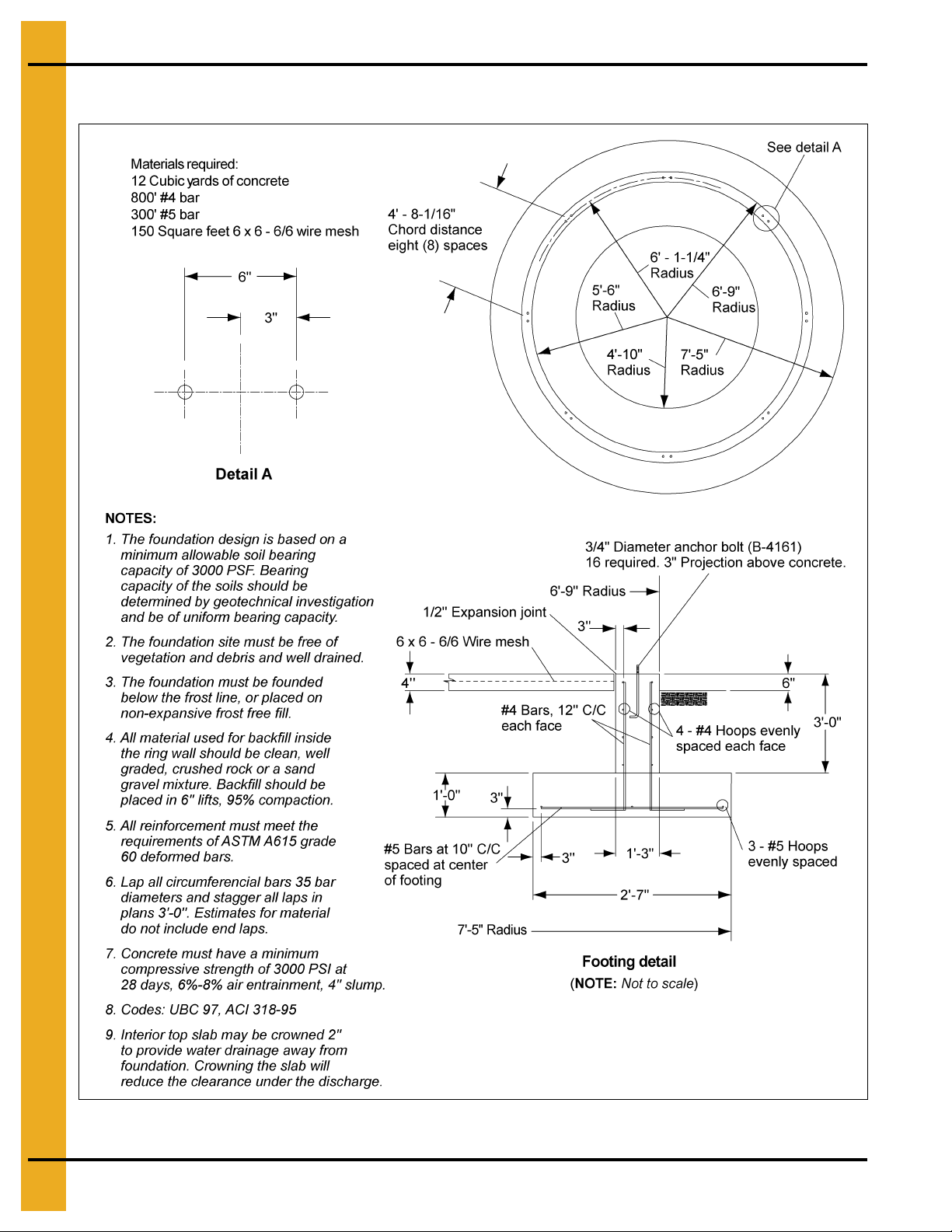

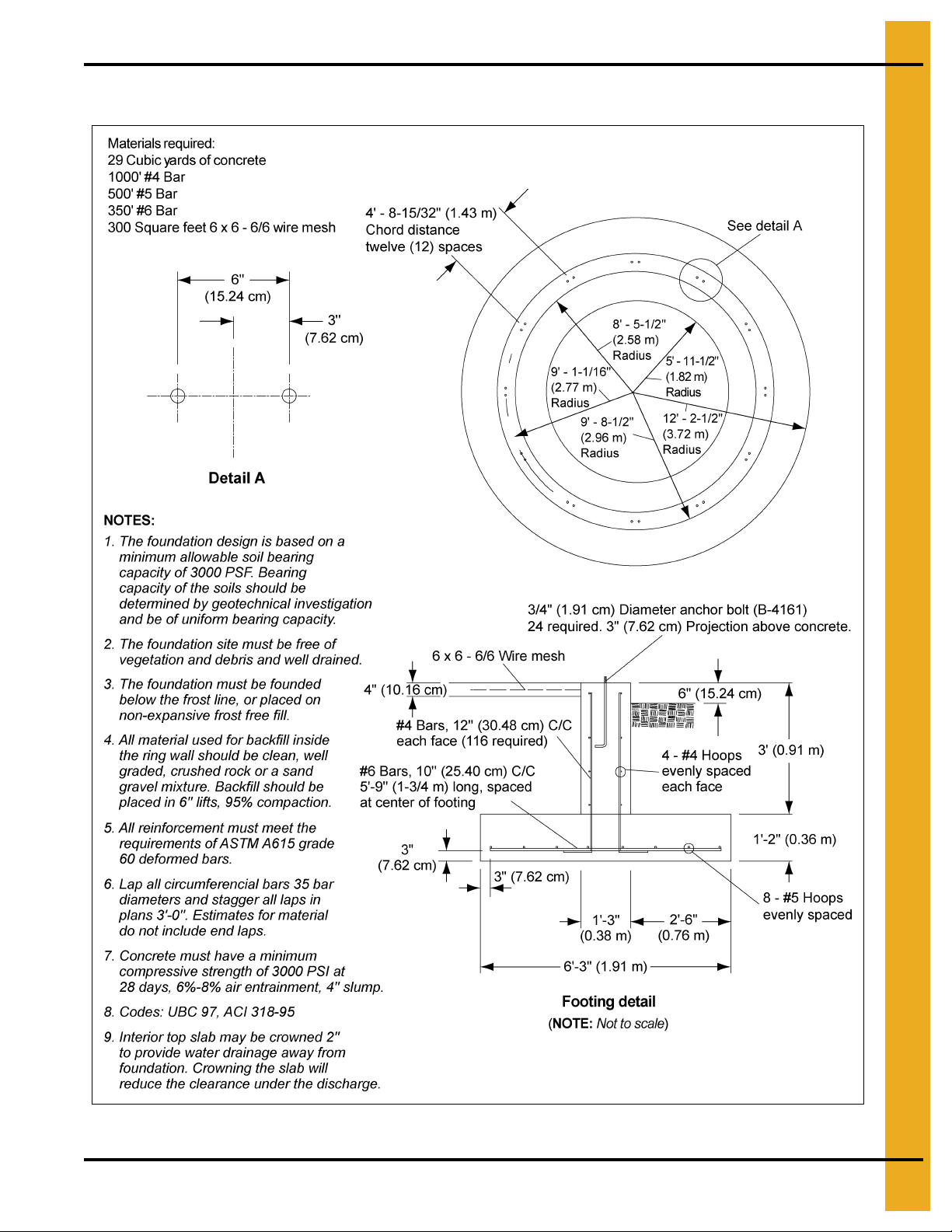

12' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 16

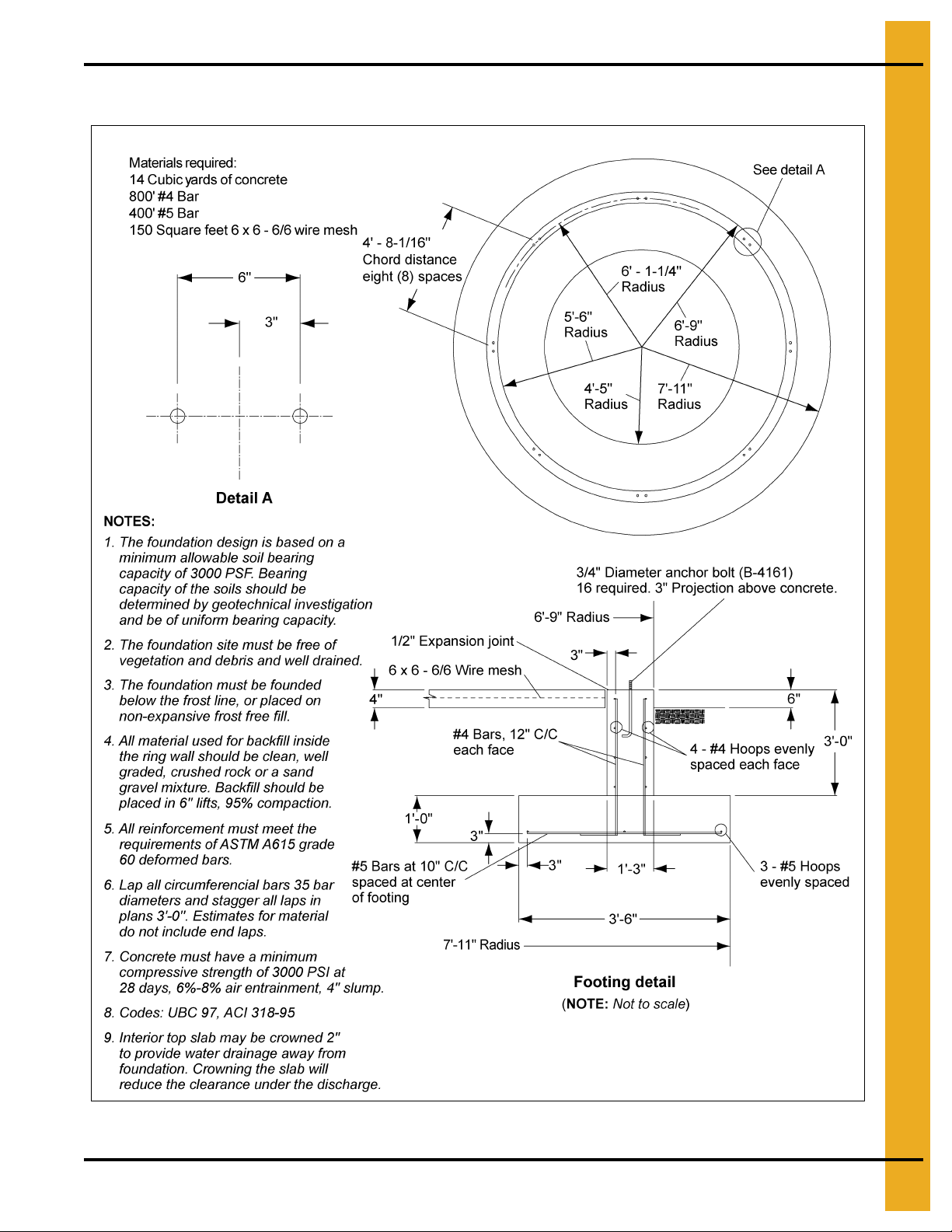

12' Diameter Commercial Hopper Tank Foundation for 13-17 Rings ................................................. 17

15' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 18

15' Diameter Commercial Hopper Tank Foundation for 13-17 Rings ................................................. 19

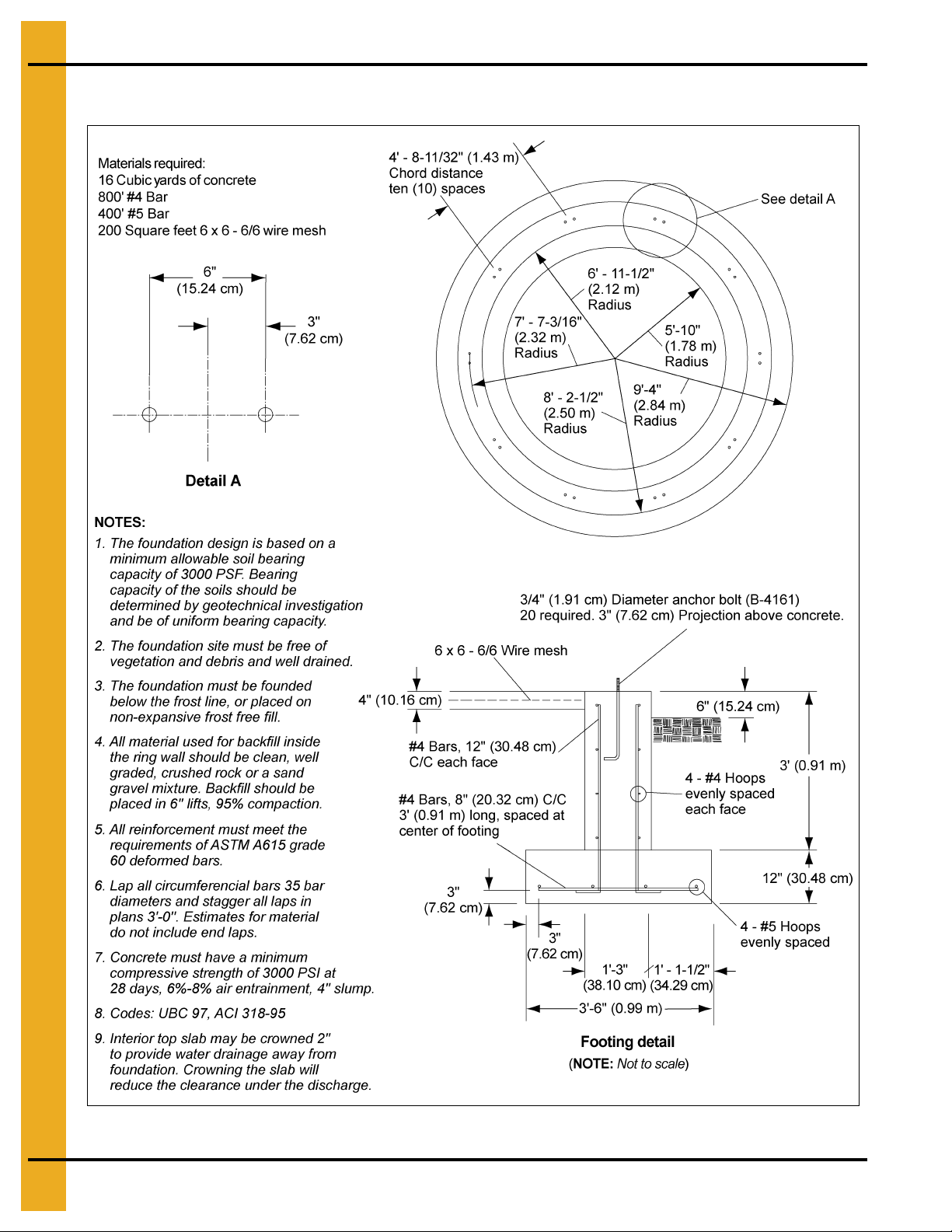

18' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 20

18' Diameter Commercial Hopper Tank Foundation for 13-19 Rings ................................................. 21

21' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 22

21' Diameter Commercial Hopper Tank Foundation for 13-19 Rings ................................................. 23

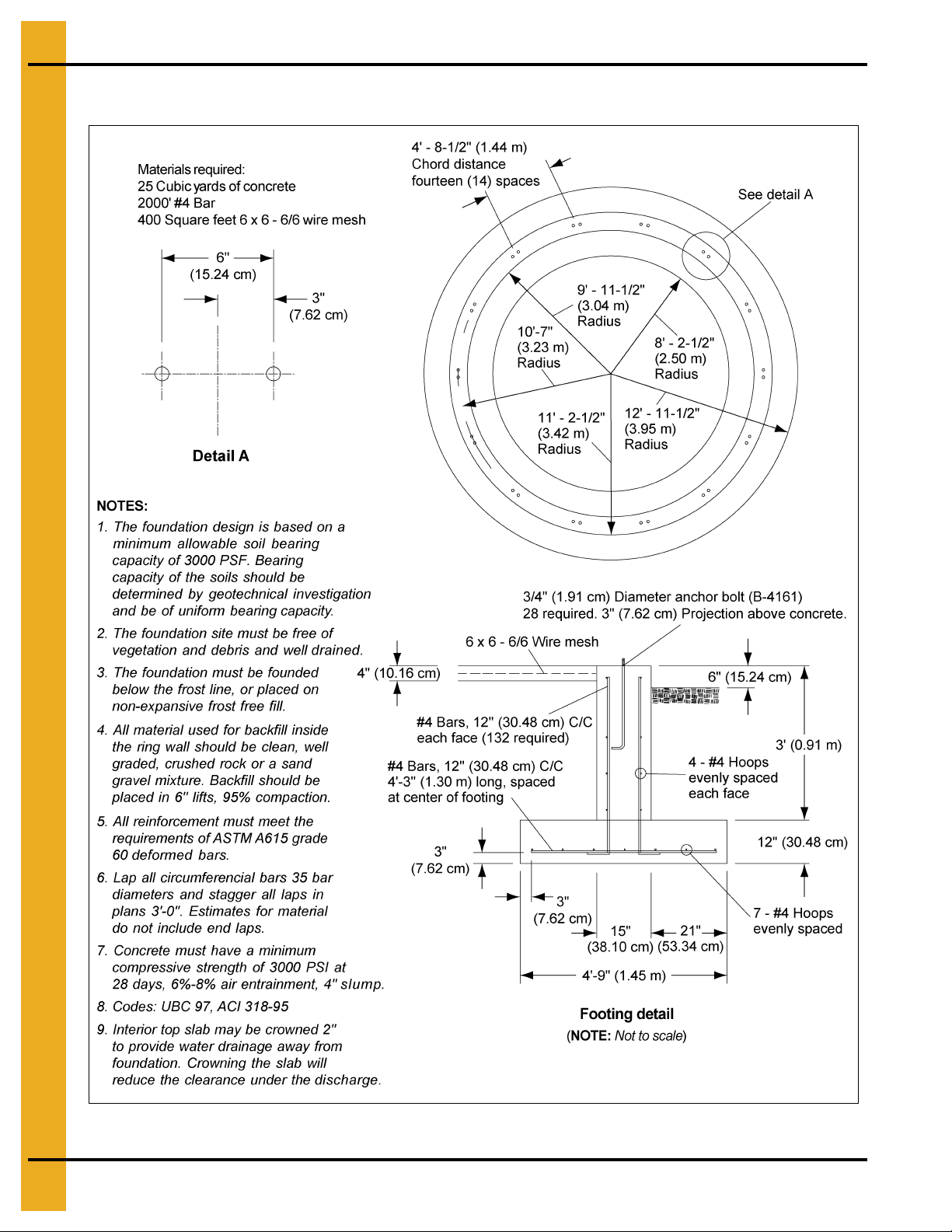

24' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 24

24' Diameter Commercial Hopper Tank Foundation for 13-19 Rings ................................................. 25

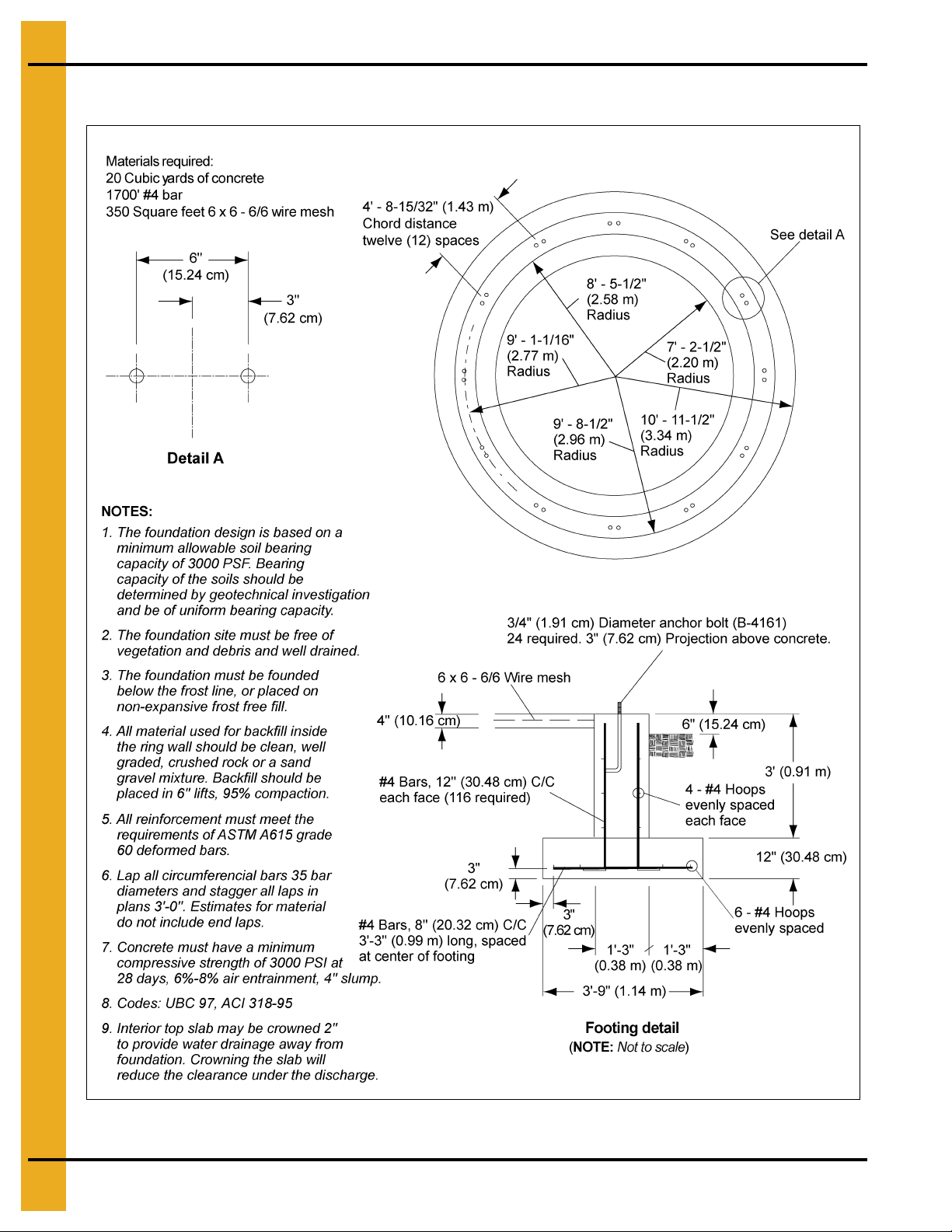

27' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 26

27' Diameter Commercial Hopper Tank Foundation for 13-19 Rings ................................................. 27

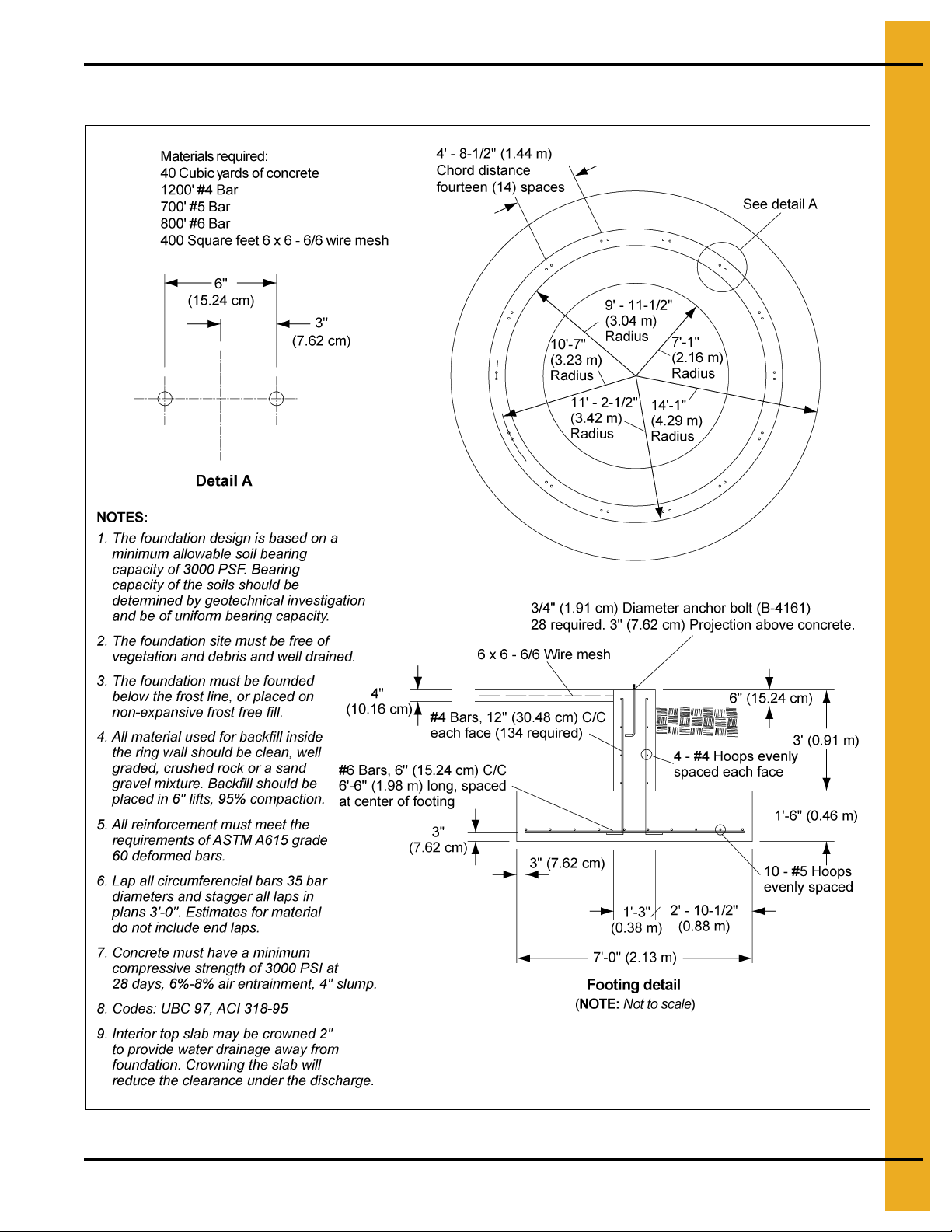

30' Diameter Commercial Hopper Tank Foundation up to 12 Rings ................................................... 28

30' Diameter Commercial Hopper Tank Foundation for 13-19 Rings ................................................. 29

CHT Column Heights ... ... .... ... ... ... .... ... ... .......................................... ... ... ............................................. 30

Substructure Parts .............................................. ... ... .... ... ... ... .......................................... ................... 31

Typical NCHT Column ........................................................................................................................ 32

Chapter 5 15'-24' Hopper Assembly ...................................................................................................................33

Hopper Section Assembly 15'-24' (4.57 m-7.32 m) Diameter Hopper Tanks ..................................... 33

18'-21' (5.49 m-6.40 m) 60° “X” Bracing Detail ............................................. ...................................... 38

Chapter 6 27'-30' Hopper Assembly ...................................................................................................................39

Hopper Section Assembly 27'-30' (8.23 m-9.14 m) Diameter Hopper Tanks ..................................... 39

Chapter 7 Sidewall Assembly .............................................................................................................................43

Sidewall Erection Instructions ... ... .......................................... .... ... ... ... ... .... ... ... ... ................................ 43

Decal Sheet Placement ....................................................................................................................... 43

Chapter 8 Lifting Jack .........................................................................................................................................44

Lifting Jack Usage .................................. ... ... .... ... ... ... .......................................... .... ... ... ...................... 44

Color Code Chart ................................................................................................................................ 45

Chapter 9 Hardware .............................................................................................................................................46

Identifying Bolt Grades ........................... ... ... .... ... .......................................... ... ... .... ............................ 46

Hardware Identification Notes ....................................... .......................................... ............................ 47

2.66" Commercial Tank Bolting Requirements 2 Stiffeners per Sidewall Sheet ................................. 51

Caulking Detail .................................................................................................................................... 52

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 3

Table of Contents

Chapter 10 Stiffeners ...........................................................................................................................................53

Commercial Stiffeners for 2.66" Corrugation ..................................................................................... 54

2.66'' Corrugation Commercial Stiffener Splice Details ..................................................................... 55

10 Gauge and 11 Gauge Stiffener Bearing Splice ............................................................................ 57

5 Gauge, 6 Gauge, 8 Gauge and 9 Gauge Stiffener Bearing Splice ................................................. 58

Laminated Stiffener Splice 2.66" Corrugation .................................................................................... 59

Laminated to Universal Stiffener Splice 2.66" Corrugation ................................................................ 61

Stiffener to Sidewall Connections 3 Post Tanks ................................................................................ 62

Non-Laminated Stiffener to Sidewall Detail ....................................................................................... 63

Laminated Stiffener to Sidewall Detail ............................................................................................... 64

Universal Stiffener Starting Location 2.66" Reverse Corrugation Outside Stiffener Only .................. 65

Wind Ring Assembly ......................................................................................................................... 66

Stiffener Shim Plate Detail (Use when Necessary) ........................................................................... 67

Chapter 11 Flashing Instructions (Optional) .....................................................................................................68

Chapter 12 Doors .................................................................................................................................................70

Access Door Weldment Assembly Hardware Package (PLS-41985) ................................................ 70

Chapter 13 Aeration .............................................................................................................................................71

Aeration Package (Optional) ............................................................................................................. 71

Chapter 14 Ladders .............................................................................................................................................74

Ladder Support Detail ........................................................................................................................ 74

Chapter 15 Hoisting .............................................................................................................................................75

Hoist Instructions ............................................................................................................................... 75

Chapter 16 Warranty ............................................................................................................................................79

4 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of

lading to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 5

2. Safety

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

DANGER

WARNING

CAUTION

NOTICE

6 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

2. Safety

This product has sharp edges, which may cause serious injury. T o avoid injury, handle sharp

edges with caution and always use proper protective clothing and equipment.

General Safety Statement

Our foremost concern is your safety and the safety of others associated with grain handling equipment.

This manual is to help you understand safe operating procedures and some problems that may be

encountered by the operator and other personnel.

As owner and/or operator, you are responsible to know what requirements, hazard s, and precautions exist

and inform all personnel associated with the equipment or in the area. Safety precautions may be required

from the personnel. Avoid any alterations to the equipment, which may produce a very dangerous

situation, where SERIOUS INJURY or DEATH may occur.

You should consider the location of the bin site relative to power line locations or electrical transmission

equipment. Contact your local power company to review your installation plan or for information

concerning required equipment clearance. Clearance of portable equipment that may be taken to the bin

site should also be reviewed and considered. Any electrical control equipment in contact with the bin

should be properly grounded and installed in accordance with National Electric Code provisions and other

local or national codes.

This product is intended for the use of grain storage only. Any other use is a misuse of the product.

Sidewall bundles or sheets must be stored in a safe manner. The safest method of storing sidewall

bundles is laying horizontally with the arch of the sheet upward, like a dome. Sidewall sheets stored on

edge must be secured so that they cannot fall over and cause injury. Use care when handling and moving

sidewall bundles.

Personnel operating or working around equipment should read this manual. This manual must be

delivered with equipment to its owner. Failure to read this manual and its safety instructions is a misuse

of the equipment.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 7

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet, and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built-up grease, oil, and debris.

Maintain Equipment

and Work Area

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

8 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

2. Safety

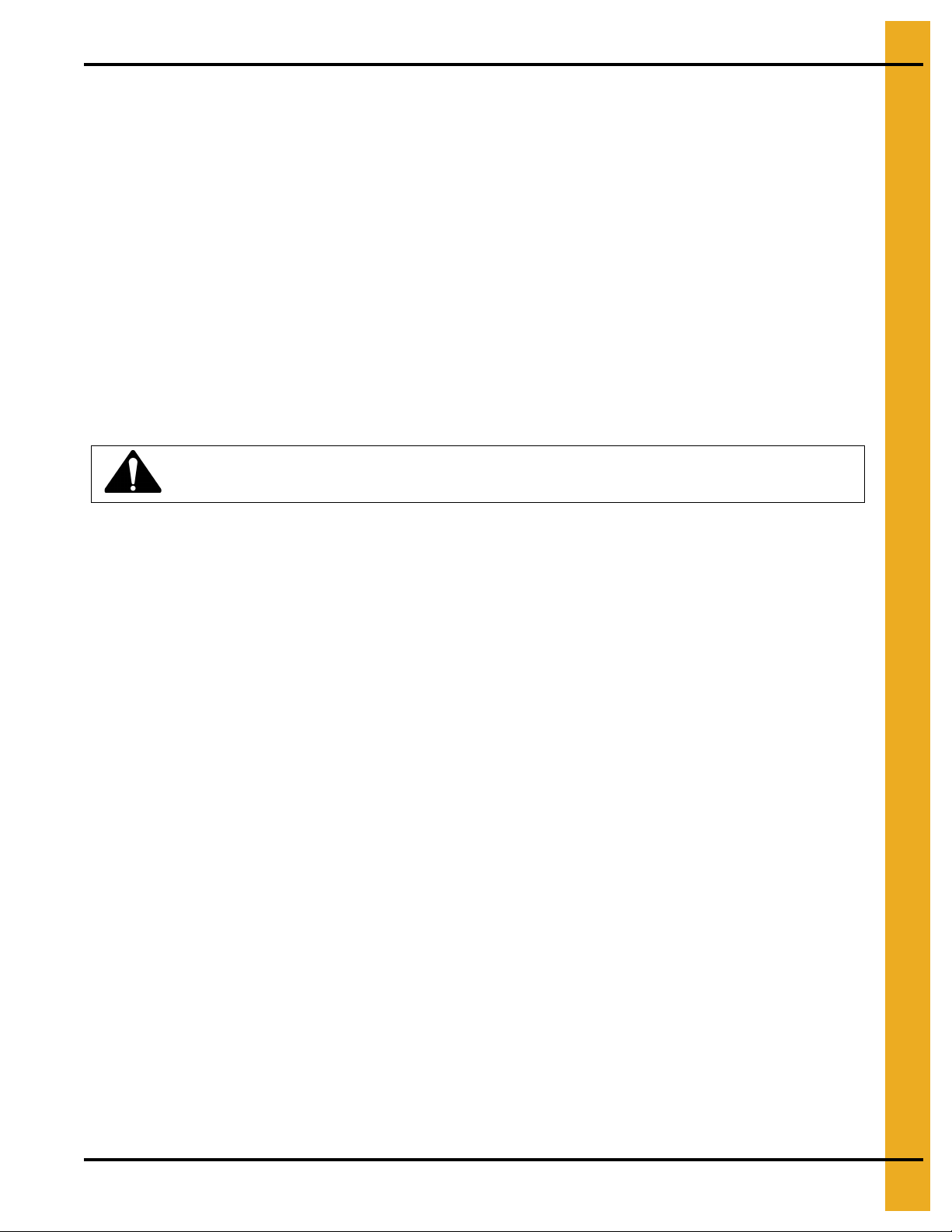

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

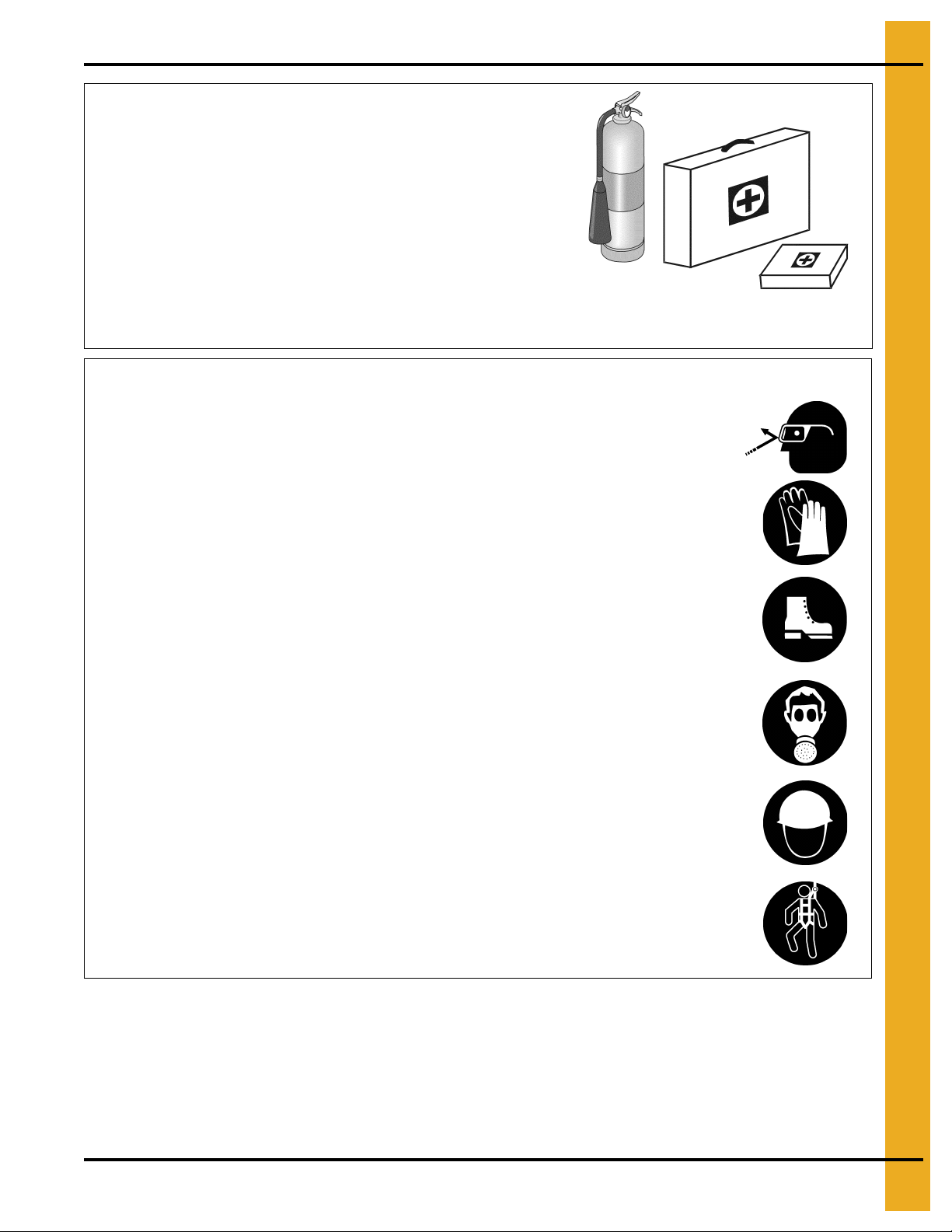

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on plastic

or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 9

2. Safety

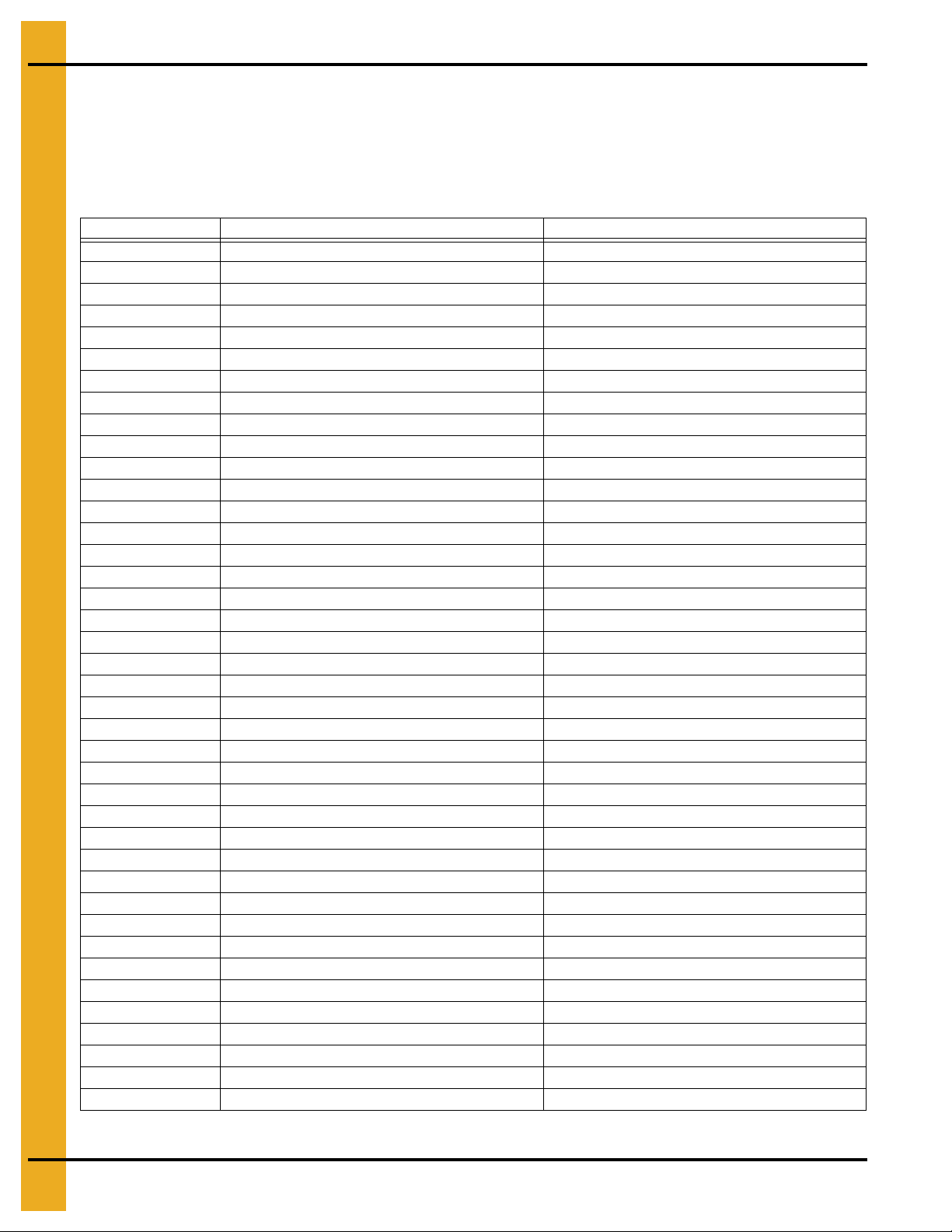

Safety Sign-Off Sheet

As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe operating and

safety procedures for this auger. This sign-off sheet is provided for your convenience and personal record

keeping. All unqualified persons are to stay out of the work area at all times. It is strongly recommended that

another qualified person who knows the shut down procedure be in the area in the event of an emergency.

Date Employee Name Supervisor Name

10 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

2. Safety

Proper Storage of Grain Bin/Silo Materials Prior to Construction

Wet storage stain (rust) will develop when closely packed bundles of galvanized material, such as sidewall

and roof sheets, have moisture present. Inspect roof and sidewall bundles on arrival for any moisture. If

moisture is present, it must not be allowed to remain between the sheets. Separate the sheets or panels

immediately and wipe them down. Spray with a light oil or diesel fuel.

If possible, sidewall bundles, roof sheets and other closely packed galvanized materials should be stored

in a dry, climate controlled building. If outdoor storage is unavoidable, the materials should be stored so

that they are raised above the ground and vegetation. Any stacking and spacing materials should not be

corrosive or wet. Be sure to protect materials from the weather, but permit air movement around the

bundles if possible.

Storing roof bundles and sidewall sheets at a slight incline can also help minimize the presence of

moisture. Storing the bundles with the center of the dome up (like an arch) is one option for minimizing

moisture during storage. Sidewall bundles can also be stored on edge but must be secured so that they

do not fall over and cause injury.

If “white rust” or “wet storage stain” occurs, contact the manufacturer immediately about ways to minimize

the adverse effect upon the galvanized coating.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 11

3. Decals

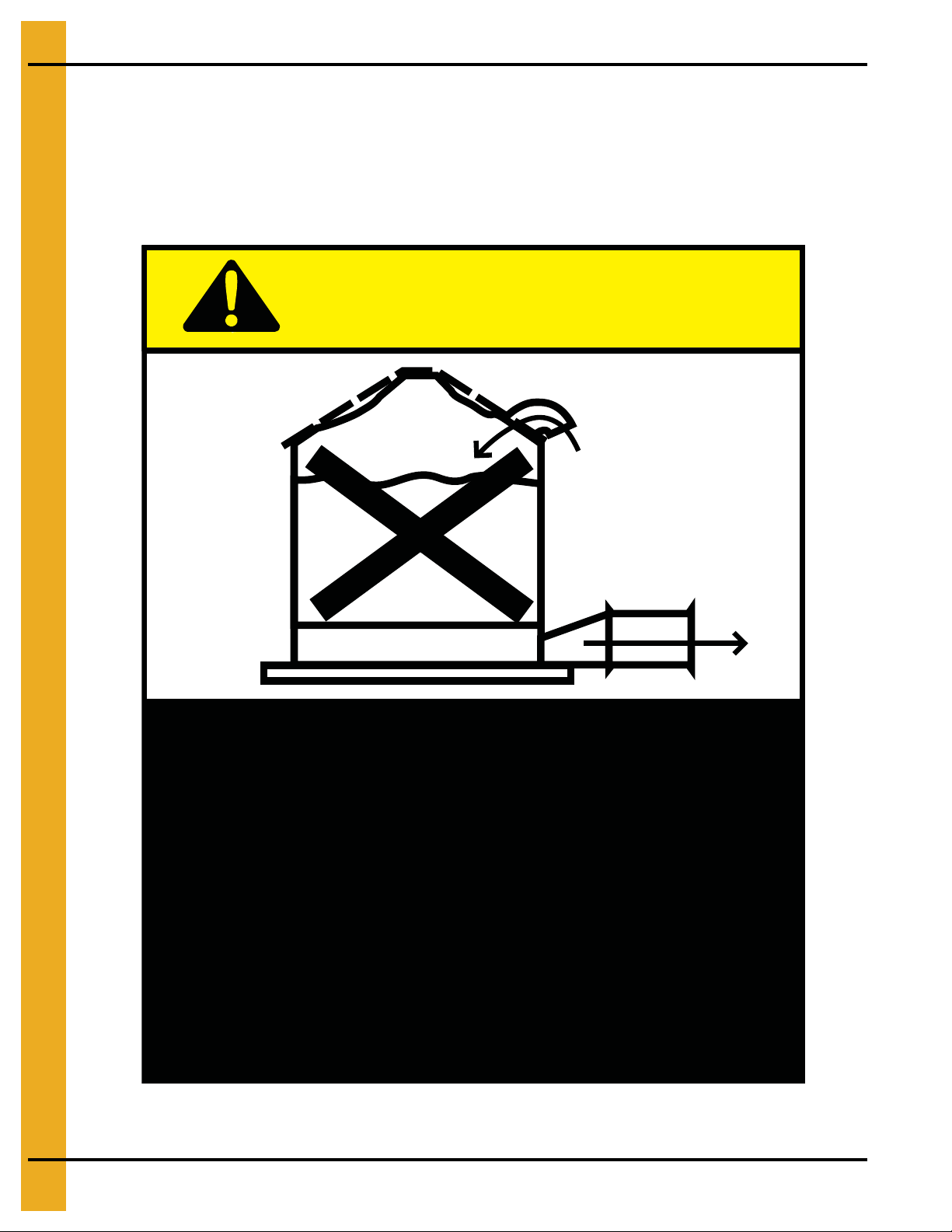

The manufacturer does not warrant any roof damage caused by excessive vacuum or internal

pressure from fans or other air moving systems. Adequate ventilation and/or “makeup air” devices

should be provided for all powered air handling systems. The manufacturer does not reco mmend

the use of downward flow systems (suction). Severe roof damage can result from any block age of

air passages. Running fans during high humidity/cold weather conditions can cause air exhaust

or intake ports to freeze.

CAUTION!

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

DC-969

12 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

3. Decals

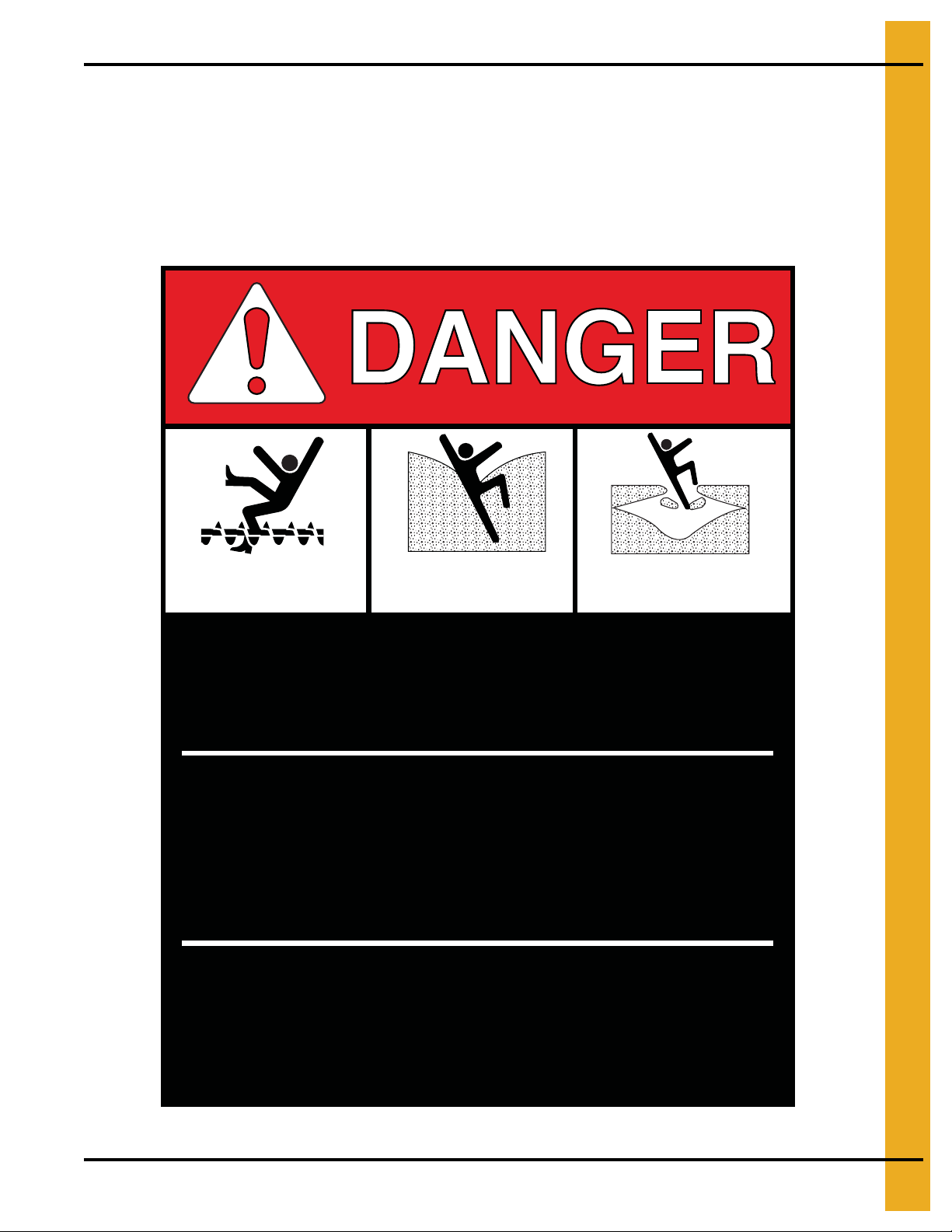

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring,

24" porthole door cover and roof manway cover. If a decal has been damaged or is missing in any of these

locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

Failure to heed these

warnings will result in

serious injury or death.

DC-GBC-1A

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 13

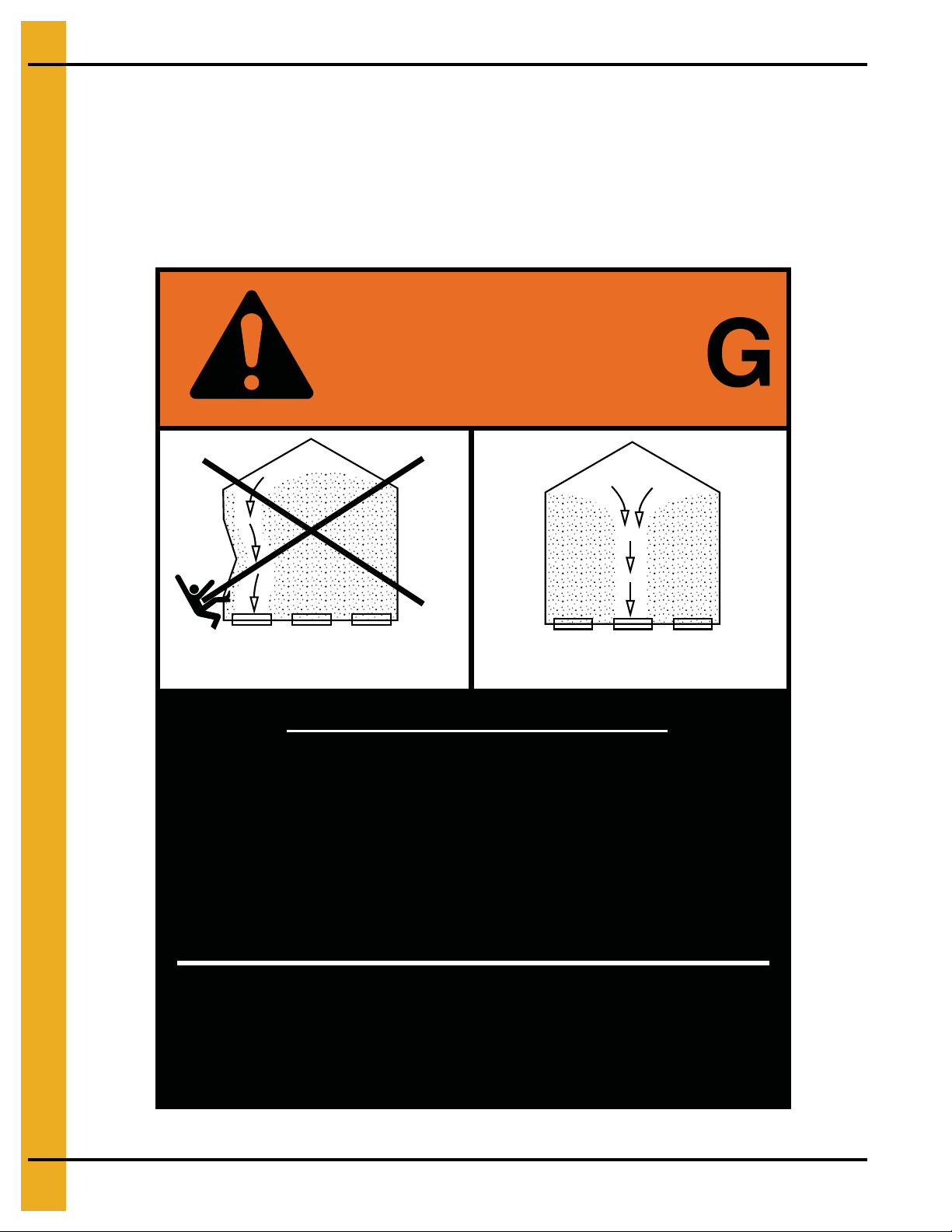

3. Decals

Failure to heed these warnings

could result in serious injury, death,

structural damage or collapse of tank.

1. Use CENTER FLOOR OUTLET ONLY until NO grain

remains above this outlet.

2. Side floor outlets to be used ONLY when above

condition is satisfied.

3. Lock all side floor outlets to avoid accidental

premature use.

4. See manufacturers instructions for proper use of

factory supplied sidedraw (wall) discharge systems.

UNLOADING INSTRUCTIONS:

DC-GBC-2A

WARNIN

DON’T

DO

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring,

24" porthole door cover and roof manway cover. If a decal has been damaged or is missing in any of these

locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

14 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Sidewall and stiffener gauge sheets

are not included in this manual.

They may be obtained by calling

GSI if they are not attached to the

front of this manual.

®

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 15

4. Foundation

12' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4A

16 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

12' Diameter Commercial Hopper Tank Foundation for 13-17 Rings

Figure 4B

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 17

4. Foundation

15' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4C

18 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

15' Diameter Commercial Hopper Tank Foundation for 13-17 Rings

Figure 4D

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 19

4. Foundation

18' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4E

20 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

18' Diameter Commercial Hopper Tank Foundation for 13-19 Rings

Figure 4F

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 21

4. Foundation

21' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4G

22 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

21' Diameter Commercial Hopper Tank Foundation for 13-19 Rings

Figure 4H

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 23

4. Foundation

24' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4I

24 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

24' Diameter Commercial Hopper Tank Foundation for 13-19 Rings

Figure 4J

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 25

4. Foundation

27' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4K

26 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

27' Diameter Commercial Hopper Tank Foundation for 13-19 Rings

Figure 4L

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 27

4. Foundation

30' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 4M

28 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

30' Diameter Commercial Hopper Tank Foundation for 13-19 Rings

Figure 4N

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 29

4. Foundation

CHT Column Heights

Figure 4O Standard Commercial Hopper Tank Column Heights

Tank Diameter Hopper Slope

12' 45 7' - 11-7/8" 2.44 32 813

15' 45 9' - 5-3/8" 2.88 32 813

15' 60 14' - 4-5/8" 4.39 32 813

18' 45 11'-1/8" 3.36 32 813

18' 60 16' - 11-5/8" 5.17 32 813

21' 45 12'-5" 3.79 32 813

21' 60 19' - 6-3/4" 5.96 32 813

24' 45 13' - 10-7/8" 4.24 32 813

27' 40 12' - 2-7/8" 3.73 28 71 1

27' 45 15' - 4-3/8" 4.68 32 813

30' 40 13' - 4-7/8" 4.09 28 71 1

30' 45 16' - 10-1/4" 5.14 32 813

“A” Dimension “B” Dimension

Feet Meters Inches Millimeters

30 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

4. Foundation

Substructure Parts

Part List for Substructure for Commercial Hopper Tanks

Tank Size 15' - 45° 15' - 60° 18' - 45° 18' - 60°

Color Code Yellow Black and Y ellow Red Black and Red

Column Weldment CHT-1201 (10) SCHT-1444 (10) CHT-1184 (12) SCHT-1475 (12)

Compress Angle Weldment CHT-1202 (10) SCHT-1438 (10) CHT-1209 (12) SCHT-1986 (12)

Hopper Collar Weldment CHT-1135 (1) SCHT-1434 (1) CHT-1136 (1) SCHT-1466 (1)

“X” Bracing Rod CHT-1203 (20) SCHT-1432 (40) CHT-1175 (24) SCHT-1473 (48)

“X” Bracing Rod Size 3/4" x 100" 7/8" x 166" 3/4" x 116" 3/4" x 107"

Top R.H. Hopper Panel CHT-1390 (10) SCHT-1941 (10) CHT-1375 (12) SCHT-1987 (12)

Top L.H. Hopper Panel CHT-1391 (10) SCHT-1940 (10) CHT-1374 (12) SCHT-1988 (12 )

Bottom R.H. Hopper Panel N/A N/A N/A N/A

Bottom L.H. Hopper Panel N/A N/A N/A N/A

Compression Channel N/A N/A N/A N/A

Support Hardware CHT-1392 (1) SCHT-1949 (1) CHT-1373 (1) SCHT-1896 (1)

Tank Size 21' - 45° 21' - 60° 24' - 45° 27' - 40° 30' - 40°

Color Code Blue Black and Blue Green Orange Purple

Column Weldment CHT-1159 (14) SCHT-1484 (14) CHT-1118 (16) CHT-1017 (18) CHT-1037 (20)

Compress Angle Weldment CHT-1167 (14) SCHT-1471 (14) CHT-1119 (16) CHT-1018 (18) CHT-1038 (20)

Hopper Collar Weldment CHT-1137 (1) SCHT-1467 (1) CHT-1133 (1) CHT-1056 (1) CHT-1036 (1)

“X” Bracing Rod CHT-1144 (28) SCHT-1481 (56) CHT-1117 (32) CHT-1026 (36) CHT-1045 (40)

“X” Bracing Rod Size 3/4" x 126" 3/4" x 120" 3/4" x 144" 3/4" x 123" 3/4" x 137"

Top R.H. Hopper Panel CHT-1421 (14) SCHT-1463 (14) CHT-1372 (16) CHT-1479 (18) CHT-1366 (20)

Top L.H. Hopper Panel CHT-1420 (14) SCHT-1462 (14) CHT-1371 (16) CHT-1478 (18) CHT-1365 (20)

Bottom R.H. Hopper Panel N/A SCHT-1461 (14) N/A CHT-1481 (18) CHT-1368 (20)

Bottom L.H. Hopper Panel N/A SCHT-1460 (14) N/A CHT-1480 (18) CHT-1367 (20)

Compression Channel N/A N/A N/A CHT-1025 CHT-1052

Support Hardware** CHT-1422 (1) SCHT-1485 (1) CHT-1370 (1) CHT-1483 (1) CHT-1369 (1)

**NOTE: The 3/8" x 1" bin bolts (with sealing washer) for attachment hopper panels to the compression

element are included in the sidewall hardware.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 31

4. Foundation

Typical NCHT Column

Figure 4P

32 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

5. 15'-24' Hopper Assembly

Hopper Section Assembly 15'-24' (4.57 m-7.32 m) Diameter

Hopper Tanks

Before placing the support columns on the anchor bolts, use a transit and surveyor’s rod to locate high

and low areas in the concrete. To assure level alignment for the support columns, use the proper supplied

shim or shims between the concrete and base plate. After leveling is completed, place the support

columns over the anchor bolts, with shim plates underneath column. Next place HT-635 washer over

anchor bolts and loosely fasten with nuts and washers (not furnished). Refer to Figure 5A.

NOTE: 15' (4.57 m) Diameter hopper tanks have 10 columns.

18' (5.49 m) Diameter hopper tanks have 12 columns.

21' (6.40 m) Diameter hopper tanks have 14 columns.

24' (7.32 m) Diameter hopper tanks have 16 columns.

Figure 5A

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 33

5. 15'-24' Hopper Assembly

Figure 5B Compression Angle Erection

Using 5/8"-11 x 1-1/2" bolts (S-4109) and 5/8" nuts (S-4110), fasten the compression angle segments to

the support clips on the support columns. A 5/8"-11 x 2-3/4" bolt (S-4108) and 5/8" nut (S-4110) may be

placed in the top hole of the support column for alignment purposes, but will be removed later when the

sidewall base stiffener is to be positioned. Refer to Figure 5C. Do not tighten bolts until hopper panels are

installed to allow alignment.

Figure 5C

34 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

5. 15'-24' Hopper Assembly

Detail B

Detail A

Begin assembling the hopper bottom by attaching a right and left pair or pairs of hopper panels to the

compression angle ring (3/8" x 1" bin bolt (S-455)) and discharge collar (1/2" x 1" hardware (S-4492)) at

four (4) opposing points as shown in Figure 5D. Caulking is required on the vertical seams of the lapped

hopper panels (Refer to Figure 5G). Splice plates which join the compression angle segments on the

back side may be installed following a pair of hopper panels. Refer to Figure 5F. Complete this assembly

by laying in alternate right and left panels moving around in one direction and lapping all sheets the

same way, See Figure 5E. Do not tighten bolts until all hopper panels are attached to each other, the

compression angle, splice plates and discharge collar.

On 15' through 24' tanks use 1/2" bolts on hopper seams.

NOTE: All bolts used in hopper assembly should be installed with the bolt heads to the inside of

the hopper.

Figure 5D Hopper Panel and Discharge

Collar Assembly

Figure 5E Lap Detail (Viewed from Inside of Bin)

Figure 5F Hopper Panel Detail

Figure 5G Caulking Detail

Figure 5H

Start at the bottom of the hopper and tighten all bolts, including anchor bolts, discharge collar, hopper

panels, splice plates and compression angle segments.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 35

5. 15'-24' Hopper Assembly

If a rack and pinion gate is purchased, install as shown in Figure 5I using 5/16" x 3/4" hardware (S-275).

Figure 5I Hopper Discharge Collar to Roller Gate

36 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

5. 15'-24' Hopper Assembly

Install “X” bracing rods as in Figure 5J, Figure 5K and Figure 5L.

When the hopper structure has been completed, it should be level to within ± 1/8" ma ximum deviation, as

compared to all other support columns as measured at the top of the compression angle ring. The support

columns must be plumb to within ± 1/2" as measured from top to bottom. Seal any gaps between

compression elements and the seal strip at column locations with silicon or other conventional means.

Figure 5J Completed Hopper Assembly

Figure 5K “X” Bracing Rods

Figure 5L

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 37

5. 15'-24' Hopper Assembly

18'-21' (5.49 m-6.40 m) 60° “X” Bracing Detail

Install “X” bracing rods as in Figure 5M, Figure 5N and Figure 5O.

When the hopper structure has been completed, it should be level to within ± 1/8" ma ximum deviation, as

compared to all other support columns as measured at the top of the compression angle ring. The support

columns must be plumb to within ± 1/2" as measured from top to bottom. Seal any gaps between

compression elements and the seal strip at column locations with silicon or other conventional means.

Figure 5M Completed Hopper Assembly

Figure 5N “X” Bracing Rods

Figure 5O

38 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

6. 27'-30' Hopper Assembly

Hopper Section Assembly 27'-30' (8.23 m-9.14 m) Diameter

Hopper Tanks

Before placing the support columns on the anchor bolts, use a transit and surveyor’s rod to locate high

and low areas in the concrete. To assure level alignment for the support columns, use the proper supplied

shim or shims between the concrete and base plate. After leveling is completed, place the support

columns over the anchor bolts, with shim plates underneath column. Next place HT-635 washer over

anchor bolts and loosely fasten with nuts and washers (not furnished). Refer to Figure 6A. Seal any

gaps between compression elements and the seal strip at column locations with silicon or other

conventional means.

Figure 6A Column Shim Plate Detail (Use when Necessary)

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 39

6. 27'-30' Hopper Assembly

Detail G

Detail H

Use a transit and surveyor’s rod to locate high and low areas in the concrete, before placing the support

columns on the anchor bolts. To assure level alignment, use the proper sup plied shim o r sh ims b etween

the concrete and base plate. After leveling, place the support columns over the anchor bolts, on the shims

and loosely fasten with nuts and washers (not supplied). Refer to Figure 6A on Page 39.

NOTE: 27' (8.23 m) Diameter hopper tanks have 18 columns.

30' (9.14 m) Diameter hopper tanks have 20 columns.

Figure 6B Compression Angle Erection

Using 5/8"-11 x 2" hardware (S-4329), fasten the inside and outside vertical compression angle segments

and splice plates to the support columns, See Figure 6A on Page 39 and Detail G in Figure 6C. Next,

attach the horizontal channels with 5/8"-11 x 1-1/2" hardware (S-4109) to the inside and outside

vertical compression angle segments and the support clips on the support columns, as shown in Detail H

in Figure 6C. Do not tighten bolts until hopper panels are installed to allow alignment.

Figure 6C

40 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

6. 27'-30' Hopper Assembly

Detail J

Detail K

Begin assembling the two (2) piece hopper bottom by attaching a right and left pair or pairs of the top

hopper panels to the compression angle ring (3/8" x 1" bin bolts (S-455) and 3/8" nut (S-456)), along with

the back side splice plates which use (3/8" x 1-1/2" bin bolts (S-5060) and 3/8" nut (S-456)). Refer to

Figure 6F. All top panel seams use 5/8" x 1" hardware (S-4210) and 5/8" nut (S-4110). Once the top panels

are positioned the bottom hopper panels may be attached to the top panels and discharge collar with

1/2" x 1" hardware (S-4492) and 1/2" nut (S-3729), at four (4) opposing points as shown in Figure 6D.

A 5/8" x 2" bolt (S-4329) and 5/8" nut (S-4110) is used on all corners of the spliced hopper panels. Refer

to Figure 6E for bolt usage on hopper panels. Caulking is required on all vertical and horizontal sea ms of

the hopper bottom, (refer to Figure 6G). Complete this assembly by laying in alternate right and left panels

moving around in one direction and lapping all sheets the same way. Do not tighten bolts until all hopper

panels are attached to each other, the compression ring, splice plates and discharge collar.

30' Commercial hopper tank has two (2) piece hopper as shown.

27' Commercial hopper tank has two (2) piece hopper as shown.

Figure 6D Hopper Panel and Discharge

Collar Assembly

Figure 6E Hopper Panel Bolt Usage

Figure 6F Hopper Panel Detail

Figure 6G Caulking and Lap

(Viewed from Inside of Bin)

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 41

6. 27'-30' Hopper Assembly

Start at the bottom of the hopper and tighten all bolts, including anchor bolts, discharge collar, hopper

panels, splice plates and compression angle segments.

Install rack and pinion roller gate as shown in Figure 5I on Page 36, using 5/16" x 3/4 " hardware (S-275).

Install “X” bracing as shown in Figure 6H, Figure 6I and Figure 6J.

When the hopper structure has been completed, it should be level to within ± 1/8 " maximum deviation, as

compared to all other support columns as measured at the top of the compression angle rin g. The support

columns must be plumb to within ± 1/2" as measured from top to bottom.

Figure 6H Completed Hopper Assembly

Figure 6I “X” Bracing Rods

Figure 6J

42 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

7. Sidewall Assembly

Sidewall Erection Instructions

Before bolting the sidewall sheets together, make sure that you are using the proper gauge steel for the

first ring. The higher gauge numbers denote the thinner materials. (For example, 22 gauge material is

thinner than 14 gauge.) In erecting most grain bins th e thinnest material usually goes on top, therefore the

first sidewall ring you assemble will be the top ring of the bin, usually the thinnest gauge. Check the various

gauges of the bin with the color code chart and begin bu ilding accordingly. REMEMBER always assemble

the top ring first.

Figure 7A

Once you have selected the proper gauge material, begin assembling all sidewall sheets. Stand on the

inside the bin, place the left panel to the inside with the right panel to the outside.

NOTE: The rope caulking is installed before each sheet is assembled. Wipe sheet clean where caulking

is to be applied. Refer to Page 52 for caulking placement.

Using correct size bin bolts throughout, begin assembling sidewall sheets end to end (overlapping the

same way throughout) until the ring is completed. All body sheet bolts are to be installed with the bolt head

and its neoprene washer to the outside and the nut on the inside. Do n ot tighten bolts u ntil all sh eets are

assembled and form a complete ring. Lifting of sidewall should be done with jacks and lifting brackets on

the stiffener bolt holes.

(See Figure 7A.)

Decal Sheet Placement

NOTE: The decal sheets are located in the second ring from the top, evenly spaced around the diameter

of the bin.

Figure 7B 2 Post

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 43

8. Lifting Jack

Lifting Jack Usage

Always consider the location of the door and other accessories prior to erecting the bin. Proper placement

of lifting jacks in relationship to anchor bolts could make a difference on odd or even ring bins. Attachment

of lifting brackets should be made on the stiffener row of bolts. The sidewall sheets are also staggered

1/2 from end to end.

Figure 8A Anchor Jacks Securely

Anchor all jacks securely with metal stakes and cable. Raise the bin just high enough to assemb le the next

ring. When lifting the bin, crank all jacks at an equal rate. This will prevent previously assembled rings from

bowing and make for easier hole alignment. To the inside

stagger the sheets and select the proper gauge material. To avoid excessive pulling of the holes in the

sidewall, some stiffener lap and splice connections may go together easier if the sidewall is not tightened

until the stiffeners have been put in place. Lower the bin on the foundation after assembling and tightening

bolts on the new ring or rings. Next, re-bolt the lifting straps to the lowest ring in place thus far.

NOTES: Add inside and outside ladders to bin walls as you continue to raise the bin.

The number of lifting jacks required is best determined by personal experience. Factors such as

bin size, soil compaction, wind velocity, jack design, etc., should be considered when deciding

how many to use. If in doubt, use one jack on every other stiffener (one per sheet). Be sure to

use heavy duty jacks for commercial installations.

of the first ring, bolt the next ring. Be sure to

44 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Color Code Chart

2.66" Commercial Stiffeners

NOTE: Some colors are different than those used for sidewall sheets.

*NOTE: Only Orange on 1 ring stiffener.

Stiffener Gauge Color Code

15 Red/Orange*

14 Green/Orange*

13 Dark Blue

12 Black

11 Pink

10 Light Blue

9 Purple

8Yellow

6 White

8. Lifting Jack

5 Fluorescent Green

5+12 Gold/Black

5+10 Gold/Light Blue

5+8 Gold/Yellow

2.66" Sidewall Gauges

NOTE: Some colors are different than those used for stiffener sheets.

Sidewall Gauge Color Code

22 White

20 Red

19 Black/Yellow

18 Orange

17 Pink/Light Blue

16 Blue

15 Brown/Red

14 Green

13 Yellow/Blue

12 Black

11 Pink

10 Light Blue

9 Blue/Orange

8Yellow

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 45

9. Hardware

Under no condition shall any other bolts be substituted for those supplied

by the manufacturer.

Grade 2 Bolts

1. Grade 2 bolts are designated with a plain head and are NOT

used in GSI grain bins/silos.

Grade 5 Bolts

2. Grade 5 bolts are designated by three (3) slash marks on the head. All 5/16" diameter bolts

are to be grade 5 or higher.

Grade 8 Bolts

3. Grade 8 bolts are designated by six (6) slash marks evenly spaced out around the

head of the bolt.

Grade 8.2 Bolts

4. Grade 8.2 bolts are designated by six (6) slash marks on the head in a sunrise pattern.

All 3/8" diameter bolts are to be grade 8 or 8.2.

Identifying Bolt Grades

(See Pages 36-39 for usage.)

CAUTION

NOTE: Bolts should not be tightened in excess of the torque specifications.

Bolt Size

5/16"-18 15 20

3/8"-16 35 42

7/16"-14 65 72

1/2"-13 95 105

Torque (Ft. Lbs.)

Minimum Maximum

46 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

9. Hardware

0.3125" x 0.750" Pre-assembled with a steel backed neoprene washer.

This bolt is used to connect horizontal and vertical seams for 14 gauge and thinner sidewall sheets

to each other. It is also used in attaching roof panels to the top sidewall sheet and attaching roof

panels and flashing to the center collar.

S-275

0.3125" x 1.250" Pre-assembled with a steel backed neoprene washer.

This bolt is primarily used to connect roof panels together where they overlap. It is also used at the

bottom of the flat bottomed bins to attach the base angle to the sidewall sheet and to attach the

sealing strip to the bottom edge of a sidewall sheet.

S-277

Hardware Identification Notes

Refer to 2.66" Commercial Tank Bolting Requirements on Page 51 for complete bolt usage.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 47

9. Hardware

S-455

0.375" x 1.000" Pre-assembled with a steel backed neoprene washer.

This bolt is used in horizontal and vertical seams for 13 gauge through 12 gauge laminate sidewall to

attach the sheets of each other. It is also used to attach the stiffener to the sidewall sheet for up to

10 gauge sidewall. It is not used to splice the stiffeners together on the flanges where they connect

to each other or the splice plates. These are also used to attach the hopper panels to the hopper

support beam for the NCHT’s with diameters of 30' and less.

NOTE: 3/8" x 1-1/2" (S-5060) A bolts are provided for laminated stiffeners and splices.

0.375" x 1.500" Pre-assembled with a steel backed neoprene washer.

It is used to connect the stiffener to the sidewall at locations where a splice plate is used to

connect the stiffener and to connect laminated stiffeners to the sidewall sheets. It is also used to

bolt stiffeners to 9 gauge and thicker sidewall. This bolt is also used to bolt horizontal and vertical

seams together on 1 1 gauge laminated and thicker and some overlap seams. It is only used to attach

the stiffener and the splice plate to the sidewall. The flanges where the stiffeners bolts to the splices

plates use a different bolt (one without a rubber washer).

S-5060

Refer to 2.66" Commercial Tank Bolting Requirements on Page 51 for complete bolt usage.

48 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

9. Hardware

0.375" x 1.000" Hex flanged head without a plastic sealing washer.

This bolt is used to splice the stiffeners together on the flanges. A steel flat washer is used on the nut

side of the connection. They are also used on the roof rafter splices for commercial roof systems.

S-7927

0.375" x 1.500" Hex flanged head without a plastic sealing washer.

This bolt is used to attach the flanges of the 5 gauge base stiffener to the splice plates and splice

laminated stiffeners together. A steel flat washer is used on the nut side of the connection.

S-7928

Refer to 2.66" Commercial Tank Bolting Requirements on Page 51 for complete bolt usage.

NOTE: The only washers shipped loose with the bins are the steel flat washers. The 5/16" steel flat washer

(S-845) is used where the base angle attaches to the sheet and some are used the main eave

clips. The 3/8" steel flat washers (S-248) are used at the stiffener splices and some are used in

the roof rafter splices.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 49

9. Hardware

Color Chart for Bin Hardware Bucket Lids

Part # Color Description

S-275 5/16" x 3/4" Bolt pre-assembled with a steel backed sealing washer

S-277 5/16" x 1-1/4" Bolt pre-assembled with a steel backed sealing washer

S-396 5/16" Hex nut

S-455 3/8" x 1" Bolt pre-assembled with a steel backed sealing washer

S-456 3/8" Hex nut

S-5060 3/8" x 1-1/2" Bolt pre-assembled with a steel backed sealing washer

S-7927 3/8" x 1" Hex flanged head bolt without

S-7928 3/8" x 1-1/2" Hex flanged head bolt without sealing washer

S-8479 7/16" Special recessed nuts

Dark Blue

Black

Red

Grey

Yellow

Orange

Light Green

Dark Brown

Light Brown

sealing washer

S-9373 3/8" Hex flanged nuts

S-9444 7/16" x 2-1/2" Bolt pre-assembled with a steel backed sealing washer

S-9445 3/8" x 2" Bolt pre-assembled with a steel backed sealing washer

S-9470 7/16" x 2" Bolt pre-assembled with a steel backed sealing washer

Dark Purple

Dark Green

Light Blue

Light Purple

50 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

9. Hardware

2.66" Commercial Tank Bolting Requirements 2 Stiffeners per

Sidewall Sheet

Sidewall Seams and Stiffener to Sidewall Bolt Usage

Sidewall Gauge Horizontal Seam Vertical Seam Stiffener to Sidewall Overlap Seam

20-19

18T

17T-16T

15Q-14Q

13Q-10Q

5/16" x 3/4"

[10]

5/16" x 3/4"

[22]

5/16" x 3/4"

[22]

5/16" x 3/4"

[22]

3/8" x 1"

[22]

A. T - Triple punched sheets (36 holes in vertical seam)

Q - Quad punched sheets (48 holes in vertical seams)

All bolts are standard bin bolts with neoprene washers. For horizontal and vertical seam bolts, the

bolt head and neoprene washers are on the outside of the bin. Refer to stiffener instructions on

stiffener to sidewall bolt usage on Page 53.

5/16" x 3/4"

[24]

5/16" x 3/4"

[36]

5/16" x 3/4"

[36]

5/16" x 3/4"

[48]

3/8" x 1"

[48]

3/8" x 1"

[8]

3/8" x 1"

[16]

3/8" x 1"

[24]

3/8" x 1"

[24]

3/8" x 1"

[24]

5/16" x 3/4"

[2]

5/16" x 3/4"

[2]

5/16" x 3/4"

[2]

5/16" x 3/4"

[2]

3/8" x 1"

[2]

B. Hardware part numbers

5/16" x 3/4" - S-275

3/8" x 1" - S-455

C. See Pages 53-59 for special instructions on stiffener to sidewall bolt usa ge f or stiffe ner splices a nd

laminated stiffeners.

D. Use 5/16" bolts and nuts when joining 14 gauge to 13 gauge on horizontal seams.

Figure 9A

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 51

9. Hardware

Caulking Detail

Figure 9B Standard, Triple and Quad Punched Sidewall Sheets as Viewed from Outside

Apply one strip of caulking near the outside edge of the outer sheet and between the outer two (2) rows

of bolts, refer to Figure 9C. A strip of caulking 10" long, should be placed along the horizontal seams.

Before bolting the next ring in place, apply one strip of caulking 10" long on the front of the underlapped

sheet at each joint. Also, a 10" strip of caulking is to be placed along the lower horizo ntal edge of lapping

sheet at every vertical seam. This will fill the space that occurs between the holes caused by the

overlapped sheets. Additional 10" strips should be used to fill gaps that occur with heavier gauges.

Figure 9C

52 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Universal Stiffener and Splice Hardware

Stiffeners Splicing Systems

10. Stiffeners

12 Gauge to 12 Gauge and Thinner

12 Gauge to 11 Gauge

through

8 Gauge to 5 Gauge and 6 Gauge

5 Gauge and 6 Gauge to

5 Gauge and 6 Gauge

5 Gauge to Laminated

Laminated to Laminated

Use SS-6966 or SS-7427 Splice 2 per Joint

Offset/Lapped Stiffener

No Separate Splices Plate

Use SS-7053 Splice

Color Code: Yellow

Use SS-7053 Splice

Color Code: Yellow

Splice Hardware Usage

(Not Including Sidewall to Splice Bolts)

Stiffeners Splicing Systems Hardware Part # Description Qty

14 Gauge and 15 Gauge Offset Stiffener Joint

12 Gauge and 13 Gauge Offset Stiffener Joint

10 Gauge and 11 Gauge

SS-7053 8 Gauge

Splice Plat e

S-7927 3/8'' x 1'' 8

S-9373 3/8" Flange Nuts 8

S-7927 3/8'' x 1'' 10

S-9373 3/8" Flange Nuts 10

S-7927 3/8'' x 1'' 16

S-9373 3/8" Flange Nuts 16

8 Gauge and 9 Gauge

5 Gauge and 6 Gauge

Laminated SS-6966 or SS-7427

SS-7053 8 Gauge

Splice Plat e

SS-7053 8 Gauge

Splice Plat e

Stiffener to Sidewall Hardware Usage

Splicing Systems Hardware Part # Description

Stiffener to Sidewall

SS-7053

Splice to Sidewall

Laminated Stiffener to Sidewall

S-7927 3/8'' x 1'' 20

S-9373 3/8" Flange Nuts 20

S-7928 3/8'' x 1-1/2'' 20

S-9373 3/8" Flange Nuts 20

S-7928 3/8'' x 1-1/2'' 30

S-9373 3/8" Flange Nuts 30

S-455 3/8" x 1"

S-456 3/8" Nuts

S-5060 3/8" x 1-1/2"

S-456 3/8" Nuts

S-5060 3/8" x 1-1/2"

S-9373 3/8" Flange Nuts

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 53

10. Stiffeners

Commercial Stiffeners for 2.66" Corrugation

Figure 10A

54 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

10. Stiffeners

See Pages 56-59 for further details.

2.66'' Corrugation Commercial Stiffener Splice Details

When installing bottom stiffeners, in some cases the stiffener with the base plate attached will not rest on

support structure. Shim plates have been furnished and should be used to fill opening between base plate

and compression element. See Page 65 for detail.

IMPORTANT: If shim plates are not used where required, the downward pressure of the stiffeners will not

be transferred directly to the foundation and bin failure could result.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 55

Figure 10B

10. Stiffeners

Figure 10C

56 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

10 Gauge and 11 Gauge Stiffener Bearing Splice

10. Stiffeners

Figure 10D

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 57

10. Stiffeners

5 Gauge, 6 Gauge, 8 Gauge and 9 Gauge Stiffener Bearing Splice

Figure 10E

58 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Laminated Stiffener Splice 2.66" Corrugation

10. Stiffeners

Figure 10F

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 59

10. Stiffeners

Figure 10G

60 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

10. Stiffeners

Laminated to Universal Stiffener Splice 2.66" Corrugation

Figure 10H

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 61

10. Stiffeners

Stiffener to Sidewall Connections 3 Post Tanks

NOTE: Use the dimensioned holes for stiffener to sidewall connections on 3 post tanks.

Figure 10I

NOTE: Some locations in the lower regions of the tank utilize close punched sheets where the stiffener

will attach more frequently.

62 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Non-Laminated Stiffener to Sidewall Detail

10. Stiffeners

Figure 10J Non-Laminated Stiffener to Sidewall Detail

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 63

10. Stiffeners

Laminated Stiffener to Sidewall Detail

Figure 10K Laminated Stiffener to Sidewall Detail

64 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

10. Stiffeners

Universal Stiffener Starting Location 2.66" Reverse Corrugation

Outside Stiffener Only

For sidewall to stiffener connections, use 3/8" x 1" bin bolt except horizontal seam. 19 Gauge and 20 gauge

sidewall sheet will bolt four (4) locations per sheet. 18 G au ge will b olt at eight (8 ) loc atio ns per shee t.

17 Gauge and thicker sidewalls will bolt every 2.66".

NOTE: Splice plate and laminated stiffener to sidewall connection use 3/8" x 1-1/2" bin bolts.

Figure 10L

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 65

10. Stiffeners

Wind Ring Assembly

Figure 10M

1. To connect wind ring pipe to the stiffeners, attach with 3/8" x 1" bolts through the flange of the

stiffener. In some case’s field drilling of wind ring locations may be required.

2. Attach wind ring pipe section to stiffener using two (2) 3/8" x 6" (S-7248) wind ring clamps.

3. Place pipes end to end without overlapping. Fasten together using two (2) wind ring couplers and

six (6) 3/8" x 1" flanged head bolts with flanged nuts. Couplers should be centered on the seam

of pipes.

Figure 10N

66 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

10. Stiffeners

Stiffener Shim Plate Detail (Use when Necessary)

The shim plates should be used where necessary to ensure the base plates are firmly supported by the

columns. Use the shim plates to fill any gaps between the base plate and the compression weldment.

Refer to Figure 10O. Attach the base stiffener to the stiffener column and compression weldment with

5/8" x 2-3/4" bolts (two (2) per stiffener). Place a washer on the top side of the stiffener base plate.

Figure 10O

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 67

11. Flashing Instructions (Optional)

1. Attach flashing to the bin wall using the pre-punched holes at 9-1/3" above the horizontal seam.

2. Attach left side of the first piece of flashing to the sidewall using the connection as shown in

Figure 11A. Working clockwise, overlap the flashing at the right hand hole of each piece of flashing.

NOTE: If bolts are installed at flashing seam location they will need to be removed.

3. At vertical seams attach flashing that is to span the vertical seams using both left and right holes.

Drill flashing holes from the outside of the bin through the sidewall sheet holes. Remove drilled

flashing and assemble vertical seam bolts and nuts. (See Figure 11C on Page 69.) Replace drilled

flashing and attach according to Figure 11B. Continue around the bin clockwise.

Figure 11A Flashing Hardware Figure 11B Vertical Seam Flashing Hardware

68 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

11. Flashing Instructions (Optional)

Figure 11C

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 69

12. Doors

Access Door Weldment Assembly Hardware Package (PLS-41985)

Figure 12A

70 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

13. Aeration

Aeration Package (Optional)

Step 1: Using reinforcing plate as a template, mark hole in hopper for cutting.

Step 2: Using a torch or saw, cut the hole in hopper sheets for tube.

Step 3: Remove enough bolts from hopper seam to allow reinforcing plate to set down on

hopper panels.

Step 4: Install reinforcing plate on inside of hopper (and outside for 27' and 30' tanks). Full weld and

field drill holes and bolt in place. Drill holes through reinforcing plate where it overlaps holes

in seam and reinstall bolts.

Step 5: Install torpedo head at open end of tube and screw in place as shown (screws not included).

Step 6: Four (4) angles with corrugated pieces welded on them are supplied for each tube (two (2)

per side). Bolt or weld each angle to the hopper sheet and screw or weld the corrugated

material to the perforated tube (#14 x 1" self-drilling tek screws not provided).

Step 7: Full weld inside and outside around perimeter of aeration tube saddle ‘tee’.

Step 8: Bolt or weld on angle ring for attachment of fan.

Step 9: Touch up any welded areas with a rust inhibitive type paint.

NOTE: When two (2) tubes are installed, second tube is to be installed 180° from first tube.

Figure 13A Typical Installation

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 71

13. Aeration

Aeration Package (Continued)

System Airflow Ra ting (CFM)

A-CHT15-14 1209

Figure 13B

A-CHT18-14 2016

A-CHT21-14 2016

A-CHT24-14 4032

A-CHT27-14 4032

A-CHT30-14 4838

Figure 13C Typical Profile

72 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Aeration Package (Continued)

13. Aeration

Figure 13D Weld Detail

Figure 13E Corrugated Angle Hold-Down Attachment Detail

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 73

14. Ladders

Ladder Support Detail

The ladder must be secured to the hopper support columns with ladder standoff brackets using support

channels and ladder brackets as shown in Figure 14A.

Figure 14A

Tank Diameter Hopper Slope # of Support Channels Hopper Ladder Brackets

12' 45 3 6

12' 60 4 8

15' 45 4 8

15' 60 6 12

18' 45 4 8

18' 60 7 14

21' 45 5 10

21' 60 8 16

24' 45 5 10

27' 40 5 10

30' 40 5 10

36' 40 6 12

36' 45 8 16

74 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Hoist Instructions

Recommendations for hoisting completed tank onto hopper bottom structure.

15. Hoisting

(All parts mentioned in this section are not

furnished.)

A crane is normally used to lift the tank and place it on top of the substructure. Technique of hoisting of

the complete tank on the hopper structure is in large part based on personal experience, equipment and

manpower. The following recommendations are intended as a guideline only.

1. Before lifting the tank, the following should be checked:

a. The columns and substructure should be checked for levelness and verified plumb and leveled

if necessary.

b. Final ladder and safety cage and door locations should be determined and clearance at these

locations verified.

c. Proper provisions should be made for safe working platforms around the top of the substructure.

2. Lifting techniques are largely influenced by personal experience and equipment capacity, however

general recommendations as follows:

a. Lifting brackets should be attached to the stiffeners. At least one bracket per sidewall sheet

should be used. These are usually attached in the third ring from the bottom of the tank. Brackets

should attach to a minimum of four (4) bolts through the stiffener. Attach cables to the lift brackets

and to the crane hook, which has been lowered through the center ring opening. Cables should

be sized to handle the entire weight of the bin. Make all lift cables of equal leng th befo r e the bin

is lifted. Refer to Figure 15A and Figure 15B on Page 76.

b. To prevent distortion of the assembled tank, a “spider” or horizontal bracing is recommended.

A suggested method of this is illustrated in the following details. This may be done by using a

center “hub” and pipe. The center hub is made of 6" schedule 40 pipe with 3" x 3" x 3/8" angle

welded to it and the pipe bolting to the hub. The second smaller pipe will bolt to the lifting brackets

attached to the stiffeners. (Refer to Figure 15C on Page 76.) Typical number of horizontal

members that should be used are shown in the chart below.

c. Use of temporary bracing across the peak collar may be needed to guide the cable. This should

be made easily removable.

Recommended Minimum

Number of Lift Brackets

Diameter # of Brackets

12' 4

15' 5

18' 6

21' 7

24' 8

27' 9

30' 10

Recommended Number

of Horizontal Brackets

Diameter # of Braces

21' 3

27' 3

12' 4

24' 4

15' 5

30' 5

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 75

15. Hoisting

Figure 15A

Figure 15B

Figure 15C

76 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

15. Hoisting

3. To simplify the setting process, bend the sealing lip inward slightly to allow sidewall sheet clearance.

Bolt the sealing strip to the bottom of the sheet and apply final sealing. Typical sealing material such

as non-reactive silicon caulk should be applied. Shim between the bottom of the stiffeners and the

compression angle ring for level alignment if necessary.

4. After tank is secured, remove the spider or horizontal bracing and all hoisting attachments

and cables.

Figure 15D Detail R

Figure 15E Detail Q

After lifting the tank, clean all dirt and debris from the base of the tank.

Figure 15F Tank on Support Columns

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 77

NOTES

78 PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

16. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s 79

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2011 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-206298

Loading...

Loading...