Page 1

2003 Top Dry Service School

GSI / Top Dry

Service School

2003

PNEG-1314

1

Page 2

2003 Top Dry Service School

Contents

Safety Pages..........................4

Product Updates...................7

Softwar e Revisions..............1 1

Batch T roubleshooting.......19

Autoflow T roubleshooting..25

Diagnostics..........................32

Warranty.............................40

2

Page 3

2003 Top Dry Service School

3

Page 4

2003 Top Dry Service School

Roof Damage Warning and Disclaimer

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM OR INTERNAL

PRESSURE FROM F ANS OR OTHER AIR MOVING

SYSTEMS. ADEQUATE VENTILATION AND/OR

"MAKEUP AIR" DEVICES SHOULD BE PROVIDED

FOR ALL POWERED AIR HANDLING SYSTEMS.

GSI DOES NOT RECOMMEND THE USE OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE

ROOF DAMAGE CAN RESULT FROM ANY

BLOCKAGE OF AIR PASSAGES. RUNNING F ANS

DURING HIGH HUMIDITY/COLD WEA THER CONDITIONS CAN CAUSE AIR EXHAUST OR INT AKE

PORTS TO FREEZE.

Operating Instructions

The principal concern of the GSI Group, Inc. ("GSI")

is your safety and the safety of others associated

with grain handling equipment. This manual is written to help you understand safe operating procedures, and some of the problems that may be encountered by the operator or other personnel.

The symbol shown is used to call your

attention to instructions concerning your

personal safety. Watch for this symbol; it points out important safety precautions. It means "ATTENTION",

"WARNING", "CAUTION", and

"DANGER". Read the message and

be cautious to the possibility of personal injury or death.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist, and to inform all personnel associated with the equipment, or who are in the fan area.

A void any alterations to the equipment. Such alterations may produce a very dangerous situation,

where serious injury or death may occur.

Safety Alert Symbol

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a misuse

of the equipment.

4

Page 5

2003 Top Dry Service School

Grain Systems, Inc.

recommends contacting your

local power company , and

having a representative

survey your installation so

the wiring is compatible with

their system, and adequate

power is supplied to your

unit.

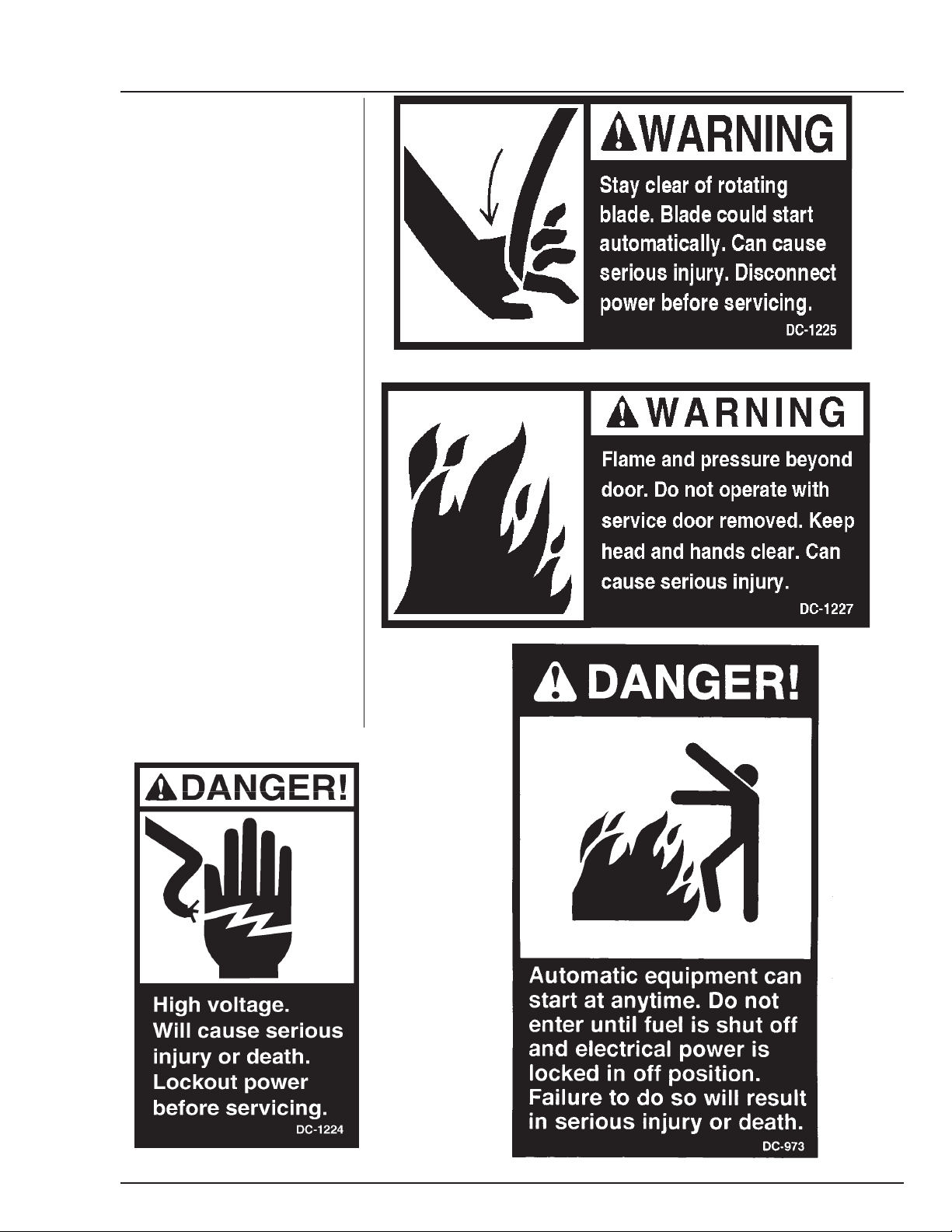

Safety decals should be read

and understood by all people in the

grain handling area. The rotating

blade, fire warning decals and

voltage danger decal must be displayed on the fan can. The bottom right decal should be present

on the inside bin door cover of the

two ring door, 24" porthole door

cover and the roof manway cover.

If a decal is damaged or is

missing contact:

Grain Systems, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to

you.

5

Page 6

2003 Top Dry Service School

READ THESE INSTRUCTIONS

BEFORE OPERA TION AND SER VICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maxi-

mum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature

of a grain dryer having a gas burner,

high voltage electrical equipment and

high speed rotating parts, does

present a hazard to personnel, which

can not be completely safeguarded

against, without interfering with efficient operation and reasonable access to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary conveyors, which may start without warning when the dryer is operating on

automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propellor, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry . Fine material increases resistance to airflow

and requires removal of extra moisture.

This product is intended for the use of grain handling only. Any other

use is considered a misuse of the product.

Some edges of the product components can be sharp. It is recommended that each component of this product be examined to determine if there are any safety considerations to be taken. Any and all

necessary personal protective equipment should be worn at all tines

when handling, assembling, installing and operation of the product

and/or components.

Guards are removed for illustration purpose only. All guardsmust be

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE OUT-

SIDE OF THE DRYER

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommendations within this manual, and make

it a practice to regularly inspect the

operation of the unit for any developing problems or unsafe conditions.

Take special note of the safety precautions listed above before attempting to operate the dryer.

6

Page 7

2003 Top Dry Service School

GSI / Top Dry

Product Updates

* Adjustable Drying Chamber High Level Rotary Switch

* Plenum Hi-Limit

* Software Updates

7

Page 8

DR YING CHAMBER HILIMIT ROTARY

SWITCH INSTALLATION

Assemble 1/4” shaft to rotary switch with 1/4”

coupler and rolled pins. Next Screw 1-1/4” pipe

coupler to bottom of rotary switch. Insert 1-1/4”

pip through adjustable roof mount weldment.

Leave 1-1/4” pipe sticking out the top of the

weldment 3” as shown in Diagram. Install paddle

to 1/4” shaft assembly with coupler and rolled pins.

Switch assembly is now ready to mount to roof.

2003 Top Dry Service School

3.00”

COMPRESSION COUPLER

ROOF MOUNT PLATE

8

Page 9

2003 Top Dry Service School

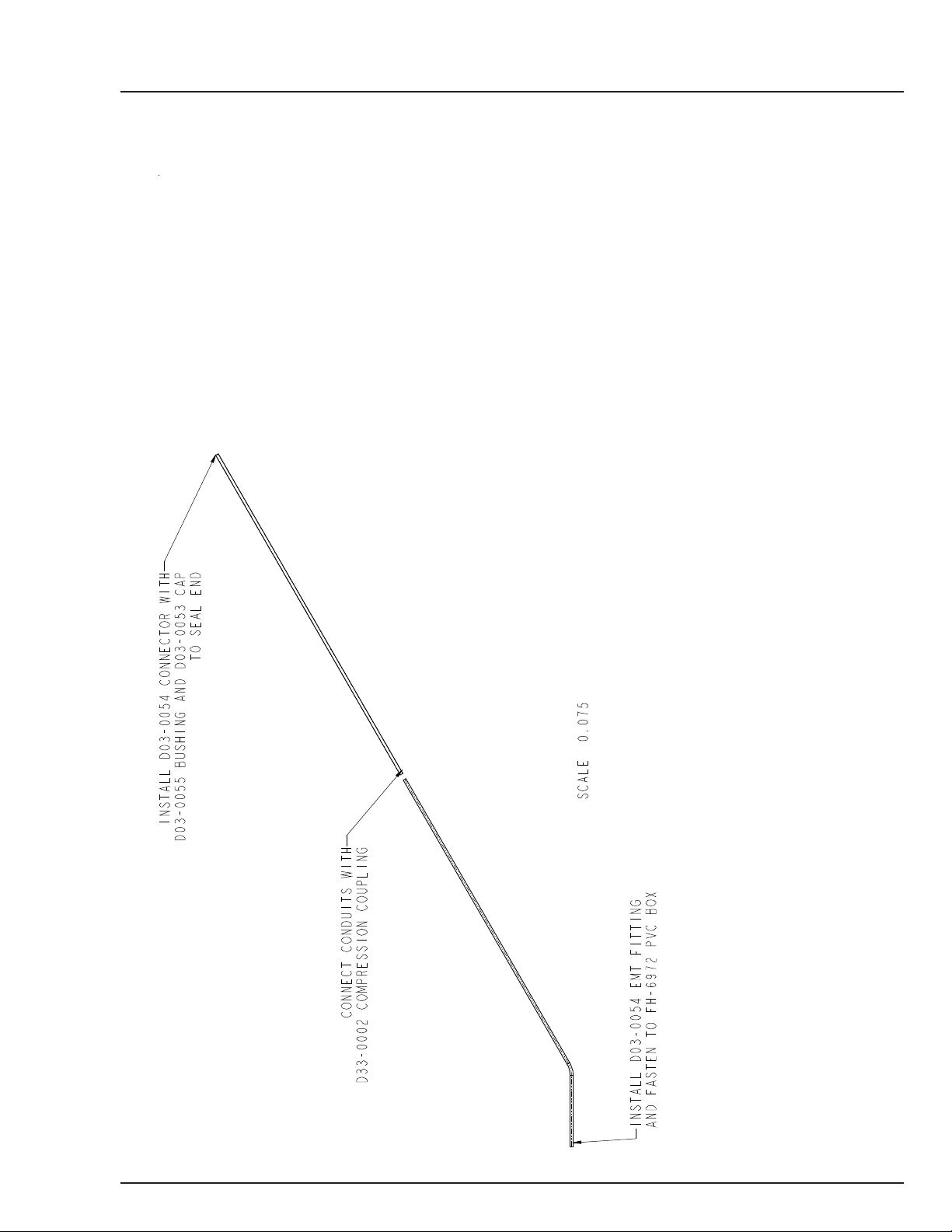

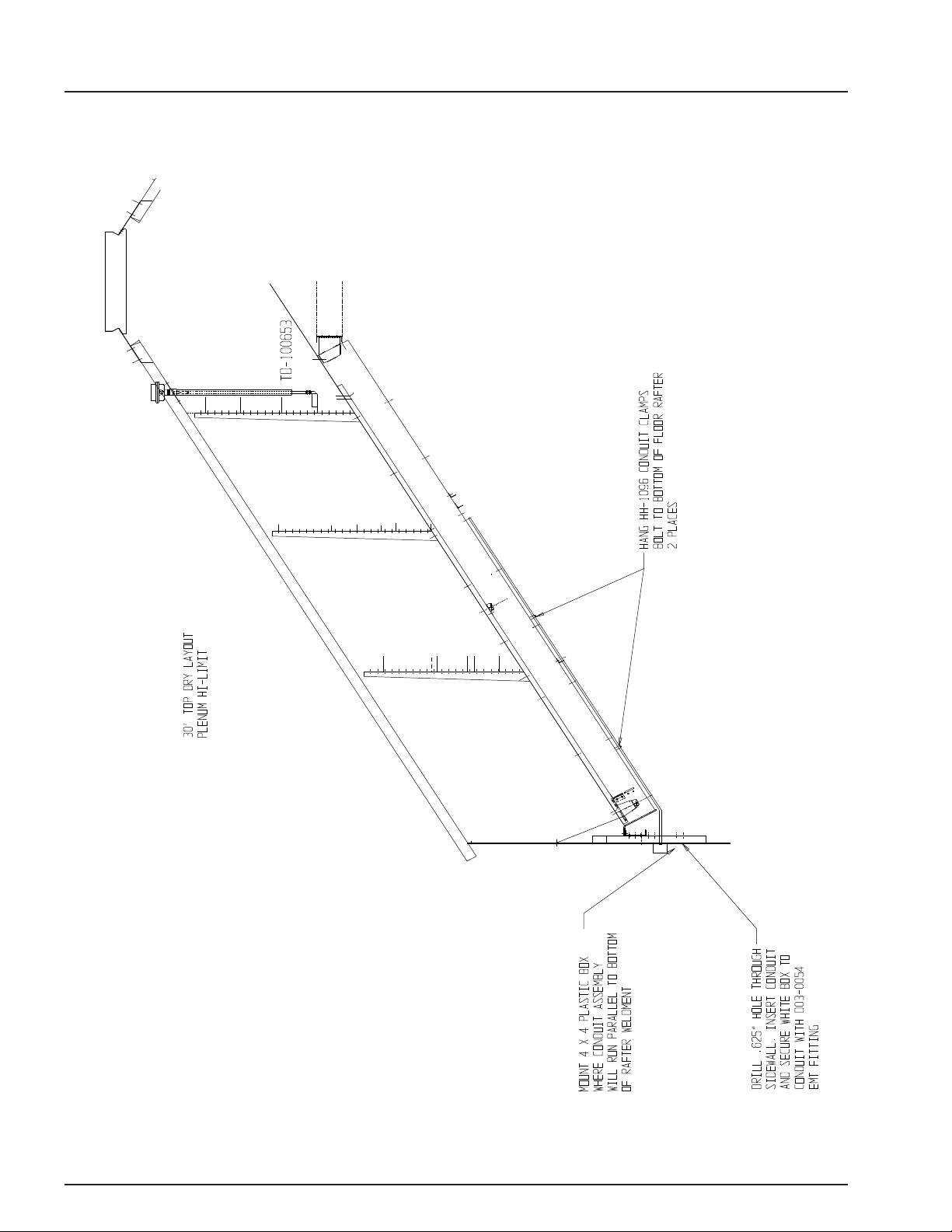

TOP DRY PLENUM HI LIMIT INSTALLATION

1. Assemble two pieces of conduit together with coupler.

2. Mount conduit clamps to conduit assembly.

3. Locate conduit assembly on the bottom of a rafter at least 2 feet to one side of the fan

entrance. Do not install between two f an entr ance s.

4. Mark bin wall where conduit will pass through and drill a hole just large enough to allow the

conduit to pass through. Seal this with caulking when complete.

5. Install white PVC box assembly on outside of bin wall.

6. Insert 10’ capillary into condu it assembly.

7. Connect SJO cord to hi limit and connect wires to terminals 20 and 21 on the master fan

terminal strip. These terminals are J7-08, and J7-03.

9

Page 10

2003 Top Dry Service School

10

Page 11

2003 Top Dry Service School

GSI / Top Dry

Software Revisions

11

Page 12

2003 Top Dry Service School

N

p

p

N

Network Autoflow Display Board Software Revisions

*********************************************************************

VERSION: 2.15 REVISED BY: Steve Logue RELEASE DATE: Oct 17, 2002

OTE: This Version does NOT support Wat chdog and the Heater Version MUST be 1.09. HEATER VERS – 1.09 IO

VERS – 1.07

1) The "FAN DELAY" is now called "MOTOR DELAY".

2) Added a way for GSI to reset total hours.

3) Here is a list of switches/features which can be found under the setup screens accessed via holding in on MODIFY whil e

owering on the Control Power.

Below is a description for each defin in g w hat it means t o disable/enable them :

i)

AIRSWITCH

requirements for the burner

regardless of the actual air switch state.

ii)

LOW LE VEL SWITCH

state of the rotary swi tc h.

When disabl ed the dryer will think the l ow level switch is always covered.

iii)

WET TANK SWITCH

always covered w it h grain.

iv)

START FANS WITH

Disabled means dryer will

start according to drying chamber low level switch.

v)

AERATION FAN BYPASS

dryer shutdow n.

4) The REFILL TIM ER and the TIME UNTIL LOAD OFF screens are only shown w hen t he dr yer is set for Autobat c h mode.

5) There are two more settings available under the "Power on and Modify key in" se quence for the user to set how many de gr ees a

measured temperature can

exceed a set poi nt w ithout causing an overheat. The user can set 10 -> 50 degrees above the setpo in t to be an overheat conditi on.

The default for the plenum

temp is 20F and the default for the grain temp is 30F.

6) The low level rotary switch function is the same as it was in 2.14, but now instead of giving a warning which states "DRY

CHAMBER EMPTY " whe n

it become s un c overed it gives "LOW LEVE L SW EXPOSED ."

7) Added an Out of Grain Timer. The time value can be changed under the setup but ton. This timer starts whenever either fill

systems is running and the load

switch is in the auto position. The timer is reset when both load augers stop. If the timer runs out of time an OUT OF GRAIN

warning is issued. The

default is 20 minutes. Any time the value of this Timer is change d th e new val ue takes effect immediately.

8) Changed warning for wet bin empty to state "WET BIN SW EXPOSED" instead of saying “DRYER OUT OF GRAIN”.

9) Renamed "FILL 1 DE LAY" to "FIL L SY S TE M #1 ". Changed name of "FILL 2 DELAY" to "HI LEVEL SW". The HI

LEVEL SW delay is always

available on both one and two fill sys t em dr yers and is used to make sure the dryer is full s o you don't get bogus shu t downs. The

FILL SYSTE M #1 delay is

only available when you are set for two fill systems and it is use d to es ta blish auger cleanout time.

10) If the Storage Bin Hig h Lim i t is det ected as failed (the N.C. pin and the N.O. pin from the swit ch are both reporting the sam e

voltage, 0 or 12 volts) a

warning is reported as “BIN HI LIMIT SW BAD”.

11) If wet supply rotar y switch becomes unco ver e d t her e i s a tim er w hi ch m us t expire before a warni ng is given. This timer/delay

was called "AUX 1 DELAY",

but is now termed "WET BIN SW. delay" It is found under t he DELAYS key.

12) The time a user has to think about making a chang e to a timer/setpoint bef or e i t au tomatically proceeds to the next selection

screen has been doubled.

13) Changed the name of de lay/timer "LOW LEVEL TIMER" to "LO L EVEL SWITCH."

14) Enabled the "START FANS WITH HIGH" switch function. There was previously a screen available to select this function, but

it was never active.

15) The cool down timer is now set to the reload valu e of the cool timer whenever any one of the four foll ow i ng s hutdowns takes

lace:

i) Dry and Hold swit c h i s turned to on state. ii) Grain falls awa y from wet bin supply switch.

iii) Storage chamber is full. iv) Dryer is o ut of gr ain.

16) Fans Off Delay now defaults to 0 minutes i nstead of 1 minute and has an upper limit of 5 minutes. This delay can be f ound

under the “delay” key.

17) The dryer functions the same whether the l oad s w i tch is in auto or on, but the o ut of gr ai n timer only times dow n while the load

switch is in the auto position

and one of the load a ugers i s run ni ng.

*********************************************************************

VERSION: 2.14 REVISED BY: Steve Logue RELEASE DATE: Sept 20, 2002

OTE: This Version does NOT support Wat chdog and the Heater Version MUST be 1.09 not the Watchdog version 1.10.

1) Fixed software so the bur ner differential could be set to one degre e a nd i t would remain there after loss of power.

-> Enabled means you will get a shutdown when a fan loses airflow. Disabled will satisfy the dryer's airflow

-> Enabled mea ns th e dr ying chamber low level sw itch will act as normal, i.e, w ill in dicate the real

-> Enabled means this switch will act as normal. Disabled means the dryer will think this switch is

HIGH -> Enabled means the dryer will start f ans according to state of dr ying chamber hi level switch.

-> Enabled means the B Y PASS is active, which all ows t he aer at ion fan to continue to ru n af ter a

12

Page 13

2003 Top Dry Service School

p

N

N

g

*********************************************************************

VERSION: 2.11 REVISED BY: Steve Logue RELEASE DATE: October 27, 2000

1) Burner differential would not stay at 1 deg F w hen the dryer was tur n of f , usi ng 2.10, now it does.

2) When grain reaches the St or age Chamber Rotary Switch, the dryer will enter a "Cool Down Mode". The fan will run and coo l

thegrain for 10 minutes before

shutting dow n due to a Storage Cham ber Full error.

3) When grain falls away from the Wet Supply Rot a ry Switch, th e dryer will ente r a "Cool Down Mode" after the fill syst em shut

off. The fan will run and

cool the grai n f or 10 minutes before shut t i ng down due to a No Wet Supply error.

4) When the Dry & Hold switch is placed in the "On" position the dryer will enter a "C ool D ow n Mode" for 20 minutes bef ore

stopping. This only happens at

the end of the dry cycle.

5) Corrected a problem with t he Fans Off Delay. If there is tim e on this delay, the fans and heaters will shut off duri ng the unload

cycle, after the unl oad cycle

is complete the delay counts down. The fans and heaters will not start again until the delay has reached zero.

6) Corrected a problem with the Time Until Load Off percentage set in the set-up mode. Now, in Auto batch only, the Fill Systems

will shut off if grain has not

reached th e dr y chamber high level rotar y s w i tch within the set perce nta ge of the dry timer is comple te d. Example: 1 hr dry

time, 50% Time Until Load off.

The fill systems w i ll shut off regardles s of ro tary switch status aft er 30min has expired.

7) Corrected a problem with t he Refill Delay. Now, i n Au t o bat ch O nly. The Refill Delay begins to count down af ter t he unload

cycle is completed. If grai n

has not reached t he dr yi ng chamber low level rot ary sw i tch before this delay reac hes zer o, a dr y chamber empty error is gi ven.

*********************************************************************

VERSION: 2.10 REVISED BY: Steve Logue RELEASE DATE: Sept 11, 2000

1) Changed the Minimum Burner Differential t o 1 Deg Fahrenheit

2) Fixed the problem wh er e th e bur ner w as not shutting off whe n th e Dry & Hold switch was pla ced i n t he "O n" position, the Dry

Cycle was complete, and the

Dryer was in the Cool Cycle. Now, when the Dry & Hol d swit ch i s pla ced i n t he "O n" position, and the Dry Cycle is complete,

the dryer will shut th e bur ner

off and will cool for the amount of ti m e on t he C ool Timer before sto ppi ng.

3) Fixed a problem wher e the dr yer w as not shutting down wit h an "O ut of Grain" error when the Wet Supply Ro t ar y Sw i tch was

exposed. Now whe n th e Wet

Supply R otary Switch is exposed, the Fill #1, and Fill #2 delay will count down and shut off Fill System #1 & #2, then the dryer

will shut down with an "Out

of Grain" er r or. If there is still grain aga inst the Low Level Rotary Switch, the dryer can be rest ar t ed by pr ess i ng the Stop switch

to clear the error, turning

the Load Auger switch to the "Off" pos i t i on, and pressing the Star t switch. When the Star t swi tch is pressed the screen will say

"Press <Enter> to Dry

Remaining Grain". If the <enter> button is pressed the dryer will restart. NOTE: If the Load Auger switch is left in the "Auto"

osition an "Out of Grain"

error will be gi ven on startup.

*********************************************************************

VERSION: 2.09 REVISED BY: Steve Logue RELEASE DATE: May 15, 2000

1.) Selection screen for On-Off burner. This cannot be used i n conjunction with di es el bur ner .

OTE: Must change heater software also. Use fol lowing version number or higher: Heater ==> 1.09

*********************************************************************

VERSION: 2.08 REVISED BY: Steve Logue RELEASE DATE: May 12, 2000

1.) Changed the burner differential setup screen to correctly display Celsius temperatures.

2.) Now only a year above 2000 may be ent er ed upon setting the dat e.

3.) Burner differential is now gr eater than 1 and less th an 10 degrees.

*********************************************************************

VERSION: 2.07 REVISED BY: Steve Logue RELEASE DATE: April 25, 2000

1.) Changed the checksum m ethod for the networ k t o help insure data integrity.

2.) Force aeration fan to start bef or e drying fans start , un less aeration switch is in off position.

3.) Load systems can not start for five seconds after start of system.

OTE: Must change heater and I/O softwar e also. Use following versi on number or higher:

*********************************************************************

VERSION: 2.06 REVISED BY: Steve Logue RELEASE DATE: April 20, 2000

1.) Stopped the abi lity to change the grain setp oi nt from heaters.

*********************************************************************

VERSION: 2.05 REVISED BY: Steve Logue RELEASE DATE: March 30, 2000

1.) Fixed a problem wit h fan 1 reporting air sw itch already engage d if f an 2 had not started yet .

2.) Fixed the low level disabling softwar e s o a w ar ning is not reported when the high level grain switch detec ts gr ain without the

*********************************************************************

VERSION: 2.04 REVISED BY: Steve Lo

Heater ==> 1.07 IO ==> 1.07

low level detec ting grain.

ue RE LE A SE DATE: Feb 25, 2000

13

Page 14

2003 Top Dry Service School

p

*********************************************************************

VERSION: 2.01 REVISED BY: Steve Logue RELEASE DATE: October 4, 1999

1) Attempted to fix the pr oblem of grain setpo in t ch anging by itself.

2) Fixed problem of batch dry e r always shutting down with a "DRYING CHAMBER EMPTY" war ni ng. A delay called the "RE FILL TIMER" allows the

dryer to fill back up.

*********************************************************************

VERSION: 2.00 REVISED BY: Jeff Falconer RELEASE DATE: January 6, 1999

1) Fixed hour timer so dryer w i ll now show running time of dr yer .

2) Changed the way the dryer s hut dow n when using the dry and hold switch, now it will cool the grain usin g the cool timer before it s hut s down to prevent hea t

buildup of grain past the grain temp set points thereby causing a shutdown condition. Works in Autoflow and AutoBatch modes.

3) Fixed the clock to properly roll over in the year 2000.

4) Added a user batch coun t an d us er tim er i ndependent from th e Total batch and Total tim e all ow i ng monitoring of di f f e r ent us er s dr ying grain or diff er ent

fields for compar ison of drying time.

5) Added a test procedure for the keypad. Turning all of the control switch es t o th e right (on position) and holding in the stop switch while turning on the

control power acti vates it. User can now test each individual keypad switc h f or m alfunction or stuck keys. (Taken out in 2.03)

6) Added control switc h testing by pressing and hold the plenum and gr ain switches in while t ur ni ng on the control power. Thi s w ill allow the user to test for

failed switches or computer failure to detect switch positi on changes. (Changed in 2.03 to turn power on w ith H elp key depressed)

7) Removed garbage displayed when user selected to view total runni ng time and total batches.

8) Added a check to make sure the dump switch is always i n th e A ut o pos i stion. Otherwise if left in manual close will caus e th e dryer never to dump.

9) Fixed several bugs t hat were reported to use by users and dealers.

10) I added the ability to reset the Total Dryer running time by pressing the HOUR and RESET button together and turn on the dryer.

11) Removed watchdog option in Extended setup mode sin ce w a t chdog has not been impl em ented yet.

12) Changed the wording to some of the error messages concerning th e ro tary switches to help eliminate some confusion of which switch was at fault.

13) Moisture contr ol light w ill now flash to give a visual indication that t he dr yer is in temperature hold.

*********************************************************************

VERSION: 1.06 REVISED BY: STEVE LOGUE RELEASE DATE: November, 98

1.) Fixed dryer so the grain hi limit occurs at 20 F above the grain temp setp oi nt.

2.) Made timeout on the open/close of the actuator 20 seconds ins te a d of 15 se conds. This extra tim e w as added to compensate for the weaker batteries taking

longer to close the chutes.

*********************************************************************

VERSION: 1.05 RELEASE DATE: September, 98

1.) Made the out of grain t imer active.

*********************************************************************

VERSION: 1.04 RELEASE DATE: July, 98

1.) The application of 12v to terminal number j1-20 will shutdown the dryer and give an indication that the bin is full due to the high level of s t at ic pres sure

within."BIN AIR PRESSURE LIM" will be displayed on screen's top line until the user corrects the problem. (Originally looked for lack of 12v, fixed in

2.00)

2.) Corrected the hour met er pr oblem.

3.) Changed how the dry tim er is displayed: Now when the dr y tim er goes to zero it will begin counting upward at the user s et time as long as the dryer rema ins

in temp hold.

*********************************************************************

VERSION: 1.03 RELEASE DATE: March, 98

1.) Added software t o allow the aeration fan to cont i nue r unning even if there was a dr yer s hutdown. The aeration fa n BYPASS mode must be sel ect ed under

setup.

*********************************************************************

VERSION: 1.02 RELEASE DATE: Jan, 98

1.) The Bin high limit rotary sw itch i s moni t or ed in both states to insure that a switch failure has not taken place. If both sw i tches are in the same state a switch

failure is report e d.

*********************************************************************

VERSION: 1.01 RELEASE DATE: NO OFFICIAL DATE ASSIGNED

1.) Added burner differ ential adjustm e nt to b e se t at m as t er under extended setup.

2.) Gary Woodruff 's sof twa re f or hol ding the fans off during a portion of the dr y cycle. This is adjusted under delays.

3.) Attempted to make the dr yer dry remaining grain when a wet supply em pty error takes place.

4.) Added software t o display a negative incr em ent ing counter, where the dry timer used to be, dur in g t e mp hold. (Changed in 1.04)

*********************************************************************

VERSION: 1.00 RELEASE DATE: SEPTEMBER 16, 1997

1.) We changed resist or num ber 107 on the displa y board from 10K to 3.0K to allow the contrast to work without resetti ng the computer.

2.). Put in a contrast adjustment for the display. While turning the cont r ol pow e r on, hold in on the screens key, and this will enter t he c ontrast adjustment mode.

Now use the UP/DOWN arrow keys to adjust. If the screen is solid black press the down arrow key, if nothi ng appears on the screen pr es s th e up ar r ow

keys. NOTE: You ca nnot hold in on the UP/DOWN arrow keys to adjust , you must continue t o pr ess and t hen release them or not hing will happen.

3.) Put Software in for 3

*********************************************************************

VERSION: 0.05 RELEASE DATE: 1996

This was the first version released for customer o

rd

Fan and Heater.

eration. This particular ver s i on could only control 2 Fan and Heaters.

14

Page 15

2003 Top Dry Service School

G

b

Heater and Batch Top Dry Revisions

--------------------------------

0.30 Released OCTOB E R 23, 1998

------------------------------------------------------------

1) FLAME TIME OUT IS NOW 10 SECONDS. THE IGNITOR SHUTS OFF IN ABOUT 7.5 SECONDS.

0.29 Released OCTOB E R 22, 1998

------------------------------------------------------------

1) ELIMINATE THE DEISEL OPTION -- FORCE THAT FLAG TO ALWAYS BE RESET. THIS CAUSED A 36 SECOND FLA

TIME OUT WHICH THE HARDWARE IS NOT SETUP TO ACCEPT. IF DEISEL OPTION IS REQUIRED AT SOME LATER

DATE -- WILL HAVE TO MODIFY SOFTWARE TO REDUCE FLAME TIME OUT BACK TO 12 SECONDS MAX OR

CHANGE THE HARDWARE.

2) DEFAULT FAN DELAY = 0 SECONDS ( FOR SLAVES )

0.28 Released August 24, 1998

------------------------------------------------------------

1) CREATE O / noO FLAG -- FOR EITHER IGNITOR OR HOT SURFACE IGNITION -- WHEN SET THIS IS USED FOR A

HOT SURFACE IGNITION SYSTEM -- SO THAT AT THE END OF THE PURGE DELAY THE IGNITOR COMES ON FOR 5

SECONDS BEFORE THE GAS VALVE TURNS ON. NOTE: I DID NOT USE I / noI BECAUSE IF THIS SOFTWARE WAS PUT

ON AN OLD DRYER -- IT WOULD DEFAULT TO noI -- IF THEY DID NOTHING. SINCE H / noH IS ALREADY BEING

USED FOR HUMIDITY -- I JUST USED O.

2) WHEN THE " O " FLAG IS SET -- AFTER THE 9 SECOND IGNITOR PERIOD THE IGNITOR DOES NOT TURN OFF

3) IN THE " O " MODE A FLAME OUT CAUSE THE GAS VALVES TO GO OFF FOR 5 SECONDS WHILE THE HOT

SUFACE INGITION COMES ON. THE WAY I DID THIS WAS TO RESET THE PURGE TIMER TO 5 SECONDS -- SO ON

THE DISPLAY TH E " PURGE " COMES UP -- THIS WA S THE EASIEST WAY TO ACCOM PLISH THI S.

4) CREATE d / nod FLAG -- FOR DIESEL FIRED SYSTEM. THIS SYSTEM HAS NO PURGE DELAY ( ACTUALLY 1

SECOND PURGE ) AND A 36 SECOND FLAME OUT TIME.

?????????????????????????????????????????

SHOULD THERE BE A LITTLE MORE PURGE DELAY --- SAY 5 SECONDS INCASE SOMEONE ACCIDENTLY SET THE

WRONG FLAG.

5) IF THE OPERATOR SET BOT THE " O " AND " d " FLAG THE " d " FLAG WILL NOT SET.

0.27 Released August 22, 1998

------------------------------------------------------------

1) Fixed problem in the Non Top Dry where after 30 minutes Error 3 shut the dryer down.

0.26 Released April 2 9, 1 998

------------------------------------------------------------

1) CHANGE FLAME OUT TIME TO 12 SECONDS -- IGNITOR SHUTS OFF IN 9 SECONDS -- 3 SECONDS LATER IF NO

FLAME -- SHUT DOWN -- NO FLAME. (CHANGED IN .30)

2) INCLUDE " FLAME " SYMBOL IN THE AMBIENT TEMPERATURE AND HUMIDITY MODES

3) ALLOW HUMIDITY DIFFERENTIAL TO BE SET TO 2 %

4) DON'T DESTROY " MODE " REGISTER WHEN EXITING THE PROGRAM MODE

0.25 Released April 2 7, 1 998

------------------------------------------------------------

1) Add a mode select for t he hum i di ty and ambient temperature. Using the mode sw i t ch ( Fan bypass ).

C.24 ???????????????????? ??

C.23 Released OCTOBER 29, 1997

------------------------------------------------------------

1) FIXED PROBLEM WHERE IF BOTH THE MASTER AND SLAVE HAVE THEIR OWN INDEPENDENT ERRORS -- THE

SLAVE DOES NOT FLICKER

BACK AND FORTH BETWEEN IT ERROR AND THE MASTER ERROR -- SLAVES ERROR HAS PRIORITY ON THE

SLAVE UNIT AND THE MASTER HAS PRIORITY ON MASTER UNIT.

2) IF THERE IS AN INCONSISTANCY BETWEEN MASTER AND SLAVE ( ERROR 9, 10 OR 11 ) -- THE MASTER TRIES

RESENDING THE IGNITOR COMMANDS 50 TIMES AND RECHECKING BEFORE ISSUING THE ERROR

.23 Released OCTOBER 22, 1997

------------------------------------------------------------

1) EXTEND THE IGNITOR ON TIME TO 14 SECONDS AND THE LAST 4 SECONDS SHUT THE IGNITOR OFF (changed in

.26)

A.23 Released OCTOB ER 15, 1997

------------------------------------------------------------

1) ALLOW 20 SECONDS FOR ILLEGAL FLAME SENSE

15

Page 16

2003 Top Dry Service School

SECONDS -- EXIT THE PROGRAM MODE.

0.22 Released OCTOB E R 22, 1996

------------------------------------------------------------

1) FIXED THE PROBLEM WHERE IF YOU SET IN 3.2 HOURS -- THE HOURS IMMEDIATELY WENT TO .32 WHEN YOU

EXITED THE PROGRAM

MODE

2) *CLEARING OF THE NOVRAM IS NOW ACCOMPLISHED BY POWERING UP WITH THE PROGRAM SWITCH HELD

DOWN ( LOWER LEFT *

*SWITCH ) -- WHEN THE " 0 " COMES UP -- ENTER A " 7 " WITH THE INCREM EN T SW ITCH -- THEN PUS H THE

PROGRAM SWITCH AGAIN *

*" - - - " COMES UP -- YOU HAVE 2 SECONDS TO DEPRESS THE INC DEC SWITCHES AT THE SAME TIME TO

CLEAR THE NOVRAM *

0.21 Released OCTOB E R 2, 1996

------------------------------------------------------------

1) FIXED THE PROBLEM THAT I CREATED IN VERSION # 0.20 WHERE THE ERROR 3 CAME ON -- SPARE

TEMPERATURE OPEN

2) WHEN IN TOP DRY MODE THE CYCLE FLAG IS ALWAYS SET

0.20 Released SEPTE MB ER 12, 1996

------------------------------------------------------------

1) CREATE A NEW MODE THAT WILL MAKE IT SO THAT BOTH THE GRAIN TEMPERATURE MUST EXCEED THE

LIMIT AND THE DRY TIME

MUST BE EXCEEDED BEFORE ADVANCING TO THE COOL CYCLE ON THE TOP DRY

2) IF THE GRAIN TEMPERATURE GETS TO 200 -- ALWAYS ADVANCE TO THE COOL CYCLE -- IN ALL MODES OF TOP

DRY, ---> IF THE 10

MINUTE GRAIN TIMER HAS GONE TO 0.

3) FIXED PROBLEM ( I THINK ) WHERE THE TEMPERATURE WOULD MOMENTARILY JUMP UP TO 275 DEGREES -WHEN THE THERMISTOR

SWITCH-OVER OCCURED ON THE BOARD

0.19 Released JUNE 8, 19 96

------------------------------------------------------------

1) HUMIDITY SOFTWARE

0.18 Released MARCH 1 3, 1996

------------------------------------------------------------

1) DON'T ADVANCE TO COOL CYCLE IN TOP DRY MODE FOR 10 MINUTES AFTER STARTING THE DRYER

-- ALLOW THE GRAIN TEMPERATURE SENSOR TO STABILIZE

2) WHEN THE SLAVE POWERS UP WITH THE FAN ON -- THERE WAS A LOT OF DISPLAY FLICKER -- CORRECT THAT

PROBLEM

0.17 Released OCTOB E R 17, 1995

------------------------------------------------------------

1) FIXED THE PROBLEM WITH THE TOP DRY MASTER NOT SHUTTING THE FAN OFF WHEN THE SLAVE GOT AN

ERROR

2) WHEN GETTING ONE OF THE LIMIT ERRORS, ETC -- THAT JUST DISPLAYS A LEGEND -- ON THE MAIN DISPLAY

INSTEAD OF DISPLAYING

TEMPERATURE -- DISPLAY: 0 0 0

ERROR

0.16 Released OCTOB E R 16, 1995

------------------------------------------------------------

1) Raised the Error 12 V oltage Limit from >155 to >195 volts for 120 volt systems. <155 vol ts st ill the error 12 limit f or 240 volt

systems.

0.15 Released OCTOB E R 14, 1995

------------------------------------------------------------

1) CORRECTED THE PROBLEM WHERE WITH CERTAIN ERRORS YOU COULD NOT VIEW THE AMOUNT OF TIME

THE DRYER HAS BEEN

DOWN DUE TO ERROR CONDITION

2) IF THE " STANDARD DRYER " ( NOT TOP DRY ) FINDS A SLAVE INCONSISTANCY ERROR -- ERROR # 9, 10 O 11 -IT WILL TRY RESTARTING

THE SLAVE FOR 5 SECONDS BEFORE IT GIVES UP

3) CORRECTED THE BUG IN VERSION 14 SOFTWARE WHERE THE REMAINING HOURS WERE NOT STORED FOR

DRY AND COOL TIME -- ALL

16

Page 17

2003 Top Dry Service School

)

CAN VIEW THE HOURS THAT HAVE PASSES SINCE THE SHUT DOWN BEGAN. MAX NUMBER OF HOURS = 218

HOURS ( 9.1 DAYS ) *

2) ADDED ERROR NUMBER 13 ==>> + 11 LIMIT SHORTED

3) LIMIT MAX TEM P ERA T U RE SE TTI NG TO 23 0

0.11 Released AUGUST 16, 1995

------------------------------------------------------------

1) MAKE THE SPARE RELAY ACT THE SAME AS THE FAN RELAY -- BOTH OPEN AND CLOSE AT THE SAME TIME

0.10 Released July 12 , 19 95

------------------------------------------------------------

1) If the Heater shuts dow n due to a “ Illegal Flame “ Se nsing problem – Flame o n wh en no gas valves are on Error 7. Leave the

Fan on till that problem goes away. When the Heater Control detect No Flame – The Fans are Shut Down.

The Fans are left in the State they were in when the error was detected. That is – If the Error 7 occurs on the Power Up – Don’t turn

the Fans on – That must be due to some other prob lem.

In a Master / Slave heater – Only the Heater with the Flame since problem keeps it’s fan on.

In the Timed Shut D ow n Modes the Fans are left on t ill it is confirmed that the Fla m e has gone away. This is for Top Dry and

Regular Fan and Heater.

In the Top Dry when the Grain Temperature excedes the limit – The Fans are left on till it is confirmed that the Flame has gone away.

0.09 Released May 27, 1995

------------------------------------------------------------

1) In all test modes shut the outputs off.

2) ON May 31, 199 5 -- changed the flash decod e bytes to program the entire chip rather than th e fir s t 256 k bi ts -- left the version at

0.09

0.08 Released April 1 8, 1 995

------------------------------------------------------------

1) Fixed the probl em w her e w hen the humidity was to o high or the grain temp was to high the display flas h r eal f as t.

0.07 Released Good Friday i n t he Y ear of O ur Lord 1995

------------------------------------------------------------

1) Fixed the probl e m w it h t he er r or not being displaye d on t he top dry remote.

2) Allow the remote to reset the Coo l an d Dry timers if the Inc and Dec switches are depr essed at the same time.

0.06 RELEASED 3/23/95

-----------------------------

1) IF THE HUMIDITY INPUT IS SHORTED TO + 11 VOLTS ADVANCE TO THE COOL CYCLE

2) IF THE HUMIDITY IS TO HIGH TO BEGIN WITH -- THE D_RH AND D_PERCENT FLASH ON AND OFF FOR A FEW

SECONDS

0.05 RELEASED 3/23/95

-----------------------------

1) ADDED WATCH DOG SOFTWARE

0.04 RELEASED 3/06/95

-----------------------------

1) FILT ER THE FLA M E PRESEN T INDICATOR

2) FILTER THE ERROR 12 -- WRONG VOLTAGE ERROR

0.03 RELEASED 1 2/ 05/94

-----------------------------

1) IN THE TOP DRY MODE WHEN AN ERROR OCCURS WHILE RUNNING -- EITHER COOL OR DRY TIME -- THE

TIMER IS SAVED AND AFTER

POWER OFF AND ON AND CORRECTING THE ERROR THE TIMER RESUME WHERE IT LEFT OFF.

YOU CAN CLEAR THE TIMER BY DEPRESSING THE INC AND DEC SWITCHES AT THE SAME TIME.

2

17

Page 18

2003 Top Dry Service School

PROGRAMMABLE DELAY FOR TOP DRY FANS *

The dry time and cool time " car r ots " on the display bot h f lash indicating -it is i n the program delay time m ode.--- NOTE: THIS CAN BE DONE ON THE

MASTER

0.01 RELEASED 1 0/ 11/94

-----------------------------

1) ADDED MODE TO ALLOW TOP DRY TO HAVE REMOTE PLUS 2 SLAVES

2) ADDED ERROR # 12 -- WRONG VOLTAGE ERROR

3) PUT REVISION LEVEL ON POWER UP SCREEN

* 4) IF THE START SWITCH IS HELD IN THROUGH THE POWER UP SCREEN -- TILL AFTER THE VERSION NUMBER DISPLAY -- ALL

SEGMENTS

LIGHT TO ENABLE EASIER DECAL ALIGNMENT. *

ORIGINAL RELEASE 9/29/94

-------------------------

18

Page 19

2003 Top Dry Service School

Series 2000 Batch Errors

* Dipswitch Settings

* Error Messages and solutions

* Operation TIps

GSI / Top Dry

and troubleshooting

19

Page 20

2003 Top Dry Service School

Configuration Dip

Switches (Normally Done

At Gsi)

These switches are used to configure the heater control for various

types of heaters.

Multiple heaters connected together

through the serial link.

Top Dry stand

alone with no remote display at the

bottom-dip switch

6 on/all others off.

Top Dry master

with a remote display at the bottomdip switch 6 & 7

on/all others off.

Top Dry master

with a remote display at the bottom

and one slave fan

heater-dip switch 6

& 8 on/all others

off.

Top Dry master

with a remote display at the bottom

and 2 slave fan

heater-dip switch

6, 7 & 8 on/all others off.

Top Dry remote

display at the bottom-dip switch 1 &

6 on/all others off.

Top Dry 2nd fan

heater-dip switch 2

& 6 on/all others

off.

Top Dry 3rd fan

heater-dip switch

1, 2 & 6 on/all others off.

20

The backside of the control board, showing the dip switch placement.

Page 21

2003 Top Dry Service School

Limit Switches

The following limit switch errors light up individually on

the heaters LCD screen:

PLENUM, HOUSING , V APOR, TEMP HI LIMIT

Multiple Heater Error Conditions

T wo or more heaters may be connected together through

the serial link. If the master cannot communicate with a

slave controller, the master will display "SLA" on the

main display and the "RX" "TX"

symbols will be flashing. If a limit switch error or one

of the error numbers 1 through 8 occurs, that error

is displayed on the slave where the error originates.

The master displays "SLA ERROR".

MISC ERROR NUMBERS

1 2 3 4 5 6

Plenum temperature probe 1

open

Plenum temperature probe 1

short

Grain temperature probe 2

open

Grain temperature probe 2

short

Airflow open

7 8 9 10 11 12

Illegal flame

sense

Error 7 is

most likely

caused by stuck

open solenoid.

Error 7 will not

shut down fan

until loss of

flame is detected

by control.

Flame probe

short error

Slave #1 inconsistent with master with either

the drying grain

flag or the LP

main solenoid or

cycle solenoidmost likely the

slave got reset

powering up

with the solenoids off

(Errors 9 through 11 are displayed only if multiple heaters are

tied together through serial link).

Note: Temperature sensor connection-the temperature sen-

sor (bolt) must always be connected to the master . In the case

of the Top Dry, both temperature sensors must be connected

to the master (unit at the top). Top Dry grain temperature

input is connected to J7 pins 14 and 18.

Slave #2

inconsistent

same as error 9

for slave #1

Slave #3

inconsistent

same as error 9

for slave #1

Airflow short

Wrong voltage.

Dip switch #5 is

the voltage selector switch. If

dip switch #5 in

"ON" that selects 240 VAC. If

the unit has only

120 V AC applied,

error 12 will

show up. If dip

switch #5

is"OFF" that selects 120 VAC. If

the unit has 240

V AC applied error 12 will show

up.

This is important because

if the fan heater

is set up at GSI

for 120 VAC and

the customer

connects to 240

VAC the heater

control will work,

but if allowed to

operate the solenoids will have

240 VAC applied

to them which

will damage solenoids.

21

Page 22

2003 Top Dry Service School

Error Details

Error #1 Plenum T emperature Probe Open. The two wires for checking this error are on terminals 24 and

25 they are labeled J7-12 and J7-13. The wires must be removed from the terminals to receive a correct

reading. This must be checked with a Ohm Meter . If the probe is open you will not receive any reading on

your meter because there is no continuity between the wires. It is like you cut the wire in half. If there is

resistance there is a certain resistance reading for current temperature of the probe. See Chart at the back

of this section to verify that the sensor is correct. If the sensor is correct you probably did not have a good

connection from one of your wires to the terminal strip.

Error #2 Plenum T emperature Probe Short. This error is indicating that the Plenum T emperature probe is

shorted. This will also need to be check with a Ohm meter and if it is shorted will read no resistance as if

you were checking both ends of one wire. Remember to disconnect the wires before checking.

Error #3 Grain T emperature Probe Open. This error is indicating the Grain T emperature Probe located in

the drying chamber on a leleveleveling band is shorted.. The terminals for checking the Grain T emperature

Probe are 22 and 23 and are labeled J7-14 and J7-18. The process for checking this error are the same as

in error #1. Remember to disconnect the wires from these terminals before checking them.

Error #4 Grain T emperature Probe Short. This error is indicating that the Grain T emperature Probe is

shorted. This is the same Probe as in error #3 and is checked like Error #2.

Error #5 Airflow Open. This error is indicating the airflow proving switch is in its open state and should be

closed verifying there is no airflow so the fan heater will start. This must be checked with a Ohm meter and

can be done directly on the airswitch terminals labeled N.O. And Common. This can also be checked on

the terminal strip between terminals 12 and 14. They are labeled J7-09 and J7-10. The Airswitch can

usually be adjusted and correct this error.

Error #6 Airflow Short. This error is indicating that the airswitch is stuck in both a normally open and

normally closed state and needs to be adjusted, cleaned, or replaced.

Error #7 Illegal Flame Sense. This error is indicating that there was a flame sensed at a time it should not

have. This is usually caused by a solenoid valve not closing properly . You can detect a solenoid not closing

properly by watching the pressure gauge on the gas train. After the unit cycles off the pressure gauge will not

drop immediately , it will gradually drop to zero or you can witch the flame and see if it is shutting off immediately or gradually burning out.

Error #8 Flame Probe Short. When this Error is given it can be either the flame probe is touching a metal

surface or The flame probe wire has shorted to ground somewhere. T o fix adjust the probe or replace the

wire to the to of it.

22

Page 23

2003 Top Dry Service School

W e use two (2) different types of sensors (NTC thermistor on the Series 2000, and an encapsulated

sensor on the E.M.C.S ) in our dryers. The resistance of the sensors varies according to the outside temperature.

For example, on the E.M.C.S. for every one (1) degree rise in temperature the resistance increases 4.8 ohms.

However, on the Series 2000 dryer , the sensor reacts just the opposite, the resistance rises with colder temperatures.

The charts displayed above will help when troubleshooting any sensor problems.

23

Page 24

Special Wire Terminals

p

2003 Top Dry Service School

SERIES 2000 BATCH TOPDRY TIPS

Operation Tips for Top Dry Batch

J7-10 or J7-13

Any unused third terminal on any network connector is also a 12 volt ground.

1. When ever you see 000 on the Screen there is an Error some where on the screen.

2. To F or ce a new time setting while the Dryer is runn ing Pus h the “Inc” (Up Arrow) and the

“Dec” (Down Arrow) keys at the same time

3. To change the Second Fan Start delay hold down the “Program Dry/Cool Timers” and “Program

Temperature”

keys and turn on the power switch. Note this must be done on the Master Fan and cannot be done of the

Slave

Fan or at the Remote Display.

4. Turning Dip Switch 3 ON disables the Air Flow monitoring function for testing. Remember to turn

OFF before

leaving the Dryer as loss of airflow will not shut down the dryer if the switch is left on.

5. You can select two modes for when the Drying Proces s stops.

A. Standard sett ing whic h will shut down if either Grain Temperature OR Dry Time is met.

B. Optional setting in which both Grain Temperature AND Dry Time must be met.

To change this setting use the followin g steps.

1. While holding the Program Key in turn Power switch on.

The Screen should read “0”

2. Release the Program button and press the “Inc” (Up Arrow ) key 3 time s.

The screen should read “3”.

3. Press the Program Button until you see “NoL” (Sta ndard se tting)

Press the “Inc” (Up Arrow) or “Dec” (Down Arrow) keys to change to “L”

on stand alone unit - 12 volt Ground for use with a tester.

“NoL” - Will s to p drying when meeting either the Time OR Temperature Settings.

“L” - Will stop drying only if both Time AND Temperat u r e S ett i n gs are met.

6. To Clear the NOVRAM

Hold down the Program key (lower left key) and power the unit up. When the “0” comes up Enter a “7”

with the

Increment key (Up Arrow) and then push the Program Key again. When the “--- “ comes up you have 2

Seconds

to depress the “Inc” (Up Arrow) and “Dec” (Down Arrow) keys at the same time.

(Do not do this unless you are told to or are at a last resort to fix inconsistent behavior of the board)

7. When an Error shuts down the Dryer you can determine how long ag o the shutdown occurred by

ushing the

“Dec” (Down Arrow) Key. It will read in hours with a maximum of 218 (9.1 days).

8. Drying Time has a minimum setting of 10 minutes no matter what time is set.

24

Page 25

2003 Top Dry Service School

11. DIP Switch Settings (Turn on Switches named and leave all others off)

Top Dry Master

Stand Alone - No Remote Display 6 ON

With Remote Display 6 & 7 ON

Top Dry Master with Slave

With or Withou t Remote Dis pla y 6 & 8 ON Slave 2 and 6 ON

Top Dry Master with 2 Slaves

With or With out Re m ote Displa y 6,7 & 8 ON First Slave 2 & 6 ON Second Slave 1,2 &6 ON

Top Dry Remote Display

12.

Temperature Sensor Testing

A. You can find charts with the Resistance readings at various Temperatures in the following manuals

Located in

PNEG-630 Portable Dryer – Trouble Shooting Fe b 1999. pdf

PNEG-377 Fan & Heater – Service Manual Feb 2000.pdf

The Batch Top Dry’s use the Thermister type sensors, the bolt st yle for the Plenum and the Grain Temperature.

You have to disconnect the wires before testing. Check the charts listed above for readings at othe r te m p eratures.

Resource 2002 CD

in the “

Resources – Manuals

1 & 6 ON

” Folder

Page 54

Page 50

(Portable Dryers | Trouble Shooting – Oper ating Tips)

(Fans and Heaters | Trouble Shooting Guide)

10-15-02

1.

25

Page 26

Series 2000 Autoflow Errors

and troubleshooting

* Error Messages and solutions

* Operation tips

2003 Top Dry Service School

GSI / Top Dry

26

Page 27

2003 Top Dry Service School

Error Messages

When the dryer shuts down the user can

quickly determine what caused the shutdown by

viewing the display on the dryer control panel. The

Electronic Monitoring Control System displays the error

message and sounds a warning signal to alert the user.

The displayed error conditions and their electrical cause

are as follows:

Burner 1 Loss Flame

The flame sensor in burner number one has

failed to detect flame. Either the burner failed to light

or the flame sensor needs to be adjusted. The flame

sensor is the sensor attached to the burner, and has a

single lead. If the burner is lighting but the unit is still

shutting down due to loss of flame the flame sensor

needs to be adjusted. The flame sensor can be adjusted

by bending it so it is immersed in flame. If the burner is

not lighting make sure that the dryer is getting fuel, all

solenoids are opening, and the ignitor is sparking.

Burner 2 Loss Flame

and automatically resets itself when cool. The vaporizer is adjusted by loosening the bolt and moving the

vaporizer coil away from the flame.

Fan 2 V apor High Limit

The LP gas vapor temperature sensor located

on the gas pipe train downstream from the vaporizer

coil on fan and heater number two has opened indicating that the vaporizer coil is running too hot and must be

adjusted. This sensor is set at 200 degrees Fahrenheit

and automatically resets itself when cool. The vaporizer is adjusted by loosening the bolt and moving the

vaporizer coil away from the flame.

Fan 1 Housing High Limit

The temperature high limit located on the

housing on fan and heater number one opened, indicating that the housing towards the bin has overheated.

This high limit sensor is set at 200 degrees Fahrenheit

and must be manually reset.

The flame sensor in burner number two has

failed to detect flame. Either the burner failed to light

or the flame sensor needs to be adjusted. The flame

sensor is the sensor attached to the burner, and has a

single lead. If the burner is lighting but the unit is still

shutting down due to loss of flame the flame sensor

needs to be adjusted. The flame sensor can be adjusted

by bending it so it is immersed in flame. If the burner is

not lighting make sure that the dryer is getting fuel, all

solenoids are opening, and the ignitor is sparking.

Fan 1 V apor High Limit

The LP gas vapor temperature sensor located

on the gas pipe train downstream from the vaporizer

coil on fan and heater number one has opened indicating that the vaporizer coil is running too hot and must be

adjusted. This sensor is set at 200 degrees Fahrenheit

Fan 2 Housing High Limit

The temperature high limit located on the

housing on fan and heater number two opened, indicating that the housing towards the bin has overheated.

This high limit sensor is set at 200 degrees Fahrenheit

and must be manually reset.

Plenum High Limit

An over temperature condition has occurred

inside the dryer plenum. The plenum high limit is set

automatically on the Hi-lo thermostat when the cycle

set-point is adjusted and resets automatically when

cooled. The lo-fire gas pressure needs to be lowered,

or the cycle setpoint on the Hi-lo thermostat needs to be

increased if the error is displayed frequently .

27

Page 28

2003 Top Dry Service School

Fan 1 Motor Overload

The thermal overload in the control box on fan

number one has tripped, indicating an overcurrent

condition. The overload must be reset manually .

Fan 2 Motor Overload

The thermal overload in the control box on fan

number two has tripped, indicating an overcurrent

condition. The overload must be reset manually .

Fan 1 Loss Of Airflow

The contacts on the airswitch, located in the bin

sidewall and attached to fan and heater number one,

have opened due to the fan not turning, or the airswitch

may need to be adjusted.

Drying Chamber Overflow

Bin Grain High Limit Full

The grain level in the storage chamber has

reached the storage chamber high level rotary switch

located 3 feet below the fan and heater(s). Grain will

have to be removed from the storage chamber before

the unit can be restarted.

Bin High Limit Switch Bad

The storage chamber high level switch has

failed. Both the normally open and the normally closed

sides of the switch are in the same state.

Out Of Grain

The out of grain timer has ran for longer than it

was set. Either you are out of grain or the fill system is

filling to slow .

The grain level in the drying chamber has

reached the drying chamber overflow rotary switch.

Grain will have to be dumped from the drying chamber

to the storage chamber before the unit can be restarted.

This error indicates that either the drying chamber high

level rotary switch is faulty or the time on the Load

delay or Aux. 1 delay needs to be lowered.

28

Page 29

2003 Top Dry Service School

W et Supply Empty Press <Enter> T o Dry Re-

maining Grain

Fill 1 Motor Overload

This message is displayed when the start button

is pushed and grain has fallen away from the wet

supply rotary switch and there is still grain against the

drying chamber low level rotary switch. If the enter

button is pushed the dryer will restart, but the fill

system(s) will not restart.

Cannot Start Dryer Wet Supply Empty

This message is displayed when the start button

is pushed and grain has fallen away from the wet

supply rotary switch and there is no grain against the

drying chamber low level rotary switch. Grain will have

to be put into the wet supply tank or the drying chamber

to start the dryer.

Low Level Switch Exposed

This message is displayed when grain falls

away from the drying chamber low level rotary switch

after the Wet Bin Switch Delay has reached zero. If

the error is being caused due to the settling of grain

after the fans start the time on the Wet Bin Switch

Delay can be lengthened.

The thermal overload in the fill system control

box for fill system number one has tripped, indicating an

overcurrent condition. The overload must be reset

manually .

Fill 2 Motor Overload

The thermal overload in the fill system control

box for fill system number two has tripped, indicating an

overcurrent condition. The overload must be reset

manually .

Aeration Overload

The thermal overload in the fill system control

box for the aeration fan has tripped, indicating an

overcurrent condition. The overload must be reset

manually .

Grain High Limit

The grain temperature in the drying chamber is

too high. The grain temperature reached a point where

it was five degrees less than the plenum cycle setpoint.

29

Page 30

2003 Top Dry Service School

b

p

Network Autoflow Tips

Present Version Numbers: Display 2.15 Heater 1.09 IO 1.07

Note: Disp lay version 2.14 and 2.15 will not work with Heater version 1.10 you must us e ve rs ion

1.09.

Important Software and Troubleshooting tips

Special Wire Terminals

for use with a tester.

1. When ever you install a new display board. After you flash the software in and restart you may see an

ERROR Message with some garbage characters or a negative number for temperature such as -2785

degrees. Do a Hard Boot by holding the Reset key and turn ing the power on to correct this stuck register

value.

2.

Always do a Hard Boot after ins t alling a new Dis play board.

3.

If you have a blank or all black screen see the Contrast Adjustment in Tip #1

4. Also when flashing new software to the IO Board turn off the load auger breaker(s). Due to a design

characteristic th e load auger(s) will run w h enever the IO b o ard is being f l as h ed.

5. If the Fan motors run, but the augers and aeration fan do not, make sure the 110 volt breaker on the IO

oard is turned on.

6. The newest Display boa rds (5/1/ 02)ca n now be used on e it her a Topdry or Po rta ble Dr yer. In the past a

Dryer Display board

had to have wires soldered in place for the Meter Roll Speed Pot and they can also be used on either a

Top Dry or Portable

Dryer. The past Top Dry Display board without these wires cou ld be used on a Top Dr y only. The

newest boards now have a

six pin connector that the Dryer Meter Roll Speed Pot is connected to.

7. If you get a plenum High Limit Error on startup w ith a new system or after installing new software on a

Two Fan Top Dry

check to see if a jumper from J7-3 to J7-15 fixes it.

8.

Grain Temperature Sensors

the flat of the floor.

- The third unused terminal on any network connector is a 12 V ground

are 10 ½” from the top of the floor rib. Older Top Drys were 14” from

Version Specific changes

Version 2.15 See separate Sheet at page 3 for subst ant ial changes in operation.

Version 2.14 1. Extended Setup is now accessed by holdi ng down the Modify key while

powering up

2. Low limits were set. 150 degrees for Grain High limit and 200 degrees for Pl enum

High limit.

Version 2.11

will be en ter ed.

The fan will run and cool the grain for

Full error.

When grain leav es the

out of grain error .

When the

stopping.

Version 2.06

Version 2.04

present

existing Plenum Air Switch.

Version 2.03

Version 1.02

to insure th at a switch

failure has not taken

1.

When grain reaches the Storage Chamber Rotary Switch

10 minutes

Wet Supply Rota ry Switch

Dry & Hold switch

Sto pped t he ab ility to change the grain setpoint from heaters.

Made all air switches active once again. New venturi Air Switches must be

on each fan where more then one fan is in use. Single Fan systems can cont inue to use the

The user can no longer go into

Release Date Jan of 98 the Bin High L imit rotary sw itch is now monitored in bo th sta tes

lace. If both switches are in the same state a switch failure is reported.

is placed in th e " O n " p osition the fan w ill Cool for

before shutting down due to a Storage Chambe r

. The fan will cool for

Extended Set Up

while the dryer is running.

a "Cool Down M o de"

10 minutes

before giving

20 minutes

before

30

Page 31

2003 Top Dry Service School

p

8)

Bin Hig h Pressure Limit

and give an indication

that the bin is full due to th e high level of static pressure within. "

be displayed on

screen's top line until the user corre cts the problem. (Originally looked for lack of 12v, reversed in

2.00)

9) There is a

Total time allowing

intermediate mo nitoring of batches and time. You

Key. You

Hour Meter

10)

Master & Slave Fan & Heater Dipswitch Setting s

Pg 42 Fan 1 (Master) #1 OFF / All others ON

Pg 50 Fan 2 (Slave 1) #2 OFF / All others ON

Pg 51 Fan 3 (Slave 2) #1 & #2 OFF / All others ON

Information above from PNEG -900 included in the CD in the Top Drys/Top Dry Fans & Htrs

Operation Charts folder as

99 Series 2000 AutoFlow - Insta lla ti on Pneg-900 July 1999.pdf

11)

Temperature Sensor Testing

1. You can find charts with the Resistance readings a t various Tempe r a tures in the following

manuals

Located in

PNEG-630 Portable Dryer – Trouble Shooting Feb 1999.pdf

Shooting – Operating Tips )

PNEG-377 Fan & Heater – Service Manual Feb 2000.pdf

Shooting Guide)

The Network Top Dry’s use the Thermiste r type senso rs , the bolt style for the Plenum and for the

Grain Temp erature.

You have to disconnect t he wires be fore tes ti ng. Che ck the charts listed above for readings at other

temperatures.

User Batch Count and User Timer or Hour Meter

Reset the User

by holding in the “

Resource 2002 CD

. The application of 12v to terminal number

BIN AIR PRESSURE LIM

independent from the Total batch and

Reset the User Batch

” key while turning on the “

Hours

in the “

Resources – Manuals

” Folder

Page 54

Page 50

Control Power

(Fans and Heaters | Trouble

will shutdown the dryer

J2-20

" will

Count from the “Setup”

”.

(Portable Dryers | Trouble

11)

SETUP

As of Software version 2.14 extended setup is reached by holding down the Modify key while

owering up.

A)

1) S et t he Clock.

2) Enable/Disable Air Switches. Disable f or adj us tment purposes only.

3) Enable/Disable Low Level Test. Enab le to ignore low level

4) Enable/Disable Wet Tank Test. Enable to run wi th no g r ain in Wet Tank.

5) Choose to start with fans on high or low. Low for US & Canada, High for Europe. (Did not

work until 2.15)

6) Aeration Fan Bypass Selection. When bypassed Fan does not shut down when Top Dry shuts

down.

7) Setup fill systems. One or Two Auger System.

8) Select type of dryer. AF1 = 1 fan or AF2 = 2 fan (Auto Flow) AB1 or AB2 (Auto Batch)

9) Select Temperature Scale - Fahrenhe it or Centigrade.

10) Select burner ON/OFF or HI/LO.

11) Select diesel burner.

Default = 20

Default = 30

– What can be changed and the order they show up on the screen. (See 2.15 for changes)

EXTENDED SETUP

12) As of Version 2.15 The Plenum High L imit is adj us tab le from 10 to 50 deg. above setpoint.

13) As of Version 2.15 The Grain High Limit i s adjus ta ble from 10 to 50 deg. above se tpoint.

: (Control Circuit must be off to access prior to version 2.14)

31

Page 32

Version 2.15 Changes

p

b

2003 Top Dry Service School

New Features

1.

Out of Grain Timer

time and shuts down the Top Dry, goes throug h the “Cle anout” of the Augers procedure and then gives an “

Warning. Default setting is 20 minutes . The “Load” switch “ON” position works exactly like “Auto” but ignores the Timer.

– Located under the “

” key. This Timer monitors how long the Load system runs inc luding delay

Setup

Out of Grain

”

2.

The High Limits on the Grain and Plenum Temperatures

oints that a “

above the set points. Both are settable from 10 to 50 degrees . These set ting s are acce sse d by turning on the “

while holding down the “M

determined there is no fire hazard. This in effect gives the system an “

3. The

the Top Dry and display of the “

variations in where the switch needs to be loca te d for differences in the moisture of the incoming grain. The New Out of Grain

Timer will make this De lay less likely to be used however.

4. Implemented the “

functional.

Grain or Plenum High Limit

odify

Wet Bin Rotary Switch

Start Fans with High

” key, in the

now has a

Wet Bin SW Exposed

” Warning will be displayed. Defaults are 30 de grees for the Gr ai n and 20 degree s

Extended Setup

Delay Setting

” Warning after grain no longer covers the switch. This is to allow for

” feature th at was previously listed in th e “

are now settable. User selects how many degrees above the set

Con trol P ower

, so they can be re set to allow op er ation after the User has

Emergency Cooling

accessed f r o m the “

Delay

” capability.

” Key. This will delay the shutting do wn of

Extended Setup

” list but was not

”

Changed Names

1. “

Fan Delay

start but also the time between when any Fan or Loa ding Moto rs star t.

2. When the

Chamber Empty

3. When the

4. The Delay f o rmerly called the “

Drying Chamber Low level Sw itch is now called the “

” is now “

Drying Chamb er Low Level Rotary Switch

Wet Bin Rotary Switch

Motor De lay

”.

” to better describe the fact that the delay not only delays the time between when the Fans

is exposed it will now say “

Out of Grain

” Delay which delayed the shutting down of the system if grain came off the

Lo level SW

is exposed it will now say “

Wet Bin SW Exposed

” Delay.

Lo Level SW Exposed

” not “

Dryer out of Grain

” not “

Dry

”

5. Under the

that were described as “

and Disabled means it is not monitored.

A. AIRSWITCH - Enabled means you will get a shutdown when a fan loses airflow. Disabled will satisfy the dryer's airflow

requirements for the burner regardle s s of the actua l a ir switc h state.

B. LOW LEVEL SWITC H - E n ab led means the d r y ing chamber lo w level switch w ill act as normal, i.e, w ill indicate the real

state of the rotary sw itch and will s hu t d o w n after the user set delay when u ncovered . When disabled the dryer will think the low

level switch is always covered.

C. WET TANK SWITCH - Enabled means this switch will act as normal, shutting down the system when uncovered.

Disabled means the dryer will think thi s switc h is always covered with grain.

D. START FANS WITH HIGH - Enabled means the dryer will star t fans according to stat e of d r ying cham ber h i level switch.

Disabled means dryer will star t according to drying chamber low level switch.

E. AERATION FAN BYPA SS - Enabled means the BYPASS is on an d th e Fan will run whenev e r th e “Cont r o l Power”

switch is tur ned on.

Extended Setup

accessed by holding down the “

” are now named as just the Switch itse lf . En abling the sw itch means it is monitored b y the System

Tests

Modify

” key while tu rn ing on the “

Con trol P ower

” those ite ms

Simplifications & Improvements

1. In the Auto Flow Mode the “

2. Instead of using a different name for the Delay which affe ct s the Dryin g Chamber Low Level Rotary Switch depending on

whether the system is set for a 1 fill or 2 fill system it will always be called “

3. Instead of Delay, that affects when the Fill 1 load sy s tem s tops in a 2 fill system , c hangi ng nam e s and com ing up on screen

when a 1 fill system has been set it will only show up when a 2 fill sy stem has been set and will be called “

4. The amount of time the Delays and other setting s sta y on the screen be fore movi ng to th e next has been doubled.

Refill Timer

” and “

Time until load off

” Batch only screens will not show up.

Hi Level SW

” Delay.

Fill System #1

” Delay .

5. The Cool Down feature which runs after an “

after t he system stop s because the “

een set for.

10-16-02

32

Stop and Hold

Out of Grain

” switch has been turned on, now Cools for whatever t ime the Coo l Tim er has

”, “

Storage Bin Full

” or “

Wet Bin SW Exposed

” shutdown or

Page 33

2003 Top Dry Service School

Software Diagnostics

* Series 2000 Batch Fan & Heater

* Series 2000 Autoflow Display

* Series 2000 Autoflow Fan & Heater

GSI / Top Dry

33

Page 34

2003 Top Dry Service School

Series 2000 Batch Fan / Heater

Initializing the Novram

• Turn the Control Power “ off “.

• Hold down the Program T emperature

switch.

• Turn the Control Power switch “on “

with the Program T emperature switch

held down.

• Press the Increase switch until 7 is on

the display .

• Press the Program T emperature switch

again.

• Y ou have two seconds to depress the

Increase or Decrease switches at the

same time.

• The NOVRAM has been initialized.

NOTE: The computer has now been cleared of all

memory , including the type of dryer it is and all

Set-up variables.

34

Page 35

2003 Top Dry Service School

Series 2000 Batch Fan / Heater

Programming Set-up Variables

• Turn the Control Power “ off “

• Turn the Control Power switch “ on “

with the Program T emperature switch

held down.

• Press the Increase switch until 3 is on

the display .

• Press the Program T emperature switch

again.

•C or no C will bill displayed.

• Use the Increase or Decrease switch to

toggle between C or no C.

C - Hi-Lo cycling heater

no C - On/Off cycling heater

• When the correct selection is on the

screen press the Program T emperature switch again.

•H or no H will be displayed.

• Use the Increase or Decrease switch to

toggle between H or no H.

H - Humidity sensor present

no H - No humidity sensor

present

• When the correct selection is on the

screen press the Program T emperature

switch again.

•F or C will be displayed.

• Use the Increase or Decrease switch to

toggle between F or C.

F - T emperatures displayed in

Fahren- heit.

C-T emperatures displayed in

Celsius.

• When the correct selection is on the

screen press the Program T emperature

switch again.

•L or no L will be displayed.

• Use the Increase or Decrease switch

to toggle between L or no L.

L - The dryer will advance to

the Cool cycle when the Dry

timer has reached zero and the

Grain temperature set point

has been met.

noL - The dryer will advance

to the Cool cycle when either

the Dry timer has reached zero

or the Grain temperature set

point has been met.

• When the correct selection is on the

screen press the Program T emperature

switch again.

35

Page 36

2003 Top Dry Service School

Series 2000 Batch Fan / Heater

CAUTION: DO NOT A TTEMPT BELOW PROCEDURE WITH GAS LINE CONNECTED.

Diagnostic Mode

• Turn the Control Power “ off “.

• Hold down the Program T emperature switch.

• Turn the Control Power switch “on “

with the Program T emperature switch

held down.

• Press the Increase switch until 8 is on

the display .

• Press the Program T emperature switch

again.

• Press the Program Dry time switch to

engage the Fan starter-Fan will be

displayed.

• Press the Increase switch to make the

ignitor spark-IN will be displayed.

• Press the Program T emperature switch

to open the LP and Main Solenoid- LP

will be displayed.

• Press the Start switch to open the

Cycle solenoid -CS will be displayed.

• Turn the control power “off” to exit

the Diagnostic mode.

36

Page 37

2003 Top Dry Service School

Series 2000 Autoflow Display

Keypad Test

• Turn the Control Power “of f”.

• Turn the Control Power switch “on”

with the Help Switch pressed.

• The Keypad Switches can now be tested.

Control Switch Tests

• Turn the Control Power “of f” .

• Turn the Control Power switch “on”

with the Plenum and Grain Switches pressed.

• The Control Switches can now be tested.

37

Page 38

2003 Top Dry Service School

Series 2000 Autoflow Fan / Heater

CAUTION: DO NOT A TTEMPT BELOW PROCEDURE WITH GAS LINE CONNECTED.

Diagnostic Mode

• Turn the Control Power “ off “.

• Hold down the Program T emperature switch.

• Turn the Control Power switch “on “

with the Program T emperature switch

held down.

• Press the Program Dry time switch to

engage the Fan Starter.

• Press the Program T emperature switch

to start theIgnitor.

• Press the Hours x 1000 switch to open

the Ssolenoid.

• Turn the control power “off” to exit

the Diagnostic mode.

38

Page 39

2003 Top Dry Service School

THE GSI GROUP , INC. ("GSI") WARRANTS ALL PRODUCTS MANUF ACTURED BY GSI TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE

AND CONDITIONS FOR A PERIOD OF TWEL VE MONTHS AFTER RET AIL SALE TO THE

ORIGINAL END USER OF SUCH PRODUCTS. GSI'S ONLY OBLIGATION IS, AND

PURCHASER'S SOLE REMEDY SHALL BE FOR GSI, T O REPAIR OR REPLACE, AT GSI'S

OPTION AND EXPENSE, PRODUCTS THA T , IN GSI'S SOLE JUDGMENT, CONT AIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVER Y AND SHIPMENT CHARGES TO AND FROM GSI'S F ACTOR Y WILL BE PURCHASER'S RESPONSIBILITY . EXPENSES INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR

WRITTEN AUTHORIZA TION FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE

SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY

OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH

(i) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A

PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR

BENEFITS. PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED

ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS

WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI

SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS WHICH

CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE PRODUCT

NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS

ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN

OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE REPONSIBILITY TO RESEARCH AND COMPLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION

39

Page 40

2003 Top Dry Service School

40

Loading...

Loading...