Page 1

Moisture Sampler

Installation Manual

PNEG-1283

Date: 10-09-09

PNEG-1 28 3

Page 2

2 PNEG-1283 Moisture Sampler

Page 3

Table of Contents

Contents

Chapter 1 Safety .................................................................................................................................................. 4

Safety Guidelines .......................................................................................................................... ... .. 4

Safety Instructions ..................... ... .... .......................................... ... ............................................. ... ... .. 5

Chapter 2 Decals ................................................................................................................................................. 6

Chapter 3 Installation ......................................................................................................................................... 7

Chapter 4 Parts List .......................................................................................................................................... 16

Moisture Sampler ............................................................................................................................. 16

Chapter 5 Assembly Instructions ......................... .................................................... ....................................... 18

Moisture Sampler Assembly (D04-0550) ............................... .... ... ... ... ... ....................................... ... 18

Moisture Sampler Update Kit (D04-0532) Assembly Instructions .................................................... 20

Chapter 6 Warranty ........................................................................................................................................... 21

PNEG-1283 Moisture Sampler 3

Page 4

2. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

WARNING! BE ALERT!

Personnel operating or working around electric fans should read this manual. This

manual must be delivered with the equipment to its owner. Failure to read this manual

and its safety instructions is a misuse of the equipment.

4 PNEG-1283 Moisture Sampler

Page 5

2. Safety

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating p rocedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation where SERIOUS INJURY or DEATH may occur.

PNEG-1283 Moisture Sampler 5

Page 6

3. Decals

If the decal used for this installation is damaged or is missing contact:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

WARNING

Automatically controlled

belt drive can start at

anytime. Keep hands

clear. Failure to do so

could result in serious

injury.

Decal DC-1944

Decal DC-1944 is located on the bottom auger belt guard

and the front bearing plate (which is visible when the bottom

auger belt guard is removed). An alternate location would be

at the rear of the dryer for portable dryers equipped with the

Front Discharge Option.

AVERTISSEMENT

La conduite

automatiquement

contrôlée de la courroie

peut démarrer à tout

moment. Gardez les

mains éloignées.

L’omission de faire ceci

pourra résulter à de

sérieuses blessures.

DC-1944

6 PNEG-1283 Moisture Sampler

Page 7

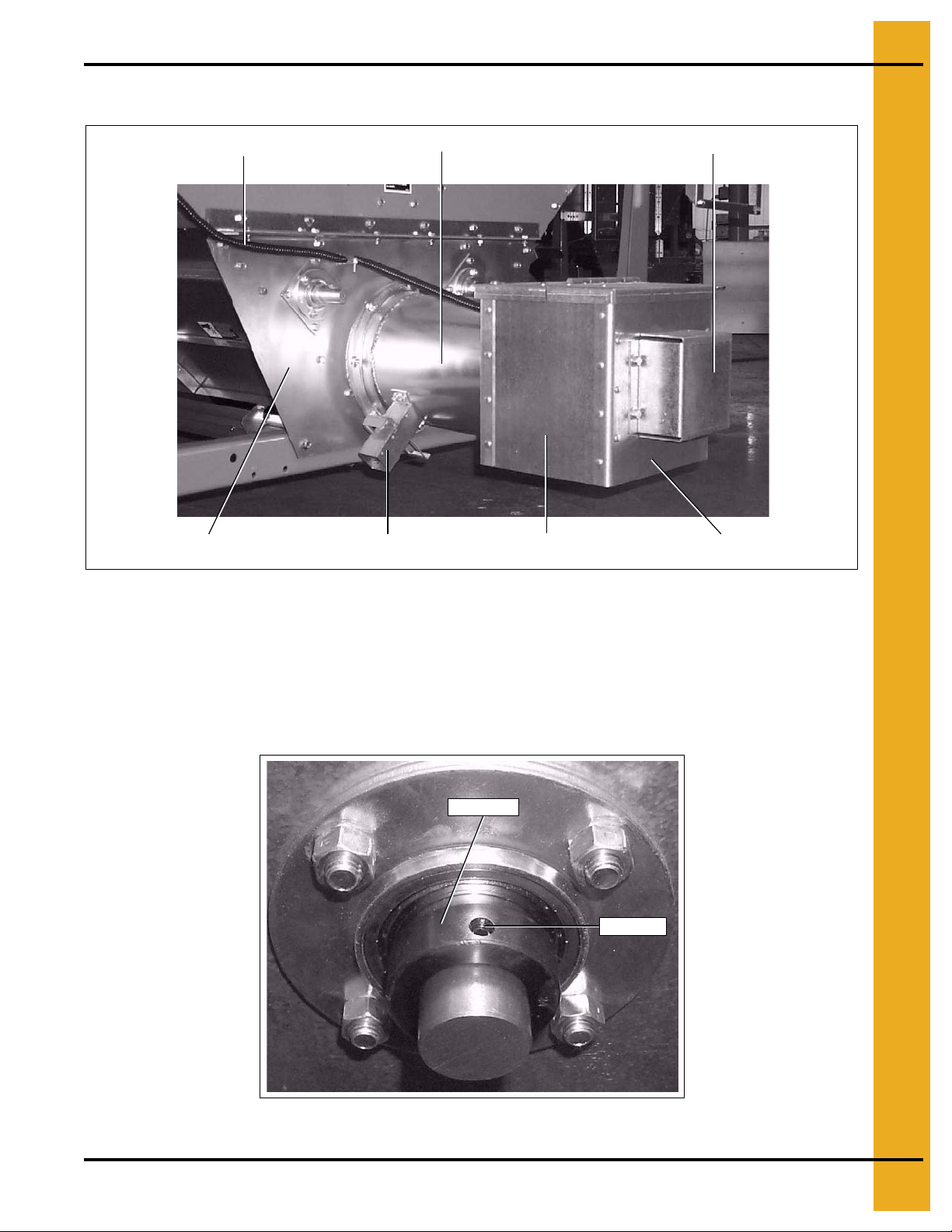

Installation Instructions for Dryers Made before September 2002

4. Installation

Discharge switch conduit

Unload auger bearing plate

Auger tube

Standard grain sampler

Figure 4A

Discharge side panel

Auger bearing shield

Discharge box bearing plate

1. Remove the auger bearing shield. (See Figure 4A.)

2. Remove the lock collar from the auger shaft. (See Figure 4B.) To remove the lock collar loosen the

set screw and then locate the dimpled hole on the side of the lock collar. Using a hammer and

punch, set the punch in the dimpled hole and hit it in a clockwise direction until the lock collar is

freed from the bearing.

Lock collar

Set screw

Figure 4B

PNEG-1283 Moisture Sampler 7

Page 8

4. Installation

3. Disconnect the tilt switch and remove conduit from the discharge box. (See Figure 4C.)

Tilt switch

Figure 4C

4. Remove the discharge box assembly from the dryer by removing eight (8) 5/16" bolts, then sliding

the discharge box off the discharge auger.

5. Remove the standard grain sampler from the discharge box assembly auger tube.

6. Hold the Moisture Sampler assembly up to the side of the discharge box assembly. Square the

drive end of the Moisture Sampler with the overlapping edge of the discharge bearing plate and

the bottom edge of the discharge side panel. (See Figure 4D.) Mark the location of the three (3)

bolt holes.

Discharge bearing plate

Discharge side panel

Square up here

Figure 4D

7. On the discharge side plate at the drive end of the Moisture Sampler drill three (3) 3/8" holes at the

marks made in Step 6.

8. Using a sheet of paper make a template of the back side of the mounting plate on the drive end of

the Moisture Sampler. Use this template to mark the square hole in the discharge side panel.

Including the three (3) bolt holes in the template will help to ensure correct hole alignment.

9. Cut out the square hole marked out in Step 8.

8 PNEG-1283 Moisture Sampler

Page 9

4. Installation

10. Now put the Moisture Sampler assembly up to the discharge box again and put in the 5/16" bolts

and nuts and tighten just enough to firmly hold Moisture Sampler in place. Use a marker and mark

the four (4) holes at the sensor end of the assembly as shown in Figure 4E. Also mark the square

hole inside the sample tube as shown in Figure 4E.

Mark and cut square hole

Mark and drill holes with a

5/16" drill bit

Figure 4E

11. Remove the Moisture Sampler again and drill the four (4) bolt holes at the sensor end with a 3/8"

drill bit and cut out the square hole marked out in Step 10.

PNEG-1283 Moisture Sampler 9

Page 10

4. Installation

12. Install Moisture Sampler discharge cover (D01-2305-8) in top two (2) holes drilled in the box end

using 5/16" bolt (S-6606). (See Figure 4F.)

Moisture sampler discharge cover

Figure 4F

13. Now install the Moisture Sampler over the two (2) bolts used to install the Moisture Sampler

discharge cover in Step 12 and install remaining 5/16" bolt (S-6606) and n uts (S-3611) in the bottom

hole (do not tighten hardware yet). Attach the sensor end using 5/16" bolts (S-8135) and nuts

(S-3611) making sure that the heads of the bolts are on the inside of the discharge box tube. Now

tighten all seven (7) bolts attaching the Moisture Sampler.

14. Remove the four (4) bolts and lock nuts that hold the auger bearing and flangette the discharge box

bearing plate. Flip the auger bearing so that the outside is now the inside, then re-install bearing

flangette and hardware.

15. Before re-installing the discharge box slide the bearing lock collar onto the auger shaft with the

locking side of the collar facing the rear end of the auger shaft.

16. Now slide the discharge box/Moisture Sampler assembly over the auger and re-attach to the

discharge bearing plate on the dryer.

17. Engage the lock collar with the auger bearing and with a hammer and punch strike it in a clockwise

direction to set it with the bearing, then tighten set screw.

10 PNEG-1283 Moisture Sampler

Page 11

Flangette

4. Installation

Auger shaft

Lock collar

Bearing

Discharge box

bearing plate

Figure 4G

18. Install sheave (018-1047-2) and bushing (D32-0016) on the bottom auger shaft that extends

through the discharge box. The key that comes with the bushing is not needed fo r this installation.

Slide bushing into the sheave (leave loose, do not force the bushing in). Slide sheave and bushing

onto the auger shaft. Insert bushing bolts through the non-threaded holes of the bushing (thread ed

holes are for bushing removal) and thread into the holes of the sheave. Tighten bolts evenly until

bushing is snug against the auger shaft but still loose enough to slide on auger shaft so that its

position can be adjusted in a later step.

Figure 4H

PNEG-1283 Moisture Sampler 11

Page 12

4. Installation

19. To install the Moisture Sampler drive belt, loop the belt over one of the sheaves and the stretch it

over the other one. Belt direction is marked with an arrow on belt. If necessary remove any belt

links. After the belt is installed the sheave on the auger shaft can be adjusted forward or back for

proper belt alignment. The slot in the end plate can be used t o tension the belt. When eve rything is

aligned tighten the auger shaft sheave and any other hardware left loose.

Figure 4I

20. Install the belt guard using four (4) 3/8" bolts (S-7927) and nuts (S-968).

Bolt locations for belt guard

4 ea. 3/8"-16 x 1" bolt (S-7927)

4 ea. 3/8"-16 nut (S-968)

Figure 4J

12 PNEG-1283 Moisture Sampler

Page 13

4. Installation

Installation Instructions for Dryers with New Discharge Box Assembly

Moisture sampler

cover plate (D01-1885)

Standard grain sampler

Moisture sampler tube

cover plate (D01-1886)

Figure 4K

1. Remove the Moisture Sampler tube cover plate (D01-1886). (See Figure 4K.)

2. Remove the Moisture Sampler cover plate (D01-1885). (See Figure 4K.)

3. Install the Moisture Sampler using three (3) 5/16" bolts (S-8135) and nuts (S-3611) on the drive end

and four (4) 5/16" bolts (S-8135) nuts (S-3611) on the sensor end making sure the heads of the

bolts are on the inside of the auger tube.

PNEG-1283 Moisture Sampler 13

Page 14

4. Installation

Sensor end

4 ea. 5/16"-18 x 1-1/4" bolt (S-8135)

4 ea. 5/16"-18 nut (S-3611)

Figure 4L

4. Complete Steps 18-20 starting on Page 11.

Drive end

3 ea. 5/16"-18 x 1-1/4" bolt (S-8135)

3 ea. 5/16"-18 nut (S-3611)

14 PNEG-1283 Moisture Sampler

Page 15

NOTES

PNEG-1283 Moisture Sampler 15

Page 16

5. Parts List

Moisture Sampler

11

13

9

12

4

16 PNEG-1283 Moisture Sampler

Page 17

5. Parts List

Moisture Sampler Parts List

Ref # Part # Description Qty

1 017-1451-8 Sheave, AK46H 4.2 PD 1

2 D03-0845 Bearing, Spherical Flange Mounted 5/8" 2

3 D04-0530 Moisture Sampling Auger Assembly 1

4 D01-1888 Moisture Sampler Belt Guard 1

5 D01-1944-8 Moisture Sampler Weldment IV 1

6 D01-1871 Moisture Sampler End Plate Three (3) Hole 1

7 D01-2337 Moisture Sampler Lid III 1

8 D01-2338 Moisture Sampler III End Plate Two (2) Hole 1

9 FH-4429-1 Latch, Control Box 5

10 FH-5536 Bushing, 5/8" Bore Browning H 019-1040-5 1

11 018-1047-2 Sheave, AK32H 1

12 D01-2305-8 Moisture Sampler Discharge Cover 2008 1

13 D32-0016 Busing, H 1-1/2" Split Taper 1

14 S-2041 Split Lock Washer, 1/4" ZN 9

15 S-1101 Bolt, HHCS 1/4"-20 x 1/2" ZN Grade 2 5

16 S-1102 Hex Nut 1/4"-20 ZN Grade 2 9

17 S-1429 Bolt, HHCS 1/4"-20 x 3/4" ZN Grade 2 4

18 S-8426 Square Key, 3/16" x 1" Long 1

19 S-8472 Screw, TCSF #8-32 x 3/8" HWHS ZN 14

20 S-3611 Flanges Nut 5/16"-18 YDP Grade 2 5

21 S-4276 Bolt, HHCS 5/16"-18 x 1-1/4" ZN Grade 5 5

22 3FH1201 Latch, Tension, Reg. Base. Zinc 2

N/A DC-1944 Decal, Belt Drive Warning, CE, CSA Harm 2

N/A D03-0861 V-Belt, 4L 280 3'

N/A PNEG-1283 Moisture Sampler Installation Manual 1

PNEG-1283 Moisture Sampler 17

Page 18

6. Assembly Instructions

Moisture Sampler Assembly (D04-0550)

See Page 19 for additional details.

Ref # Part # Description Qty

1 D01-1944-8 Moisture Sampler Weldment IV 1

2 FH-4429-1 Latch, Control Box 5

3 D01-2337 Moisture Sample Lid III 1

4 D01-2338 Moisture Sampler III End Plate Two (2) Hole 1

5 D01-1871 Moisture Sampler End Plate Three (3) Hole 1

6 D04-0530 Moisture Sampling Auger Assembly 1

7 D03-0845 Self-Aligning Bearing, 5/8" I.D. 2

8 FH-5536 Bushing, 5/8" Bore Browning H 019-1040-5 1

9 3FH1201 Latch-Tension, Reg. Base. Zinc 2

10 017-1451-8 Sheave, AK46H 4.2 PD 1

2. D01-1888 Belt guard to be included but not shown.

3. HDW-1945-8 Moisture Sampler hardware to be included but not shown.

4. S-8426 to be placed in slot between shaft on D04-0530 and FH-5536.

5. S-8472 (14) to fasten FH-4429-1 and 3FH1201 latches to D01-1944-8.

6. Place S-4276 (5) and S-3611 (5) in FH-4429-1 latches.

7. S-1101 (5), S-2041 (5) and S-1102 (5) to fasten D01-2338 and D01-1871 to D01-1944-8.

8. S-1429 (4), S-2041 (4) and S-1102 (4) to fasten D03-0845 bearings to D01-2338 and D01-1871.

NOTE: 1. DC-1944 to be placed on top of D01-1944-8.

18 PNEG-1283 Moisture Sampler

Page 19

6. Assembly Instructions

Moisture Sampler Assembly (D04-0550) (Continued)

Ref # Part # Description Qty

1 D01-1944-8 Moisture Sampler Weldment IV 1

2 FH-4429-1 Latch, Control Box 5

3 D01-2337 Moisture Sample Lid III 1

4 D01-2338 Moisture Sampler III End Plate Two (2) Hole 1

5 D01-1871 Moisture Sampler End Plate Three (3) Hole 1

6 D04-0530 Moisture Sampling Auger Assembly 1

7 D03-0845 Self-Aligning Bearing, 5/8" I.D. 2

8 FH-5536 Bushing, 5/8" Bore Browning H 019-1040-5 1

9 3FH1201 Latch-Tension, Reg. Base. Zinc 2

10 017-1451-8 Sheave, AK46H 4.2 PD 1

PNEG-1283 Moisture Sampler 19

Page 20

6. Assembly Instructions

Moisture Sampler Update Kit (D04-0532) Assembly Instructions

To replace parts used on the D01-1945-8 Moisture Sampler assembly - Sold from 1/1/07 to 7/1/09

1. Begin by removing the belt guard, belt, Moisture Sampler lid, end plates, bearings, sampler auger,

and sheave, along with any associated hardware.

2. Assemble the bearings (D03-0845) to the end plates (D01-1871 and D01-2338) with the 1/4" bolts,

lock washers and nuts.

3. Mount the three (3) hole end plate (D01-1871) to the bottom of the Moisture Sampler body with the

1/4" bolts, lock washers, and nuts.

4. Insert the sampling auger (D04-0530) into the bearing on the three (3) hole end plate.

5. Insert the shaft at the top of the auger into the bearing on the two (2) hole plate (D01-2338) and

mount the plate to the Moisture Sampler body. Ensure that the slot in the two (2) hole plate is

closest to the discharge box.

6. Insert the shaft at the top of the auger into the split taper bushing (FH-5536) and place the square

key in the slot for both parts. Attach the sheave (017-1451-8) to the bushing with the bushing bolts.

Tightening these bolts will position the bushing and sheave on the auger shaft. Position such that

the sheave center is aligned with the unload auger pulley.

7. The belt is installed on the unload auger pulley and rolled onto the sheave. This belt can be

tensioned by tightening the bolt in the slot on the two (2) hole plate in the desired position. Ensure

that the belt is stretched tight.

8. Latch the lid (D01-2337) onto the Moisture Sampler body.

9. Drill two (2) 3/8" holes at a position 1" below the bottom g uard holes in the discharge box. Assemble

the belt guard (D01-1888) to the discharge box using the current top holes and the newly drilled

bottom holes.

20 PNEG-1283 Moisture Sampler

Page 21

7. Warranty

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive

components, shall be free from defects in materials for a period of time beginning on the twelfth (12

the date of purchase and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period).

th

) month from

During the extended warranty period, GSI will replace the frame or basket components that prove to be defective

under normal conditions of use without charge, excluding the labor, transportation, and/or shipping costs incurred in

the performance of this extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE

OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT,

SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user.

GSI shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer,

agent or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment

at initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the location

and installation of products manufactured or sold by GSI.

9101239_1_CR_rev7.DOC (revised July 2009)

PNEG-1283 Moisture Sampler 21

Page 22

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2009 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

Loading...

Loading...