Page 1

2002 Top Dry Service School

GSI / Top Dry

2002 Service School Manual

PNEG-1263

1

Page 2

2002 Top Dry Service School

Contents

Safety Pages..........................4

Product Updates...................5

Software Revisions..............10

Technical Data....................17

Software Diagnostics..........21

Warranty.............................27

2

Page 3

2002 Top Dry Service School

3

Page 4

Safety

2002 Top Dry Service School

Roof Damage Warning and Disclaimer

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM OR INTERNAL

PRESSURE FROM FANS OR OTHER AIR MOVING

SYSTEMS. ADEQUATE VENTILATION AND/OR

"MAKEUP AIR" DEVICES SHOULD BE PROVIDED

FOR ALL POWERED AIR HANDLING SYSTEMS.

GSI DOES NOT RECOMMEND THE USE OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE

ROOF DAMAGE CAN RESULT FROM ANY

BLOCKAGE OF AIR PASSAGES. RUNNING FANS

DURING HIGH HUMIDITY/COLD WEATHER CONDITIONS CAN CAUSE AIR EXHAUST OR INTAKE

PORTS TO FREEZE.

Operating Instructions

The principal concern of the GSI Group, Inc. ("GSI")

is your safety and the safety of others associated

with grain handling equipment. This manual is written to help you understand safe operating procedures, and some of the problems that may be encountered by the operator or other personnel.

The symbol shown is used to call your

attention to instructions concerning your

personal safety. Watch for this symbol; it points out important safety precautions. It means "ATTENTION",

"WARNING", "CAUTION", and

"DANGER". Read the message and

be cautious to the possibility of personal injury or death.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist, and to inform all personnel associated with the equipment, or who are in the fan area.

Avoid any alterations to the equipment. Such alterations may produce a very dangerous situation,

where serious injury or death may occur.

Safety Alert Symbol

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a misuse

of the equipment.

4

Page 5

Safety

2002 Top Dry Service School

Grain Systems, Inc.

recommends contacting your

local power company, and

having a representative

survey your installation so

the wiring is compatible with

their system, and adequate

power is supplied to your

unit.

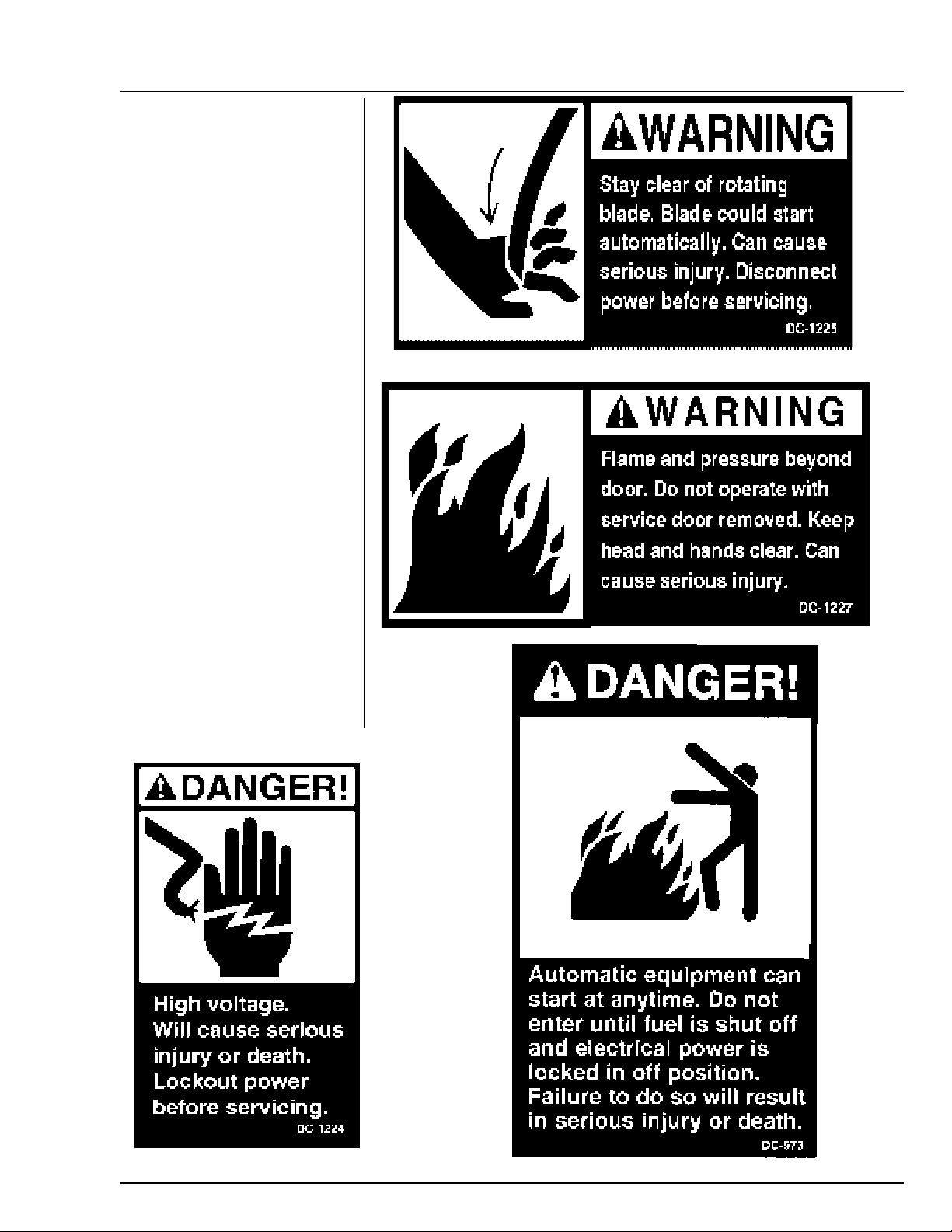

Safety decals should be read

and understood by all people in the

grain handling area. The rotating

blade, fire warning decals and

voltage danger decal must be dis-

played on the fan can. The bot-

tom right decal should be present

on the inside bin door cover of the

two ring door, 24" porthole door

cover and the roof manway cover.

If a decal is damaged or is

missing contact:

Grain Systems, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to

you.

5

Page 6

Safety

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maxi-

mum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

READ THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

2002 Top Dry Service School

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature

of a grain dryer having a gas burner,

high voltage electrical equipment and

high speed rotating parts, does

present a hazard to personnel, which

can not be completely safeguarded

against, without interfering with ef-

ficient operation and reasonable ac-

cess to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary convey-

ors, which may start without warn-

ing when the dryer is operating on

automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propellor, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

This product is intended for the use of grain handling only. Any other

use is considered a misuse of the product.

Some edges of the product components can be sharp. It is recom-

mended that each component of this product be examined to deter-

mine if there are any safety considerations to be taken. Any and all

necessary personal protective equipment should be worn at all tines

when handling, assembling, installing and operation of the product

and/or components.

Guards are removed for illustration purpose only. All guardsmust be

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE OUT-

SIDE OF THE DRYER

Continued safe, dependable opera-

tion of automatic equipment de-

pends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommen-

dations within this manual, and make

it a practice to regularly inspect the

operation of the unit for any devel-

oping problems or unsafe conditions.

Take special note of the safety pre-

cautions listed above before attempt-

ing to operate the dryer.

6

Page 7

Product Updates

2002 Top Dry Service School

GSI / Top Dry

Product Updates

* Duct Work - See PNEG-1089

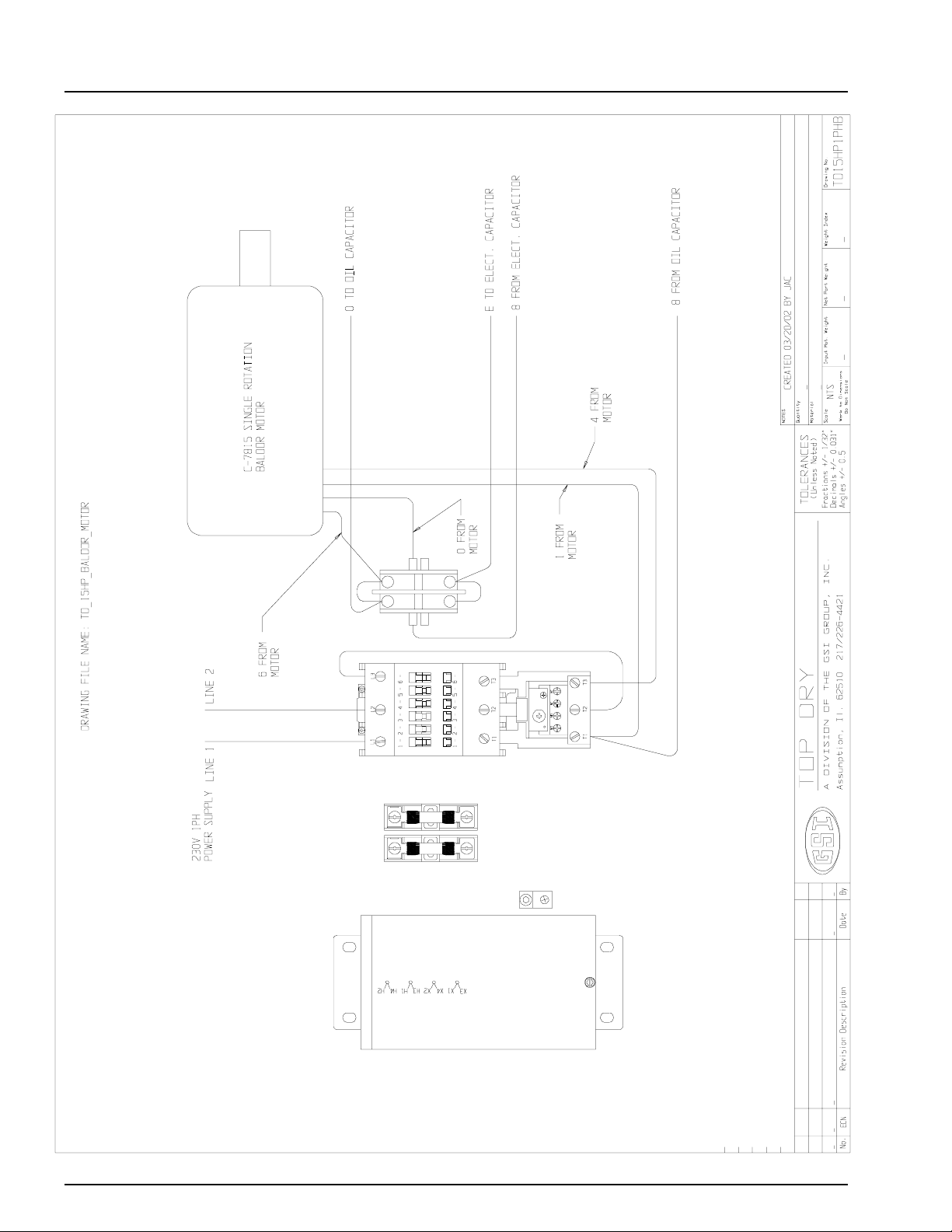

* 15HP 1PH Baldor Single Rotation Motor

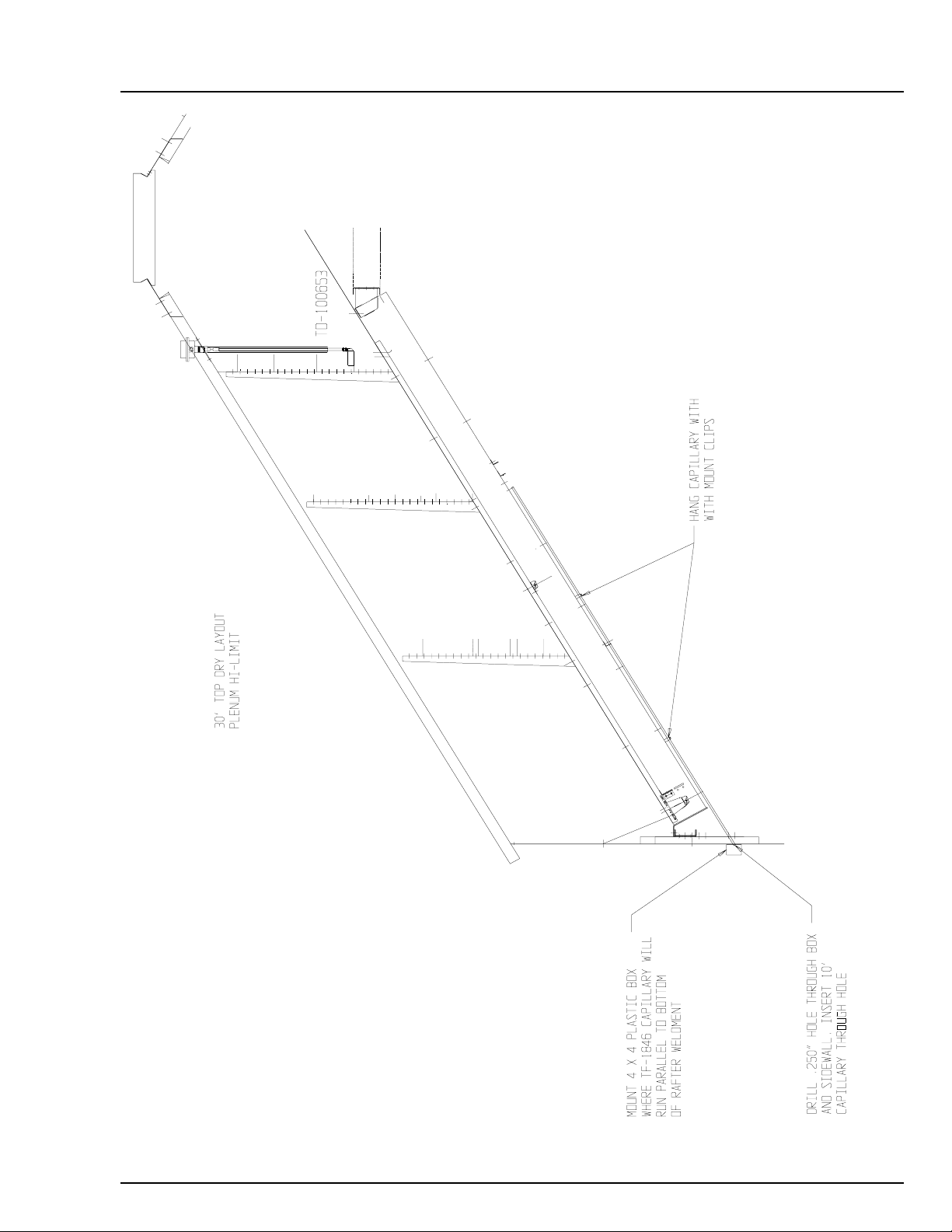

* Plenum Hi-Limit \ Grain Hi-Limit

7

Page 8

15 HP 1PH Baldor

2002 Top Dry Service School

8

Page 9

Plenum Hi-Limit

2002 Top Dry Service School

9

Page 10

Grain Hi-Limit

2002 Top Dry Service School

10

Page 11

Software revisions

p

N

2002 Top Dry Service School

Network Autoflow Display Board Software Revisions

VERSION: 2.13

1) Added software for Watchdog

*********************************************************************

VERSION: 2.12 RELEASE DATE: Sept 7, 2001

HEATER VERS – 1.09 IO VERS – 1.07

1) Increased the speed at which a "BIN HI OVERFLOW" warning is given which also brings up the correct warning on 2 wire

installs. We started using

3 wires with version 1.02 January of 1998

2) When cool down mode is entered, the fans will not start unless in the "AUTO" or "ON" position. This includes the drying fans

and the aeration fan.

*********************************************************************

VERSION: 2.11 RELEASE DATE: October 27, 2000

1) Burner differential would not stay at 1 deg F when the dryer was turn off, using 2.10, now it does.

2) When grain reaches the Storage Chamber Rotary Switch, the dryer will enter a "Cool Down Mode". The fan will run and cool

thegrain for 10 minutes before

shutting down due to a Storage Chamber Full error.

3) When grain falls away from the Wet Supply Rotary Switch, the dryer will enter a "Cool Down Mode" after the fill system shut

off. The fan will run and

cool the grain for 10 minutes before shutting down due to a No Wet Supply error.

4) When the Dry & Hold switch is placed in the "On" position the dryer will enter a "Cool Down Mode" for 20 minutes before

stopping. This only happens at

the end of the dry cycle.

5) Corrected a problem with the Fans Off Delay. If there is time on this delay, the fans and heaters will shut off during the unload

cycle, after the unload cycle

is complete the delay counts down. The fans and heaters will not start again until the delay has reached zero.

6) Corrected a problem with the Time Until Load Off percentage set in the set-up mode. Now, in Auto batch only, the Fill Systems

will shut off if grain has not

reached the dry chamber high level rotary switch within the set percentage of the dry timer is completed. Example: 1 hr dry

time, 50% Time Until Load off.

The fill systems will shut off regardless of rotary switch status after 30min has expired.

7) Corrected a problem with th e Refill Delay. Now, in Au to batch On ly. The R efill Delay begins to count down after the unload

cycle is completed. If grain

has not reached the drying chamber low level rotary switch before this delay reaches zero, a dry chamber empty error is given.

*********************************************************************

VERSION: 2.10 RELEASE DATE: Sept 11, 2000

1) Changed the Minimum Burner Differential to 1 Deg Fahrenheit

2) Fixed the problem where the burner was not shutting off when the Dry & Hold switch was placed in the "On" position, the Dry

Cycle was complete, and the

Dryer was in the Cool Cycle. Now, when the Dry & Hold switch is placed in the "On" position, and the Dry Cycle is complete,

the dryer will shut the burner

off and will cool for the amount of time on the Cool Timer before stopping.

3) Fixed a problem where the dryer was not shutting down with an "Out of Grain" error when the Wet Supply Rotary Switch was

exposed. Now when the Wet

Supply Rotary Switch is exposed, the Fill #1, and Fill #2 delay will count down and shut off Fill System #1 & #2, then the dryer

will shut down with an "Out

of Grain" error. If there is still grain against the Low Level Rotary Switch, the dryer can be restarted by pressing the Stop switch

to clear the error, turning

the Load Auger switch to the "Off" position, and pressing the Start switch. When the Start switch is pressed the screen will say

"Press <Enter> to Dry

Remaining Grain". If the <enter> button is pressed the dryer will restart. NOTE: If the Load Auger switch is left in the "Auto"

osition an "Out of Grain"

error will be given on startup.

*********************************************************************

VERSION: 2.09 RELEASE DATE: May 15, 2000

1.) Selection screen for On-Off burner. This cannot be used in conjunction with diesel burner.

OTE: Must change heater software also. Use following version number or higher: Heater ==> 1.09

*********************************************************************

VERSION: 2.08 RELEASE DATE: May 12, 2000

1.) Changed the burner differential setup screen to correctly display Celsius temperatures.

2.) Now only a year above 2000 may be entered upon setting the date.

3.) Burner differential is now greater than 1 and less than 10 degrees.

*********************************************************************

VERSION: 2.07 RELEASE DATE : April 25, 2000

1.) Changed the checksum method for the network to help insure data integrity.

2.) Force aeration fan to start before drying fans start, unless aeration switch is in off position.

3.) Load systems cannot start for five seconds after start of system.

11

Page 12

Software revisions

VERSION: 2.03 RELEASE DATE: October 27, 1999

***** NOTE: This software originated from 1.06 and is intended to fix version 2.00.*****

1) Added diesel option which if selected pulses the igniter relay on for about 1/2second after power to burner is on.

2) Took out option for modem string until it is needed.

3) Added safeties for thermistor shorts and opens.

4) By holding in on the HELP switch while turning on power you may check for proper wiring of the control panel switches and for correct operation of

keypad.

5) Made hour meter active. Reset it by holding in on the HOURS key while turning on the power. Press HOURS key to view.

6) Moisture control light flashes in temp hold mode.

7) Added software to indicate to the user that the DUMP switch is not in the AUTO position.

8) If the DRY & HOLD switch is in the ON position the dryer now goes through the cool cycle before shutting down. The cool timer is displayed while this is

happening. (Changed to a set 20 minutes in 2.11)

9) Changed software so the dryer won't shutdown while changing model number on the dryer.

10) The user can no longer go into EXTENDED SETUP while the dryer is running.

11) The warning of BIN HIGH PRESSURE LIMIT is now active high - in other words it must get 12VDC on pin J2-20 in order to give a shutdown.

*********************************************************************

VERSION: 2.02 RELEASE DATE: October 7, 1999

1) Changed the "Batch percentage off" selection screen to a screen which allows you to enter a time (just like any other timer) at which the dryer will shut off

loading in the DRY TIME. The timer is called the BATCH FILL TIME.

*********************************************************************

VERSION: 2.01 RELEASE DATE: October 4, 1999

1) Attempted to fix the problem of grain setpoint changing by itself.

2) Fixed problem of batch dryer always shutting down with a "DRYING CHAMBER EMPTY" warning. A delay called the "REFILL TIMER" allows the

dryer to fill back up.

*********************************************************************

VERSION: 2.00 RELEASE DATE: January 6, 1999

1) Fixed hour timer so dryer will now show running time of dryer.

2) Changed the way the dryer shut down when using the dry and hold switch, now it will cool the grain using the cool timer before it shuts down to prevent heat

buildup of grain past the grain temp set points thereby causing a shutdown condition. Works in Autoflow and AutoBatch modes.

3) Fixed the clock to properly roll over in the year 2000.

4) Added a user batch count and user timer independent from the Total batch and Total time allowing monitoring of different users drying grain or different

fields for comparison of drying time.

5) Added a test procedure for the keypad. Turning all of the control switches to the right (on position) and holding in the stop switch while turning on the

control power activates it. User can now test each individual keypad switch for malfunction or stuck keys. (Taken out in 2.03)

6) Added control switch testing by pressing and hold the plenum and grain switches in while turning on the control power. This will allow the user to test for

failed switches or computer failure to detect switch position changes. (Changed in 2.03 to turn power on with Help key depressed)

7) Removed garbage displayed when user selected to view total running time and total batches.

8) Added a check to make sure the dump switch is always in the Auto posistion. Otherwise if left in manual close will cause the dryer never to dump.

9) Fixed several bugs that were reported to use by users and dealers.

10) I added the ability to reset the Total Dryer running time by pressing the HOUR and RESET button together and turn on the dryer.

11) Removed watchdog option in Extended setup mode since watchdog has not been implemented yet.

12) Changed the wording to some of the error messages concerning the rotary switches to help eliminate some confusion of which switch was at fault.

13) Moisture control light will now flash to give a visual indication that the dryer is in temperature hold.

*********************************************************************

VERSION: 1.06 RELEASE DATE: November, 98

1.) Fixed dryer so the grain hi limit occurs at 20 F above the grain temp setpoint.

2.) Made timeout on the open/close of the actuator 20 seconds instead of 15 seconds. This extra time was added to compensate for the weaker batteries taking

longer to close the chutes.

*********************************************************************

VERSION: 1.05 RELEASE DATE: September, 98

1.) Made the out of grain timer active.

*********************************************************************

VERSION: 1.04 RELEASE DATE: July, 98

1.) The application of 12v to terminal number j1-20 will shutdown the dryer and give an indication that the bin is full due to the high level of static pressure

within."BIN AIR PRESSURE LIM" will be displayed on screen's top line until the user corrects the problem. (Originally looked for lack of 12v, fixed in

2.00)

2.) Corrected the hour meter problem.

3.) Changed how the dry timer is displayed: Now when the dry timer goes to zero it will begin counting upward at the user set time as long as the dryer remains

in temp hold.

*********************************************************************

VERSION: 1.03 RELEASE DATE: March, 98

1.) Added software to allow the aeration fan to continue running even if there was a dryer shutdown. The aeration fan BYPASS mode must be selected under

setup.

*********************************************************************

VERSION: 1.02 RELEASE DATE: Jan, 98

1.) The Bin high limit rotary switch is monitored in both states to insure that a switch failure has not taken place. If both switches are in the same state a switch

failure is reported.

*********************************************************************

VERSION: 1.01 RELEASE DATE: NO OFFICIAL DATE ASSIGNED

1.) Added burner differential adjustment to be set at master under extended setup.

2.) Gary Woodruff's software for holding the fans off during a portion of the dry cycle. This is adjusted under delays.

3.) Attempted to make the dryer dry remaining grain when a wet supply empty error takes place.

4.) Added software to display a negative incrementing counter, where the dry timer used to be, during temp hold. (Changed in 1.04)

*********************************************************************

2002 Top Dry Service School

12

Page 13

Software revisions

2002 Top Dry Service School

VERSION: 1.00 RELEASE DATE: SEPTEMBER 16, 1997

1.) We changed resistor number 107 on the display board from 10K to 3.0K to allow the contrast to work without resetting the

computer.

2.). Put in a contrast adjustment for the display. While turning the control power on, hold in on the screens key, and this will enter

the contrast adjustment mode. Now use the UP/DOWN arrow keys to adjust. If the screen is solid black press the down arrow

key, if nothing appears on the screen press the up arrow keys. NOTE: You cannot hold in on the UP/DOWN arrow keys to

adjust, you must continue to press and then release them or nothing will happen.

3.) Put Software in for 3

*********************************************************************

VERSION: 0.05 RELEASE DATE: 1996

This was the first version released for customer operation. This particular version could only control 2 Fan and Heaters

rd

Fan and Heater.

NOTE: remember to always do a hard reboot after installing new software to the display board or the IO

board. Shut off all gas valves when installing new software in all burners.

13

Page 14

Software revisions

2002 Top Dry Service School

Series 2000 Autoflow Heater Software Changes

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.10

DATE CHANGED: MAY 15, 2000

RELEASE DATE: MAY 15, 2000

1.) Added software for watchdog.

NOTE: This must be used with display version 2.13.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.09

DATE CHANGED: MAY 15, 2000

RELEASE DATE: MAY 15, 2000

1.) Provided On-Off burner option.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.08

DATE CHANGED: MAY 12, 2000

RELEASE DATE: MAY 12, 2000

1.) Fixed software to correctly display celsius temperatures.

2.) Increased the hysteresis of the air switch to avoid

unnecessary shutdowns.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.07

DATE CHANGED: APRIL 25, 2000

RELEASE DATE: APRIL 25, 2000

1.) Changed the way the check sum works.

2.) No longer allow the grain temp setpoint to be changed here.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.06

DATE CHANGED: MARCH 30, 2000

RELEASE DATE: MARCH 30, 2000

14

1.) Made airswitch active for all fans/heaters.

Page 15

Software revisions

2002 Top Dry Service School

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.05

DATE CHANGED: DECEMBER,1999

RELEASE DATE: DECEMBER,1999

1.) Made a selection for diesel burner. Ignition relay

is pulsed on after burner starts to reset diesel module.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.04

RELEASE DATE: September, 1998

1.) Changed software so the ignitor comes on when the burner

initially attempts to light and then it goes off about

five seconds later and we try to sense flame then.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.03

RELEASE DATE: Jan, 1998

1.) Fixed software so that if slave loses contact with

master everything shuts down accordingly.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.02

RELEASE DATE: DECEMBER 17, 1997

1.) The master now sends the plenum temperature differential

to the fan/heaters as a byte on the network.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.01

RELEASE DATE: DECEMBER 1997

1.) Changed software so plenum temperature decides which temperature

scale the heater software is on. This fixes a problem of the

plenum temperature going to 86F and stopping.

*********************************************************************

15

Page 16

Software revisions

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 1.00

RELEASE DATE: OCTOBER 20, 1997

1.) When the three fan autoflow was introduced some of the rural

drying centers were having problems dealing with copious

amounts of initation current. The other problem complicating

this precarious situation is that all fans must start

simultaneously in order to prevent the last fan from rotating

backwards. In order to deal in the most efficient manner with

both of the above stated problems we implemented a soft start

scenario which provides a 66% reduction in startup current.

*********************************************************************

SOFTWARE: SERIES 2000 AUTOFLOW HEATER BOARD

VERSION: 0.05

RELEASE DATE: 1996

2002 Top Dry Service School

THIS WAS THE FIRST VERSION RELEASED FOR CUSTOMER OPERATION.

NOTE: remember to always do a hard reboot after installing new software to the display board or the IO

board. Shut off all gas valves when installing new software in all burners.

Current Top Dry Software

Top Dry Series 2000 Autoflow-

Display Computer Board – Version 2.13

Heater Computer Board – Version 1.10

Input / Output Board – Version 1.07

Top Dry Series 2000 Batch Heater-

Series 2000 Batch – version .30

16

Page 17

2002 Top Dry Service School

* Top Dry Sidewall Gauges

* Top Dry Stiffener Gauges

* Fan Blade Data

Technical Data

GSI / Top Dry

Technical data

17

Page 18

Technical Data

NOMINAL DIA. NUMBER OF RINGS Sidewall Sidewall Sidewall Sidewall Sidewall Sidewall Sidewall Sidewall Sidewall Sidewall Sidewall

OF SIDEWALL (Ft) OF SIDEWALL Base Ring Ring #2 Ring #3 Ring #4 Ring #5 Ring #6 Ring #7 Ring #8 Ring #9 Ring #10 Ring #11

18 5 20ga 20ga 20ga 20ga 20ga

18 6 20ga 20ga 20ga 20ga 20ga 20ga

18 7 20ga 20ga 20ga 20ga 20ga 20ga 20ga

21 5 20ga 20ga 20ga 20ga 20ga

21 6 20ga 20ga 20ga 20ga 20ga 20ga

21 7 20ga 20ga 20ga 20ga 20ga 20ga 20ga

21 8 18ga 20ga 20ga 20ga 20ga 20ga 20ga 20ga

24 5 20ga 20ga 20ga 20ga 20ga

24 6 20ga 20ga 20ga 20ga 20ga 20ga

24 7 18ga 20ga 20ga 20ga 20ga 20ga 20ga

24 8 18ga 18ga 20ga 20ga 20ga 20ga 20ga 20ga

24 9 17ga 18ga 18ga 20ga 20ga 20ga 20ga 20ga 20ga

24 10 17ga 17ga 18ga 18ga 18ga 20ga 20ga 20ga 20ga 20ga

27 5 18ga 18ga 18ga 20ga 20ga

27 6 18ga 18ga 18ga 18ga 20ga 20ga

27 7 18ga 18ga 18ga 18ga 18ga 20ga 20ga

27 8 17ga 18ga 18ga 18ga 18ga 18ga 20ga 20ga

27 9 17ga 17ga 18ga 18ga 18ga 18ga 18ga 20ga 20ga

27 10 17ga 17ga 17ga 18ga 18ga 18ga 18ga 18ga 20ga 20ga

2002 Top Dry Service School

30 5 18ga 18ga 18ga 18ga 20ga

30 6 18ga 18ga 18ga 18ga 18ga 20ga

30 7 17ga 18ga 18ga 18ga 18ga 18ga 20ga

30 8 17ga 17ga 18ga 18ga 18ga 18ga 18ga 20ga

30 9 17ga 17ga 17ga 18ga 18ga 18ga 18ga 18ga 20ga

30 10 16ga 17ga 17ga 17ga 18ga 18ga 18ga 18ga 18ga 20ga

30 11 16ga 17ga 17ga 17ga 17ga 18ga 18ga 18ga 18ga 18ga 20ga

36 5 17ga 18ga 18ga 18ga 20ga

36 6 17ga 18ga 18ga 18ga 18ga 20ga

36 7 16ga 17ga 18ga 18ga 18ga 18ga 20ga

36 8 16ga 16ga 17ga 18ga 18ga 18ga 18ga 20ga

36 9 16ga 16ga 16ga 17ga 18ga 18ga 18ga 18ga 20ga

36 10 15ga 16ga 16ga 16ga 17ga 18ga 18ga 18ga 18ga 20ga

36 11 14ga 15ga 15ga 16ga 16ga 17ga 18ga 18ga 18ga 18ga 20ga

Top Dry Sidewall Gauges

18

Page 19

Technical Data

2002 Top Dry Service School

NOMINAL DIA. NUMBER OF RINGS Stiffener Stiffener Stiffener Stiffener Stiffener Stiffener Stiffener Stiffener Stiffener Stiffener Stiffener

OF SIDEWALL (Ft) OF SIDEWALL Base Ring Ring #2 Ring #3 Ring #4 Ring #5 Ring #6 Ring #7 Ring #8 Ring #9 Ring #10 Ring #11

18 5 14ga 16ga 16ga 16ga

18 6 14ga 16ga 16ga 16ga

18 7 12ga 14ga 16ga 16ga 16ga

21 5 14ga 16ga 16ga 16ga

21 6 14ga 16ga 16ga 16ga

21 7 12ga 14ga 16ga 16ga 16ga

21 8 12ga 14ga 16ga 16ga 16ga

24 5 14ga 16ga 16ga 16ga

24 6 12ga 14ga 16ga 16ga

24 7 12ga 14ga 16ga 16ga 16ga

24 8 12ga 14ga 12ga 16ga 16ga

24 9 10ga 12ga 12ga 14ga 14ga 16ga

24 10 8ga 10ga 12ga 14ga 16ga 16ga

27 5 14ga 16ga 16ga 16ga

27 6 12ga 14ga 16ga 16ga

27 7 12ga 14ga 16ga 16ga 16ga

27 8 12ga 12ga 14ga 16ga 16ga

27 9 10ga 12ga 14ga 16ga 16ga 16ga

27 10 8ga 10ga 12ga 14ga 16ga 16ga

30 5 12ga 14ga 16ga 16ga

30 6 12ga 14ga 16ga 16ga

30 7 12ga 12ga 14ga 16ga 16ga

30 8 10ga 12ga 14ga 16ga 16ga

30 9 10ga 12ga 12ga 14ga 16ga 16ga

30 10 8ga 10ga 12ga 14ga 16ga 16ga

30 11 8ga 10ga 12ga 12ga 14ga 16ga 16ga

36 5 12ga 14ga 16ga 16ga

36 6 12ga 12ga 14ga 16ga

36 7 10ga 12ga 14ga 14ga 16ga

36 8 10ga 12ga 12ga 14ga 16ga

36 9 8ga 10ga 12ga 14ga 14ga 16ga

36 10 8ga 10ga 12ga 12ga 14ga 16ga

36 11 8ga 8ga 10ga 12ga 14ga 14ga 16ga

Top Dry Stiffener Gauges

19

Page 20

Technical Data

2002 Top Dry Service School

20

Page 21

Software Diagnostics

2002 Top Dry Service School

GSI / Top Dry

Software Diagnostics

* Series 2000 Batch Fan & Heater

* Series 2000 Autoflow Display

* Series 2000 Autoflow Fan & Heater

21

Page 22

Software Diagnostics

Series 2000 Batch Fan / Heater

2002 Top Dry Service School

Initializing the Novram

• Turn the Control Power “ off “.

• Hold down the Program Temperature

switch.

• Turn the Control Power switch “on “

with the Program Temperature switch

held down.

• Press the Increase switch until 7 is on

the display.

• Press the Program Temperature switch

again.

• You have two seconds to depress the

Increase or Decrease switches at the

same time.

• The NOVRAM has been initialized.

NOTE: The computer has now been cleared of all

memory, including the type of dryer it is and all

Set-up variables.

22

Page 23

2002 Top Dry Service School

Software Diagnostics

Series 2000 Batch Fan / Heater

Programming Set-up Variables

• Turn the Control Power “ off “

• Turn the Control Power switch “ on “

with the Program Temperature switch

held down.

• Press the Increase switch until 3 is on

the display.

• Press the Program Temperature switch

again.

•C or no C will bill displayed.

• Use the Increase or Decrease switch to

toggle between C or no C.

C - Hi-Lo cycling heater

no C - On/Off cycling heater

• When the correct selection is on the

screen press the Program Temperature switch again.

•H or no H will be displayed.

• Use the Increase or Decrease switch to

toggle between H or no H.

H - Humidity sensor present

no H - No humidity sensor

present

• When the correct selection is on the

screen press the Program Temperature

switch again.

•F or C will be displayed.

• Use the Increase or Decrease switch to

toggle between F or C.

F - Temperatures displayed in

Fahren- heit.

C-Temperatures displayed in

Celsius.

• When the correct selection is on the

screen press the Program Temperature

switch again.

•L or no L will be displayed.

• Use the Increase or Decrease switch

to toggle between L or no L.

L - The dryer will advance to

the Cool cycle when the Dry

timer has reached zero and the

Grain temperature set point

has been met.

noL - The dryer will advance

to the Cool cycle when either

the Dry timer has reached zero

or the Grain temperature set

point has been met.

• When the correct selection is on the

screen press the Program Temperature

switch again.

23

Page 24

Software Diagnostics

2002 Top Dry Service School

Series 2000 Batch Fan / Heater

CAUTION: DO NOT ATTEMPT BELOW PROCEDURE WITH GAS LINE CONNECTED.

Diagnostic Mode

• Turn the Control Power “ off “.

• Hold down the Program Temperature switch.

• Turn the Control Power switch “on “

with the Program Temperature switch

held down.

• Press the Increase switch until 8 is on

the display.

• Press the Program Temperature switch

again.

• Press the Program Dry time switch to

engage the Fan starter-Fan will be

displayed.

• Press the Increase switch to make the

ignitor spark-IN will be displayed.

• Press the Program Temperature switch

to open the LP and Main Solenoid- LP

will be displayed.

• Press the Start switch to open the

Cycle solenoid -CS will be displayed.

• Turn the control power “off” to exit

the Diagnostic mode.

24

Page 25

Software Diagnostics

2002 Top Dry Service School

Series 2000 Autoflow Display

Keypad Test

• Turn the Control Power “off”.

• Turn the Control Power switch “on”

with the Help Switch pressed.

• The Keypad Switches can now be tested.

Control Switch Tests

• Turn the Control Power “off” .

• Turn the Control Power switch “on”

with the Plenum and Grain Switches pressed.

• The Control Switches can now be tested.

25

Page 26

Software Diagnostics

2002 Top Dry Service School

Series 2000 Autoflow Fan / Heater

CAUTION: DO NOT ATTEMPT BELOW PROCEDURE WITH GAS LINE CONNECTED.

Diagnostic Mode

• Turn the Control Power “ off “.

• Hold down the Program Temperature switch.

• Turn the Control Power switch “on “

with the Program Temperature switch

held down.

• Press the Program Dry time switch to

engage the Fan Starter.

• Press the Program Temperature switch

to start theIgnitor.

• Press the Hours x 1000 switch to open

the Ssolenoid.

• Turn the control power “off” to exit

the Diagnostic mode.

26

Page 27

2002 Top Dry Service School

THE GSI GROUP, INC. ("GSI") WARRANTS ALL PRODUCTS MANUFACTURED BY GSI TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE

AND CONDITIONS FOR A PERIOD OF TWELVE MONTHS AFTER RETAIL SALE TO THE

ORIGINAL END USER OF SUCH PRODUCTS. GSI'S ONLY OBLIGATION IS, AND

PURCHASER'S SOLE REMEDY SHALL BE FOR GSI, TO REPAIR OR REPLACE, AT GSI'S

OPTION AND EXPENSE, PRODUCTS THAT, IN GSI'S SOLE JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI'S FACTORY WILL BE PURCHASER'S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE PURCHASER WITHOUT PRIOR

WRITTEN AUTHORIZATION FROM AN AUTHORIZED EMPLOYEE OF GSI SHALL BE THE

SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY

OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH

(i) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A

PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR

BENEFITS. PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED

ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS

WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI

SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS WHICH

CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE PRODUCT

NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS

ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN

OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE REPONSIBILITY TO RESEARCH AND COMPLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION

27

Page 28

2002 Top Dry Service School

28

June 18th, 2002

Loading...

Loading...