Page 1

Enclosed Belt

Conveyor

Installation and Operation Manual

PNEG-1204

DATE: 10-16-06

PNEG-1204

Page 2

Introduction

READ THIS MANUAL carefully to learn how to

properly use and install equipment. Failure to do

so could result in personal injury or equipment

damage. This manual and safety signs on your

equipment may be available in other languages.

(Consult with your dealer to see what is available)

INSPECT the shipment immediately upon arrival.

The Customer is responsible for ensuring that all

quantities are correct. Report any damage or

shortages by recording a detailed description on

the Bill of Lading to justify the Customer’s claim

from the Transport Firm. Our responsibility for

damage to the equipment ends with acceptance

by the delivering carrier. Save all paperwork and

documentation furnished with any of the enclosed

belt conveyor components.

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your equipment and should be

easily accessible when needed.

WARRANTY is provided as part of the company’s

support program for customers who use and

maintain their equipment as described in the

manual. The warranty is explained on the warranty page located on the inside back cover of

this manual.

This warranty provides you the assurance that the

company will back its products where defects

appear within the warranty period. In some circumstances, the company also provides field

improvements, often without charge to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to

change its performance beyond the factory specifications, the warranty will become void and field

improvements may be denied.

i

Page 3

Use of the Equipment Information page will help you identify your equipment in the case that you need to

call your dealer or installer. This information should be filled out and kept on record.

Equipment Information

Model Number:__________________________

Serial Number:___________________________

Material Handling

1004 East Illinois Street

Assumption, Illinois 62510 USA

Phone: (217) 226-4421

FAX: (888) 741-3004

e-mail: gsi@grainsystems.com

Date Purchased:____________________

Dealer/Distributor Name and Phone Number:

ii

Page 4

Table of Contents

Introduction.....................................................................................i

Equipment Information ...................................................................ii

Safety Guidelines...........................................................................1

Safety ............................................................................................2

Safety Decal Locations. .................................................................5

Overview ........................................................................................9

Intermediate Section Installation .....................................................10

Cover Installation............................................................................12

Loader Installation ..........................................................................13

Motor & T orque Arm II Reducer Installation......................................14

Reducer ....................................................................................15

T orque Arm................................................................................16

T orque Arm Bracket...................................................................1 6

Motor Mount Brackets ...............................................................17

Motor Mount Adjustment Plate ...................................................17

Rear Guard ...............................................................................17

Sheaves and Belts ....................................................................18

V-Belt Adjustment ......................................................................18

Front Guard ...............................................................................19

Reducer Lubrication ..................................................................19

Finding Belt Center Line.................................................................19

Squaring the Belt End ....................................................................20

Check Belt Squareness .................................................................20

Installation of Belt ...........................................................................21

Splicing Belt...................................................................................22

Belt T ension ...................................................................................26

Belt Tracking..................................................................................27

Spouting.........................................................................................30

Spouting Location ..........................................................................31

Belt Conveyor Loading...................................................................32

Motion Sensor Option ....................................................................33

Pressure Plug Switch Option..........................................................34

Starting Conveyor...........................................................................35

Care & Maintenance ......................................................................36

Troubleshooting..............................................................................37

T orque Arm II Appendix...................................................................38

Imperial Bearings Appendix ...........................................................49

All information, illustrations, photos, and specifications in this manual

are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

iii

Page 5

NOTES

iv

Page 6

Safety

SAFETY GUIDELINES

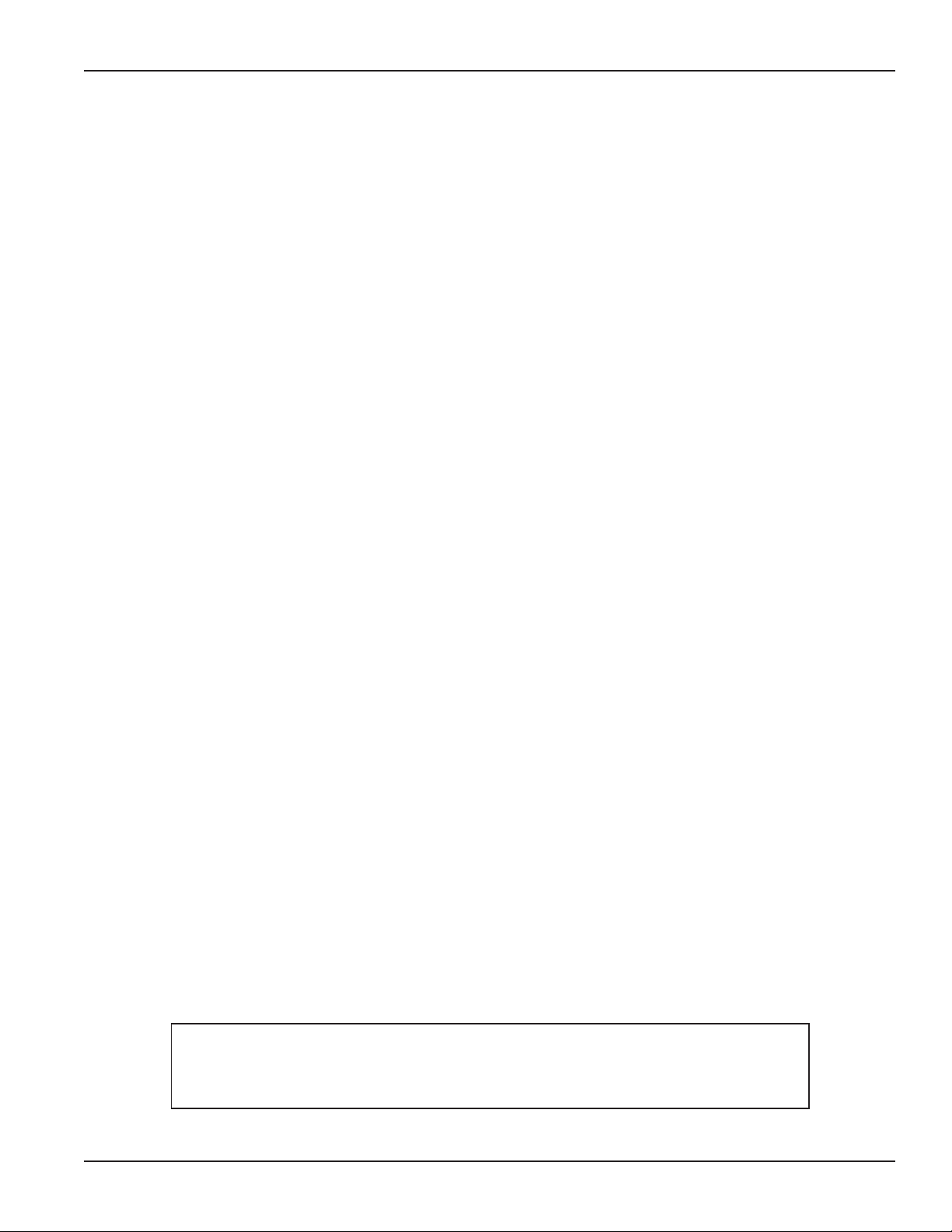

This manual contains information that is important for you, the owner/operator , to know and

understand. This information relates to protecting personal safety and preventing equipment

problems. It is the responsibility of the owner/operator to inform anyone operating or working in

the area of this equipment of these safety guidelines. To help you recognize this information, we

use the symbols that are defined below. Please read the manual and p ay attention to these

sections. Failure to read this manual and it’s safety instructions is a misuse of the equipment and

may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury .

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury .

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury .

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

NOTE indicates information about the equipment that

you should pay special attention to.

1PNEG-1204 Enclosed Belt Conveyors

Page 7

Safety

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual

and on your machine safety signs. Keep signs in

good condition. Replace missing or damaged

safety signs. Be sure new equipment components and repair parts include the current safety

signs. Replacement safety signs are available

from the manufacturer.

Learn how to operate the machine and how to

use controls properly . Do not let anyone operate

without instruction.

Keep your machinery in proper working condition. Unauthorized modifications to the machine

may impair the function and/or safety and affect

machine life.

If you do not understand any part of this manual

and need assistance, contact your dealer.

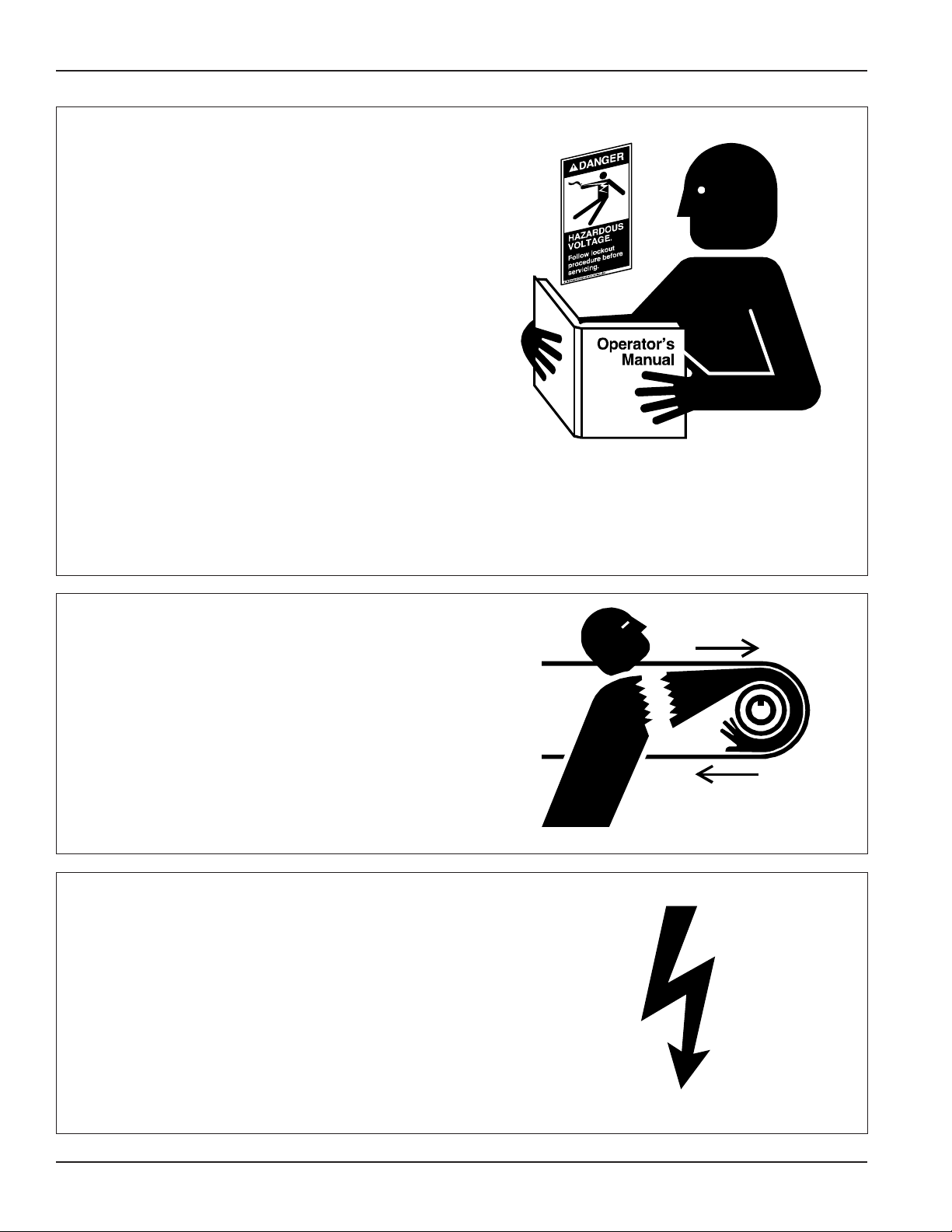

STAY CLEAR OF ROTATING IDLER

Entanglement in rotating idlers can cause serious injury or death.

Keep all shields and covers in place at all times.

Wear close fitting clothing. S top and lock out

power source before making adjustments,

cleaning, or maintaining equipment.

OPERATE MOTOR PROPERLY

Do not operate electric motor equipped units

until motors are properly grounded.

Disconnect power on electrical driven units

before resetting motor overloads.

Do not repetitively stop and start the drive in

order to free a plugged condition. Jogging the

drive in this type of condition can damage the

conveyor and/or drive components.

2

PNEG-1204 Enclosed Belt Conveyors

Page 8

PRACTICE SAFE MAINTENANCE

Understand service procedures before doing

work. Keep area clean and dry .

Never lubricate, service, or adjust machine while

it is in operation. Keep hands, feet, and clothing

from rotating belt and idlers.

Keep all parts in good condition and properly

installed. Fix damage immediately . Replace

worn or broken parts. Remove any build up

grease, oil, or debris.

Safety

REMOVE PAINT BEFORE WELDING OR

HEATING

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint

is heated by welding, soldering, or using a torch.

Do all work outside or in a well ventilated area.

Dispose of paint and solvent properly.

Remove paint before welding or heating:

• If you sand or grind paint, avoid breathing the

dust. Wear an approved respirator .

• If you use solvent or paint stripper , remove

stripper with soap and water before welding.

Remove solvent or stripper containers and

other flammable material from area. Allow

fumes to disperse at least 15 minutes before

welding or heating.

3PNEG-1204 Enclosed Belt Conveyors

Page 9

Safety

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy .

Keep emergency numbers for doctors, ambu-

lance service, hospital, and fire department near

your telephone.

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to help prevent

breathing potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help

protect your head and toes from falling debris.

Eye Protection

Gloves

Steel Toe

Boots

Respirator

Hard Hat

4

PNEG-1204 Enclosed Belt Conveyors

Page 10

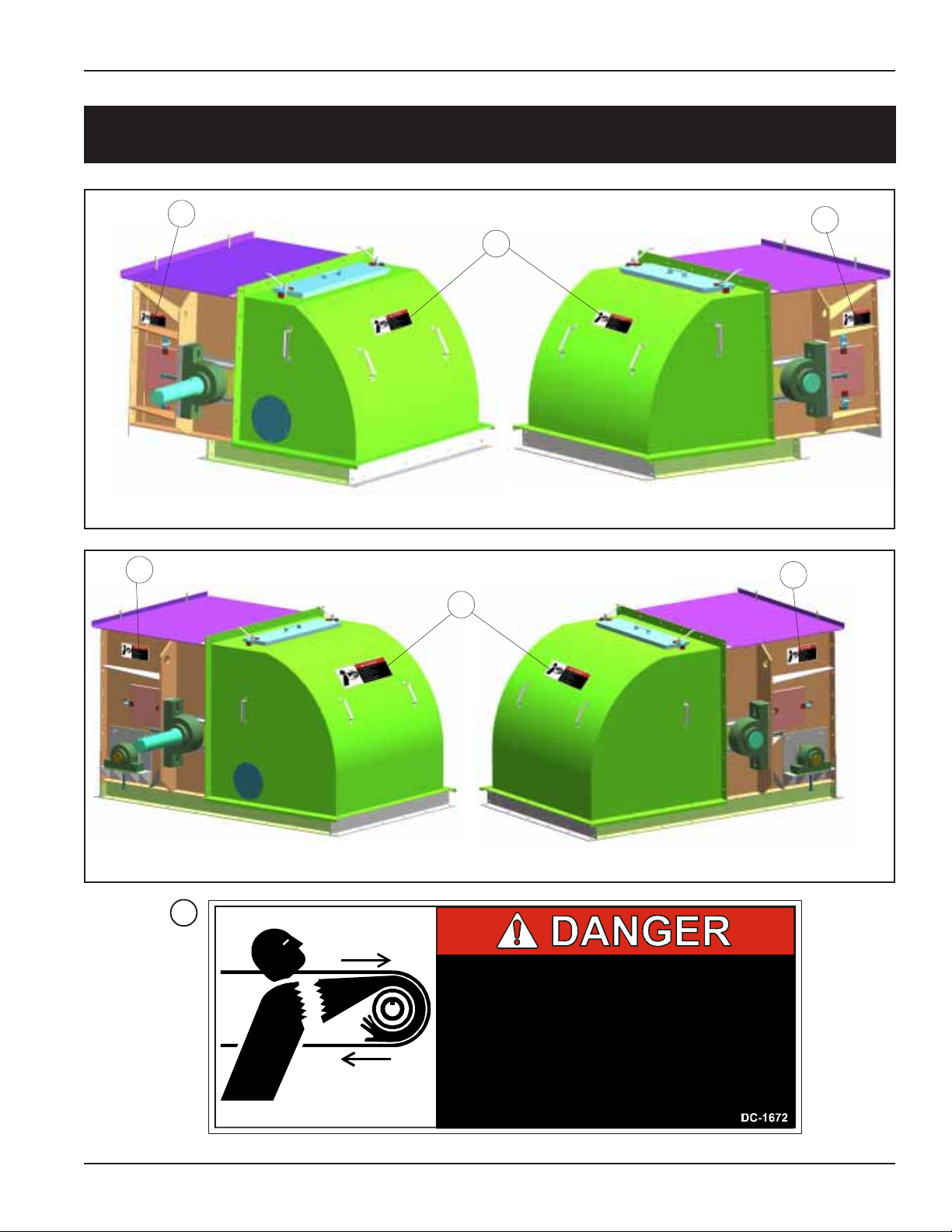

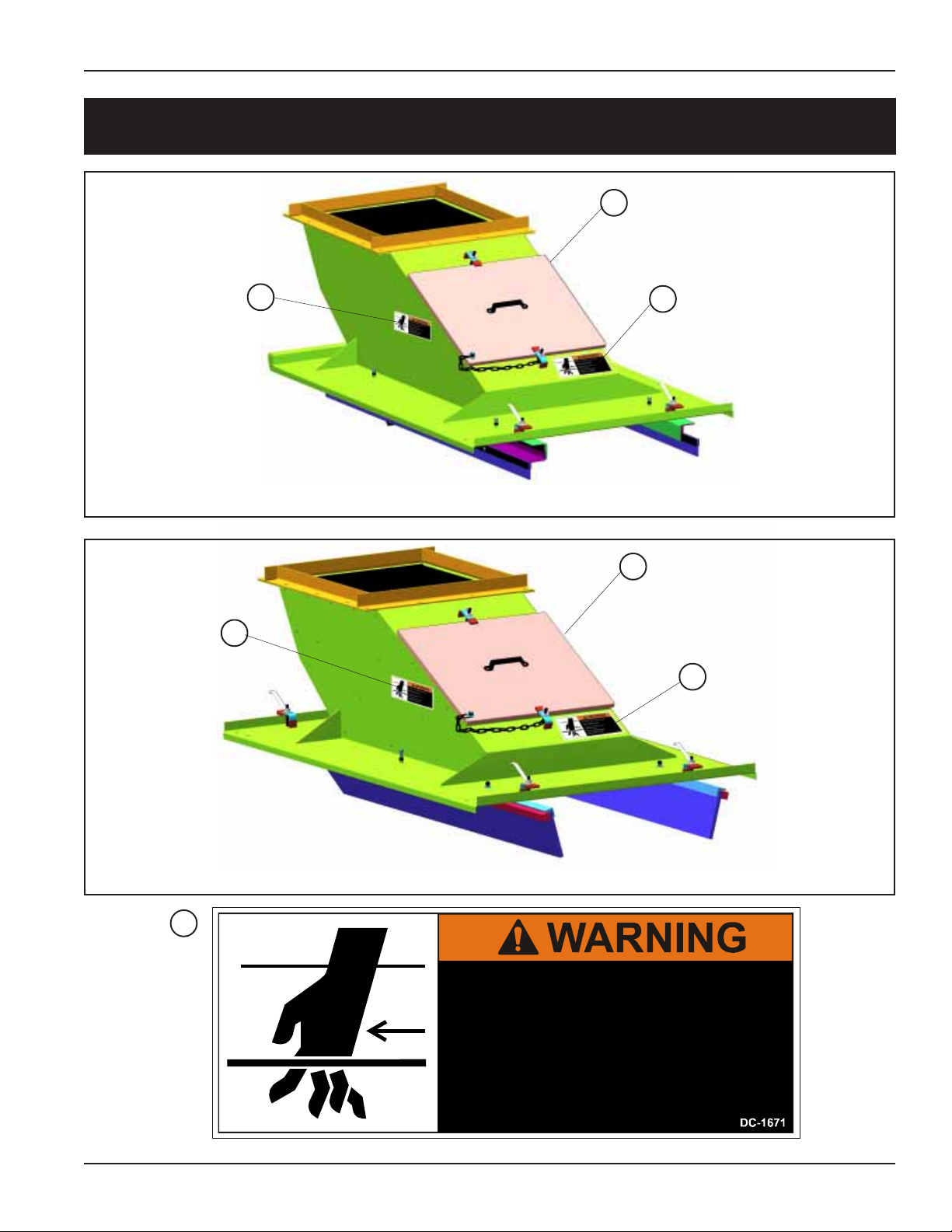

HEAD SECTION DECAL LOCATIONS

Decals

1

1

1

STANDARD HEAD SECTION

1

1

1

1

DC-1672

SNUB HEAD SECTION

ROTATING BELT AND PULLEY WILL

CUT OR ENTANGLE.

KEEP HANDS CLEAR

Disconnect and lockout power before

adjusting or servicing.

Failure to heed will result in

personal injury or death.

5PNEG-1204 Enclosed Belt Conveyors

Page 11

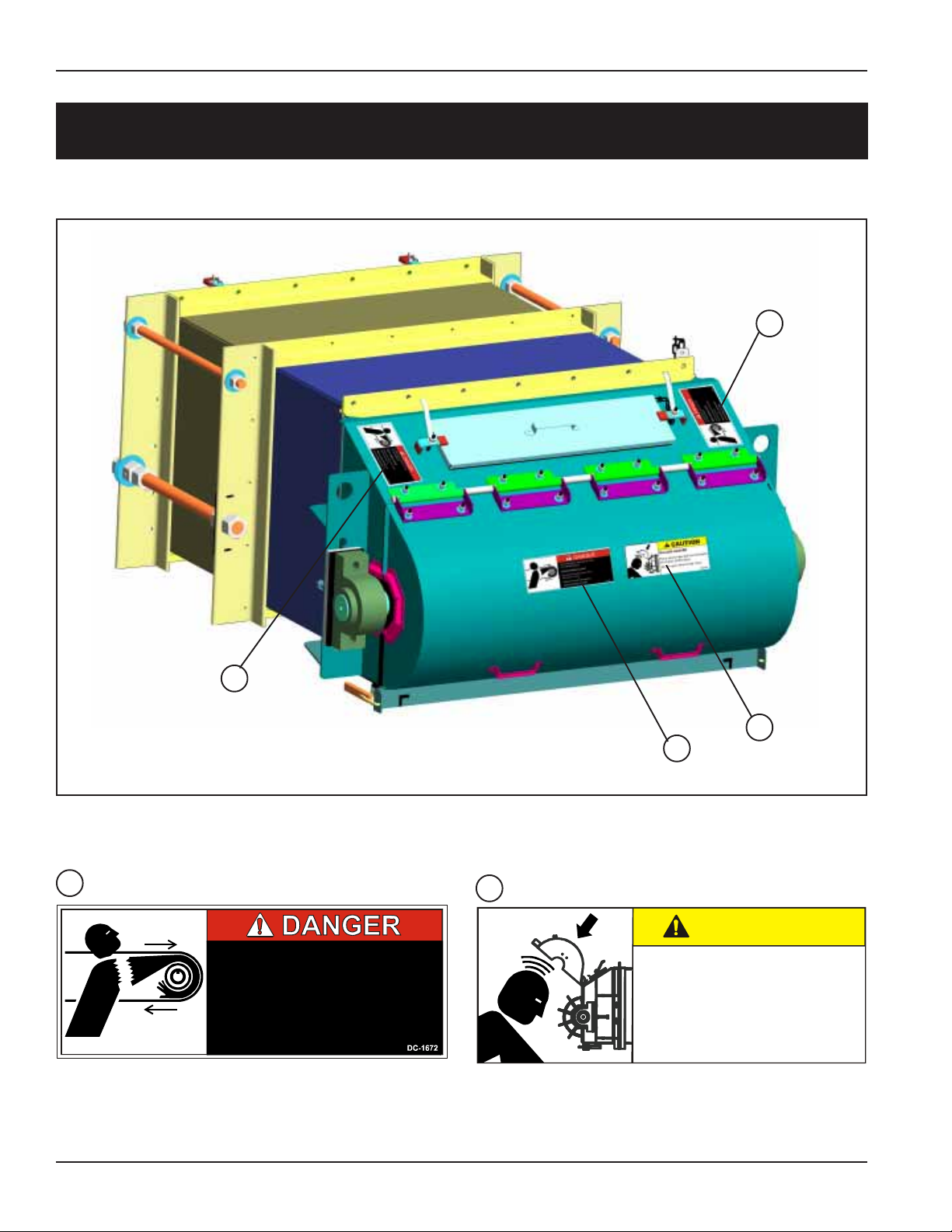

Decals

TAIL SECTION DECAL LOCATIONS

1

1

DC-1672

1

BELT CONVEYOR TAIL SECTION

ROTATING BELT AND PULLEY WILL

CUT OR ENTANGLE.

KEEP HANDS CLEAR

Disconnect and lockout power before

adjusting or servicing.

Failure to heed will result in

personal injury or death.

2

DC-1690

2

1

CAUTION

FALLING HAZARD

Open shroud may fall if unrestrained

and cause bodily injury.

Secure open shroud with chain.

DC-1690

6

PNEG-1204 Enclosed Belt Conveyors

Page 12

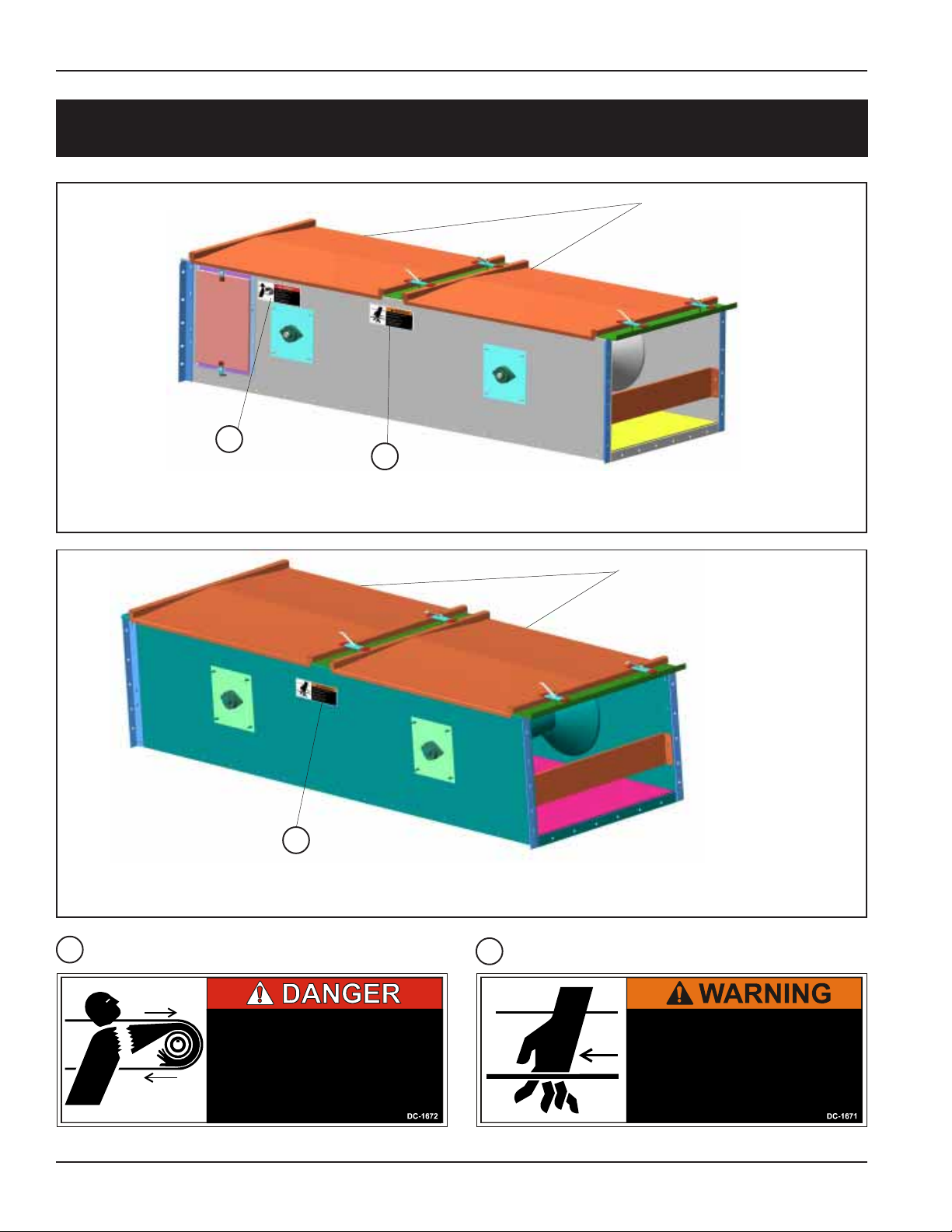

LOADER SECTION DECAL LOCATIONS

Decal On Right Side In

2

Same Location as

Decal on Left Side.

Decals

2

FIXED SKIRT LOADER

2

Decal On Right Side In

2

Same Location as

Decal on Left Side.

2

2

2

DC-1671

SWING-UP SKIRT LOADER

MOVING BELT CAN CUT OR ENTANGLE.

KEEP HANDS CLEAR

Disconnect and lockout power before

adjusting or servicing.

Failure to heed can result in

perso n a l injury or death .

7PNEG-1204 Enclosed Belt Conveyors

Page 13

Decals

INTERMEDIATE SECTION DECAL LOCATIONS

Decals On Right Side

In Same Location as

Decals on Left Side.

1

2

1

DC-1672

INTERMEDIATE INSPECTION SECTION

2

STANDARD INTERMEDIATE SECTION

2

DC-1671

Decal On Right Side In

Same Location as

Decal on Left Side.

ROTATING BELT AND PULLEY WILL

CUT OR ENTANGLE.

KEEP HANDS CLEAR

Disconnect and lockout power before

adjusting or servicing.

Failure to heed will result in

personal injury or death.

8

PNEG-1204 Enclosed Belt Conveyors

MOVING BELT CAN CUT OR ENTANGLE.

KEEP HANDS CLEAR

Disconnect and lockout power before

adjusting or servicing.

Failure to heed can result in

personal injury or death.

Page 14

Conveyor Assembly

CONVEYOR ASSEMBLY

OVERVIEW

1. Remove any banding and crating material.

Arrange all the conveyor components in such

a fashion that all are easily accessible.

2. Locate sturdy items to serve as blocking (i.e.

wood blocks, saw horses, etc.). Blocking is

used to support the conveyor sections above

the ground to help in assembly . Locate and

place the conveyor sections on the blocking

in order , starting with the head section and

concluding with the tail section.

3. A clearance of at least the width of the

conveyor is recommended on all sides of the

unit. Less clearance may be acceptable

however, serious consideration must be

given to methods of maintenance, removal

and replacement of the conveyor and/or its

parts.

4. The standard conveyor is constructed with

one discharge located at the drive end. If

tripper discharge sections are to be used,

the location(s) must be determined before

continuing with the conveyor assembly . It

may be necessary to position a shorter

intermediate section to serve as a spacer in

order to accommodate the placement of the

tripper discharge(s) where required.

5. Always consult with the approval prints for

exact conveyor layout. Maintain adequate

clearance for tail extension.

6. During installation of the conveyor , string a

chalk line along the conveyor sides to assure

that the conveyor is being assembled in a

straight line. All hardware should be included

with your conveyor. It is recommended that all

flanges be caulked to seal the conveyor to

keep the dust in and the weather out.

7. After all sections are caulked and bolted, the

loader(s) is/are ready to be installed.

Loaders must be installed with the grain

stream moving in the same direction and

same speed as the conveyor belt. (See page

30 for recommended spout loading).

8. After location of the loader(s) (as to spouts,

gates, and valves) has been established, the

loader(s) are bolted to the conveyor . Do not

weld loader(s) to the conveyor . (See page 13

for loader installation).

9. Belt may now be hand fed through the

conveyor. Make sure when splicing belt that

each cut is clean, square and straight.

Detailed belt assembly instructions are listed

on pages 20 - 29. These instructions should

be followed closely and read thoroughly

before starting this step.

10.Check drive belts for tension. Also check the

oil level in the speed reducer. Reducers are

shipped without oil. Refer to page 41 for

the type and quantity of oil. (DO NOT overfill

reducer.)

9PNEG-1204 Enclosed Belt Conveyors

Page 15

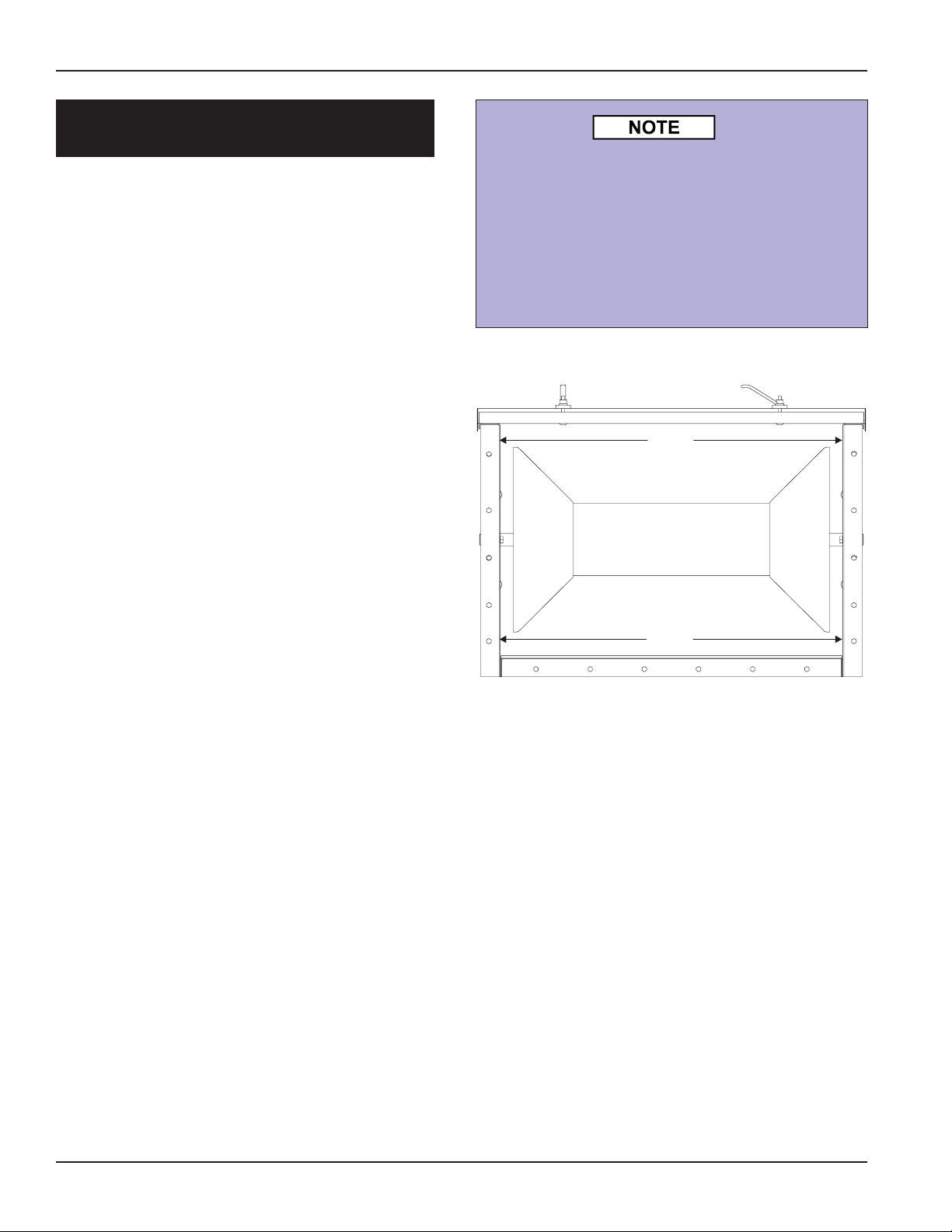

Conveyor Assembly

INTERMEDIATE SECTION

INSTALLATION

MAKE SURE TO READ ASSEMBLY

OVERVIEW ON PAGE 9 FIRST.

1. Intermediate sections are supplied in standard ten foot (10') lengths. Depending on

your application and individual specifications

however, shorter sections may be required to

accommodate a desired overall length.

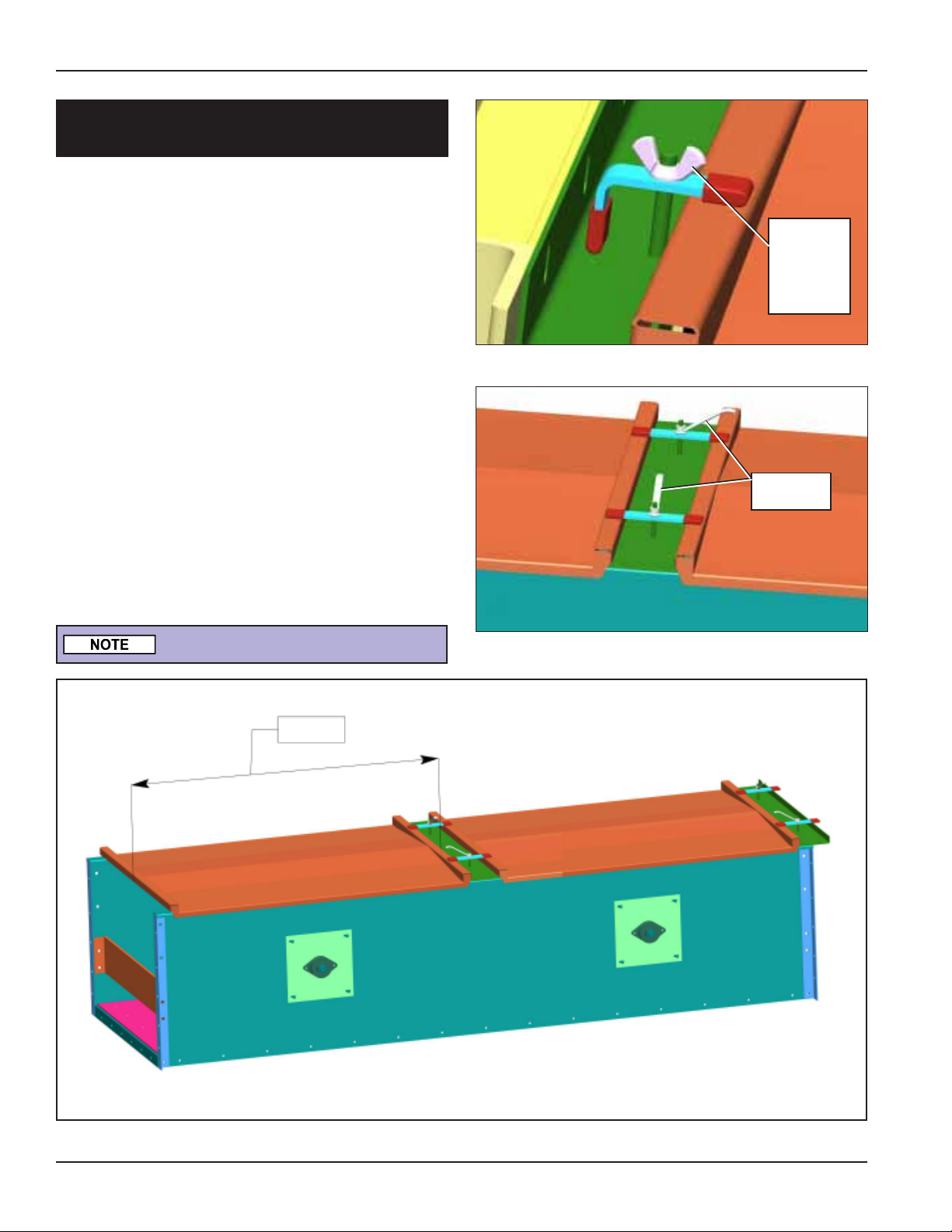

2. After making sure the flanges are aligned,

tighten all hardware on the trough section.

(It is recommended that the flanges are

caulked to insure sealing from dust and

outside moisture.)

It is critical for straitness of the conveyor

that the sides and bottom flanges are

aligned flush. Also, it is important that the

inside dimensions of the box measure

equidistant from side-to-side both top and

bottom of the intermediate section

(Dimension A = Dimension B). See diagram

below.

A

3. During assembly of the intermediate sections, carefully inspect each flange joint to

ensure that the inside bottom and side surfaces of the intermediates are flush. A chalk

line is helpful during this phase of the assembly to ensure the proper alignment of the

intermediate section surfaces. The maximum run-out in any direction should be

+/- 1/4". Make sure the conveyor is level in

horizontal applications.

4. Proceed by attaching the head and tail

assemblies using the same alignment procedures and precautions noted in the preceding

paragraph.

B

End View of Intermediate Section

(Liners not shown for clarity)

10

PNEG-1204 Enclosed Belt Conveyors

Page 16

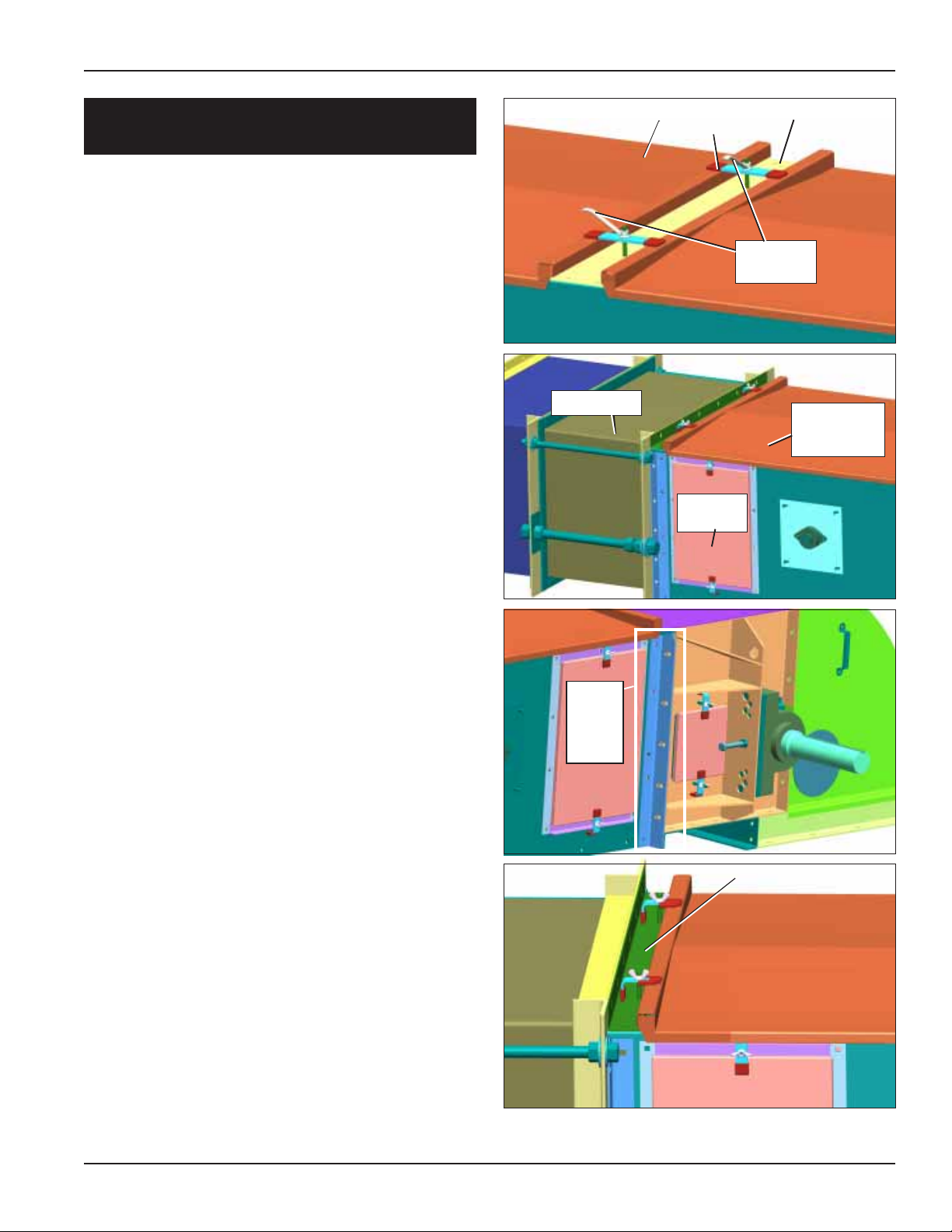

Conveyor Assembly

INTERMEDIATE SECTION

INSTALLATION (CONT.)

1. Intermediate Sections bolt together along the

side and bottom flanges. The covers are

fastened to the cover channels by flat clips

and easy grip handles.

2. St andard intermediate sections do not have

a direction in which they bolt to other

intermediate sections. The cover channels

connect intermediate sections on both ends.

3. T wo inspection intermediate sections are

included on each installation. They should be

assembled at the head and tail. The

inspection holes should be oriented closest

to the head or tail.

4. The inspection door end of each

intermediate section has adapter angles

with slotted holes for bolting to head or

tail sections.

Tail Section

Cover

Flat

Clips

Inspection

Door

Cover Channel

Easy Grip

Handles

Intermediate

Inspection

Section

5. A special cover channel is provided with the

tail as shown at right.

Adapter

Angle

with

Slotted

Holes

Tail Cover Channel

11PNEG-1204 Enclosed Belt Conveyors

Page 17

Conveyor Assembly

COVER INSTALLATION

1. Fasten covers to the belt conveyor with the

3/8" easy grip handles provided. Adequately

tighten the 3/8" handles so that the covers

are in tight contact with conveyor cross

channels.

2. When a loader is on the conveyor, the cover

section may have to be cut accordingly to

accommodate the loader . For installation of

a loader, see Loader Inst allation on page 13.

3. Conveyor covers are made to fit over the

entire width and half the length of a conveyor

intermediate section. Standard covers measure approximately 4' 7" in length. When a

loader is ordered, the cover may be measured and cut to take up the displacement of

the loader housing. This depends on the

position of the loader.

3/8" Wing

Nut on Tail

Section to

Secure

Cover.

Easy Grip

Handles

DO NOT Walk on Conveyor Covers!

4' 7"

12

Standard Cover Length

PNEG-1204 Enclosed Belt Conveyors

Page 18

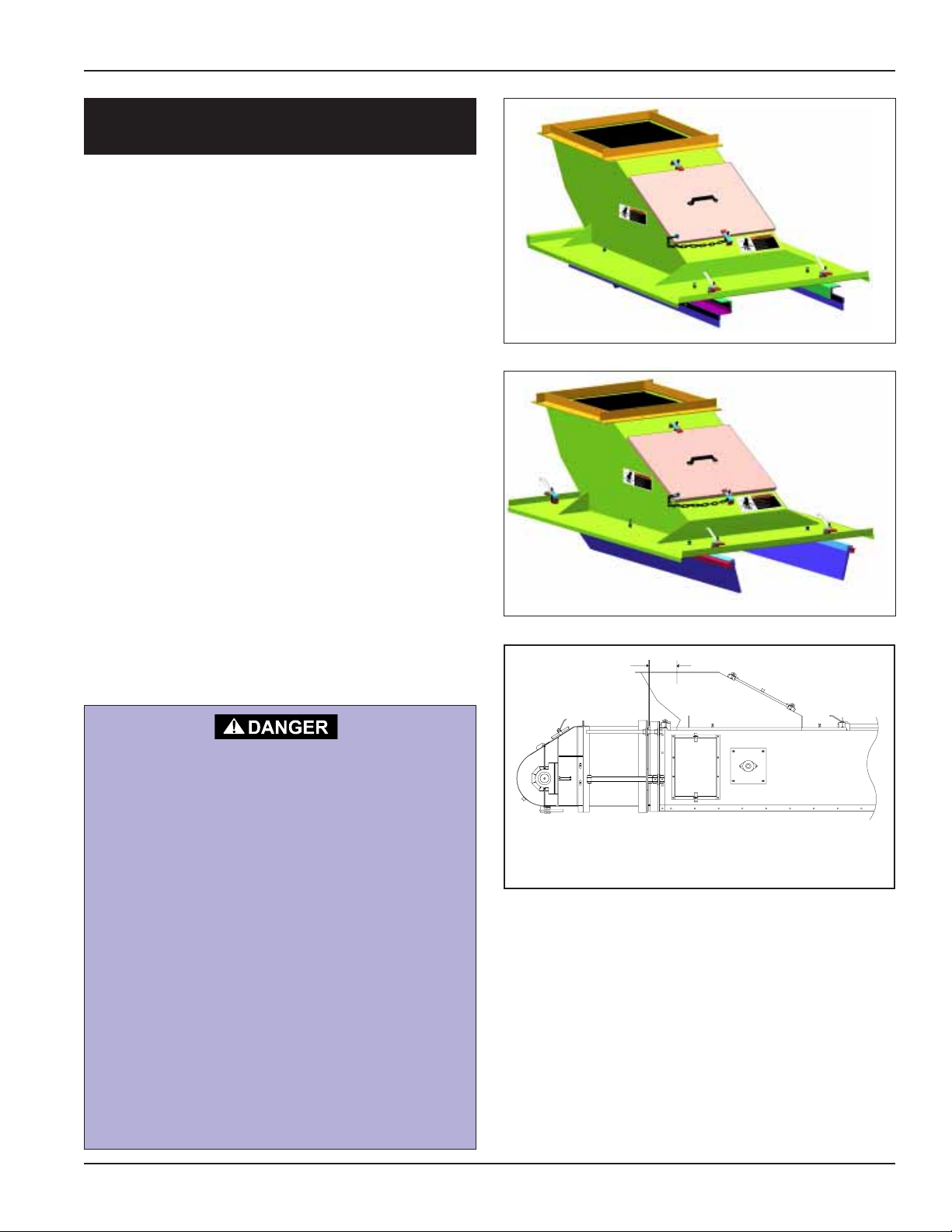

LOADER INSTALLATION

Fixed Skirt Loader

1. The fixed skirt loader always attaches at the

tail end so no cover modifications should be

necessary . The soft rubber skirts are adjustable and can be set to lightly touch the conveyor belt.

Swing-Up Skirt Loader

1. If the loader doesn’t line up exactly with an

intermediate cover, the intermediate covers

will need to be cut to fit. If this is necessary ,

properly position loader and cut a section

from the covers so they will fit between the

cover channel bolted to next section and the

loader flange. Weld cover back together to

achieve required length. Repaint welded

area to prevent rusting.

2. The UHMW swing-up skirts should not touch

the conveyor belt as they can cause wear to

the belt. Use the adjustable set screws to

locate the position of the skirts.

Conveyor Assembly

Fixed Loader

Swing Up Skirt Loader

6"

REMOVE PAINT BEFORE

WELDING OR CUTTING

Avoid hazardous fumes that can be generated

when paint is heated by welding or torching.

Do all work outside or in a well ventilated

area. Dispose of paint and solvent properly.

Remove paint before welding or heating:

• If you sand or grind paint, avoid breathing

the dust. Wear an approved respirator.

• If you use solvent or paint stripper,

remove stripper with soap and water

before welding. Remove solvent or strip

per containers and other flammable

material from area. Allow fumes to

disperse at least 15 minutes before

welding or heating.

GSI’s recommendation for loader installation includes

a minimum distance of no less than 6" between the

center of loader inlet and the tail assembly .

13PNEG-1204 Enclosed Belt Conveyors

Page 19

Motor Assembly

MOTOR AND SHAFT TORQUE ARM II INSTALLATION

Motor

Drive

Pulley

V-Belt

Belt

Guard

Bracket

Belt

Guard

Driven

Pulley

Keep as close

as possible

Hex Nut

Motor Adjustment Plate

Jackscrew

Motor Mount Base Plate

Allow sufficient distance between bushing and

bearing to remove bushing assembly bolts.

Head

Section

Intermediate

Inspection

Section

Torque Arm

Bracket

NOTE: Belt Guards Not

Shown for Clarity .

Head Section

Motor

Torque Arm

Turnbuckle Assembly

Driven

Pulley

Drive Pulley

V-Belt

Hood

Reducer

Drive

14

PNEG-1204 Enclosed Belt Conveyors

Page 20

Motor Assembly

MOTOR AND TORQUE ARM II

REDUCER INSTALLATION

Reducer

1. T o aid in the installation of the reducer onto

the shaft, remove any protective coating film

from the shaft.

2. Place key in the keyway on the drive shaft.

3. Attach inside bushing to the reducer drive.

4. Line up the keyway on reducer with key on

shaft and slide the reducer drive onto the

drive shaft.

5. Slide outside bushing onto shaft and attach

to reducer drive. Once reducer drive is in

place, fully tighten both bushings.

(See page 38 for more details.)

Bushing

Key

Conveyor

Drive

Shaft

Shaft

Mount

Reducer

Conveyor

Drive Shaft

Bushing

Shaft

Mount

Reducer

BELT GUARD

COVER

DC-995

DC-994

DC-994

DC-995

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

WARNING

Shear point. Keep hands

clear of moving parts. Do

not operate with guard

removed. Disconnect

and lockout power before

servicing.

DC-995

DC-994

15PNEG-1204 Enclosed Belt Conveyors

Page 21

Motor Assembly

MOTOR AND TORQUE ARM II

REDUCER INSTALLATION

T orque Arm Turnbuckle Assembly

6. Install the torque arm between the 2 plates

that are located on the bottom of the reducer

drive. Secure using bolt with washer and lock

nuts. Attach the other end to the torque arm

bracket on the conveyor using two bolts,

washers, and locknuts. T ighten the torque arm

by turning the turnbuckle. Adjust the position

of the reducer. The reducer should be in a

vertical position as shown on page 14.

T orque Arm Bracket

(CONT.)

Plates on

Reducer Drive

T orque Arm

7. The torque arm bracket is mounted under the

first intermediate section. Locate bracket by

matching an existing set of holes in the

intermediate side that allows the turnbuckle

assembly to be as short as possible with the

reducer in a vertical position.

The holes in the intermediate side must

be drilled out to 9/16" Diameter. Att ach

with provided hardware.

Torque

Arm

Bracket

Torque

Arm

Bracket

T orque Arm

Assembly

Turnbuckle

T orque Arm

Plates

on

Reducer

Drive

16

Turnbuckle

PNEG-1204 Enclosed Belt Conveyors

Page 22

Motor Assembly

MOTOR AND TORQUE ARM II

REDUCER INSTALLATION

Motor Mount Brackets

8. Remove three bolts from each side of the

reducer housing. Use a set of holes in the

motor mount upright brackets that allows the

motor plate to be as close as possible to the

top of the conveyor. Check this location by

temporarily positioning the belt guard on the

reducer with the hole in the guard centered

over the reducer input shaft. This will show

the correct motor position for the lengths of

v-belts provided. Attach by replacing bolts

through brackets and housing. T ighten bolts

securely.

Motor Mount Adjustment Plates

(CONT.)

Motor

Mount

Bracket

Attached to

Reducer

Nuts

Jackscrews

Motor Mount

Adjustment

Plate

9. Thread nuts onto jackscrews. Place bolt

through motor mount bracket and base plate.

Thread another nut onto jackscrews to

secure. Repeat for 3 remaining jackscrews.

10.Thread another nut onto all four jackscrews.

Place adjustment plate onto jackscrews.

Thread another nut onto each jackscrew to

secure adjustment plate. Use these nuts to

adjust the motor height.

1 1.Attach the motor to the adjustment plate

using bolts and locknuts.

Drive Guard Rear Panel

12.Install the rear panel of the drive guard before

mounting the sheaves. The rear panel has

two (2) mounting brackets with slotted holes.

Attach these left-hand and right-hand belt

guard mounting brackets to the motor mount

frame. Then fasten rear panel of belt guard to

the belt guard brackets. After the rear panel

is in place, install sheaves onto motor and

reducer.

Base

Plate

17PNEG-1204 Enclosed Belt Conveyors

Page 23

Motor Assembly

Sheaves and Belts

13.Assemble the V-belt driven sheave to the

input shaft of the shaft mount reducer . Insert

the bushing into sheave hub. Match holes in

bushing and hub (not threads). Put screws

into holes that are farthest apart. Slip entire

unit with key onto shaft. Align the driver and

driven sheaves and tighten the retaining

screws. During tightening, it is possible for

the sheave to move out of alignment or

become out of square. For maximum V -Belt

life, the driven sheave should remain both

perpendicular to the drive shaft and aligned

with the drive sheave. Slip the V -belts over

both the driver and driven sheaves.

V-Belt Adjustment

Too much tension shortens belt life.

Check belt tension frequently during

the first 24-48 hours of operation.

14.Adjustment of V-belt tension is achieved by

tightening the hex nuts located on the four (4)

jackscrews of the motor base. Adjust motor

base equally at all four jackscrews to

maintain shaft alignment. Belts are

designed to fit loose upon installation. When

the V -belt tension is correct, tighten the top

nut on the jackscrews to lock the motor base

in position. Proper tension is 1/64" of

deflection per one (1") inch of sheave centers

on one side of belt, centered between

sheaves. (See diagram below.)

Sample Deflection Problem:

3-1/2' Span = 21/32" of Deflection (Approximately 11/16")

1. 3-1/2' = 42"

2. 1/64" = .015625"

3. 42" x .015625" = .65625"

4. .65625" = 21/32" of Deflection

18

PNEG-1204 Enclosed Belt Conveyors

Page 24

Front Guard Panel

Belt Width

15.Install the front drive guard panel over the four

corner mounting studs. Secure with washers

and nuts provided.

Belting Assembly

Lubricate Reducer Drive

16.Fill the shaft mount reducer with the

manufacturer’s recommended oil.

(See Page 41.)

Lubricate Bearings

17. Grease bearings on head, tail and idlers.

Lubricate bearings according to bearing

manufacturer’s recommendations.

(See Page 52.)

Grease

Bearing

Housing

Grease Idler

Bearings

FINDING BELT CENTER LINE

1. T o find the belt center line, measure the belt

width at five points. S tarting near the end of

the belt, measure the belt width in 10" intervals, marking them as you measure. Each

measurement shall then be divided in two

and marked. Using a straight edge, draw a

center line using the points as a guide. (See

diagram at right)

Centerline

10” 10” 10” 10”

Center Point of Width Measurements

Belt End

19PNEG-1204 Enclosed Belt Conveyors

Page 25

Belting Assembly

SQUARING THE BELT END

1. A double arc method is used on establishing

a cut line on the belt. After a center line has

been drawn, pick a point on the center line

about two times the belt width. From this

point, strike an arc across the width of the

belt end. A nail may be used as a pivot point

with twine used as the arm of the arc. Tie a

marking tool (chalk, for example) to the end

of the twine.

Pivot Point of

1st Arc

Belt Width

2. A second set of arcs is struck with the pivot

point of the arc on center line and close to

the belt end. Where the two arcs intersect

each other are points on which a cut line is

drawn.

The second arc should be slightly less than

half of the width of the belt.

Intersection

Point

Pivot Point of

2nd Arc

Cut Line

Centerline

CHECK THE SQUARENESS OF

THE BELT CUT

1. T o check for the accuracy of the cut made,

measure lengthwise 50 inches from each

edge of the belt. Using a straight edge, draw

a line diagonally across the belt. This should

be done from the 50 inch point to the end

corner on the opposite side of the belt. Do

the same procedure in reverse to form an “x”.

The intersection point of the two lines of the

“x” should be in line with the center line of the

belt.

Belt

Centerline

Intersection

Point

Diagonal Line

Cut

Edge

of Belt

Intersection

Point

20

PNEG-1204 Enclosed Belt Conveyors

Page 26

Belting Assembly

INSTALLATION OF BELT

1. Hand thread the belt through the conveyor

with the tail section in a retracted position.

Attach a tightening device to each end of the

belt to prevent damage to the belt. Place a

2" x 12" piece of wood width wise on top of

an intermediate section where the belt ends

are to be brought together. Bring the belt

seam together over the 2" x 12" piece of

wood for a working surface to be used for

splicing. (See diagram below.) The belt

splice can now be installed following step-bystep directions on the following four pages.

TAIL

END

2" x 12" Block of Wood

Field cut, square, and

punch holes in field

this end of belt.

Conveyor

Belt Ends

DIRECTION OF BELT TRAVEL

Factory Supplied Splice

Protector (Flipper)

Install Flippers on end belt

that has been pre-punched

and cut by factory.

HEAD

END

Intermediate Section with Covers Removed

Detail installation of belting into conveyor.

Install belting into tail end.

IMPORTANT: Note the direction of the flippers on belt.

Flippers are installed to aid in cleanout of tail shroud.

21PNEG-1204 Enclosed Belt Conveyors

Page 27

Belting Assembly

SPLICING THE BELT

1. Support belt ends with wood plank. Nail

Flexco T emplate in position with belt ends

tight against lugs.

2. Spray template holes with Flexco Silicone

Lubricant. Punch or bore bolt holes. Remove

template.

Splice protector design may vary due to type of

conveyor. I.E. - Reversible conveyors and

conveyors with low-profile head discharges do

not have splice protectors with tails (flippers).

1

2

2

22

PNEG-1204 Enclosed Belt Conveyors

Page 28

Belting Assembly

SPLICING THE BELT

3. T o assemble bottom plate insert 2 bolt s and

attach clip.

4. Fold one belt end back and insert bolts in

one row of holes.

5. Align bolts with template teeth and place the

other belt end over bolts. Remove template.

6. Place top plates over bolts using bolt horn.

(Cont.)

3

4

5

6

23PNEG-1204 Enclosed Belt Conveyors

Page 29

Belting Assembly

SPLICING THE BELT

7. Start nut s on bolts by hand.

8. Cut Flexco-Lok T ape 3-1/2 times the belt

width and feed tape under top plates, under

the bottom plates, then back under top

plates.

9. Pull tape tight and hold in position by tightening a fastener at each end. Then tighten all

other plates.

10.Tighten all nuts uniformly . NOTE: A flexco

Power Wrench used with an impact tool will

speed this step considerably .

(Cont.)

7

8

9

24

10

PNEG-1204 Enclosed Belt Conveyors

Page 30

Belting Assembly

SPLICING THE BELT

1 1.Hammer plates in belt with wood block.

Retighten nuts.

12. Break off excess bolt ends using two bolt

breakers. Peen or grind bolts to finish.

13. Place flippers on belt. The flipper should be

located so the tail of the flipper covers the

splice. Note direction of belt travel. The

flippers are evenly spaced across the belt

with a 1/4" gap between them. There will be a

larger gap between the outside flipper and

the edge of the belt.

14. Punch or bore holes. Att ach flippers using

same connectors as splice. Repeat steps

10-12.

(Cont.)

11

15. Finished splice.

12

13

Direction of

Rotation

25PNEG-1204 Enclosed Belt Conveyors

Page 31

Belting Assembly

BELT TENSION

1. IMPORTANT: The belt tension should be

checked every day of use for the first few

days. Conveyor belts stretch when new and

must be checked at regular intervals. After

approximately two weeks of usage, checks of

belt tension may be done at less frequent

intervals.

2. After splice has been installed and 2" x 12"

piece of wood is removed, belt is ready to be

tightened.

3. The belt is tightened by turning the take-up

rods located on the tail section. Make sure

that they are adjusted equally to prevent

misalignment. The conveyor belt should be

tightened enough to prevent the belt from

slipping on the drive pulley . When done

adjusting take-up rods, tighten nuts against

flanges to lock in place.

After an hour of running, the belt should be

retightened and thereafter checked at

regular intervals. Take-Up Rods are for

tightening belt only. They are not to be

used to adjust belt tracking.

Leveling Rod

Do Not over tighten belt. Over

tightening can cause premature

wear of bearings and shafts.

To tighten

belt tension,

adjust tail

section in this

direction.

Leveling Rod

T ake-Up Rod

Take-Up Rod

Nuts

26

Flanges

TAIL SECTION

PNEG-1204 Enclosed Belt Conveyors

Page 32

BELT TRACKING

Squareness of the Conveyor

1. Before tracking procedure is begun, each

section should be square and straight so

there is no unequal weight distribution. Check

conveyor intermediate sections for any

extensive damage such as cave-in sides,

etc. Idlers should be checked for looseness. If

idlers are loose, re-center and tighten set

screws on bearing lock collar .

2. After intermediate sections are bolted

together , a chalk line should be strung along

the sides of the conveyor, making sure that it

is in a straight line. Loosening bolts on the

intermediate frames will permit slight

adjustment of the intermediate sections.

Belting Assembly

3. After conveyor has been installed, check to

see if the unit is level (width wise). The

conveyor must be level for proper belt

tracking.

Shims

Bearing

Bearing

Adjustment

Bolts

Shims

Bearing

TAIL SECTION HEAD SECTION

27PNEG-1204 Enclosed Belt Conveyors

Page 33

Belting Assembly

Tracking Adjustment

4. Belt tracking adjustment is initiated by moving the bearing adjustment bolts. These are

located on both sides of the head and tail

sections. Belt tracking adjustments are made

by adding or removing shims under bearing

as necessary . DO NOT use take-up rods to

correct belt tracking.

5. Adjustment of the idlers is done by loosening

eight bolts. These bolts hold the bearings in

place and are located on both sides of the

conveyor sections (four on each side). Af ter

loosening these bolts, the end of the idler can

shift either forward or backward.

Bearing

Adjustment

Bolts

Bearing

Adjustment

Bolts

28

Loosen these

four nuts on

both sides for

adjustment.

PNEG-1204 Enclosed Belt Conveyors

Page 34

General Tracking/Training Procedures

Belting Assembly

6. Tracking the belt is a process of adjusting

idlers, pulleys, and loading conditions in a

manner that will correct any tendencies of the

belt to run other than true.

7. A normal sequence of training is to start with

the top pulleys in the direction of belt travel.

St art with the belt empty . After tracking is

completed, run the belt with a full load and

recheck tracking.

8. Tracking adjustment is done while the belt is

running and should be spread over some

length of the conveyor preceding the region

of trouble. The adjustment may not be immediately apparent, so permit the belt to run for

several minutes and at least three full belt

revolutions after each idler adjustment to

determine if additional “tracking” is required.

9. After adjustment, if the belt has overcor-

rected, it should be restored by moving back

the same idler, and not by shif ting additional

idlers or rollers.

13.The basic and primary rule which must be

kept in mind when tracking a conveyor belt is

simple, “THE BELT MOVES TOWARD

THAT END OF THE ROLL/IDLER IT CONTACTS FIRST.”

14.The reader can demonstrate this for himself

very simply by laying a small dowel rod or

round pencil on a flat surface in a skewed

orientation. If a book is now laid across the

dowel rod and gently pushed by one’s finger

in a line directly away from the experimenter,

the book will tend to shift to the left or right

depending upon which end of that dowel rod

the moving book contacts first.

10.If the belt runs to one side at a particular point

or points on the conveyor structure, the cause

will probably be due to the alignment, or

leveling of the structure, or to the idlers and

pulleys immediately preceding that particular

area, or a combination of these factors.

1 1.If a section or sections of the belt run off at all

points along the conveyor , the cause is

possibly in the belt itself, in the belt not being

joined squarely , or in the loading of the belt.

With regard to the belt, this will be due to

camber. It s condition should improve after it

is operated under full load tension. It is a rare

occasion when a cambered belt (less than

1/2%) needs to be replaced.

12.When replacing a used belt, go through the

system and square and level all rollers, idlers,

pulleys and bed before training a new belt.

29PNEG-1204 Enclosed Belt Conveyors

Page 35

Loading

SPOUTING

1. Below are the recommended and incorrect

ways to attach spouting to load the conveyor .

Contact the GSI Material Handling Department if there are any questions about loading

conditions.

RECOMMENDED

Grain Flow

Belt Direction

AVOID

INCORRECT

Grain stream centered on the belt. Grain moving in the

same direction and at the same speed as the belt.

Grain Flow

Belt Direction

This causes excessive wear of belting and off center

loading on belt which causes spillage. This method of

loading results in grain tumbling on belt.

Grain Flow

30

Belt Direction

Grain should be loaded in the same direction

of belt travel and at the same speed.

PNEG-1204 Enclosed Belt Conveyors

Page 36

SPOUTING LOCATION

1. Grain should come out from storage and

make a 90° turn by use of baffles and load

straight into the conveyor at approximately a

45° angle.

Belt Direction

Pit

or

Bin

Loading

Pit or Bin

Belt Direction

SIDE VIEWTOP VIEW

END VIEW

31PNEG-1204 Enclosed Belt Conveyors

Page 37

Loading

BELT CONVEYOR LOADING

1. St art with a light load and gradually work up

to the load that the conveyor was designed to

handle. Check chutes to see that the material

is being directed onto the center of the belt.

Off-center load will affect belt alignment in

that the belt will run off center . A central load

will maintain belt alignment.

2. The loading point of a belt conveyor is the

critical point. Here the conveyor receives its

major abrasion and practically all of its impact. The ideal condition is to have the

material flow onto the belt at the same speed

and direction of travel as the belt, with a

minimum amount of impact, and to load the

belt on center.

CORRECT - Evenly Loaded

3. Adjust the skirts to prevent side spillage of

material and to keep the load central on the

belt. The maximum distance between

skirtboards customarily is two thirds the width

of a trough belt.

4. The skirt lengths are designed to stop side

spillage. The material should also be at rest

on the belt before it reaches the end of the

skirt. If the material is still tumbling as it

passes the skirt end, the skirts should be

lengthened.

INCORRECT - Loaded to One Side

Belt Shift

Spill

EFFECT OF IMPROPER LOADING

32

PNEG-1204 Enclosed Belt Conveyors

Page 38

MOTION SENSOR OPTION

WHIRLIGIG - WG1-4B

Installation Instructions

ALWAYS OBSERVE LOCKOUT AND TAGOUT PROCEDURES BEFORE, DURING

AND AFTER INSTALLA TION.

DO NOT REMOVE THE WHIRLIGIG

COVER. THE ROTATING COMPONENTS

UNDER THE COVER COULD CAUSE

SERIOUS INJURY.

1. Shaft ends are predrilled and tapped from

the factory .

2. Thread the WHIRLIGIG onto the machine

shaft using 5/8" open ended wrench and

suitable thread locking adhesive (Loctite or

similar).

Options

3. Install the sensor to the WHIRLIGIG baseplate. T wo sets of predrilled holes are provided for M800 sensor. Fit the sensor to

leave an approximate 2mm gap between

sensor face and cover.

A universal bracket (WGB18/30) is supplied

for fitting 18mm or 30mm sensors.

4. Connect the sensor in accordance with

manufacturer’s instructions and observe all

relevant electrical & OSHA regulations.

5. Fix the flexible strap securely to the static

structure. (If required).

TIP: The M800 speedswitch and system

function can be tested by placing a thin

metal plate between the sensor and the

cover of the WHIRLIGIG. When installing

other industry standard sensors, leave a

small gap between the sensor & the

WHIRLIGIG cover for this purpose.

M800 Sensor

Cylindrical Sensor

18/30mm Bracket

(Supplied)

10mm Screws (4)

(Supplied)

50mm Screws (4)

(Supplied)

Flexible Conduit

T ap Shaft for 1/2" UNC Centered

Cover

The Whirligig

Monitored Shaft

Flexible Strap

33PNEG-1204 Enclosed Belt Conveyors

Page 39

Options

PRESSURE PLUG

SWITCH OPTION

Monitor MODEL GX, Part No.7-8150 - Neoprene

diaphragm, standard switch

ELECTRICAL INSTALLATION

1. Hazardous Location Precautions

Observe the regulations listed in the National

Electrical Code regarding equipment in

hazardous locations. In particular , insure

power is disconnected whenever the cover is

removed, insure the cover and case mating

surfaces are not damaged, and upon

completion, ensure cover screws are secure

and that no gaskets or sealer has been used

between the cover and case surfaces.

2. Output Contacts

Route wires through the 1/2" NPT conduit

entrance. No power is required to operate

the diaphragm bin monitors. All electrical

installation is done directly to the terminals of

the output switch. The switch terminals are

designated with “3” (COM-common),

“2” (N.C.-normally closed), and “1” (N.O.normally open). When the diaphragm is not

sensing material, the switch is in the normal

condition (i.e. N.C. contact is closed to COM,

and N.O. contact is open to COM). However ,

when the diaphragm senses material, the

switch is opposite from normal condition

(i.e.N.C. contact is open to COM, and N.O.

contact is closed to COM). Be sure to comply

with all electrical specifications listed within

this bulletin.

34

PNEG-1204 Enclosed Belt Conveyors

Page 40

STARTING CONVEYOR

1. Check for and remove any tools or debris

that may have been left in the conveyor

during installation.

2. Tighten the take-up rods on the t ail section

equally . The belt should be tightened sufficiently to prevent slippage between the drive

pulley and belt and to conform to the crown

on the crowned head pulley .

3. Install covers after belt has been trained.

SECURE SHROUD DURING MAINTENANCE

Start-Up

Slot

Shroud

Chain

While accessing the tail pulley, the tail shroud

may either be removed or pivoted in an upright

position. If pivoted upright, then secure the

shroud by placing the chain in the slot as shown.

35PNEG-1204 Enclosed Belt Conveyors

Page 41

Maintenance

CARE & MAINTENANCE

Before any maintenance is performed

to the conveyor, power must be shut

off and locked out to prevent

accidental start up!

Welding

Welding on or to the conveyor may cause damage to both the conveyor and its electrical system. If welding is necessary, precautions should

be taken to protect the conveyor . Should it be

necessary to fasten anything to the conveyor

permanently , careful consideration should be

given to methods of maintenance, removal and

replacement of the conveyor and/or its parts.

Motor

The care and maintenance section is provided with

the intention of helping to extend the useful life of the

unit. Like all equipment, the useful life of the conveyor is greatly reduced if not used wisely and well

maintained.

Please follow the next few simple steps to insure

the safety and longevity of your equipment.

• Check all bearings and moving parts daily

during use.

• Lubricate bearings according to bearing

manufacturer’s recommendations.

(See page 52.)

• Follow manufacturer’s recommendations for

gear reducer lubrication and maintenance.

(See page 41.)

• Inspect the V-belt s periodically for proper

tension and wear. V-belts should be

replaced as necessary. If replacement or

tension adjustment is required, please refer to

the Shaft Mount Reducer Assembly Section

on page 15.

• The belting and belt idlers should be

checked periodically for wear and damage.

Should replacement of these components be

required, contact the manufacturer.

Bearings

Connect the conveyor motor to a power source

according to the motor manufacturer’s instructions and recommendations. To avoid injury it is

recommended that a certified electrician perform

the motor wiring. A shut off switch should be

placed near the motor so that the system may

easily be shut down to help prevent accidents

during maintenance. It is important to check

proper motor shaft rotation before installing drive

belts

Support

Include adequate support for the conveyor assembly to be installed at intervals no greater than

10 feet. It is recommended that supports be

installed at vertical portions of flanges leaving

bottoms of intermediate sections clear. By

attaching supports in this manner, the removable

bottoms are unobstructed for ease of replacement. Support legs are available as an option.

STORAGE

If the unit is to be inactive for an extended period,

the following procedures are recommended.

• Thoroughly clean the unit.

• Loosen the V-belt tension. Doing so

relieves the stress placed on the bearings

and shafts of the drive and tail sections.

Lubricate bearings at regular intervals. If one

bearing is re-lubricated, all other bearings should

also be lubricated. Do not over lubricate as this will

destroy bearing seals.

36

• Lubricate shafts and drive chain

components with a good grade of light

machine oil.

PNEG-1204 Enclosed Belt Conveyors

Page 42

Troubleshooting

TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION PAGE

Conveying belt drifts

sideways.

Material buildup on

idler pulley , drive pulley

or between sections

and belt.

Belt not properly tracked.

Belt splice not square.

Material not placed on

center of belt.

Machine is not straight.

Machine not level.

Material buildup on

pulleys.

Material getting under

belt.

Track belt over pulleys.

Check splice squareness, re-splice.

Direct material through loader and

spouting.

Check machine alignment with chalk

line or string.

Check and level sections.

Clean pulleys, retrack belt.

Remove buildup from pulleys and

sections.

Track conveying belt.

Check machine alignment and

levelness.

27, 28, 29

21

30, 31, 32

9, 10, 27

27

--

--

27,28, 29

9, 10, 27

Lack of capacity .

Loader not being used.

Conveying belt slippage.

Eliminate point(s) where material may

be entering under belt.

Use loader to position material on

center of belt. All material must be

directed through hopper.

Tighten so belt conforms to crowned

pulleys.

--

--

35

37PNEG-1204 Enclosed Belt Conveyors

Page 43

TORQUE ARM II REDUCER

INSTALLATION

1. Use lifting bracket to lift reducer.

2. Determine the running positions of the reducer. (See Fig. 1)

Note that the reducer is supplied with 6 plugs; 4 around the

sides for horizontal installations and 1 on each face for vertical

installations. These plugs must be arranged relative to the

running positions as follows:

Mounting

Position

Position A Plug Level Drain Vent Plug Plug

Position B Drain Vent Plug Level Plug Plug

Position C Level Plug Vent Drain Plug Plug

Position D Vent Drain Level Plug Plug Plug

Position E Level Plug Plug Drain Vent Plug

Position F Plug Drain Level Plug Plug Vent

Below 15 RPM output speed, oil level must be adjusted to reach the highest

oil level plug. If reducer position is to vary from those shown in Figure 1, either

more or less oil may be required. Consult Dodge.

Output Speeds 15 RPM and Below

123456

Vent and Plug Locations

Horizontal Installations - Install the magnetic drain plug in the

hole closest to the bottom of the reducer. Throw away the tape

that covers the filter/ventilation plug in shipment and install plug

in topmost hole. Of the 2 remaining plugs on the sides of the

reducer, the lowest one is the minimum oil level plug.

Vertical Installations - Install the filter/ventilation plug in the

hole provided in the upper face of the reducer housing as

installed. If space is restricted on the upper face, install the vent

in the highest hole on the side of the reducer per Figure 1.

Install a plug in the hole in the bottom face of the reducer. Do

not use this hole for the magnetic drain plug. Of the remaining

holes on the sides of the reducer, use the plug in the upper

housing half for the minimum oil level plug.

Figure 1 – Mounting Positions

HORIZONTAL MOUNTING

POSITION A

5 (NEAR)

6 (FAR)

POSITION C POSITION D

2

4 (NEAR)

3 (FAR)

4

1

3

3

1

4

2

5 (NEAR)

6 (FAR)

VERTICAL MOUNTING

5

6

2

1

POSITION B

5 (NEAR)

6 (FAR)

3

POSITION FPOSITION E

1

2

4

1

4

2

6

5

3

1

5 (NEAR)

6 (FAR)

4 (NEAR)

3 (FAR)

2

The running position of the reducer in a horizontal application is

not limited to the four positions shown in Fig. 1. However, if

running position is over 20° in position "B" & "D" or 5° in position

"A" & "C", either way from sketches, the oil level plug cannot be

used safely to check the oil level, unless during the checking,

the torque arm is disconnected and the reducer is swung to

within 20° for position "A" & "C" or 5° for position "B" & "D" of

the positions shown in Fig. 1. Because of the many possible

positions of the reducer, it may be necessary or desirable to

make special adaptations using the lubrication filling holes

furnished along with other standard pipe fittings, stand pipes

and oil level gauges as required.

3. Mount reducer on driven shaft as follows:

WARNING: To ensure that drive is not unexpectedly started,

turn off and lock out or tag power source before proceeding.

Remove all external loads from drive before removing or

servicing drive or accessories. Failure to observe these

precautions could result in bodily injury.

For Taper Bushed Reducer: Mount reducer on driven shaft

per instruction in Torque-Arm II Bushing Installation section of

this manual.

4. Install sheave on input shaft as close to reducer as practical.

(See Fig. 2)

5. If not using a Dodge Torque-Arm II motor mount, install

motor and V-belt drive so belt will approximately be at right

angles to the centerline between driven and input shaft. (See

Fig. 3) This will permit tightening the V-belt with the torque arm.

6. Install torque arm and adapter plates reusing the reducer

bolts. The adapter plates will fit in any position around the input

end reducer.

Mounting

Position

Position A Level Plug Drain Vent Plug Plug

Position B Drain Vent Level Plug Plug Plug

Position C Plug Level Vent Drain Plug Plug

Position D Vent Drain Level Plug Plug Plug

Position E Level Plug Plug Drain Vent Plug

Position F Plug Drain Level Plug Plug Vent

Output Speeds Above 15 RPM

123456

Vent and Plug Locations

38

7. Install torque arm fulcrum on a flat and rigid support so that

the torque arm will be approximately at right angles to the

centerline through the driven shaft and the torque arm anchor

screw. (See Fig. 4) Make sure that there is sufficient take-up in

the turnbuckle for belt tension adjustment when using V-belt

drive.

PNEG-1204 Enclosed Belt Conveyors

Page 44

CAUTION: Unit is shipped without oil. Add proper amount of

recommended lubricant before operating. Failure to observe

this precaution could result in damage to or destruction of the

equipment

8. Fill gear reducer with recommended lubricant. See Table 2.

KEEP

CLOSE

INPUT

SHAFT

DRIVEN

SHAFT

KEEP

CLOSE

Figure 2 – Reducer and Sheave Installation

RIGHT ANGLE OR

MAY VARY 30°

V-BELT

DRIVE

V-BELT

DRIVE MAY

BE LOCATED

TO THE

RIGHT IF

DESIRED

Standard Taper Bushings:

1. One bushing assembly is required to mount the reducer on

the driven shaft. An assembly consists of two tapered bushings,

bushing screws and washers, two bushing backup plates and

retaining rings, and necessary shaft key or keys. The driven

shaft must extend through the full length of the reducer. If the

driven shaft does not extend through the reducer do not use the

standard tapered bushings; instead use the short shaft bushings

as described in the Short Shaft Bushings section that follows.

The minimum shaft length, as measured from the end of the

shaft to the outer edge of the bushing flange (see Figure 5), is

given in Table 1.

2. Install one bushing backup plate on the end of the hub and

secure with the supplied retaining ring. Repeat procedure for

other side.

3. Place one bushing, flange end first, onto the driven shaft and

position per dimension “A”, as shown in Table 1. This will allow

the bolts to be threaded into the bushing for future bushing and

reducer removal.

4. Insert the output key in the shaft and bushing. For easy of

installation, rotate the driven shaft so that the shaft keyseat is at

the top position.

Figure 3 – Angle of V-Drive

RIGHT ANGLE OR

MAY VARY 20° IN

TENSION OR

COMPRESSION

TORQUE-ARM

AND BELT

TAKE-UP

TORQUE

ARM MAY

BE LOCATED

TO THE

RIGHT IF

DESIRED

Figure 4 – Angle of Torque-Arm

TORQUE-ARM II BUSHING

INSTALLATION

WARNING: To ensure that drive is not unexpectedly started,

turn off and lock out or tag power source before proceeding.

Remove all external loads from drive before removing or

servicing drive or accessories. Failure to observe these

precautions could result in bodily injury.

5. Mount the reducer on the driven shaft and align the shaft key

with the reducer hub keyway. Maintain the recommended

minimum distance “A” from the shaft bearing.

6. Insert the screws, with washers installed, in the unthreaded

holes in the bushing flange and align with the threaded holes in

the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing screws. Tighten the

screws lightly. If the reducer must be positioned closer than

dimension “A”, place the screws with washers installed, in the

unthreaded holes in the bushing before positioning reducer

making sure to maintain at least 1/8” between the screw heads

and the bearing.

7. Place the second tapered bushing in position on the shaft

and align the bushing keyway with the shaft key. Align the

unthreaded holes in the bushing with the threaded holes in the

bushing backup plate. If necessary, rotate the bushing backup

plate to align with the bushing holes. Insert bushing screws, with

washers installed in the unthreaded holes in the bushing.

Tighten screws lightly.

8. Alternately and evenly tighten the screws in the bushing

nearest the equipment to the recommended torque given in

Table 1. Repeat procedure on outer bushing.

The Dodge Torque-Arm II Reducer is designed to fit both

standard and short length driven shafts. The Standard Taper

Bushings series is designed where shaft length is not a concern.

The Short Shaft Bushing series is to be used where the driven

shaft does not extend through the reducer.

Short Shaft Bushings:

1. One bushing assembly is required to mount the reducer on

the driven shaft. An assembly consists of one long tapered

bushing, one short tapered bushing, one tapered bushing

wedge, bushing screws and washers, two bushing backup

39PNEG-1204 Enclosed Belt Conveyors

Page 45

plates and retaining rings, and necessary shaft key or keys.

The driven shaft does not need to extend through the reducer

for the short shaft bushing to operate properly. The minimum

shaft length, as measured from the end of the shaft to the outer

edge of the bushing flange (see Figure 5), is given in Table 1.

MINIMUM SHAFT LENGTH

A

hub, install the flange end first so that the thin taper is pointing

outwards towards the long bushing as shown in Figure 6. The

wedge is properly installed when it snaps into place in the

reducer hub.

Figure 6 – Short Shaft Bushing and Output Hub Assembly

Figure 5 – Minimum Recommended Dimensions

Table 1 – Minimum Mounting Dimensions and Bolt Torques

Minimum Required Shaft Length

Reducer Size Standard Taper Bushing Short Shaft Bushing

TA0107L 6.83 4.32

TA1107H 6.95 4.43

TA2115H 7.80 4.80

TA3203H 8.55 5.46

TA4207H 8.94 5.66

TA5215H 10.33 6.35

TA6307H 10.82 6.72

TA7315H 11.87 7.62

TA8407H 12.82 8.10

TA9415H 13.74 8.56

TA10507H 15.46 9.67

TA12608H 18.32 11.60

Bushing Screw Information and Minimum Clearance for Removal

Reducer Size Fastener Size Torque in Ft.-Lbs. A

TA0107L 5/16-18 20 – 17 1.08

TA1107H 5/16-18 20 – 17 1.20

TA2115H 3/8-16 20 – 17 1.20

TA3203H 3/8-16 20 – 17 1.20

TA4207H 3/8-16 26 – 23 1.48

TA5215H 1/2-13 77 – 67 1.81

TA6307H 1/2-13 77 – 67 1.81

TA7315H 1/2-13 77 – 67 2.06

TA8407H 1/2-13 77 – 67 2.06

TA9415H 5/8-11 86 – 75 2.39

TA10507H 5/8-11 86 – 75 2.39

TA12608H 5/8-11 86 – 75 2.39

2. The long bushing is designed to be installed from the side of

the reducer opposite the driven equipment as shown in Figure 6.

The long bushing when properly installed is designed to capture

the end of the customer shaft that does not extend through the

reducer. Normally the reducer would be mounted such that the

input shaft extends from the side of the reducer opposite the

driven equipment however the reducer design allows installation

of the reducer to be mounted in the opposite direction.

3. Install the tapered bushing wedge into the hollow bore of the

reducer from the same side as the long bushing will be installed.

When installing the tapered bushing wedge into the reducer

4. Align the tapered bushing wedge keyway with the reducer

hub keyway. The keyway in the wedge is slightly wider than the

keyway in the reducer hub allowing for easier installation.

5. Install one bushing backup plate on the end of the hub and

secure with the supplied retaining ring. Repeat procedure for

other side.

6. Install the short bushing; flange first, on the driven shaft and

position per dimension “A”, as shown in Table 1. This will allow

the bolts to be threaded into the bushing for future bushing and

reducer removal.

7. Insert the output key in the shaft and bushing. For easy of

installation, rotate the driven shaft so that the shaft keyseat is at

the top position.

8. Mount the reducer on the driven shaft and align the shaft key

with the reducer hub keyway. Maintain the recommended

minimum distance “A” from the shaft bearing.

9. Insert the screws, with washers installed, in the unthreaded

holes in the bushing flange and align with the threaded holes in

the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing screws. Tighten the

screws lightly. If the reducer must be positioned closer than

dimension “A”, place the screws with washers installed, in the

unthreaded holes in the bushing before positioning reducer

making sure to maintain at least 1/8” between the screw heads

and the bearing.

10. Place the long bushing in position on the shaft and align the

bushing keyway with the shaft key. Use care to locate the long

bushing with the tapered bushing wedge installed earlier. Align

the unthreaded holes in the bushing with the threaded holes in

the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing holes. Insert bushing

screws, with washers installed in the unthreaded holes in the

bushing. Tighten screws lightly.

11. Alternately and evenly tighten the screws in the bushing

nearest the equipment to the recommended torque given in

Table 1. Repeat procedure on outer bushing.

40

PNEG-1204 Enclosed Belt Conveyors

Page 46

Bushing Removal for Standard Taper or Short Shaft

Bushings:

1. Remove bushing screws.

2. Place the screws in the threaded holes provided in the

bushing flanges. Tighten the screws alternately and evenly until

the bushings are free on the shaft. For ease of tightening

screws make sure screw threads and threaded holes in the

bushing flanges are clean. If the reducer was positioned closer

than the recommended minimum distance “A” as shown in

Table 1, loosen the inboard bushing screws until they are clear

of the bushing flange by 1/8”. Locate two (2) wedges at 180

degrees between the bushing flange and the bushing backup

plate. Drive the wedges alternately and evenly until the bushing

is free on the shaft.

LUBRICATION

IMPORTANT: Because reducer is shipped without oil, it is

necessary to add the proper amount of oil before operating

reducer. Use a high-grade petroleum base rust and oxidation

inhibited (R&O) gear oil - see tables. Follow instructions on

reducer warning tags, and in the installation manual.

Under average industrial operating conditions, the lubricant

should be changed every 2500 hours of operation or every 6

months, whichever occurs first. Drain reducer and flush with

kerosene, clean magnetic drain plug and refill to proper level

with new lubricant.

CAUTION: Too much oil will cause overheating and too little

will result in gear failure. Check oil level regularly. Failure to

observe this precaution could result in bodily injury.

3. Remove the outside bushing, the reducer, and then the

inboard bushing.

Under extreme operating conditions, such as rapid rise and fall

of temperature, dust, dirt, chemical particles, chemical fumes, or

oil sump temperatures above 200°F, the oil should be changed

every 1 to 3 months, depending on severity of conditions.

Table 2 – Oil Volumes

Reducer † Position A † Position B † Position C † Position D † Position E † Position F

TA0107L

TA1107H

TA2115H

TA3203H

TA4207H

TA5215H

TA6307H

TA7315H

TA8407H

TA9415H

TA10507H

TA12608H

Size

Single 0.7 0.6 0.5 0.5 0.7 0.6 1.4 1.3 1.3 1.2 1.5 1.4

Double 0.7 0.6 0.5 0.5 0.6 0.6 1.3 1.3 1.2 1.2 1.4 1.3

Single 1.3 1.3 0.7 0.7 0.7 0.6 1.7 1.6 1.5 1.4 1.9 1.8

Double 1.3 1.3 0.7 0.7 0.6 0.6 1.7 1.6 1.5 1.4 1.9 1.8

Single 2.1 2.0 1.2 1.2 1.1 1.0 2.7 2.5 2.3 2.2 3.1 2.8

Double 2.1 2.0 1.1 1.1 1.0 1.0 2.6 2.5 2.4 2.3 3.0 2.9

Single 2.8 2.7 1.6 1.6 1.8 1.7 4.1 3.9 3.3 3.1 4.4 4.2

Double 2.8 2.7 1.5 1.4 1.7 1.6 4.0 3.8 3.4 3.3 4.2 4.0

Single 4.4 4.2 2.6 2.5 2.9 2.8 7.4 7.0 6.3 6.0 7.8 7.3

Double 4.4 4.2 2.5 2.4 2.8 2.6 7.3 6.9 6.4 6.0 7.5 7.1

Single 7.4 7.0 4.9 4.7 5.8 5.5 13.2 12.5 11.6 11.0 13.1 12.4

Double 7.4 7.0 4.7 4.4 5.5 5.2 12.9 12.2 11.4 10.8 12.6 11.9

Single 8.8 8.4 5.8 5.5 6.6 6.2 16.1 15.3 13.2 12.5 16.1 15.3

Double 8.8 8.4 5.5 5.2 6.2 5.9 15.8 15.0 13.9 13.1 15.3 14.5

Single 8.4 8.0 11.8 11.1 13.9 13.2 22.5 21.3 22.1 20.9 25.1 23.7

Double 8.4 8.0 10.8 10.3 13.2 12.5 22.0 20.9 22.4 21.2 23.1 21.8

Single N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Double 7.7 7.3 11.7 11.1 13.7 12.9 25.1 23.8 24.0 22.7 25.8 24.4

Single N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Double 17.0 16.1 16.8 15.9 18.1 17.1 33.2 31.4 33.2 31.4 38.6 36.5

Single N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Double 38.0 36.0 27.6 26.1 25.8 24.4 53.5 50.6 53.8 50.9 56.1 53.0

Single N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

Double 53.0 50.2 41.5 39.3 37.1 35.1 70.7 66.9 72.2 68.3 80.4 76.1

▲Qt L ▲Qt L ▲Qt L ▲Qt L ▲Qt L ▲Qt L

Approximate Volume of Oil to Fill Reducer to Oil Level Plug

Oil quantity is approximate. Service with lubricant until oil runs out of oil level hole.

† Refer to Figure 1 for mounting positions.

▲ US measure: 1 quart = 32 fluid ounces = .94646 liters.

Below 15 RPM output speed, oil level must be adjusted to reach the highest oil level plug. If reducer position is to vary from those shown in Figure 1, either more or less

oil may be required. Consult Dodge.

41PNEG-1204 Enclosed Belt Conveyors

Page 47

Table 3 – Oil Recommendations

ISO Grades For Ambient Temperatures of 50˚F to 125˚F

Output

RPM

301 – 400 320 320 320 220 220 220 220 220 220 220 220 220

201 – 300 320 320 320 220 220 220 220 220 220 220 220 220

151 – 200 320 320 320 220 220 220 220 220 220 220 220 220

126 – 150 320 320 320 220 220 220 220 220 220 220 220 220

101 – 125 320 320 320 320 220 220 220 220 220 220 220 220

81 – 100 320 320 320 320 320 220 220 220 220 220 220 220

41 – 80 320 320 320 320 320 220 220 220 220 220 220 220

11 – 40 320 320 320 320 320 320 320 320 320 320 220 220

1 – 10 320 320 320 320 320 320 320 320 320 320 320 320

TA0107L TA1107H TA2115H TA3203H TA4207H TA5215H TA6307H TA7315H TA8407H TA9415H TA10507H TA12608H

Torque-Arm II Reducer Size

ISO Grades For Ambient Temperatures of 15˚F to 60˚F

Output

RPM

301 – 400 220 220 220 150 150 150 150 150 150 150 150 150

201 – 300 220 220 220 150 150 150 150 150 150 150 150 150

151 – 200 220 220 220 150 150 150 150 150 150 150 150 150

126 – 150 220 220 220 150 150 150 150 150 150 150 150 150

101 – 125 220 220 220 220 150 150 150 150 150 150 150 150

81 – 100 220 220 220 220 220 150 150 150 150 150 150 150

41 – 80 220 220 220 220 220 150 150 150 150 150 150 150

11 – 40 220 220 220 220 220 220 220 220 220 220 150 150

1 – 10 220 220 220 220 220 220 220 220 220 220 220 220

Notes:

1. Assumes auxiliary cooling where recommended in the catalog.

2. Pour point of lubricant selected should be at least 10°F lower than expected minimum ambient starting temperature.

3. Extreme pressure (EP) lubricants are not necessary for average operating conditions. When properly selected for specific applications, TORQUE-ARM II backstops are

suitable for use with EP lubricants.

4. Special lubricants may be required for food and drug industry applications where contact with the product being manufactured may occur. Consult a lubrication

manufacturer’s representative for his recommendations.

5. For reducers operating in ambient temperatures between -22°F (-30°C) and 20°F (–6.6°C) use a synthetic hydrocarbon lubricant, 100 ISO grade or AGMA 3 grade (for

example, Mobil SHC627). Above 125°F (51°C), consult DODGE Gear Application Engineering (864) 288-9050 for lubrication recommendation.

6. Mobil SHC630 Series oil is recommended for high ambient temperatures.

TA0107L TA1107H TA2115H TA3203H TA4207H TA5215H TA6307H TA7315H TA8407H TA9415H TA10507H TA12608H

Torque-Arm II Reducer Size

42

PNEG-1204 Enclosed Belt Conveyors

Page 48

GUIDELINES FOR TORQUE-ARM II

When placing the reducer into service:

REDUCER LONG-TERM STORAGE

During periods of long storage, or when waiting for delivery or

installation of other equipment, special care should be taken to

protect a gear reducer to have it ready to be in the best

condition when placed into service.

By taking special precautions, problems such as seal leakage

and reducer failure due to lack of lubrication, improper

lubrication quantity, or contamination can be avoided. The

following precautions will protect gear reducers during periods of

extended storage:

Preparation:

1. Drain oil from the unit. Add a vapor phase corrosion

inhibiting oil (VCI-105 oil by Daubert Chemical Co.) in

accordance with Table 4.

2. Seal the unit airtight. Replace the vent plug with a standard

pipe plug and wire the vent to the unit.

3. Cover all unpainted exterior parts with a waxy rust

preventative compound that will keep oxygen away from the

bare metal. (Non-Rust X-110 by Daubert Chemical Co. or

equivalent)

1. Fill the unit to the proper oil level using a recommended

lubricant. The VCI oil will not affect the new lubricant.

2. Clean the shaft extensions with petroleum solvents.

3. Assemble the vent plug into the proper hole.

Follow the installation instructions provided in this manual.

Table 4 – Quantities of VCI #105 Oil

Reducer Size Quantity (Ounces / Milliliter)

TA0107L 1 / 30

TA1107H 1 / 30

TA2115H 1 / 30

TA3203H 1 / 30

TA4207H 1 / 30

TA5215H 2 / 59

TA6307H 2 / 59

TA7315H 3 / 89

TA8407H 3 / 89

TA9415H 4 / 118

TA10507H 6 / 177

TA12608H 8 / 237

VCI #105 and #10 are interchangeable.

VCI #105 is more readily available.

4. The instruction manuals and lubrication tags are paper and

must be kept dry. Either remove these documents and store

them inside, or cover the unit with a durable waterproof cover

which can keep moisture away.

5. Protect reducer from dust, moisture, and other contaminants

by storing the unit in a dry area.

6. In damp environments, the reducer should be packed inside

a moisture-proof container or an envelope of polyethylene

containing a desiccant material. If the reducer is to be stored

outdoors, cover the entire exterior with a rust preventative.

43PNEG-1204 Enclosed Belt Conveyors

Page 49

OIL VISCOSITY EQUIVALENCY CHART

KINEMATIC

VISCOSITIES

cSt/

40°C 100°C

2000

1000

800

600

500

400

300

200

100

80

60

50

40

30

cSt/ ISO

70

60

50

40

30

20

10

9

8

7

6

5

VG

1500

1000

680

460

320

220

150

100