Page 1

SERIES 2

Incline Chain

Conveyor

Installation and Operation Manual

PNEG-1187

PNEG-1187

Page 2

Introduction

READ THIS MANUAL carefully to learn how to

properly use and install equipment. Failure to do

so could result in personal injury or equipment

damage.

INSPECT THE SHIPMENT immediately upon

arrival. The Customer is responsible for ensuring

that all quantities are correct. Report any damage

or shortages by recording a detailed description

on the Bill of Lading to justify the Customer’s claim

from the Transport Firm. Our responsibility for

damage to the equipment ends with acceptance

by the delivering carrier. Save all paperwork and

documentation furnished with any of the incline

conveyor components.

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your equipment and should be

easily accessible when needed.

WARRANTY is provided as part of the company’s

support program for customers who use and

maintain their equipment as described in the

manual. The warranty is explained on the warranty page located on the inside back cover of

this manual.

This warranty provides you the assurance that the

company will back its products where defects

appear within the warranty period. In some circumstances, the company also provides field

improvements, often without charge to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to

change its performance beyond the factory specifications, the warranty will become void and field

improvements may be denied.

i

Page 3

Use of the Equipment Information page will help you identify your equipment in the case that you need to

call your dealer or installer. This information should be filled out and kept on record.

Equipment Information

Model Number:__________________________

Serial Number:___________________________

Material Handling

1004 East Illinois Street

Assumption, Illinois 62510 USA

Phone: (217) 226-4421

FAX: (888) 741-3004

e-mail: gsi@grainsystems.com

Date Purchased:____________________

Dealer/Distributor Name and Phone Number:

ii

Page 4

Table of Contents

Introduction ...................................................................................i

Equipment Information ..................................................................ii

Safety Guidelines ..........................................................................1

Safety ............................................................................................2

Safety Decal Locations. ................................................................6

Installation .....................................................................................11

Care & Maintenance .....................................................................17

Option............................................................................................18

Troubleshooting ............................................................................19

All information, illustrations, photos, and specifications in this manual

are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

iii

Page 5

NOTES

iv

Page 6

1

Series 2 Incline Chain Conveyors

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidelines. To help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention to.

PNEG-1187

Page 7

2

Safety

GENERAL SAFETY GUIDELINES

1. DO NOT make any alterations to the equipment. Such alterations may produce a very

dangerous situation, where SERIOUS INJURY or DEATH may occur.

2. This equipment shall be installed in accordance with any regulations or installation codes

that are required by law. Authorities having jurisdiction should be consulted before installations are made.

3. Untrained operators subject themselves and others to SERIOUS INJURY or DEATH.

NEVER allow untrained personnel to operate this equipment.

4. Keep children and other unqualified personnel out of the working area at ALL times.

5. NEVER start equipment until ALL persons are clear of the work area.

6. DO NOT operate electric motor equipped units until motors are properly grounded.

Series 2 Incline Chain Conveyors

7. Keep hair, loose clothing, and shoestrings away from rotating and moving parts.

8. NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate

the equipment.

9. Disconnect power on electrical driven units before resetting motor overloads.

10. Make sure someone is nearby who is aware of the proper shutdown sequence in the event

of an accident or emergency.

11. NEVER work alone.

12. ALWAYS think before acting. NEVER act impulsively around the equipment.

13. Do not repetitively stop and start the drive in order to free a plugged condition. Jogging the

drive like this can damage the conveyor and/or drive components.

14. Keep off the equipment at all times.

15. NEVER attempt to assist machinery operation or to remove trash from equipment while in

operation.

PNEG-1187

Page 8

3

Series 2 Incline Chain Conveyors

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual

and on your machine safety signs. Keep signs in

good condition. Replace missing or damaged

safety signs. Be sure new equipment components and repair parts include the current safety

signs. Replacement safety signs are available

from the manufacturer.

Learn how to operate the machine and how to

use controls properly. Do not let anyone operate

without instruction.

Keep your machinery in proper working condition. Unauthorized modifications to the machine

may impair the function and/or safety and affect

machine life.

Safety

If you do not understand any part of this manual

and need assistance, contact your dealer.

STAY CLEAR OF MOVING PARTS

Entanglement in rotating sprockets, chains, and

wiper flights can cause serious injury or death.

Keep all shields and covers in place at all times.

Wear close fitting clothing. Stop and lock out

power source before making adjustments,

cleaning, or maintaining equipment.

OPERATE MOTOR PROPERLY

Do not operate electric motor equipped units

until motors are properly grounded.

Disconnect power on electrical driven units

before resetting motor overloads.

Do not repetitively stop and start the drive in

order to free a plugged condition. Jogging the

drive in this type of condition can damage the

conveyor and/or drive components.

PNEG-1187

Page 9

4

Safety

PRACTICE SAFE MAINTENANCE

Understand service procedures before doing

work. Keep area clean and dry.

Never lubricate, service, or adjust machine while

it is in operation. Keep hands, feet, and clothing

from rotating parts.

Keep all parts in good condition and properly

installed. Fix damage immediately. Replace

worn or broken parts. Remove any build up

grease, oil, or debris.

Series 2 Incline Chain Conveyors

REMOVE PAINT BEFORE WELDING OR

HEATING

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint

is heated by welding, soldering, or using a torch.

Do all work outside or in a well ventilated area.

Dispose of paint and solvent properly.

Remove paint before welding or heating:

• If you sand or grind paint, avoid breathing the

dust. Wear an approved respirator.

• If you use solvent or paint stripper, remove

stripper with soap and water before welding.

Remove solvent or stripper containers and

other flammable material from area. Allow

fumes to disperse at least 15 minutes before

welding or heating.

PNEG-1187

Page 10

5

Series 2 Incline Chain Conveyors

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near

your telephone.

WEAR PROTECTIVE CLOTHING

Safety

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to help prevent

breathing potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help

protect your head and toes from falling debris.

Eye Protection

Gloves

Steel Toe

Boots

Respirator

Hard Hat

PNEG-1187

Page 11

6

Decals

Moving parts can crush

without guards in place.

result in serious injury.

Series 2 Incline Chain Conveyors

Head Section Decal Locations

1

and cut. Keep hands

clear. Do not operate

Failure to do so could

DC-972

PNEG-1187

Page 12

7

Series 2 Incline Chain Conveyors

Moving parts can crush

without guards in place.

result in serious injury.

Tail Section Decal Locations

Decals

PNEG-1187

1

and cut. Keep hands

clear. Do not operate

Failure to do so could

DC-972

Page 13

8

Decals

2

Series 2 Incline Chain Conveyors

Trough Section Decal Location

2

Exposed conveyors

and moving parts can

cause serious injury.

Lockout power

before removing covers

or inspection door.

DC-1230

o

b

r

e

in

Lo

fo

sp

c

c

r

e

a

a

ko

e

c

E

nd

us

u

re

tio

xp

e

t

m

n

o

m

se

p

o

d

se

o

ri

o

w

v

o

D

C

d

v

i

o

e

in

o

-1

ng

us

r

g

r.

2

c

o

p

i

n

c

3

0

n

a

ju

o

v

v

r

r

e

ey

ts

y

.

rs

o

c

rs

an

2

Exposed conveyors

and moving parts can

cause serious injury.

Lockout power

before removing covers

or inspection door.

DC-1230

PNEG-1187

Page 14

9

Series 2 Incline Chain Conveyors

Bend Section Decal Location

2

Decals

2

2

Exposed conveyors

and moving parts can

cause serious injury.

Lockout power

before removing covers

or inspection door.

DC-1230

PNEG-1187

Page 15

10

Decals

Series 2 Incline Chain Conveyors

Bypass Inlet Decal Location

2

2

2

Exposed conveyors

and moving parts can

cause serious injury.

Lockout power

before removing covers

or inspection door.

DC-1230

PNEG-1187

Page 16

11

Series 2 Incline Chain Conveyors

The head, tail, and intermediate sections of the chain conveyor are shipped

pre-assembled direct from the factory.

Installation

FIG. 1

Head Assembly

FIG. 3

Intermediate Trough Assembly

with Center Pan

FIG. 2

Tail Assembly

FIG. 4

Intermediate Trough Assembly

with Slide Rails

PNEG-1187

Page 17

12

Installation

Series 2 Incline Chain Conveyors

Intermediate Trough Section Assembly

Before assembling conveyor trough sections together

remove covers. It is recommended that you store your

covers in a protected area in order to minimize any possible damage. Remember to retain factory shipped hardware for conveyor cover installation.

Intermediate trough sections are supplied in standard

ten foot (10') lengths. Depending on your application

and individual specifications however, shorter sections

may be required to accommodate a given overall length.

Intermediate sections are supplied with slide rails or a

center pan. The sections with slide rails are generally

used on the horizontal portion of the conveyor. The

sections with the center pans are generally used on the

inclined portion of conveyor.

Note: It is critical for straitness of the conveyor

that the sides and bottom flanges are aligned flush.

Also, it is important that the inside dimensions of

the box measure equidistant from side-to-side both

top and bottom of the trough box (Dimension A =

Dimension B). See Fig. 5.

During assembly of each trough section to the next section, carefully inspect each flange joint to ensure that the

inside bottom and center pan/slide rail side surfaces of

the trough are flush. A chalk line is helpful during this

phase of the assembly to ensure the proper alignment of

the trough surfaces. The maximum run-out in any direction should be +/- 1/4". This proper alignment will minimize wear on flights and other potential damage to the

conveyor. Make sure that the conveyor is level in horizontal applications.

Proceed by attaching the head and tail assemblies using

the same alignment procedures and precautions noted in

the preceding paragraph.

Center Pan

Bottom Plate

FIG. 5

Center Pan Trough Section Shown

PNEG-1187

Page 18

13

Series 2 Incline Chain Conveyors

Installation

Cover Assembly Installation

Before installing the covers, an adhesive back foam

strip may be applied to provide a seal against the

elements. Starting at the tail assembly, place the Tail

Section Cover on top of the Tail Section assembly.

Apply the adhesive back foam strip to the top surface

of the protruding lip before installing the next cover

(See Fig. 7). This recommended installation sequence should ensure that water will shed away from

cover seam connections.

When an inlet is on the conveyor, a cover section

may have to be cut accordingly to accommodate

the inlet. For installation of an inlet, see Inlet

Assembly and Installation.

Inlet Assembly and Installation

One inlet is typically provided per conveyor. Inlets

mounted too close to the tail chain sprocket will allow

grain to come in contact with the sprocket and chain

pinch. This may cause excessive damage to any grain

being conveyed. The minimum distance from tail splice

joint to the nearest edge of the inlet assembly should

be 6".

If the conveyor is control fed and has a center pan,

another opening in the center pan should start at the

edge of the inlet and extend a distance of twice the inlet

opening, towards the tail. The width of the opening

should be determined by starting the opening a distance of 1-1/4" from the inside edge of the conveyor.

(See Fig. 6)

The inlet can be attached with continuous weld seams.

If intermittently welded, it is important to use caulking

or sealing around the inlet area in order to seal the unit.

(Inlet Opening)

Similarly, it is recommended that if inlets are welded

onto the conveyor, this procedure should occur prior

to installation of motor and/or other electrical devices.

By not following this precaution, owner assumes all risks

associated with this type of installation.

Foam Strip

PNEG-1187

FIG. 6

Inlet Assembly

FIG. 7

Foam Strip Placement

Page 19

14

Installation

Series 2 Incline Chain Conveyors

Drag Chain Assembly Installation

All chain now supplied with new conveyors will be installed in a like manner, regardless of type. Correct

total chain length has been determined for your installation by the manufacturer. The conveyor drag chain is

shipped in approximate 10 foot lengths with an additional pre-cut short section, if necessary (refer to packing list). The chain may be installed at any time during

conveyor assembly.

It is recommended however, that you position the

chain over the center pan or slide rail return assemblies and the sprockets in the head and tail assemblies. The UHMW wear pads should be in front of

the welded chain flights in the direction of chain travel

(see diagram below). Connect chain lengths together

with connecting links and/or pins.

Tighten the drag chain assembly using the take-up

screws located on each side of the tail section or on

the take-up head. After the chain is tight, check that

the head and tail shafts are square to the box sides. If

the shafts are not square, loosen the tighter of the two

adjuster screws until the shafts are square. Lock the

adjuster screws by tightening the hex nuts against the

cross-ways “C” channel.

Rotate the chain, now on the sprockets, at least one

complete revolution. Check to see that the chain and

its wear pads are not catching on flanges or rubbing on

the trough sides due to the sprockets not being centered within the box. Ensure a “break-in” period

whereby the chain is allowed to run and seat itself. After running it for an adequate period of time stop the

machine, disconnect and lockout the power source. Retighten as necessary and remove any excess chain portions. Repeat this process as necessary.

FIG. 8

81X Chain Assembly

FIG. 9

4" Pitch Roller Chain Assembly

Direction of Chain Travel

Bottom Run

PNEG-1187

Page 20

15

Series 2 Incline Chain Conveyors

Installing Shaft Mount Reducers

Installation

Assemble torque arm bracket to conveyor per installation instructions found on page 18.

To aid in the installation of the reducer onto the shaft,

remove any protective coating film from shaft. Slide

the reducer onto the drive shaft extending from the side

of the conveyor head section. Using the instructions

and hardware supplied with the reducer, assemble it to

the conveyor drive shaft.

Assemble motor mount to the reducer. Refer to installation instructions provided with motor mount.

Install the rear panel of the drive guard before mounting

the sheaves. The rear panel has four (4) mounting brackets with slotted holes. Attach the lower brackets to the

matching reducer assembly bolts. Attach the upper

brackets to the matching holes in the front motor mount

support.

Assemble the V-belt driven sheave to the input shaft of

the shaft mount reducer. Slide the sheave hub onto the

shaft and insert the square key. Attach the hub sheave

using the supplied retaining screws. The retaining screws

pass through the non-threaded holes of the hub and

into the sheave. Align the driver and driven sheaves

and tighten the retaining screws. During tightening, it is

possible for the sheave to move out of alignment or become out of square. For maximum V-Belt life, the driven

sheave should remain both perpendicular to the drive

shaft and aligned with the drive sheave. Slip the V-belts

over both the driver and driven sheaves.

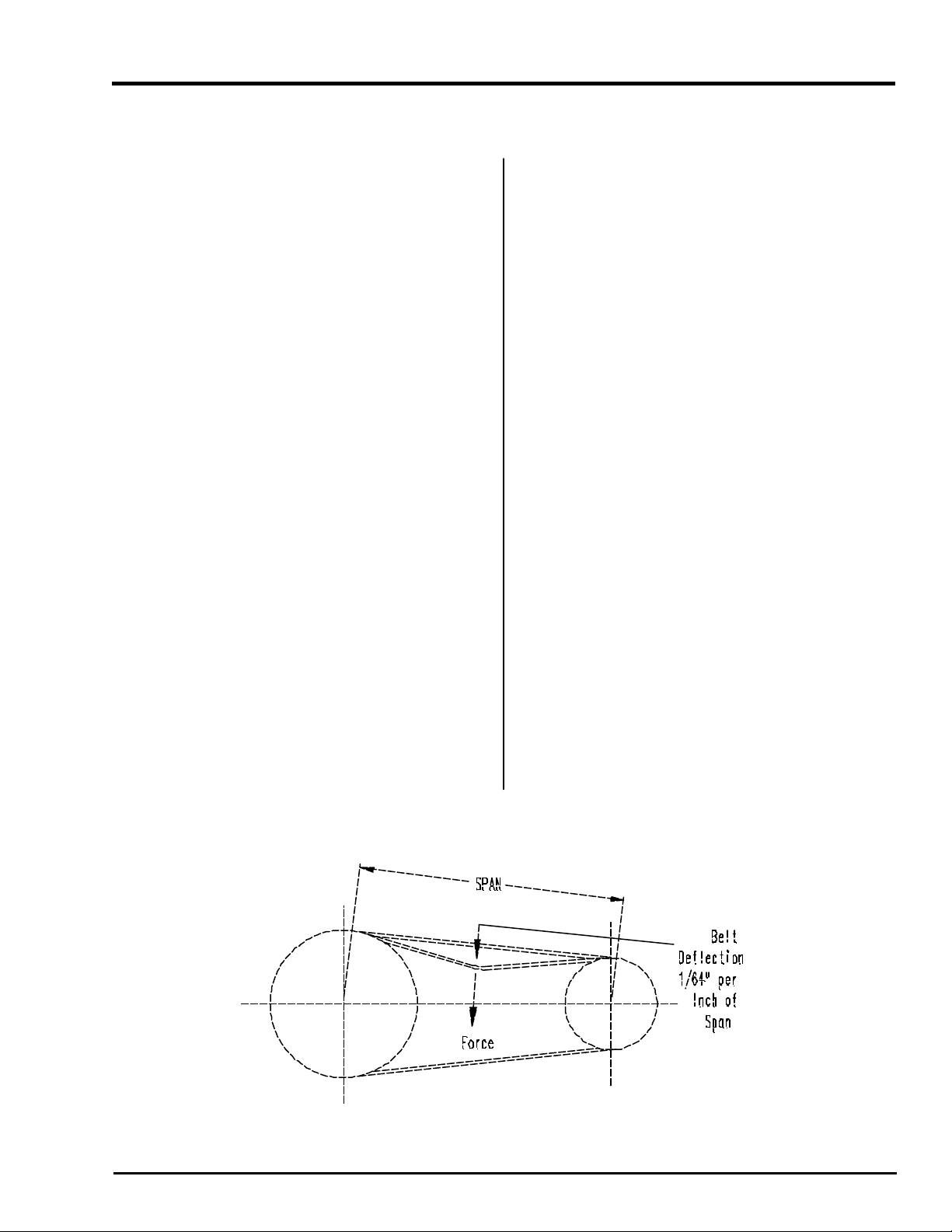

Adjustment of V-belt tension is achieved by tightening the hex nuts located on the four (4) jackscrews

of the motor base. Adjust motor base equally at all

four bolts to maintain shaft alignment. Belts are

designed to fit loose upon installation. When the

V-belt tension is correct, tighten the top nut on the

jackscrews to lock the motor base in position.

Proper tension is 1/64" of deflection per one (1") inch

of sheave centers on one side of belt, centered between sheaves.

Note: Too much tension shortens belt life. Check

belt tension frequently during the first 24-48 hours

of operation.

Install the front drive guard panel over the four

corner mounting studs. Secure with washers and

nuts provided.

Fill the shaft mount reducer with the manufacturer’s

recommended oil. A list of recommended oil can be

found in the gear reducer instructions.

FIG. 10

Belt Deflection

PNEG-1187

Page 21

16

Installation

Series 2 Incline Chain Conveyors

Welding

Welding on or to the conveyor may cause damage to

both the conveyor and its electrical system. If welding

is necessary, measures should be taken to protect the

conveyor. Should it be necessary to fasten anything to

the conveyor permanently, careful consideration should

be given to methods of maintenance, removal and replacement of the conveyor and/or its parts. (Please

refer to Inlet Installation on pg.13 for the recommended

guidelines).

Motor

Connect the conveyor motor to a power source according to the motor manufacturer’s instructions and

recommendations. To avoid injury it is recommended

that a certified electrician perform the motor wiring. A

shut off switch should be placed near the motor so that

the system may easily be shut down to help prevent

accidents during maintenance. It is important to check

proper motor shaft rotation before installing drive belts

Support

The recommended general guidelines in this area include adequate support for the conveyor assembly to

be installed at intervals no greater than 10 feet. It is

recommended that supports be installed at vertical portions of flanges leaving bottoms of trough sections clear.

By attaching supports in this manner, the removable bottoms are unobstructed for ease of replacement. Support legs are available as an option.

Clearance

A clearance of at least the width of the conveyor is recommended on all sides of the unit. Less clearance may

be acceptable however, serious consideration must be

given to methods of maintenance, removal and replacement of the conveyor and/or its parts.

PNEG-1187

Page 22

17

Series 2 Incline Chain Conveyors

Maintenance

Care and Maintenance

Before any maintenance is performed to

the conveyor, power must be shut off and

locked out to prevent accidental start up!

The care and maintenance section is provided with the

intention of helping to extend the useful life of the unit.

Like all equipment, the useful life of the conveyor is

greatly reduced if not used wisely and well maintained.

Please follow the next few simple steps to ensure

the safety and longevity of your equipment.

w Check all bearings and moving parts daily

during use.

Storage

If the unit is to be inactive for an extended period,

the following procedures are recommended.

w Thoroughly clean the unit.

w Loosen the drag chain tension. Doing so

relieves the stress placed on the bearings

and shafts of the drive and tail sections.

w Lubricate drag chains, shafts and drive

components with a good grade of light

machine oil.

w Lubricate bearings according to bearing

manufacturer’s recommendations.

w Follow manufacturer’s recommendations for

gear reducer lubrication and maintenance.

w Inspect the V-belts periodically for proper

tension and wear. V-belts should be

replaced as necessary. If replacement or

tension adjustment is required, please refer to

the Shaft Mount Reducer Assembly Section

on page 15.

w The Drag Chain and Sprockets should be

checked periodically for wear, damage and

proper adjustment. Any broken or bent

paddles should be replaced or straightened.

Should adjustment or replacement of the

drag chain be required, refer to the

Assembly Section on page 14.

PNEG-1187

Page 23

18

Options

Torque Arm Bracket

Series 2 Incline Chain Conveyors

Installation

When a drive package is ordered with the conveyor

system, a torque arm bracket is provided.

The torque arm bracket is pre-punched for ease of installation to the unit. Begin installation of this option by

first determining the location of the torque arm bracket

relative to the range of extension allowed by the shaft

mount reducer’s torque arm. The bracket will extend

on the same side of the conveyor as the head shaft.

Remove the four bolts necessary from the bottom of

the conveyor plate.

Drill the four holes in the conveyor’s bottom to accommodate the 5/8" hardware provided. Attach the torque

arm bracket to the conveyor using four 5/8” hardware.

Under any circumstances, do not use the 3/8" bolts

previously removed from the conveyor bottom to

attach the torque arm to the conveyor.

Standard Bypass Inlets

The Bypass Inlets come pre-assembled from the

factory. The inlets are available in 3' and 10'

sections. The hogback is stationary in bypass

inlets. Bypass inlets must be mounted horizontally.

If not mounted horizontally, capacity will be reduced.

Install shaft mount reducer to head shaft per instructions on page 14.

Next, match the size of the hardware to the reducer

manufacturer’s torque arm. Use this hardware to attach the torque arm to the bracket. Adequately tighten

all hardware.

When installing torque arm bracket keep angle

(A) of torque arm and reducer between -15°

and +15° of 90° per manufacturer’s recommendations. This angle is shown in Fig. 11.

Torque Arm

Fig. 11

PNEG-1187

Page 24

19

Series 2 Incline Chain Conveyors

Troubleshooting

Trouble Shooting Guide

Problem Cause Solution

Low capacity Improper chain speed Check the shaft RPM

Improper feed Check the grain level at inlet

Plugging Check the discharges

Noisy operation Loose UHMW Paddles Check all bolts on chain and

Bottom and /or Center Pan/ Intermediate Sections

Slide Rails Not Aligned Check Intermediate Trough Section

joints and make flush

Misalignment at Flange Check Intermediate Trough Section

Connections joints and make flush

Worn Drive Components Check oil level and shaft seals

belt misalignment; loose belts

Worn Sprocket Replace

Uneven UHMW Conveyor Misalignment Check the conveyor alignment

paddle wear Sprocket Slipped Check set screws on sprockets

Uneven sprocket wear Worn chain Replace chain (see pg. 14)

Improper alignment Check the sprocket alignment

Consult your contractor for added assistance.

PNEG-1187

Page 25

20

NOTES

Series 2 Chain Conveyors

Page 26

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (“GSI”) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO

REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP.

ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE

IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE,

OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED

PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH

IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE

AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS

OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED.

MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL

ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT

ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH ALL

FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

Page 27

This Equipment shall be installed in accor dance

with the current installation codes and applicable

regulations which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installation occurs.

Rev: 10-16-2006

1004 East Illinois Street

Assumption, IL 62510

217-226-4421 Phone

Loading...

Loading...