Page 1

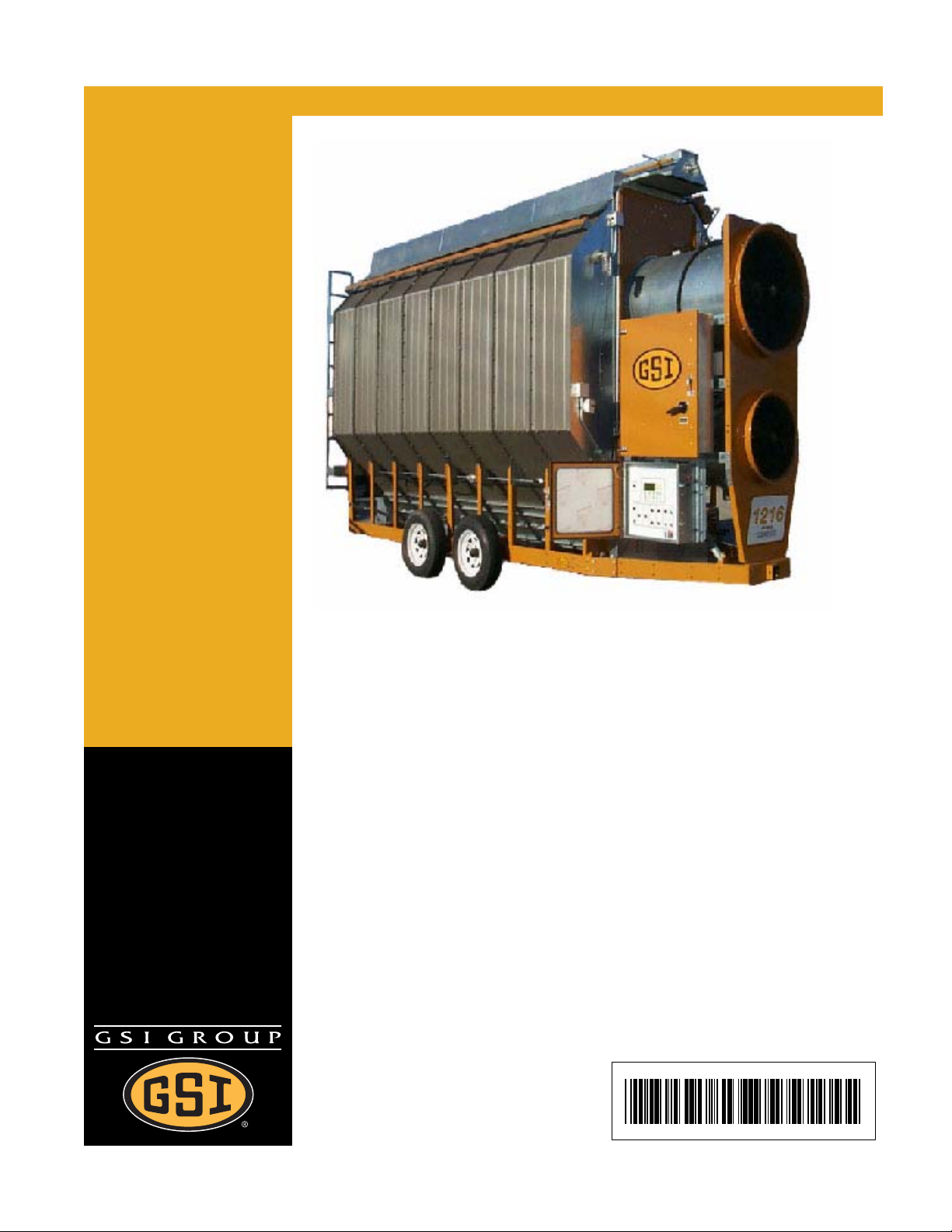

GSI Network Portable

Dryer Models

Troubleshooting and Reference Manual

PNEG-1181

Date: 09-18-07

PNEG-1181

Page 2

2 PNEG-1181 Portable Dryer Troubleshooting

Page 3

Table of Contents

Contents

Chapter 1 Safety .................................................................................................................................................. 5

Safety Guidelines ............................................................................................................................... 5

Dryer Safety Instructions and Information .......................................................................................... 6

Safety Precautions ........................................................... ... ... .... ... ... ... ... ............................................ 7

Chapter 2 Decals .................................................................................................................................................9

Chapter 3 Operation Tips ................................................................................................................................. 11

Network Dryer Operation Tips .......... .......................................... ... ... ... ... .... ...................................... 11

Chapter 4 Setup Screens ................................................................................................................................. 13

Special Network Dryer Setup Screens ............................................................................................. 13

Chapter 5 Dryer Operation ............................................................................................................................... 14

Network Dryer Options Explanation ................................................................................................. 14

Chapter 6 Programming ................................................................................................................................... 16

Programming Instructions Using Palm Pilot ..................................................................................... 16

Programming Network Dryer Using Palm Pilot ............. ... ... .......................................... ... ... ............. 17

Programming Instructions Using Flash Programmer ....................................................................... 18

Programming Network Dryer Using Flash Programmer ................................................................... 19

Chapter 7 Board Hook Up ................................................................................................................................ 20

Programmer Hook Up Diagram ........................................................................................................ 20

Network Display Board ..................................................................................................................... 21

Input/Output Board ........................................................................................................................... 22

Chapter 8 Troubleshooting Tips ...................................................................................................................... 23

Possible Safety Circuit Shut Down Messages ................................................................................. 23

Input/Output Errors ........................................................................................................................... 27

Master Display Generated Errors ..................................................................................................... 29

PNEG-1181 Portable Dryer Troubleshooting 3

Page 4

Table of Contents

Chapter 9 Wiring Reference ............................................................................................................................. 31

2 Fan Network Dryer Internal Wiring ................................................................................................ 31

2 Fan Network Dryer Internal Jumper Wiring ................................................................................... 32

Upper Control Back Panel Wiring .................................................................................................... 33

Network Upper Control Panel Wiring (220 Volt 3PH) ........................ ... ....... ...... ....... ...... ....... ...... ..... 34

Network Upper Control Panel Wiring (380, 460 and 575 Volt 3PH) ................................................. 35

2 Fan Network Power Circuit Diagram (220 Volt 1PH) (1 of 2) ........................................................ 36

Network Power Circuit Diagram (220 Volt 1PH) (2 of 2) .................................................................. 37

2 Fan Network Power Circuit (220 Volt 3PH) (1 of 2) ...................................................................... 38

Network Power Circuit (220 Volt 3PH) (2 of 2) ................................................................................. 39

2 Fan Network Power Circuit Diagram (440 Volt 3PH) (1 of 2) ........................................................ 40

Network Power Circuit Diagram (440 Volt 3PH) (2 of 2) .................................................................. 41

Network Control Circuit (Main Display Board) (1 of 4) ..................................................................... 42

Network Control Circuit (Input/Output Board) (2 of 4) ................. ..................................................... 43

Network Control Circuit (Meter Roll Sensor-SCR Board) (3 of 4) .................................................... 44

Network Control Circuit (Fan/Heater Board) (4 of 4) ........................................................................ 45

Upper Terminal Strip ........................................................................................................................ 46

Network Upper Terminal Strip (With Moisture Manager Hookup/Relay) .......................................... 47

Moisture Manager Hookup (Network or Competitor) ....................................................................... 48

Input/Output Board Voltage Testing (Located in Upper Control Box) .............................................. 49

Lower Control Box Back Panel Wiring ............................................................................................. 50

Network Fan/Heater Interface (Located in Heater Control Box) .................... ... .... ... ... ..................... 51

Network Fan/Heater Computer Pinouts ........................................................................................... 52

Fan/Can Control Box Wiring (Example: Single Phase Power) ....................... .......... ......... .......... ..... 53

Lower Junction Box Wire Routing .................................................................................................... 54

Upper Junction Box (Wiring) ............................................................................................................ 55

Network Dryer Meter Roll Sensor Rearview (Wiring) ....................................................................... 56

Testing Procedures and Location of Grain Temperature Sensors .................................................. 57

Procedure for Locating, Testing and Replacing a Defective Grain Temperature Sensor ................ 58

Sensor Chart .................................................................................................................................... 60

Procedure for Locating, Testing and Replacing a Defective Plenum Temperature Sensor ............. 61

Procedures for Replacing Network SCR Board .................................................... ... ........................ 63

Chapter 10 Dryer Parts ..................................................................................................................................... 64

Dryer Front Panel (Part Locations) ................................................................................................ 64

Dryer Fan/Can Side View (Part Locations) .................................................................................... 65

Plenum and Grain High Limit Locations ......................................................................................... 66

Chapter 11 Air Switch Tip ................................................................................................................................ 67

Network Series Air Switch Adjustment ........................................................................................... 67

Chapter 12 SCR Board Setup .......................................................................................................................... 69

SCR Board Terminals and Min./Max. Adjustment Locations ......................................................... 69

Setting SCR Board Maximum Voltage ........................................................................................... 70

Setting SCR Board Minimum Voltage ............................................................................................ 71

Chapter 13 Cross Reference ............................................................................................................................ 72

Overload Cross Reference Chart ................................. ... ... .... ... ... .......................................... ........ 72

Motor Cross Reference Chart ........................................................................................................ 74

Chapter 14 Warranty ......................................................................................................................................... 75

4 PNEG-1181 Portable Dryer Troubleshooting

Page 5

1. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

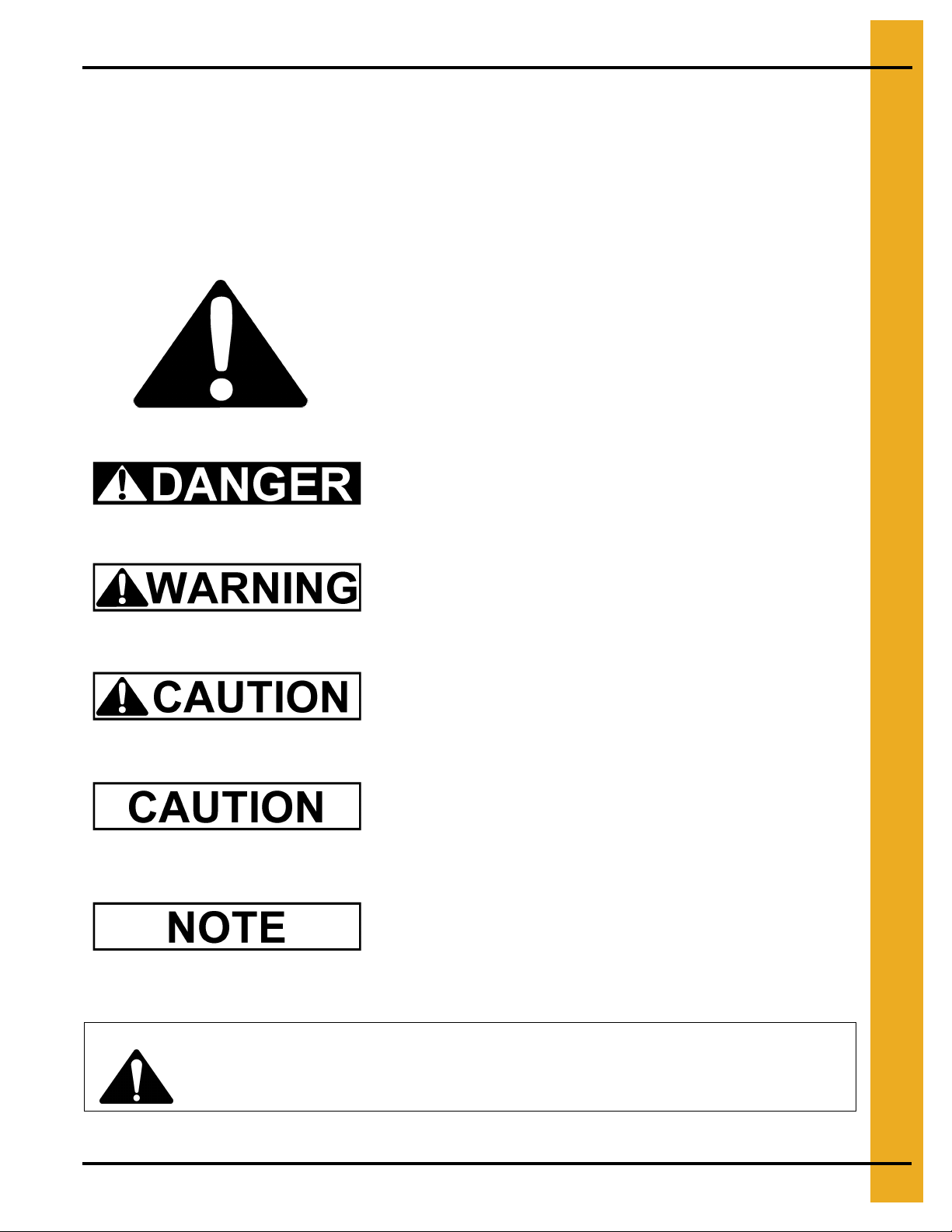

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

WARNING! BE ALERT!

Personnel operating, working or servicing portable dryers should read this manual.

Failure to read this manual and its safety instructions is a misuse of the equipment.

PNEG-1181 Portable Dryer Troubleshooting 5

Page 6

1. Safety

Dryer Safety Instructions and Information

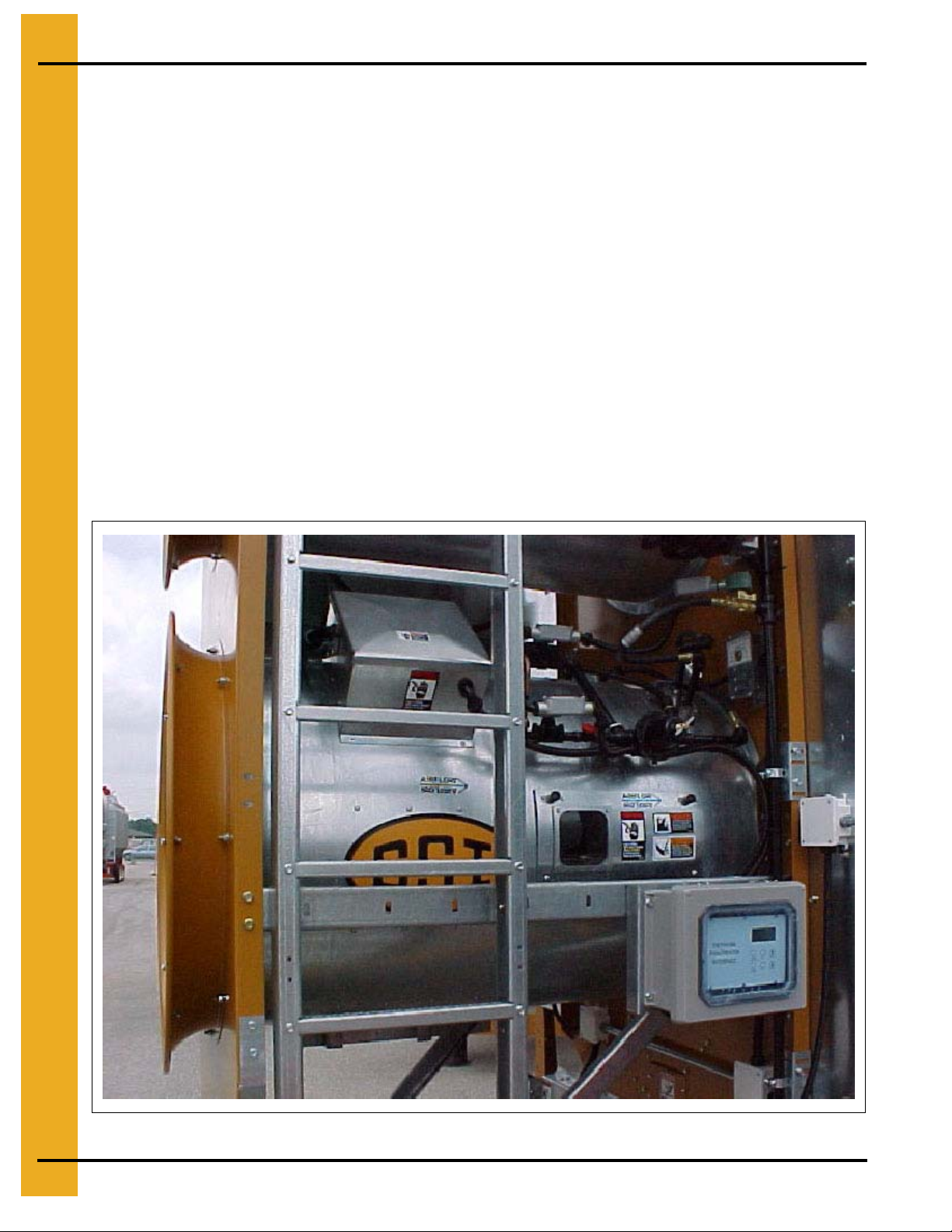

Thank you for choosing a GSI Network Portable Grain Dryer. It is designed to provide excellent

performance and service for many years.

This manual refers to the troubleshooting of the Network Dryer models. Different models are available

for liquid propane or natural gas fuel supply, with either single phase 230 volt, or three phase 230, 460,

575 volt electrical power. (Also 380 volt 50 Hz).

The GSI Group recommends contacting the local power company and having a representative survey

the installation so that wiring is compatible with the system and adequate power is supplied.

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requ irements, hazards and p recautions

exist, and to inform all personnel associated with the equipment or in the area . Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation, where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Figure 1A

6 PNEG-1181 Portable Dr yer Troubleshooting

Page 7

1. Safety

Safety Precautions

READ THESE INSTRUCTIONS BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before attempting to operate the dryer.

2. Power supply should be OFF for service of electrical components. Use CAUTION in checking

voltage or other procedures requiring the power to be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, DO NOT operate the

dryer. Shut down and repair before further operation.

4.

NEVER

5. Set pressure regulator to avoid excessive gas pressure applied to the burner during ignition and

when the burner is in operation. DO NOT exceed maximum recommended drying temperature.

6. Keep the dryer clean. DO NOT allow fine material to accumulate in the plenum or drying chamber.

Clean grain is easier to dry. Fine material increases resistance to airflow and requires removal of

extra moisture.

7. Use CAUTION in working around high speed fans, gas burners, augers and auxiliary conveyors

which START AUTOMATICALLY.

attempt to operate the dryer by jumping or otherwise bypassing any safety devices on the unit.

8. DO NOT operate in any area where combustible material will be drawn into the fan.

9. BEFORE attempting to remove or reinstall any propeller, make sure to read the recommended

procedure listed within the servicing chapter of the fan manual.

This product is intended for the use of grain handling only. Any other use is considered a misuse

of the product.

Some edges of the product components can be sharp. Inspect each component to determine

what specific safety considerations to be taken. Any and all necessary personal protective

equipment should be worn at all times when handling, assembling, installing and operating the

product and/or components.

NOTE:

Throughout this manual, guards are removed for illustration purposes only. All guards must be

in place before and during operation.

PNEG-1181 Portable Dryer Troubleshooting 7

Page 8

1. Safety

Use Caution in the Operation of this Equipment

The design and manufacture of this dryer is targeted to maximize operator safety. However, grain

dryers have inherently hazardous components: a gas burner, high voltage electrical equipment, high

speed rotating parts, etc. It is not possible to fully safeguard against all hazards without impeding

efficient operation and reasonable access to components. Therefore, a careful and knowledgeable

owner/operator is the best insurance against an accident.

Use extreme caution when working around high speed fans, gas-fired heaters, augers and auxiliary

conveyors, which may start without warning when the dryer is operating on automatic control.

Keep the dryer clean. Not allow fine material to accumulate in the plenum chamber or surrounding the outside of the dryer.

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable drying system, follow the recommendations within the Owner’s

Manual, and make it a practice to regularly inspect the operation of the unit for any developing problems

or unsafe conditions.

Take special note of all safety precautions before attempting to operate the dryer.

8 PNEG-1181 Portable Dr yer Troubleshooting

Page 9

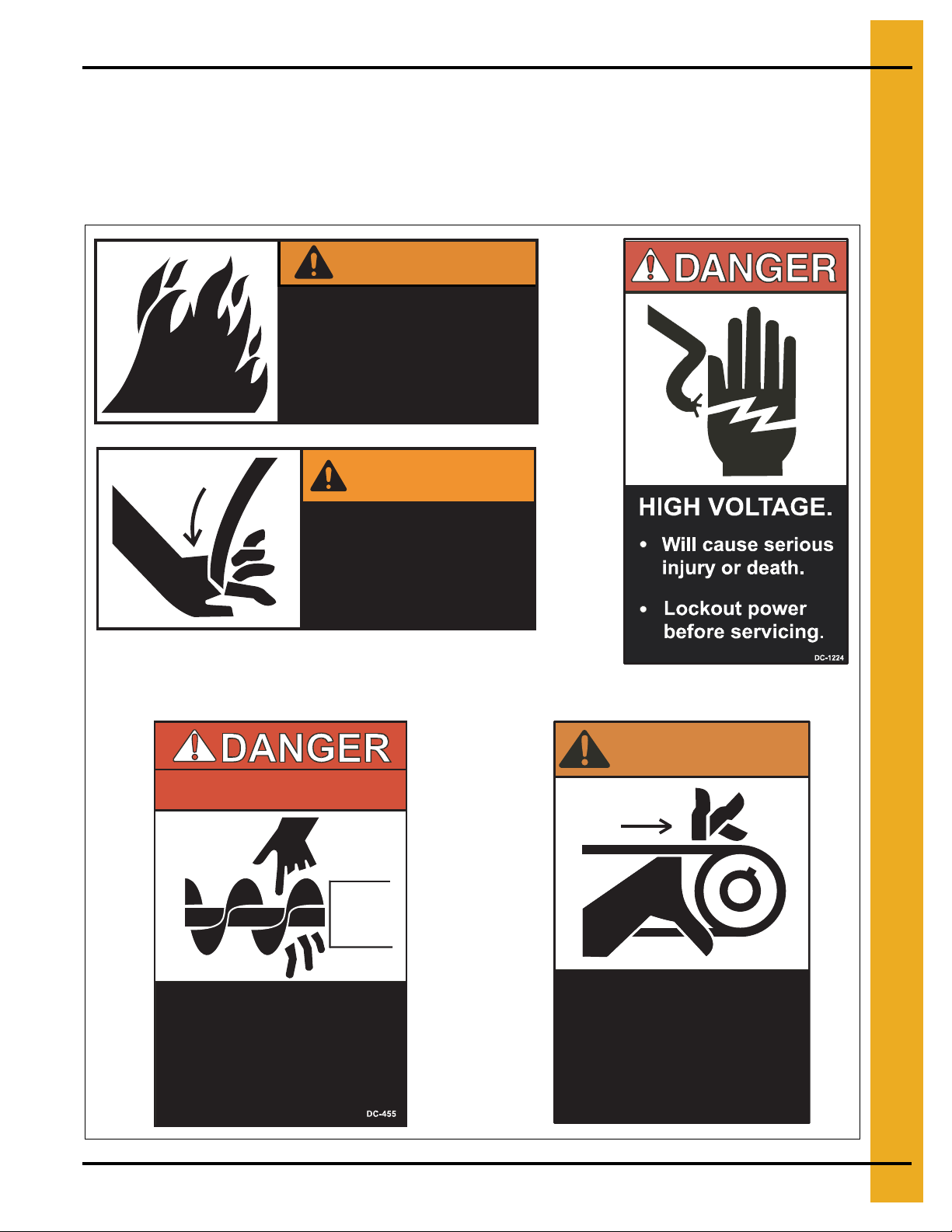

2. Decals

ROTATING AUGER

KEEP HANDS, FEET, HAIR AND

CLOTHING AWAY FROM INTAKE.

DO NOT REMOVE OR MODIFY

ANY GUARDS.

KEEP CHILDREN AWAY.

FAILURE TO DO SO WILL

RESULT IN SERIOUS

INJURY OR DEATH.

Safety decals should be read and understood by all people in and around the dryer area. If the following safety

decals are not displayed on your dryer, or if they are damaged, contact GSI for replac eme nt.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 217-226-4421

WARNING

Flame and pressure beyond

door can cause serious

injury. Do not operate with

service door removed. Keep

head and hands clear.

DC-1227

WARNING

ROTATING AUGER

Stay clear of rotating

blade. Blade could start

automatically. Can cause

serious injury. Disconnect

power before servicing.

DC-1225

WARNING!

FAILURE TO DO SO WILL

PNEG-1181 Portable Dryer Troubleshooting 9

RESULT IN SERIOUS

INJURY OR DEATH.

KEEP HANDS, FEET, HAIR AND

CLOTHING AWAY FROM INTAKE.

DO NOT REMOVE OR MODIFY

ANY GUARDS.

KEEP CHILDREN AWAY.

High speed belt drive

operating overhead.

Can cause serious injury.

Keep head and hands

clear. Do not enter when

dryer is running.

DC-1064

Page 10

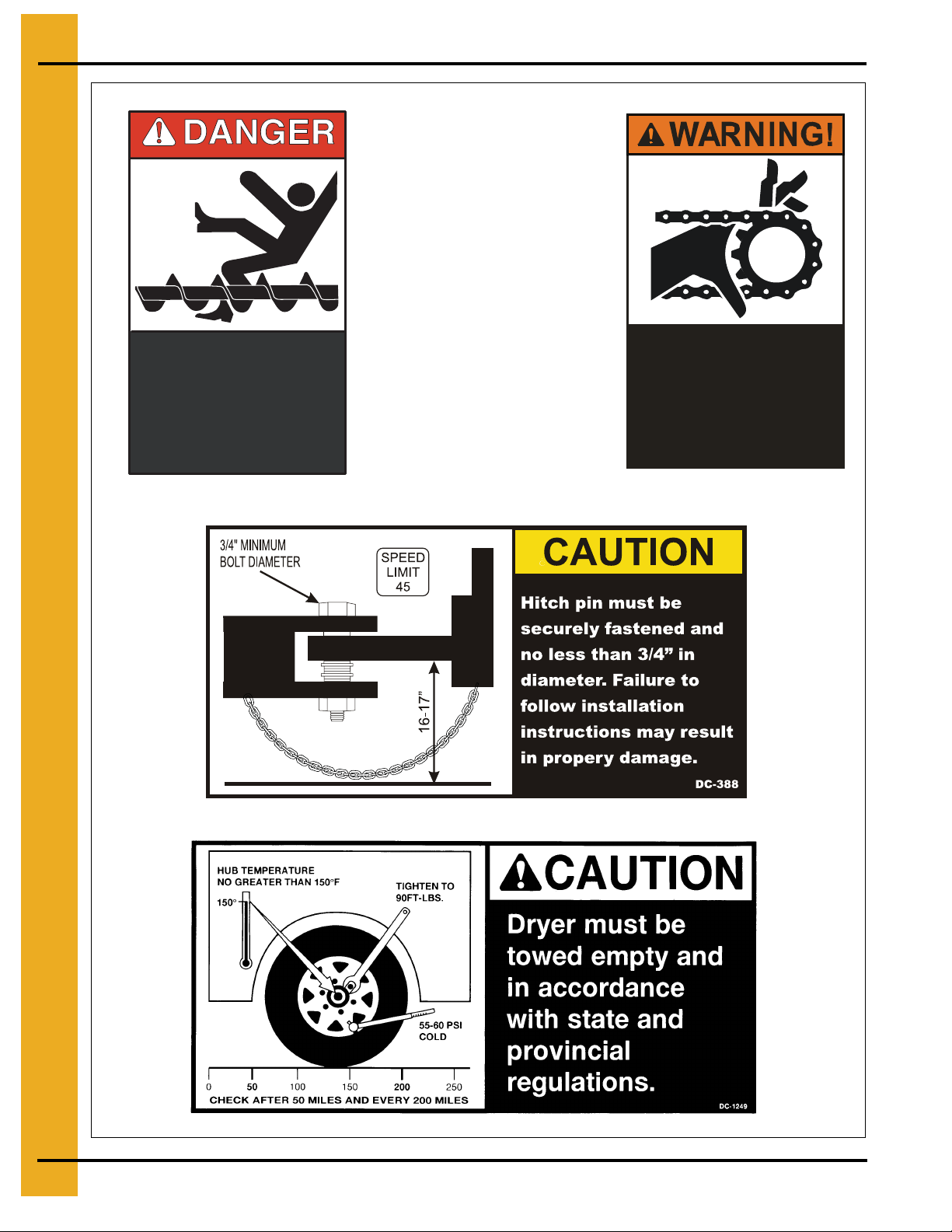

2. Decals

Rotating auger will crush

and cut. Auto equipment

can start at anytime. Do not

enter until electric power is

locked in off position. Failure

to do so will result in serious

injury or death.

DC-974

Moving parts can crush

and cut. Keep hands

clear. Do not operate

without guards in place.

Failure to do so could

result in serious injury.

DC-972

10 PNEG-1181 Portable Dryer Troubleshooting

Page 11

3. Operation Tips

Network Dryer Operation Tips

Important Software and Troubleshooting Tips (Software Version 1.08 and Up).

Present Software Version Numbers: Display 1.19 Heater 1.19 Input/Output 1.18

1. Stuck register value. After installing a new display board and “flashing” the software in, an error

message with “garbage” characters or a negative number for the temperature may appear. To

correct this, hard reboot the system by holding down the reset key and turning the power ON.

Always perform a hard boot after installing a new Display board.

2. If after a hard rebot the screen is still blank, the contrast may need to be adjusted. See tip #6 under

General Tips and Suggestions to adjust the contrast.

3. When flashing new software to the Input/Output board, turn OFF the leveling auger breaker. Due

to design, the leveling auger will run whenever the Input/Output board is being flashed.

4. If only the load and unload augers will not run check to make sure the 110 volt breaker on the Input/

Output board is turned ON.

5. The newest display boards (5/01/02) can now be used on either a Top Dry or Portable Dryer.

In the past a dryer display board had to have wires soldered in place for the meter roll speed

potentiometer. The newest boards have a six pin connector that connects to the meter roll

speed potentiometer.

6. The metering roll speed potentiometer connection at the potentiometer is correct when the visible

copper on the connector is in the bottom.

7. As dryers age, the contacts in the safeties start reducing the amount of DC voltage passed through

and may need to be replaced. Check the voltage if repeated error warnings are received from what

appears to be a good safety.

General Tips and Suggestions

1. In software version 1.19, the moisture control differential was reduced from 4° to 2°. As a result, the

dryer will cycle quicker and control moisture better.

2. In software version 1.18, the ability to calibrate bushels readings was added.

3. In software version 1.17 and greater, holding down the UP and DOWN arrow keys while changing

the timer or delay setting will start changing the setting at a much faster rate.

4. In version 1.17 and greater, pressing reset while changing a timer or delay setting will return the

setting to its default setting.

5. To enter the switch and keypad test function for diagnostic purposes, press and hold the HELP

button in. Turn ON the control power and release the HELP button. Turn any of the switches or

press any of the keypad buttons, and the one that you activated will be displayed on the screen.

6. To enter the screen adjustment mode, press the SCREENS button while turning the control power

on. Use the UP and DOWN arrow keys to adjust the current level of contrast. NOTE: Continued

depression of the arrow keys (UP or DOWN) will not adjust the contrast. Instead, each press and

release of the arrow keys (UP or DOWN) will adjust the contrast slightly. Because of this, adjusting

the contrast from a dark or blank screen to a visible screen will require many (100 or more) repeated

presses of the arrow keys.

PNEG-1181 Portable Dryer Troubleshooting 11

Page 12

3. Operation Tips

Network Dryer Operation Tips (Continued)

7. To return all options and settings to the factory defaults, press and hold the RESET button. Turn

the control power ON and release the RESET button. NOTE: ALL settings will be erased and all

options will return to the factory defaults.

8. To disable the air pressure switches, press and hold both the GRAIN and PLENUM buttons. Turn

ON the control power and release the buttons.

9. To erase all shut downs in the computer history, press and hold both the DRY and COOL buttons

and turn ON the control power. Release the buttons.

10. To view the shut down history of the dryer, press the UP and DOWN arrow buttons at the same

time, prior to pressing the START switch on the dryer. 256 dryer shut downs are stored in memory.

Performing this keystroke sequence while changing a timer or a delay setting, will change the

setting to 0.01.

11. Press the SCREENS button while the dryer is running to access the following data:

A. Out of Grain - View “Out of Grain” Timer

Set “Out of Grain” Timer

Check “Last Load” Time

B. View Grain Temps

C. User Hour Meter (Hour meter can be reset here also).

D. Meter Roll Speed Average. (Monitors the percentage of time the meter rolls spend on both high

and low speed.)

12. Press the

A. Enter the BPH factor (software version 1.18)

B. Reset batch counter

C. Clear total bushels

D. Change user message

13. Press DELAYS button before pressing start on the dryer in order to access the following Delays:

A. Load Delay

B. Out of Grain

C. Fan Delay

D. Unload Clean Out Delay

SETUP

button, before pressing start on the dryer in order to change the following settin gs:

12 PNEG-1181 Portable Dryer Troubleshooting

Page 13

4. Setup Screens

Special Network Dryer Setup Screens

There are certain dryer features that rarely need to be changed a nd which should be carefully considered

before adjusting. To access these advanced features, with the power OFF, press and hold the

button and then turn ON the control power for the dryer. Release the

MODIFY

button and the advanced

feature screens will be available.

Pressing ENTER after releasing the Modify button will allow you to view and/or change the special setup

screens in the following sequential order:

Option Select

1. Turn Meter Rolls OFF No——Yes

2. Air Switch Testing Yes——No

3. Meter Roll Reverse No——Yes

A. Reverse Time 5 Minutes, but is adjustable

B. Forward Time 55 Minutes, but is adjustable

4. Select Unload Method 2 Speed——3 Speed

5. Select Dryer Address 01——for use with the Watchdog program only

6. Attempt to Refill No——Yes

7. Enter Model Number Dryer Model Number NOTE: Dryer Model Number mu st

be exact in order for the dryer to operate properly.

8. Temperature Scale Fahrenheit——Celsius

9. Change Burner Setup Enter to Change——Reset to Bypass

A. High/Low Fire or ON/OFF Fire High/Low Fire——ON/OFF Fire

B. Active or Inactive Active——Inactive

10. Set Time and Date Time and Date

1 1. Load System End Fill——Center Fill——Dual Fill

12. Unit of Measure Bushels——Metric Tons

13. Change Burner Differential Enter to Change——Reset to Bypass

A. Set Burner Differential in Degrees Default is 3 Deg rees in High/Low and 1° in ON/OFF Fire

This default is not effecti ve unt i l software version 1.16

MODIFY

Selections in bold are the default settings

Series 2000 Fan and Heater Dip Switch Settings:

NOTE: These are set at the factory but will need to be reset when changing out a board.

Fan 1 #1 OFF / All Others ON

Fan 2 #2 OFF / All Others ON

Fan 3 #1 and #2 OFF / All Others ON

Fan 4 #3 OFF / All Others ON

Fan 5 #1 and #3 OFF / All Others ON

Fan 6 #2 and #3 OFF / All Others ON

PNEG-1181 Portable Dryer Troubleshooting 13

Page 14

5. Dryer Operation

Network Dryer Options Explanation

Turn Meter Rolls OFF

This option does not actually turn off the metering rolls. Changing this setting to YES removes the

sensor board from the circuit and allows the dryer to operate normally, but without any meter roll

information displayed on the screen. This is useful in the event of a sensor board failure. The sensors

on the rear of the dryer and the computer monitor whether or not the metering rolls are turning when the

UNLOAD is running. They also calculate the RPM, total bushels and Bushels Per Hour (BPH) of the

grain flowing across the meter rolls. If the meter rolls do not show movement in a two-minu te period, the

computer will shut down the dryer with a Meter Roll Drive System Failure. If, upon restarting the dryer

the meter rolls work properly, the drive system itself is okay and the problem is the sensor board itself.

Run the dryer normally by switching this setting to YES. Replace the board as soon as possible and

return this setting to ON when possible.

Air Switch Testing

Setting this option to NO allows the dryer to run without proving airflow. When a fan starts, it has

20 seconds to develop air pressure in the plenum of the dryer. If pressure develops, the dryer operates

normally. If no pressure develops, the dryer will shut down with a Loss of Airflow Shut Down error

message. Changing this setting to NO allows the user to run the fan on the dryer if a switch becomes

defective. It also allows the user to run the fan on the dryer without grain inside of it. This option resets

every time there is a dryer power loss of the dryer control power is shut OFF. Therefore, when restarted,

the setting will default back to YES and require proof of airflow again. Change this option to NO to run the

fan on the dryer without grain or with a defective switch until it is replaced.

Meter Roll Reverse

When set to YES, the meter rolls will run in the normal direction but, will occasionally slow to a stop and

then run in the reverse direction for a short period of time. The amount of time the meter rolls run in

forward and in reverse is adjustable and programmable. This option will not be used regularly but is

useful when grain conditions are very poor.

Select Unload Method

The Select Unload Method is set to a default of 2 Speed. In this setting, meter rolls will speed up and

slow down as needed to maintain constant grain moisture at the discharge of the dryer. While a

3 Speed option is under development, it is not available on this software and this setting should, remain

on 2 Speed.

Select Dryer Address

Most owners will not use this setting as it requires the use of the GSI Watchdog software program to

operate. This option allows the user to assign an address for each dryer on the network to be monitored

by the Watchdog program. The system can monitor up to 10 dryers and log dryer functions whenever

any of the dryers are running.

Attempt to Refill

Setting this option to YES enables the dryer to monitor the Out of Grain Timer. When the dryer runs low

and the Out of Grain Timer runs down, the dryer will go into a “hold” mode instead of shutting down. In

the “hold” mode, the unload auger shuts down, the burner turns off and the fan and the load auger

continue to run. If the dryer fills back up with grain, the burner will turn on again and the unload auger

will start up as well.

14 PNEG-1181 Portable Dryer Troubleshooting

Page 15

5. Dryer Operation

Dyer Model Number

This setting is critical to proper function of the dryer. The actual model number of the dryer is located

here and that number contains a great deal of valuable information about the dryer, including: number

of fans, number of modules, and the length of the dryer. This data is used by the computer to operate

the dryer properly. If any of this information is incorrect, the dryer will not operate properly and may not

operate at all. Use tremendous caution when changing this setting.

Temperature Scale

This option allows the user to toggle the temperature scale between Fahrenheit to Celsius.

Change Burner Set-Up

This setting controls the operation of each fan/heater unit on the dryer. Users can run any burner, or any

combination of burners, on either High/Low Fire or On/OFF Fire. This setting also allows users to render

a problem fan/heater inactive, thereby removing it from the programming of the dryer and allowing the

remainder of the dryer to continue running until the problem fan/heater can be repaired or replaced.

Set Time and Date

Use this setting to enter, store and adjust the time and date information.

Select Load System

While most dryers use the end fill option, GSI dryers also have the ability to run center fill and dual fill

modes if needed.

Unit of Measure

This setting allows the dryer to perform calculations in metric tons instead of bushels. This option is

useful for applications in foreign countries.

Change Burner Differential

The burner differential is the number of degrees that a fan/heaters temperature must drop before it will

cycle. Proper burner cycling means three (3) to four (4) times a minute the fan/heater should cycle from

high to low pressure. For this to happen, the burner must first reach the set point. The set point is the

desired running temperature for the plenum, usually around 220 degrees. When this temperature is

reached, the burner will shut off one solenoid and divert all of the gas through the low pressure ball

valve and the low pressure solenoid. Turn down the low pressure ball valve far enough to allow the

temperature to start to fall. When the temperature falls the number of degrees set by the differential, the

burner will cycle back to high. Keep in mind the burner should cycle three (3) to four (4) times a minute.

PNEG-1181 Portable Dryer Troubleshooting 15

Page 16

6. Programming

Programming Instructions Using Palm Pilot

There are three (3) boards to program on the Network Dryer: Display Board (lower control box),

Input/Output Board (upper control box), and Heater Interface Board (by Fan/Can housing).

1. Turn the control power on the dryer to the OFF position.

2. Locate the programming jack on each individual board:

• Display Board (lower control panel) - (DB-9) located at bottom of board.

• Input/Output Board (upper panel) - (DB-9) located at bottom of board.

• Heater Interface Board (by fan/can housing) - (J2 connector) located on back of board.

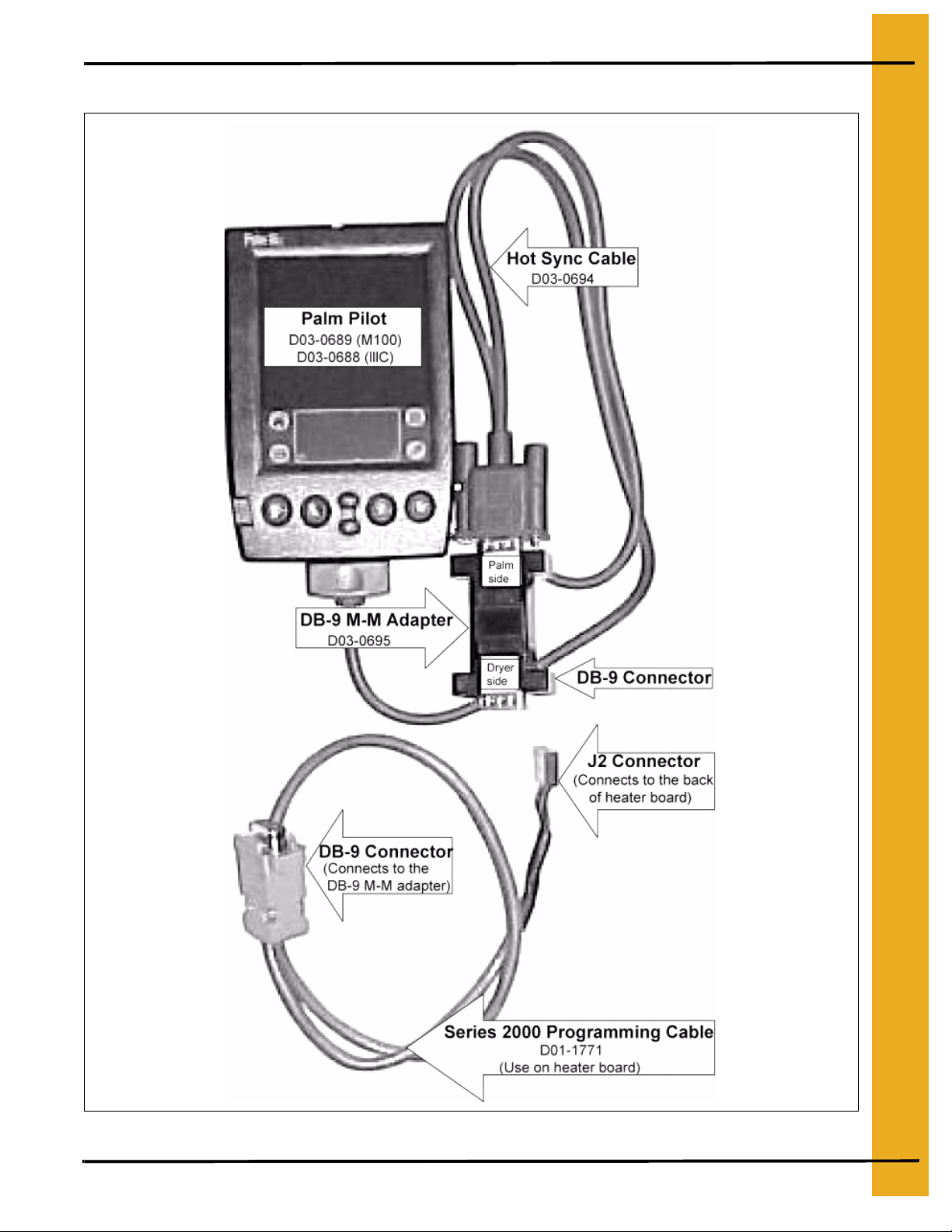

NOTE: Refer to See Figure 6A on Page 17.

3. If programming the Input/Output Board or Display Board, connect the DB-9 connector from the

Palm Pilot to the board.

4. If programming the Heater Interface Board, connect the J2 connector on the series 2000 cable to

the J2 connector on the back of the board.

5. Unplug the network connection (yellow and blue wires) to the board being programmed.

6. On the Palm Pilot, select the program for that particular board and select it by “tapping” on it.

7. Turn the dryer control power back ON.

8. The programming process begins by erasing the present program and starting the new program.

9. The screen will display a confirmation screen when the transfer of the software is complete.

10. Turn the dryer control power OFF and remove the connector from the board. Plug the network wires

back into the board being programmed.

11. Turn ON the dryer and the opening screens on the dryer will indicat e the latest version of software.

There are two Palm Pilot kits available from GSI for order:

Ref # Part # Description

D03-0692 (Palm Flash Program Kit Deluxe)

1 D01-1771 Series 2000 Programming Cable

2 D03-0688 Palm Pilot IIIC (color)

3 D03-0694 Palm Pilot Hot Sync Cable

4 D03-0695 Palm Flash 9 Pin M-M Adapter

5 D03-0709 Disk, CD-ROM Palm Flash Software

D03-0693 (Palm Flash Program Kit Economy)

6 D01-1771 Series 2000 Programming Cable

7 D03-0689 Palm Pilot M100 (black & white)

8 D03-0695 Palm Flash 9 Pin M-M Adapter

9 D03-0709 Disk, CD-ROM Palm Flash Software

16 PNEG-1181 Portable Dryer Troubleshooting

Page 17

Programming Network Dryer Using Palm Pilot

6. Programming

Figure 6A

PNEG-1181 Portable Dryer Troubleshooting 17

Page 18

6. Programming

Programming Instructions Using Flash Programmer

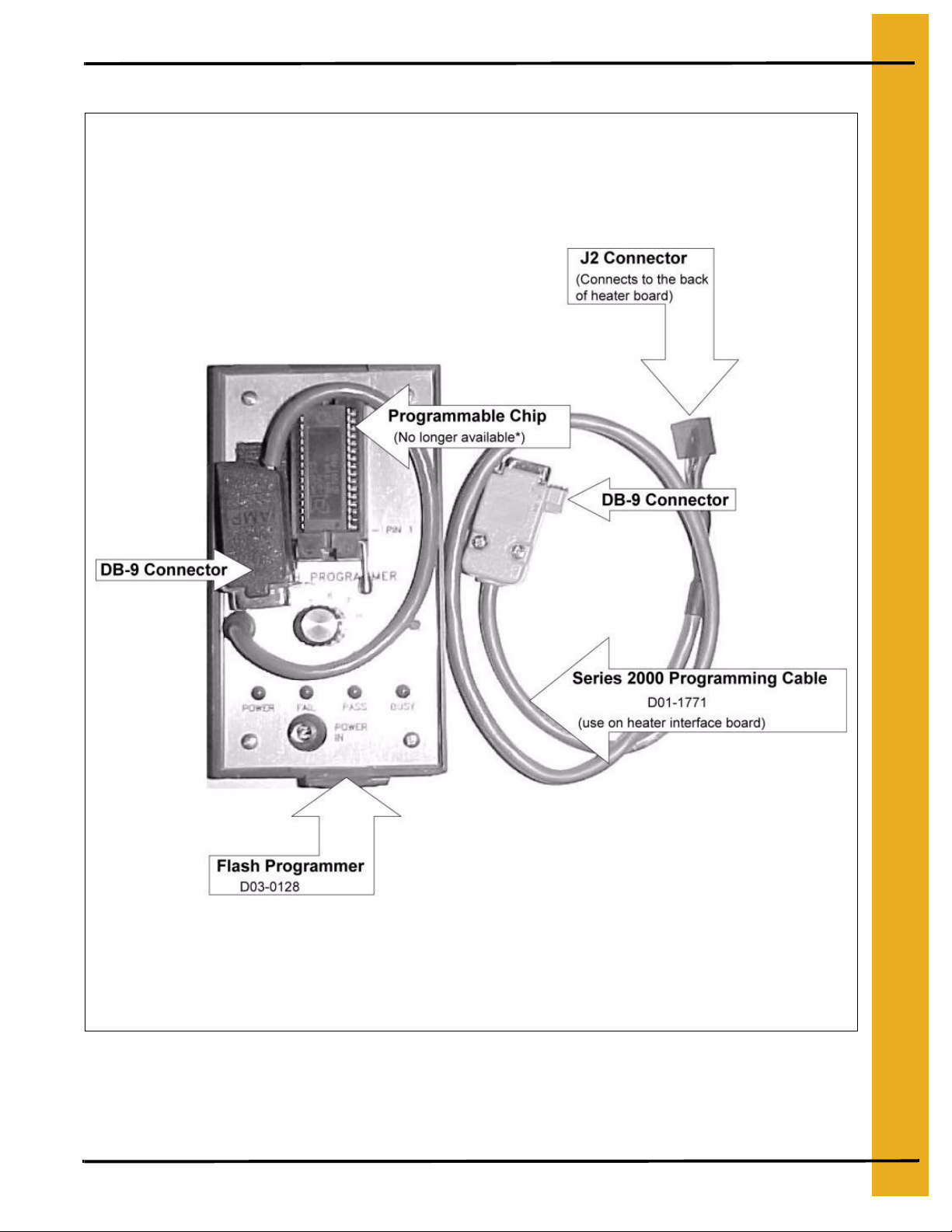

There are three (3) boards on the Network Dryer to program: Display Board (lower control box),

Input/Output Board (upper control box), and the Heater Interface Board (Fan/Can housing).

1. Turn the control power on the dryer to the OFF position.

2. Locate the programming jack on each individual board:

• Display Board (lower control panel) - (DB-9) located at bottom of board.

• Input/Output Board (upper panel) - (DB-9) located at bottom of board.

• Heater Interface Board (by fan/can housing) - (J2 connector) located on back of board.

NOTE: Refer to See Figure 6B on Page 19.

3. If programming the Input/Output Board or Display Board, connect the DB-9 connector from the

Flash Programmer to the board.

4. If programming the Heater Interface Board, connect the J2 connector on the series 2000 cable to

the J2 connector on the back of the board.

5. Unplug the network connection (yellow and blue wires) to the board being programmed.

6. Make sure the rotary switch on the programmer is set to position 8.

7. Turn the dryer control power back ON.

8. The four lights on the programmer will come ON, then three will go out leaving only the power light

still illuminated.

9. Push the Start button on the programmer to start the transfer of software.

10. The Busy light will flash until the transfer process is complete.

11. When completed, the Pass light will illuminate, indicating a successful transfer.

12. After a successful transfer, turn control power OFF, remove connector from the board and plug the

network wires back into the board being programming.

13. If the Fail light flashes, check the connection and repeat the above process.

14. Turn ON the dryer and the opening screens of the dryer should indicate the latest version of software.

18 PNEG-1181 Portable Dryer Troubleshooting

Page 19

Programming Network Dryer Using Flash Programmer

6. Programming

Figure 6B

*The Flash Programmer can still be used to program the dryer but the programmable chip for it is no

longer available. Therefore, GSI recommends using a Palm Pilot for programming.

PNEG-1181 Portable Dryer Troubleshooting 19

Page 20

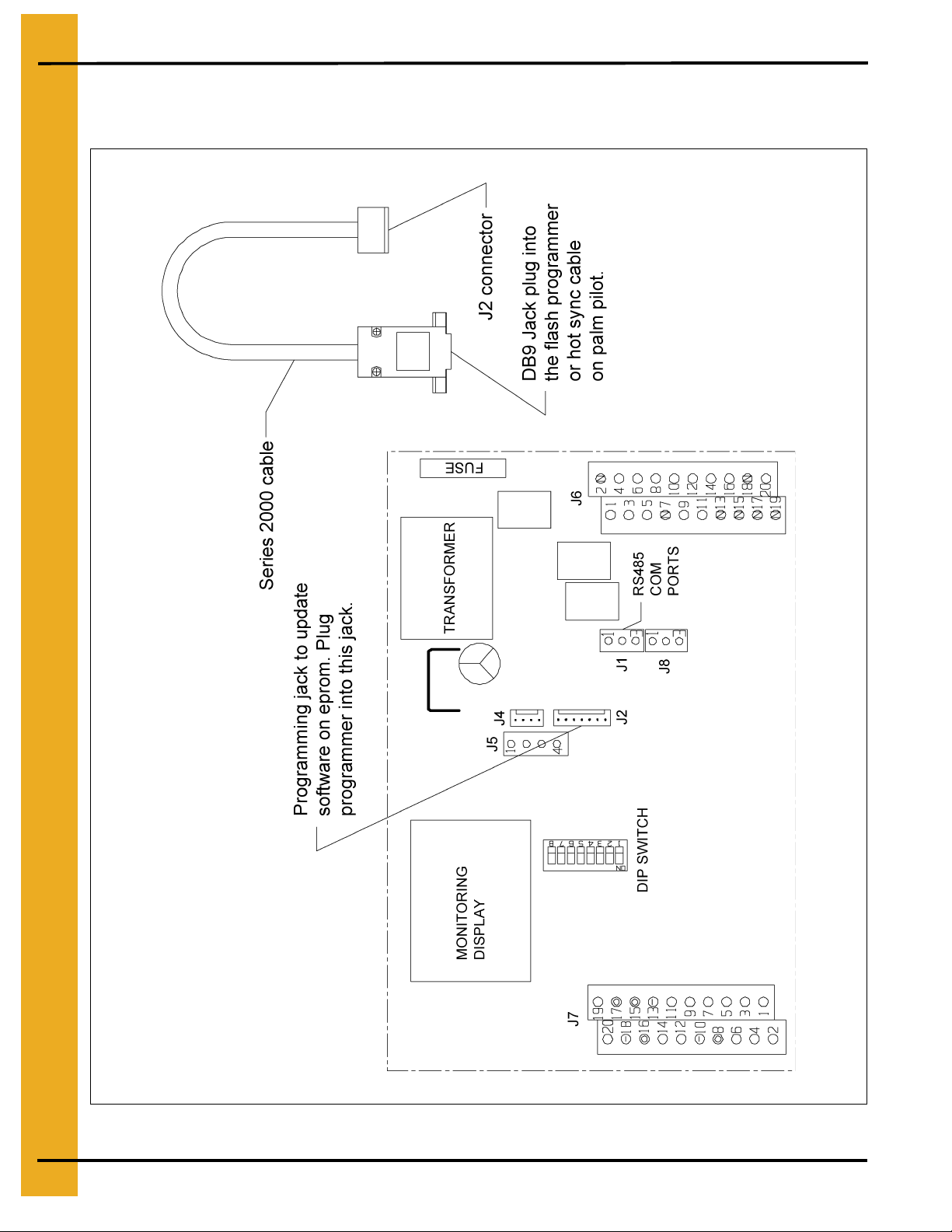

7. Board Hook Up

Programmer Hook Up Diagram

(Located in Heater Control Box) (Back of Heater Board)

Figure 7A

20 PNEG-1181 Portable Dryer Troubleshooting

Page 21

Network Display Board

(Located in the lower control panel) (Back of Board)

7. Board Hook Up

Network

Terminal connections

(blue and yellow wires)

DB-9 Connector

This is used for

programming the board.

Figure 7B

PNEG-1181 Portable Dryer Troubleshooting 21

DB-9 Connector

This is used for

Watchdog Program

.

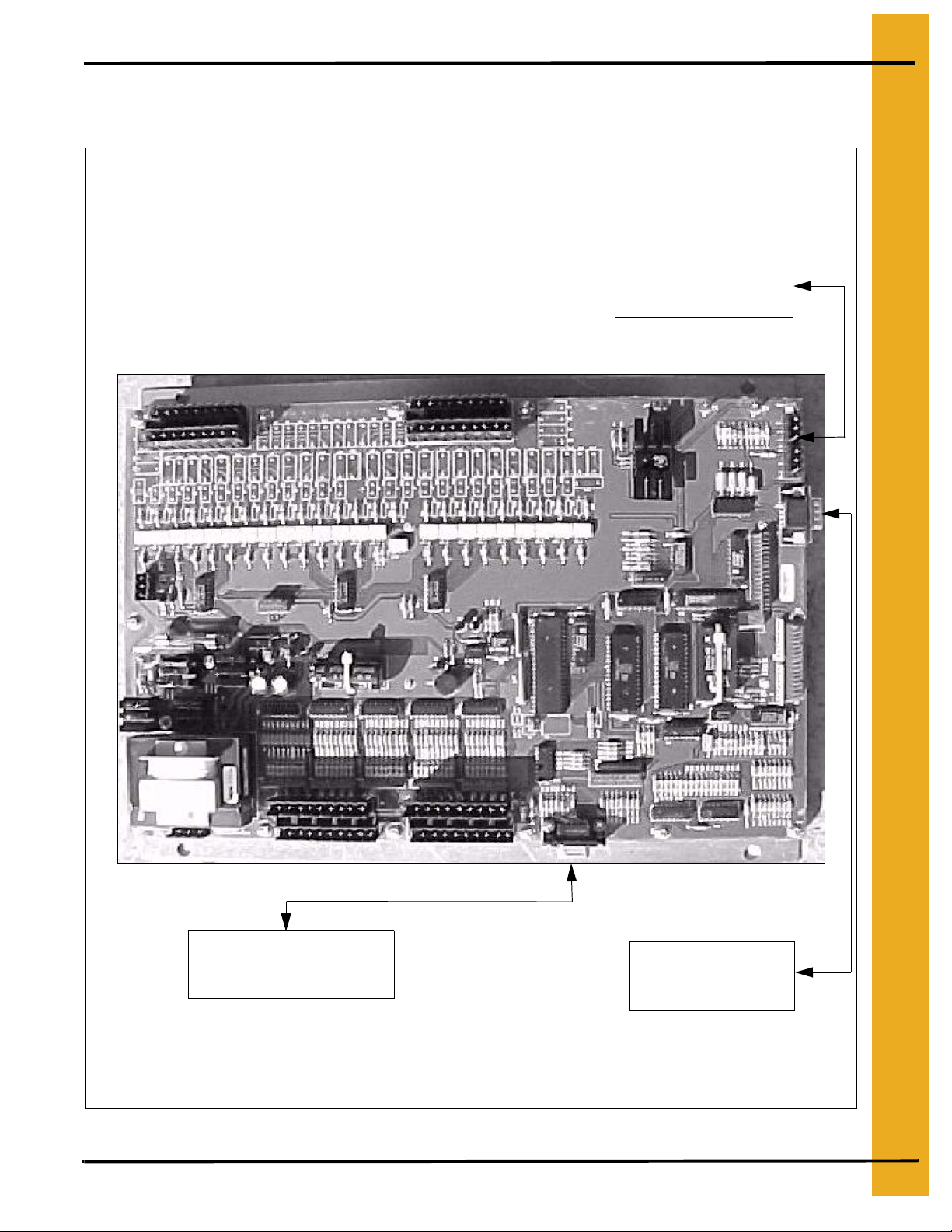

Page 22

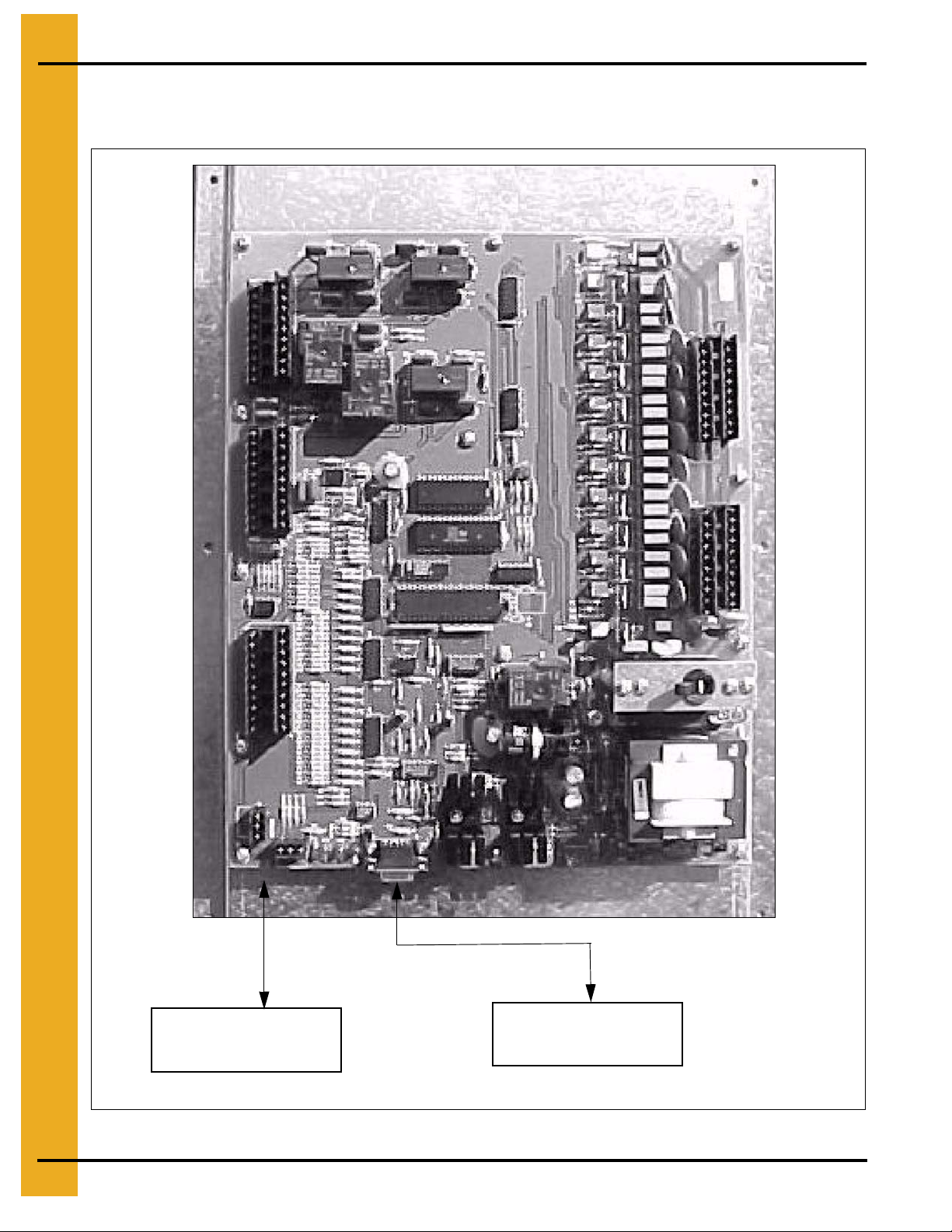

7. Board Hook Up

Input/Output Board

(Located in Upper Control Panel)

Network

Terminal connections

(blue and yellow wires)

Figure 7C

22 PNEG-1181 Portable Dryer Troubleshooting

DB-9 Connector

This is used for

programming the board.

Page 23

8. Troubleshooting Tips

Possible Safety Circuit Shut Down Messages

Viewing the Shut Down History

The shut down history can store up to 200 shut down warnings. When the dryer exceeds this amount,

the oldest shut down will be erased and replaced with the current shut down warning.

To view the shut down history (Warnings):

• Turn the Control Power to ON.

• Wait until the time and date screen appears and then press the START button.

• Press the increase and decrease buttons at the same time while the dryer is stopped. Then,

scroll through the history by pressing either the increase or decrease buttons. Press enter

to exit this screen or press stop to clear the shut down warning.

Shut Down Message Listing

The following is a list of all possible shut down messages for the network dryer. They are broken down

with their associated controller where the error originated. The message on the screen will show

WARNING at the top followed by the error, time, date and in which fan/heater the error occurred.

FAN X LOSS OF AIRFLOW

Fan 1 Loss of Airflow: The contacts in the air switch have opened due to insufficient air pressure in

the plenum. The message will identify which plenum caused the shut down.

Hints

Verify that the fan is running and that the dryer is completely full of grain. If the air pressure switch is

sensing air pressure, the blue light in the fan switch will come on after the fan has reached half speed. If

it does not, adjust the air switch using a straight blade screw driver to turn the adjusting screw on the air

switch counter-clockwise.This will make it more sensitive to air pressure. If this does not solve the problem,

inspect the wiring circuit of the air pressure switch. Each air pressure switch is wired to the Network

fan/heater Interface located on each individual fan/can box. Use a voltmeter on the following terminals:

Black Probe (J7-10) DC Negative

Red Probe (J7-09) 0 VDC Fan Running Red Probe (J7-09) 5 VDC Fan Stopped

Red Probe (J7-11) 5 VDC Fan Running Red Probe (J7-11) 0 VDC Fan Stopped

If operating correctly, the voltmeter should display the reading listed above.

Any other reading may indicate a bad switch, computer board, air pressure

switch or wiring.

If all this fails to work, remove the wires from the air pressure switch and remove the switch from the

dryer. Blow into the air tube to simulate air pressure in the plenum. The switch should have an open

circuit. Blow into the switch to close it. If it fails to close try adjusting it or replacing it.

Remember

1. Dryer must be full of grain. (Make sure fill is keeping up with unload.)

2. Check to see if light comes ON when fan is running.

3. Make sure the bulb is good. It is a 110 VAC.

PNEG-1181 Portable Dryer Troubleshooting 23

Page 24

8. T roubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

4. Make adjustments on air pressure switch one quarter turn at a time.

5. Clean air pressure switch tube to make sure it is not plugged.

6. More on how to adjust air switch on Page 57.

AIR SWITCH X STUCK

Air Switch 1 Stuck: Air pressure switch contacts have closed prior to the fan starting, indicating a

freewheeling blade or improper adjustment of the air switch. The error message will show on which fan

the error occurred.

HOUSING X HIGH LIMIT

Housing 1 High Limit: This occurs when there is an overheat in the fan housing of 200°F and a

thermo disc has opened. It is located directly on top of the individual fan housing and must be manually

reset. The high limit is wired directly to the fan/heater interface mounted to that particular fan. If it does

not clear after resetting and pushing the stop button, check the fan/heater interface. The error message

shows on which fan/heater the error occurred.

Use a voltmeter on the following terminals:

Black probe (J7-10) DC negative

Red probe (J7-16) 12 VDC output

Red probe (J7-02) 12 VDC when closed

GRAIN X OVERHEAT

Grain 1 Overheat: This occurs when the grain temperature in one of the columns has reached

210°F. The fixed temperature thermo disc has opened. This will automatically reset when it cools down.

Check each grain column and make sure the grain is moving down the column screen. If it does not clear

after pushing the stop button, check the fan/heater interface.

Use a voltmeter on the following terminals:

Black probe (J7-10) DC negative

Red probe (J7-08) 12 VDC output

Red probe (J7-05) 12 VDC when closed

PLENUM X OVERHEAT

Plenum 1 Overheat:

300°F. The fixed temperature thermo disc has opened. This will automatically reset when it co ols down. If

it does not clear after pushing the stop button, check the fa n/heater interface.

Use a voltmeter on the following terminals:

Black probe (J7-10) DC negative

Red probe (J7-15) 12 VDC output

Red probe (J7-03) 12 VDC when closed

This occurs when the plenum temperature inside the p lenum has reached

24 PNEG-1181 Portable Dryer Troubleshooting

Page 25

8. Troubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

VAPOR X HIGH LIMIT

Vapor 1 High Limit:

the vaporizer, has opened indicating that the vaporizer is ru nnin g too hot and must be adju ste d. This senso r

is set at 200°F and will automatically reset itself when cool. Adjust the vaporizer coil away from the burner

flame. Make sure the LP tank has fuel in it. Also, try switching to ON/OFF cycle rather than High/Low,

especially on warmer days. If the error still does not clear after pushing the stop button, check the fan/heater

interface. The error message shows on which heater this condition occurred.

Use a voltmeter on the following terminals:

Black probe (J7-10) DC negative

Red probe (J7-16) 12 VDC output

Red probe (J7-01) 12 VDC when closed

The LP gas vapor temperature sensor, located in the ga s pipe train downstream from

GRAIN TEMP OPEN X

Grain Temp Open 1: This error indicates there is a open condition with one of the grain temperature

sensors located inside the left or right grain columns. This could be a open sensor or the sensor wires

could be disconnected. These sensors are wired to a fan/heater interface, which one depends on the

model of dryer. Refer to the Dryer Front Panel Parts Location Wiring for location of the actual sensors.

The terminals they are wired to are as follows:

Grain Temp Sensor Ground - (J7-18)

Grain Temp Sensor - (J7-14)

When testing these sensors to see if they are bad refer Temperature Chart (Series 2000 Temp Sensors)

on Page 60 and also Grain Sensor Testing on Page 57.

GRAIN TEMP SHORT X

Grain Temp Short 1: This error indicates a shorted condition with one of the grain temperature

sensors located inside the left or right grain columns. This could be a shorted sensor or the sensor wires

could be shorted together. The sensors are wired to a fan/heater interface. Refer to the Dryer Front

Panel Parts Location Wiring more complete information.

The terminals they are wired to are as follows:

Grain Temp Sensor Ground - (J7-18)

Grain Temp Sensor - (J7-14)

When testing these sensors to see if they are bad, refer to the Temperature Chart (Series 2000 Temp

Sensors) on Page 60 and also Grain Sensor Testing on Page 57.

PLENUM TEMP OPEN X

Plenum Temp Open 1: This error indicates an open condition with the plenum temperature sensor

located inside the plenum chamber. This could be an open sensor or the sensor wires could be

disconnected. These sensors are wired to a fan/heater interface, which one depends on number of

plenums. The error message will show in which plenum the opening occurred. Refer to the Dryer Front

Panel Parts Location Wiring for location of the actual sensors. The terminals they are wired to are as

follows:

Plenum Temp Sensor Ground - (J7-13)

Plenum Temp Sensor - (J7-12)

PNEG-1181 Portable Dryer Troubleshooting 25

Page 26

8. T roubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

PLENUM TEMP SHORT X

Plenum Temp Short 1: This error indicates a shorted condition with the plenum temperature sensor

located inside the plenum chamber. This could be a short in the sensor or the sensor wires. These

sensors are wired to a fan/heater interface, which sensor contains the short depends on number of

plenums. The error message will show in which plenum the short occurred. Refer Dryer Front Panel

Parts Location Wiring for location of the actual sensors.

The terminals they are wired to are as follows:

Plenum Temp Sensor Ground - (J7-13)

Plenum Temp Sensor - (J7-12)

FLAME LOSS X

Flame Loss 1:

been established. This may be caused by the flame probe no t being directly in the flame path, loss of fuel, or

a problem with the burner circuit. Sometimes, the loss of flam e occurs when the burner cycles to Low Fire. To

correct this error, adjust the gas pressure or adjust the flame probe to where it is in the flame path at all times.

Remove the access door on the side of the fan/heater housing to allow access to the flame probe.

Another way to see if the burner is sensing flame correctly is to watch the light in the burner switch. If it

starts to flicker, an adjustment may need to be made on the flame probe. The flame probe wire and

ground wire are connected to the fan/heater interface. The error messag e will show in which heater the

flame loss has occurred.

The terminals they are wired to are as follows:

Flame Probe Ground - (J7-20)

Flame Probe Wire - (J7-19)

This error indicates that the flame probe has failed to detect a burner flame that had already

Make sure power is OFF while adjusting the gas pressure or flame probe to

correct the Flame Loss error.

IGNITION FAILURE X

Ignition Failure 1: This happens when the burner fails to light. Make sure the fuel source has been

turned ON, all valves are ON, especially the Maxon valve. The Maxon valve has to be reset every time

an error occurs or there is a loss of power. Check the wiring, igniter gap (which needs to be about 1/8")

and make sure there is a spark. The igniter is located inside the fan/heater housing and the wiring

from it goes directly to the ignition transformer, which is located in the fan/can box on the outside of the

fan/heater housing. Access the igniter by removing the access door on the side of the fan/heater housing

or entering through the rear door of the dryer.

Make sure power is OFF while adjusting the igniter.

Power to the ignition transformer is received from the fan/heater interface. The error message will show

in which heater the ignition failure has occurred.

The terminals the ignition transformer are wired to are as follows:

Transformer Ground - (J6-02) AC Neutral

Transformer Power - (J6-06) AC Power 120 VAC

26 PNEG-1181 Portable Dryer Troubleshooting

Page 27

8. Troubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

ILLEGAL FLAME X

Illegal Flame 1:

when the burner is supposed to be OFF. Example, after being shut down , the dryer and the heater

continue to burn due to a solenoid stuck open. Th e error m essage will s how in which he ater the ille gal flame

has occurred.

This message is displayed when the flame detection circuit of the heater senses flame

MOTOR OVERLOAD X

Motor Overload 1: This indicates that one of the fan motor thermal overloads has opened. This

overload is located in the fan/can box on the side of the fan/heater housing. The overload must be

manually reset by pushing the red button. The message will display in which fan the overload has

occurred. If the error does not clear after resetting the overload and pushing the stop button. You might

have to check in the fan/heater interface located nearest that same fan/can. The overload is connected

to the fan/heater interface. This is the only overload that is located here, the rest are located in the upper

main panel. Refer to the Motor Overload below for more motor overload information.

Use a voltmeter on the following terminals:

Black Probe (J7-10) DC negative

Red Probe (J7-15) 12 VDC output

Red Probe (J7-04) 12 VDC when closed

Input/Output Errors

The following is a list of errors that are generated with the Input/Output board. This board is located in

the upper control box of your Network Dryer.

Motor Overload

The following are messages that may show up under this sh ut down. These overloads are located in the

upper panel. This means that the thermal overload has opened on the motor indicated on the display.

The overload has to be manually reset by pushing the red button on the overload. This indicates that

this motor might be operating under an abnormal work load. This condition causes the motor to pull more

current (ampere) over its rated full load ampere. It may be necessary to have an electrician to che ck the

motors operating amperage. The name tag on the motor will indicate the full load ampere (FLA) in

relationship with the incoming voltage. The overload has a normally closed set of contacts. To these

contacts from the Input/Output board is sent 12 VDC, when the overload opens so do these contacts.

Below will indicate which terminals to check for that particular overload shut down. When checking DC

voltage you must have a DC negative. The DC negative is located on the Input/Output board where the

network connections are terminated. It is a three terminal block connection, use the unused terminal for

the DC negative. Refer Input/Output Board Voltage Testing Wiring.

LOAD MOTOR OVERLOAD

Use a voltmeter on the following terminals:

Black probe-unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-09) 12 VDC output

Red probe (J2-11) 12 VDC when closed

PNEG-1181 Portable Dryer Troubleshooting 27

Page 28

8. T roubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

AUX LOAD OVERLOAD

Use a voltmeter on the following terminals:

Black probe - unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-09) 12 VDC output

Red probe (J2-10) 12 VDC when closed

UNLOAD MOTOR OVERLOAD

Use a voltmeter on the following terminals:

Black probe - unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-09) 12 VDC output

Red probe (J2-09) 12 VDC when closed

AUX UNLOAD MOTOR OVERLOAD

Use a voltmeter on the following terminals:

Black probe - unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-09) 12 VDC output

Red probe (J2-12) 12 VDC when closed

REAR DISCHARGE

This indicates that the lid on the grain discharge box has opened. This could be caused by the grain not

being taken away fast enough or not at all. Checking the grain take away system will usually fix this

problem. There is 12 VDC sent out from the Input/Output board to the mercury switch loca ted under the

discharge box lid and must return to the board or this error will appear.

Use a voltmeter on the following terminals:

Black probe - unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-07) 12 VDC output

Red probe (J2-05) 12 VDC when closed

USER SAFETY

A shut down has occurred due to a user installed safety switch that has opened. The connections to this

are on the terminal strip located in the upper panel. There is 12 VDC sent out and must return or this

error will appear. This input is normally jumpered when it leaves the factory on the terminal strip. If in use

this has normally been installed by an electrician.

Use a voltmeter on the following terminals:

Black probe - unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-07) 12 VDC output

Red probe (J2-01) 12 VDC when closed

28 PNEG-1181 Portable Dryer Troubleshooting

Page 29

8. Troubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

METER ROLLS FAILED

This is usually caused by either a defective meter roll sensor or the meter rolls not turning beca use of a

broken drive chain, jammed meter roll, bad motor or gear case. The meter roll sensor is located in a

white plastic box on the rear of the dryer. The box is mounted on the end of the meter roll drive shaft.

12 VDC is sent out to the meter roll sensor, which in turn sends a pulse signal back to the terminal strip

in the upper panel. (The meter rolls must be turning in order for the pulse signal t o return). After checking

to make sure the meter rolls are turning, the following may need to be checked.

Refer to the Network Dryer Meter Roll Sensor Rearview Wiring in the manual.

Use a voltmeter on the following terminals:

Black probe - (J3-04) 12 VDC negative

Red probe (J3-07) 12 VDC output

Red probe (J3-03) meter roll return (If you are not able to read a pulse signal with your meter. Set your

meter to read DC voltage and you should be able to read a varying DC voltage. Some where between

0 VDC and 12 VDC).

OUT OF GRAIN

The Out of Grain Timer has timed out. A mercury switch located on top of the dryer in a white plastic box

resets the timer. It is connected to a paddle that is moved by grain as the dryer fills. Shut down usually

occurs when the loading equipment has difficulty keeping up with the dryer output or when the wet

supply has run out of grain. The length of time set for the timer can be increased, however, the top

hopper of the dryer should always have grain in it. If the side screens open up at anytime, the dryer is

losing heat as well as efficiency. Therefore, the fill equipment must be big enou gh to handle the capacity

of the dryer. Also, keep in mind that the Out of Grain Timer is only in op eration when the loa d switch is

in the AUTO position.

Black probe - unused terminal where the network connections are terminated (Input/Output Board)

Red probe (J3-07) 12 VDC output

Red probe (J2-01) 12 VDC when the dryer is calling for grain

Red probe (J2-01) 0 VDC when the dryer is full

Master Display Generated Errors

The following is a list of errors that come from the Master Display Board located in the lower control box.

CONT-BATCH MODE CHNG

This error occurs when switching the dryer mode switch from the Continuous Flow to the Staged Batch

mode while the dryer is running. To avoid this shut down, stop the dryer before switching modes. Press

the stop button to clear.

NETWORK FAILED: FH1

This error is generated when a fan/heater board (near the fa n/can housing) loses its communication link

with the Input/Output board (on the upper control panel) and the Master Display Board (on the lower

control panel). Check the blue and yellow wires marked N1-01 and N1-02 on a three (3) terminal plug

to make sure they are plugged in tightly. Also check and make sure the blue and yellow wires have

continuity between each other (blue to blue and yellow to yellow). The error message displayed will show

which fan/heater has lost communication. Example FH1-FH2-FH3 etc. Press STOP to clear.

PNEG-1181 Portable Dryer Troubleshooting 29

Page 30

8. T roubleshooting Tips

Possible Safety Circuit Shut Down Messages (Continued)

NETWORK F AILED: Input/Output

This error occurs when the Input/Output Board (upper control panel) has lost its communications link

with the Master Display Board (lower control panel) and the fan/heater Boards. Check the blue and

yellow wires marked N1-01 and N1-02 on a three (3) terminal plug to make sure they are plugged in

tightly. Check and make sure the blue and yellow wires have continuity between each other (blue to blue

and yellow to yellow). There are three (3) LED lights next to the three (3) terminal plug, one is for power

and the others indicate data being transmitted between the boards. The two labeled RXD and TXD

should be flashing randomly back and forth, this indicates network activity. Press stop to clear.

NETWORK FAILED: MAST

This error occurs when the Master Display Board (lower control panel) has lost its communications

link with the Input/Output Board (upper control panel) and the fan/heater Boards. Check the blue and

yellow wires marked N1-01 and N1-02 on a three (3) terminal plug to make sure they are plugged in

tightly. Also check and make sure the blue and yellow wires have continuity between each other

(blue to blue and yellow to yellow). Press stop to clear.

30 PNEG-1181 Portable Dryer Troubleshooting

Page 31

2 Fan Network Dryer Internal Wiring

(Back of Control Panel Switches to Display Board)

9. Wiring Reference

PNEG-1181 Portable Dryer Troubleshooting 31

Page 32

9. Wiring Reference

2 Fan Network Dryer Internal Jumper Wiring

32 PNEG-1181 Portable Dryer Troubleshooting

Page 33

Upper Control Back Panel Wiring

9. Wiring Reference

PNEG-1181 Portable Dryer Troubleshooting 33

Page 34

9. Wiring Reference

Network Upper Control Panel Wiring (220 Volt 3PH)

34 PNEG-1181 Portable Dryer Troubleshooting

Page 35

9. Wiring Reference

Network Upper Control Panel Wiring (380, 460 and 575 Volt 3PH)

PNEG-1181 Portable Dryer Troubleshooting 35

Page 36

9. Wiring Reference

2 Fan Network Power Circuit Diagram (220 Volt 1PH) (1 of 2)

36 PNEG-1181 Portable Dryer Troubleshooting

Page 37

9. Wiring Reference

Network Power Circuit Diagram (220 Volt 1PH) (2 of 2)

PNEG-1181 Portable Dryer Troubleshooting 37

Page 38

9. Wiring Reference

2 Fan Network Power Circuit (220 Volt 3PH) (1 of 2)

38 PNEG-1181 Portable Dryer Troubleshooting

Page 39

Network Power Circuit (220 Volt 3PH) (2 of 2)

9. Wiring Reference

PNEG-1181 Portable Dryer Troubleshooting 39

Page 40

9. Wiring Reference

2 Fan Network Power Circuit Diagram (440 Volt 3PH) (1 of 2)

40 PNEG-1181 Portable Dryer Troubleshooting

Page 41

9. Wiring Reference

Network Power Circuit Diagram (440 Volt 3PH) (2 of 2)

PNEG-1181 Portable Dryer Troubleshooting 41

Page 42

9. Wiring Reference

Network Control Circuit (Main Display Board) (1 of 4)

42 PNEG-1181 Portable Dryer Troubleshooting

Page 43

9. Wiring Reference

Network Control Circuit (Input/Output Board) (2 of 4)

PNEG-1181 Portable Dryer Troubleshooting 43

Page 44

9. Wiring Reference

Network Control Circuit (Meter Roll Sensor-SCR Board) (3 of 4)

44 PNEG-1181 Portable Dryer Troubleshooting

Page 45

Network Control Circuit (Fan/Heater Board) (4 of 4)

9. Wiring Reference

PNEG-1181 Portable Dryer Troubleshooting 45

Page 46

9. Wiring Reference

Upper Terminal Strip

46 PNEG-1181 Portable Dryer Troubleshooting

Page 47

9. Wiring Reference

Network Upper Terminal Strip (With Moisture Manager Hookup/Relay)

PNEG-1181 Portable Dryer Troubleshooting 47

Page 48

9. Wiring Reference

Moisture Manager Hookup (Network or Competitor)

48 PNEG-1181 Portable Dryer Troubleshooting

Page 49

9. Wiring Reference

Input/Output Board Voltage Testing (Located in Upper Control Box)

PNEG-1181 Portable Dryer Troubleshooting 49

Page 50

9. Wiring Reference

Lower Control Box Back Panel Wiring

50 PNEG-1181 Portable Dryer Troubleshooting

Page 51

9. Wiring Reference

Network Fan/Heater Interface (Located in Heater Control Box)

PNEG-1181 Portable Dryer Troubleshooting 51

Page 52

9. Wiring Reference

Network Fan/Heater Computer Pinouts

52 PNEG-1181 Portable Dryer Troubleshooting

Page 53

9. Wiring Reference

Fan/Can Control Box Wiring (Example: Single Phase Power)

PNEG-1181 Portable Dryer Troubleshooting 53

Page 54

9. Wiring Reference

Lower Junction Box Wire Routing

54 PNEG-1181 Portable Dryer Troubleshooting

Page 55

Upper Junction Box (Wiring)

9. Wiring Reference

PNEG-1181 Portable Dryer Troubleshooting 55

Page 56

9. Wiring Reference

Network Dryer Meter Roll Sensor Rearview (Wiring)

56 PNEG-1181 Portable Dryer Troubleshooting

Page 57

9. Wiring Reference

Testing Procedures and Location of Grain Temperature Sensors

The grain sensors terminate at the Heater Board located by the fan/can housing. Single module with two

fans, grain sensors are wired to bottom heater board. On a stack dryer with multiple fan/heaters, the

sensors will be terminated on the bottom Heater Board of the second module. It does not matter if the

second module has one fan/heater or two fan/heaters. If a bad sensor is suspected, always check the

heater board first. There are two white wires connected to J7-18 and two black wires connected to

J7-14. Check the resistance of the (thermistor) senso r according to the temperature in t he grain column.

Disconnect the two sets of wires and with the meter set to ohms scale, place one meter probe on the

black set of wires and the other probe on the white set. It should read somewhere close to the Chart on

Page 60. Example: Temperature 70°F should read about 11K on the meter. If this does not = 11K go

back to the white junction boxes as indicated above. (See Page 58.)

PNEG-1181 Portable Dryer Troubleshooting 57

Page 58

9. Wiring Reference

Procedure for Locating, Testing and Replacing a Defective Grain

Temperature Sensor

Symptoms of a bad sensor may include:

• Temperature readings that are not consistent with the ambient outside temperature or with any

known or verified grain temperatures entering the dryer.

• Grain temperature open or grain temperature short on network dryers.

• Display readings of 255°F or -127°C.

Figure 9A Grain Thermistor Sensor

T roubleshooting:

1. Locate the left and right grain sensor electrical boxes on the dryer. (See Figure 9B.)

2. Open each box by removing the lid, which is held in place by four (4) phillips head bolts and nuts.

3. Determine which wires to test by identifying the wire routing.

Grain thermal

overheat wires

Sensor wires

(small white

26 Ga.)

Grain thermal

overheat wires

Mounting screws

Grain thermal

overheat switch

Sensor wires (small

white 26 Ga.)

Figure 9B

4. The grain sensor wires are small white wires (26 Ga.) and are connected to a 18 Ga. white and a

18 Ga. black wire with two (2) of the smaller (26 Ga.) grain sensor wires butt connected together.

5. The grain thermal overheat switch is a black disk mounted on a silver bracket with two (2) black

18 Ga. wires connected to two (2) colored wires.

6. Disconnect the white and black 18 Ga. wires from the smaller white grain sensor wires.

58 PNEG-1181 Portable Dryer Troubleshooting

Page 59

9. Wiring Reference

Procedure for Locating, Testing and Replacing a Defective Grain

Temperature Sensor (Continued)

7. Strip back about 1/4 inch from the end of each 26 Ga. sensor wire.

8. With an ohm meter, set the scale to 20k (if it is not an autorange model).

9. Place the black lead into the butt connected wire connection with the 2-26 Ga. wires.

10. Connect the red lead to either of the disconnected 26 Ga. wires and note the reading.

11. Move the red lead to the other disconnected 26 Ga. wire and note this reading.

12. Repeat Step 6 through Step 11 on the other side of the dryer.

13. Notice that three (3) readings will be very close to each other, but one reading will be different. The

different reading identifies the defective sensor. (Compare readings to Resistance/Temperature

Chart on Page 60.)

14. If a replacement sensor is not immediately available, jump to How to Bypass the Grain

Temperature Sensor.

Sensor Replacement:

15. The grain sensors are mounted to the grain overheat capillary and need to be removed together.

16. To remove the overheat switch, disconnect the grain thermal overheat wires.

17. Remove the two (2) self-tapping screws and slide the bracket, overheat switch and sensors out of

the conduit.

18. Remove the tape surrounding the defective grain sensor and then remove the sensor.

19. Place the new sensor upon the capillary and apply tape to secure it.

20. Slide the overheat switch and sensors back into the conduit until the bracket for the overheat switch

is in the same mounting position as before.

21. Replace both mounting screws into the overheat switch mounting bracket.

22. Butt connect together one wire from each of the grain sensors.

23. Connect one of the remaining grain sensor wires to the black 18 Ga. wire.

24. Connect the other remaining grain sensor to the white 18 Ga. wire.

25. Connect one of the grain overheat switch wire to each one of the colored wires.

26. Reconnect the other side of the dryer following steps 22 through 24.

27. Double check the wire connections and replace the covers on the boxes.

How to Bypass the Grain Temperature Sensor

If an extra grain sensor is not immediately available to replace the defective one, it is possible to rewire

the sensors so that only one (1) sensor monitors the grain temperature rather than four (4) sensors. The

dryer will continue to operate normally with only one sensor, however, it will only monitor a small section

of the grain columns.

1. On the side of the dryer in which sensor is defective, leave this sensor and the joining sensor

disconnected from the white and black 18 Ga. wires. Be sure to cap these 18 Ga. wires OFF.

2. On the other side of the dryer, take one of the small white grain sensor wires and connect it to the

white 18 Ga. wire.

3. From the same sensor connected to the white 18 Ga. wire, connect the other small white grain

sensor wire to the black 18 Ga. wire.

4. Double check the wire connections then replace the covers on the boxes.

PNEG-1181 Portable Dryer Troubleshooting 59

Page 60

9. Wiring Reference

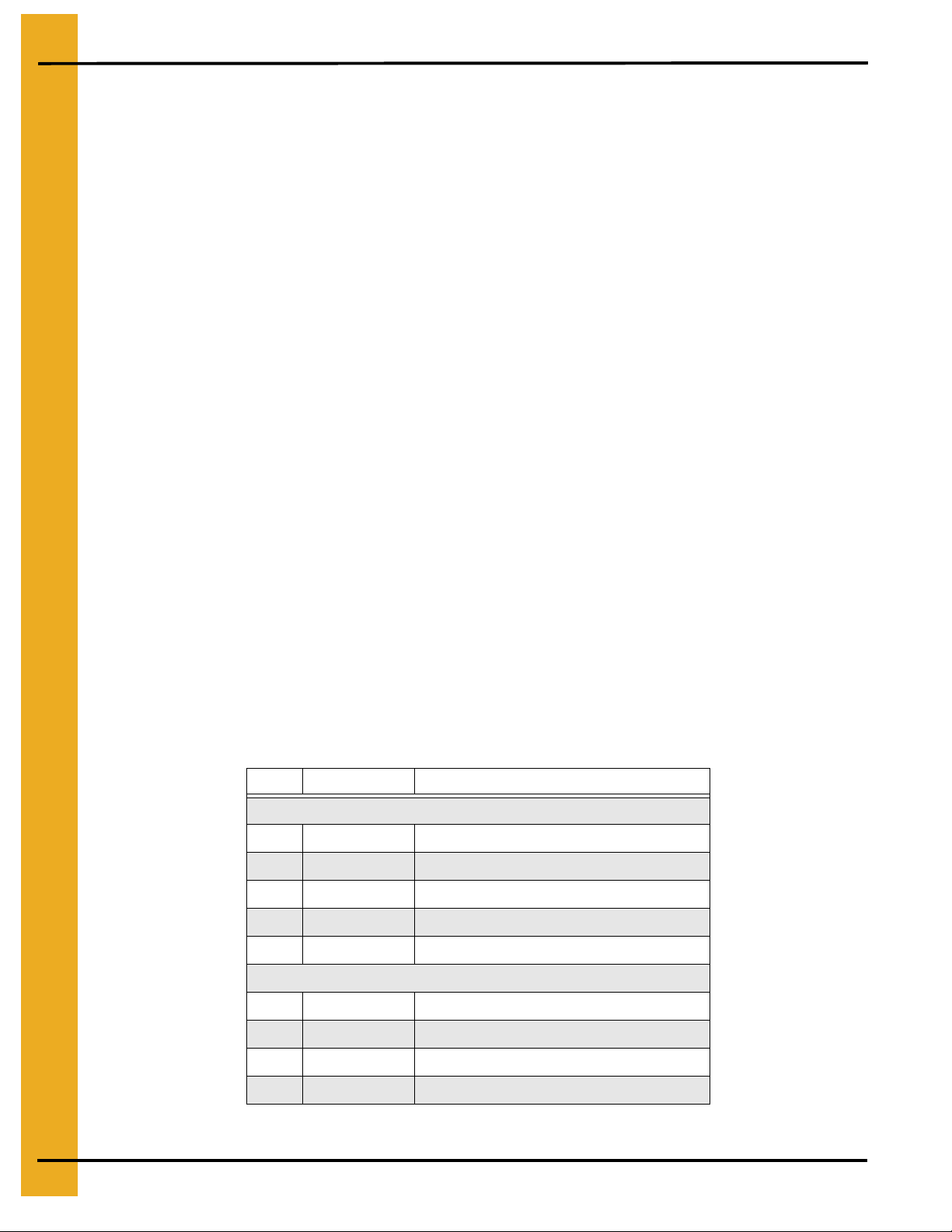

Sensor Chart

Resistance and Temperature Chart

°F Ohms °F Ohms °F Ohms °F Ohms °F Ohms °F Ohms °F Ohms

28 36,601 62 14,546 96 6,382 130 3,047 164 1,565 198 855.7 232 494.3

29 35,565 63 14,179 97 6,238 131 2,985 165 1,536 199 841.4 233 86.8

30 34,562 64 13,822 98 6,097 132 2,925 166 1,508 200 827.3 234 479.4

31 33,591 65 13,475 99 5,960 133 2,865 167 1,480 201 813.6 235 472.1

32 32,650 66 13,139 100 5,826 134 2,807 168 1,453 202 800.1 236 464.9

33 31,739 67 12,811 101 5,696 135 2,751 169 1,427 203 786.8 237 457.9

34 30,856 68 12,493 102 5,569 136 2,696 170 1,401 204 773.8 238 451

35 30,000 69 12,184 103 5,446 137 2,642 171 1,375 205 761.1 239 444.2

36 29,171 70 11,884 104 5,325 138 2,589 172 1,350 206 748.6 240 437.6

37 28,368 71 11,591 105 5,208 139 2,537 173 1,326 207 736.3 241 431

38 27,590 72 11,307 106 5,093 140 2,487 174 1,302 208 724.3 242 424.6

39 26,835 73 11,031 107 4,981 141 2,438 175 1,279 209 712.5 243 418.3

40 26,104 74 10,762 108 4,872 142 2,390 176 1,256 210 700.9 244 412.1

41 25,394 75 10,501 109 4,766 143 2,343 177 1,234 211 689.6 245 406

42 24,707 76 10,247 110 4,663 144 2,297 178 1,212 212 678.4 246 400

43 24,040 77 10,000 1 11 4,562 145 2,252 179 1,190 213 667.5 247 394.1

44 23,394 78 9,760 112 4,463 146 2,208 180 1,169 214 656.8 248 388.3

45 22,767 79 9,526 113 4,367 147 2,165 181 1,149 215 646.2 249 382.7

46 22,159 80 9,298 114 4,273 148 2,123 182 1,129 216 635.9 250 377.1

47 21,569 81 9,077 115 4,182 149 2,082 183 1,109 217 625.8

48 20,997 82 8,862 116 4,093 150 2,042 184 1,089 218 615.8

49 20,442 83 8,652 117 4,006 151 2,003 185 1,070 219 606.1

50 19,903 84 8,448 118 3,921 152 1,965 186 1,052 220 596.5

51 19,380 85 8,249 119 3,838 153 1,927 187 1,034 221 587.1

52 18,873 86 8,056 120 3,757 154 1,890 188 1,016 222 577.9

53 18,380 87 7,868 121 3,678 155 1,855 189 998.3 223 568.8

54 17,902 88 7,685 122 3,601 156 1,820 190 981.2 224 559.9

55 17,438 89 7,506 123 3,526 157 1,785 191 964.4 225 551.2

56 16,988 90 7,333 124 3,453 158 1,752 192 947.9 226 542.6

57 16,551 91 7,164 125 3,381 159 1,719 193 931.8 227 534.2

58 16,126 92 6,999 126 3,311 160 1,687 194 915.9 228 525.9

59 15,714 93 6,839 127 3,243 161 1,655 195 900.4 229 517.8

60 15,313 94 6,682 128 3,176 162 1,624 196 885.2 230 509.8

61 14,924 95 6,530 129 3,111 163 1,594 197 870.3 231 502

60 PNEG-1181 Portable Dryer Troubleshooting

Page 61

9. Wiring Reference

Procedure for Locating, Testing and Replacing a Defective

Plenum Temperature Sensor

Symptoms of a bad sensor may include:

• Temperature readings that are not consistent with the ambient outside temperature or with a verified

plenum temperature that has been taken with a thermometer.

• Erratic plenum display readings.

• Plenum temp open or plenum temp short.

T roubleshooting:

1. There is only one sensor to check for each plenum. The process of checking the sensor is similar

to checking the grain sensors.

2. The actual plenum sensor is located in the plenum just inside the rear access door to the left.

(Facing the rear of the dryer) (See Figure 9D on Page 62.)

3. Start at the heater board that is associated with the plenum sensor to be checked.

(Each plenum has its own plenum sensor.)

4. The wires from the sensor (which are butt connected at the sensor) go through a conduit in the

plenum section of the dryer. This conduit terminates at a white plastic 4" x 4" junction box. This box

is located on the front of the dryer to the right of the fan/heater. (Facing the front of the dryer.) From

that point to the heater board.

5. The wires are connected to terminals J7-12 (white wire) and J7-13 (black wire) on the back of th e

heater board. (See Figure 9C of heater board.)

Figure 9C Heater Board (Part No. HF-7276N)

6. Unhook these wires.

7. Check for resistance in relationship to a known temperature. (See Resistance/Temperature Chart

on Page 60.)

PNEG-1181 Portable Dryer Troubleshooting 61

Page 62

9. Wiring Reference

Procedure for Locating, T esting and Replacing a Defective Plenum

Temperature Sensor (Continued)

8. With an ohm meter, set the scale to 20k (if it is not an autorange model).

9. Place one probe of the meter on one wire g oing out to the sensor and the other pro be to the other wire.

10. The meter should read close to the Resistance/Temperature Chart on Page 60.

11. If the wiring from the heater board to the sensor is okay but the resistance is not close to what is

on the chart, a bad plenum bolt sensor is likely.

The picture below is of the plenum bolt sensor in the plenum of dryer. See the previous Page on 61 for

more information.

Figure 9D Plenum Bolt Sensor (Part No. HF-7236)

The picture below is of the 4" x 4" plastic junction box wiring. Which is located to the right of the

fan/heater facing the dryer. It contains the plenum thermal overheat and a junction point where the wires

from the plenum sensor are butt connected together.

Plenum 300 Degree Overheat (10' Length) (Part No. D03-0004)

Plenum 300 Degree Overheat (24' Length) (Part No. D03-0377)

Figure 9E

62 PNEG-1181 Portable Dryer Troubleshooting

Page 63

9. Wiring Reference

Procedures for Replacing Network SCR Board

The following three pages will explain how to calibrate the SCR board on a Network Dryer. Remember

when replacing a SCR board on a Network Dryer that it takes a special top board. Not replacing it with

the proper board could cause damage to the Dryer’s Input/Output board.

The necessary part numbers are listed below:

1. D03-0679-SCR Drive Board (complete top and bottom board without resistor) (Network Only)

2. D03-0592-SCR Drive Board Top Unit (Network Only)

3. D03-0711-SCR Drive Board Bottom Unit (Used On all Dryers)

4. D03-0039-1/3HP Resistor

5. D33-0001-3/4HP Resistor

Before starting the replacement procedure, set the dryer up as follows:

1. All fan and heater switches to the OFF position and the load switch to the OFF position.

2. Control power to the ON position.

3. Push the dryer power switch (make sure that the switch button illuminates).

4. Moisture control switch to the OFF position.

5. Dryer mode switch to Continuous Flow position.

6. Unload switch to 2 Speed position.

Moisture

control switch

Unload switch

Drying mode switch

Meter roll speed

control potentiometer

Figure 9F Control Panel Switch Locations

PNEG-1181 Portable Dryer Troubleshooting 63

Page 64

10. Dryer Parts

Dryer Front Panel (Part Locations)

64 PNEG-1181 Portable Dryer Troubleshooting

Page 65

Dryer Fan/Can Side View (Part Locations)

10. Dryer Parts

1

2

4

3

5

6

1. Fan/can Box: Fan motor contactor and overload - ignition transformer - igniter and flame probe

wire connections.

2. LP Pipe Train.

3. Air Switch.

4. Access Door: Flame probe - igniter.

5. 4" x 4" White Plastic Junction Box: Plenum (bolt) sensor wire connection - Plenum high limit.

6. Fan Heater Control Box: Heater interface board.

PNEG-1181 Portable Dryer Troubleshooting 65

Page 66

10. Dryer Parts

Plenum and Grain High Limit Locations

66 PNEG-1181 Portable Dryer Troubleshooting

Page 67

1 1 . Air Swit ch Tip

Network Series Air Switch Adjustment

1. With the Load Auger, Fan, Heater, and Unload switches in the OFF position, turn ON the Control

power then push the Dryer Power Start switch.

2. With power applied to the dryer, flip one of the fan switches to the ON position and watch for the

light to illuminate the fan switch knob. If the light illuminates when the fan reaches half its full speed,

then no adjustment is required. However, if the light does not illuminate until the fan is running at

full speed or the light does not illuminate at all and the dryer shuts down, then the air switch is

adjusted too high (skip to step 3a). If the light illuminates before the fan reaches half its full speed

the air switch is adjusted too low (skip to step 3b).

3a. If the light illuminates after the fan reaches full speed or did not illuminate at all and the dryer shut

down then the air switch needs to be made more sensitive. Turn adjustment screw counter

clockwise (more sensitive). Make this adjustment on the air switch 1/4 turn at a time and each time

restart the fan and watch to see when the light illuminates.