Page 1

PNEG-11 2 8

Chain Loop System

without Controls

Owner ’s Manual

PNEG-1128

Date: 07-26-13

Page 2

2 PNEG-1128 Chain Loop System without Controls

Page 3

Table of Contents

Contents

Chapter 1 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ..................... ... .... .......................................... ... ........................................................ 6

Grain Bin Safety ............................... ... ... ... ... ......................................................................................... 9

Chapter 2 Decals .................................................................................................................................................. 10

Decal Placement ........................................................................................................................... ...... 11

Chapter 3 Information .......................................................................................................................................... 13

Chain Loop System Information .......................................................................................................... 13

Final Inspection Check List ................................................................................................................. 14

Chapter 4 Operation ............................................................................................................................................ 15

Operating the Chain Loop System ... ... ... ... ... .... ... .......................................... ... ... .... ... ... ... ... .... ... ......... 15

Chapter 5 Management and Maintenance ......................................................................................................... 17

Maintenance ..................................... ............ ............. ................. ............ ............. ....................... ... ... ... 17

Chain and Paddles .............................................................................................................................. 18

Chapter 6 Installation .......................................................................................................................................... 19

Tube and Corner Assembly ............................................................................................................. ... 21

Drive Assembly ................................................................................................................................... 22

Chain Loop Torque Arm Repair Kit ..................................................................................................... 23

Drive Box Assembly Instructions ......................................................................................................... 26

Discharge with Gate Assembly ........................................................................................................... 27

Unload Well Installation ....................................................................................................................... 28

Chain and Paddles .............................................................................................................................. 29

Inspection Corner ................................................................................................................................ 31

Ground Control Kit for Discharge Gates ............................................................................................. 32

Inlet Dump Hopper Assembly ............................................................................................................. 36

Chapter 7 Troubleshooting ................................................................................................................................. 38

Chapter 8 Component Dimensions .................................................................................................................... 39

8", 10" and 12" Component Dimensions ............................................................................................. 39

8", 10" and 12" Bin Well and Dump Hopper Dimensions .................................................................... 41

PNEG-1128 Chain Lo op System without Controls 3

Page 4

Table of Contents

Chapter 9 Parts List ............................................................................................................................................. 44

8" and 10" Chain and Paddles ............................................................................................................ 46

12" Chain and Paddles (8120141) ...................................................................................................... 47

8" and 10" Discharge Gate .................................................................................................................. 48

12" - (7 Gauge) Discharge Gate (8120194) ................... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .. 49

12" - (10 Gauge) Discharge Gate (8120090) ...................................................................................... 50

Chain Loop Drive Components ........................................................................................................... 52

8" (15 HP) Drive Components (8081365) ........................................................................................... 55

8" (20 HP) Drive Components (8081363) ........................................................................................... 56

8" (15 HP-20 HP) Drive Components (8081362) ................................................................................ 57

10" (20 HP) Drive Components (8101526) ......................................................................................... 58

10" (15 HP-20 HP) Drive Components (8101525) .............................................................................. 59

8" (25 HP-30 HP) Drive Components (8081360) ................................................................................ 60

8" (25 HP-30 HP) Drive Components (8081359) ................................................................................ 61

10" (25 HP-30 HP) Drive Components (8101517) .............................................................................. 62

10" (25 HP-30 HP) Drive Components (8101516) .............................................................................. 63

10" (40 HP) Drive Components (8101513) ......................................................................................... 64

10" (50 HP) Drive Components (8101514) ......................................................................................... 65

10" (40 HP-50 HP) Drive Components (8101511) .............................................................................. 66

8" (15 HP) Drive Components (8081271) ........................................................................................... 67

8" (20 HP) Drive Components (8081285) ........................................................................................... 68

8"-10" (25 HP-30 HP) Drive Components (8081296) .......................................................................... 69

10" (40 HP) Drive Components (8101303) ......................................................................................... 70

10" (50 HP) Drive Components (8101331) ......................................................................................... 71

Belt Guard Assembly TA3 (8120217) ................................................................................................. 72

Belt Guard Assembly TA4 (8120211) ................................................................................................. 74

Belt Guard Assembly TA5 (8120214) ................................................................................................. 75

12" 7 Gauge (30 HP) Drive Components (8120000) ........................................................................... 76

12" 7 Gauge (40 HP-50 HP) Drive Components (8120144) ............................................................... 78

12" 7 Gauge (60 HP) Drive Components (8120163) ........................................................................... 80

12" 10 Gauge (30 HP) Drive Components (8120175) ......................................................................... 82

12" 10 Gauge (40 HP-50 HP) Drive Components (8120179) .................................. ... ... ... ... .... ... ... ... .. 84

12" 10 Gauge (60 HP) Drive Components (8120180) ......................................................................... 86

8" and 10" Inlet Dump Hoppers ........................................................................................................... 88

12" (7 Gauge) 42-1/2" Inlet Dump Hoppers (8120121) ....................................................................... 89

12" (7 Gauge) 102-1/2" Inlet Dump Hoppers (8120127) ......... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ..... 90

12" (7 Gauge) 122-1/2" Inlet Dump Hoppers (8120134) ......... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ..... 91

12" (10 Gauge) 42-1/2" Inlet Dump Hoppers (8120185) ......... .... ... ... .......................................... ... ... .. 92

12" (10 Gauge) 102-1/2" Inlet Dump Hoppers (8120186) ................................................................... 94

12" (10 Gauge) 122-1/2" Inlet Dump Hoppers (8120187) ................................................................... 95

8" and 10" Standard Corner ................................................................................................................ 96

12" (7 Gauge) Standard Corner (8120031) ......................................................................................... 98

12" (10 Gauge) Standard Corner (8120176) ........................ ............................................. ................ 100

8" and 10" Inspection Corner ............................................................................................................ 102

12" (7 Gauge) Inspection Corner (8120051) .................................. ... ... ... .... ...................................... 104

12" (10 Gauge) Inspection Corner (8120177) ................................................................................... 106

Chain Loop Torque Plate Assembly .................................................................................................. 108

Chapter 10 Warranty .......................................................................................................................................... 109

4 PNEG-1128 Chain Loop System without Controls

Page 5

1. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1128 Chain Loop System without Controls 5

Page 6

1. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Operate Motor Properly

In an emergency, shut down the power source.

Turn OFF and lock out all power sources before performing

any maintenance.

Do not operate electric motor equipped units until motors are

properly grounded.

Disconnect power on electrical driven units before resetting

motor overloads.

Do not repetitively stop and start the drive in order to free a

plugged condition. Jogging the drive in this manner can damage

the equipment and/or drive components.

Electric Shock Hazard

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6 PNEG-1128 Chain Loop System without Controls

Page 7

1. Safety

Stay Clear of Moving Parts

Entanglement in rotating impeller arms will cause serious injury

or death.

Keep all shields and covers in place at all times.

Wear close fitting clothing. S top and lock out power source before

making adjustments, cleaning, or maintaining equipment.

Entanglement Hazard

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built up grease oil and debris.

Maintain Equipment

and Work Area

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

PNEG-1128 Chain Loop System without Controls 7

Page 8

1. Safety

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1128 Chain Loop System without Controls

Page 9

1. Safety

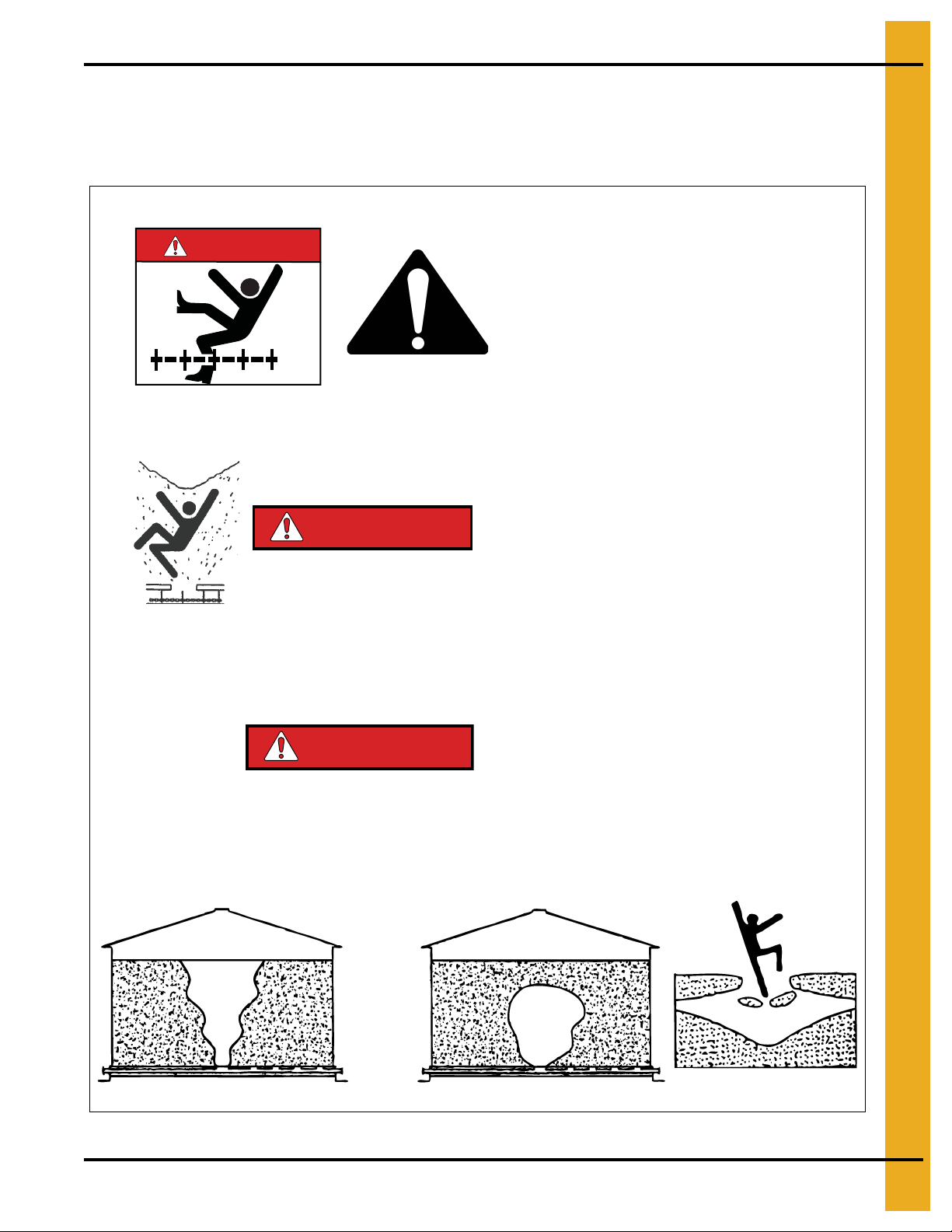

DANGER

DANGERDANGER

DANGERDANGER

DO NOT ENTER A GRAIN BIN UNLESS POWER

IS LOCKED OUT TO ALL BIN EQUIPMENT.

DO NOT ENTER A GRAIN BIN IF THE GRAIN HAS

BRIDGED OR STOPPED FLOWING NORMALLY. THE

GRAIN CAN COLLAPSE WITHOUT WARNING AND

CAN TRAP, BURY AND CAUSE SUFFOCATION.

DO NOT ENTER A GRAIN BIN WHILE GRAIN IS

BEING REMOVED. FLOWING GRAIN CAN

TRAP, BURY AND CAUSE SUFFOCATION.

Grain Bin Safety

The Chain Loop System is generally used to move grain into or from grain bins. Be aware of the dangers

inherit in grain bins.

DANGER

PNEG-1128 Chain Loop System without Controls 9

Page 10

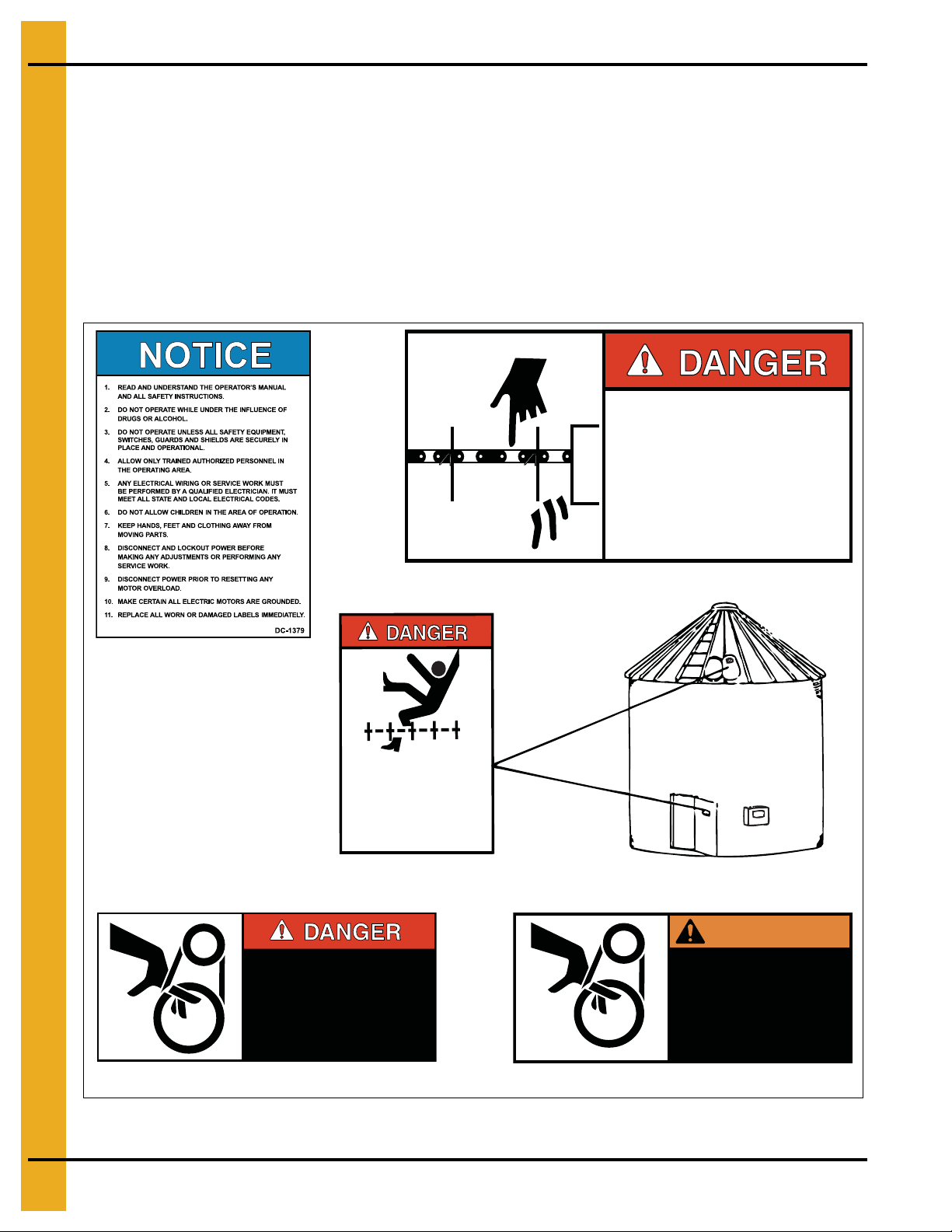

2. Decals

8107006

MOVING CHAINS AND PADDLES!

THIS BIN IS EQUIPPED WITH A CHAIN LOOP SYSTEM

WHICH CAN KILL OR DISMEMBER.

KEEP CLEAR OF ALL CHAIN AND PADDLES AND

NEVER ENTER THIS BIN UNLESS ALL POWER IS

DISCONNECTED AND LOCKED OUT.

FAILURE TO DO SO WILL RESULT IN SERIOUS INJURY

OR DEATH!

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-994

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-995

WARNING

This decal is provided in

the Owner’s Manual

Packet. Place on the bin

during Installation.

8107001

DC-1379

DC-994

DC-995

8107006

THE DECALS SHOWN ON THIS PAGE MUST BE DISPLAYED AS SHOWN

Replacements are available upon request. Write to the following address:

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

NOTE: 1. The decals on this page are not actual size.

2. Keep all decals wiped clean at all times.

3. All decals must be replaced if they are destroyed, missing, painted over or can no longer

be read.

SHEAR POINT

Do not operate with cover open.

Keep clear of moving chain and

paddles.

Do not remove or modify guards.

Disconnect and lockout power

before servicing.

Failure to do so will result in

Serious INJURY or DEATH.

8107001

10 PNEG-1128 Chain Loop System without Controls

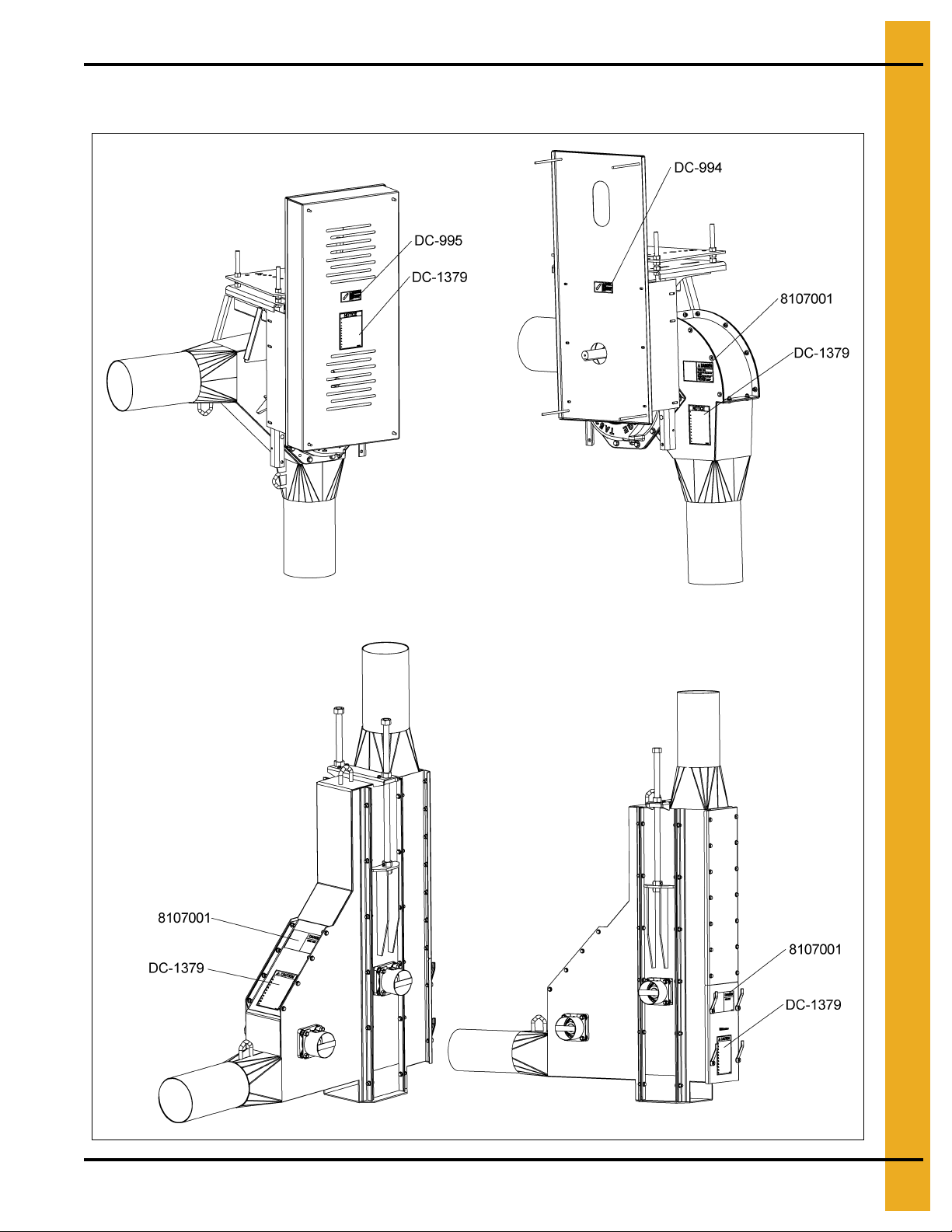

Page 11

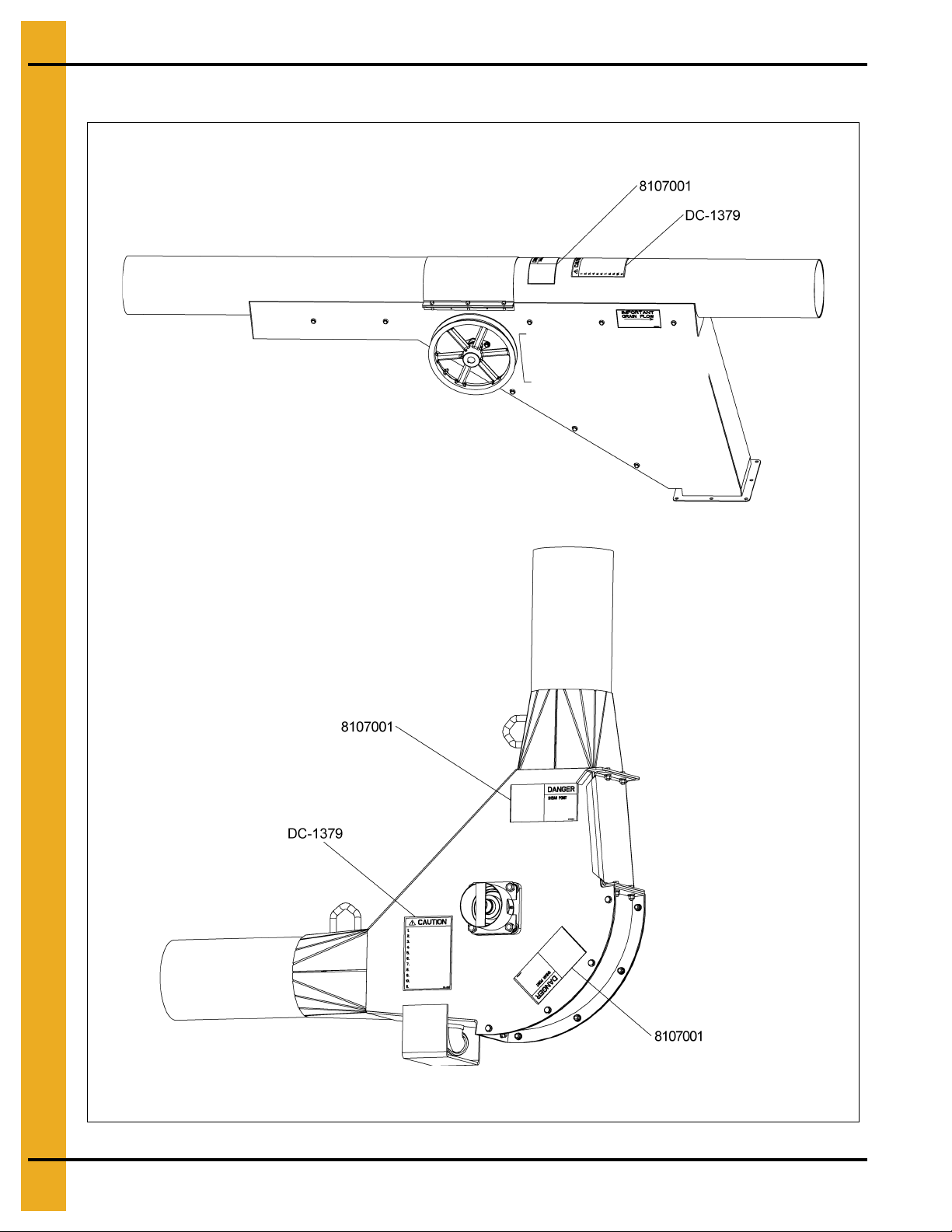

Decal Placement

NOTE: Cover and sheaves removed

for clarity.

2. Decals

PNEG-1128 Chain Loop System without Controls 11

Page 12

2. Decals

Decal Placement

12 PNEG-1128 Chain Loop System without Controls

Page 13

3. Information

Chain Loop System Information

A Chain Loop System is a chain and paddle conveyor moving through a round housing. A loop system

allows you to do total loading and unloading with a single drive. Chain Loop Systems will handle a wide

range of free flowing materials. They are primarily intended for grain and grain products. They will move

material into and out of grain storage structures, vehicles, dryers and other facilities with ease and

gentleness. The Chain Loop System is well suited for blending materials while being transferred from one

storage unit to another.

The height and length of the system is limited by the combined horsepower required to move the grain.

The vertical Chain Loop System requires greater horsepower per foot, so the taller units will be more

limited in the overall horizontal length. System lengths of several hundred feet are common. However,

relatively small systems to accomplish more specific tasks are also available.

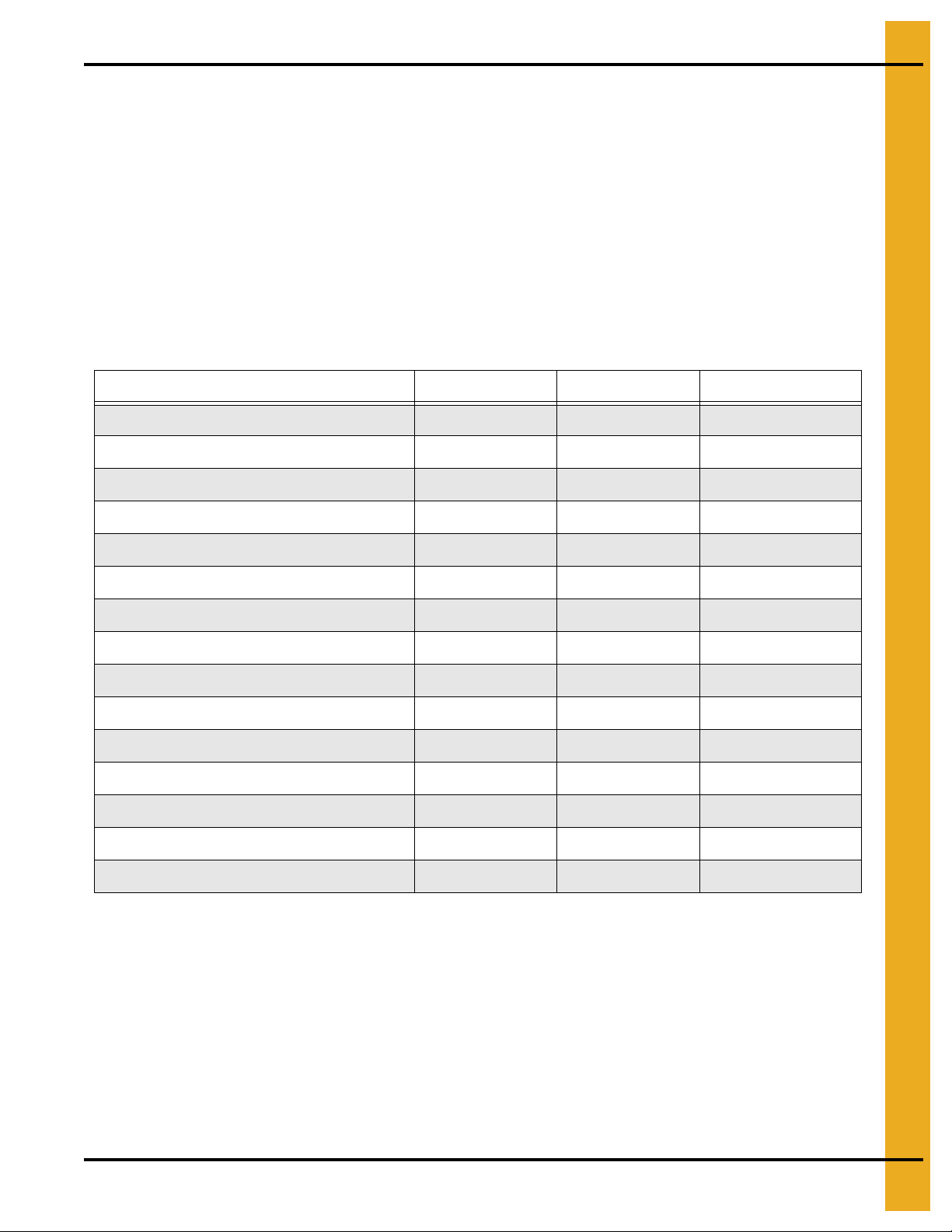

Chain Loop System Specifications

8" 10" 12"

*Maximum capacity in BPH (Tons/Hr) 4000 (100) 6000 (150) 1000 (250)

Chain travel in FPM (Meters, Min) 325 (99) 325 (99) 400 (122)

Head shaft RPM 94 94 83

Corner housing thickness, galvanized (mm) 7 Ga. (4.8) 5 Ga. (4.8) 3/16" (4.8)

Galvanized tubing wall thickness (mm) 12 Ga. (2.7) 12 Ga. (2.7) 10 Ga. (3.47) 7 Ga. (5)

Paddle thickness (UHMW) (mm) 3/8" (9.5) 1/2" (12.7) 1/2" (12.7)

Corner shaft diameter (mm) 2" (50.8) 3" (76.2) 3-7/16" (87.3)

Conveyor chain 81XHH 81XHH 81XHH

Conveyor sprocket 16 Tooth 16 Tooth 22 Tooth

*Power requirements

Per foot vertical (KW/M) 0.35 (0.86) 0.5 (1.22) 0.75 (1.84)

Per foot horizontal (KW/M) 0.08 (0.19) 0.11 (0.27) 0.18 (0.44)

Weight per foot lbs (KG/M)

Empty 12 (17.9) 15 (22.3) 24 (35.8) 30 (44.7)

Full of 56 lb. per bu. material 28 (41.7) 40 (59.5) 59 (88) 65 (97)

* Clean dry grain

PNEG-1128 Chain Loop System without Controls 13

Page 14

3. Information

Final Inspection Check List

The Chain Loop System requires an inspection before start-up after the assembly is complete and before

each use. The following are critical areas to be inspected.

1. Make sure that the main power isolator is locked in the “OFF” position and that the

WARNING

only key is in the possession before removing any shields and inspection covers.

2. Check all safety decals and replace any that are worn, missing or illegib le.

part numbers and location.

3. Check for proper chain tension and adjust if necessary. See Page 29 for full instructions.

4. Check that the discharge gates open and close completely. Remove the inspection cover from the

top of the discharge gate and make sure that the gate is clean inside.

5. Check the lubricant level in the gear reducer at the drive corner. See Page 17 for

lubrication specifications.

NOTE: The gear reducer is shipped dry and needs to be filled to the proper level before use.

6. Check the condition of the drive belts and make sure that they are aligned and tensioned properly.

7. Check that the corner sprockets are centered in the housings. Realign the sprockets and tight en the

set screws if necessary.

8. Check overall structural integrity of the Chain Loop System and make sure that all supports and

components are secure.

9. Check to make sure that the chain moves freely (this is particularly important if the temperature is

below freezing). Use a pipe wrench on the end of each of the corner shafts to manually move

the chain.

10. Make sure all shields and safety guards are in place before restoring power.

See Pages 10-12

for decal

WARNING

14 PNEG-1128 Chain Loop System without Controls

Page 15

4. Operation

Lock out the main power source before removing any inspection covers or

shields necessary to empty the system.

CAUTION

Operating the Chain Loop System

The Chain Loop is generally used to transfer grain to or from storage bins. Grain can be fed into the system

through an inlet dump hopper or through center or intermediate grain wells in the storage b ins. Wells from

more than one bin can be opened at the same time to blend the contents of different bins. The system is

usually oriented vertically (with the tube running under the storage bins), or at an angle with the bottom

tube running along the sides and the top tube running over the fill holes of the storage bins. Horizontal

installations are also possible - check with your dealer for special gear reducer lubrication requirements

for horizontal installations.

The Chain Loop System should always be run under partial load for a period of time to polish the tube

walls before attempting to run at full load. This is especially true when breaking in a new system but equally

important after being idle for a length of time. Observe the amp meter on the drive motor while running

with a partial load until the amperage starts to decline. This is an indication that the tube walls have been

polished enough to handle a larger load.

It is very important to avoid stopping the chain under a loaded condition. Never attempt to restart until the

Loop System has been emptied of as much grain as possible.

CAUTION

Observe the following basic sequence for using the Chain Loop System to fill storage bins.

1. Open the discharge gate above the destination bin.

2. If available, open the discharge gate above a bin downstream from the destin ation bin to be used as

an overflow.

3. Start the Chain Loop drive motor. Station an individual at the control box to observe the amp gauge

of the drive motor.

4. Let grain flow into the inlet dump hopper. Open the flow control by adjusting the chains on the hopper

a small amount at a time to make sure that the amperage does not exceed the capability of the drive

motor. NOTE: Some materials and grains such as soybeans flow very easily, so it is important to

make sure that the center shield in the inlet hopper is adjusted low enough to prevent overloading

the system.

5. Let the Chain Loop run until the system is empty.

6. Close the discharge gates and the dump hopper flow control when through filling.

7. Shut down the drive motor.

8. Make sure to lock out the power source before leaving the work area.

PNEG-1128 Chain Loop System without Controls 15

Page 16

4. Operation

Operating the Chain Loop System (Continued)

Observe the following basic sequence for using the Chain Loop System to transfer grain from

storage bins.

1. Open the discharge gate above the withdrawal bin.

2. Open the discharge gate above the destination bin or truck-loading spout.

3. Start the Chain Loop drive motor. Station an individual at the control bo x to ob serve the amp g auge

of the drive motor.

4. Open the slide gate under the withdrawal bin a little at a time to make sure that the amperage does

not exceed the capability of the drive motor.

5. Close the discharge gate above the destination bin or truck when full. DO NOT SHUT DOWN THE

CHAIN LOOP DRIVE MOTOR AT THIS TIME.

6. Close the slide gate under the withdrawal bin.

7. Run the Loop System until all remaining grain in the tube has been returned to the withdrawal bin.

8. Shut down the drive motor.

CAUTION

A sweep auger may be placed in the bin after all the grain has been removed that will gravity-flow

through the center well. Shut down and lock out all power to the Chain Loop System b efore installing the

sweep auger.

If intermediate bin wells are being used, they should be opened after grain has stopped flowing into the

center well and before the sweep auger is placed in the bin. (See Figure 4B.) Shut down and lock out the

Chain Loop System before installing the sweep auger.

9. Make sure to lock out the power source before leaving the work area.

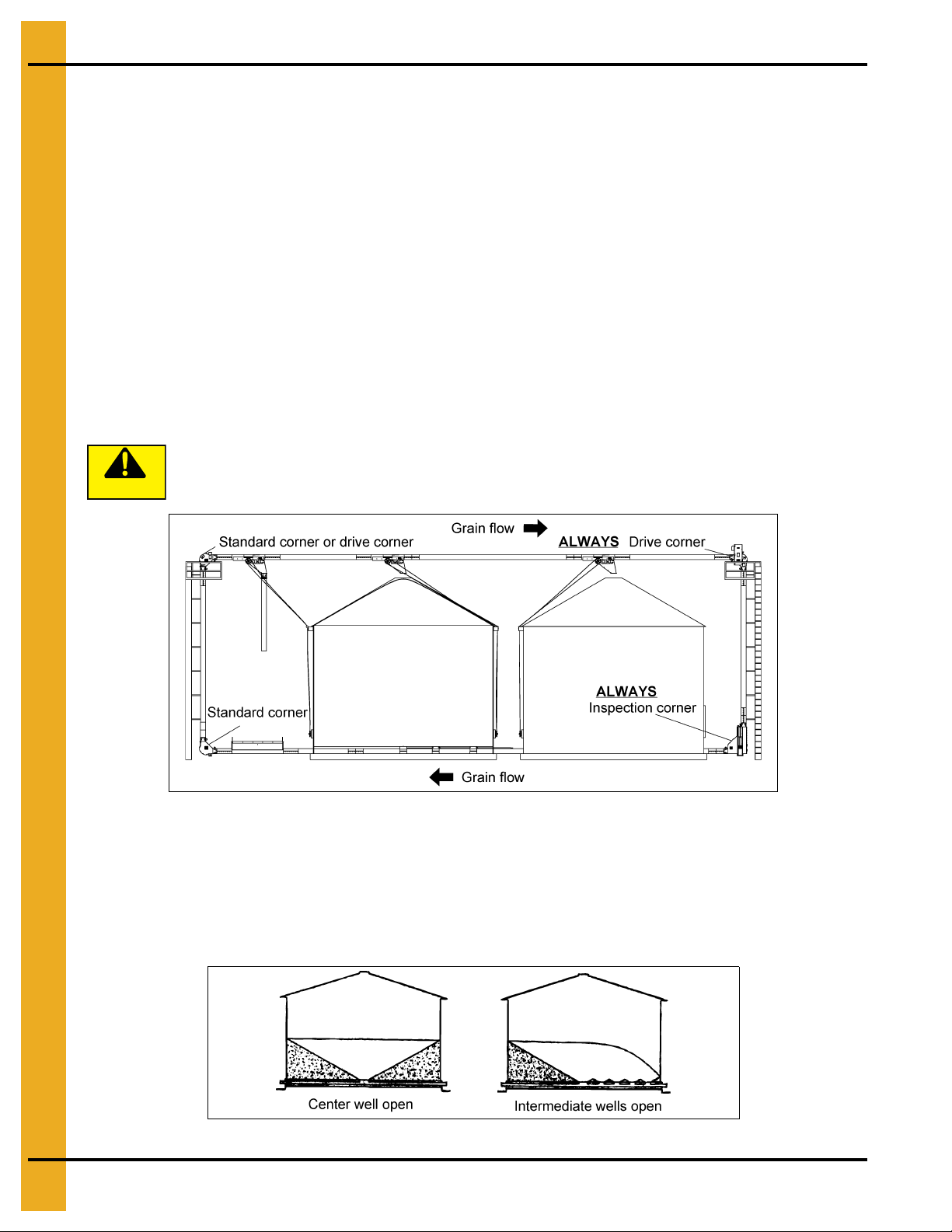

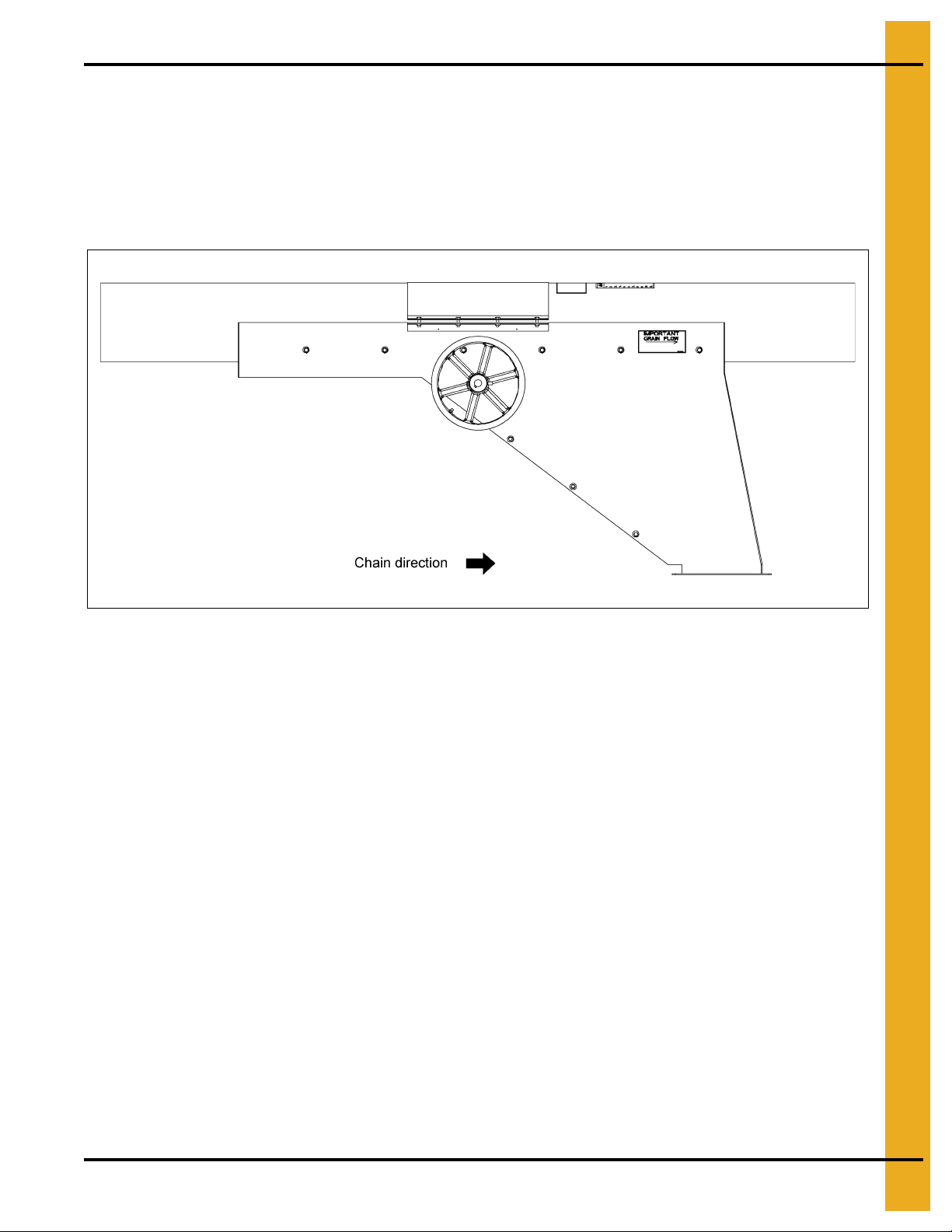

Figure 4A

Figure 4B

16 PNEG-1128 Chain Loop System without Controls

Page 17

5. Management and Maintenance

CAUTION

Lock out the main power source before performing any maintenance or

service inspections.

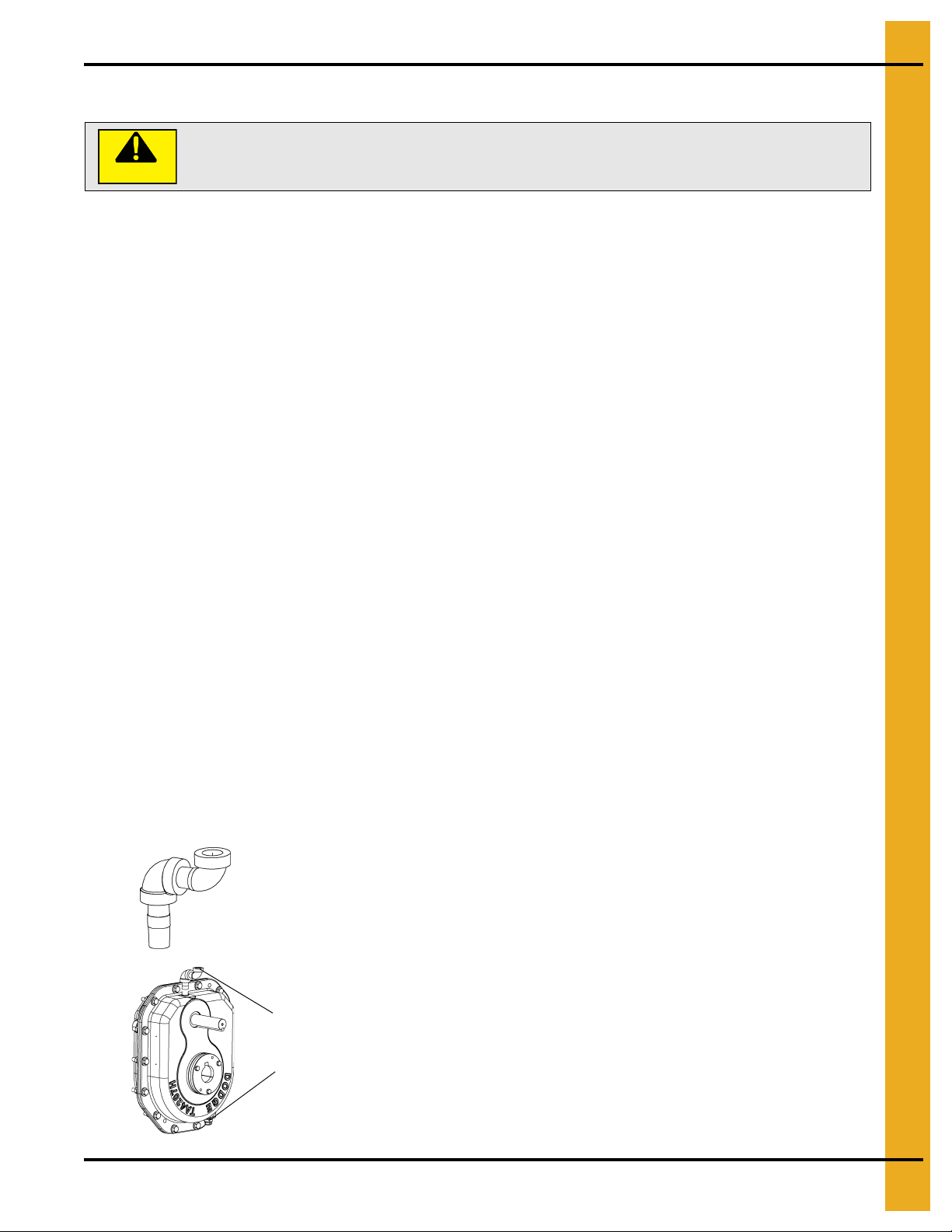

8101333 - 1/2" Vent elbow assembly

(Used on TA 4, TA5 and TA6 reducers in “D” position)

8101335 - 3/8" Vent elbow assembly

(Used on TA3 reducers in “D” position)

To install vent elbow assembly:

(Reducer is shown in “D” position - Input shaft at the top)

• Remove magnetic drain plug from the top of the reducer and replace

with the proper vent elbow assembly.

• Remove vent plug from the bottom of the reducer and replace with

the magnetic drain plug from the top.

• Install the vent plug in the top of the vent elbow assembly.

Maintenance

Dodge Gear Reducer

Use the information that is on the gear reducer nameplate, the warning tags and the Dodge instruction

manual that is included with the Chain Loop manual to determine specific maintenan ce instructions for the

gear reducer used on the system. When referring to the dodge manual, n ote that the reducer is mou nted

in the “D” position on the Chain Loop.

NOTE: The gear reducer is shipped dry and must be filled to the proper level before use.

Use a high-grade petroleum base rust and oxidation inhibited SAE 90 weight gear oil for ambient

temperatures from 15°F to 125°F (-10°C to 52°C). Oils with an “EP” additive are not recommended for

average conditions (see the lubrication section of the dodge manual). Use the check oil plug for

determining the correct amount of oil; too much oil will cause overheating and too little will cause bearing

and gear failure. The approximate quantity of oil for each reducer size is:

Model TA3203H 4.0 qt (3.80L) - for 15-20 HP motors

T A4207H 7.3 qt (6.90L) - for 25-30 HP motors

TA5215H 12.9 qt (12.2L) - for 40 HP motors

TA6307H 15.8 qt (15.0L) - for 60 HP motors

The oil should be changed at the beginning of every harvesting season if the Chain Loop is used for

seasonal grain handling. It should be changed after 2500 hours of operation or every 6 months if used

under average industrial conditions. The oil should be changed more frequently if used under extreme

operating conditions such as large changes in ambient temperatures, dust, dirt, chemical particles,

chemical fumes or oil sump temperatures above 200°F.

Drain the reducer, clean the magnetic plug and flush with kerosene before refilling with new oil.

Drive Belts

Check to make sure that drive belts are tensioned and aligned properly. Use a straight edge to check the

alignment with the motor and reducer sheaves. Adjust all the motor tensioning rods equally to keep the

motor shaft parallel to the reducer shaft.

Vent Elbow Installation Instructions

PNEG-1128 Chain Loop System without Controls 17

Page 18

5. Management and Maintenance

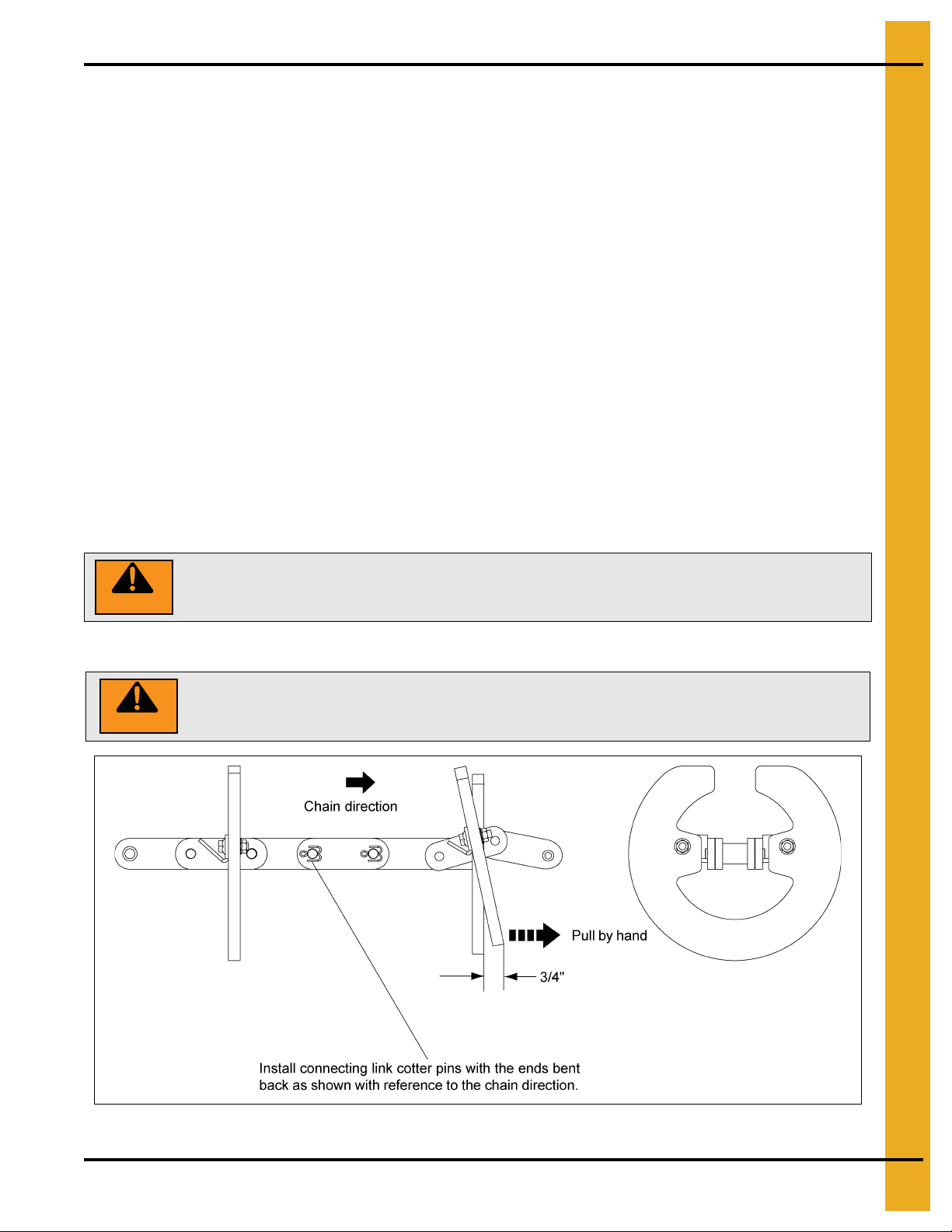

Chain and Paddles

Check for proper chain tension. Open the inspection door at the inspection corner and check chain tension

by pulling the bottom edge of a paddle by hand. The paddle tip sho uld not move more than 3/4" when the

chain is properly tensioned. (See Page 29.)

The Chain Loop chain has connecting links spaced every 10'. Check these links to make sure that they

are securely fastened and that the cotter pins are bent back correctly. (See Figure 6M on Page 30.)

Check the lock nuts used to fasten the paddles to the chain brackets. They should be tightened to a torque

specification of 20 ft. lbs. (2.8 KG-M or 26 N-M).

Adjust the chain tension by loosening the locking jam nuts on the adjusting screw and turning the screw

to move the inspection corner sprocket. Turning the adjusting screw clockwise will tighten the chain and

turning it counterclockwise will loosen the chain. Remove chain links if there is not enough travel in the

adjusting screw to tighten the chain. Adjust each side equally to keep the sprocket shaft square with the

corner housing. (See Figure 6N on Page 31.)

Spray a light coating of oil on the chain after a season of use.

Corner Shaft Bearings

The bearings for the corner sprockets are sealed bearings and require only a small amount of

multi-purpose grease every 50 hours. Check bearings for wear and that the locking collars are secure.

Corner Sprockets

Inspect the condition of corner sprockets for teeth wear and that they are centrally aligned in each of the

corner housings.

18 PNEG-1128 Chain Loop System without Controls

Page 19

6. Installation

It is expected that an experienced millwright or contrac tor will provide the supporting structure and

do the installation of a Chain Loop System including the electrical wiring and the control box.

All electrical wiring and controls should be in accordance with local regulations (BS767: 1992 or the

National Electric Code).

NOTE: It is recommended that an amp meter for the drive motor be installed close to the inlet hopper so

an operator can easily monitor and avoid overloading the system.

The supporting structure needs to comply with local wind loads and soil supporting requirements as well

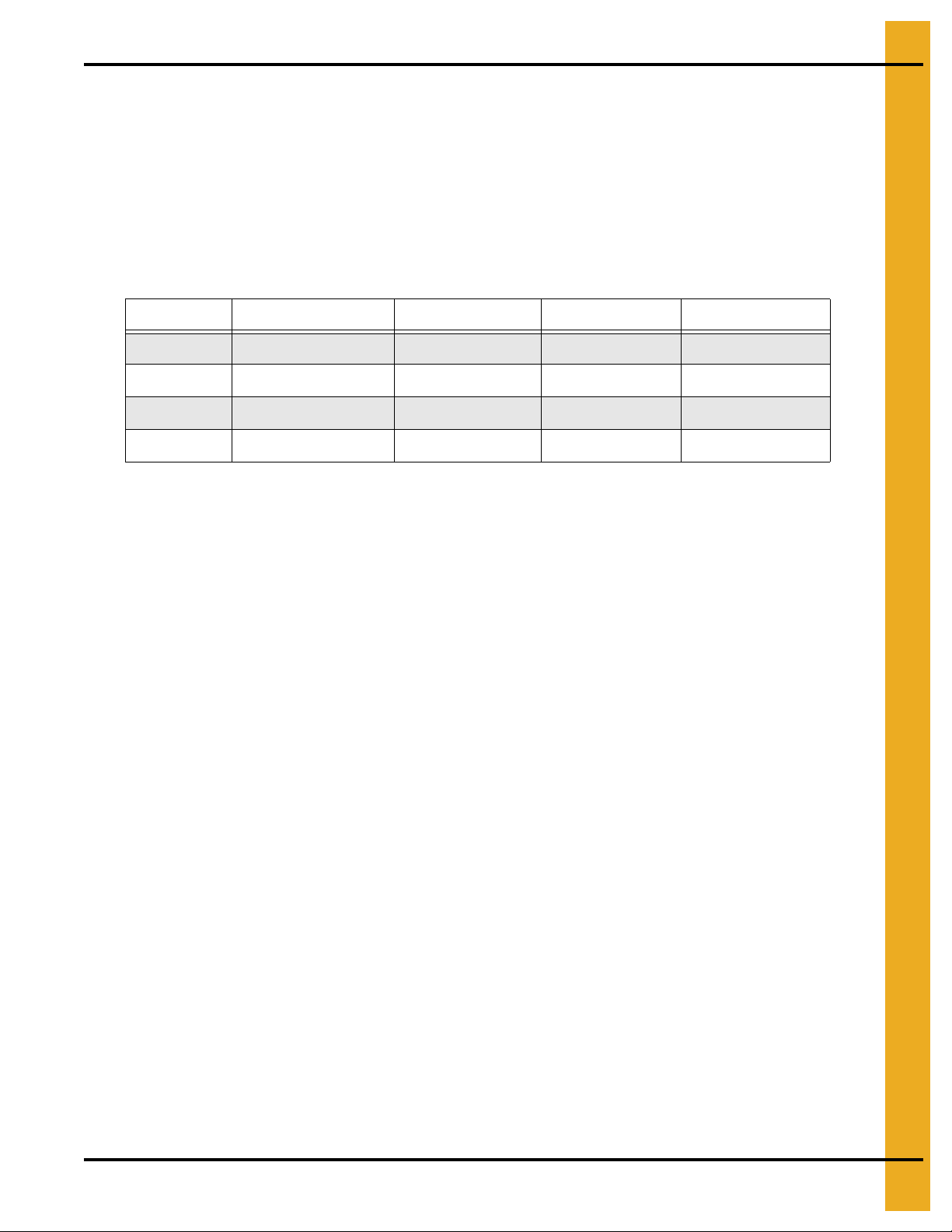

as support the weight of the Chain Loop System. Component weights full of grain are:

System Size Tube (Full) Discharge Gate Standard Corner Drive Corner

8" 29 lbs/ft (43.1 KG/M) 411 lbs. (187 KG) 342 lbs. (155 KG) 1 103 lbs. (502 KG)

10" 40 lbs/ft (59.5 KG/M) 533 lbs. (242 KG) 489 lbs. (222 KG) 1394 lbs. (634 KG)

12" 10 Gauge 59 lbs/ft (88 KG/M) 1024 lbs. (466 KG) 919 lbs. (418 KG) 2406 lbs. (1094 KG)

12" 7

Gauge 65 lbs/ft (97 KG/M) 1084 lbs. (493 KG) 933 lbs. (424 KG) 2420 lbs. (1101 KG)

NOTE: Each calculation includes the respective chain.

A layout should be drawn to show the exact location of grain bins, inlets, outlets, the control box, outlet

control kits, the power source and the supporting structure. The layout should consider future expansion,

the ability to mix grains from several locations, the grain direction, the operation of slide gates, the use of

other conveyors to fill or unload bins and whether the Chain Loop tube is under the center of or beside the

grain bins. Chain Loop Systems are provided with one (1) or two (2) drive corners depending on the power

requirements of each system. Drive corners are always located at the upper corners, and the drive corner

for single drive systems must be located at the far end of the top chain run. This will allow the drive corner

to pull grain up from the loading hopper and across the top to the storage bins. The inspection corner is

always located on the ground furthest from the loading hopper. This allows proper chain

tensioning throughout the system. (See Figure 4A on Page 16.)

It is important to slide components together tightly and to have the clamping band centered on the joint

before tightening the bands. All cuts should be made square and the inside diameter chamfered to ensure

that the ends butt together tightly during assembly. Even small gaps left in the tubing system during

assembly will gradually close during operation of the Chain Loop causing the chain to require frequent

inspection and tightening. (See Page 21.)

General guidelines to consider are:

1. The Chain Loop will move grain in one direction only; it is not reversible.

2. Provide room for service and maintenance at each of the corners and discharge gates.

3. Avoid having any part of the system under grade to eliminate water accumulation problems.

4. Provide adequate footings for solid supporting structures.

5. Minimize the loaded distance by placing the inlet hopper as close to the vertical tube as possible.

6. There can be no twist in the chain/paddles. The opening should be oriented so that the open side of

the paddle will pass across the sprockets.

PNEG-1128 Chain Loop System without Controls 19

Page 20

6. Installation

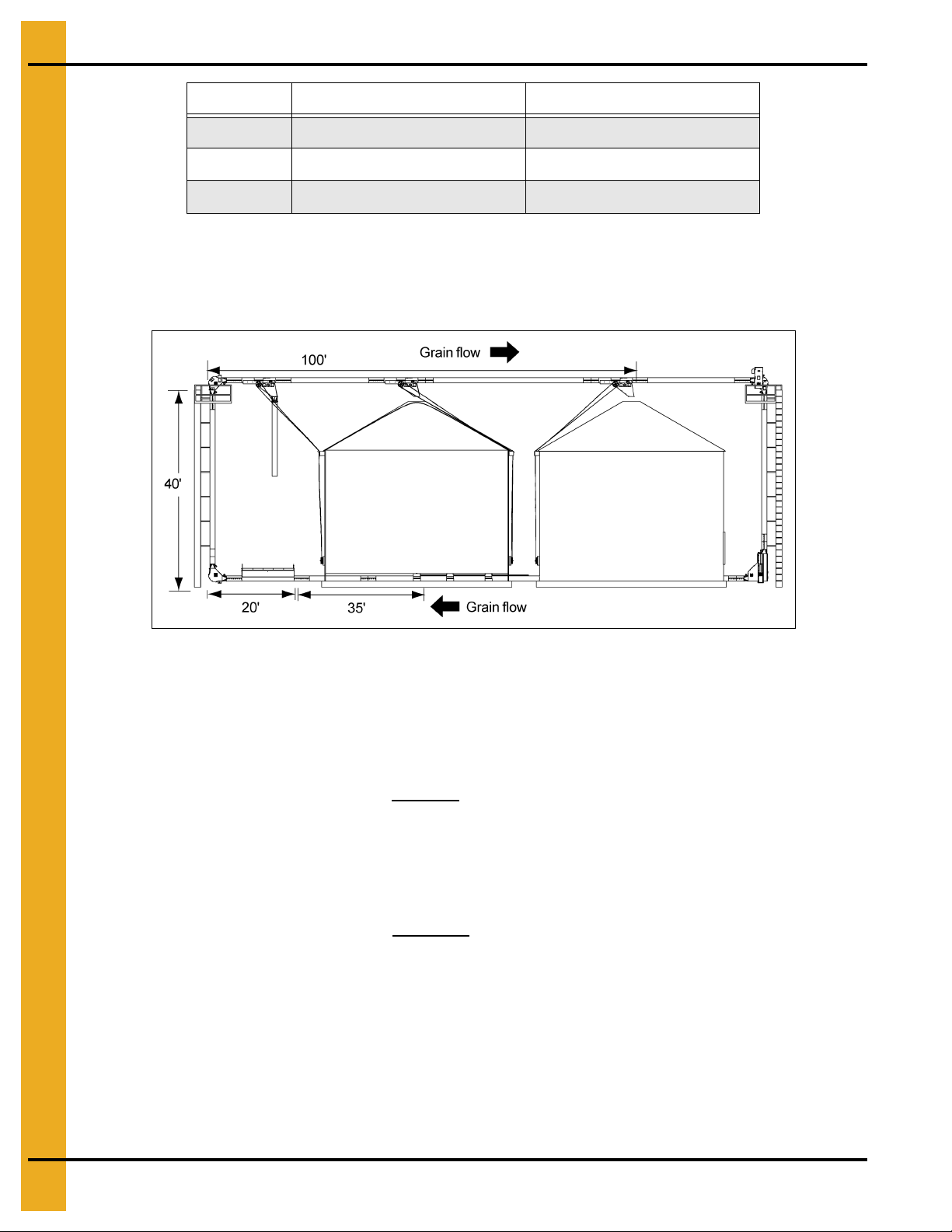

System Size Vertical Factor Horizontal Factor

8" 0.35 HP/loaded foot (0.86 Kw/M) 0.08 HP/loaded foot (0.19 Kw/M)

10" 0.50 HP/loaded foot (1.22 Kw/M) 0.11 HP/loaded foot (0.27 Kw/M)

12" 0.75 HP/loaded foot (1.84 Kw/M) 0.18 HP/loaded foot (0.44 Kw/M)

The system should be designed to minimize the distance grain must be moved. The example shows the

dump hopper located next to the vertical tube. If it were located on the other side of the grain bins

then the system would have to move grain that much farther before taking it up and over to the

discharge gates.

Figure 6A

This example illustrates a system and the power requirements for different functions of a Chain

Loop System.

If the main requirement is maximum filling rate, then the motor size for this 8" system would be:

0.35 HP/ft x 40 vertical ft. = 14 HP plus

0.08 HP/ft x (20 + 100 horizontal ft.) = 9.6 HP

= 23.6 (Use a 25 HP motor)

If the requirement is maximum flow rate while moving grain from bin to bin as well as a maximum filling

rate, then the motor size would be:

0.35 HP/ft x 40 vertical ft. = 14 HP plus

0.08 HP/ft x (35 + 20 + 100 horizontal ft.) = 12.4 HP

= 26.4 (Use a 30 HP motor)

20 PNEG-1128 Chain Loop System without Controls

Page 21

6. Installation

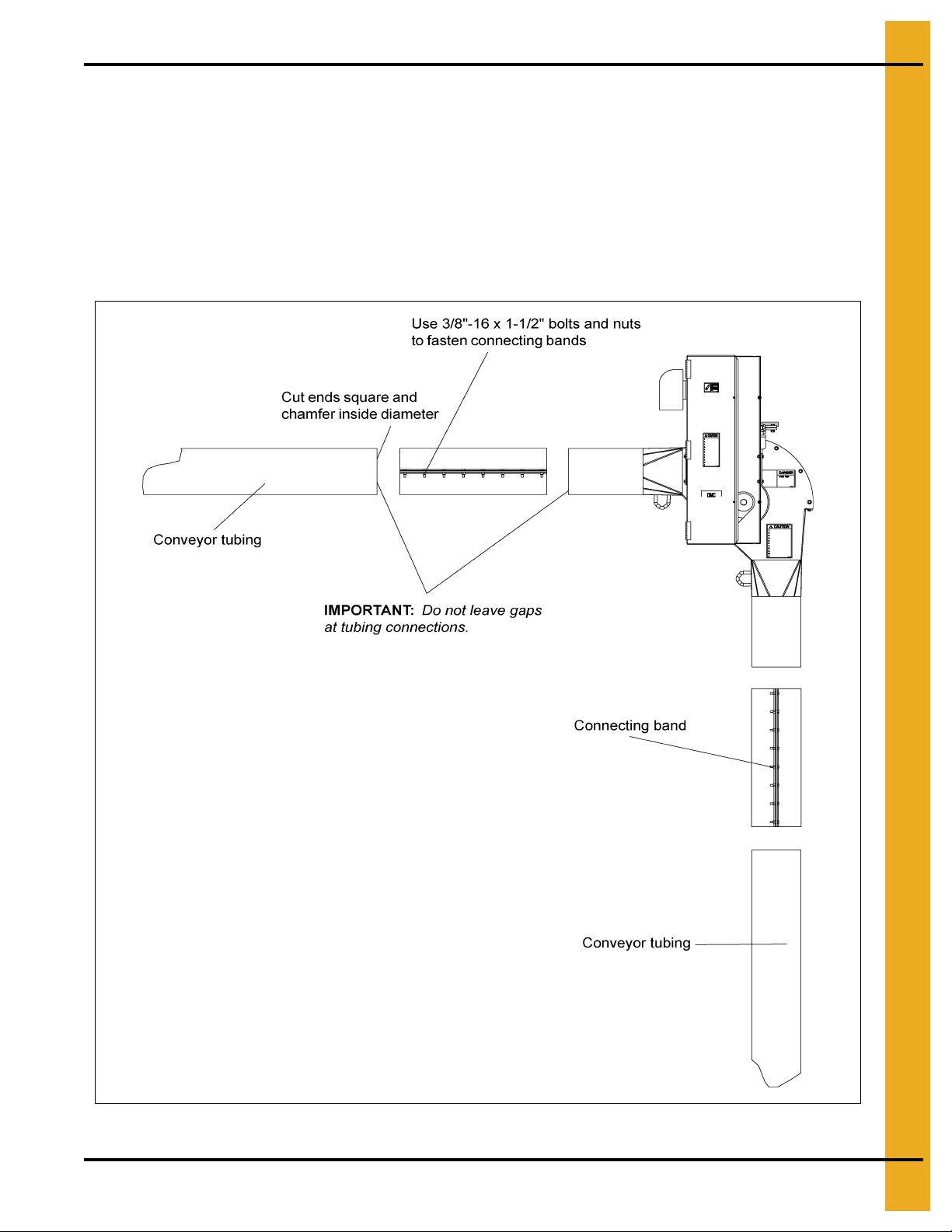

Tube and Corner Assembly

Lay the sections out in order so as to determine what portions to assemble prior to actual placement in

the system.

When cutting tubes to exact length, the ends must be cut square and any burrs on the ends must be

removed by chamfering the inside diameter. Join tube and corner components together with connecting

bands. Slide the tube sections tight together and space the connecting band in equal amounts on both

parts of the connection. Tighten the bolts in the band.

Fasten the discharge in place within the tube with connecting bands.

Figure 6B

PNEG-1128 Chain Loop System without Controls 21

Page 22

6. Installation

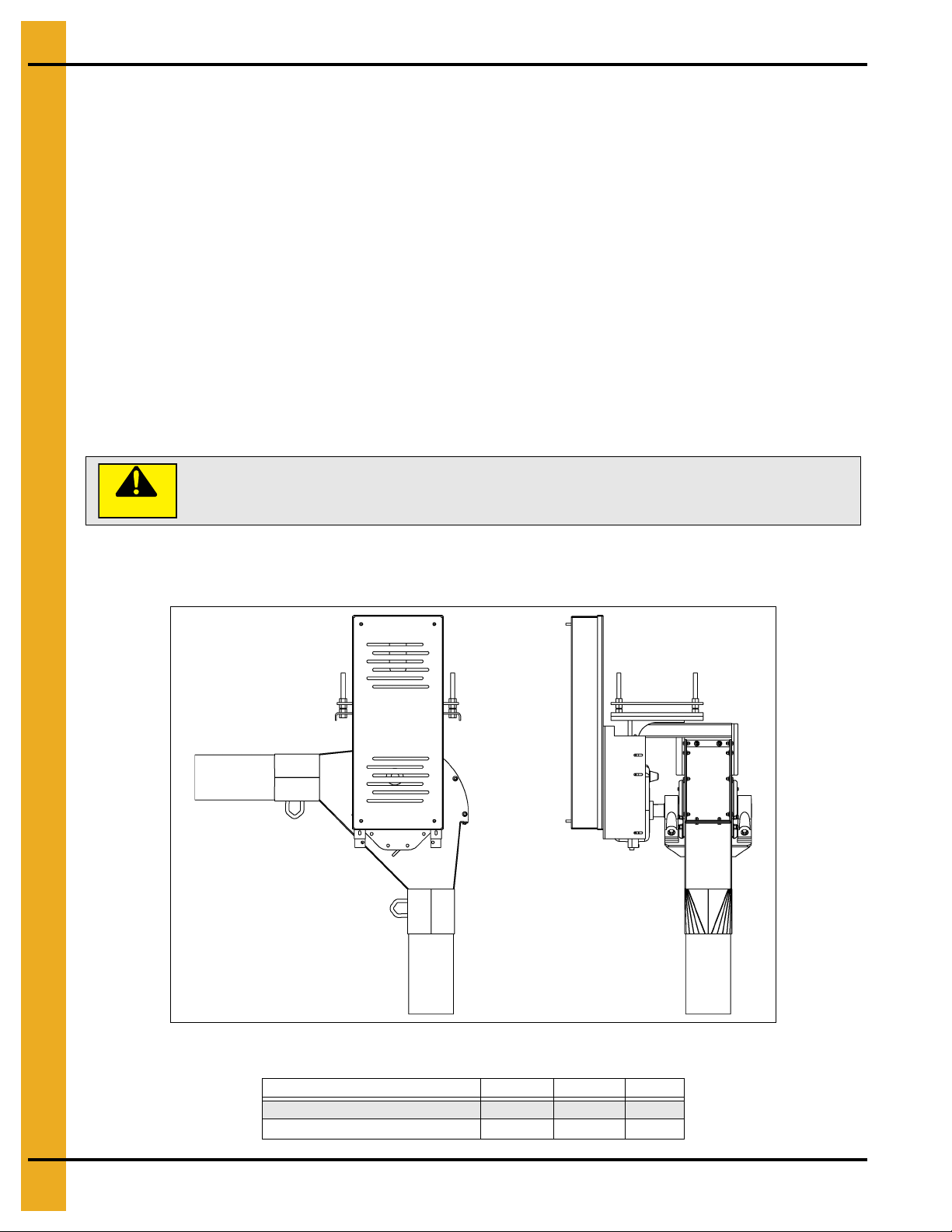

CAUTION

Keep all safety shields and devices in place.

Drive Assembly

The Chain Loop System is powered by an electric 1750 RPM motor.

IMPORTANT: Use the proper size motor to ensure satisfactory operation. Too small of a motor will not

supply the horsepower required to achieve capacity and damage to the motor may occur.

Too large of a motor may cause high stress on components resulting in shorter life.

See Page 13 for motor size specifications.

IMPORTANT: Use the motor sheave furnished. If other size sheaves are used or substituted, improper

chain speed and unsatisfactory operation will result.

Mount the sheaves as close to the belt guard back as possible. Align sheaves by using a straight edge,

placed across the outer faces of both sheaves. Secure in place using taper lock bushing. Be sure drive

keys are properly installed. Check sheave alignment again after sheaves are secured to shafts.

Install the belts onto the sheaves and set belt tension. To tighten belts, turn the 3/4" nuts on the motor

mount rods to raise the motor mount assembly. Raise all the rods the same distance so the motor mount

assembly is parallel with the top.

Check that all fasteners are tightly secured. Close and fasten belt guard.

The gear reducer is shipped without oil. It is necessary to add the proper amount of oil before running. Use

a high grade petroleum base, rust and oxidation inhibited R and O gear oil. Follow the instructions on the

reducer name plate, warning tags and in the installation manual attached to the reducer.

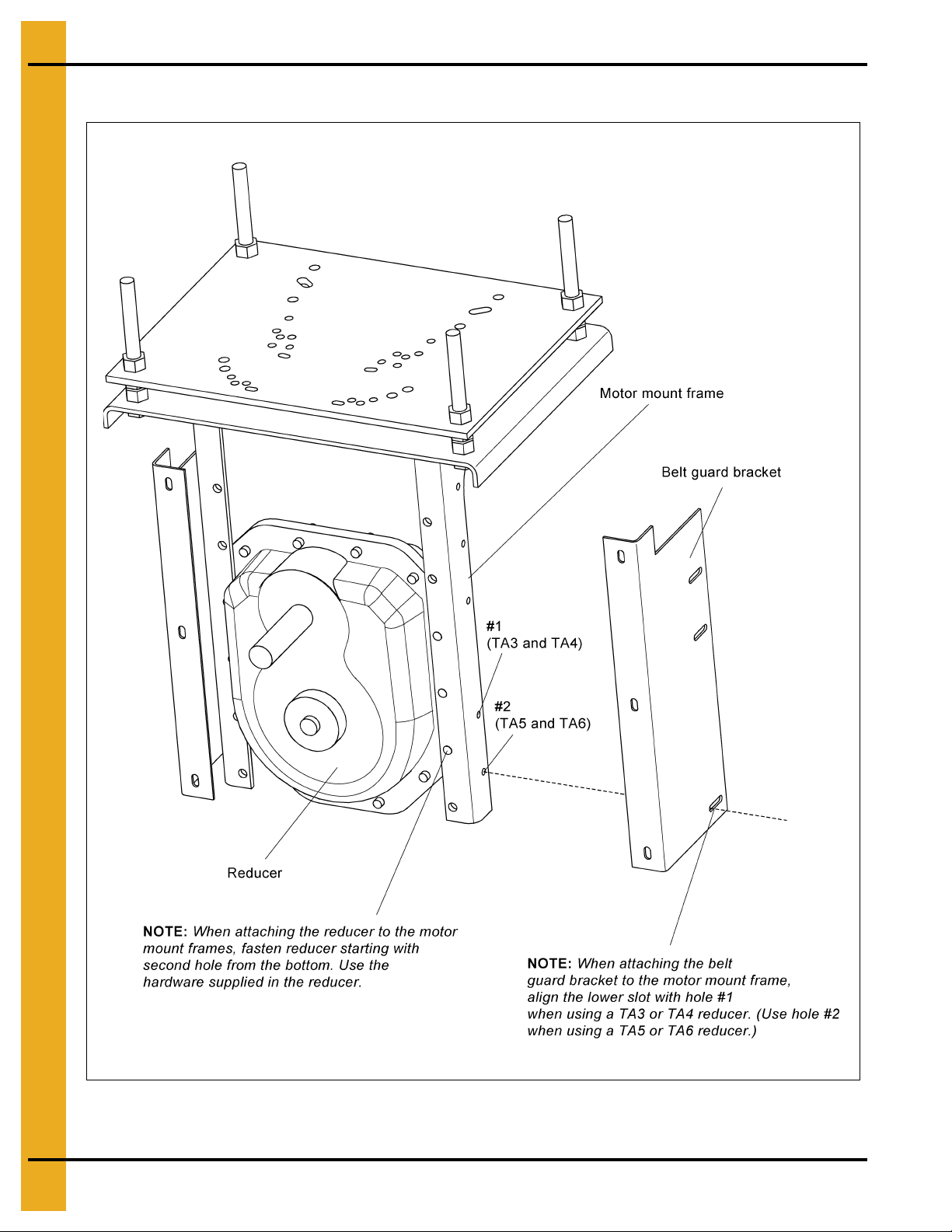

Figure 6C Sample Drive Assembly

Unit Size 8" 10" 12"

Recommended Chain Speed 325 325 400

Corner Shaft RPM 93 93 83

22 PNEG-1128 Chain Loop System without Controls

Page 23

6. Installation

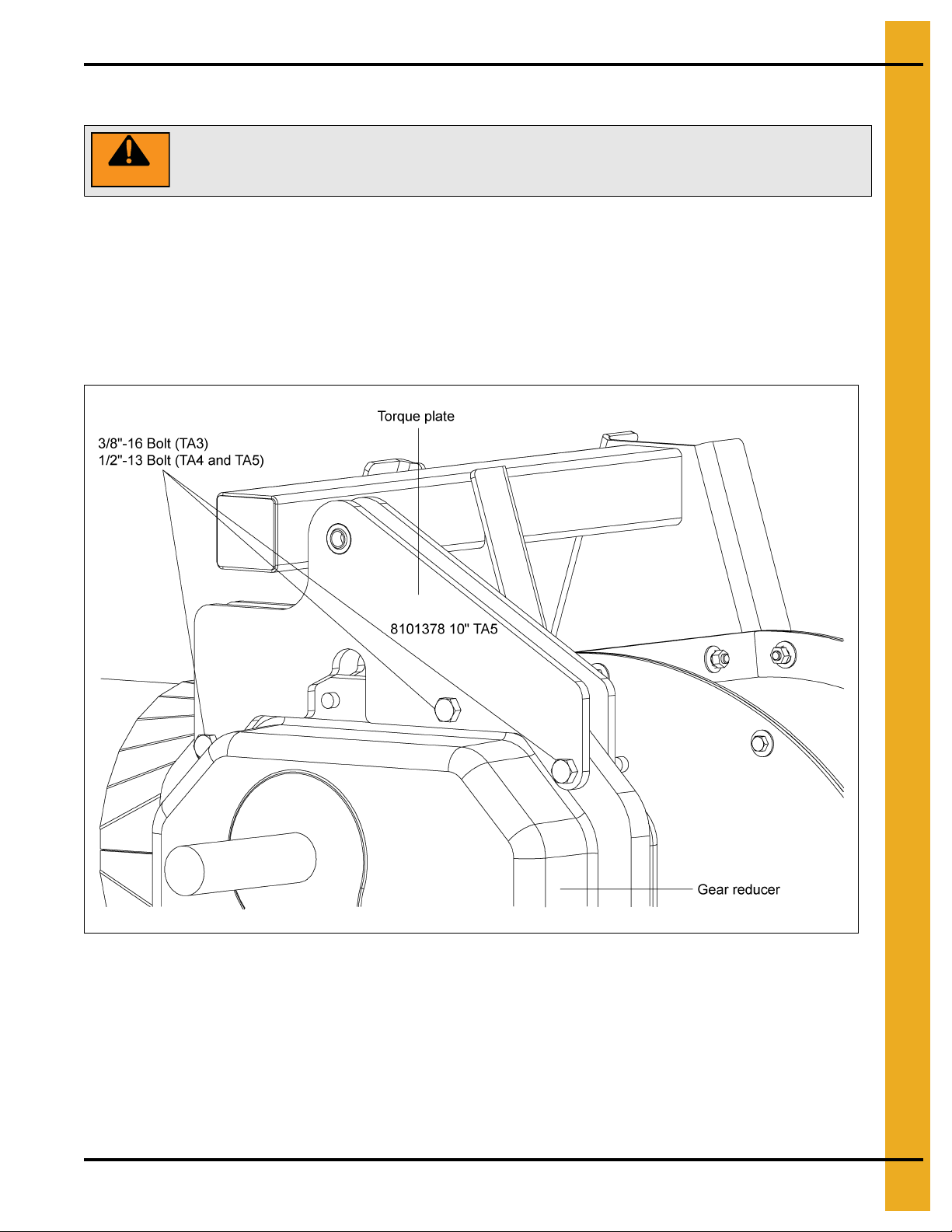

WARNING

Secure the motor mount from both sides to prevent the drive unit from pivoting

either direction on the shaft.

Chain Loop Torque Arm Repair Kit

NOTE: Motor mount and belt guard removed for clarity.

Attach both torque plate assemblies to each side of the gear reducer using the bolts pr ovided. Re-use the

lock washer and hex nut provided with the gear reducer. (See Figure 6D.)

NOTE: Leave the hardware loose to allow for ease of assembly.

TA3 - 3/8"-16 Bolt

TA4 and TA5 - 1/2"-13 Bolt

Figure 6D

PNEG-1128 Chain Loop System without Controls 23

Page 24

6. Installation

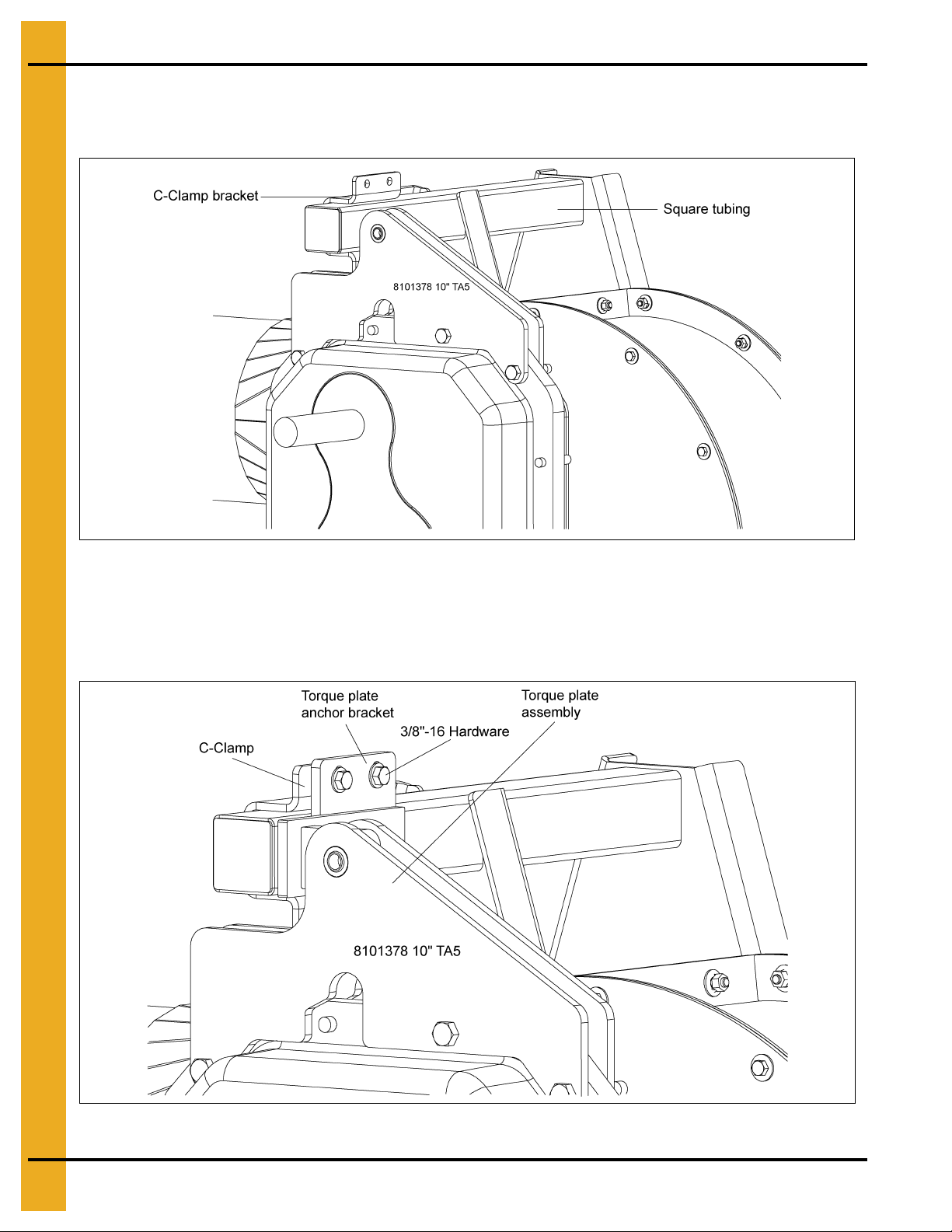

Chain Loop Torque Arm Repair Kit (Continued)

Place the C-clamp bracket to the back side of the square tubing. (See Figure 6E.)

Figure 6E

Place the torque plate anchor bracket between the torque plate assemblies and attach it to the C-clamp

using the 3/8"-16 hardware. (See Figure 6F.)

NOTE: Leave the hardware loose to allow for ease of assembly.

Figure 6F

24 PNEG-1128 Chain Loop System without Controls

Page 25

6. Installation

Chain Loop Torque Arm Repair Kit (Continued)

Attach the torque plate anchor bracket to the torque plates using the two (2) 1/2" flat washers, shoulder

bolt and 3/8"-16 nylock nut.

Tighten the hardware attaching the torque plate assemblies to the gear reducer after tightening the

shoulder bolt hardware. (See Figure 6G.)

Figure 6G

Move the torque plate anchor bracket on the square tube so the torque plate assemblies are aligned

vertical. Once aligned, the 3/8"-16 hardware attaching the torque plate anchor bracket to the C-clamp can

be tightened. (See Figure 6H.)

NOTE: Washers must be on the outside of each torque plate assembly.

Figure 6H

PNEG-1128 Chain Loop System without Controls 25

Page 26

6. Installation

Drive Box Assembly Instructions

Figure 6I

26 PNEG-1128 Chain Loop System without Controls

Page 27

6. Installation

Discharge with Gate Assembly

The discharge unit includes an 8' long section (12' long in 12" system). Locate the outlet of the discharge

in the desired location. It may be necessary to cut exact lengths of other tube conveyor sections to locate

the discharge unit in its proper place. The discharge with gate is designed for chain travel in only one

direction. Make sure it is oriented properly by comparing the appearance to the diagram or referring to the

decal on the discharge unit. Operation in the wrong direction can cause paddle damage.

Figure 6J

When cutting tubes to exact length, the ends must be cut square and any burrs on the ends must be

removed by chamfering the inside diameter. Join tube and discharge gate together with connecting bands.

Slide the tube sections tightly together and space the connecting band in equal amounts on both parts of

the connection.

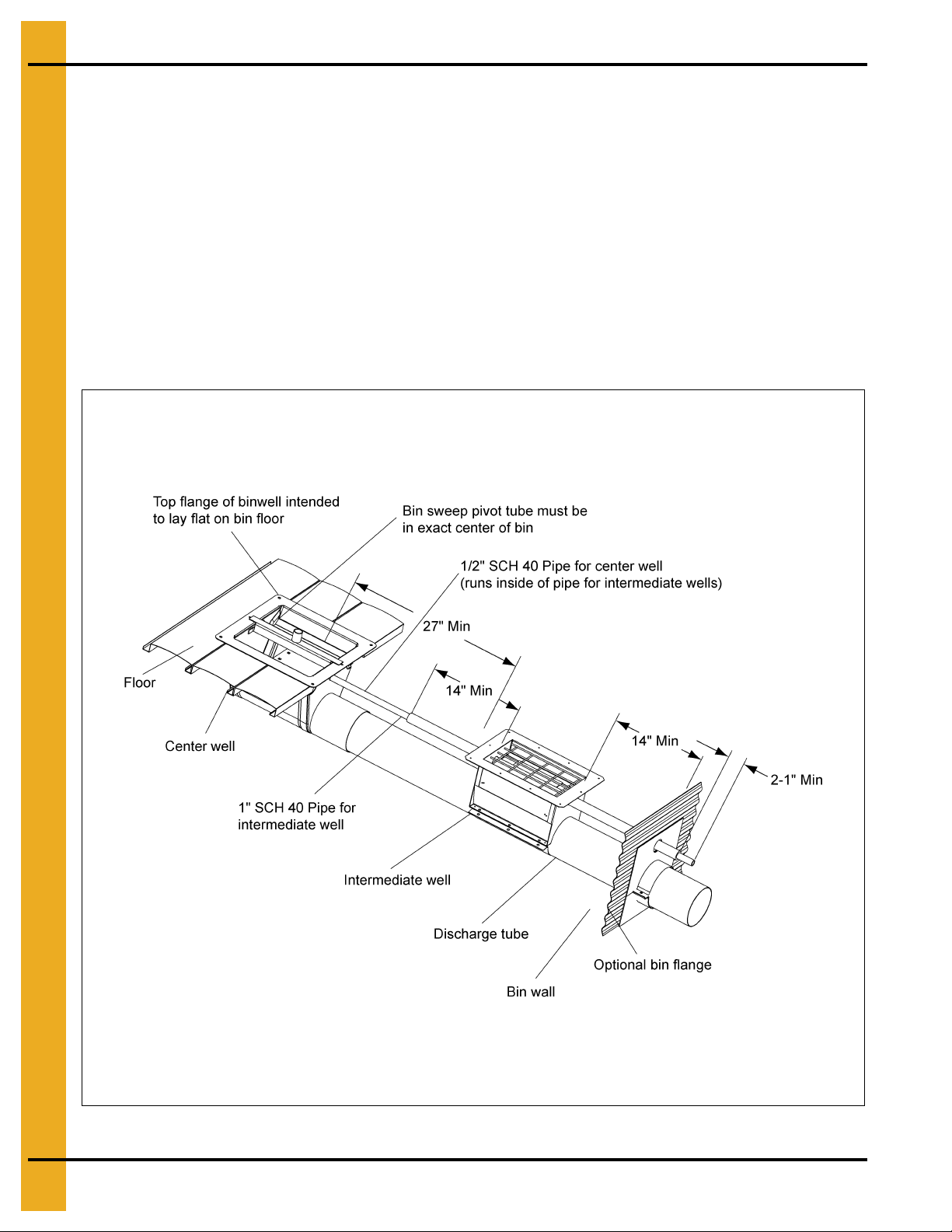

Bin well installation for Chain Loop Systems installed under a row of grain bins.

Position the center bin well so that the bin sweep pivot is at the center of the bin and on top of the Chain

Loop tube. Intermediate wells may be placed on the tube between the center and bin wall if desired.

Use Figure 6K on Page 28 for minimum spacing requirements and as a guide to mark and cut the openings

for the wells in the tube.

NOTE: Do not cut the opening with the chain and paddles inside the tube or they may be damaged.

The control pipe for the center well (1/2" pipe) should fit inside the pipe used for the intermediate wells (1"

pipe). With the center and intermediate wells closed, drill a hole through both control pipes so that a bolt

can be used to lock both pipes together. This will allow both slide gates to be operated together.

Open the slide gate in the center well and withdraw grain until no more flows. Close the center well

slide-gate and place the bolt in the hole drilled through both control rods. The intermediate well

slide-gates can now be operated with the center well.

PNEG-1128 Chain Loop System without Controls 27

Page 28

6. Installation

Unload Well Installation

General Information

Observe the minimum spacings shown in the illustration below. (See Figure 6K.) Wells should be

positioned on the tube so that the gates will open when control pipes are pulled out and away from the

center of the bin.

A control pipe kit may be ordered from your dealer. For the center well, use 1/2" SCH. 40 pipe

(-7/8" O.D.). For the intermediate well(s) use 1" SCH. 40 pipe (-1 3/8" O.D.). It may be necessary to

support the unload well(s) and/or discharge tube from below with blocks or other material.

Consult the manufacturer of the bin floor for information on cutting openings in the floor for unload wells,

for sealing around unload wells and for proper support of the floor around the unload wells and

discharge tube.

Figure 6K

28 PNEG-1128 Chain Loop System without Controls

Page 29

6. Installation

WARNING

Make sure all shields and safety guards are in place before restoring power.

WARNING

Turn OFF and lock out the main power source BEFORE removing any

inspection covers or shields.

Chain and Paddles

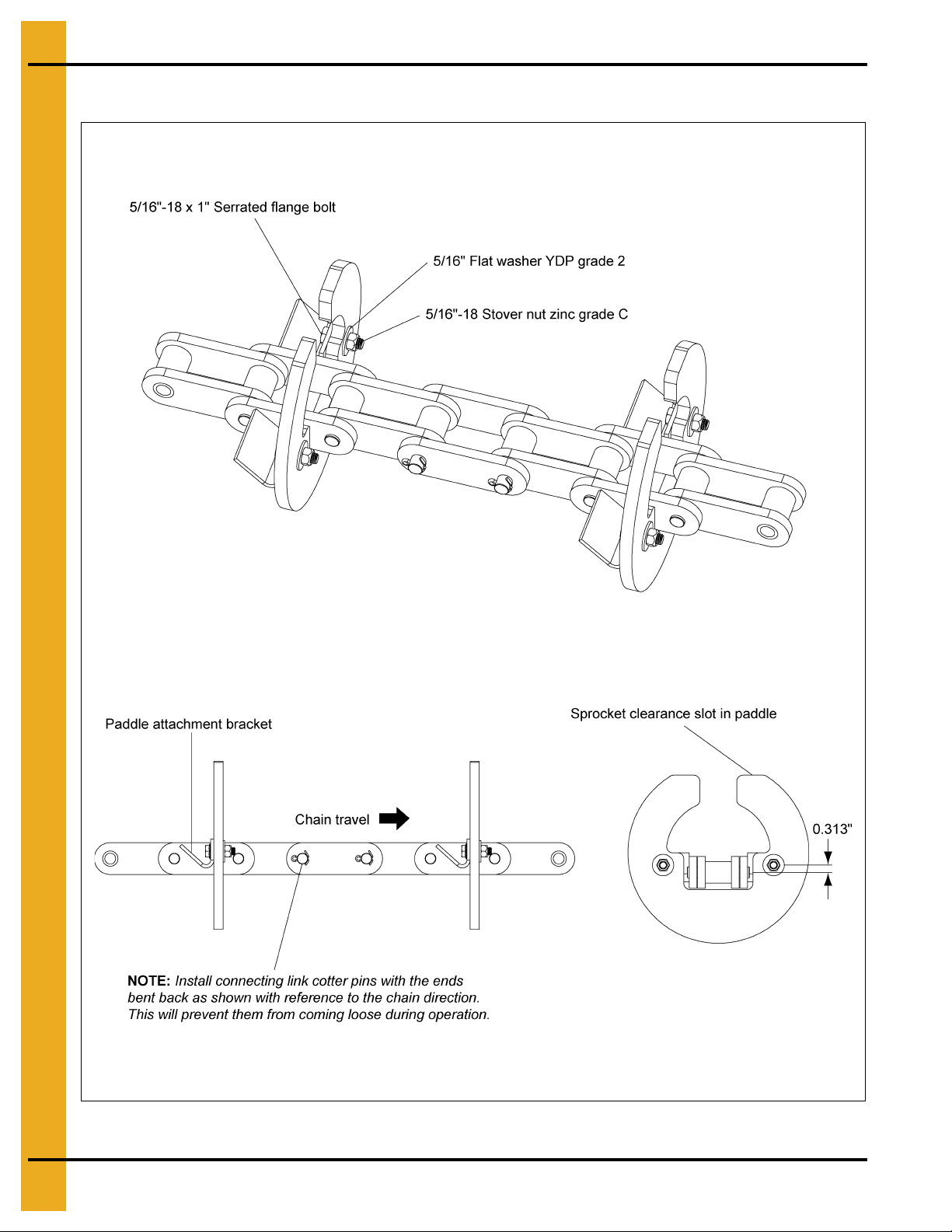

The paddles are attached to the chain with 5/16" x 1" serrated flange bolts, flat washers and locking nuts.

Make sure that the slots in the chain paddle brackets are oriented as shown in Figure 6M on Page 30.

The head of the bolt should be inside the “V” shaped chain paddle bracket and the washer and nut

should be against the face of the plastic paddle. Make sure all hardware is tightened properly to a

torque of 20 ft. lbs.

The chain is shipped in 10' lengths and needs to be spliced as shown in Figure 6M on Page 30. Make sure

to bend the ends of the cotter pins as shown to prevent them from working loose and causing the chain

to break.

Use an electrical fish tape or wire to pull the chain through the tube assembly. It is possible for the chain

to twist a full 360° during this process. Visually check the chain through open inspection covers at the

discharge gates and openings for wells to make sure that this has not happened.

Adjust the tightening screws in the inspection corner all the way up and connect the final chain link through

the access door in the inspection corner after removing as much chain slack as possible. Tighten the chain

by turning the adjusting screws clockwise; adjust each side equally to keep the sprocket shaft square with

the housing. Remove chain links if there is not enough travel in the adjusting screw to tighten the chain.

Make sure that the sprocket shaft is square to the housing by measuring the shaft position on both sides

of the housing. (See Figure 6N on Page 31.)

The chain should be tightened until the paddles are nearly rigid on the chain. The tips of the paddles

should only move 3/4" when grabbed and pulled by hand.

Check and re-tension the chain after the system has been trial run while empty.

Figure 6L

PNEG-1128 Chain Loop System without Controls 29

Page 30

6. Installation

Chain and Paddles (Continued)

Figure 6M Chain and Paddles

30 PNEG-1128 Chain Loop System without Controls

Page 31

Inspection Corner

6. Installation

Figure 6N

PNEG-1128 Chain Loop System without Controls 31

Page 32

6. Installation

Ground Control Kit for Discharge Gates

Determine the best location for each ground control kit. Note that each kit comes with 100' of cable, which

should be adequate for individual bin installations.

The cable idler pulley bracket is usually mounted at the top of the bin wall, just under the roof eave, in line

with the control wheel on the discharge gate. The ground control wheel-mounting bracket should be

mounted to the bin wall directly under the idler pulley bracket at a convenient operating height. It is

important to keep the cable in line with the control wheels on both the discharge gate and at the ground

to avoid having the cable “walk off” either wheel.

The ground control wheel can be mounted to the same bin as the discharge gate, or to an adjacent bin

(See Figure 6O and Figure 6P.)

Figure 6O

Figure 6P

32 PNEG-1128 Chain Loop System without Controls

Page 33

6. Installation

Ground Control Kit for Discharge Gates (Continued)

Each control system should be marked to identify which discharge gate is being controlled.

Each control system should be marked after installation to clearly identify whether the discharge gate is

open or closed.

Set screws in the ground control wheel can be used to lock the wheel in position to prevent accidental

opening or closing of the discharge gate.

Assemble the idler pulleys to the mounting bracket on the inside surface if the cable is going to a discharge

gate on the same bin. Assemble them on the outside if the cable is going to an adjacent bin. Attach the

idler pulley bracket to the bin wall just under the eave to ensure that the cable will clear the bin roof.

Attach the ground control wheel bracket to the bin wall directly below the idler bracket. Assemble the

wheel-mounting bracket loosely to the wall bracket and slide it up as far as possible. Assemble the control

wheel to the shaft and secure with cotter pins. (See Page 35.)

Figure 6Q

PNEG-1128 Chain Loop System without Controls 33

Page 34

6. Installation

Ground Control Kit for Discharge Gates (Continued)

Make sure that the discharge gate is half open and wrap the cable 3-1/2 times around the discharge

gate control wheel. Note that turning the wheel clockwise will close the gate.

Secure the cable to the wheel with the cable clamp by attaching it to the approximate middle of the

3-1/2 wraps of cable. This will ensure that the gate will fully open and close without restriction from the

cable clamped to the wheel.

Make sure that the discharge gate is still half open.

Route the cable back through the right idler pulley and down to the ground control wheel.

At the ground control wheel, turn the wheel until the cable clamp is up and wrap the cable 3-1/2 times

around it.

Secure the cable clamp to the middle wrap.

Splice the ends of the cable with a cable clamp. With the discharge gate half open, the splice should be

at least 5' away from the pulleys and control wheels.

Slide the ground wheel bracket down to take up any slack in the cable and tighten in place.

Check the installation by turning the ground wheel clockwise to fully close the discharge gate and

counterclockwise to fully open the gate without any restrictions from the cable splice or the clamps on the

control wheels.

If the rotation is wrong, then reverse the direction of the 3-1/2 wraps on the ground control wheel.

34 PNEG-1128 Chain Loop System without Controls

Page 35

Ground Control Kit for Discharge Gates (Continued)

6. Installation

Figure 6R Ground Control Kit Parts

Ground Control Kit Parts List

Ref # Part # Description Qty

1 Bolt-Car, Standard Third-Grade 2 3/8"-16 UNC x 0.75, Plated 2

2 8101157 Bracket-Bin Wall Mount Ground Control Kit 1

3 8101158 Bracket-Control Wheel, Weldment Zinc Plated 8101159 1

4 8101156 Bracket-Pulley Mount, Ground Control Kit 1

5 8101153 Control Wheel - w/ Clamp 90° Discharge w/ Gate 1

6 Lock Nut, Flange, 1/4"-20 UNC (Whiz Lock) Plated 8

7 Lock Nut, Flange, 3/8"-16 UNC (Whiz Lock) Plated 2

8 Cotter Pin, Standard 3/16" x 1-3/4" Long 2

9 Pulley-Hot House, (Nolin Milling No #) 2

10 Screw-MF Flange Whiz Lock 1/4"-20 UNC x 3/4", Plated 8

11 Screw - s/ Drill, WH Hex Head 1/4"-14 x 1", (Tek 3) Plated 12

12 Flat Washer, Standard 3/8", Plated 2

13 Flat Washer, Standard 1", Plated 2

PNEG-1128 Chain Loop System without Controls 35

Page 36

6. Installation

See Page 37 for

further detail

Inlet Dump Hopper Assembly

The dump hopper will include a length of tubular conveyor from 6' to 11' depending on the length of d ump

hopper selected. It will also include a top safety screen or drive over grating. Th ere is a grain flow control

inside the hopper that is adjustable using chains mounted at each end. A dump hopper is to receive grain

into the Chain Loop System and should be located at a point along the bottom conveyor portion. Usually

dump hoppers are located near the standard corner where the chain and paddles turn to carry grain up.

For drive over systems, the grate must be supported by a concrete structure. (See Figure 6S.)

Figure 6S

A hopper with top safety screen may be used in non-drive over situations. The top safety screen will not

support vehicles. Make sure either the top safety screen or drive-over grating is in place on the hopper.

Fasten the inlet dump hopper assembly in place within the tubular conveyor with connecting bands.

Figure 6T

NOTE: When the system is not in use, it is a good practice to cover the hopper with a rubber mat to help

keep water, animals and debris out.

36 PNEG-1128 Chain Loop System without Controls

Page 37

6. Installation

Figure 6U

PNEG-1128 Chain Loop System without Controls 37

Page 38

7. Troubleshooting

1. Chain is slipping on the drive sprocket

a. Check the chain tension and tighten at the inspection corner if necessary.

b. Check for obstructions in the system. The paddles may be catching at joints in the tubing.

c. Check to make sure that the sprockets are centered in the corner housings.

d. Avoid starting the system under load. Let the system run until empty before shutting down. If shut

down does occur while the system is loaded, remove as much grain as possible and turn the

corner sprockets by hand with a pipe wrench to loosen the chain before turning the power

back ON.

2. Grain recycling back to the fill point

a. Check to make sure that the discharge gate is open.

b. Check and clean out the slide gate in the discharge gate.

c. Chain speed may be too fast. The drive corner shaft speed should be 94 RPM.

3. Drive belts are slipping

a. Check the drive motor amperage and make sure that the motor is not overloaded.

b. Tighten belts if slippage occurs when the drive motor is not fully loaded.

4. System is not delivering full capacity

a. Make sure that grain is not over running the discharge gate and returning to the fill-point.

b. Chain speed may be too slow. The drive corner shaft speed should be 94 RPM.

c. High moisture grain will move at a lower capacity than dry grain.

d. Check for obstructions in the inlet hopper.

e. Check to make sure that the chain has not been installed with a twist. (See Page 29.)

5. Paddles breaking

a. Check to make sure that the sprockets are centered in the corner housings.

b. Avoid starting the system under load. Let the system run until empty before shutting down.

If shut down does occur while the system is loaded, remove as much grain as possible and

turn the corner sprockets by hand with a pipe wrench to loosen the chain before turning the power

back ON.

c. Check to make sure that the paddles are fastened securely to the chain brackets.

d. Let the system “break-in” and the tubing become polished before loading to full capacity.

e. If you hear paddles “clicking” at a joint, check for gaps in the tubing. This will require loosening the

bolts in the connecting band to be able to see the tube joint.

6. Chain failure

a. Check to make sure that the master connecting links have been installed correctly.

(See Figure 6M on Page 30.)

b. Check for obstructions in the system.

c. Avoid starting the system under load. Let the system run until empty before shutting down.

38 PNEG-1128 Chain Loop System without Controls

Page 39

8", 10" and 12" Component Dimensions

Figure 8A

Drive Corners

Horse Power 8" System 10" System 12" 10 Gauge 12" 7 Gauge

15 8081365

20 8081363 8101526

25-30 8081360 8101517 8120181 8120009

40 8101513 8120182 8120143

50 8101514 8120183 8120171

60 8120184 8120162

8. Component Dimensions

Dimension

“A” 42-1/16" (1069) 42-1/2" (1080) 55-11/16" (1415) 55-11/16" (1415)

“B” 29-7/16" (748) 34" (864) 33" (838) 33" (838)

“C” 48-3/4" (1239) 50-1/4" (1277) 63-5/16" (1609) 63-5/16" (1609)

“D” 70-7/8" (1801) 81-7/8" (2081) 101-15/16" (2574) 101-15/16" (2574)

“E” 33-1/8" (842) 37-9/16" (955) 45-1/2" (1156) 45-1/2" (1156)

8" System

inches (mm)

10" System

inches (mm)

12" 10 Gauge System

inches (mm)

12" 7 Gauge System

inches (mm)

Figure 8B

Standard Corners

Dimension

“A” 50-7/32" (1275) 51-21/32" (1312) 65-25/32" (1670) 65-25/32" (1670)

“B” 48-3/4" (1238) 50-1/16" (1271) 63-9/32" (1607) 63-9/32" (1607)

“C” 42-1/16" (1068) 42-1/2" (1080) 55-11/16" (1415) 55-11/16" (1415)

Assembly P.N. 8081021 P.N. 8101021 P.N. 8120176 P.N. 8120031

8" System

inches (mm)

10" System

inches (mm)

12" 10 Gauge System

inches (mm))

12" 7 Gauge System

inches (mm)

PNEG-1128 Chain Loop System without Controls 39

Page 40

8. Component Dimensions

8", 10" and 12" Component Dimensions (Continued)

Figure 8C

Discharge Gates

Dimension

“A” 30-1/16" (764) 32-1/16" (814) 54-11/16" (1388) 54-11/16" (1388)

“B” 96" (2438) 96" (2438) 144" (3657) 144" (3657)

“C” 79" (2007) 79" (2007) 123-63/64" (3148) 123-63/64" (3148)

Assembly 8081206 8101206 8120090 8120194

8" System

inches (mm)

10" System

inches (mm)

12" 10

inches (mm)

Gauge System

12" 7 Gauge System

inches (mm)

Figure 8D

Inspection Corners

Dimension

“A” 53-5/8" (1362) 54-5/8" (1387) 67-19/32" (1717) 67-19/32" (1717)

“B” 70-7/16" (1789) 71-1/2" (1816) 86-3/32" (2187) 86-3/32" (2187)

“C” 78-19/32" (1996) 80-21/32" (2049) 96-3/16" (2443) 96-3/16" (2443)

“D” 58-15/16" (1497) 61-1/8" (1553) 75-7/32" (1911) 75-7/32" (1911)

“E” 8-3/8" (213) 10-3/8" (264) 12-3/16" (309) 12-3/16" (309)

“F” 13-7/8" (1492) 15-7/8" (403) 25-5/16" (643) 25-5/16" (643)

Assembly 8081048 8101048 8120177 8120051

8" System

inches (mm)

40 PNEG-1128 Chain Loop System without Controls

10" System

inches (mm)

12" 10 Gauge System

inches (mm)

12" 7 Gauge System

inches (mm)

Page 41

8. Component Dimensions

8", 10" and 12" Bin Well and Dump Hopper Dimensions

Figure 8E

Inlet Hopper Part Numbers and Dimensions

Assembly Description

(Hopper Width)

42-1/2" w/ Drive-over Grates 8089025 8109035 8129021 8129024 72" (1829)

42-1/2" Hopper Assembly Only 8081106 8101106 8120185 8120121 72" (1829)

62-1/2" w/ Drive-over Grates 8089027 8109027 92" (2337)

62-1/2" Hopper Assembly Only 8081107 8101107 92" (2337)

102-1/2" w/ Drive-over Grates 8089029 8109039 8129022 8129025 132" (3353)

102-1/2" Hopper Assembly Only 8081108 8101108 8120186 8120127 132" (3353)

122-1/2" w/ Drive-over Grates 8129023 8129026 152" (3861)

122-1/2" Hopper Assembly Only 8120187 8120134 152" (3861)

125" w/ Drive-over Grates 8089031 8101166L 155" (3937)

125" Hopper Assembly Only 8081166 8101166 155" (3937)

144-1/2" w/ Drive-over Grates 8089033 8109043 168" (4267)

144-1/2" Hopper Assembly Only 8081109 8101109 168" (4267)

Dimension

“A” (Top of Drive-over Grate) 22-1/2" (572) 24-3/8" (619) 24-13/32" (620) 24-13/32" (620)

“B” (Top of Hopper Flange) 18-3/4" (476) 20-3/4" (527) 21-3/8" (543) 21-3/8" (543)

8" System 10" System

8" System

inches (mm)

10" System

inches (mm)

Part #

12" 10 Gauge

System

12" 10 Gauge

System inches (mm)

12" 7 Gauge

System

12" 7 Gauge System

inches (mm)

Dimension

“C”

inches (mm)

Figure 8F

Rack and Pinion Controls

Dimension

Length 15-1/2" (394) 15-1/2" (619) 15-1/2" (619)

Top Width 7-1/4" (476) 7-1/4" (476) 7-1/4" (476)

Height*

*(ctr. of tube to top)

Assembly GK1768 GK1772 GK1787

8" System

inches (mm)

9-1/2" (241) 10-1/2" (267) 11-1/2" (292)

PNEG-1128 Chain Loop System without Controls 41

10" System

inches (mm)

12" System

inches (mm)

Page 42

8. Component Dimensions

8", 10" and 12" Bin Well and Dump Hopper Dimensions (Continued)

Figure 8G

Center Wells

8" System 10" System

Dimension

“A” 17-1/8" (435) 17-1/8" (435) 17-1/8" (435) 17-9/32" (439)

“B” 13" (330) 13" (330) 13" (330) 13" (330)

“C” 16" (406) 16" (406) 18" (457) 18" (457)

“D” 12" (305) 12" (305) 13-3/4" (349) 13-3/4" (349)

“E” 7-3/4" (197) 7-3/4" (197) 9-1/2" (241) 9-1/2" (241)

“F” 3-1/8" (79) 3-1/8" (79) 3-3/8" (86) 3-3/8" (86)

“G” 11-3/4" (298) 11-3/4" (298) 14-1/2" (368) 14-1/2" (368)

Assembly GK2785 8081192 GK1943 8101192

w/o Rollers

inches (mm)

with Roller

inches (mm)

w/o Rollers

inches (mm)

with Roller

inches (mm)

Figure 8H

Large Center Wells

Dimension

“A” 13" (330) 13" (330) 13" (330)

“B” 21-27/32" (555) 23-3/4" (603) 23-3/4" (603)

“C” 25-31/32" (659) 28" (711) 28" (711)

“D” 17-5/32" (436) 17-9/32" (439) 17-9/32" (439)

“E” 3-9/32" (83) 4-1/16" (103) 4-1/16" (103)

“F” 7-23/32" (196) 9-13/32" (239) 10-3/8" (263)

“G” 11-25/32" (299) 14-1/2" (368) 16-1/2" (419)

Assembly 8081238 8101254 8120101

8" System inches with Roller

inches (mm)

42 PNEG-1128 Chain Loop System without Controls

10" System inches with Roller

inches (mm)

12" System inches with Roller

inches (mm)

Page 43

8. Component Dimensions

8", 10" and 12" Bin Well and Dump Hopper Dimensions (Continued)

Figure 8I

Intermediate Wells

8" System 10" System

Dimension

“A” 11-5/8" (295) 13-1/8" (333) 17-1/8" (435) 17-1/8" (435) 17-1/8" (435) 22-1/4" (565)

“B” 7-1/2" (191) 7-5/16" (186) 13" (330) 13" (330) 13" (330) 14-1/4" (362)

“C” 16-1/2" (419) 19-1/4" (489) 18" (457) 18" (457) 22" (559) 34-1/2" (876)

“D” 13-1/2" (343) 13-1/2" (343) 13-7/8" (352) 13-7/8" (352) 17-7/8" (454) 13-1/8" (333)

“E” 7" (178) 7-5/8" (194) 9-1/2" (241) 9-1/2" (241) 9-1/2" (241) 10" (254)

“F” 2-3/4" (70) 1-15/16" (49) 2-1/8" (54) 2-1/8" (54) 2-1/8" (54)

“G” 11" (279) 11-5/8" (295) 14-1/2" (368) 14-1/2" (368) 14-1/2" (368) 16" (406)

Assembly GK2779 GK5182 GK1942 8101193 8101194 *GK2927

w/o Rollers

inches (mm)

with Rollers

inches (mm)

w/o Rollers

inches (mm)

with Rollers

inches (mm)

* 12" Commercial intermediate well drawing below. (See Figure 8J.)

w/o Slide Gate

inches (mm)

*12" System

with Rollers

inches (mm)

Figure 8J

12" Well (Intermediate)

Product # Description Weight

GCBW1250 12" Intermediate 54 lbs.

PNEG-1128 Chain Loop System without Controls 43

Page 44

9. Parts List

1. 8" and 10" Chain and Paddles - (See Page 46.)

2. 12" Chain and Paddles (8120141) - (See Page 47.)

3. 8" and 10" Discharge Gate - (See Page 48.)

4. 12" - (7 Gauge) Discharge Gate (8120194) - (See Page 49.)

5. 12" - (10 Gauge) Discharge Gate (8120090) - (See Page 50-51.)

6. Chain Loop Drive Components - (See Page 52-54.)

7. 8" (15 HP) Drive Components (8081365) - (See Page 55.)

8. 8" (20 HP) Drive Components (8081363) - (See Page 56.)

9. 8" (15 HP-20 HP) Drive Components (8081362) - (See Page 57.)

10. 10" (20 HP) Drive Components (8101526) - (See Page 58.)

11. 10" (15 HP-20 HP) Drive Components (8101525) - (See Page 59.)

12. 8" (25 HP-30 HP) Drive Components (8081360) - (See Page 60.)

13. 8" (25 HP-30 HP) Drive Components (8081359) - (See Page 61.)

14. 10" (25 HP-30 HP) Drive Components (8101517) - (See Page 62.)

15. 10" (25 HP-30 HP) Drive Components (8101516) - (See Page 63.)

16. 10" (40 HP) Drive Components (8101513) - (See Page 64.)

17. 10" (50 HP) Drive Components (8101514) - (See Page 65.)

18. 10" (40 HP-50 HP) Drive Components (8101511) - (See Page 66.)

19. 8" (15 HP) Drive Components (8081271) - (See Page 67.)

20. 8" (20 HP) Drive Components (8081285) - (See Page 68.)

21. 8"-10" (25 HP-30 HP) Drive Components (8081296) - (See Page 69.)

22. 10" (40 HP) Drive Components (8101303) - (See Page 70.)

23. 10" (50 HP) Drive Components (8101331) - (See Page 71.)

44 PNEG-1128 Chain Loop System without Controls

Page 45

9. Parts List

24. Belt Guard Assembly TA3 (8120217) - (See Page 72.)

25. Belt Guard Assembly TA4 (8120211) - (See Page 74.)

26. Belt Guard Assembly TA5 (8120214) - (See Page 75.)

27. 12" 7 Gauge (30 HP) Drive Components (8120000) - (See Page 76-77.)

28. 12" 7 Gauge (40 HP-50 HP) Drive Components (8120144) - (See Page 78-79.)

29. 12" 7 Gauge (60 HP) Drive Components (8120163) - (See Page 80-81.)

30. 12" 10 Gauge (30 HP) Drive Components (8120175) - (See Page 82-83.)

31. 12" 10 Gauge (40 HP-50 HP) Drive Components (8120179) - (See Page 84-85.)

32. 12" 10 Gauge (60 HP) Drive Components (8120180) - (See Page 86-87.)

33. 8" and 10" Inlet Dump Hoppers - (See Page 88.)

34. 12" (7 Gauge) 42-1/2" Inlet Dump Hoppers (8120121) - (See Page 89.)

35. 12" (7 Gauge) 102-1/2" Inlet Dump Hoppers (8120127) - (See Page 90.)

36. 12" (7 Gauge) 122-1/2" Inlet Dump Hoppers (8120134) - (See Page 91.)

37. 12" (10 Gauge) 42-1/2" Inlet Dump Hoppers (8120185) - (See Page 92.)

38. 12" (10 Gauge) 102-1/2" Inlet Dump Hoppers (8120186) - (See Page 94.)

39. 12" (10 Gauge) 122-1/2" Inlet Dump Hoppers (8120187) - (See Page 95.)

40. 8" and 10" Standard Corner - (See Page 96-97.)

41. 12" (7 Gauge) Standard Corner (8120031) - (See Page 98-99.)

42. 12" (10 Gauge) Standard Corner (8120176) - (See Page 100-101.)

43. 8" and 10" Inspection Corner - (See Page 102-103.)

44. 12" (7 Gauge) Inspection Corner (8120051) -

45. 12" (10 Gauge) Inspection Corner (8120177) - (See Page 106-107.)

46. Chain Loop Torque Plate Assembly - (See Page 108.)

PNEG-1128 Chain Loop System without Controls 45

(See Page 104-105.)

Page 46

9. Parts List

8" and 10" Chain and Paddles

8" and 10" Chain and Paddles Parts List

Ref # Part # Description

1 8101145 Paddle 10", UHMW 10" Chain Loop System

1 8081145 Paddle 8", UHMW 8" Chain Loop System

2 S-8324 5/16"-18 Stover Nut Zinc Grade C

3 S-845 Flat Washer 5/16" USS SAE YDP Grade 2

4 S-7470 5/16"-18 x 1" Serrated Flange Bolt Zinc Grade 5

5 S-9159 1/8" x 3/4" Cotter Pin Zinc

6 CE-00764 Link Connecting, #81 x with Side Plate and Cotter Pin

6 CE-00766 Link Connecting, #81 x HH with Side Plate and Cotter Pin

7 8101162 - 8" Chain Standard, 81 x with Brackets and Connecting Link

7 8101163 - 10" Chain Heavy Duty, 81 x HH with Brackets and Connecting Link

46 PNEG-1128 Chain Loop System without Controls

Page 47

12" Chain and Paddles (8120141)

9. Parts List

12" Chain and Paddles (8120141) Parts List

Ref # Part # Description Qty

1 8120140 Chain with Bracket 12' 81 x HH with Conlk 1

2 8120139 Paddle, 12" Chain Loop UHMW 9

3 S-8135 Flange Bolt 5/16"-18 x 1-1/4" ZN Grade 5 18

4 S-845 Flat Washer 5/16" USS SAE YDP Grade 2 18

5 S-7382 Nylock Nut 5/16"-18 ZN Grade 5 18

PNEG-1128 Chain Loop System without Controls 47

Page 48

9. Parts List

8" and 10" Discharge Gate

Ref # Part # Description Qty

1 8081093 Access Panel-Weldment 8" 90° Discharge with Gate 1

1

8101093 Access Panel-Weldment 10" 90° Discharge with Gate

2 8081096 Access Door-Assembly 8" 90° Discharge with Gate 1

2

8101096 Access Door-Assembly 10" 90° Discharge with Gate

3 8081097 Slide Gate-Weldment 8" 90° Discharge with Gate 1

3

8101097 Slide Gate-Weldment 10" 90° Discharge with Gate

4 8081351 Chain Loop 8" Discharge Gate Rail 2

4 8101501 Chain Loop 10" Discharge Gate Rail 2

5 8081103 Shaft-1" O.D. x 16-1/4" Zinc Plated 8081104 1

8101103 Shaft-1" O.D. x 17-3/4" Zinc Plated 8101104

5

6 8101153 Control Wheel - w/ Clamp 90° Discharge w/ Gate 1

7 8081203 Discharge w/ Gate-90, 8" Zinc Plated 8081182 1

7

8101203 Discharge w/ Gate-90, 10" Zinc Plated 8101182

8 Lock Nut, 5/16"-18 UNC Nylon Lock, Plated Grade 2 9

9 Lock Nut, Flange, 5/16"-18 UNC (Whiz Lock) Plated 8

10 Lock Nut, Flange, 3/8"-16 UNC (Whiz Lock) Plated 4

11 Hex Bolt, Standard Third-Grade 2 5/16"-18 UNC x 1", Plated 8

12 Hex Bolt, Standard Third-Grade 2 5/16"-18 UNC x 3", Plated 1

13 Screw-Flange Whiz Lock 3/8"-16 UNC x 1/2", Plated 4

14 Screw-Flange Whiz Lock 5/16"-18 UNC x 3/4", Plated 20

15 Key-Square 1/4" x 2" 1

16 PT0134 Bearing-w/ Housing, 1" Bronze Insert, 2 Hole 2

17 PT1088 Sprocket-(Hub Type) 19 Tooth, 1" I.D., #50 1

1

1

1

1

1

48 PNEG-1128 Chain Loop System without Controls

Page 49

12" - (7 Gauge) Discharge Gate (8120194)

9. Parts List

12" - (7 Gauge) Discharge Gate (8120194) Parts List

Ref # Part # Description Qty

1 8120195 Discharge Gate Weld 7 Gauge 1

2 MHC01377 Bearing, Light Duty 1-1/8" 2

3 8120091 Shaft - Discharge Gate 1

4 MHC00999 Gear, Spur 8 DP 26T 1-1/8" Bore 1

5 8120088 Slide Gate Weld - Discharge Gate 1

6 8120086 Bottom Cover Weldment 1

7 8120093 UHMW Slide Bar - Discharge Gate 2

8 S-845 Flat Washer 5/16" USS SAE YDP Grade 2 64

9 S-7721 Bolt, HHCS 5/16"-18 x 1-1/4" ZN Grade 2 30

10 S-7382 Nylock Nut 5/16"-18 ZN Grade 5 43

11 8120169 12" x 22" Half Band 1

12 S-7409 Flat Washer 3/8" SAE ZN Grade 2 8

13 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

14 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 4

15 S-1196 Bolt, HHCS 5/16"-18 x 1" ZN Grade 5 12

16 3FH0887 Spring Pin 1/4" x 3" Plated 1

17 8120089 Control Wheel - Discharge Gate 1

18 S-7601 Bolt, HHCS 5/16"-18 x 3" ZN Grade 2 1

19 S-8762 Clamp, 3/16" Cable Zinc Plated 1

PNEG-1128 Chain Loop System without Controls 49

Page 50

9. Parts List

12" - (10 Gauge) Discharge Gate (8120090)

50 PNEG-1128 Chain Loop System without Controls

Page 51

9. Parts List

12" - (10 Gauge) Discharge Gate (8120090) Parts List

Ref # Part # Description Qty

1 8120080 Discharge Gate Weld 10 Gauge 1

2 MHC01377 Bearing , Light Duty 1-1/8" Bore 2

3 8120091 Shaft - Discharge Gate 1

4 MHC00999 Gear, Spur 8 DP 26T 1-1/8" Bore 1

5 8120088 Slide Gate Weld - Discharge Gate 1

6 8120086 Bottom Cover Weldment 1

7 8120093 UHMW Slide Bar - Discharge Gate 2

8 S-845 Flat Washer 5/16" USS SAE YDP Grade 2 64

9 S-7721 Bolt, HHCS 5/16"-18 x 1-1/4" ZN Grade 2 30

10 S-7382 Nylock Nut 5/16"-18 ZN Grade 5 43

11 8120169 12" x 22" Half Band 1

12 S-7409 Flat Washer 3/8" SAE ZN Grade 2 8

13 S-7515 Bolt, HHCS 3/8"-16 x 1-1/2" Grade 5 4

14 S-7383 Nylock Nut 3/8"-16 ZN Grade 5 4

15 S-1196 Bolt, HHCS 5/16"-18 x 1" ZN Grade 5 12

16 3FH0887 Spring Pin 1/4" x 3" Plated 1

17 8120089 Control Wheel - Discharge Gate 1

18 S-7601 Bolt, HHCS 5/16"-18 x 3" ZN Grade 2 1

19 S-8762 Clamp, 3/16" Cable Zinc Plated 1

PNEG-1128 Chain Loop System without Controls 51

Page 52

9. Parts List

Chain Loop Drive Components

50 Hz - International Chain Loop Motors - 50 Hz

Hz Part # Size Voltage Shaft Diameter (Lbs) (Kgs)

50 1500-3-50 15 HP 220/380/440 3 PH 1-5/8" 264.0 119.7

50 2000-3-50 20 HP 220/380/440 3 PH 1-5/8" 277.0 125.6

50 2500-3-50 25 HP 220/380/440 3 PH 1-7/8" 480.0 217.7

50 3000-3-50 30 HP 220/380/440 3 PH 1-7/8" 380.0 172.4

50 4000-3-50 40 HP 220/380/440 3 PH 2-1/8" 571.0 259.0

8" Motor Pulleys, Bushings and Drive Belts - 50 Hz

HP Part Part # Description Qty (Lbs) (Kg)

Motor Pulley PT0703 4 Grade B6.0 SD 1 11.73 5.3

Motor Pulley Bushing GC06516 SD x 1-5/8" Bore 1 1.6 0.7

15 HP

20 HP

25-30 HP

Reducer Pulley GC09690 4 Grade B6.2 SD 1 25 11.3

Reducer Bushing CE-00614 SD x 1-3/8" Bore 1 3.8 1.7

Drive Belts 020-1035-3 BX59 3 0.9 0.4

Motor Pulley KD-PDS0028 2 Grade 5V 9.0 SK 1 23 10.4

Motor Pulley Bushing GC03810 SK x 1-5/8" Bore 1 5 2.3

Reducer Pulley KD-PDS0018 2 Grade 5V 9.25 SK 1 38 17.2

Reducer Bushing PT0778 SK x 1-3/8" Bore 1 9 4.1

Drive Belts KD-PDV0017 5VX710 4 1.1 0.5

Motor Pulley MHC01668 3 Grade 5V 9.0 SF 1 36 16.3

Motor Pulley Bushing MHC01162 SF x 1-7/8" Bore 1 9 4.1

Reducer Pulley MHC01160 3 Grade 5V 9.25 SF 1 44 19.9

Reducer Bushing GC07551 SF x 1-7 / 16 " Bo re 1 9 4.1

Drive Belts MHC00604 5VX800 3 1.1 0.5

10" Motor Pulleys, Bushings and Drive Belts - 50 Hz

HP Part Part # Description Qty (Lbs) (Kg)

Motor Pulley KD-PDS0028 2 Grade 5V 9.0 SK 1 23 10.4

Motor Pulley Bushing GC03810 SK x 1-5/8" Bore 1 5 2.3

20 HP

25-30 HP

40 HP

50 HP

Reducer Pulley KD-PDS0018 2 Grade 5V 9.25 SK 1 38 17.2

Reducer Bushing PT0778 SK x 1-3/8" 1 9 4.1

Drive Belts KD-PDV0017 5VX710 4 1.1 0.5

Motor Pulley MHC01668 3 Grade 5V 9.0 SF 1 36 16.3

Motor Pulley Bushing MHC01162 SF x 1-7/8" Bore 1 9 4.1

Reducer Pulley MHC01160 3 Grade 5V 9.25 SF 1 44 19.9

Reducer Bushing GC07551 SF x 1-7 / 16 " Bo re 1 9 4.1

Drive Belts MHC00604 5VX800 3 1.1 0.5

Motor Pulley MHC01717 4 Grade 5V 8.5 E 1 36 16.3

Motor Pulley Bushing MHC01540 E x 2-1/8" Bore 1 9 4.1

Reducer Pulley KD-PDS0016 4 Grade 5V 9.0 E 1 44 19.9

Reducer Bushing MHC01537 E x 1-5/8" Bore 1 9 4.1

Drive Belts MHC00604 5VX800 3 1.2 0.5

Motor Pulley KD-PDS0021 4 Grade 5V 10.3 E 1 36 16.3

Motor Pulley Bushing MHC01540 E x 2-1/8" Bore 1 9 4.1

Reducer Pulley KD-PDS0029 4 Grade 5V 10.9 E 1 44 19.9

Reducer Bushing MHC01537 E x 1-5/8" Bore 1 9 4.1

Drive Belts CE-00562 5VX900 4 1.2 0.5

52 PNEG-1128 Chain Loop System without Controls

Page 53

Chain Loop Drive Components (Continued)

USA and Countries with 60 Hz Power

Chain Loop Motors - 60 Hz

Hz Part # Size Voltage Shaft Diameter (Lbs) (Kgs)

60 3EL5069 15 HP 230, 1 PH 1-5/8" 314.0 142.4

60 MTR-0022 15 HP 230/460 3 PH 1-5/8" 234.0 106.1

60 MTR-0025 20 HP 230/460 3 PH 1-5/8" 264.0 119.7

60 MTR-0054 25 HP 230/460 3 PH 1-7/8" 396.0 179.6

60 MTR-0056 30 HP 230/460 3 PH 1-7/8" 433.0 196.4

60 MTR-0063 40 HP 230/460 3 PH 2-1/8" 514.0 233.1

60 MTR-0067 50 HP 230/460 3 PH 2-1/8" 579.0 263.0

60 MTR-0069 60 HP 230/460 3 PH 2-3/8" 747.0 339.0

8" Motor Pulleys, Bushings and Drive Belts - 60 Hz

9. Parts List

HP Part Part # Description Qty (Lbs) (Kg)

Motor Pulley CE-00582 3 Grade B6.4 SD 1 11.73 5.3

Motor Pulley Bushing GC06516 SD x 1-5/8" Bore 1 1.6 0.7

15 HP

20 HP

25-30 HP

Reducer Pulley GC07874 3 Grade B8.0 SK 1 25 11.3

Reducer Bushing PT0778 SK x 1-3/8" Bore 1 3.8 1.7

Drive Belts MHC00823 BX61 3 0.9 0.4

Motor Pulley 3311A1 4 Grade B6.4 SD 1 23 10.4

Motor Pulley Bushing GC06516 SD x 1-5/8" Bore 1 5 2.3

Reducer Pulley GC06676 4 Grade B8.0 SK 1 38 17.2

Reducer Bushing PT0778 SK x 1-3/8" 1 9 4.1

Drive Belts MHC00823 BX61 4 1.1 0.5

Motor Pulley MHC01566 3 Grade B11.0 SK 1 36 16.3

Motor Pulley Bushing CE-00617 SK x 1-7/8" Bore 1 9 4.1

Reducer Pulley MHC01567 3 Grade B13.6 SK 1 44 19.9

Reducer Bushing GC06687 SK x 1-7/16" Bore 1 9 4.1

Drive Belts D02-0067 BX85 3 1.1 0.5

PNEG-1128 Chain Loop System without Controls 53

Page 54

9. Parts List

Chain Loop Drive Components (Continued)

10" Motor Pulleys, Bushings and Drive Belts - 60 Hz

HP Part Part # Description Qty (Lbs) (Kg)

Motor Pulley 3311A1 4 Grade B6.4 SD 1 23 10.4

Motor Pulley Bushing GC06516 SD x 1-5/8" Bore 1 5 2.3

20 HP

25-30 HP

40 HP

50 HP

Reducer Pulley GC06676 4 Grade B8.0 SK 1 38 17.2

Reducer Bushing PT0778 SK x 1-3/8" 1 9 4.1

Drive Belts MHC00823 BX61 4 1.1 0.5

Motor Pulley MHC01566 3 Grade B11.0 SK 1 36 16.3

Motor Pulley Bushing CE-00617 SK x 1-7/8" Bore 1 9 4.1

Reducer Pulley MHC01567 3 Grade B13.6 SK 1 44 19.9

Reducer Bushing GC06687 SK x 1-7/16" Bore 1 9 4.1

Drive Belts D02-0067 BX85 3 1.1 0.5

Motor Pulley MHC01668 3 Grade 5V 9.0 SF 1 36 16.3

Motor Pulley Bushing GT3-0068 SF x 2-1/8" Bore 1 9 4.1

Reducer Pulley MHC01531 3 Grade 5V 11.3 SF 1 44 19.9

Reducer Bushing MHC01669 SF x 1-5/8" Bore 1 9 4.1

Drive Belts MHC00039 5VX850 3 1.2 0.5

Motor Pulley KD-PDS0016 4 Grade 5V 9.0 E 1 36 16.3

Motor Pulley Bushing MHC01540 E x 2-1/8" Bore 1 9 4.1

Reducer Pulley MHC01699 4 Grade 5V 11.3 E 1 44 19.9

Reducer Bushing MHC01537 E x 1-5/8" Bore 1 9 4.1

Drive Belts MHC00039 5VX850 4 1.2 0.5

12" Motor Pulleys, Bushings and Drive Belts - 60 Hz

HP Part Part # Description Qty (Lbs) (Kg)