Page 1

ASSEMBLY MANUAL FOR

PNEG-1096

LADDERS,

SAFETY CAGES,

& PLATFORMS

Owner's Manual

Manual# PNEG-1096

PRINTED: 2/2004

2.66" INSIDE STIFFENED FLAT BOTTOM TANKS

2.66" OUTSIDE STIFFENED FLAT BOTTOM TANKS

4.00" INSIDE STIFFENED FLAT BOTTOM TANKS

4.00" OUTSIDE STIFFENED FLAT BOTTOM TANKS

2.66" COMMERCIAL HOPPER TANKS

4.00" FARM-COM HOPPER TANKS

Page 2

Page 3

TABLE OF CONTENTS

2.66" INSIDE STIFF. LADDER SAFETY CAGE & PLATFORM INSTR.

LADDER PLACEMENT/PLATFORM SUPPORT ASSEMBLY

EXTENSION RAILS/EAVE ADJUSTABLE BRACES

PLATFORM & HANDRAIL ASSEMBLY/EAVE SAFETY CAGE

2.66" INSIDE STIFFENED TANK LAYOUT

2.66" LADDER OFFSET CHART

SAFETY CAGE BELL SECTIONS

REST PLATFORM OFFSET LOCATION

INSIDE LADDER PLACEMENT AND SUPPORTS

2.66" OUTSIDE STIFF. LADDER SAFETY CAGE & PLATFORM INSTR.

LADDER PLACEMENT/PLATFORM SUPPORT FOR 2-POST/3-PANEL

LADDER PLACEMENT/PLATFORM SUPPORT FOR 3-POST/3 & 4-PANEL

EXTENSION RAILS/EAVE ADJUSTABLE BRACES

PLATFORM & HANDRAIL ASSEMBLY/EAVE SAFETY CAGE AND EXTENSION

2.66" OUTSIDE STIFFENED TANK LAYOUT

2.66" LADDER OFFSET CHART

SAFETY CAGE BELL SECTIONS

INSIDE LADDER PLACEMENT AND SUPPORTS

4.00" INSIDE STIFF. LADDER SAFETY CAGE & PLATFORM INSTR.

LADDER PLACEMENT/PLATFORM SUPPORT ASSEMBLY

EXTENSION RAILS/EAVE ADJUSTABLE BRACES

PLATFORM & HANDRAIL ASSEMBLY/EAVE SAFETY CAGE AND EXTENSION

4.00" INSIDE STIFFENED TANK LAYOUT

4.00" LADDER OFFSET CHART

SAFETY CAGE BELL SECTIONS

REST PLATFORM OFFSET LOCATION

INSIDE LADDER PLACEMENT AND SUPPORTS

4.00" OUTSIDE STIFF. LADDER SAFETY CAGE & PLATFORM INSTR.

LADDER PLACEMENT/PLATFORM SUPPORT ASSEMBLY FOR TANKS 4 - 9 RINGS

EXTENSION RAILS/EAVE ADJUSTABLE BRACES

PLATFORM & HANDRAIL ASSEMBLY/EAVE SAFETY CAGE AND EXTENSIONS

INSIDE LADDER PLACEMENT AND SUPPORTS

LADDER PLACEMENT/PLATFORM SUPPORT ASSEMBLY FOR TANKS 10 - 14 RINGS

EXTENSION RAILS/EAVE ADJUSTABLE BRACES

PLATFORM & HANDRAIL ASSEMBLY

4.00" OUTSIDE STIFFENED TANK LAYOUT AND LADDER OFFSET CHART

EAVE SAFETY CAGE & BELL SECTIONS

REST PLATFORM OFFSET LOCATION

INSIDE LADDER PLACEMENT AND SUPPORTS

2.66" COMM. HOPPER TANKS (NCHT)

2.66" (NCHT) TANK LAYOUT AND LADDER OFFSET CHART

LADDER SUPPORTS

ACCESS TO SIDEWALL DOOR AND CONNECTED TO HOPPER COLUMNS

400" FARM-COM HOPPER TANKS (FCHT)

4.00" (FCHT) TANK LAYOUT AND LADDER OFFSET CHART

LADDER PLACEMENT

ACCESS TO SIDEWALL DOOR AND CONNECTED TO HOPPER COLUMNS

2.66" OUTSIDE STIFF. OPTIONAL EXTENTED PLATFORM

LADDER PLACEMENT

PLATFORM PACKAGE LS-6683

PLATFORM PACKAGE LS-6683 CONNECTED TO HOPPER COLUMNS

PNEG-1096 Ladder , Safety Cage, & Platforms

10-12

13

14-15

16

17

18

19

20-21

22-23

24-25

26

27-29

30

31

32

33-34

35-37

38

39-40

41

42

43

44

45-46

47-49

50

51-52

53-54

55-56

57

58

59

60-61

62

63-64

65-66

67

68

69-70

71

72

73-74

75

76

3

Page 4

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator , to know and under-

stand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidelines. T o help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury .

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury .

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury .

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention to.

4

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 5

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this

manual and safety signs on your equipment.

Keep signs in good condition. Replace missing

or damaged safety signs. Be sure new equipment components and repair parts include the

current safety signs. Replacement safety signs

are available from the manufacturer.

Never work alone.

If you do not understand any part of this manual

and need assistance, contact your dealer.

INSTALL EQUIPMENT PROPERLY

Safety

Read ALL Safety Information.

This equipment shall be installed in accordance

with the current installation codes and

applicable regulations which should be carefully

followed in all cases. Authorities having

jurisdiction should be consulted before

installations are made.

STAY CLEAR OF HOISTED EQUIPMENT

Always use proper lifting/hoisting

equipment when assembling or

disassembling equipment.

Do not walk or stand under hoisted equipment.

Always use sturdy and stable supports when

needed for installation.

Follow

Building

Codes.

Crush

Hazard.

PNEG-1096 Ladder , Safety Cage, & Platforms

5

Page 6

Safety

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job. Keep hair, loose clothing, &

shoestrings away from rotating & moving parts.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to prevent breathing

potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help protect

your head and toes from falling debris.

Eye Protection

Gloves

Steel Toe

Boots

Respirator

Hard Hat

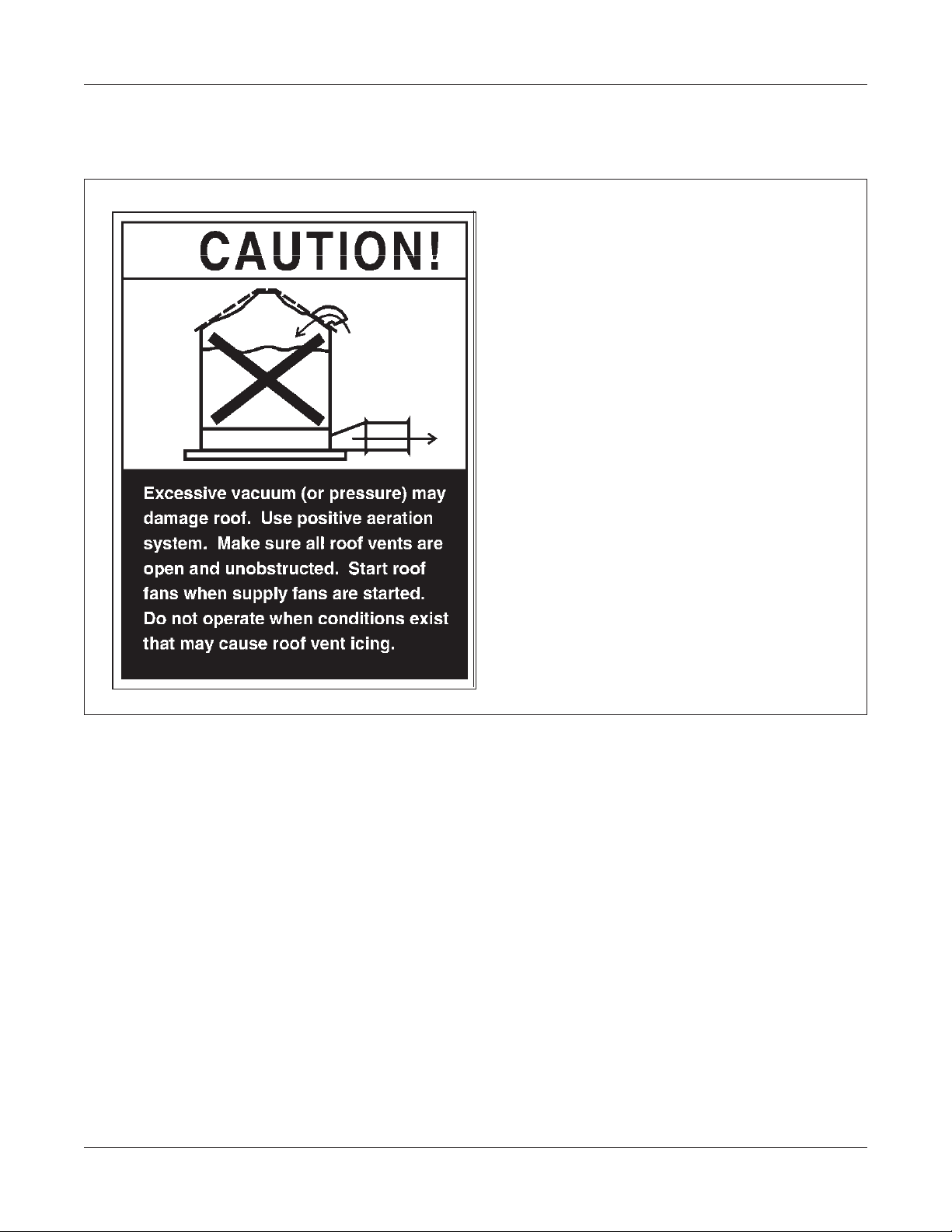

PREPARE FOR EMERGENCIES

Make sure someone is nearby who is aware of

the proper emergency procedures in the event of

an accident or emergency.

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy .

Keep emergency numbers for doctors, ambu-

lance service, hospital, and fire department near

your telephone.

Have Emergency

Equipment Ready.

6

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 7

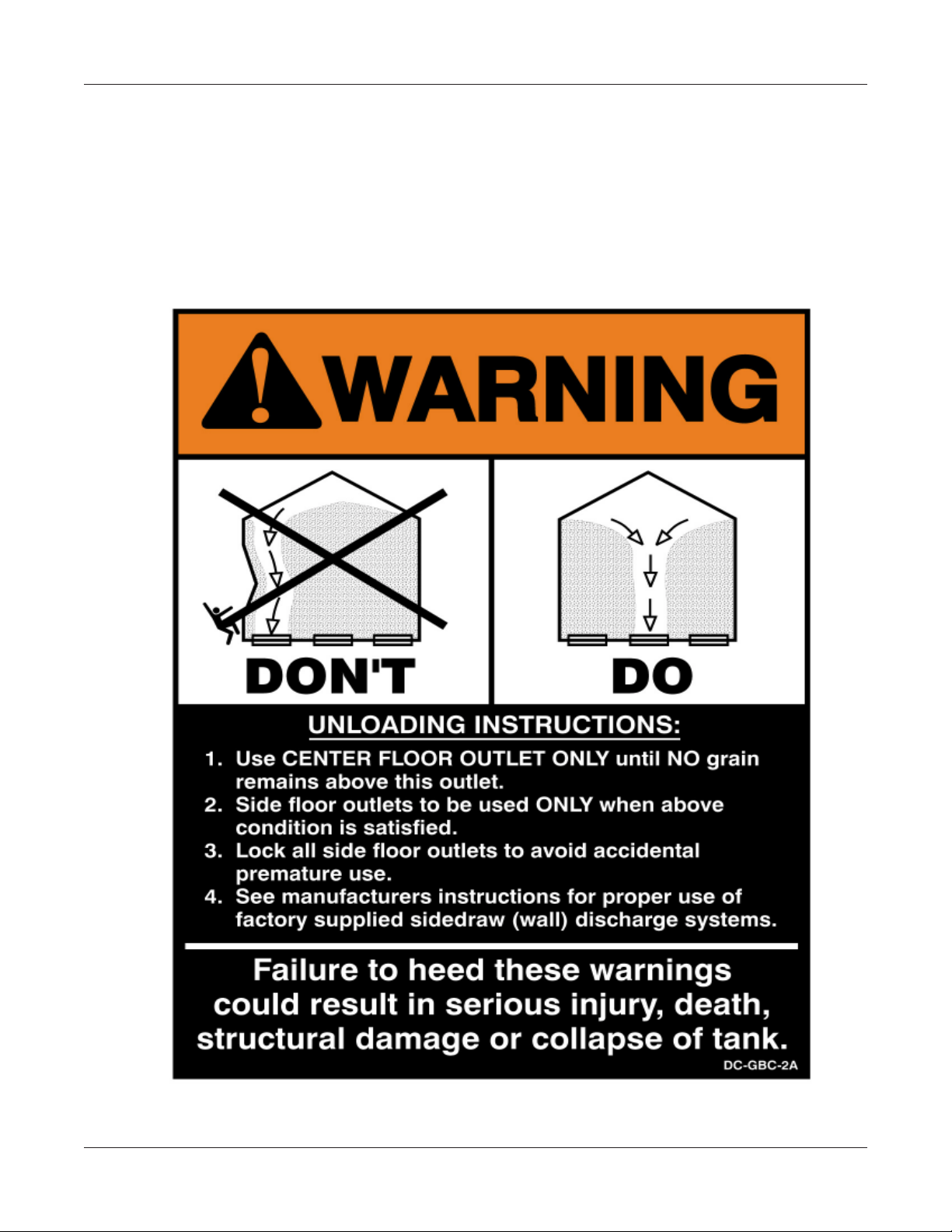

Roof Disclaimer

Roof Damage Warning and Disclaimer

THE MANUFACTURER DOES NOT

WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM

OR INTERNAL PRESSURE FROM

FANS OR OTHER AIR MOVING

SYSTEMS. ADEQUA TE VENTILA TION

AND/OR "MAKEUP AIR" DEVICES

SHOULD BE PROVIDED FOR ALL

POWERED AIR HANDLING SYSTEMS.

THE MANUFACTURER DOES NOT

RECOMMEND THE USE OF

DOWNWARD FLOW SYSTEMS

(SUCTION). SEVERE ROOF DAMAGE

CAN RESULT FROM ANY BLOCKAGE

OF AIR PASSAGES. RUNNING FANS

DURING HIGH HUMIDITY/COLD

WEATHER CONDITIONS CAN CAUSE

AIR EXHAUST OR INTAKE PORTS TO

FREEZE.

PNEG-1096 Ladder , Safety Cage, & Platforms

7

Page 8

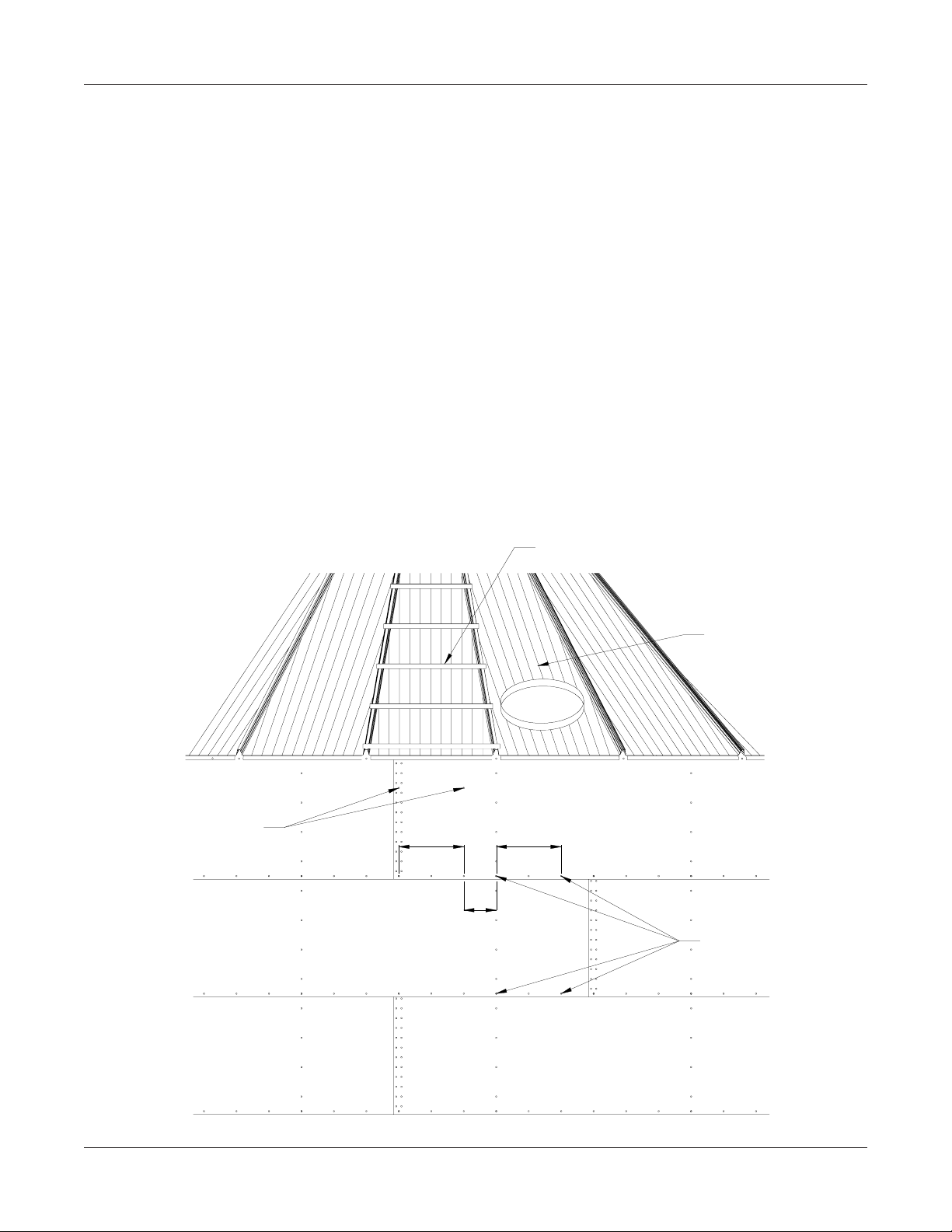

Safety Decal

ATTENTION: The decal shown below should be present on the inside of the two ring door cover , 24"

porthole door cover and the roof manway cover. If a decal has been damaged or is missing in any of these

locations contact the manufacturer for a free replacement decal.

DECALS

P.O. BOX 20

ASSUMPTION, IL. 62510-0020

(217) 226-4421

8

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 9

Safety Decal

ATTENTION: The decal shown below should be present on the outside of the two ring door cover, 24”

porthole door cover and roof manway cover. If a decal has been damaged or is missing in any of these

locations contact the manufacturer for a free replacement decal.

DECALS

P .O. BOX 20

ASSUMPTION, IL. 62510-00020

(217)-226-4421

PNEG-1096 Ladder , Safety Cage, & Platforms

9

Page 10

2.66 INSIDE STIFFENED

THIS SECTION

CORRUGATED

FOR 2.66"

GRAIN BINS

INSIDE STIFFENED

10

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 11

2.66 INSIDE STIFFENED

LADDER SAFETY CAGE, AND PLATFORM INSTRUCTIONS

All packages have been structured with the correct components for each ring height grain

bin from 6 rings to 37 rings. Be sure and follow the complete instruction sheets for correct

placement of parts. Failure to do so may result in improper fit of parts or shortage of parts. Read

through the complete set of instructions before proceeding with erection of grain bin.

Considerable thought must be given as to location of ladders and platforms in relation to other

equipment and structures.

STARTING LOCATION OF LADDERS

Ladder placement is very critical as to assure proper fit of all parts later on as safety cage is

bolted in place. Locate the proper place for the roof ladder and manway this will establish the

location of the ladder . Ladder must be centered directly below the roof ladder. Refer to the diagram below for proper location of field drilled holes (3/8"). Holes must be 18 3/4" apart and 8"

below the top horizontal row of holes directly in line with the holes to be used for the platform

mounting angle. Platform must be located 9 3/8" to the right of the ladder holes. All of these

dimensions are very critical to assure proper fit of all parts!

FIELD DRILL

3/8" HOLES (2)

ROOF LADDER

MANWAY PANEL

18 3/4"18 3/4"

9 3/8"

HOLES FOR PLATFORM

REV . 9/12/-00

PNEG-1096 Ladder , Safety Cage, & Platforms

11

Page 12

2.66 INSIDE STIFFENED

Roof Sheet

8"

Outside

Standoff

LS-121

6.1/4"

8"

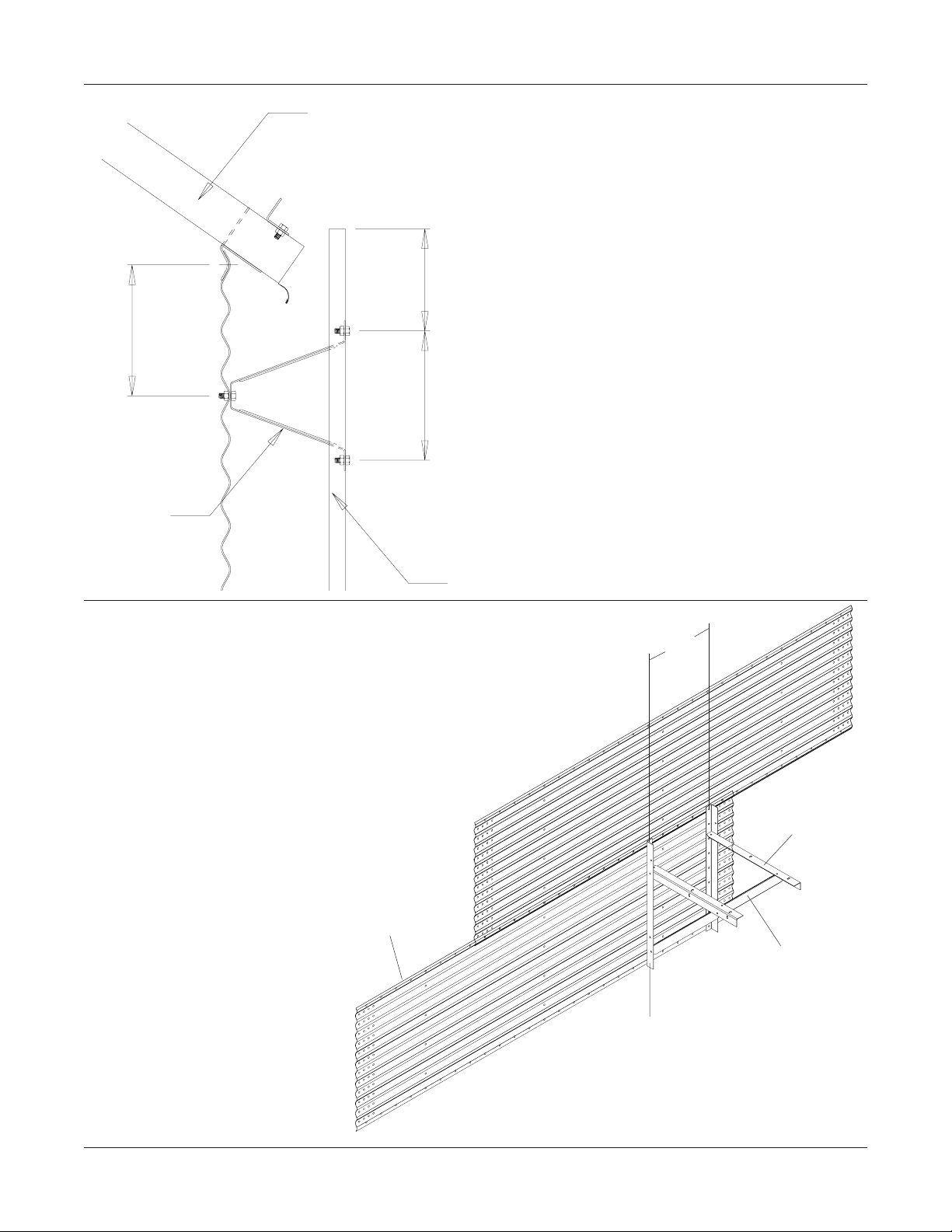

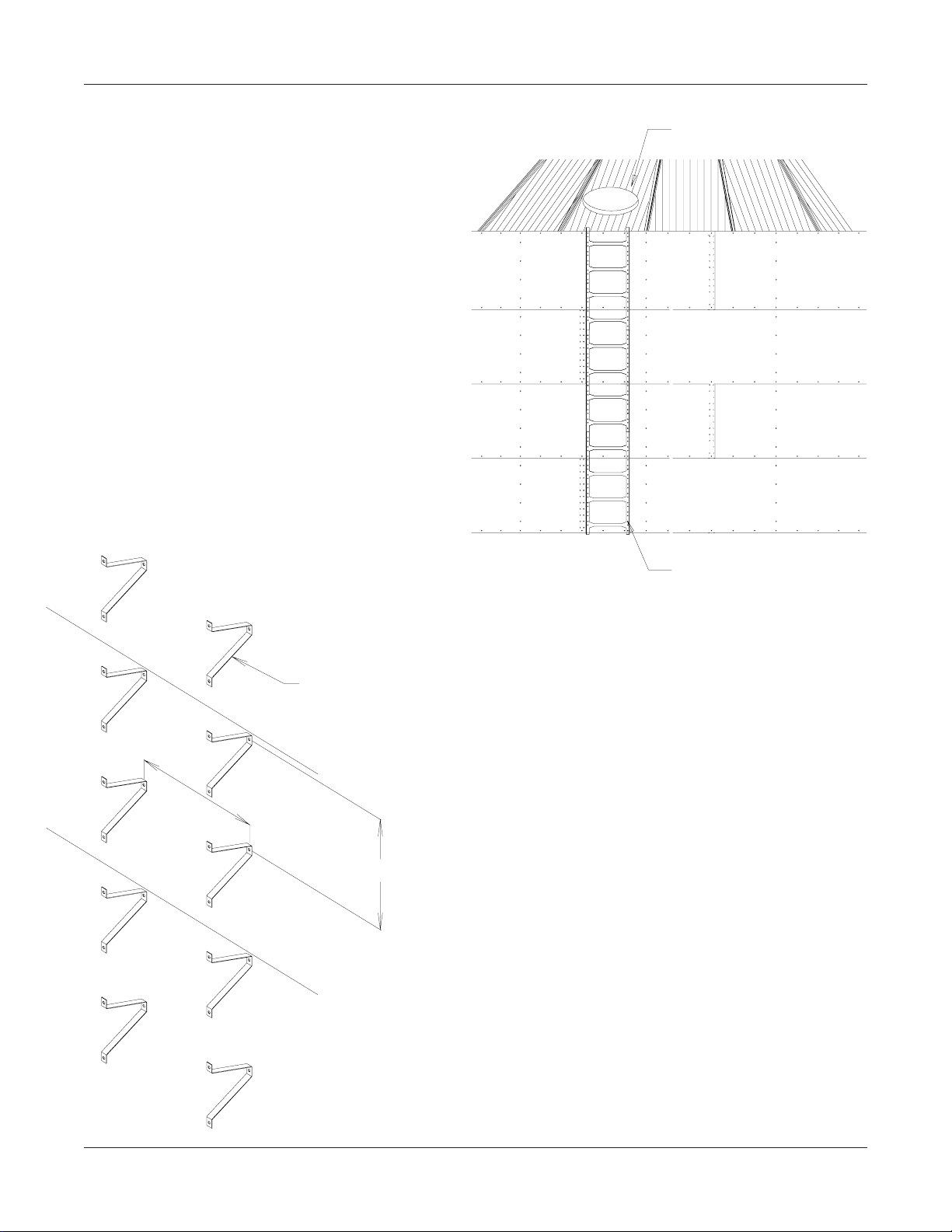

LADDER PLACEMENT

Ladder placement on the grain bin is very

important at this time. Refer to the diagram

at the left and follow the correct dimensions as

shown. Ladder standoff must be located

8" below the horizontal seam. Check your

ladder to make sure the ladder rung dimples

are to the top surface. Attach ladder to the

standoffs using the holes located 6 1/4"

from the end of ladder section. Use 5/16" x

3/4" bin bolts for these connections. Now all

standoffs must be located in horizontal seam

holes (repeating every 32") until reaching

the first rest platform. Refer to the section

in these instructions that references the location of intermediate rest platforms for further

hole locations.

PLATFORM SUPPORT ASSEMBLY

When starting the platform support, you

must attach the mounting angle to the

sidewall of the grain bin. Refer back to the

first page for the correct holes to be used

by the platform. Attach the angle using

5/16" x 3/4" bolts and nuts, tighten at this

time. Next, bolt the support angle to the

mounting angle again using the proper

holes. Attach the brace angle to the

mounting angle as shown in the diagram

at left. Use 5/16" x 3/4" bolts and nuts for

all connections.

Horizontal Seam

Ladder Section

LDR-4002

18 3/4''

LS-370

Support Angle

LS-369

Brace Angle

30 3/4"

12

LS-6705

Mounting Angle 34"

REV. 10/9/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 13

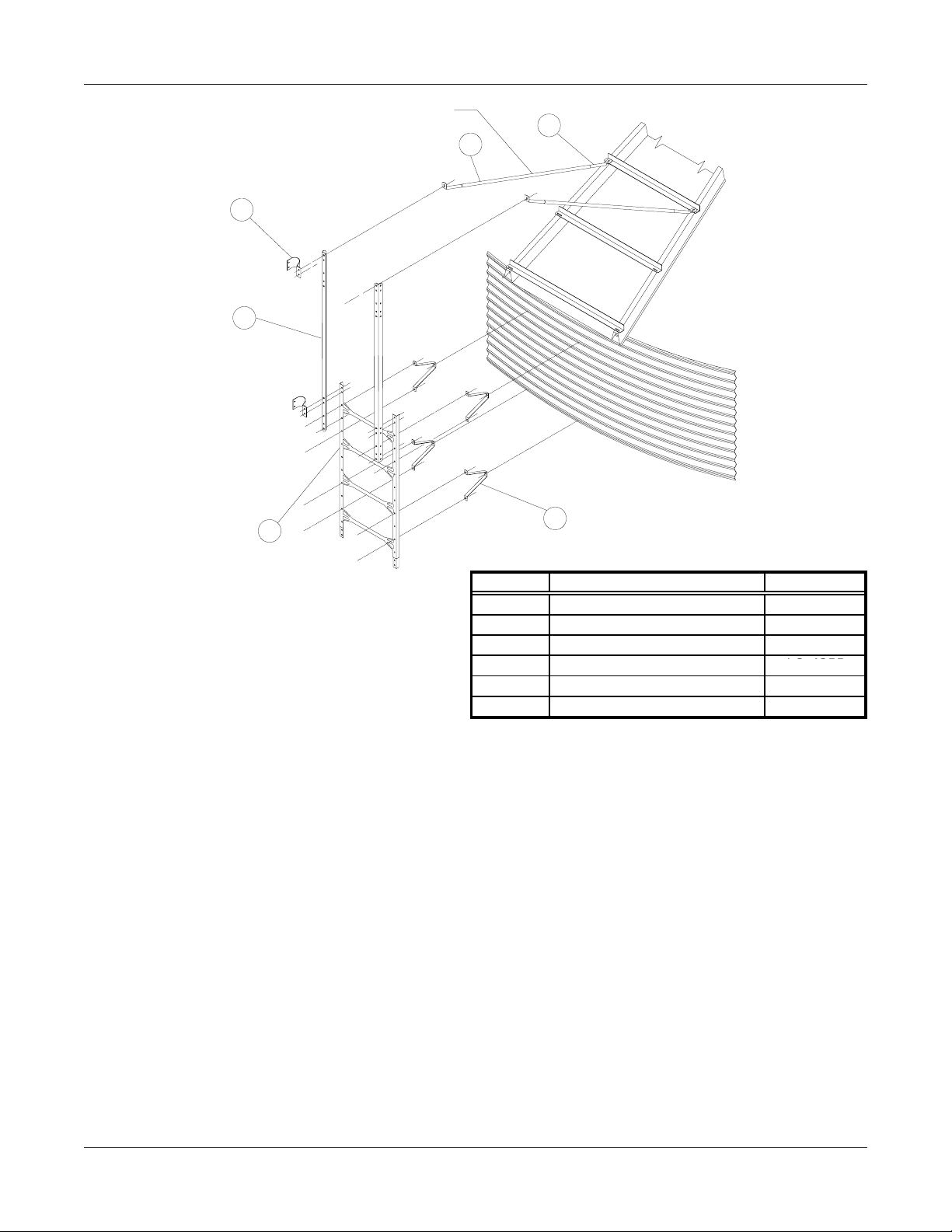

2.66 INSIDE STIFFENED

FIELD DRILL 5/16'' HOLES

(4) PER BRACE

3

4

5

1

2

6

REF. NO. DESCRIPTION PART NO.

Note: Reference previous page for the

first ladder standoff starting location.

EXTENSION RAILS

1 END TUBE LS-6616

2 CENTER TUBE LS-6615

3 SAFETY CAGE BRACKET LS-4349

4 SAFETY CAGE EXT. RAIL LS-4355

5 LADDER SECTION LDR-4002

6 OUTSIDE STANDOFF LS-121

LS-6696

Extension rails are provided to extend the side rails of the ladder above the eave of the

roof and to support the safety cage at that point. T wo rails have been provided, one for each

side of the ladder . Refer to diagram above for proper location and assembly of the extension

rails in relation to the ladder . Use 5/16" x 3/4" bolts and nuts to attach the ladder. Tighten the

bolts at this time.

EAVE ADJUSTABLE BRACES

After extension rails are firmly attached, the adjustable braces must be attached at this

time. A larger diameter tube and two smaller diameter tubes are used to make up one

adjustable brace. Slip the smaller tubes inside the larger tube and attach one smaller tube to

the top of the extension rail. Adjust the other smaller tube so the bottom of the flattened tube

reaches the roof rib. Field drill four 5/16" holes through both large and small adjustable tubes

and bolt together using 1/4" x 1.1/2" bolts and nuts. This will keep the adjustable brace from

slipping.

Attach the safety cage brackets to the extension rail and ladder as shown in the

diagram. Brackets must be placed every 44". This will occur at every ladder joint. Use 5/16" x

3/4" bolts and nuts.

REV. 9/11/01

PNEG-1096 Ladder , Safety Cage, & Platforms

13

Page 14

2.66 INSIDE STIFFENED

LS-6697

Safety Cage Platform

Extension Angles

(Flours. Green)

LS-373

Platform

LS-5283

SafetyCage Hoop

Adapter Angle

41" (T yp.)

LS-294

End Handrail

24.3/8" (White)

LS-295

Front Handrail

31.7/8" (Black)

LS-371

Platform Vertical

Angle 42" (Yellow)

LS-372

Vert. Entrance Angle

46" (Orange)

Extension Rails or Ladder

(Ladder to be used on

Intermediate Platform)

Extension Angle

Platform

LS-5285 Safety

Cage Hoop

Adjuster Plate

LS-5284 Safety Cage

Adapter Hoop

LS-4351 Safety Cage

Hoof Half

EXTENSION ANGLE DETAIL

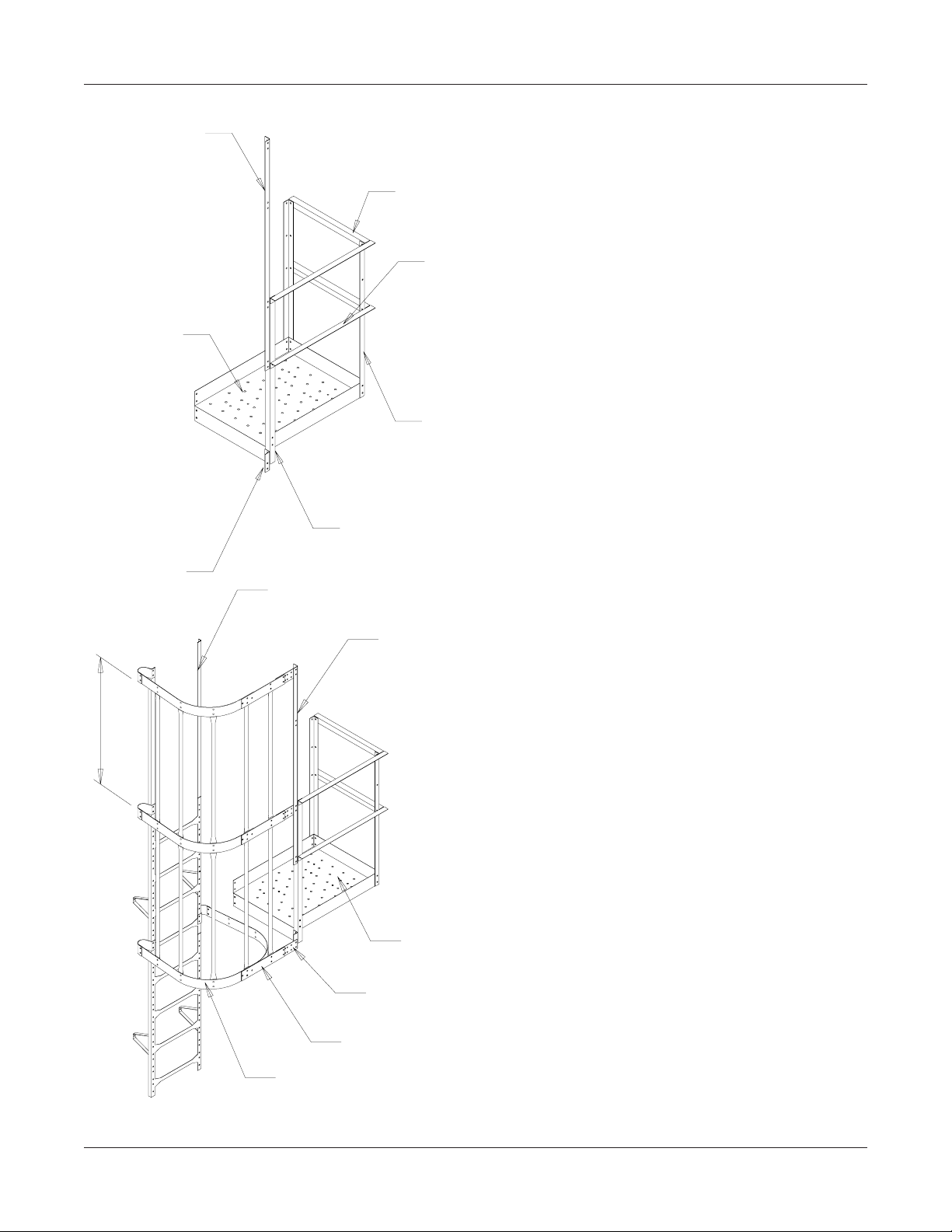

PLATFORM AND HANDRAIL

ASSEMBLY

Start by attaching the platform itself to

the platform support using 5/16" x 3/4"

bolts and nuts. Place all the vertical

angles in place, making sure to place

the vertical entrance angle to the left

front corner of the platform. After all vertical angles are in place attach front and

side handrails as shown in the diagram.

Use 5/16" x 3/4" bolts and nuts in all

connections.

EAVE SAFETY CAGE &

INTERMEDIATE REST PLA TFORM

Before attaching any pieces to the ladder or platform some preassembly will

be required. Take the safety cage hoop

adjuster plate and the safety cage

adapter hoop and bolt together using the

proper holes, (as shown on following

page.) Be sure the proper holes are used

depending on the diameter of the grain

bin. Be sure to use the 5/16" x 3/4" bolt

with the head of the bolt to the inside of

the safety cage. Using the improper

holes will make the safety cage more difficult to assemble. Y ou may now bolt this

assembly to the safety cage hoop half,

tighten bolts as you go. One of the assemblies will take 2 hoop halves and be

positioned just below the platform as

shown in the diagram. Take the assembly and attach to the safety cage bracket

and to the platform extension angle or

the hoop adapter angle. Refer to the diagram for more information. If holes don't

align properly go back and make sure

the ladder and platform are correctly positioned on grain bin in relationship to one

another . Make any corrections necessary

to complete the assembly as shown.

14

REV. 9/13/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 15

2.66 INSIDE STIFFENED

WHEN ATTACHING SAFETY CAGE TO PLATFORM, THE HOOP ADJUSTER PLATE MUST BE USED

TO COMPENSATE FOR THE DIFFERENT BIN CURVATURES. NOTE: (THIS PLATE IS NOT NEEDED

FOR 90' & 105' DIAMETER BINS.) BOLT THE PROPER END TO THE EXTENSION ANGLE OR ADAPTER

HOLE. NOW LOCATE PROPER HOLES IN HOOP ADJUSTER PLATE AND BOLT TO THE SAFETY CAGE

ADAPTER HOOP.

12'-15'

21'-24'

18'

30'-33'

27'

36'-42'

48'

60'

75'-78'

72'

EAVE SAFETY CAGE

After all three hoop assemblies are in

place you may attach the 44" vertical

supports from hoop to hoop. This will

require 10 supports, 5 between each

set of hoops. Again use the truss

head bolts with bolt head to the inside

of safety cage.

LS-4353 Safety Cage

44" Vertical Support

LS-4353 Safety Cage

44" Vertical Support

BOLT TO

EXTENSION

ANGLE OR

ADAPTER

ANGLE

LS-6697 Safety

Cage Platform

Extension Angle

LS-4349 Safety Cage

Standard Bracket

REV. 9/14/01

PNEG-1096 Ladder , Safety Cage, & Platforms

LS-4351

Safety Cage

Hoop Half

SAFETY CAGE EXTENSION

The safety cage extension package is designed to be

added on to the bottom of the existing safety cage above

it. Attach the vertical support pieces to the existing hoop

halves above using the 5/16" x 3/4" bolt and nuts. Fasten

the package to the safety cage brackets and attach the

bottom of the vertical supports to the hoop halves and

tighen bolts. Continue to use the extension packages as

the usage chart reflect on the following page.

Whereas you formerly had all extension packages bundled

and listed under the LS-4365LB part number you will now

have a combination of LS-4366LB (A package of two (2)

extension kits) and LS-4365LB (The original single extension kit).

15

Page 16

16

2.66 INSIDE STIFFENED

2.66" INSIDE STIFFENED LADDER

OFFSET AND PLATFORM LAYOUT

PNEG-1096 Ladder , Safety Cage, & Platforms

A

2nd

A

B

2nd

13th

A

B

C

2nd

12th

22nd

A

B

C

2nd

10th

19th

D

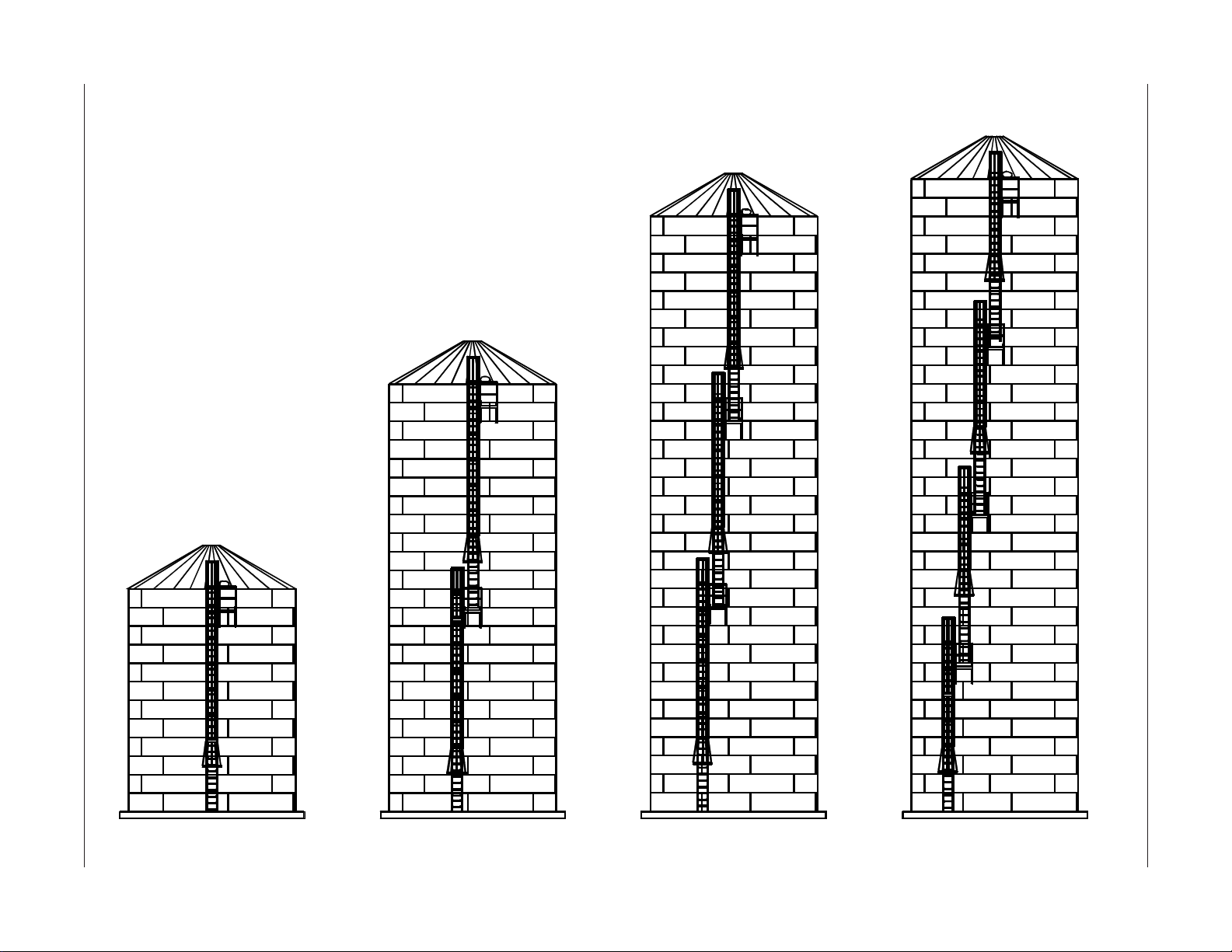

12 RINGS 23 RINGS 32 RINGS 34 RINGS

27th

Page 17

PNEG-1096 Ladder, Safety Cage, & Platforms

ITEM

Platform Located in Ring22222222222 2222222222 22222222222

Ladder Section (LDR-4002)55677896666 688889966669999977777

Bell Safety Cage (LS-4364LB)111111111111111111111 11111111111

Safety Cage Extension- 1233452222 244445522224444433333

Platform Package 11111111111 1111111111 11111111111

Eave Safey Cage (LS-5289)111111111111 11111111 1 11111111111

LS-5293 6 Rings

LS-5294 7 Rings

LS-5295 8 Rings

LS-5296 9 Rings

LS-5297 10 Rings

LS-5298 11 Rings

LS-5299 12 Rings

B

Platform Located in Ring 9 9 9 9 9 11 11 11 11 13 13 9 9 9 9 12 12 12 12 12 10 10 10 10 10

Ladder Section (LDR-4002)6678 98991091099 9 98899988888

Bell Safety Cage (LS-4364LB)1111 1 11111111 111111111111

Safety Cage Extension11234 34454544 4 43344433333

Platform Package 11111111111111 11111111111

Eave Safey Cage (LS-5289)1111 1 11111111 111111111111

2.66" INSIDE STIFFENED

LADDER OFFSET CHART

LS-5300 13 Rings

LS-5301 14 Rings

LS-5302 15 Rings

LS-5303 16 Rings

LS-5304 17 Rings

LS-5305 18 Rings

LS-5306 19 Rings

LS-5307 20 Rings

LS-5308 21 Rings

LS-5309 22 Rings

LS-5310 23 Rings

LS-5311 24 Rings

LS-5312 25 Rings

LS-5313 26 Rings

LS-5314 27 Rings

LS-5315 28 Rings

LS-5316 29 Rings

LS-5317 30 Rings

LS-5318 31 Rings

LS-5319 32 Rings

LS-6693 33 Rings

LS-6694 34 Rings

C

Platform Located in Ring 18 18 18 18 20 20 22 22 22 19 19 19 19 19

Ladder Section (LDR-4002)78 9 999891088888

Bell Safety Cage (LS-4364LB)11 1 11111111111

Safety Cage Extension233 43434533333

Platform Package 11 111111111111

Eave Safey Cage (LS-5289)11111111111111

D

Platform Located in Ring 27 27 27 27 27

Ladder Section (LDR-4002)789910

Bell Safety Cage (LS-4364LB)11111

Safety Cage Extension23445

Platform Package 11111

Eave Safey Cage (LS-5289)11111

LS-6707 35 Rings

LS-6708 36 Rings

LS-6709 37 Rings

2.66 INSIDE STIFFENED

17

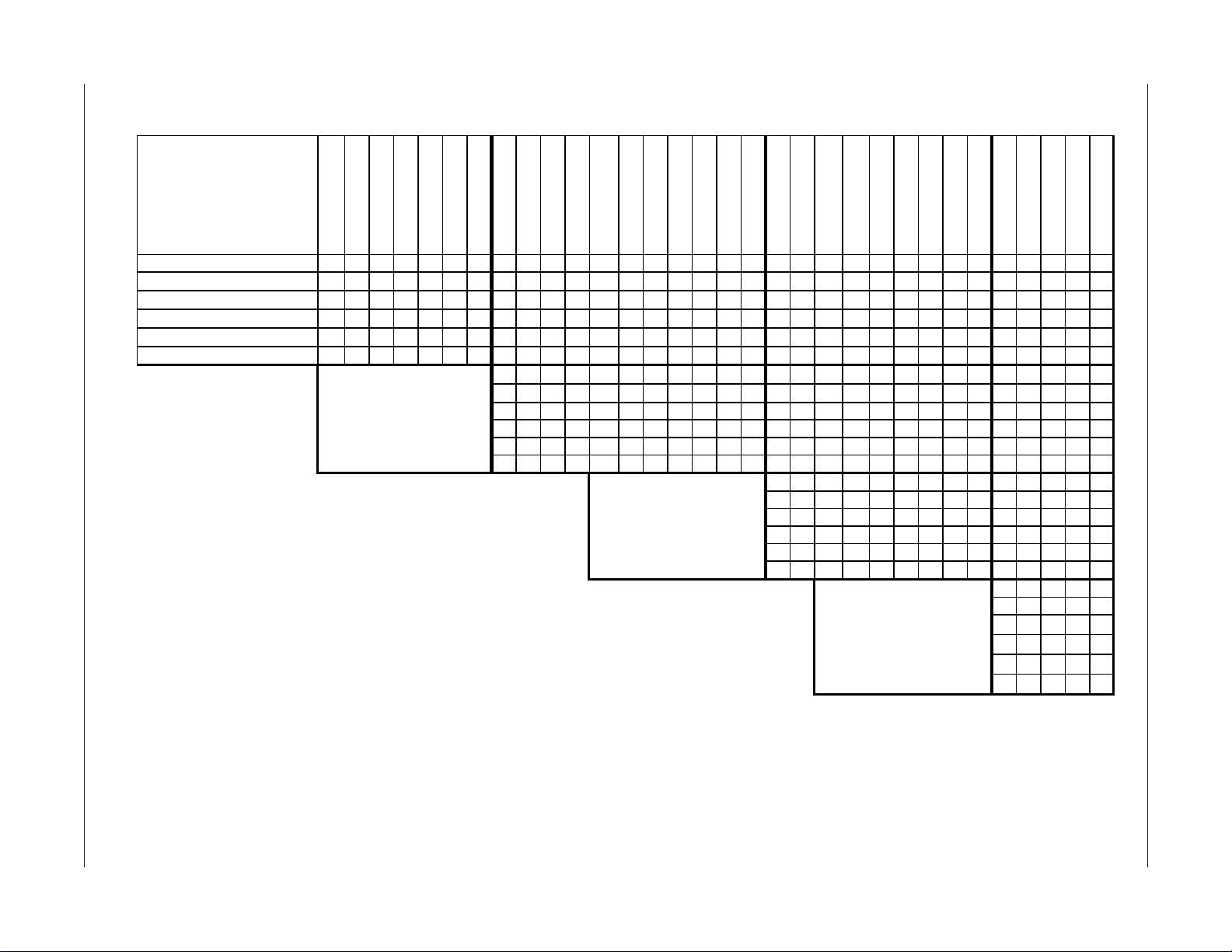

LADDER, SAFETY CAGE, AND PLATFORM USAGE LOCATION CHART

THE CHART ABOVE SHOULD BE IN CONJUNCTION WITH THE DIAGRAMS ON THE PREVIOUS PAGE. FOLLOW THE PROPER LETTER

DESIGNATION FROM THE DIAGRAM TO THE CHART FINDING THE PROPER RING GRAIN BIN AND USE THE AMOUNTS OF LADDERS

AND SAFETY CAGES SHOWN IN CHART BELOW. FOR SAFETY CAGE BELL SECTION SIZE (22" OR 44") SEE CHART ON FOLLOWING

PAGE.

Page 18

2.66 INSIDE STIFFENED

LS-4353 Safety Cage

LS-4354 Safety Cage

44" Vertical Support

22" Vertical Support

LS-4352 Safety Cage

Bell Hoop Half (Red)

LS-4352 Safety Cage

Bell Hoop Half (Red)

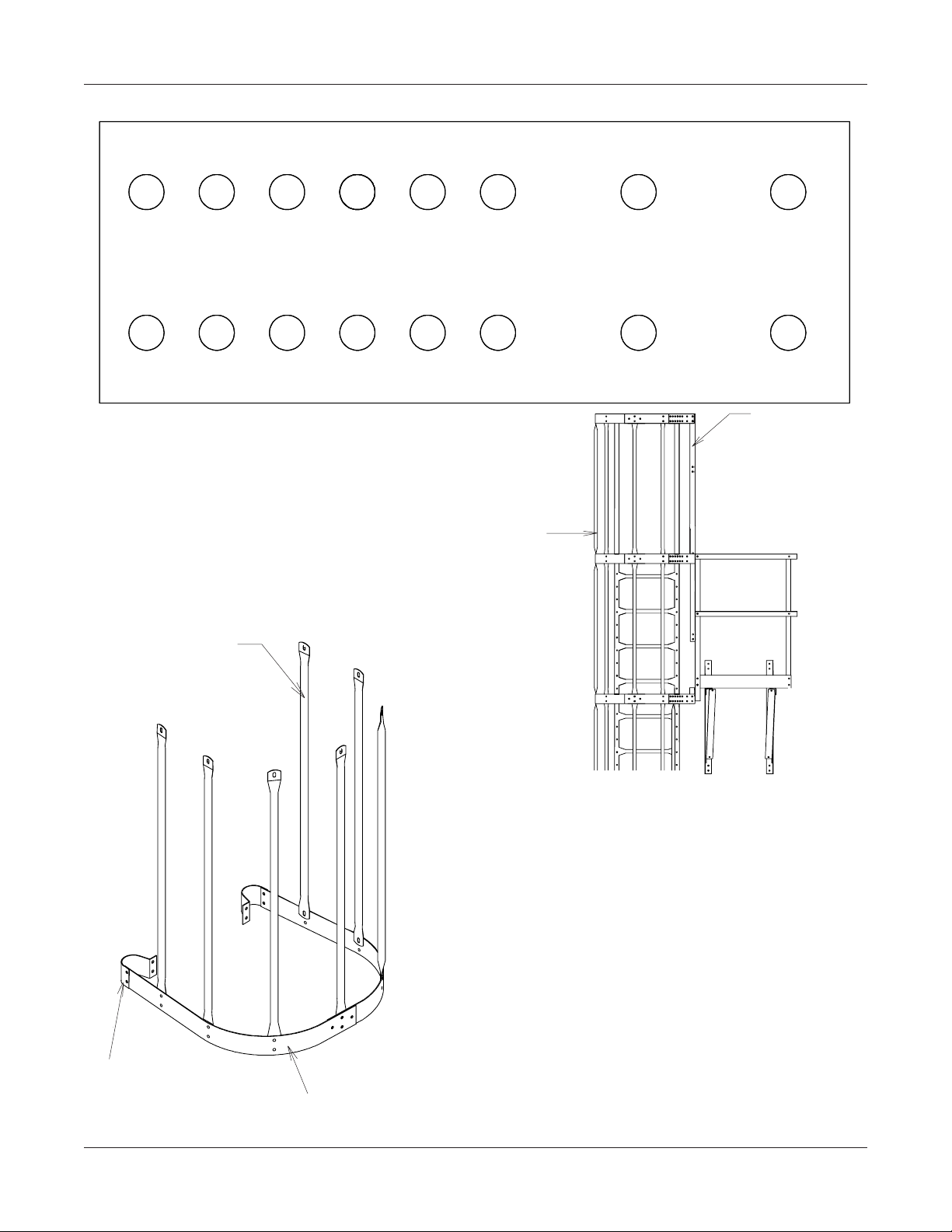

SAFETY CAGE BELL SECTIONS (22" or 44")

The safety cage bell section is to be used at the point of termination of the safety cage just

above the rest platforms or the concrete. Refer to the usage chart at the bottom of the page to

determine the correct bell section, attach the vertical supports to the existing hoop halves. Now ,

fasten the bell safety cage brackets (red) to the ladder (some field drilling may be necessary at

this point.) Attach the special bell safety cage hoop halves to the bell brackets and attach the

vertical supports to the bell hoop halves. The vertical supports will have to be bent at the flat

area to allow for the angle of the bell section.

BELL SAFETY CAGE LOCATION CHART

THE BELL SAFETY CAGE PACKAGE GOES ON THE BOTTOM OF A RUN OF SAFETY CAGE AND TERMINATES

JUST ABOVE THE CONCRETE OR PLATFORM. THE CHART GIVES THE SIZE OF BELL SECTION (22" or 44")

TO BE USED WITH THE RUN OF SAFETY CAGE STARTING AT THE TOP RING OF GRAIN BIN COMING DOWN

AND ENDING JUST ABOVE THE PLATFORMS AND/OR CONCRETE. FOLLOW THE DIAGRAMS AND THE

PROPER LETTER DESIGNATION AND REFERENCE THE CHART BELOW FOR PROPER SAFETY CAGE PLACEMENT.

ITEM

LS-5293 6 Rings

LS-5294 7 Rings

LS-5295 8 Rings

LS-5296 9 Rings

LS-5297 10 Rings

LS-5298 11 Rings

LS-5299 12 Rings

LS-5300 13 Rings

LS-5301 14 Rings

LS-5302 15 Rings

LS-5303 16 Rings

LS-5304 17 Rings

LS-5305 18 Rings

LS-5306 19 Rings

LS-5307 20 Rings

LS-5308 21 Rings

LS-5309 22 Rings

LS-5310 23 Rings

LS-5311 24 Rings

LS-5312 25 Rings

LS-5313 26 Rings

LS-5314 27 Rings

LS-5315 28 Rings

LS-5316 29 Rings

LS-5317 30 Rings

LS-5318 31 Rings

LS-5319 32 Rings

LS-6693 33 Rings

LS-6694 34 Rings

LS-6707 35 Rings

Safety Cage Bel l S i ze 44 44 22 22 44 44 22 44 44 44 44 44 22 22 22 22 22 44 44 44 44 44 44 44 44 44 44 44 44 44 44 44

Safety Cage Bell Size 22 44 22 22 22 22 44 44 44 44 22 22 22 22 22 22 22 44 44 44 22 22 22 22 22

Safety Cage Bell Size 22 22 22 44 44 44 44 44 22 22 22 22 22 22

Safety Cage Bell Size 44 44 44 44 44

LS-6708 36 Rings

22" P ACKAGE P ART NUMBER IS LS-4363LB

44" P ACKAGE P ART NUMBER IS LS-4364LB

REV. 9/13/00

18

PNEG-1096 Ladder , Safety Cage, & Platforms

LS-6709 37 Rings

Page 19

8"

18.3/4"

18.3/4"

9.3/8"

2.66 INSIDE STIFFENED

REST PLATFORM OFFSET LOCATION

Follow the diagram at the left of the page very

carefully to insure proper transition of ladder to

platform to ladder offset. Some field drilling will

be necessary at this point to locate the standoffs

correctly . P ay special attention to the dimensions

given. (Holes to be 3/8" dia.) For platform support

assembly reference the platform support

assembly detail.

DETAIL "A"

8"

INTERMEDIATE SAFETY CAGE

PLATFORM MOUNTING ANGLES

1.000"

DETAIL "A"

Follow the instructions refering to the eave safety cage package for this assembly. The only

difference will be the extension rails in the eave safety cage package. This package will have

the ladder instead.

REV. 2-15-95

PNEG-1096 Ladder , Safety Cage, & Platforms

19

Page 20

2.66 INSIDE STIFFENED

INSIDE LADDER PLACEMENT

The inside ladder package includes

the ladders and double the amount

of standoffs. Begin by positioning the

ladder directly under the manhole roof

panel and place the standoffs every 16"

vertically on the sidewall sheets using

the horizontal seam holes for every other

hole location. Us 5/16" x 3/4" bin bolts

to attach the standoffs to the sidewall of

the grain bin. Refer to the diagram on

the right.

Manway Sheet

18.3/4"

LS-121 LADDER

STANDOFFS

16" TYP.

Inside Ladder

INSIDE OF GRAIN BIN

INSIDE LADDER STANDOFFS

REQUIREMENTS

Field drilling will be necessary for the standoffs

located in the middle of the sidewall sheet. Drill

2 holes 3/8" diameter directly in line with the

horizontal seam holes 18 3/4" apart. Continue

down the sidewall with standoffs at every 16"

spacing. Refer to the diagrams at the left.

20

REV. 5-25-95

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 21

2.66 INSIDE STIFFENED

INSIDE LADDER SUPPORTS

After completing the inside ladder it will be necessary to support the bottom of the ladder

to the concrete. Depending on the actual installation, the amount of support may vary . The

supports are not supplied by the manufacturer . Usually the supports can be made of 1" x 1" x 1/

8" angle iron bolted directly to the ladder using 2 bolts 5/16" x 1". If a bin sweep is to be used in

the grain bin, other considerations may be necessary to assure there is no

interference with the equipment.

SUPPORTS ARE NOT SUPPLIED BY GSI

SUPPORTS ARE NOT SUPPLIED

BY GRAIN SYSTEMS, INC.

PNEG-1096 Ladder , Safety Cage, & Platforms

21

Page 22

2.66 OUTSIDE STIFFENED

THIS SECTION

FOR 2.66"

CORRUGATED

GRAIN BINS

OUTSIDE STIFFENED

22

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 23

2.66 OUTSIDE STIFFENED

LADDER SAFETY CAGE, AND PLATFORM INSTRUCTIONS

All packages have been structured with the correct components for each ring height

grain bin from 25'-6" Eave to 98'-7" Eave. Be sure and follow the complete instruction sheets

for correct placement of parts. Failure to do so may result in improper fit of parts or shortage

of parts. Read through the complete set of instructions before proceeding with erection of grain

bin. Considerable thought must be given as to location of ladders and platforms in relation to

other equipment and structures.

STARTING LOCATION OF LADDERS

Ladder placement is very critical as to assure proper fit of all parts later on as safety cage is

bolted in place. Locate the proper place of roof ladder and manway this will establish the

location of the ladder . Ladder must be centered directly below the roof ladder. Refer to the

diagram below for proper location of field drilled holes (3/8"). Holes must be 18 3/4" apart and

8" below the top horizontal row of holes directly in line with the holes pre-punched in the

horizontal seam for the first 2 ladder standoff brackets. The diagrams also show that the

platform uses stiffener holes. Both platform vertical support angles must be located in the

stiffener holes on 2-post tanks and 1 vertical support angles in stiffener holes on 3-post tanks,

as shown in details. These dimensions and locations are very critical to assure proper fit of all

parts.

2-POST

ROOF LADDER

FIELD DRILL

3/8" HOLES (2)

18.3/4"

MANWAY PANEL

TDP-5008N

FLOURS.

GREEN/BLACK

REV. 9/20/00

PNEG-1096 Ladder , Safety Cage, & Platforms

23

Page 24

2.66 OUTSIDE STIFFENED

ROOF LADDER

MANWAY SHEET

FIELD DRILL

3/8" HOLES

8"

Outside Standoff

LS-121

Roof Sheet

6.1/4"

8"

18.3/4"

56.1/4"

4"

FIELD DRILL

3/8" HOLES

LADDER PLACEMENT

Ladder placement on the grain bin is very important at this time. Refer to the diagram at the

left and follow the correct dimensions as shown.

Ladder standoff must be located 8" below the

horizontal seam. Check your ladder to make sure

the ladder rung dimples are to the top surface.

Attach ladder to the standoffs using the holes

located 6 1/4" from the end of ladder section.

Use 5/16" x 3/4" bin bolts for these connections.

Now all standoffs must be located in horizontal

seam holes (repeating every 32") until reaching

the first rest platform. Refer to the section in these

instructions that references the location of intermediate rest platforms for further hole locations.

24

Ladder Section

LDR-4002

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 25

2.66 OUTSIDE STIFFENED

3 - POST / 4 -PANEL PER SIDEWALL SHEET

Roof Sheet

8"

Outside Standoff

LS-121

PNEG-1096 Ladder , Safety Cage, & Platforms

LADDER PLACEMENT

Ladder placement on the grain bin is very important at this time. Refer to the diagram at the

left and follow the correct dimensions as shown.

Ladder standoff must be located 8" below the

horizontal seam. Check your ladder to make sure

6.1/4"

the ladder rung dimples are to the top surface.

Attach ladder to the standoffs using the holes

located 6 1/4" from the end of ladder section.

Use 5/16" x 3/4" bin bolts for these connections.

8"

Now all standoffs must be located in horizontal

seam holes (repeating every 32") until reaching

the first rest platform. Refer to the section in these

instructions that references the location of intermediate rest platforms for further hole locations.

Ladder Section

LDR-4002

25

Page 26

2.66 OUTSIDE STIFFENED

FIELD DRILL 5/16'' HOLES

(4) PER BRACE

1

2

3

4

5

REF. NO. DESCRIPTION PART NO.

Note: Reference previous page for the

first ladder standoff starting location.

6

1 END TUBE LS-6616

2 CENTER TUBE LS-6615

3 SAFETY CAGE BRACKET LS-4349

4 SAFETY CAGE EXT. RAIL LS-4355

5 LADDER SECTION LDR-4002

6 OUTSIDE STANDOFF LS-121

LS-6696

EXTENSION RAILS

Extension rails are provided to extend the side rails of the ladder above the eave of

the roof and to support the safety cage at that point. T wo rails have been provided, one for each

side of the ladder . Refer to diagram above for proper location and assembly of the extension

rails in relation to the ladder . Use 5/16" x 3/4" bolts and nuts to attach the ladder. Tighten the

bolts at this time.

EAVE ADJUSTABLE BRACES

After extension rails are firmly attached, the adjustable braces must be attached at this

time. A larger diameter tube and two smaller diameter tubes are used to make up one adjustable brace. Slip the smaller tubes inside the larger tube and attach one smaller tube to the top

of the extension rail. Adjust the other smaller tube so the bottom of the flattened tube reaches

the roof rib. Field drill four 5/16" holes through both large and small adjustable tubes and bolt

together using 1/4" x 1.1/2" bolts and nuts. This will keep the adjustable brace from slipping.

Attach the safety cage brackets to the extension rail and ladder as shown in the diagram.

Brackets must be placed every 44". This will occur at every ladder joint. Use 5/16" x 3/4" bolts

and nuts.

REV. 9/21/01

26

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 27

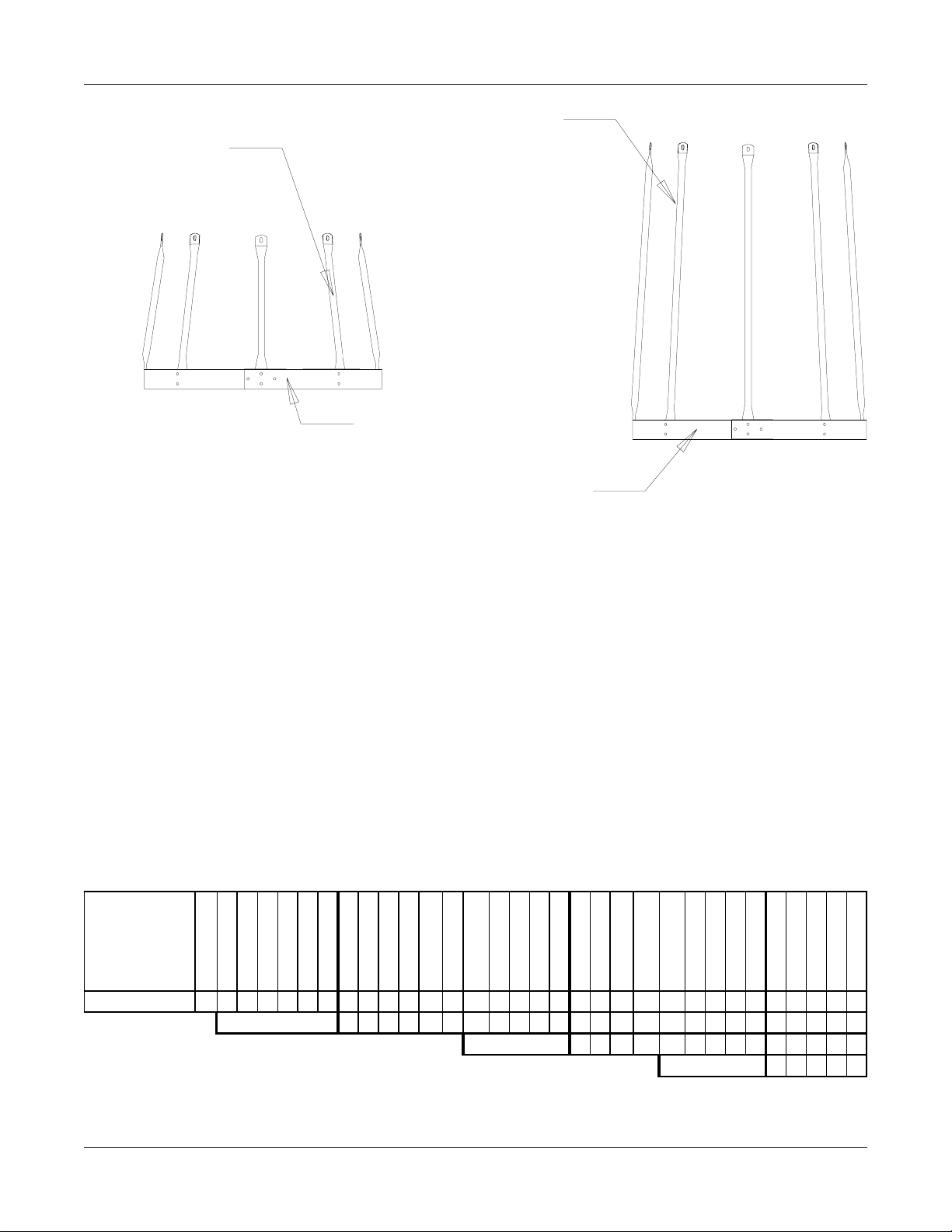

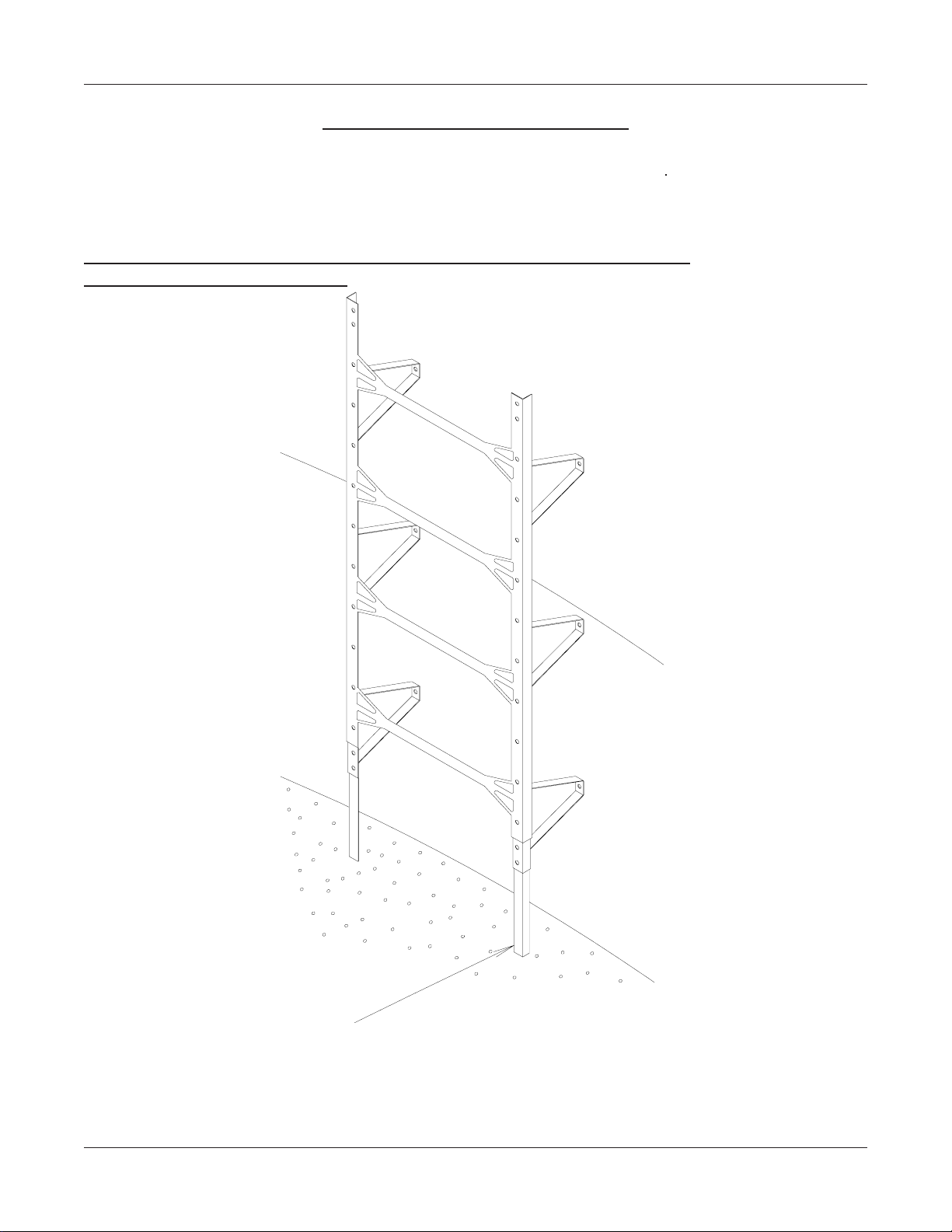

PLATFORM ASSEMBLY

2.66 OUTSIDE STIFFENED

NOTE: THE PLATFORM SUPPORTS SHOULD BE

MOUNTED ON THE BIN FIRST . THE PLA TFORM FLOOR

SHOULD THEN BE ASSEMBLED ONTO THE SUPPORT

FRAME. LEAVE PLATFORM SUPPORT TO FL OOR

BRACE BOL TS LOOSE UNTIL FLOOR AND TOEPLA TES

ARE SECURE.

LS-6621 (PINK) VERTICAL

ENTRANCE ANGLE (46'')

LS-6702 (RED)

HANDRAIL (58'')

TDP-5011 PLATFORM

TOE PLATE

TDP-5002 (PINK/BLACK)

HANDRAIL (30'')

Assemble the platform support frame

using 5/16" x 3/4" truss head bolts

and nuts. When attaching vertical

supports to stiffeners or sidewall,

locate the vertical supports according

to the instructions on previous pages.

Now, proceed to the platform floor and

handrails. Align holes on platform

floor with the holes on platform supports and bolt together using 5/16" x

3/4" truss head bolts and nuts. Be

sure and attach platform toe plates at

the same time you attach the platform

floor. Vertical entrance angle will bolt

to platform floor , toeplate and platform

support. Handrail post bolts to platform floor and toeplate as shown.

NOTE: On 18' and smaller 3 post

tanks, move platform support angles

and diagonal support angles away

from wall and field drill vertical

support angle to allow stiffener

clearance.

LS-6703

PLATFORM FLOOR

LS-6698

PLATFORM SUPPORT

LS-6699 (BROWN) LEFT HAND

DIAGONAL SUPPORT ANGLE

TDP-5008N(FL.GREEN/BLACK)

VERTICAL SUPPORT ANGLE

TDP-5011 PLATFORM

TOE PLATE

LS-371 (YELLOW)

HANDRAIL POST (2)

USE UPPER HOLE IN DIAGONAL BRACE WHEN

CONNECTING TO PLATFORM SUPPORT

LS-6700 (BLUE) RIGHT HAND

DIAGONAL SUPPORT ANGLE

(SEE DETAIL)

LS-6701 (ORANGE)

FLOOR BRACE

UPPER HOLE

BRACE DETAIL

REV. 10/3/01

PNEG-1096 Ladder , Safety Cage, & Platforms

27

Page 28

2.66 OUTSIDE STIFFENED

EAVE SAFETY CAGE

Before attaching any pieces to the ladder or platform, some preassembly will be required. Take the safety cage hoop adjuster plates and bolt them onto the extension angle as

shown. Bolt the safety cage adapter hoops and safety cage hoop halves together using the

proper holes, as shown. Be sure to use the 5/16" x 3/4" bolt with the head of the bolt to the

inside of the safety cage. Y ou may now bolt these assemblies to the safety cage brackets and

hoop adjuster plates, tighten bolts as you go. One of the assemblies will take 2 hoop halves

and be positioned just below the platform as shown in the diagram.

44'' TYP.

BOTTOM TO BOTTOM

LS-6696 (GREEN)

EXTENSION RAIL

LS-4351 SAFETY CAGE

HOOP HALF

LS-5284 SAFETY CAGE

HOOP ADAPTERS

LS-5285 SAFETY CAGE

HOOP ADJUSTER PLATE

LS-6697 (FL. GREEN)

EXTENSION ANGLES

LS-6622 SAFETY CAGE

HOOP ADJUSTER ANGLE

28

PLATFORM ASSEMBLY

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 29

VERTICAL SUPPORTS

2.66 OUTSIDE STIFFENED

LS-5286 (FL. GREEN)

LS-6697

SAFETY CAGE PLATFORM

EXTENSION ANGLE

After all three hoop assemblies are in place you

may attach the 44" vertical supports from hoop

assembly to hoop assembly , as shown. This will

require 14 supports, 7 between each set of hoops.

Bolts should have the head of the bolt to the inside

of the safety cage.

SAFETY CAGE

Attach the vertical support pieces to the existing

hoop halves above using the 5/16" x 3/4" bolts

and nuts (with the heads on the inside of the cage).

Fasten two hoop halves together and to the safety

cage brackets. Bolt the safety cage brackets to the

ladder , the supports to the hoop halves and tighten

bolts. Continue in the same manner .

LS-4353 SAFETY CAGE

44" VERTICAL SUPPORT

LS-4349 SAFETY CAGE

STANDARD BRACKET

LS-4353 SAFETY CAGE

44" VERTICAL SUPPORT

Whereas you formerly had all extension packages

bundled and listed under the LS-4365LB part number

you will now have a combination of LS-4366LB

(A package of two (2) extension kits) and LS-4365LB

(The original single extension kit).

44" SAFETY CAGE BELL SECTION

The safety cage bell section is to be used at the

point of termination of the safety cage just above

the concrete or platform (generally 7 to 8 feet).

Attach the vertical supports to the existing hoop

halves. Attach the special bell safety cage hoop

halves to the brackets and attach to the vertical

supports. Fasten the safety cage brackets to the

ladder (some field drilling may be required).

Tighten all bolts at this time. The vertical supports

will have to be bent at the flat area to allow for the

angle of bell section.

REV. 9/25/01

PNEG-1096 Ladder , Safety Cage, & Platforms

LS-4351 SAFETY CAGE

HOOP HALF

LS-4353 SAFETY CAGE

44" VERTICAL SUPPORT

LS-4352 SAFETY CAGE

BELL HOOP HALF

29

Page 30

30

2.66" OUTSIDE STIFFENED LADDER

2.66 OUTSIDE STIFFENED

OFFSET AND PLATFORM LAYOUT

PNEG-1096 Ladder , Safety Cage, & Platforms

A

2nd

A

B

2nd

13th

A

B

C

2nd

12th

22nd

A

B

C

2nd

10th

19th

D

12 RINGS 23 RINGS 32 RINGS 34 RINGS

27th

Page 31

PNEG-1096 Ladder, Safety Cage, & Platforms

ITEM

LSO-25-06

25'-6" EAVE

LSO-29-02

29'-2" EAVE

LSO-32-10

12 RINGS

32'-10" EAVE

LSO-36-06

13 RINGS

36'-6" EAVE

LSO-40-02

15 RINGS

40'-2" EAVE

LSO-43-10

16 RINGS

43'-10" EAVE

LSO-47-06

47'-6" EAVE

LSO-51-02

19 RINGS

51'-2" EAVE

LSO-54-10

20 RINGS

54'-10" EAVE

LSO-58-06

22 RINGS

58'-6" EAVE

LSO-62-02

23 RINGS

62'-2" EAVE

LSO-65-10

Ladder Section

(LDR-4002) 7855667788 9 6777787777

Bell Safety Cage

(LS-4364LB) 1111111111 1 1111111111

Safety Cage

A

Extension 34112233445 233334333 3

Platf orm Pkg.

(LS-6618) 1111111111 1 1111111111

Eave Sfty. Cage

(LS-6619) 1111111111 1 1111111111

Ladder Section

(LDR-4002) 56677889107778888888

Bell Safety Cage

(LS-4364LB) 11111111 1 1111111111

Safety Cage

B

Extension 12233445 5 3334443333

Pl a tf or m Pkg.

(LS-6618) 11111111 1 1111111111

In t. Sfty. Cage

(LS-6620) 11111111 1 1111111111

Ladder Section

(LDR-4002) 778899888 8

Bell Safety Cage

C

(LS-4364LB) 1111111111

Safety Cage

Extension 334455333 3

Platf orm Pkg.

(LS-6618) 1111111111

Int. Sft y. Cage

(LS-6620) 1111111111

24 RINGS

2.66" OUTSIDE STIFFENED

LADDER OFFSET CHART

LADDER, SAFETY CAGE, AND PLATFORM USAGE LOCATION CHART

THE CHART ABOVE SHOULD BE IN CONJUNCTION WITH THE DIAGRAMS ON THE PREVIOUS PAGE. FOLLOW THE PROPER LETTER

DESIGNATION FROM THE DIAGRAM TO THE CHART FINDING THE PROPER RING GRAIN BIN AND USE THE AMOUNTS OF LADDERS

31

AND SAFETY CAGES SHOWN IN CHART BELOW. FOR 44" SAFETY CAGE BELL SECTION SEE FOLLOWING PAGE.

65'-10" EAVE

LSO-69-06

26 RINGS

D

69'-6" EAVE

LSO-73-02

27 RINGS

73'-2" EAVE

LSO-76-10

29 RINGS

76'-10" EAVE

LSO-80-06

30 RINGS

80'-6" EAVE

LSO-84-02

32 RINGS

84'-2" EAVE

LSO-87-10

33 RINGS

87'-10" EAVE

Ladder Section

(LDR-4002) 7 8 9 10

Bell Safety Cage

(LS-4364LB) 1 1 1 1

Safety Cage

Extens ion 2 3 4 5

Platfor m Pkg.

(LS-6618) 1 1 1 1

In t. Sfty. Cage

(LS-6620) 1 1 1 1

LSO-91-03

34 RINGS

91'-3" EAVE

LSO-94-11

35 RINGS

94'-11" EAVE

LSO-98-07

36 RINGS

98'-7" EAVE

2.66 OUTSIDE STIFFENED

Page 32

2.66 OUTSIDE STIFFENED

SAFETY CAGE BELL SECTIONS

The safety cage bell section is to be used at the point of termination of the safety cage just

above the rest platforms or the concrete. Fasten the bell safety cage brackets (red) to the ladder

(some field drilling may be necessary at this point.) Attach the special bell safety cage hoop

halves to the bell brackets and attach the vertical supports to the bell hoop halves. The vertical

supports will have to be bent at the flat area to allow for the angle of the bell section.

LS-4353 Safety Cage

44" Vertical Support

LS-4352 Safety Cage

Bell Hoop Half (Red)

THE BELL SAFETY CAGE PACKAGE GOES ON THE BOTTOM OF A RUN OF SAFETY CAGE AND TERMINATES

JUST ABOVE THE CONCRETE OR PLATFORM.

REV. 3/25/01

32

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 33

INSIDE LADDER

2.66 OUTSIDE STIFFENED

MANWAY SHEET

INSIDE LADDER PLACEMENT

The inside ladder package includes the ladder

and double the amount of standoffs as the

outside ladder package. Begin by positioning

the ladder directly under the manhole roof

panel and place the standoffs every 16" vertically on the sidewall sheets using the horizontal seam holes for every other hole location.

Use 5/16" x 3/4" bin bolts to attach the standoffs

to the sidewall of the grain bin. Refer to the

diagrams to the left and below .

INSIDE OF GRAIN BIN

INSIDE LADDER STANDOFF

REQUIREMENTS

Field drilling will be necessary for the

standoffs located in the middle of the

sidewall sheet. Drill 2 holes 3/8" diameter

directly in line with the horizontal seam

holes 18.3/4" apart. Continue down the

sidewall with standoffs at every 16"

spacing. Refer to the diagram.

LS-121 LADDER

STANDOFFS

18.3/4"

16" TYP.

(See note concerning

Commercial Hopper T anks)

REV. 9/20/00

PNEG-1096 Ladder , Safety Cage, & Platforms

33

Page 34

2.66 OUTSIDE STIFFENED

INSIDE LADDER SUPPORTS

After completing the inside ladder it will be necessary to support the bottom of the ladder

to the concrete. Depending on the actual installation, the amount of support may vary . The

supports are not supplied by the manufacturer . Usually the supports can be made of 1" x 1" x 1/

8" angle iron bolted directly to the ladder using 2 bolts 5/16" x 1". If a bin sweep is to be used in

the grain bin, other considerations may be necessary to assure there is no interference with the

equipment.

34

SUPPORTS ARE NOT SUPPLIED BY GSI

SUPPORTS ARE NOT SUPPLIED

BY GRAIN SYSTEMS, INC.

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 35

4.00 INSIDE STIFFENED

THIS SECTION

FOR 4.00"

CORRUGATED

GRAIN BINS

INSIDE STIFFENED

PNEG-1096 Ladder , Safety Cage, & Platforms

35

Page 36

4.00 INSIDE STIFFENED

LADDER SAFETY CAGE, AND PLATFORM INSTRUCTIONS

All packages have been structured with the correct components for each ring height

grain bin from 4 rings to 24 rings. Be sure and follow the complete instruction sheets for

correct placement of parts. Failure to do so may result in improper fit of parts or shortage of

parts. Read through the complete set of instructions before proceeding with erection of grain

bin. Considerable thought must be given as to location of ladders and platforms in relation to

other equipment and structures.

STARTING LOCATION OF LADDERS

Ladder placement is very critical as to assure proper fit of all parts later on as safety

cage is bolted in place. Locate the proper place for the roof ladder and manway this will

establish the location of the ladder . Ladder must be centered directly below the roof ladder .

Refer to the diagram below for proper location of field drilled holes (3/8"). Holes must be

18 3/4" apart and 8" below the top horizontal row of holes directly in line with the holes to be

used for the platform mounting angle. Platform must be located 9 3/8" to the right of the ladder

holes. All of these dimensions are very critical to assure proper fit of all parts!

FIELD DRILL

3/8" HOLES (2)

18.3/4"

12"

ROOF LADDER

18.3/4"

9.3/8"

MANWAY PANEL

HOLES FOR PLATFORM

36

REV. 9/18/00

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 37

4.00 INSIDE STIFFENED

8"

Outside

Standoffs

LS-121

Roof Sheet

18 3/4''

6.1/4"

8"

Ladder Section

LDR-4002

LADDER PLACEMENT

Ladder placement on the grain bin is very

important at this time. Refer to the diagram at

the left and follow the correct dimensions as

shown. Ladder standoff must be located 8"

below the horizontal seam. Check your ladder

to make sure the ladder rung dimples are to

the top surface. Attach ladder to the standoffs

using the holes located 6 1/4" from the end of

ladder section. Use 5/16" x 3/4" bin bolts for

these connections. Now all standoffs must be

located in horizontal seam holes (repeating

every 44") until reaching the first rest platform.

Refer to the section in these instructions that

references the location of intermediate rest

platforms for further hole locations.

PLATFORM SUPPORT ASSEMBLY

LS-6705

Mounting

Horizontal Seam

PNEG-1096 Ladder , Safety Cage, & Platforms

Angle 35"

When starting the platform support, you

must attach the mounting angle to the

sidewall of the grain bin. Refer back to the

first page for the correct holes to be used

by the platform. Attach the angle using

5/16" x 3/4" bolts and nuts, tighten at this

time. Next, bolt the support angle to the

mounting angle again using the proper

holes. Attach the brace angle to the

mounting angle as shown in the diagram

at left. Use 5/16" x 3/4" bolts and nuts for

all connections.

LS-369

Brace Angle

30-3/4"

LS-370

Support Angle

30.3/4"

REV.10/9/01

37

Page 38

4.00 INSIDE STIFFENED

FIELD DRILL 5/16'' HOLES

(4) PER BRACE

3

4

5

1

2

6

REF. NO. DESCRIPTION PART NO.

1 END TUBE LS-6616

Note: Reference previous page for the

first ladder standoff starting location.

2 CENTER TUBE LS-6615

3 SAFETY CAGE BRACKET LS-4349

4 SAFETY CAGE EXT. RAIL LS-4355

5 LADDER SECTION LDR-4002

6 OUTSIDE STANDOFF LS-121

LS-6696

EXTENSION RAILS

Extension rails are provided to extend the side rails of the ladder above the eave of

the roof and to support the safety cage at that point. T wo rails have been provided, one for each

side of the ladder . Refer to diagram above for proper location and assembly of the extension

rails in relation to the ladder . Use 5/16" x 3/4" bolts and nuts to attach the ladder. Tighten the

bolts at this time.

EAVE ADJUSTABLE BRACES

After extension rails are firmly attached, the adjustable braces must be attached at this

time. A larger diameter tube and two smaller diameter tubes are used to make up one

adjustable brace. Slip the smaller tubes inside the larger tube and attach one smaller tube to

the top of the extension rail. Adjust the other smaller tube so the bottom of the flattened tube

reaches the roof rib. Field drill four 5/16" holes through both large and small adjustable tubes

and bolt together using 1/4" x 1.1/2" bolts and nuts. This will keep the adjustable brace from

slipping.

Attach the safety cage brackets to the extension rail and ladder as shown in the

diagram. Brackets must be placed every 44". This will occur at every ladder joint. Use 5/16" x

3/4" bolts and nuts.

REV. 9/25/01

38

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 39

LS-6697

Safety Cage Platform

Extension Angles

(Flours. Green)

LS-373

Platform

LS-5283

SafetyCage Hoop

Adapter Angle

41" (T yp.)

REV.9/25/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Extension Rails or Ladder

(Ladder to be used on

Intermediate Platform)

LS-5284 Safety Cage

Adapter Hoop

LS-4351 Safety Cage

Hoof Half

LS-294

Front Handrail

24.3/8" (White)

LS-295

Front Handrail

31.7/8" (Black)

LS-371

Platform Vertical

Angle 42" (Y ellow)

LS-372

Vert. Entrance Angle

46" (Orange)

Extension Angle

Platform

LS-5285 Safety

Cage Hoop

Adjuster Plate

4.00 INSIDE STIFFENED

EXTENSION ANGLE DETAIL

PLATFORM AND HANDRAIL

ASSEMBLY

Start by attaching the platform itself to the

platform support using 5/16" x 3/4" bolts and

nuts. Place all the vertical angles in place,

making sure to place the vertical entrance

angle to the left front corner of the platform.

After all vertical angles are in place attach

front and side handrails as shown in the diagram. Use 5/16" x 3/4" bolts and nuts in all

connections.

Safety cage platform extension angles and

safety cage hoop adapter angle will be with

the eave safety cage package. These can

now be attached to the vertical entrance

angle. Refer to the diagram at the left.

EAVE SAFETY CAGE &

INTERMEDIATE REST PLATFORM

Before attaching any pieces to the ladder or

platform some preassembly will be required.

T ake the safety cage hoop adjuster plate and

the safety cage adapter hoop and bolt together using the proper holes, (as shown on

following page.) Be sure the proper holes are

used depending on the diameter of the grain

bin. Be sure to use the 5/16" x 3/4" bolt with

the head of the bolt to the inside of the safety

cage. Using the improper holes will make the

safety cage more difficult to assemble. You

may now bolt this assembly to the safety

cage hoop half, tighten bolts as you go. One

of the assemblies will take 2 hoop halves and

be positioned just below the platform as

shown in the diagram. T ake the assembly and

attach to the safety cage bracket and to the

platform extension angle or the hoop adapter

angle. Refer to the diagram for more information. If holes don't align properly go back

and make sure the ladder and platform are

correctly positioned on grain bin in relationship to one another. Make any corrections

necessary to complete the assembly as

shown.

39

Page 40

4.00 INSIDE STIFFENED

WHEN ATTACHING SAFETY CAGE TO PLATFORM, THE HOOP ADJUSTER PLATE MUST BE USED

TO COMPENSATE FOR THE DIFFERENT BIN CURVATURES. NOTE: (THIS PLATE IS NOT NEEDED

FOR 90' & 105' DIAMETER BINS.) BOLT THE PROPER END TO THE EXTENSION ANGLE OR ADAPTER

HOLE. NOW LOCATE PROPER HOLES IN HOOP ADJUSTER PLATE AND BOLT TO THE SAFETY CAGE

ADAPTER HOOP.

30'-33'

27'

36'-42'

48'

60'

75'-78'

72'

EAVE SAFETY CAGE

After all three hoop assemblies are in place

you may attach the 44" vertical supports from

hoop to hoop. This will require 10 supports, 5

between each set of hoops. Again use the truss

head bolts with bolt head to the inside of safety

cage.

LS-4353 Safety Cage

44" Vertical Support

LS-4353 Safety Cage

44" Vertical Support

BOLT TO

EXTENSION

ANGLE OR

ADAPTER

ANGLE

LS-6697 Safety

Cage Platform

Extension Angle

LS-4349

Safety Cage Standard

Bracket

40

LS-4351

Safety Cage

Hoop Half

SAFETY CAGE EXTENSION

The safety cage extension package is designed to be

added on to the bottom of the existing safety cage above

it. Attach the vertical support pieces to the existing hoop

halves above using the 5/16" x 3/4" bolt and nuts. Fasten the package to the safety cage brackets and attach

the bottom of the vertical supports to the hoop halves

and tighen bolts. Continue to use the extension packages as the usage chart reflect on the following page.

Whereas you formerly had all extension packages

bundled and listed under the LS-4365LB part number you

will now have a combination of LS-4366LB (A package

of two (2) extension kits) and LS-4365LB (The original

single extension kit).

REV. 9/25/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 41

PNEG-1096 Ladder , Safety Cage, & Platforms

4.00" INSIDE STIFFENED LADDER

OFFSET AND PLATFORM LAYOUT

A

2nd

A

2nd

10th

A

B

C

2nd

9th

17thB

4.00 INSIDE STIFFENED

41

9 RINGS 17 RINGS

24 RINGS

Page 42

42

PNEG-1096 Ladder , Safety Cage, & Platforms

ITEM

LDR-4019 4 RINGS

Platform Located in Ring

Ladder Section

A

(LDR-4002)

Bell Safety Cage

(LS-4364LB)

Safety Cage Extension

Platform Package

Eave Safety Cage

(LS-5289)

B

LDR-4020 5 RINGS

1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2 1-2

456789667788996778899

111111111111111111111

-12345223344552334455

111111111111111111111

111111111111111111111

Platform Located in Ring

Ladder Section

(LDR-4002)

Bell Safety Cage

(LS-4364LB)

Safety Cage Extension

Platform Package

Int. Safety Cage

(LS-5290)

4.00" INSIDE STIFFENED

LADDER OFFSET CHART

LDR-4021 6 RINGS

LDR-4022 7 RINGS

LDR-4023 8 RINGS

LDR-4024 9 RINGS

6-7 6-7 7-8 7-8 8-9 8-9 9-10 9-10 6-7 7-8 7-8 8-9 8-9 9-10 9-10

LDR-4025 10 RINGS

LDR-4026 11 RINGS

LDR-4027 12 RINGS

LDR-4028 13 RINGS

LDR-4029 14 RINGS

LDR-4030 15 RINGS

LDR-4031 16 RINGS

LDR-4032 17 RINGS

LDR-4033 18 RINGS

LDR-4034 19 RINGS

LDR-4035 20 RINGS

LDR-4036 21 RINGS

LDR-4037 22 RINGS

LDR-4038 23 RINGS

LDR-4039 24 RINGS

6778899 10889999 10

111111111111111

-12345223344552

111111111111111

111111111111111

Platform Located in Ring

Ladder Section

(LDR-4002)

Bell Safety Cage

(LS-4364LB)

C

Safety Cage Extension

Platform Package

Int. Safety Cage

(LS-5290)

12-13 13-1414-1515-16 15-16 16-17 17-18

8888999

1111111

3333444

1111111

1111111

4.00 INSIDE STIFFENED

LADDER, SAFETY CAGE, AND PLATFORM USAGE LOCATION CHART

THE CHART ABOVE SHOULD BE IN CONJUNCTION WITH THE DIAGRAMS ON THE PREVIOUS PAGE. FOLLOW THE PROPER

LETTER DESIGNATION FROM THE DIAGRAM TO THE CHART FINDING THE PROPER RING GRAIN BIN AND USE THE AMOUNTS

OF LADDERS AND SAFETY CAGES SHOWN IN CHART.

Page 43

SAFETY CAGE BELL SECTIONS

LS-4353 Safety Cage

44" Vertical Support

4.00 INSIDE STIFFENED

LS-4352 Safety Cage Bell Hoop Half (Red)

SAFETY CAGE BELL SECTIONS

The safety cage bell section is to be used at the point of termination of the safety cage just

above the rest platforms or the concrete. Attach the vertical supports to the existing hoop

halves. Now , fasten the bell safety cage brackets (red) to the ladder (some field drilling may be

necessary at this point.) Attach the special bell safety cage hoop halves to the bell brackets

and attach the vertical supports to the bell hoop halves. The vertical supports will have to be

bent at the flat area to allow for the angle of the bell section.

REV. 10-16-95

PNEG-1096 Ladder , Safety Cage, & Platforms

43

Page 44

4.00 INSIDE STIFFENED

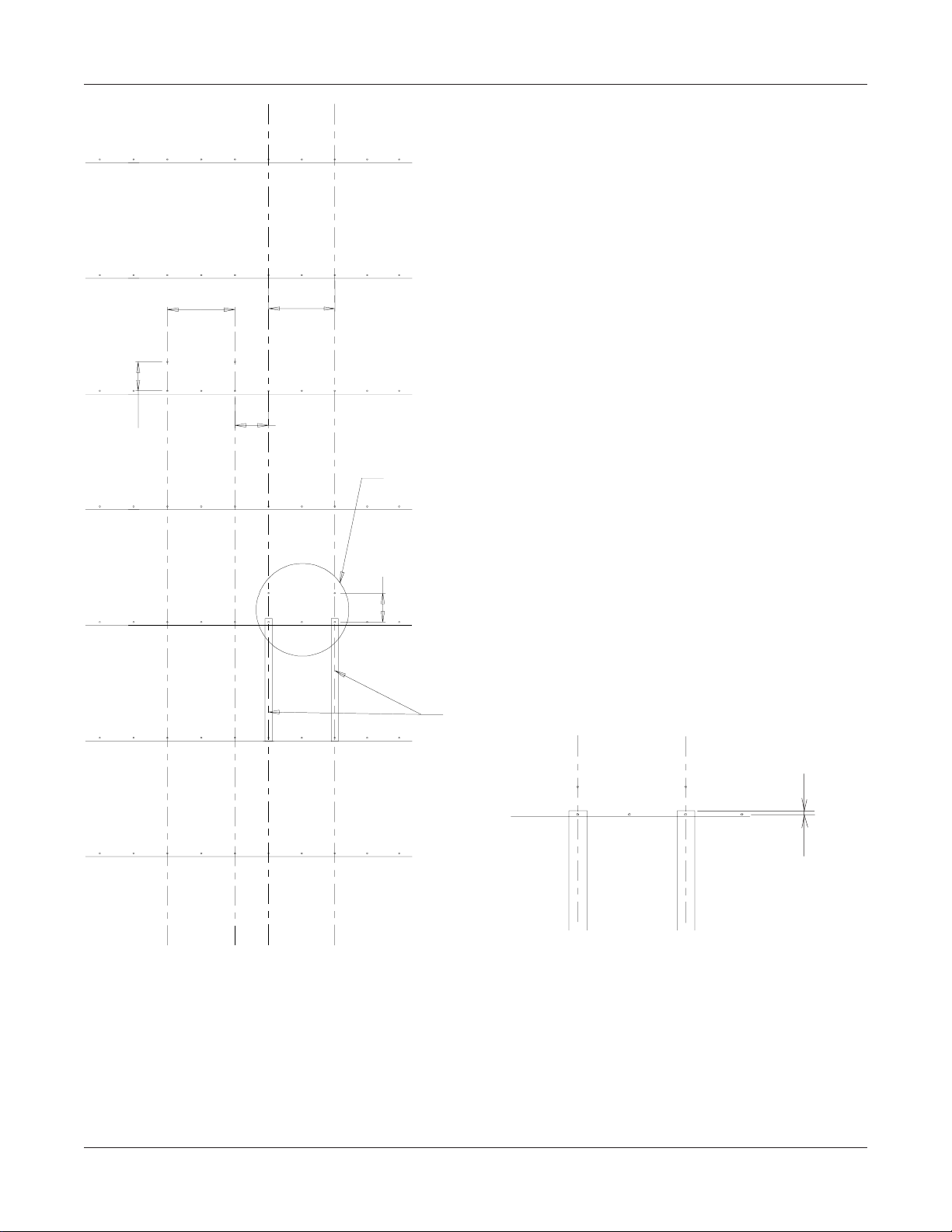

REST PLATFORM OFFSET LOCATION

12"

18.3/4"

18.3/4"

9.3/8"

Follow the diagram at the left of the page very

carefully to insure proper transition of ladder to

platform to ladder offset. Some field drilling will

be necessary at this point to locate the standoffs

correctly . P ay special attention to the dimensions

given. (Holes to be 3/8" dia.)

DETAIL "B"

12"

PLATFORM MOUNTING ANGLES

13.000"

12.000"

DETAIL "B"

INTERMEDIATE SAFETY CAGE

Follow the instructions refering to the eave safety cage package for this assembly. The only

difference will be the extension rails in the eave safety cage package. This package will have

the ladder instead.

REV. 11-15-94

44

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 45

INSIDE LADDER PLACEMENT

The inside ladder package includes the ladders and double the amount of standoffs.

Begin by positioning the ladder directly under the manhole roof panel and place the

standoffs every 22" vertically on the sidewall

sheets using the horizontal seam holes for

every other hole location. Us 5/16" x 3/4" bin

bolts to attach the standoffs to the sidewall

of the grain bin. Refer to the diagram on the

right.

4.00 INSIDE STIFFENED

Manway Sheet

18.3/4"

Inside Ladder

INSIDE OF GRAIN BIN

LS-121 LADDER

STANDOFFS

22" TYP.

INSIDE LADDER STANDOFFS REQUIREMENTS

Field drilling will be necessary for the standoffs located in

the middle of the sidewall sheet. Drill 2 holes 3/8" diameter

directly in line with the horizontal seam holes 18 3/4" apart.

Continue down the sidewall with standoffs at every 22"

spacing. Refer to the diagrams at the left.

REV. 5-25-95

PNEG-1096 Ladder , Safety Cage, & Platforms

45

Page 46

4.00 INSIDE STIFFENED

INSIDE LADDER SUPPORTS

After completing the inside ladder it will be necessary to support the bottom of the ladder

to the concrete. Depending on the actual installation, the amount of support may vary . The

supports are not supplied by the manufacturer . Usually the supports can be made of 1" x 1" x 1/

8" angle iron bolted directly to the ladder using 2 bolts 5/16" x 1". If a bin sweep is to be used in

the grain bin, other considerations may be necessary to assure there is no

interference with the equipment.

SUPPORTS ARE NOT SUPPLIED BY GSI

SUPPORTS ARE NOT SUPPLIED

BY GRAIN SYSTEMS, INC.

46

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 47

4.00 OUTSIDE STIFFENED

THIS SECTION

FOR 4.00"

CORRUGATED

GRAIN BINS

OUTSIDE STIFFENED

PNEG-1096 Ladder , Safety Cage, & Platforms

47

Page 48

4.00 OUTSIDE STIFFENED

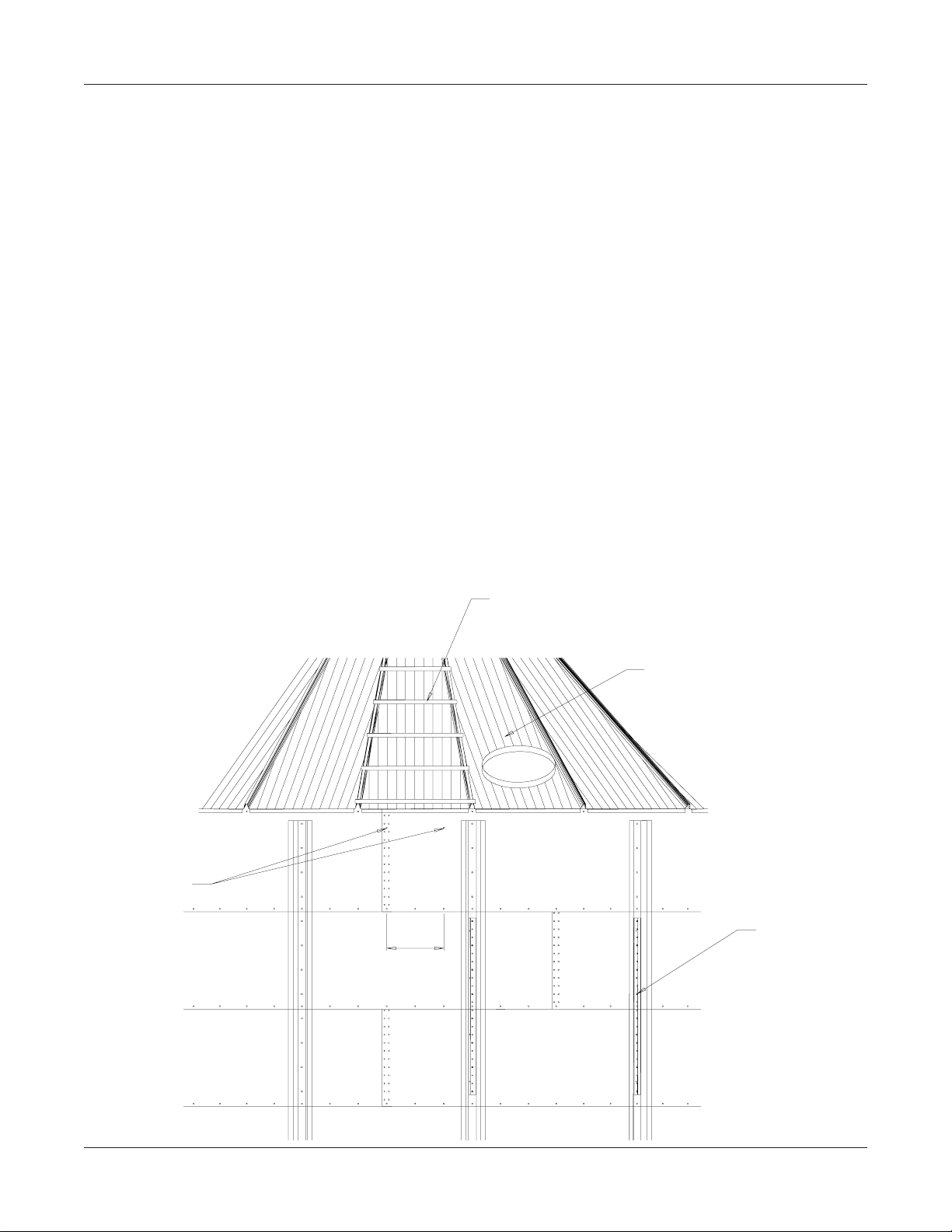

LADDER SAFETY CAGE, AND PLATFORM INSTRUCTIONS

4 - 9 RINGS ONLY

All packages have been structured with the correct components for each ring height

grain bin from 4 ring to 9 ring. Be sure and follow the complete instruction sheets

for correct placement of parts. Failure to do so may result in improper fit of parts or shortage

of parts. Read through the complete set of instructions before proceeding with erection of grain

bin. Considerable thought must be given as to location of ladders and platforms in relation to

other equipment and structures.

STARTING LOCATION OF LADDERS

Ladder placement is very critical as to assure proper fit of all parts later on as safety cage is

bolted in place. Locate the proper place of roof ladder and manway this will establish the

location of the ladder . Ladder must be centered directly below the roof ladder. Refer to the

diagram below for proper location of field drilled holes (3/8"). Holes must be 18 3/4" apart and

8" below the top horizontal row of holes directly in line with the holes pre-punched in the

horizontal seam for the first 2 ladder standoff brackets. The diagrams also show that the

platform uses stiffener holes. Both platform vertical support angles must be located in the

stiffener holes on 2-post tanks and 1 vertical support angles in stiffener holes on 3-post tanks,

as shown in details. These dimensions and locations are very critical to assure proper fit of all

parts.

2-POST

FIELD DRILL

3/8" HOLES (2)

ROOF LADDER

18.3/4"

MANWAY PANEL

12.00"

LS-6705

48

REV. 10/9/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 49

4.00 OUTSIDE STIFFENED

8"

Outside

Standoffs

LS-121

Roof Sheet

6.1/4"

8"

Ladder Section

LDR-4002

LADDER PLACEMENT

Ladder placement on the grain bin is very

important at this time. Refer to the diagram at

the left and follow the correct dimensions as

shown. Ladder standoff must be located 8"

below the horizontal seam. Check your ladder

to make sure the ladder rung dimples are to

the top surface. Attach ladder to the standoffs

using the holes located 6 1/4" from the end of

ladder section. Use 5/16" x 3/4" bin bolts for

these connections. Now all standoffs must be

located in horizontal seam holes (repeating

every 44") until reaching the first rest platform.

Refer to the section in these instructions that

references the location of intermediate rest

platforms for further hole locations.

PLATFORM SUPPORT ASSEMBLY

LS-6705

Mounting

Angle 34''

Horizontal Seam

PNEG-1096 Ladder , Safety Cage, & Platforms

When starting the platform support, you

must attach the mounting angle to the

sidewall of the grain bin. Refer back to the

first page for the correct holes to be used

by the platform. Attach the angle using

5/16" x 3/4" bolts and nuts, tighten at this

time. Next, bolt the support angle to the

mounting angle again using the proper

holes. Attach the brace angle to the

mounting angle as shown in the diagram

at left. Use 5/16" x 3/4" bolts and nuts for

all connections.

LS-370

Support Angle

30.3/4"

LS-369

Brace Angle

30-3/4"

REV.10/10/01

49

Page 50

4.00 OUTSIDE STIFFENED

FIELD DRILL 5/16'' HOLES

(4) PER BRACE

3

4

5

1

2

6

REF. NO. DESCRIPTION PART NO.

1 END TUBE LS-6616

Note: Reference previous page for the

first ladder standoff starting location.

2 CENTER TUBE LS-6615

3 SAFETY CAGE BRACKET LS-4349

4 SAFETY CAGE EXT. RAIL LS-4355

5 LADDER SECTION LDR-4002

6 OUTSIDE STANDOFF LS-121

LS-6696

EXTENSION RAILS

Extension rails are provided to extend the side rails of the ladder above the eave of

the roof and to support the safety cage at that point. T wo rails have been provided, one for each

side of the ladder . Refer to diagram above for proper location and assembly of the extension

rails in relation to the ladder . Use 5/16" x 3/4" bolts and nuts to attach the ladder. Tighten the

bolts at this time.

EAVE ADJUSTABLE BRACES

After extension rails are firmly attached, the adjustable braces must be attached at this

time. A larger diameter tube and two smaller diameter tubes are used to make up one

adjustable brace. Slip the smaller tubes inside the larger tube and attach one smaller tube to

the top of the extension rail. Adjust the other smaller tube so the bottom of the flattened tube

reaches the roof rib. Field drill four 5/16" holes through both large and small adjustable tubes

and bolt together using 1/4" x 1.1/2" bolts and nuts. This will keep the adjustable brace from

slipping.

Attach the safety cage brackets to the extension rail and ladder as shown in the

diagram. Brackets must be placed every 44". This will occur at every ladder joint. Use 5/16" x

3/4" bolts and nuts.

REV. 9/25/01

50

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 51

LS-6697

Safety Cage Platform

Extension Angles

(Flours. Green)

LS-373

Platform

LS-5283

SafetyCage Hoop

Adapter Angle

41" (T yp.)

REV.9/25/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Extension Rails or Ladder

(Ladder to be used on

Intermediate Platform)

LS-5284 Safety Cage

Adapter Hoop

LS-4351 Safety Cage

Hoof Half

LS-295

Front Handrail

31.7/8" (Black)

LS-371

Platform Vertical

Angle 42" (Y ellow)

LS-372

Vert. Entrance Angle

46" (Orange)

Extension Angle

Platform

LS-5285 Safety

Cage Hoop

Adjuster Plate

4.00 OUTSIDE STIFFENED

EXTENSION ANGLE DETAIL

PLATFORM AND HANDRAIL

ASSEMBLY

Start by attaching the platform itself to the

platform support using 5/16" x 3/4" bolts and

nuts. Place all the vertical angles in place,

making sure to place the vertical entrance

angle to the left front corner of the platform.

After all vertical angles are in place attach

front and side handrails as shown in the diagram. Use 5/16" x 3/4" bolts and nuts in all

connections.

Safety cage platform extension angles and

safety cage hoop adapter angle will be with

the eave safety cage package. These can

now be attached to the vertical entrance

angle. Refer to the diagram at the left.

EAVE SAFETY CAGE &

INTERMEDIATE REST PLATFORM

Before attaching any pieces to the ladder or

platform some preassembly will be required.

T ake the safety cage hoop adjuster plate and

the safety cage adapter hoop and bolt together using the proper holes, (as shown on

following page.) Be sure the proper holes are

used depending on the diameter of the grain

bin. Be sure to use the 5/16" x 3/4" bolt with

the head of the bolt to the inside of the safety

cage. Using the improper holes will make the

safety cage more difficult to assemble. You

may now bolt this assembly to the safety

cage hoop half, tighten bolts as you go. One

of the assemblies will take 2 hoop halves and

be positioned just below the platform as

shown in the diagram. T ake the assembly and

attach to the safety cage bracket and to the

platform extension angle or the hoop adapter

angle. Refer to the diagram for more information. If holes don't align properly go back

and make sure the ladder and platform are

correctly positioned on grain bin in relationship to one another. Make any corrections

necessary to complete the assembly as

shown.

51

Page 52

4.00 OUTSIDE STIFFENED

WHEN ATTACHING SAFETY CAGE TO PLATFORM, THE HOOP ADJUSTER PLATE MUST BE USED

TO COMPENSATE FOR THE DIFFERENT BIN CURVATURES. NOTE: (THIS PLATE IS NOT NEEDED

FOR 90' & 105' DIAMETER BINS.) BOLT THE PROPER END TO THE EXTENSION ANGLE OR ADAPTER

HOLE. NOW LOCATE PROPER HOLES IN HOOP ADJUSTER PLATE AND BOLT TO THE SAFETY CAGE

ADAPTER HOOP.

30'-33'

27'

36'-42'

48'

60'

EAVE SAFETY CAGE

After all three hoop assemblies are in place

you may attach the 44" vertical supports from

hoop to hoop. This will require 10 supports, 5

between each set of hoops. Again use the truss

head bolts with bolt head to the inside of safety

cage.

LS-4353 Safety Cage

44" Vertical Support

LS-4353 Safety Cage

44" Vertical Support

BOLT TO

EXTENSION

ANGLE OR

ADAPTER

ANGLE

75'-78'

72'

LS-6697 Safety

Cage Platform

Extension Angle

LS-4349

Safety Cage Standard

Bracket

52

LS-4351

Safety Cage

Hoop Half

SAFETY CAGE EXTENSION

The safety cage extension package is designed to be

added on to the bottom of the existing safety cage above

it. Attach the vertical support pieces to the existing hoop

halves above using the 5/16" x 3/4" bolt and nuts. Fasten the package to the safety cage brackets and attach

the bottom of the vertical supports to the hoop halves

and tighen bolts. Continue to use the extension packages as the usage chart reflect on the following page.

Whereas you formerly had all extension packages

bundled and listed under the LS-4365LB part number you

will now have a combination of LS-4366LB (A package

of two (2) extension kits) and LS-4365LB (The original

single extension kit).

REV. 9/25/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 53

INSIDE LADDER

4.00 OUTSIDE STIFFENED

MANWAY SHEET

INSIDE LADDER PLACEMENT

The inside ladder package includes the

ladder

and double the amount of standoffs as the

outside ladder package. Begin by positioning

the ladder directly under the manhole roof

panel and place the standoffs every 22" vertically on the sidewall sheets using the horizontal seam holes for every other hole location.

Use 5/16" x 3/4" bin bolts to attach the standoffs

to the sidewall of the grain bin. Refer to the

diagrams to the left and below .

INSIDE OF GRAIN BIN

INSIDE LADDER STANDOFF

REQUIREMENTS

Field drilling will be necessary for the

standoffs located in the middle of the

sidewall sheet. Drill 2 holes 3/8" diameter

directly in line with the horizontal seam

holes 18.3/4" apart. Continue down the

sidewall with standoffs at every 22"

spacing. Refer to the diagram.

LS-121 LADDER

STANDOFFS

18.3/4"

22" TYP.

NOTE: In Commercial Hopper Tanks with

inside ladders install brackets at 8"

spacing in the bottom two rings.

REV. 9/20/00

PNEG-1096 Ladder , Safety Cage, & Platforms

53

Page 54

4.00 OUTSIDE STIFFENED

INSIDE LADDER SUPPORTS

After completing the inside ladder it will be necessary to support the bottom of the ladder

to the concrete. Depending on the actual installation, the amount of support may vary . The

supports are not supplied by the manufacturer . Usually the supports can be made of 1" x 1" x 1/

8" angle iron bolted directly to the ladder using 2 bolts 5/16" x 1". If a bin sweep is to be used in

the grain bin, other considerations may be necessary to assure there is no interference with the

equipment.

54

SUPPORTS ARE NOT SUPPLIED BY GSI

SUPPORTS ARE NOT SUPPLIED

BY GRAIN SYSTEMS, INC.

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 55

4.00 OUTSIDE STIFFENED

LADDER SAFETY CAGE, AND PLATFORM INSTRUCTIONS

10 - 14 RINGS ONLY

All packages have been structured with the correct components for each ring height

grain bin from 10 ring to 14 ring. Be sure and follow the complete instruction sheets

for correct placement of parts. Failure to do so may result in improper fit of parts or shortage

of parts. Read through the complete set of instructions before proceeding with erection of grain

bin. Considerable thought must be given as to location of ladders and platforms in relation to

other equipment and structures.

STARTING LOCATION OF LADDERS

Ladder placement is very critical as to assure proper fit of all parts later on as safety cage is

bolted in place. Locate the proper place of roof ladder and manway this will establish the

location of the ladder . Ladder must be centered directly below the roof ladder. Refer to the

diagram below for proper location of field drilled holes (3/8"). Holes must be 18 3/4" apart and

8" below the top horizontal row of holes directly in line with the holes pre-punched in the

horizontal seam for the first 2 ladder standoff brackets. The diagrams also show that the

platform uses stiffener holes. Both platform vertical support angles must be located in the

stiffener holes on 2-post tanks and 1 vertical support angles in stiffener holes on 3-post tanks,

as shown in details. These dimensions and locations are very critical to assure proper fit of all

parts.

FIELD DRILL

3/8" HOLES (2)

ROOF LADDER

18.3/4"

2-POST

MANWAY PANEL

8"

TDP-5008N

FLO. GREEN/

BLACK

PNEG-1096 Ladder , Safety Cage, & Platforms

REV. 9/25/01

55

Page 56

4.00 OUTSIDE STIFFENED

8"

Roof Sheet

6.1/4"

8"

Outside

Standoffs

LS-121

Ladder Section

LDR-4002

LADDER PLACEMENT

Ladder placement on the grain bin is very important at this time. Refer to the diagram at the

left and follow the correct dimensions as shown.

Ladder standoff must be located 8" below the

horizontal seam. Check your ladder to make

sure the ladder rung dimples are to the top surface. Attach ladder to the standoffs using the

holes located 6 1/4" from the end of ladder section. Use 5/16" x 3/4" bin bolts for these connections. Now all standoffs must be located in horizontal seam holes (repeating every 44") until

reaching the first rest platform. Refer to the section in these instructions that references the location of intermediate rest platforms for further

hole locations.

56

REV. 4/19/01

PNEG-1096 Ladder , Safety Cage, & Platforms

Page 57

4.00 OUTSIDE STIFFENED

FIELD DRILL 5/16'' HOLES

(4) PER BRACE

3

4

5

1

2

6

REF. NO. DESCRIPTION PART NO.

1 END TUBE LS-6616

Note: Reference previous page for the

first ladder standoff starting location.

2 CENTER TUBE LS-6615

3 SAFETY CAGE BRACKET LS-4349

4 SAFETY CAGE EXT. RAIL LS-4355

5 LADDER SECTION LDR-4002

6 OUTSIDE STANDOFF LS-121

LS-6696

EXTENSION RAILS

Extension rails are provided to extend the side rails of the ladder above the eave of

the roof and to support the safety cage at that point. T wo rails have been provided, one for each

side of the ladder . Refer to diagram above for proper location and assembly of the extension

rails in relation to the ladder . Use 5/16" x 3/4" bolts and nuts to attach the ladder. Tighten the

bolts at this time.

EAVE ADJUSTABLE BRACES

After extension rails are firmly attached, the adjustable braces must be attached at this

time. A larger diameter tube and two smaller diameter tubes are used to make up one

adjustable brace. Slip the smaller tubes inside the larger tube and attach one smaller tube to

the top of the extension rail. Adjust the other smaller tube so the bottom of the flattened tube

reaches the roof rib. Field drill four 5/16" holes through both large and small adjustable tubes

and bolt together using 1/4" x 1.1/2" bolts and nuts. This will keep the adjustable brace from

slipping.

Attach the safety cage brackets to the extension rail and ladder as shown in the

diagram. Brackets must be placed every 44". This will occur at every ladder joint. Use 5/16" x

3/4" bolts and nuts.

REV. 9/25/01

PNEG-1096 Ladder , Safety Cage, & Platforms

57

Page 58

4.00 OUTSIDE STIFFENED

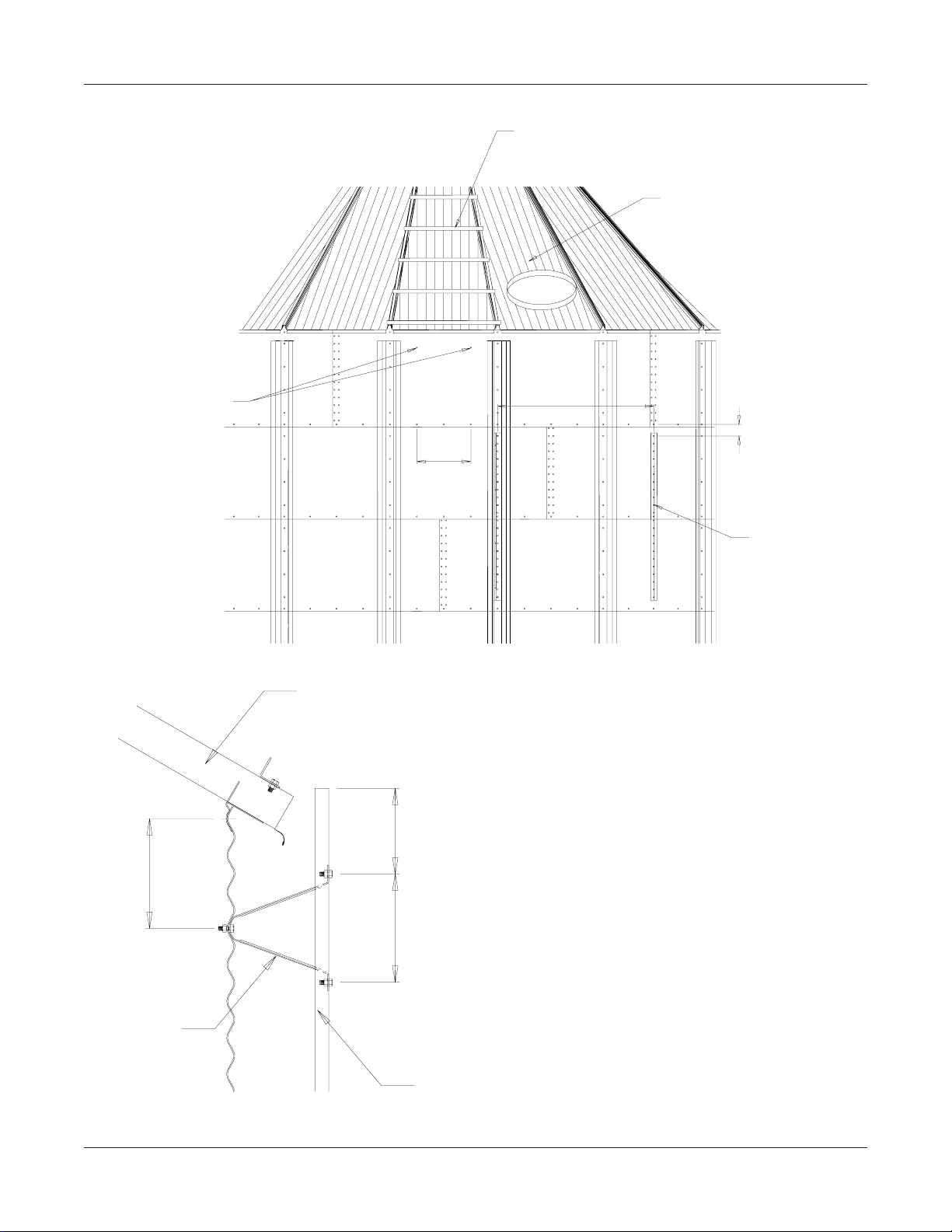

PLATFORM ASSEMBLY

NOTE: THE PLATFORM SUPPORTS SHOULD BE

MOUNTED ON THE BIN FIRST . THE PLA TFORM FLOOR

SHOULD THEN BE ASSEMBLED ONTO THE SUPPORT

FRAME. LEAVE PLATFORM SUPPORT TO FL OOR

BRACE BOLTS L OOSE UNTIL FLOOR AND TOEPLA TES

ARE SECURE.

LS-6621 (PINK) VERTICAL

ENTRANCE ANGLE (46'')

LS-6702 (RED)

HANDRAIL (58'')

TDP-5011 PLATFORM

TOE PLATE

TDP-5002 (PINK/BLACK)

HANDRAIL (30'')

Assemble the platform support frame

using 5/16" x 3/4" truss head bolts

and nuts. When attaching vertical

supports to stiffeners or sidewall,

locate the vertical supports according