Page 1

PNEG-1057

07-19-10

Revision No. 1

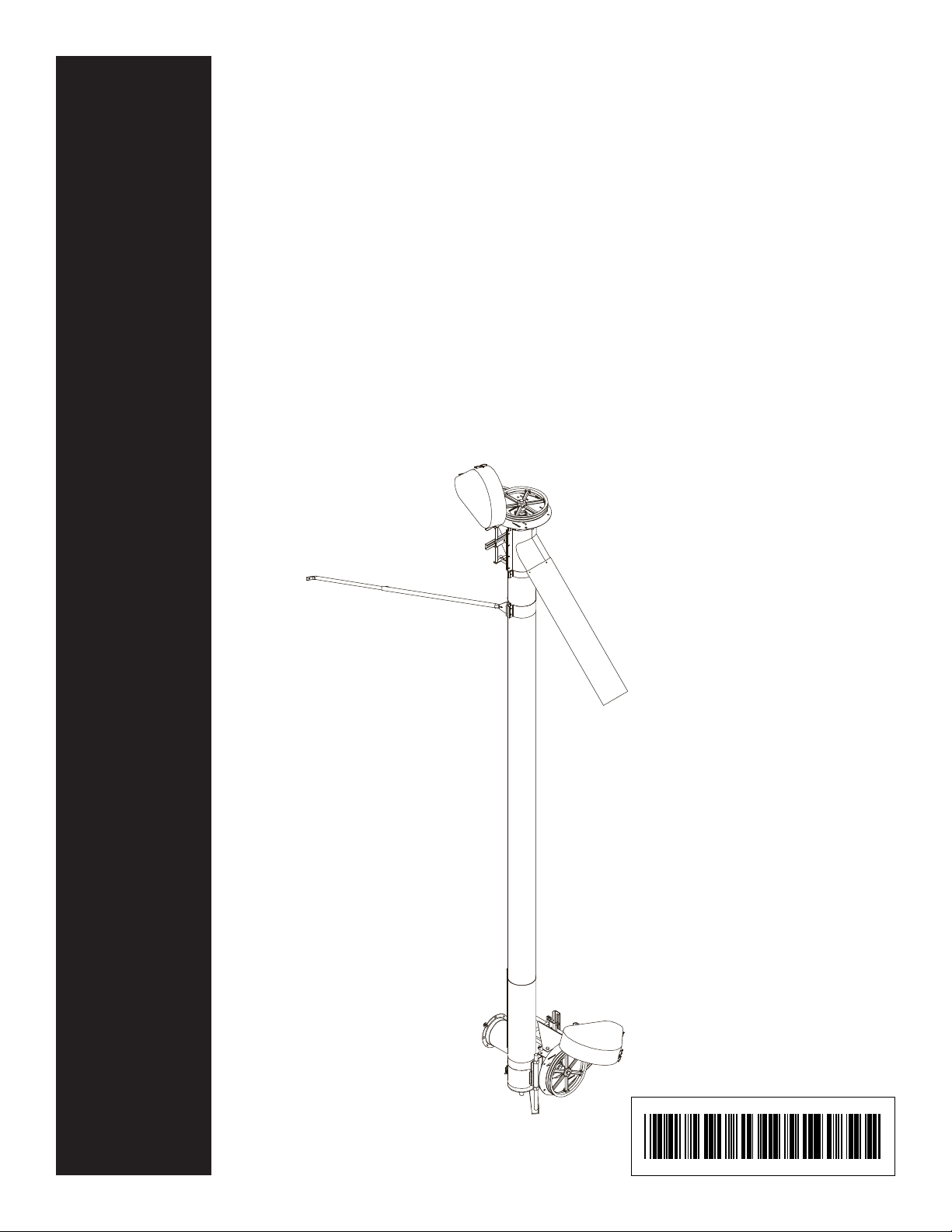

8" and 10"

Commercial Vertical

Bin Unload Auger

Assembly & Operation Manual

8" and 10" Commercial

Vertical Bin Unload Auger

PNEG-1057

07-19-10

Revision No. 1

PNEG-1057

Page 2

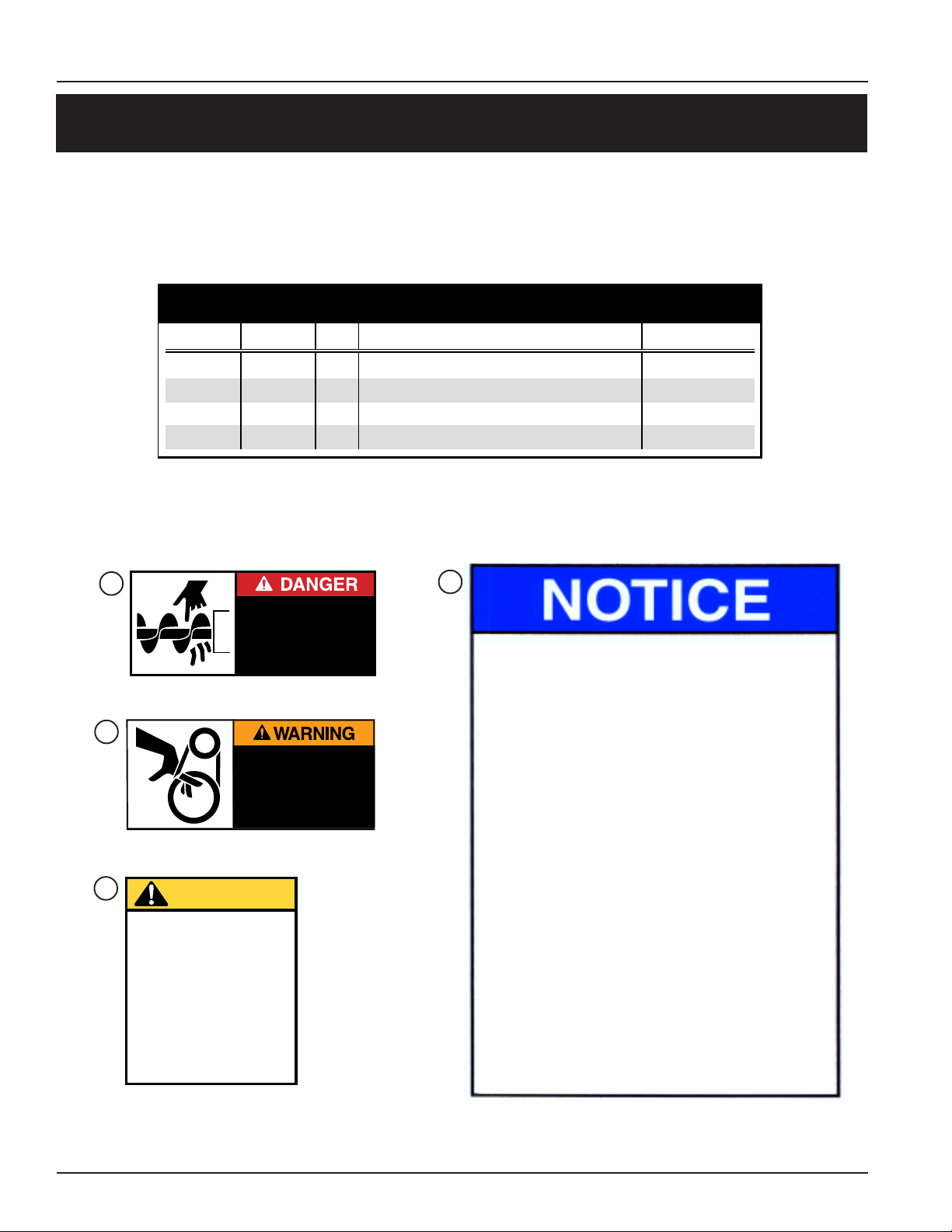

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator , to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidelines. T o help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury .

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury .

CAUTION indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury .

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention to.

Page 3

SAFETY GUIDELINES

1. General Safety Guidelines

A. DO NOT make any alterations to the equipment. Such alterations may produce a very dangerous situation,

where SERIOUS INJURY or DEATH may occur.

B. This equipment shall be installed in accordance with any regulations or installation codes that are required

by law. Authorities having jurisdiction should be consulted before installations are made.

C. Untrained operators subject themselves and others to SERIOUS INJURY or DEATH. NEVER allow

untrained personnel to operate this equipment.

D. Keep children and other unqualified personnel out of the working area at ALL times.

E. NEVER start equipment until ALL persons are clear of the work area.

F. Be sure ALL operators are adequately rested and prepared to perform ALL functions of operating this

equipment.

Safety

G . Keep hair, loose clothing, and shoestrings away from rotating and moving parts. NEVER wear loose fitting

clothing when working around augers.

H. NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate the equipment.

I. NEVER allow anyone inside a bin, truck, or wagon which is being unloaded by an auger or conveyor.

Flowing grain can trap and suffocate in seconds.

J. Make sure someone is nearby who is aware of the proper shutdown sequence in the event of an accident or

emergency.

K. NEVER work alone.

L. ALWAYS think before acting. NEVER act impulsively around the equipment.

M. Make sure ALL equipment is locked in position before operating.

N. Keep hands and feet away from the auger intake and other moving parts.

O. NEVER attempt to assist machinery operation or to remove trash from equipment while in operation.

P. NEVER drive, stand, or walk under the equipment.

Q. Use caution not to hit the auger when positioning the load.

R. Use ample overhead lighting after sunset to light the work area.

S. ALWAYS lockout ALL power to the equipment when finished unloading.

T. Keep area around intake free of obstacles such as electrical cords, blocks, etc. that might trip workers.

ii

Page 4

Safety

SAFETY GUIDELINES

2. Personal Protective Equipment

A. The proper personal protective equipment should be worn at

ALL times by anyone in the work area.

B. ALWAYS wear safety glasses when in the work area.

C. The operator should NEVER wear jewelry.

D. Loose clothing should not be worn. Any clothing that becomes

loosened should be tucked in tightly .

2-B

2-C

E. Loose or dangling shoe strings should be tucked in.

F. Long hair should be tied up and/or back.

2-D, E

2-F

iii

Page 5

SAFETY GUIDELINES

3. Emergency Shutdown Sequence

A. In an emergency , shutdown the power source.

4. Pinch Points

A Pinch Point is any place on the equipment which can injure the operator.

A. Components of this equipment have sharp edges which can scrape and/or cut an operator.

B. A moving auger can sever an operator’s limbs or even kill him/her.

5. Shields and Guards

Safety

A. ALWAYS keep ALL shields and guards in place during operation.

We will replace any missing shields or guards free of charge!

See (page VI) for more information on our Safety First program.

6. Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who works with

or around augers must have good common sense in order to be qualified. These persons must also know and

meet all other qualifications, such as:

1. Any person who has not read and/or does not understand all operation and safety

procedures is not qualified to operate any auger systems.

2. Certain regulations apply to personnel operating power machinery . Personnel under

the age of 18 years may not operate power machinery , including augers. It is your

responsibility , as owner and/or supervisor , to know what these regulations are in your

area or situation.

3. Unqualified or incompetent persons are to remain out of the work area.

4. O.S.H.A. (Occupational Safety & Health Administration) regulations state:

"At the time of initial assignment and at least annually thereafter , the employer shall

instruct every employee in the safe operation and servicing of all equipment with

which the employee is, or will be involved." (Federal Occupational Safety & Health

Standards for Agriculture. Subpart D, Section 19287.57 (a) (6).

iv

Page 6

Safety

SAFETY GUIDELINES

6. Operator Qualifications (cont.)

B. As a requirement of OSHA, it is necessary for the employer to train the employee in the safe operating and

safety procedures for this auger. W e included this sign-of f sheet for your convenience and personal record

keeping. All unqualified persons are to stay out of the work area at all times. It is strongly recommended that

another qualified person who knows the shutdown procedure is in the area in the event of an emergency. A

person who has not read this manual and understands all operating and safety instructions is not qualified to

operate the machine.

Date Employer’s Signature Employee Signature

DATE EMPLOYER' S S I GNATURE EMPLOYEE' S S I GNATURE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

v

Page 7

Safety 1st

SAFETY GUIDELINES

Our equipment is built to provide

many years of dependable service to

our customers through durable

craftsmanship.

One of the most important aspects of

our engineering is SAFETY 1

throughout all product lines. At our

company - safety is NO ACCIDENT!

That is why we have implemented a

SAFETY 1st program. Should you ever

need guards, shields, safety decals or

owner/operator manuals, simply contact

us or your local dealer, and we will

supply you with them FREE OF

CHARGE!

While it is our main goal for our

company to be the world leader in

auger manufacturing, it is always

our first priority to keep our

customers safe.

st

design

We replace missing guards and shields

FREE OF CHARGE!

If you need any of the above listed safety items or have any safety questions,

please contact the manufacturer or your local dealer .

vi

Page 8

Table of Contents

Personnel operating or working around this equipment should read this

manual. This manual must be delivered with equipment to it s owner.

Failure to read this manual and its safety instructions is a misuse of the

equipment. Any misuse of the equipment may void the warranty.

Safety Guidelines ..................................................................................... i

SAFETY 1

Table of Contents ..................................................................................... vii

Decals........................................................................................................ 1

st

................................................................................................ vi

Introduction .............................................................................................. 4

8" Vertical Assembly ................................................................................ 5

10" Vertical Assembly .............................................................................. 10

Operation & Maintenance ........................................................................ 16

Startup ....................................................................................................... 15

Shutdown.................................................................................................. 19

Troubleshooting ....................................................................................... 20

8" Parts List .............................................................................................. 21

10" Parts List ............................................................................................ 23

Warranty

vii

Page 9

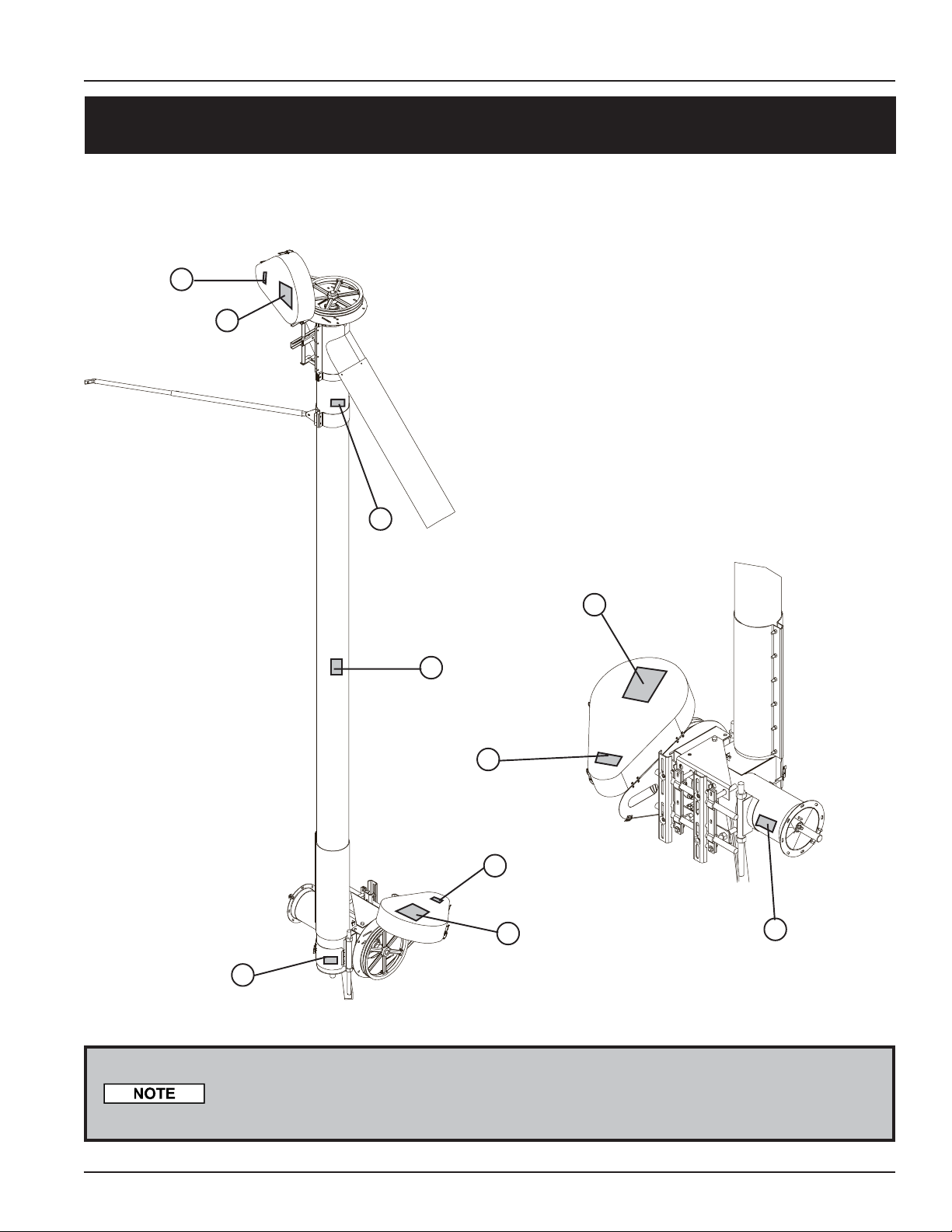

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

Safety Decals

A. The image below shows the location of the decals and safety signs which should appear on the Commercial

Vertical Bin Unload Auger . Samples and explanations of these decals are shown on page 2.

2

4

Decals

1

4

3

2

2

4

1

1

Please remember safety signs provide important safety information for people working

near bin unloading equipment that is in operation. Any safety signs that are worn,

missing, illegible or painted over should be replaced immediately. Obtain FREE

replacements by contacting your dealer.

1

Page 10

Decals

t

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

Safety Decals

The Safety Decals chart below lists all the safety decals that should be included with the auger . Inspect all decals and

replace any that are illegible, worn, or missing. Contact your dealer or the manufacturer to order replacement decals.

Ref. # Part # Qty. Descr iption Size

1 DC-1381 1

2 DC-995 1

3 DC-1234 1

4 DC-1379 1

1

2

3

!

CAUTION

FAILURE TO PROPERLY SELECT,

INSTALL OR MAINTAIN AN AUGER, ITS

DRIVE OR OTHER COMPONENTS CAN

RESULT IN DANGEROUS OPERATION.

THIS EQUIPMENT IF IMPROPERLY

SELECTED, INSTALLED OR MAINTAINED MAY FAIL AND COULD RESULT

IN SERIOUS INJURY OR PROPERTY

DAMAGE.

CHECK PRODUCT LITERATURE

AND EQUIPMENT MANUFACTURER'S

LITERATURE OR CALL THE FACTORY

FOR FURTHER INFORMATION.

SHEAR POINT

Keep clear of rotating auger and

moving parts.

Do not remove or modify guards.

Disconnect and lock out power

before servicing.

Failure to do so will result in

serious INJURY or DEATH.

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnec

and lockout power before

servicing.

DC-1234

DC-1381

DC-995

Safety Decals

Danger - Shear Point

Warning—Shear Point

Caution

Notice

4

1. READ AND UNDERSTAND THE OPERATOR’S MANUAL AND

2. DO NOT OPERATE WHILE UNDER THE INFLUENCE OF

3. DO NOT OPERATE UNLESS ALL SAFETY EQUIPMENT,

4. ALLOW ONLY TRAINED AUTHORIZED PERSONNEL IN THE

5. ANY ELECTRICAL WIRING OR SERVICE WORK MUST BE

6. DO NOT ALLOW CHILDREN IN THE AREA OF OPERATION.

7. KEEP HANDS, FEET AND CLOTHING AWAY FROM MOVING

8. DISCONNECT AND LOCKOUT POWER BEFORE MAKING ANY

9. DISCONNECT POWER PRIOR TO RESETTING ANY MOTOR

10. MAKE CERTAIN ALL ELECTRIC MOTORS ARE GROUNDED.

11. REPLACE ALL WORN OR DAMAGED LABELS IMMEDIATELY.

4-1/ 2" x 2"

4-1/ 2" x 2"

2-1/ 4" x 2-3/4"

5-1/ 8" x 7-3/8"

ALL SAFETY INSTRUCTIONS.

DRUGS OR ALCOHOL.

SWITCHES, GUARDS AND SHIELDS ARE SECURELY IN

PLACE AND OPERATIONAL.

OPERATING AREA.

PERFORMED BY A QUALIFIED ELECTRICIAN. IT MUST

MEET ALL STATE AND LOCAL ELECTRICAL CODES.

PARTS.

ADJUSTMENTS OR PERFORMING ANY SERVICE WORK.

OVERLOAD.

2

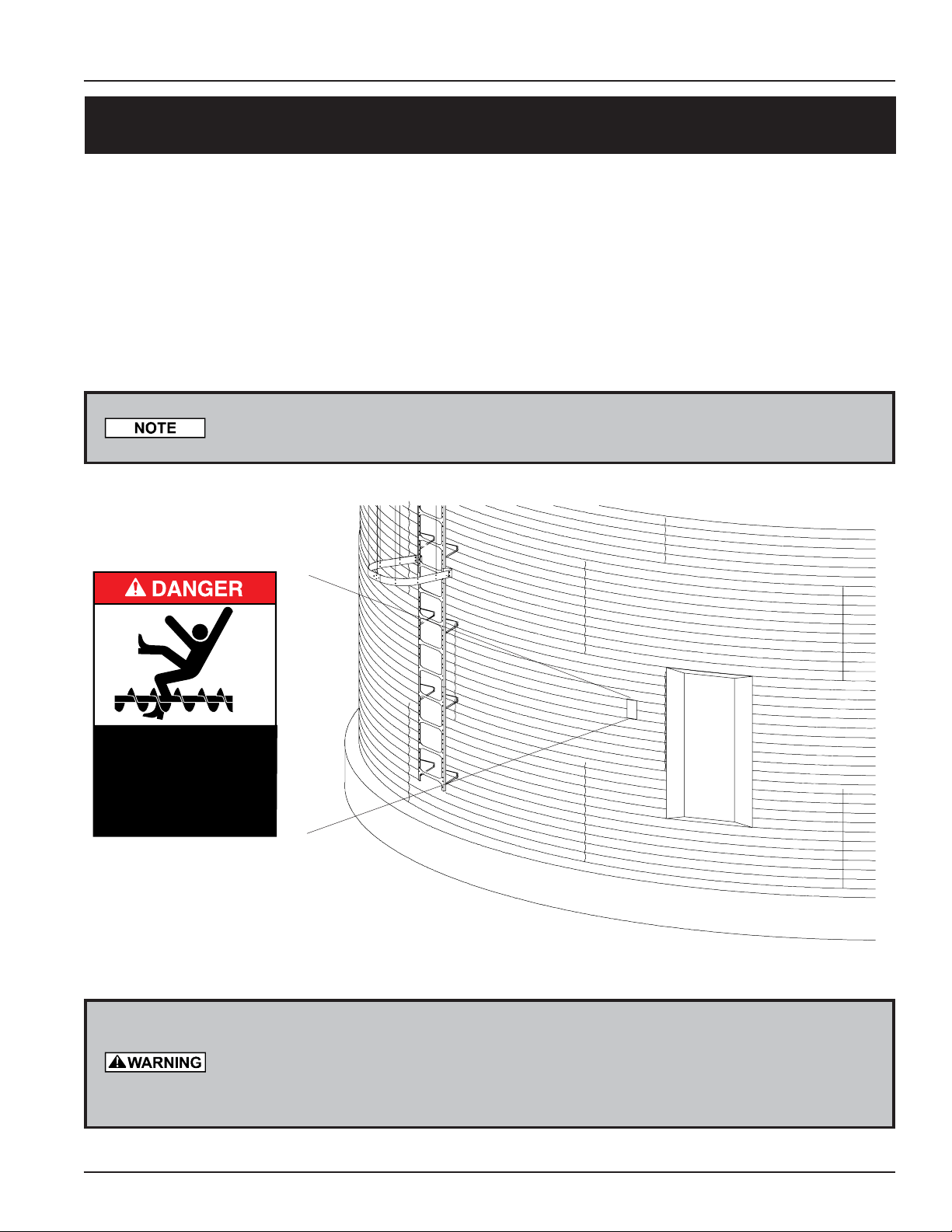

Page 11

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

Decals

Safety Decals

A. DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign should be applied

to the side of the bin near the bin opening, so it will be viewed by people entering into the bin storage building.

Do not cover any safety signs or any other signs that are already there.

B. If the safety sign location suggested is not in full view because of equipment modifications, other equipment in

the area, or any reason, then locate the safety sign in a more suitable location.

C. Be certain the surface is clean, dry and free of dirt and oil. Peel paper backing from decals and stick into place.

The adhesive backing will bond on contact.

Please remember, safety signs provide important safety information for people

working near bin unloading equipment that is in operation.

ROTATING FLIGHTING!

THIS BIN IS EQUIPPED WITH GRAIN AUGERS

WHICH CAN KILL OR DISMEMBER.

KEEP CLEAR OF ALL AUGERS AND NEVER ENTER

THIS BIN UNLESS ALL POWER IS

DISCONNECTED AND LOCKED OUT.

FAILURE TO DO SO WILL RESUL T IN

SERIOUS INJURY OR DEATH!

DC-1395

If the Safety Sign cannot be easily read for any reason or has been p ainted over,

replace it immediately. Additional Safety Signs may be obtained free of charge from

your dealer, distributor, or ordered from the factory.

Order SAFETY SIGN NO. DC-1395

3

Page 12

Introduction

1. General Information

A. We reserve the right to improve our product whenever possible and practical to do so. We

reserve the right to change, improve, and modify products at any time without obligation to

make changes, improvements, and modifications on equipment sold previously .

B. The 8" & 10" Commercial Vertical Bin Unload Augers have been designed and manufactured

to give years of dependable service. The care and maintenance of this machine will affect the

satisfaction and service obtained. By observing the instructions and suggestions we have

recommended, the owner should receive competent service for many years. If additional

information or assistance should be required, please contact the factory or your local dealer.

C. When receiving merchandise, it is important to check both the quantity of parts and their

descriptions with the packing list enclosed within each package. All claims for freight

damage or shortage must be made by the consignee within ten (10) days from the date of the

occurrence of freight damage. The consignee should accept the shipment after noting the

damage or loss.

2. Capacity

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

A. The capacities may vary greatly under varying conditions. The following factors play a role

in the performance of the auger:

• Speed • Amounts of foreign matter

• Angle of operation • Different materials

• Moisture content • Methods of feeding

B. For example, a twenty-five percent (25%) moisture could cut capacity by as much as

40% under some conditions.

4

Page 13

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

8" Vertical Assembly

1. Motor Mount Rod to Head Plate Assembly

A. Screw one 3/4" hex head nut to the top of each motor mount rod (10).

B. Slide the motor mount rods (10) through the head plate assembly (1 1).

C. Line up slot on the plate end of the motor mount rods (10) with the slot on the head plate assembly (11). Fasten

them together using 5/16" carriage bolt, a flat washer, and a nut.

D. Attach a 3/4" hex head nut onto the bottom of each motor mount rod. Tighten until nut rests against the head

plate assembly (1 1).

E. Adjust top 3/4" hex head nuts down until they rests against the top of the head plate assembly (11).

2. Tube Assembly

A. Connect the two-hole flange bearing (12) to head plate assembly (1 1) using two 7/16" x 1-1/4" bolts

with locknuts.

B. Loosen the top and bottom nuts on the head plate assembly (1 1) to allow the belt guard mounting angles (35)

to slide onto the motor mount rods (10). Once the angles are in place tighten nuts to keep rods in position.

C. Connect head drive shaft (13) to flight using two 7/16" x 2-1/4" (grade 5) bolts with locknuts.

D. Slide head plate assembly (1 1) over discharge end of tube and tighten the halfband clamp s (5) using four

5/16" x 1-1/2" bolts with nuts. Slip bearing lock collar (not shown) over head drive stub.

E. Fasten belt guard (17) to top mounting angle (35) using two 5/16" x 3/4" carriage bolts with flat washers,

lockwashers, and nuts.

Leave carriage bolts loose until later.

F. Place head drive shaft (13) through head bearing with enough extended to mount pulley (18) with key (37).

Tighten lock collar on bearing and tighten setscrews in pulley .

G . Install motor and pulley onto motor mount. (Motor and pulley are not included.) Install belts (3) and tighten

by adjusting motor height by using the four 3/4" nuts on the rods.

H. Close door on belt guard and latch.

I. Secure 45° discharge spout (6) Over the discharge opening using the head plate assembly and eight

5/16" x 1-1/2" long bolts with nuts.

5

Page 14

8" Vertical Assembly

8" Vertical Tube Assembly

7

10

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

3

17

35

13

11

37

8

5

11

17

12

4

6

35

18

Lock out all power sources while installing or maintaining equipment.

Keep all safety devices and shields in place at all times until power source is locked out.

6

Page 15

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

8" Vertical Assembly

3. Attaching Vertical Section to Bin

A. Slide bin unloading flight into bin well and unloading tube (which should already be installed in bin.)

The unloading flight for larger bin sizes may need to be bolted together . Use bolts provided in connecting stubs

located at the end of the tail flights. See the 8" Flight Chart below to determine the flight length for your bin size.

B. Bolt unloading flight to short horizontal flight (#3 on page 9) using four 7/16" x 2-3/4" long (grade 5) bolts

and locknuts.

C. Bolt flange on horizontal tube of vertical unloader to the flange of the bin unloader tube with vertical auger in

vertical position. Use eight 5/16" x 1" long bolts, lockwashers, and nuts.

8" FLIGHT CHART

Product No. Bin Dia. Part No.

GFC82400

GFC82700 27' GK1800 16' -0" x 7" O.D. Flight

GFC83000 30' GK1801 17' -6" x 7" O.D. Flight

GFC83300 33'-34' GK1802 19' -6" x 7" O.D. Flight

GFC83600 36' GK1803 20' -6" x 7" O.D. Flight

GFC83800 37'-39' GK1804 22' -6" x 7" O.D. Flight

GFC84000 40' GK1805 23' -0" x 7" O.D. Flight

GFC84200 42' GK1806 24' -0" x 7" O.D. Flight

GFC84800 48'-49' GK1808 20' -0" x 7" O.D. Flight (Head)

GFC85400

GFC86000

GFC86300

GFC86800

GFC87200

GFC87500

GFC87800

GFC88000 80' GK1808 20' -0" x 7" O.D. Flight (Head)

GFC88200 82' GK1808 20' -0" x 7" O.D. Flight (Head)

GFC89000 90' GK1808 20' -0" x 7" O.D. Flight (Head)

GFC89200 92' GK1808 20' -0" x 7" O.D. Flight (Head)

24'

54'-55' GK1808 20' -0" x 7" O.D. Flight (Head)

60' GK1808 20' -0" x 7" O.D. Flight (Head)

63' GK1808 20' -0" x 7" O.D. Flight (Head)

68'-69' GK1808 20' -0" x 7" O.D. Flight (Head)

72' GK1808 20' -0" x 7" O.D. Flight (Head)

75' GK1808 20' -0" x 7" O.D. Flight (Head)

78' GK1808 20' -0" x 7" O.D. Flight (Head)

GK1799 14' -6" x 7" O.D. Flight

GK1807 7' -0" x 7" O.D. Flight (Tail)

GK1809 10' -0" x 7" O.D. Flight (Tail)

GK1810 13' -0" x 7" O.D. Flight (Tail)

GK1811 14' -6" x 7" O.D. Flight (Tail)

GK1812 17' -0" x 7" O.D. Flight (Tail)

GK1813 19' -0" x 7" O.D. Flight (Tail)

GK1814 20' -6" x 7" O.D. Flight (Tail)

GK1815 22' -6" x 7" O.D. Flight (Tail)

GK1130 20' -0" x 7" O.D. Flight (Middle)

GK1821 4' -6" x 7" O.D. Flight (Tail)

GK1130 20' -0" x 7" O.D. Flight (Middle)

GK1823 5' -6" x 7" O.D. Flight (Tail)

GK1130 20' -0" x 7" O.D. Flight (Middle)

GK1824 9' -6" x 7" O.D. Flight (Tail)

GK1130 20' -0" x 7" O.D. Flight (Middle)

GK1825 10' -6" x 7" O.D. Flight (Tail)

Description

7

Page 16

8" Vertical Assembly

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

3. Attaching Vertical Section to Bin (cont.)

D. Adjust stand (#40 on page 9) so it holds the weight of the vertical auger .

E. Attach the support brackets and halfbands to the top half of the vertical tube by inserting the 5/16" U-bolt (4)

through the support brackets (5) and halfbands (6) and fasten together using four 5/16" nylon locknuts.

F. Attach lower telescoping tube sections (3) to the ears on the support brackets (5) using two

3/8" x 3/4" bolts with locknuts.

G . Slide the upper telescoping tube sections (1) into the lower tube sections (3). Attach upper tubes to the bin wall.

H. Secure the upper telescoping tubes to the lower telescoping tubes by tightening the square head setscrew (2).

1

1

2

3

4

5

6

4. Attaching Motor Mount to Horizontal Section

A. First, connect the head stub shaft (13) to the short flight (3) using two 7/16" x 2-3/4" (grade 5)

bolts with locknuts.

B. Connect the four-hole flange bearing with lock collar (4) and the head plate (28) together using four

7/16" x 1-1/4" bolts with locknuts.

C. Attach the head plate (28) to the tube flange using eight 5/16" x 1" bolts with flat washers,

lockwashers, and nuts.

7

D. Connect side plates (22) and (23) to head plate (28) using four 1/2" x 1" bolts with lockwashers

and nuts. Also, at the same time attach the top and bottom belt guard bracket s (27) using the same bolts.

E. Spin a 3/4" nut on the threaded rods of each strap and rod assembly (24). Insert threaded rods through holes in

side plates (22) & (23) and add four more 3/4" nuts. Leave only finger tight until later .

F. Place rods (26) in strap and rod assemblies (24) and secure with top straps (25) using

3/8" x 1-1/2" bolts with two flat washers and one nut on each bolt.

8

Page 17

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

G . Position motor mount straps (15) and clips (14) and secure to rod (26) using four 3/8" x 3" long carriage bolts

with nuts. Leave only finger tight until motor is installed and adjusted.

H. Attach belt guard (17) to belt guard mounting angles (27) using four 5/16" x 3/4" carriage bolts with flat washers

and nuts.

I. Slide bearing lock collar (4) over head stub shaft (13). Leave enough stub exposed to mount

pulley (18) on stub with drive key (37). Tighten bearing lock collar next to bearing and tighten set screws

in pulley .

J. Install pulley on head stub shaft and mount motor on strap (15). (Motor and pulley not furnished.) Install

belts (2) and align pulleys. T ighten motor to straps (15). Adjust motors along the tube and tighten with 3/8" x 3"

carriage bolts.

K. After everything has been adjusted correctly, go back and tighten all nuts and bolts.

8" Vertical Assembly

25

23

24

3

13

40

22

26

14

14

24

27

28

4

37

15

15

26

17

2

27

17

18

9

Page 18

10" Vertical Assembly

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

5. Motor Mount Rod to Head Plate Assembly

A. Screw one 7/8" hex head nut to the top of each motor mount rod (13).

B. Slide the motor mount rods through the head plate assembly .

C. Line up slot on the plate end of the motor mount rods (13) with the slot on the head plate assembly (7). Fasten

them together using 3/8" carriage bolt, a split flat washer, and a nut.

D. Attach a 7/8" hex head nut onto the bottom of each motor mount rod. Tighten until nut rests against the head

plate assembly (7).

E. Adjust top 7/8" hex head nuts down until they rests against the top of the head plate assembly (7).

6. Tube Assembly

A. Connect the four-hole flange bearing (16) to head plate assembly (7) using four 1/2" x 1-1/2" bolts with locknuts.

B. Loosen the top and bottom nuts on the head plate assembly (7) to allow the belt guard mounting angles (17) to

slide onto the motor mount rods (13). Once the angles are in place tighten nuts to keep rods in position.

C. Connect head drive stub shaft (18) to flight using two 1/2" x 3.5" (grade 5) bolts with locknuts.

D. Slide head plate assembly (7) over discharge end of tube and tighten the halfband clamps (9) using four

5/16" x 1-3/4" bolts with nuts. Slip bearing lock collar (not shown) over head drive stub.

E. Fasten belt guard (20) to top mounting angle (17) using two 5/16" x 3/4" carriage bolts with flat washers,

lockwashers, and nuts.

Leave carriage bolts loose until later.

F. Place head drive stub shaft (18) through head bearing with enough extended to mount pulley (19) with key (3).

Tighten bearing with lock collar and tighten setscrews in pulley.

G . Install motor and pulley onto motor mount. (Motor and pulley are not included.) Install belts (2) and tighten

by adjusting motor height by using the four 3/4" nuts on the rods.

H. Close door on belt guard and latch.

I. Secure 45° discharge spout (57) Over the discharge opening using the head plate assembly and eight

5/16" x 1-1/2" long bolts with nuts.

J. After everything has been adjusted, go back and tighten all nuts and bolts.

10

Page 19

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

10" Vertical Tube Assembly

13

15

10" Vertical Assembly

2

17

19

14

18

20

9

3

7

57

16

17

Lock out all power sources while installing or maintaining equipment.

Keep all safety devices and shields in place at all times until power source is locked out.

11

Page 20

10" Vertical Assembly

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

7. Attaching Vertical Section to Bin

A. Slide bin unloading flight into bin well and unloading tube (which should already be installed in bin.)

The unloading flight for larger bin sizes may need to be bolted together . Use bolts provided in connecting stubs

located at the end of the tail flights. See the 8" Flight Chart below to determine the flight length for your bin size.

B. Bolt unloading flight to short horizontal flight (#6 on page 14) using four 1/2" x 3" long (grade 5) bolts

and locknuts.

C. Bolt flange on horizontal tube of vertical unloader to the flange of the bin unloader tube with vertical auger in

vertical position. Use eight 5/16" x 1" long bolts, lockwashers, and nuts.

10" FLIGHT CHART

Product No. Bin Dia. Part No.

'

GFC10240

GFC10270

GFC10300

GFC10330

GFC10360

GFC10380

GFC10400

GFC10420

GFC10480

GFC10540

GFC10600 60' GK1835 20' -0" x 7" O.D. Flight (Head)

GFC10630 63' GK1835 20' -0" x 7" O.D. Flight (Head)

GFC10680 68'-69' GK1835 20' -0" x 7" O.D. Flight (Head)

GFC10720 72' GK1835 20' -0" x 7" O.D. Flight (Head)

GFC10750 75' GK1835 20' -0" x 7" O.D. Flight (Head)

GFC10780 78' GK1835 20' -0" x 7" O.D. Flight (Head)

GFC10800

GFC10820

GFC10900

GFC10920

24

27' GK1827 16' -0" x 7" O.D. Flight

30' GK1828 17' -6" x 7" O.D. Flight

33'-34' GK1829 19' -6" x 7" O.D. Flight

36' GK1830 20' -6" x 7" O.D. Flight

37'-39' GK1831 22' -6" x 7" O.D. Flight

40' GK1832 23' -0" x 7" O.D. Flight

42' GK1833 24' -0" x 7" O.D. Flight

48'-49' GK1835 20' -0" x 7" O.D. Flight (Head)

54'-55' GK1835 20' -0" x 7" O.D. Flight (Head)

80' GK1835 20' -0" x 7" O.D. Flight (Head)

82' GK1835 20' -0" x 7" O.D. Flight (Head)

90' GK1835 20' -0" x 7" O.D. Flight (Head)

92' GK1835 20' -0" x 7" O.D. Flight (Head)

GK1826 14' -6" x 7" O.D. Flight

GK1834 7' -0" x 7" O.D. Flight (Tail)

GK1836 10' -0" x 7" O.D. Flight (Tail)

GK1837 13' -0" x 7" O.D. Flight (Tail)

GK1838 14' -6" x 7" O.D. Flight (Tail)

GK1839 17' -0" x 7" O.D. Flight (Tail)

GK1840 19' -0" x 7" O.D. Flight (Tail)

GK1841 20' -6" x 7" O.D. Flight (Tail)

GK1842 22' -6" x 7" O.D. Flight (Tail)

GK1844 20' -0" x 7" O.D. Flight (Middle)

GK1843 4' -6" x 7" O.D. Flight (Tail)

GK1844 20' -0" x 7" O.D. Flight (Middle)

GK1845 5' -6" x 7" O.D. Flight (Tail)

GK1844 20' -0" x 7" O.D. Flight (Middle)

GK1846 9' -6" x 7" O.D. Flight (Tail)

GK1844 20' -0" x 7" O.D. Flight (Middle)

GK1847 10' -6" x 7" O.D. Flight (Tail)

Description

12

Page 21

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

10" Vertical Assembly

7. Attaching Vertical Section to Bin (cont.)

D. Adjust stand (#47 on page 14) so it holds the weight of the vertical auger .

E. Attach the support brackets and halfbands to the top half of the vertical tube by inserting the 5/16" U-bolt (4)

through the support brackets (5) and halfbands (6) and fasten together using four 5/16" nylon locknuts.

F. Attach lower telescoping tube sections (3) to the ears on the support brackets (5) using two

3/8" x 3/4" bolts with locknuts.

G . Slide the upper telescoping tube sections (1) into the lower tube sections (3). Attach upper tubes to the bin wall.

H. Secure the upper telescoping tubes to the lower telescoping tubes by tightening the square head setscrew (2).

1

1

2

3

4

5

6

8. Attaching Horizontal Motor Mount (Direct Belt Drive)

A. First, connect the head stub shaft (39) to the short flight (6) using two 1/2" x 3" (grade 5)

bolts with locknuts.

B. Connect the four-hole flange bearing with lock collar (16) to the head plate (8) together using four

1/2" x 1-1/2" bolts with locknuts.

C. Attach the head plate (8) to the tube flange using eight 5/16" x 1" bolts with flat washers,

lockwashers, and nuts.

D. Connect side plates (22) and (23) to head plate (8) using four 1/2" x 1-1/4" bolts with lockwashers

and nuts. Also, at the same time, attach the belt guard brackets (21) using the same bolts.

7

E. Spin a 3/4" nut on the threaded rods of each strap and rod assembly (24). Insert threaded rods through holes in

side plates (22) & (23) and add four more 3/4" nuts. Leave only finger tight until later .

F. Place rods (25) in strap and rod assemblies (24) and secure with top straps (26) using

3/8" x 1-1/2" bolts with two flat washers and one nut on each bolt.

13

Page 22

10" Vertical Assembly

G . Clamp belt guard mounting angle (30) to rod ends (25) with clamp bar (31) using four 5/16" x 1-3/4" bolts

with nuts.

H. Attach belt guard back (28) to belt guard mounting angles (21) using four 5/16" x 3/4" carriage bolts with flat

washers and nuts.

I. Slide bearing lock collar (40) over head stub shaft (39). Leave enough stub exposed to mount pulley (21) on stub

with drive key (41). Tighten bearing lock collar next to bearing and tighten set screws in pulley.

J. Position motor mount straps (15) and clips (14) and secure using four 3/8" x 3" carriage bolts and nuts. Leave

finger tight until later .

K. Install pulley on motor shaft and mount motor on strap (15). (Motor and pulley not furnished.) Install belts (3)

and align pulleys. Tighten motor to straps (15). Adjust motors along the tube and tighten with 3/8" x 3"

carriage bolts.

L. Set belt tension by adjusting height of motor using 3/4" nuts on rods.

L. Connect belt guard (29) by bolting belt guard clamp bar (33) to mounting angle (21) using 1/4" x 5-1/2" bolts

with nuts. Att ach second clamp bar (32) to belt guard mounting bracket s (30) using 1/4" x 5-1/2" bolts .

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

21

40

41

15

30

25

15

31

28

27

3

6

39

5

47

22

6

25

26

6

14

24

8

21

16

14

29

33

32

Page 23

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

1. Start-up and Break-In

ALWAYS keep ALL guards and shields in place, until all the power is disconnected

and locked out.

A. Make sure all belts are tensioned properly.

B. Make sure ALL shields are in place and that the belt(s) and pulley(s) are able to move freely.

C. Double check the assembly instructions to see that all parts have been assembled properly .

D. During operation of equipment, one person should be in a position to monitor the entire operation.

During the initial start-up and break-in period, the operator should note any unusual

vibrations or noises and take the appropriate action.

Make certain everyone is clear before operating or moving the machine.

Start-up

E. The bin well inside the bin should have a control gate. The gate should be closed before start-up and closed

before shutdown to allow the machine to clean out.

F. The controls for the control gate should either pull or push open, depending on the type of well you have. Use the

control gate to regulate a flow of less than full capacity until several hundred bushels of grain have been augered

to polish the flighting assembly and tube.

G. Any new screw conveyor or one that has set idle for a season should go through a “break-in” period. This

“break-in” consists of running the auger at half capacity until the screw becomes polished and smooth before

attempting to run at full capacity . It is recommended that several hundred bushels of grain be augered at

partial capacity.

Failure of your auger is very likely to occur if it is run at full capacity before the

screw has become polished.

NEVER operate augers empty for any length of time as excessive wear will result.

H. Do not stop or start augers under load, especially before the flight and tube become well polished, as this may

cause the auger to “lockup”. Make sure to use the control gate as a flow control so the vertical auger

cannot become plugged.

Excessive wear will result if auger is run at speeds in excess of what is recommended.

15

Page 24

Operation & Maintenance

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

1. 8" Vertical Commercial Bin Unloading Auger Operating Instructions

A. Parts Included: 16’-6" vertical auger, horizont al tube 24" long with flange, horizontal drive with 2 or 3 belt drive,

2 belt vertical drive with pulleys, “B” belts, motor mount, mounting brackets, belt guard and 3' discharge spout.

Y our horizontal unloading flight should be ordered separately .

B. Capacity: For cases with high moisture or high capacity requirements, use the next size larger motor .

( See Capacity Chart Below .)

MATERIAL CAPACITY - 8"

Dry Grain 1000-1500

High Moisture 800-1200

C. Vertical Drive: Use a 4.6" motor pulley for recommended auger speed of 536 RPM.

D. Horizontal Drive: Use a 3.5" motor pulley for recommended auger speed of 408 RPM.

Motor pulleys are NOT furnished with the auger.

E. Vertical Horsepower: Use a 5 H.P. Motor

F. Horizontal Horsepower: Use the horsepower chart below to find the flight length to fit your needs.

8" Horizontal Flights for Vertical Height Unloade rs

Pr oduc t No. Bin Dia. H.P.

GFC 82400 24' 3 14' -6" x 7" O. D. F light

GFC 827 00 27' 3 1 6' -0" x 7 " O.D. F l igh t

GFC 830 00 30' 5 1 7' -6" x 7 " O.D. F l igh t

GFC83300 33'-34' 5 19' -6" x 7" O. D. F light

GFC 836 00 36' 5 2 0' -6" x 7 " O.D. F l igh t

GFC83800 37'-39' 5 22' -6" x 7" O. D. F light

GFC 840 00 40' 5 2 3' -0" x 7 " O.D. F l igh t

GFC 842 00 42' 5 2 4' -0" x 7 " O.D. F l igh t

GFC84800 48'-49' 5 27' -0" x 7" O. D. F light

GFC85400 54'-55' 5 30' -0" x 7" O. D. F light

GFC 860 00 60' 5 3 3' -0" x 7 " O.D. F l igh t

GFC 863 00 63' 5 3 4' -6" x 7 " O.D. F l igh t

GFC86800 68'-69' 7 1/2 37' -6" x 7" O. D. Flight

GFC 872 00 72' 7 1 /2 3 9' -0" x 7" O.D. F l i gh t

GFC 875 00 75' 7 1 /2 4 0' -6" x 7" O.D. F l i gh t

GFC 878 00 78' 10 42' -6" x 7" O.D. F l i ght

GFC 880 00 80' 10 44' -6" x 7" O.D. F l i ght

GFC 882 00 82' 10 45' -6" x 7" O.D. F l i ght

GFC 890 00 90' 10 49' -6" x 7" O.D. F l i ght

GFC 892 00 92' 10 50' -6" x 7" O.D. F l i ght

Flight Length

G. The horsepower recommendations are for augering reasonably dry grain. High moisture grain (above 15%) will

require greater power if maximum capacity is to be maintained. The maximum possible capacity will be less

with high moisture grain than with dry grain. Use an electric motor of the correct size that operates at

1750 R. P. M.

16

Electrical controls and wiring should be installed by a qualified electrician. The

motor disconnect switches and conductor cables should comply with the National

Electrical Code and any local codes which apply. Motor starting control stations

should be so located that the operator can see that all personnel are clear of the

equipment.

Page 25

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

g

Operation & Maintenance

2. 10" Vertical Commercial Bin Unloading Auger Operating Instructions

A. Parts Included: 16’-6" vertical auger, horizont al tube 30" long with flange, horizontal drive with 2 or 3 belt drive,

2 belt vertical drive with pulleys, “B” section belts, motor mount, mounting brackets, belt guard and 3' discharge

spout. Y our horizont al unloading flight should be ordered separately .

B. Capacity: For cases with high moisture or high capacity requirements, use the next size larger motor .

( See Capacity Chart Below .)

MATERIAL CAPACITY - 10"

Dry Grain 1600-2000

High Moisture 1300-1600

C. Vertical Drive: Use a 4.6" motor pulley for recommended auger speed of 408 RPM.

D. Horizontal Drive: Use a 3.4" motor pulley for recommended auger speed of 323 RPM.

Motor pulleys are NOT furnished with the auger.

E. Vertical Horsepower: Use a 7-1/2 H.P. Motor

F. Horizontal Horsepower: Use the horsepower chart below to find the flight length to fit your needs.

10" Horizontal Flights for Vertical Height Unloaders

Product No. Bin Dia. H.P.

GFC10240 24

GFC10270 27' 5 16' -0" x 7" O.D. Flight

GFC10300 30' 5 17' -6" x 7" O.D. Flight

GFC10330 33'-34' 5 19' -6" x 7" O.D. Flight

GFC10360 36' 7 1/2 20' -6" x 7" O.D. Flight

GFC10380 37'-39' 7 1/2 22' -6" x 7" O.D. Flight

GFC10400 40' 7 1/2 23' -0" x 7" O.D. Flight

GFC10420 42' 7 1/2 24' -0" x 7" O.D. Flight

GFC10480 48'-49' 7 1/2 27' -0" x 7" O.D. Flight

GFC10540 54'-55' 7 1/2 30' -0" x 7" O.D. Flight

GFC10600 60' 10 33' -0" x 7" O.D. Flight

GFC10630 63' 10 34' -6" x 7" O.D. Flight

GFC10680 68'-69' 10 37' -6" x 7" O.D. Flight

GFC10720 72' 10 39' -0" x 7" O.D. Flight

GFC10750 75' 10 40' -6" x 7" O.D. Flight

GFC10780 78' 10 42' -6" x 7" O.D. Flight

GFC10800 80' 15 44' -6" x 7" O.D. Flight

GFC10820 82' 15 45' -6" x 7" O.D. Flight

GFC10900 90' 15 49' -6" x 7" O.D. Flight

GFC10920 92' 15 50' -6" x 7" O.D. Fli

'

5 14' -6" x 7" O.D. Flight

Flight Length

ht

G. The horsepower recommendations are for augering reasonably dry grain. High moisture grain (above 15%) will

require greater power if maximum capacity is to be maintained. The maximum possible capacity will be less

with high moisture grain than with dry grain. Use an electric motor of the correct size that operates at

1750 R. P. M.

Electrical controls and wiring should be installed by a qualified electrician. The motor

disconnect switches and conductor cables should comply with the National Electrical

Code and any local codes which apply. Motor starting control stations should be so

located that the operator can see that all personnel are clear of the equipment.

17

Page 26

Operation & Maintenance

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

3. Power Source

A. Use electric motors that operate at 1750 R.P .M.

B. Electric motors and controls should be installed by a qualified electrician and must meet the standards set by

the National Electrical Code and all local and state codes.

C. A magnetic starter should be used to protect your motor when starting and stopping. It should stop the motor in

case of power interruption, conductor fault, low voltage, circuit interruption, or motor overload. Then the motor

must be restarted manually . Some motors have built-in thermal overload protection. If this type motor is used,

use only those with a manual reset.

You should use a Main Power Disconnect Switch capable of being locked only in the

OFF position. This should be locked whenever work is being done on the auger.

Disconnect power before resetting motor overloads.

Make sure all electrical motors are grounded.

Reset and motor starting and stopping controls must be located so that the operator has

full view of the entire operation.

Shut off power to adjust , service, or clean the machinery.

Keep all safety guards and shields in place.

4. Maintenance

A. The flange bearings on the head and tail ends of all units should be lubricated on frequent intervals.

18

Never clean, adjust, or lubricate a machine that is in operation.

Page 27

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

1. Normal Shutdown

A. Make certain that bin well and unloading tubes are empty before stopping the unit.

B. Disconnect and lockout the power source before leaving the work area.

2. Emergency Shutdown

A. Know how to shut down the auger in case of an emergency.

B. Disconnect and lockout the power source.

C. Close bin well control gates.

D. Clear out as much grain from the auger and hopper as you can.

Never restart when under a full load. Starting unit under load may result in damage

to the machine. Such damage is considered abuse of the equipment.

Shutdown

E. Reconnect and unlock the power source.

F. Gradually clear the auger until there is no grain or obstructions.

3. Lockout

A. Always stop and disconnect the power source whenever the operator must leave the work area or for

maintenance of the machinery .

B. Make sure no one can operate the unload auger while the operator is not in the work area.

Use the type of main power disconnect switch that is capable of being locked

only in the off position.

3. Storage Preparation

A. Close all wells to discharge tube.

B. Be sure the unload tube is empty.

C. Make sure power source is disconnected and locked out.

D. Check to see that all fasteners are secure.

19

Page 28

Troubleshooting

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

Problem

1. The auger is vibrating.

Possible Cause

A. Damage can occur to the

auger flighting, causing noise.

Damage usually is caused

from foreign material being run

through the auger.

A. Drive belt may be overtightened,

putting head stub and flight in a

bind.

2. Capacity is too low. A. There may not be enough grain

reaching the auger.

B. The auger is moving too slowly.

Solution

A1. It may be necessary to remove the

flighting for inspection.

A1. Loosen the drive belts.

A1. Make sure the intake has not

bridged over, restricting flow . The

flighting at the intake should be

covered with grain for maximum

capacity.

B1. Check the auger speed. Low

capacity will result from speeds

slower than recommended.

3. The auger plugs.

A. The auger may be "jamming"

because too much grain is

reaching the auger.

B. The grain may be wet. B1. If wet grain or other hard-to-move

C. The auger may be jammed

with foreign material.

D. The motor may be to small or

wired incorrectly .

A1. Use the control gates to decrease

the amount of grain the auger is

gathering.

material is being augured, use a

larger size motor than recommended for normal use.

C1. Remove any foreign material in the

auger.

D1. Check wiring or consider using the

next larger size motor .

20

Page 29

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

8" PARTS ILLUSTRATION

18

17

35

Parts

38

12

10

7

8

20

21

15

11

25

37

6

26

13

5

43

18

23

4

45

19

13

28

17

49

50

47

24

14

22

27

48

52

53

46

39

42

41

44

40

21

Page 30

Parts

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

8" PARTS LIST

Ref. No. Part No. Description

4 GK 1017 1.25" B ore Flange B earing w/ Loc k

5 GK 1055 8" x 2" Wide G alvanized Halfband

6 GK 1059 8" x 4" Wide G alvanized Halfband - 12 Ga.

7 GK 1063 Motor M ount Top S trap

8 GK 1064 Motor M ount Bott om S t rap

N/S GK1317 Decals P ac kage

10 GK 1327 8" Mot or Mount W eldm ent

11 GK 1331 Drive Shaft - 1.25" O. D. x 10. 5"

12 GK 1330 1.25" Two hole flange bearing

13 GK 1329 8" Head Plat e A s s em bly

14 GK 1341 M otor M ount B ottom

15 GK 1342 Motor M ount Top

N/S GK1346 Belt V B -57

17 GK 1454 Belt G uard As s embly

18 GK 1869 Alum inum S heave - 15" x 1.25" for 2 belts

19 GK 2234 Alum inum S heave - 15" x 1.25" for 3 belts

20 GK 1891 Inner Leg Telesc oping Tube 32"

21 GK 1892 Outer Leg Telesc oping Tube 36"

22 GK 1897 Left S ide M otor M ount

23 GK 1898 Right Side M ot or Mount

24 GK 2108 8" St rap and Rod As s embly

25 GK 2109 8" Top St rap

26 GK 2110 M otor M ount 1" O. D. x 19" Long

27 GK 3096 Belt G uard Mount ing A ngle P ower Head V ertic al

28 GK 3097 8" Head Plat e for Power Head Vertic al

N/S GK3098 8" Bolt K it

N/S GK4235 HDW: M ounting Brack et V ertic al Double Drive

N/S Pneg- 1057 Manual Inst ructions

N/S Pneg-777 S hortage Claim S heet

N/S GK1317 Decal Pac k age: 6-10" Horiz ontal D rive

35 GK 1344 Belt G uard Mount ing A ngles

36 S-8276 3" K ey - 1/ 4" x 1/ 4" x 3"

37 S-4513 2" K ey - 1/ 4" x 1/ 4" x 2"

38 GK 1002 Spout

39 GK 3090 Verticle Cross A s s em bly

40 GK 3088 Support S tand A s s embly

41 GK 1017 1-1/4" Bearing 4 Hole

42 GK 3087 Head Flight 7" O. D. x 23" Long

43 GK 3086 8" O.D. x 14' -5" Unloading Tube

44 GK 1884 Tail Stub

45 GK 1004-2 Vertic al Flight Weldm ent

46 GK 1113 Rubber Was her

47 GK 1015 Connecting B and

48 GK 1328 Connecting S tub

49 S-7013 7/16" x 14" x 2-1/2" B olt

50 S-7170 7/16" Deformed Loc k nut

52 S-7522 3/8" x 16x 2" Zinc Coated G rade 2 HHCS B olt

53 S -456 3/8" Nut

22

Page 31

PNEG 1057 - 8" & 10" Commercial Vertical Bin Unloading Auger

10" PARTS ILLUSTRATION

19

Parts

32

33

29

57

40

16

18

16

9

34

23

14

20

7

11

17

13

15

46

12

44

27

56

28

22

31

30

21

15

26

4

39

14

25

22

24

18

48

51

47

55

45

47

42

50

43

41

49

54

52

53

23

Page 32

Parts

Ref. No. Part No. Description

N\S GK4235 Bolt Kit for 10" Powerhead Vertical Double Drive Auger

N\S GK4247 Mounting Bracket Hardware for 10"

7 GK1349 10" Head Plate Assembly

4 GK2561 Head Plate for Direct Belt Drive

9 GK1057 10" x 2" Wide Galvanized Halfband

N\S GK1317 6" - 10" Horizontal Drive Decal Package

11 GK1028 Telescoping Tube Less Set Screw

12 GK1033 28" Telescoping Tube

13 GK1350 10" Motor Mount W eldment

14 GK1341 Motor Mount Bottom

15 GK1342 Motor Mount Top

16 GK1343 1-1/2" Bearing Flange

17 GK1344 Belt Guard Mounting Angle

18 GK1340 Stub Drive 1.5" O.D. x 10.5"

19 GK1345 Aluminum Sheave - 15" x 1.50" for 2 belts

20 GK1454 Belt Guard Assembly

21 GK2569 Belt Guard Support

22 GK1897 Left Side Motor Mount

23 GK1898 Right Side Motor Mount

24 GK1900 10" Strap and Rod Assembly

25 GK1893 Motor Mount Rod

26 GK1901 Top Strap

27 GK2567 Sheave: 18.4" O.D.w/out Bushing Z-Belt

28 GK2568 Belt Guard Back Weldment

29 GK2565 Belt Guard Front

30 GK2017 Belt Guard Mounting Angle

31 GK2018 Clamp Bar for Mounting Agle

32 GK2019 Clamp Bar for Belt Guard

33 GK2564 Clamp Bar for Belt Guard

34 GK1301 10" x 4" Wide Galvanized Halfband

N\S PNEG-1057 8"-10" Commercial Vertical Manual Instructions

N\S PNEG-777 Shortage Claim Sheet Form

N\S GK1346 Belt V B -57

N\S GK2566 Belt V B-71

39 GK2562 1.5" O.D. x 9.5" Long Drive Stub

40 GK4248 1-1/2" SK Bushing

41 GK1882 Vertical Cross Assembly

42 GK1017 1-1/4" 4 Hole Bearing (Peer)

43 GK1113 Rubber W asher

44 GK1876 9" O.D. x 16-1/2" Long Vertical Unloading Flight

45 GK4886 1-1/4" to 1-1/2" x 9" Tail Stub

46 GK1877 10" O.D. -14' Unloading Tube

47 GK1879 Support Stand Assembly

48 1883 Connecting Band

49 2563 29" Head Flight 9" O.D. (Direct Belt Drive)

50 S-7522 Bolt HHCS 3/8" x 16" x 2" Zinc Grade 2

51 S-456 3/8" - 16 Nut

52 GK1137 1.5 x 9.5 Stub Shaft

53 S-8314 Bolt, HHCS 1/2"-13 x 3-1/2" YDP Grade 8

54 S-8315 Lock Nut 1/2"-13 ZN GRC Prevailing Torque

55 S-240 Hex Nut 1 - Zinc Grade 5

N\S S-1054 Split Lock Washer 3/8" Med. Zinc

56 GK2570 Sheave: 18.4" O.D.w/out Bushing 3-Belt

57 GK1875 Spout

N\S S-7079 U-Bolt 5/16 - 18 x 1-3/4 IW PL

N\S S-7116 Bolt HHCS 1/4-20 x 5-1/2"

10" PARTS LIST

24

8" & 10" Commercial Vertical Bin Unloading Auger - PNEG 1057

Page 33

Limited Warranty

The GSI Group, LLC. (“GSI”) warrants products which it manufactures to be free of defects in materials

and workmanship under normal usage and conditions for a period of 12 months after sale to the original

end-user or if a foreign sale, 14 months from arrival at port of discharge, whichever is earlier. The enduser’s sole remedy (and GSI’s only obligation) is to repair or replace, at GSI’s option and expense,

products that in GSI’s judgment, contain a material defect in materials or workmanship. Expenses

incurred by or on behalf of the end-user without prior written authorization from the GSI Warranty Group

shall be the sole responsibility of the end-user.

Warranty Extensions: The Limited Warranty period is extended for the following products:

Product Warranty Period

AP Fans and

Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems

Grain Systems

Farm Fans

Zimmerman

Performer Series Direct Drive

Fan Motor

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1.75" & 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Grain Bin Structural Design 5 Years

Portable & Tower Dryers 2 Years

Portable & Tower Dryer Frames

and Internal Infrastructure †

3 Years

5 Years

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger

drive components, shall be free from defects in materials for a period of time beginning on the twelfth (12

month from the date of purchase and continuing until the sixtieth (60

th

) month from the date of purchase

* Warranty prorated from list price:

0 to 3 years – no cost to end-user

3 to 5 years – end-user pays 25%

5 to 7 years – end-user pays 50%

7 to 10 years – end user pays 75%

** Warranty prorated from list price:

0 to 3 years – no cost to end-user

3 to 5 years – end-user pays 50%

† Motors, burner components and

moving parts not included. Portable

Dryer screens included. Tower Dryer

screens not included.

th

)

(extended warranty period). During the extended warranty period, GSI will replace the frame or basket

components that prove to be defective under normal conditions of use without charge, excluding the labor,

transportation, and/or shipping costs incurred in the performance of this extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION

SET FORTH ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH: (i) PRODUCT

MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR

SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING

OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR

PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without

limitation, loss of anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited

Warranty, which shall not exceed the amount paid for the product purchased. This warranty is not

transferable and applies only to the original end-user. GSI shall have no obligation or responsibility for any

representations or warranties made by or on behalf of any dealer, agent or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications

to products which it manufactured. Modifications to products not specifically delineated in the manual

accompanying the equipment at initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use,

misuse, alteration, accident or which have been improperly/inadequately maintained. This Limited Warranty

extends solely to products manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which

apply to the location and installation of products manufactured or sold by GSI.

9101239_1_CR_rev7.DOC (revised July 2009)

Page 34

This Equipment shall be installed in accordance

with the curr ent installation codes and applicable

regulations which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installation occurs.

1004 East Illinois Street

Assumption, IL 62510

Ph: (217) 226-4421

Loading...

Loading...