Page 1

C hain C onveyor

Incline Chain Conv eyor

Series

Installation and Operation Manual

PNEG-1056

1

Page 2

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidlines.To help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention to.

- 2 -

Page 3

TABLE OF CONTENTS

EQUIPMENT INFORMATION................................................................... 4

SAFETY DECAL LOCATIONS………………………………………….. 5

GENERAL PRECAUTIONS..................................................................….. 11

RECEIVING AND PRE-INSTALLATION................................................ 12

INSTALLATION………............................................................................... 13

CARE, MAINTENANCE, STORAGE......................................................... 21

OPTIONS...................................................................................................…. 25

TROUBLE SHOOTING………………………………………………….. 29

TRAINING SIGN OFF SHEET………………………………………….. 30

MAINTENANCE RECORD……………………………………………… 31

WARRANTY………………………………………………………………. 32

- 3 -

Page 4

Introduction

We encourage all personnel operating, installing, or maintaining this

equipment to thoroughly read this manual before proceeding. Successful

operation is our intention; however, if in fact you are in need of technical

advice or support, we encourage you to contact your local dealer/distributor

or contact the factory at any time during regular business hours at 217-226-

4421. Our commitment is to you the customer, and we encourage your input

and/or suggestions that would help better our product.

s

r’

o

t

ra

This manual covers general information on incline conveyor (straight and

bend incline configurations) installation. Due to the varying sizes of

equipment it would be very difficult to cover every aspect of installation. We

offer one method for erecting conveyors but many times the contractor’s

experience and techniques will work. Many times conditions and

surroundings do not allow certain practices during the erection of

equipment. We cannot be responsible for the erection of the conveyor

(unless so contracted to do so).

e

p

O

l

a

u

n

a

M

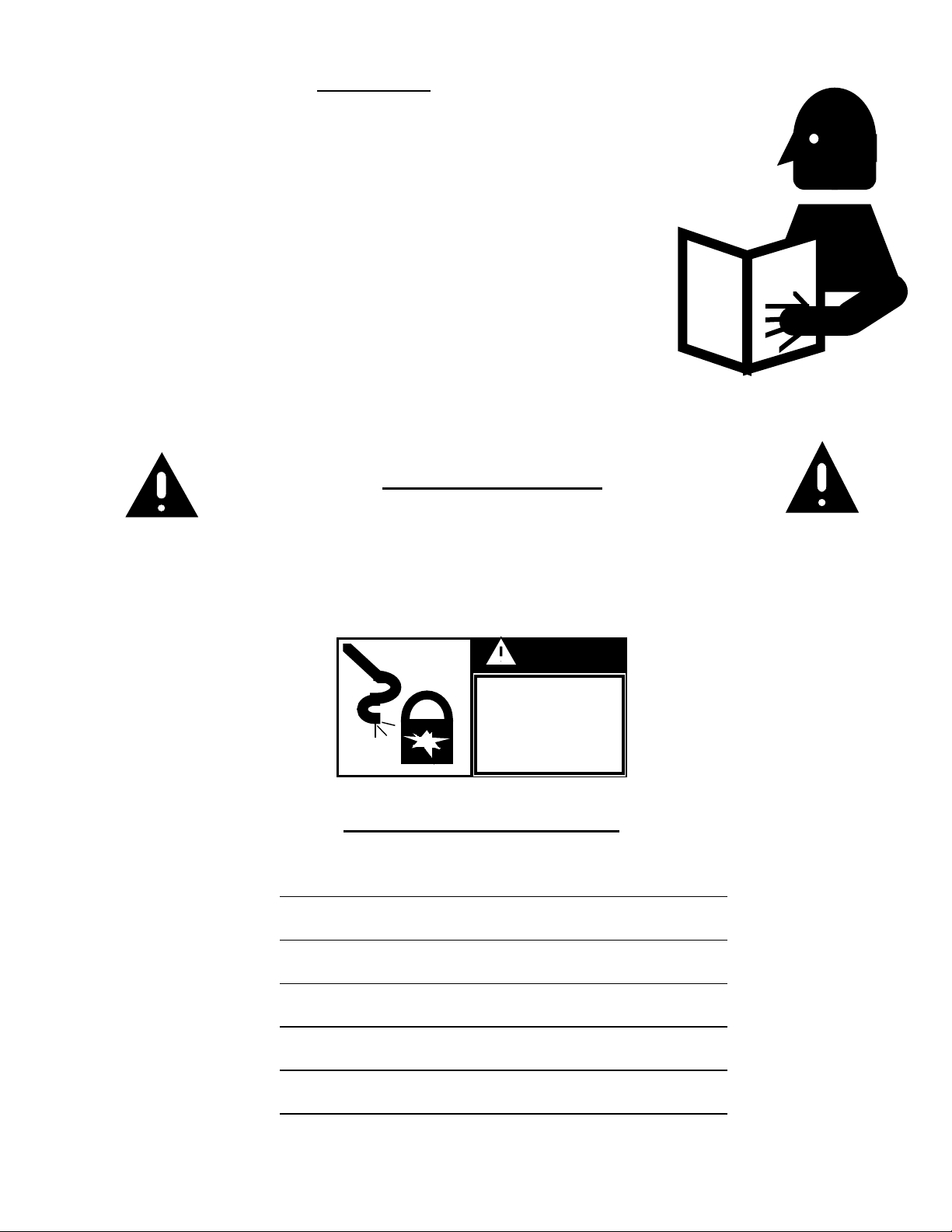

Safety Information

It is the responsibility of the buyer to make this manual available to the person

or persons involved with this equipment. Guards and safety labels have been installed prior to the

equipment leaving the manufacturing plant. These devices are not to be removed, altered, or defaced,

otherwise voiding any liability or responsibility of the manufacturer. Power lock out is very important prior

to installation, adjustment, and maintenance of the unit.

DANGER

Disconnect and

Lockout Electric

Power Before

Servicing U n it

Equipment Information

Model Number:

Serial Number:

Date Purchased:

Dealer/Distributor:

- 4 -

Page 5

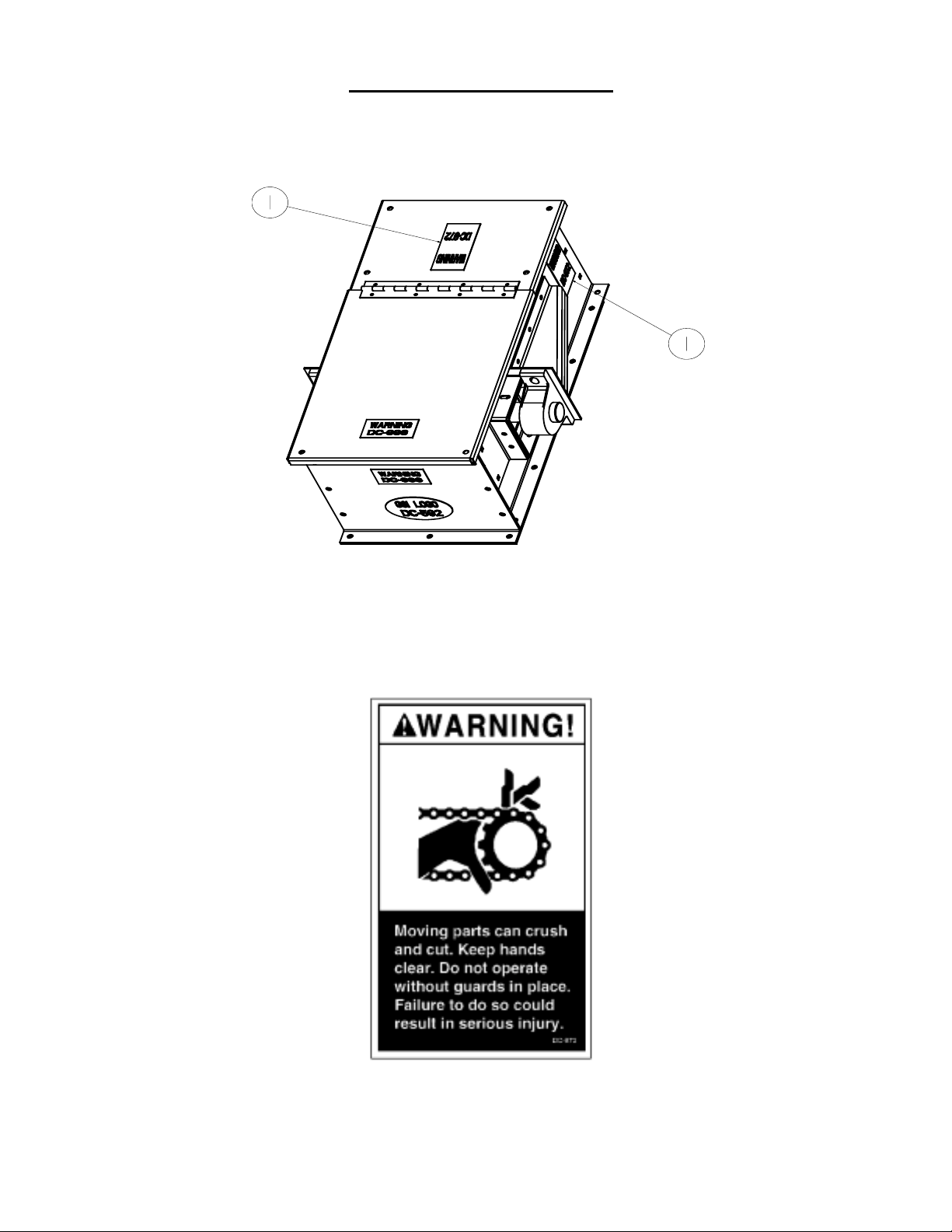

Head Section Decal Locations

1.

- 5 -

Page 6

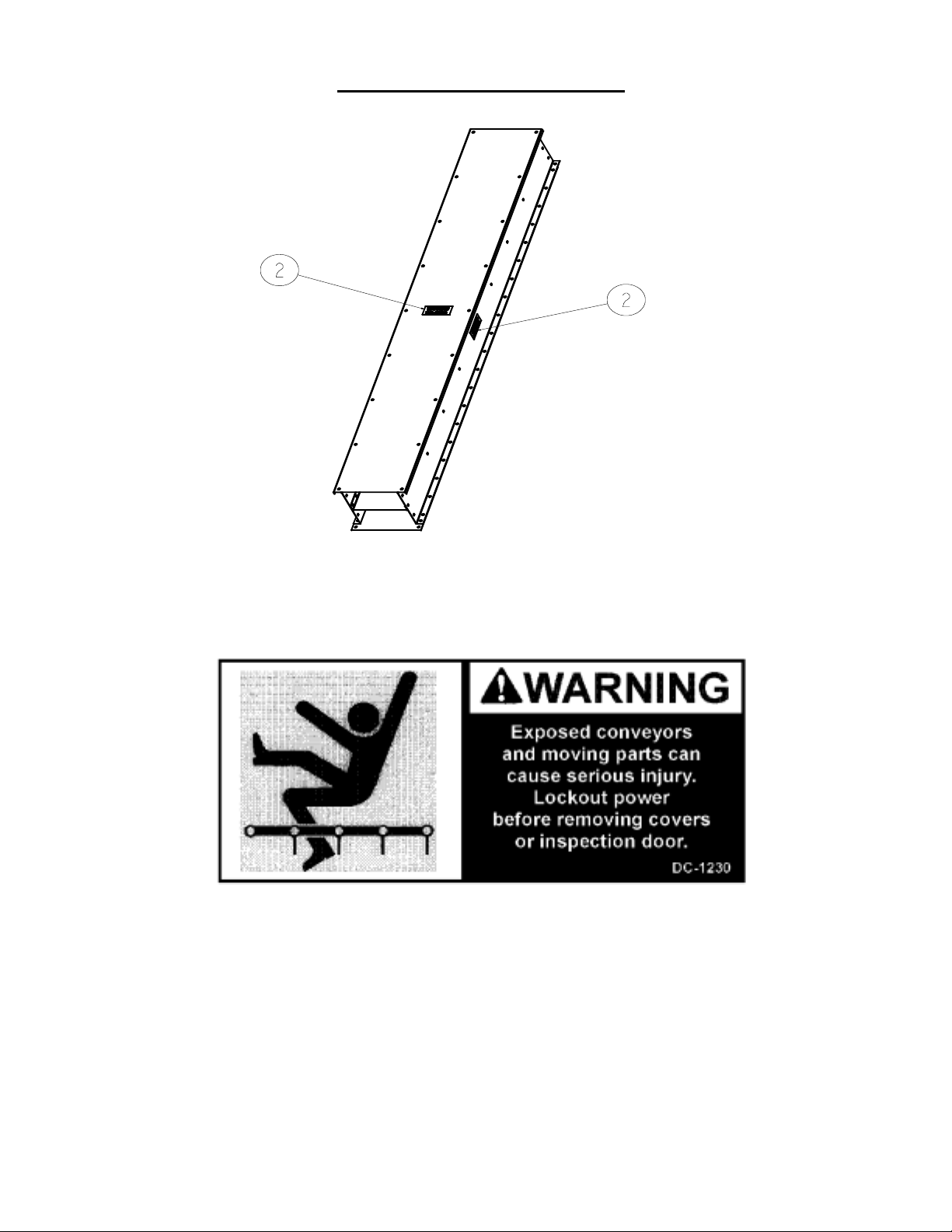

Tail Section Decal Locations

1.

- 6 -

Page 7

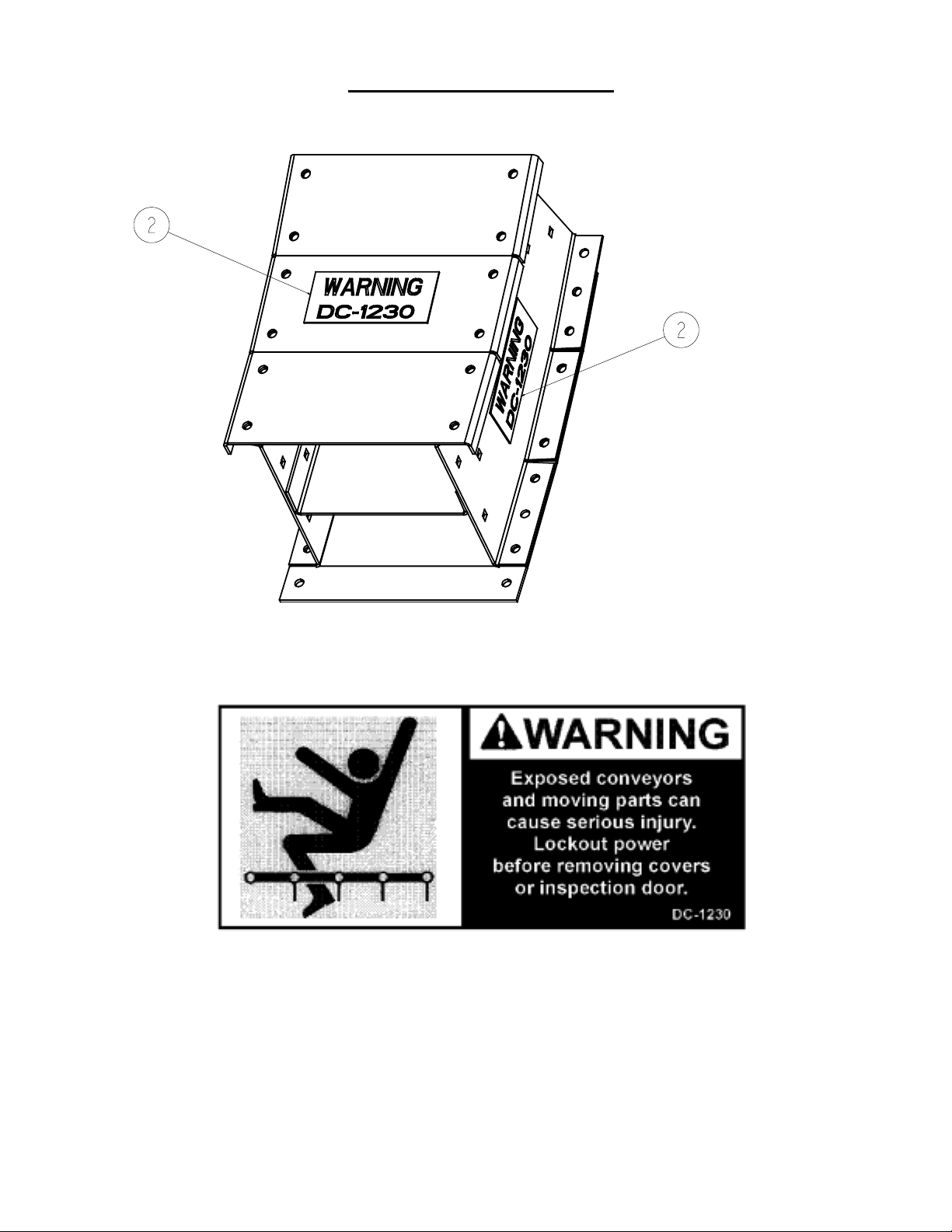

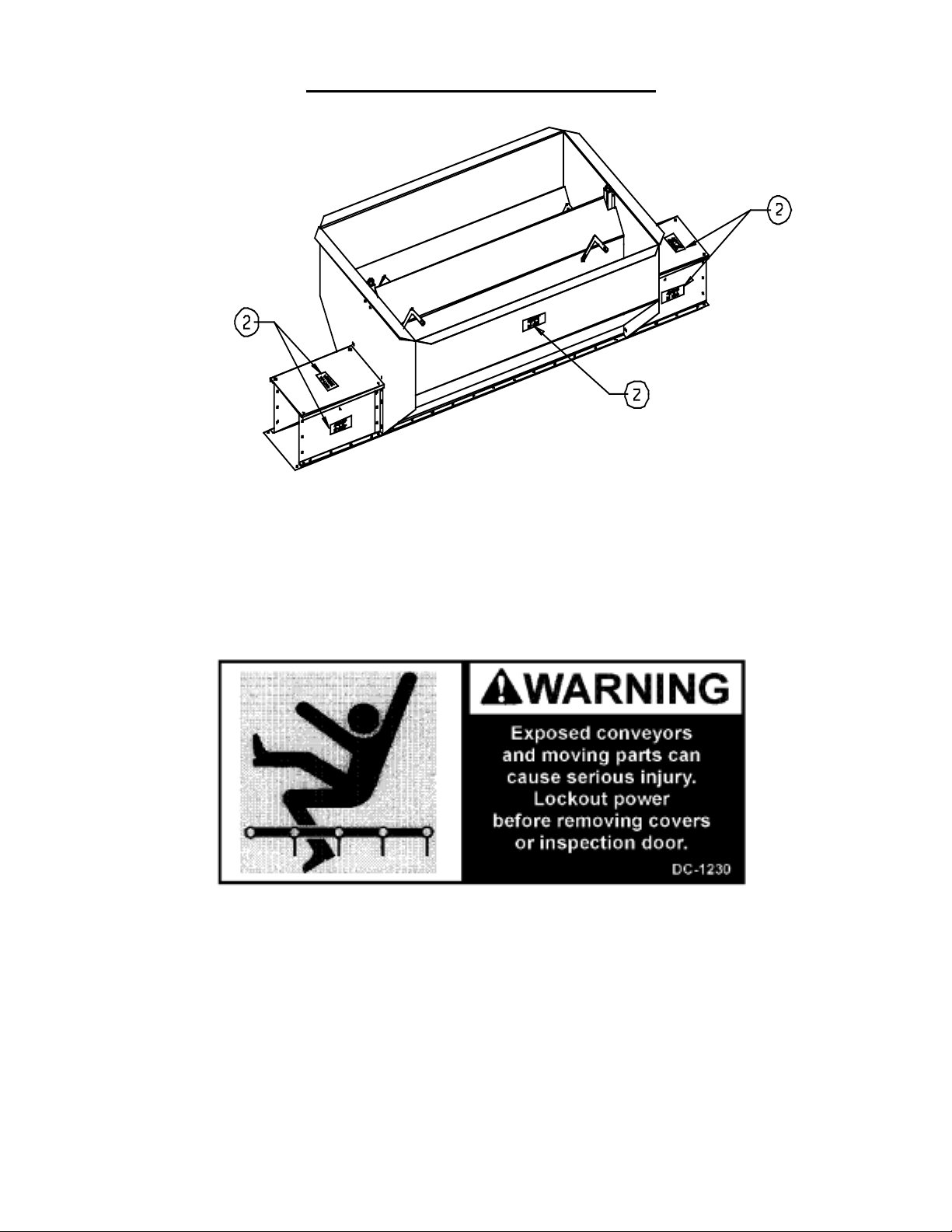

Trough Section Decal Location

2.

- 7 -

Page 8

Bend Section Decal Location

2.

- 8 -

Page 9

Bypass Inlet Decal Location

2.

- 9 -

Page 10

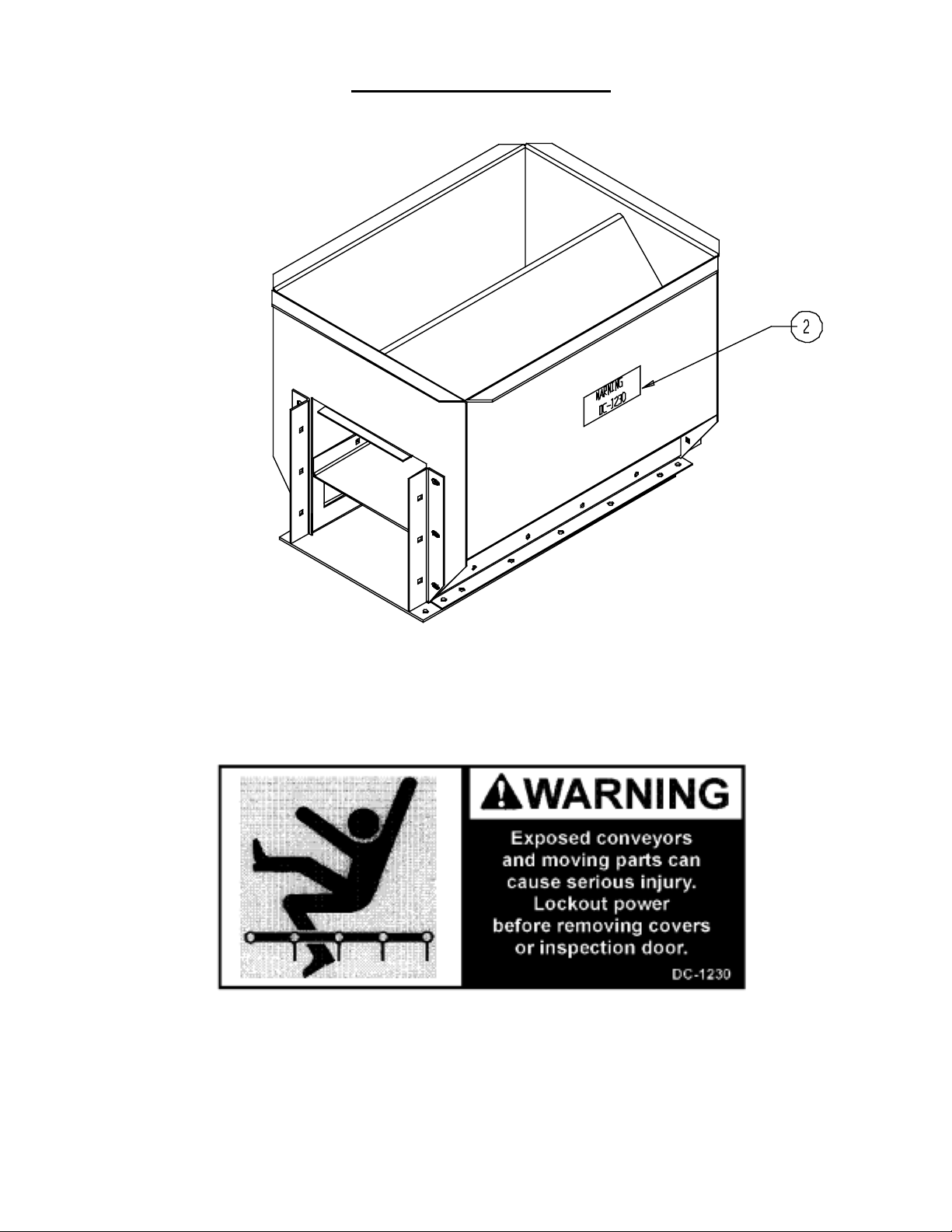

Bypass Dump Hopper Decal Location

2.

- 10 -

Page 11

CAUTION

1. Do not operate the unit before reading and understanding the

operator’s manual.

2. Keep all safety shields and devices in place.

3. Make certain everyone is clear of the equipment before operating or moving

the machine.

4. Keep hands, feet, and clothing away from moving parts.

5. Shut off and lock out all power to adjust, service, clean,

or unclog.

6. Keep off the equipment at all times.

7. Keep children, visitors, and all untrained personnel away

from machine while in operation.

8. Do not operate electric motor equipped units until motors are properly

grounded.

9. Disconnect power on electrical driven units before resetting motor overloads.

10. Do not repetitively stop and start the drive in order to free a plugged

condition. Jogging the drive in this type of condition can damage the conveyor

and/or drive components.

- 11 -

Page 12

SET-UP INSTRUCTIONS

This manual is provided by the company to aid in the assembly, operation, and maintenance of

its conveyors. Should a question arise concerning the assembly or operation of this unit not

covered by this manual, please contact the company at 217-226-4421 during regular business

hours and ask for assistance.

In this manual, right and left are determined by standing behind the unit and facing toward the

drive section (See figure below).

UNPACKING

Carefully inspect the shipment as soon as it is received. Verify that the quantity of parts and

packages corresponds to the quantity shown on the packing slip. Any discrepancies should be

clarified immediately. Please remember that any damage or missing parts must be noted on the

bill of lading at the time of delivery. Report any damage or shortages to the delivering carrier as

soon as possible. The company’s responsibility for damage to the equipment ends with the

acceptance by the delivering carrier. It is not the responsibility of the company to file claims for

damages with the appropriate carrier.

Save all paper work and documentation furnished with any of the chain conveyor

components.

- 12 -

Page 13

Installation

The following guidelines dealing with the installation of the Series I incline conveyors are

provided for your convenience. The company cannot be held responsible for the installation of

this unit.

Clearance

A clearance of at least the width of the conveyor is recommended on all sides of the unit. This

amount of clearance is not a necessity; less clearance maybe acceptable. However, serious

consideration must be given to methods of maintenance, removal and replacement of the

conveyor and/or its parts.

Support & Welding

No welding of any kind on or to the conveyor is recommended. Welding on or to the conveyor

may cause damage to both the conveyor and its electrical system. If welding is necessary, the

manufacturer prefers that the attachments or supports be welded to bottom splices. Should it be

necessary to fasten anything to the conveyor permanently, careful consideration should be given

to methods of maintenance, removal and replacement of the conveyor and/or its parts.

- 13 -

Page 14

Head Section

The head section of the conveyor is shipped pre-assembled from the factory. Each head

section has a tag with serial number. There are sub-assembly instructions in the care and

maintenance section of this manual.

Tail Section

The tail section of the conveyor is shipped pre-assembled from the factory. Each tail section has

a tag with serial number. There are sub-assembly instructions in the care and maintenance

section of this manual.

- 14 -

Page 15

Trough Assembly

Intermediate trough sections come both factory pre-assembled or unassembled. Your order

will serve as a reference to how your trough section should arrive.

Assembly sequence for trough sections unassembled:

Fasten trough bottom panel to each trough side panel using 3/8” hex head bolts and 3/8” whiz

nuts. Whiz nuts should be located on bottom side of conveyor. The trough bottom panel should

extend beyond trough side panels approximately two inches on one end and recessed

approximately two inches on the other end.

Fasten center pan, with flange up, using 3/8” carriage bolts through holes provided in trough

side panels. At the seams the carriage bolts below the center pan should be welded to the trough

side panels. Heads of carriage bolts should be inside the conveyor. For liner package assembly

check options portion of this manual.

Conveyor Assembly

Remove trough covers from trough sections to aid the conveyor assembly.

Position a head, tail or other intermediate trough section with holes in bottom flange of trough

sides aligned with holes in bottom panel of another section. Using a bottom splice, (4) 3/8” bolts

and (4) 3/8” whiz nuts fasten the two sections together. The bottom splice should cover the gap

between the two bottom panels, which is offset two inches from the gap in the trough sides.

Position trough splices over the gap between the end of the trough sections and fasten with 3/8”

carriage bolts and 3/8” whiz nuts.

Discharge

The standard conveyor is constructed with one discharge located at the drive end. Attach the

discharge transition to the bottom of the conveyor head using 3/8” bolts and 3/8” whiz nuts.

- 15 -

Page 16

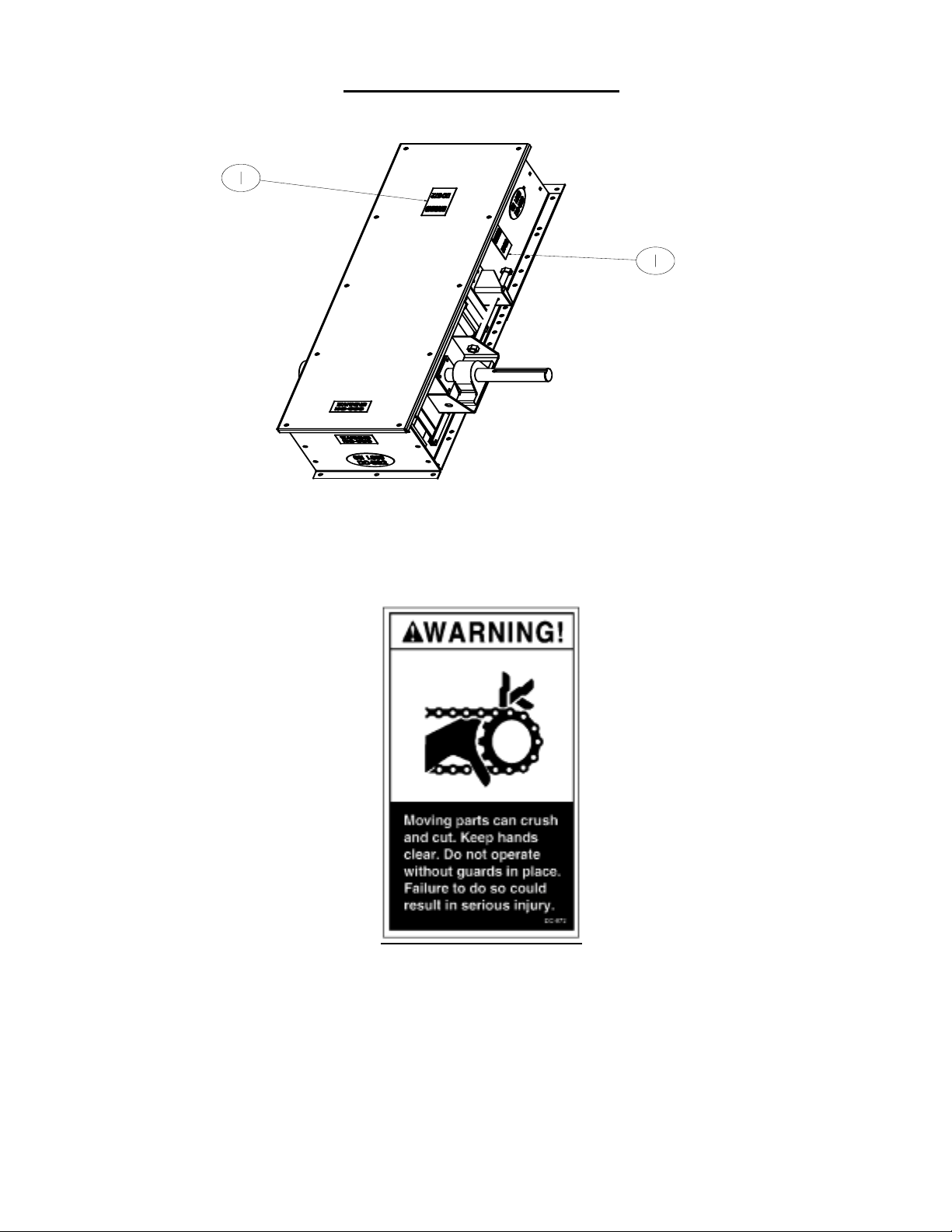

Drive Package Assembly

Using hardware provided, attach motor mount angles to

motor mount adapter. There are only two motor mount

angles on reducers up to a 3 7/16” bore. For reducers with 3

15/16” bore and larger there are four motor mount angles.

Attach motor base to motor mount adapter using

all-thread rods (4) and nuts (16) provided in hardware

package. (Note orientation of motor base.)

Attach this assembly to the reducer, using the existing

bolts in the reducer. The angles should be mounted on the

same side as the input shaft.

Remove any rust, paint or imperfections from the drive

shaft. The drive shaft must be clean and shiny before

installing the reducer drive.

Slide the reducer bushing onto the shaft.

Mount the reducer onto the drive shaft and fasten in place

using the reducer bushing and cap screws provided. Do not

tighten the bushing cap screws until the end of the drive

shaft is protruding through reducer at least a 1/8”. Make

sure adequate space remains between the bearing and the

reducer bushing to allow removal of the bushing cap screws.

- 16 -

Page 17

Attach torque arm channel to bottom of conveyor. Some holes

may have to be field drilled in bottom panel to attach torque arm

channel. The position of the torque arm channel depends on the

incline of the head. When the head is on the incline desired the

reducer should still be vertical. The torque arm channel should be

placed so the torque arm from the reducer can reach when reducer

is in the vertical position.

Connect the adjustable torque arm from the reducer to the

torque arm channel. Make sure torque arm is mounted on the side

of reducer nearest to the torque arm channel. The torque arm

should be mounted parallel to the conveyor side.

Fasten the motor to the motor mount with hardware provided.

Connect the conveyor motor to a power source according to the

motor manufacturer’s instructions and recommendations. Due to

the hazards involved with electricity, it is recommended that an

electrician perform the motor wiring. A shut off switch should be

placed near the motor so that the system may easily be shut down

to help prevent accidents during maintenance.

Attach upper belt guard bracket and lower belt guard bracket to

reducer with hardware provided. The upper bracket should be

mounted to the upper holes in the motor mount adapter. The

lower bracket is two pieces. The two pieces should be mounted

together at slotted holes and then mounted to the reducer.

- 17 -

Page 18

Place the rear belt guard panel onto the reducer

drive shaft and the motor shaft. Attach to the upper

and lower brackets with hardware provided.

Remove any rust, paint or imperfections from the

motor shaft. Install the motor sheave and sheave

bushing on the motor shaft.

Remove any rust, paint or imperfections from the

reducer drive shaft. Install the reducer sheave

and sheave bushing on the reducer drive shaft

Align the reducer sheave and the motor sheave.

With both sheaves aligned tighten all hardware.

Place the drive belts provided on the sheaves.

Adjust the all-thread on motor base to tighten

according to the instructions provided with reducer.

Proper belt tension is 1/64”of deflection per one (1“)

inch of sheave centers on one side of the belt, centered

between sheaves. (See figure 1)

Position front belt guard cover into the rear belt

guard panel and attach using the clips mounted on belt

guard panel.

Check lubricant level in the reducer before operation.

Follow manufacturer recommendations for reducer

lubrication.

- 18 -

Page 19

Chain

All chain is shipped in approximate 10 foot lengths. The UHMW wiper flights should be in

front of the welded chain flights in the direction of chain travel (see diagram).

Adjust take-up screws to position the take-up sprocket as far from the end of the conveyor as

possible. Assemble all of the sections of chain using the connecting links provided with chain

assembly. With the assembled conveyor mounted in its permanent position, install the chain

assembly in the bottom of the conveyor and wrap chain around the sprocket at the head and tail

of the conveyor. Using a ratchet cable puller, pull the two ends of the chain together. Remove

the unneeded chain and fasten the two ends together using a connecting link furnished with the

chain assembly. Adjust take-up screws to tighten the chain.

81X Chain Assembly 4” Pitch Roller Chain Assembly

- 19 -

Page 20

Cover

Rope or silicone caulk should be used on all surfaces where the trough covers splices come in

contact with the trough covers. Bolt all of the trough cover panels in place using 3/8” bolts and

3/8” whiz nuts. Leave the end bolt holes open on each trough cover for the installation of the

cover splices. Install the cover splices over the gaps in the trough covers using 3/8” bolts and

3/8” whiz nuts.

Inlet Assembly

Inlets mounted too close to the tail chain sprockets will allow grain to come in contact with the

sprocket and chain pinch. This may cause excessive damage to any grain being conveyed. The

minimum distance from the tail splice joint to the nearest edge of the inlet assembly should be

equal to the inlet opening plus 2 inches (A + 2” in Figure 2).

The angle iron guard in the middle of the inlet assembly should be in position to divert flowing

grain from the chain links.

When the proper position for the inlet is determined, a full conveyor width opening should be

cut into the conveyor cover. Another opening should be cut in the center pan. The opening

should start at the edge of the inlet and extend a distance of twice the inlet opening, towards the

tail. The width of the opening should be determined by starting the opening a distance of 1 ¼”

from inside edge of conveyor. (See Figure 2)

Using the inlet assembly provided, drill 7/16” holes in the top flange of the conveyor trough

sides.

Fasten the inlet assembly in place using 3/8” bolts and 3/8” whiz nuts.

Use the same caulking material for the inlet assemblies that was used for the trough cover

panels.

Figure 2

- 20 -

Page 21

Care and Maintenance

The care and maintenance section is provided with the intention of helping to extend the useful

life of the unit. Like all equipment, the useful life of the conveyor is greatly reduced if not used

wisely and well maintained.

Before any maintenance is performed to the conveyor,

power must be shut off and locked out to prevent

accidental start up!

Check oil level in shaft mount reducer periodically. Fill to level as recommend by

Manufacturer.

Check all bearings and moving parts daily during use.

Follow bearing manufacturer recommendations.

Lubricate all greasable fittings two to three times during the use season. Use a good grade

lubricant. Do not over-lubricate.

The V-belt(s) should be periodically inspected for proper tension and wear. V-belts should be

replaced as necessary. If replacement or tension adjustment is required, refer to the Assembly

Section(s).

The drag chain and sprockets should be checked periodically for wear, damage, and proper

adjustment. Any broken or bent paddles should be replaced or straightened. Should adjustment

or replacement of the drag chain or sprockets be required, refer to the Assembly Section(s).

Storage

If the unit is to be inactive for an extended period, the following procedures are recommended.

Thoroughly clean the unit.

Loosen the drag chain tension. Doing so relieves the stress placed on the bearings and shafts of

the drive and tail sections.

Lubricate drag chains, shafts, and drive components with a good grade of light machine oil.

- 21 -

Page 22

Incline Conveyor Head Section Sub-assembly

Assembly sequence for incline head section sub-assembly.

Fasten head bottom panel to each head side panel using 3/8” hex head bolts and 3/8” whiz nuts.

Whiz nuts should be located on bottom side of conveyor. The head bottom panel should extend

beyond head side panels approximately two inches.

Mount divider with flange up using 3/8” carriage bolts and 3/8” whiz nuts through holes

provided in head side panels. Heads of carriage bolts should be inside the conveyor

Insert key into shaft. Slide sprocket onto the head shaft. DO NOT

this time. After final assembly of head section unit, the sprocket must be centered between the

side panels before tightened into place.

Place UHMW seal sandwich (white plastic rectangle with large slot) seal onto each end of

shaft/sprocket assembly. Insert each end of shaft/sprocket assembly into take-up bearing

weldment. Place UHMW seal (white plastic square with one large hole and four smaller holes)

onto each end of shaft/sprocket assembly. Mount seal over 5/16” studs with 5/16” whiz nuts.

Insert each end of shaft/sprocket assembly into properly sized pillow block bearing. Mount

pillow block bearings to take-up bearing weldment. DO NOT TIGHTEN setscrews at this

time.

TIGHTEN setscrews at

Slide above assembly into slot at end of head until take-up bearing weldment hits take-up stop.

Fasten false panel and false panel bracket to head side panels with 3/8” carriage bolts and 3/8”

whiz nuts. Attach end panel to side panels of head with 3/8” hex head bolts and 3/8” whiz nuts.

- 22 -

Page 23

Take-up rod should have one welded nut already in place. Place another nut on rod and insert

into take-up anchor. Place two nuts onto take-up rod and insert into take-up bearing weldment.

Finish by placing nut with pre-drilled hole on rod, place roll pin through nut and rod.

Attach discharge transition weldment to head side panels using 3/8”hex head bolts and 3/8”

whiz nuts. Then attach discharge transition splice plate between head bottom panel and

discharge transition. If a bottom liner is specified, a spacer between the head bottom panel and

the discharge transition splice is furnished, and should be properly positioned between these two

components before fasteners are inserted.

Center sprocket between head side panels and tighten all setscrews.

Place cover assembly on top of conveyor and fasten with 3/8” hex head bolts and 3/8” whiz

nuts.

Incline ConveyorTail Section Sub-Assembly

Assembly sequence for incline tail section sub-assembly.

Fasten tail bottom panel to each tail side panel using 3/8” hex head bolts and 3/8” whiz nuts.

Whiz nuts should be located on bottom side of conveyor. The tail bottom panel should be

recessed approximately two inches.

- 23 -

Page 24

Insert key into shaft. Slide sprocket onto the tail shaft. DO NOT TIGHTEN setscrews at this

time. After final assembly of tail section unit, the sprocket must be centered between the side

panels before tightened into place.

Place UHMW (white plastic square with large hole) seal onto each end of shaft/sprocket

assembly. Insert each end of shaft/sprocket assembly into properly sized pillow block bearing.

DO NOT TIGHTEN setscrews at this time.

Slide above assembly into slot at end of tail until pillow block bearings can be mounted onto

the bearing weldments with the bolt, flat washers, lock washers, and nuts provided in the

hardware bag.

Bolt seal retainer bracket and false panel in place using 5/16” hex head bolts and 5/16” whiz

nuts. Fasten false panel and false panel bracket to tail side panels with 3/8” carriage bolts and

3/8” whiz nuts. Position seal retainer angle inside seal retainer bracket and push towards tail

side panel to secure the tail shaft seal. Secure the seal retainer angle in place with 5/16” hex

head bolts and 5/16” whiz nuts. Attach end panel to side panels of tail with 3/8” hex head bolts

and 3/8” whiz nuts.

Center sprocket between tail panels and tighten all setscrews.

Place cover assembly on top of conveyor and fasten with 3/8” hex head bolts and 3/8” whiz

nuts.

- 24 -

Page 25

Options

The standard Series I incline conveyors have been designed to meet most conveyor operation

criteria. However, to better serve customer special applications, a number of options are

available for the conveyors. Descriptions of the options, their installation, care and maintenance

will be covered in this section.

WARNING! POWER MUST BE

SHUT OFF AND LOCKED OUT

BEFORE ANY OPTIONS ARE

INSTALLED.

Liner Packages

Bottom A.R. liners come standard with a galvanized cover sheet. The installation is the same

as the standard 8-gage bottom.

Shock Relay

Refer to installation instructions within the shock relay package.

Standard Bypass Inlets

Standard bypass inlets come pre-assembled from the factory. The inlets are a standard 28 in.

conveyor section. The hogback is stationary in standard bypass inlets. Standard bypass inlets

must be mounted horizontally. If not mounted horizontally, capacity will be reduced.

Standard Bypass Inlet

- 25 -

Page 26

Bypass Dump Hoppers

Bypass dump hoppers come pre-assembled from the factory. The bypass dump hoppers

replace a standard 10-ft. conveyor section. The hoppers can be 6-ft., 8-ft., and 10-ft. lengths.

The hogback is adjustable in the bypass dump hoppers. Bypass dump hoppers must be mounted

horizontally. If not mounted horizontally, capacity will be reduced.

6-ft. Bypass Dump Hopper

8-ft. Bypass Dump Hopper

10-ft. Bypass Dump Hopper

- 26 -

Page 27

Grate

Grates are shipped from factory in sections.

10’ Bypass Dump Hopper Grate

8’ Bypass Dump Hopper Grate

6’ Bypass Dump Hopper Grate

- 27 -

Page 28

10 Foot Adjustable Bypass Inlets

10 foot adjustable bypass inlets come pre-assembled from the factory. The 10 foot adjustable

bypass inlets are a standard 120 in. conveyor section. The hogback is stationary, with an

adjustable baffle at each side inlet to the bottom chamber of the conveyor. 10 foot adjustable

bypass inlets must be mounted horizontally. If not mounted horizontally, capacity will be

reduced.

10 Foot Adjustable Bypass Inlet

Grate

Grates are shipped from factory in sections.

10’ Adjustable Bypass Inlet Grate

- 28 -

Page 29

Trouble Shooting

Trouble Shooting Guide

Problem Cause Solution

Low Capacity Improper chain speed Check the shaft RPM

Improper feed Check the grain level at inlet

Plugging Check the discharges

Baffle or adjustable hogback Increase opening

setting too low

Noisy Operation Loose UHMW Paddles Check all bolts on chain

Bottom and/or Divider Check intermediate trough section

not aligned Joints and make flush

Worn drive components Check oil level and shaft seals

Belt misalignment; loose belts

Worn chain and/or sprockets Check chain sprockets and chain

Uneven UHMW Conveyor Misalignment Check the conveyor alignment

Paddle Wear Sprocket Slipped Check set screws on sprockets

Uneven sprocket wear Worn chain Replace chain

Improper alignment Check sprocket alignment

Contact your local contractor for added assistance.

- 29 -

Page 30

EMPLOYER / EMPLOYEE TRAINING SIGN OFF SHEET

The company is making every effort to warn, guard, and educate the consumer when using

the various kinds of equipment that we manufacture. The company has included this sign

off sheet for you and your staff to use in the training process on installation and operation

of the equipment described in this manual. Read the entire manual, sign off, and date on

chart below.

DATE EMPLOYEE SIGNATURE DATE EMPLOYEE SIGNATURE

- 30 -

Page 31

EQUIPMENT MAINTENANCE RECORD

DATE MAINTENANCE PERFORMED INITIAL

- 31 -

Page 32

WARRANTY

THE COMPANY AS THE MANUFACTURER WARRANTS ALL PRODUCTS MANUFACTURED BY THE

COMPANY TO BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE

AND CONDITIONS FOR A PERIOD OF TWELVE MONTHS AFTER RETAIL SALE TO THE ORIGINAL

END USER OF SUCH PRODUCTS. THE COMPANY’S ONLY OBLIGATION IS, AND PURCHASER’S

SOLE REMEDY SHALL BE FOR THE COMPANY, TO REPAIR OR REPLACE, AT IT’S OPTION AND

EXPENSE, PRODUCTS THAT, IN IT’S SOLE JUDGEMENT, CONTAIN A MATERIAL DEFECT DUE TO

MATERIALS OR WORMANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM THE

COMPANY’S FACTORY WILL BE PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON

BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF THE COMPANY SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, THE COMAPANY MAKES NO

WARRANTY OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILTY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN

CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY THE COMPANY OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF THE COMPANY REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR

DESIGN OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS

OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT

STATED ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED.

THIS WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER.

THE COMPANY SHALL HAVE NO OBLIGATION OR RESPONSIBILTY FOR ANY REPRESENTATIVE OR

WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRUBTOR OF THE

COMPANY.

THE COMPANY ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION

DEFECTS WHICH CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO

THE PRODUCT NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY

ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN

DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS

ONLY PRODUCTS MANUFACTURED BY THE COMPANY. THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. THE COMAPANY RESERVES THE RIGHT

TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE REPONSIBILITY TO RESEARCH AND COMPLY

WITH ALL FEDERAL STATE AND LOCAL CODES WHICH MAY APPPLY TO THE LOCATION AND

INSTALLATION.

- 32 -

Page 33

T H E G S I G R O U P

1004 East Illinois Street

Assumption, Il 52510-0020

May-01

- 33 -

Loading...

Loading...