Page 1

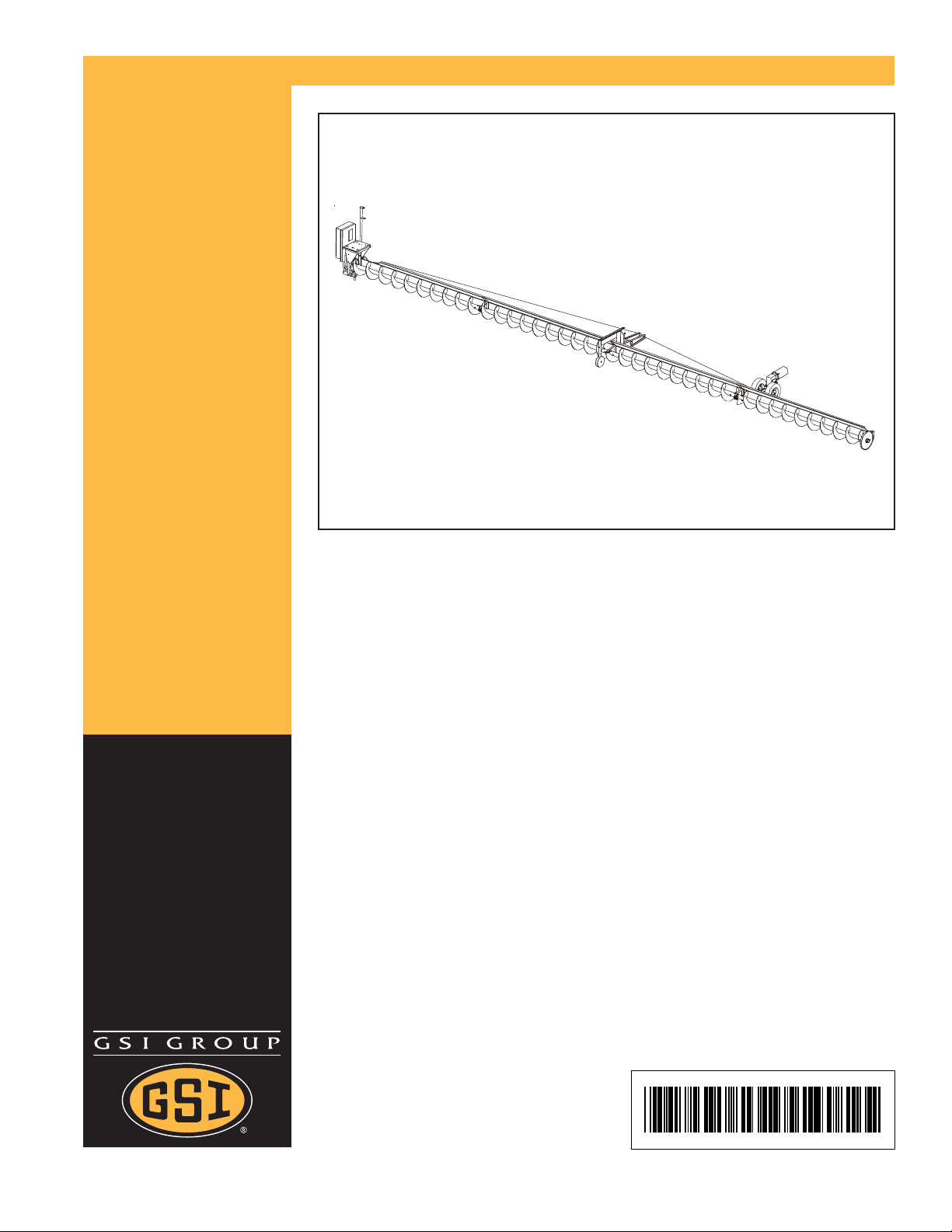

12" & 14" Commercial Bin

Sweep Auger

Assembly & Operation Manual

PNEG-1050

Date: 04-24-2007

PNEG-1050

Page 2

DO NOT STORE SWEEPS IN THE BIN!

Sweeps are NOT designed to remain in a bin during

filling, storage, or bottom (gravity) unloading. A sweep

left in a bin during these operations may be serverly

damaged. The GSI Group, Inc. will not be responsible for

such damages.

The following action may reduce damages to a sweep

remaining in a bin: Lifting the sweep off the center pivot,

positioning it parallel to the intermediate wells (along

side of - not on top of) and fully supporting the sweep to

the bin floor. However, even with this procedure, The

GSI group, Inc. will not be responsible for any damges to

the sweep.

2 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 3

Table of Contents

TABLE OF CONTENTS

Safety ......................................................................................................... 4

General Information ..................................................................................... 12

Decals ........................................................................................................ 13

Assembly Section

Chain Reducer Drive ............................................................................. 14

Flight & Shield Assembly ....................................................................... 19

Sweep Carrier & T russ Assembly........................................................... 24

Sweep Flight Back Shield...................................................................... 25

End Wheel Assembly............................................................................. 26

Sweep Tractor ....................................................................................... 27

Installation Section

Procedures for Installing Into Bin & Unloading........................................ 30

Final Cleanout ....................................................................................... 33

Power Source ............................................................................................. 34

Lubrication.................................................................................................. 35

Trouble Shooting ......................................................................................... 35

Part Lists .................................................................................................... 36

Personnel operating or working around this equipment should read this

manual. This manual must be delivered with equipment to its owner.

Failure to read this manual and its safety instructions is a misuse of the

equipment. Any misuse of the equipment may void the warranty.

12" & 14" Commercial Bin Sweep Augers PNEG-1050

3

Page 4

Safety

SAFETY GUIDELINES

This manual contains information that is important for you, the owner/operator , to know and

understand. This information relates to protecting personal safety and preventing

equipment problems. It is the responsibility of the owner/operator to inform anyone

operating or working in the area of this equipment of these safety guidelines. T o help you

recognize this information, we use the symbols that are defined below.

Please read the manual and pay attention to these sections. Failure to read this manual

and it’s safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury .

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury .

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury .

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property

damage.

NOTE indicates information about the equipment that you should pay

special attention to.

4 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 5

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual

and safety signs on your equipment. Keep signs

in good condition. Replace missing or damaged

safety signs. Be sure new equipment components and repair parts include the current safety

signs. Replacement safety signs are available

from the manufacturer.

Learn how to operate the machine and how to

use controls properly . Do not let anyone operate

without instruction.

Keep your machinery in proper working condition. Unauthorized modifications to the machine

may impair the function and/or safety and affect

machine life.

Safety

If you do not understand any part of this manual

and need assistance, contact your dealer.

PRACTICE SAFE MAINTENANCE

Understand service procedures before doing

work. Keep area clean and dry.

Never lubricate, service, or adjust machine while

it is in operation. Keep hands, feet, and clothing

from rotating belt and idlers.

Keep all parts in good condition and properly

installed. Fix damage immediately. Replace

worn or broken parts. Remove any build up

grease, oil, or debris.

12" & 14" Commercial Bin Sweep Augers PNEG-1050

5

Page 6

Safety

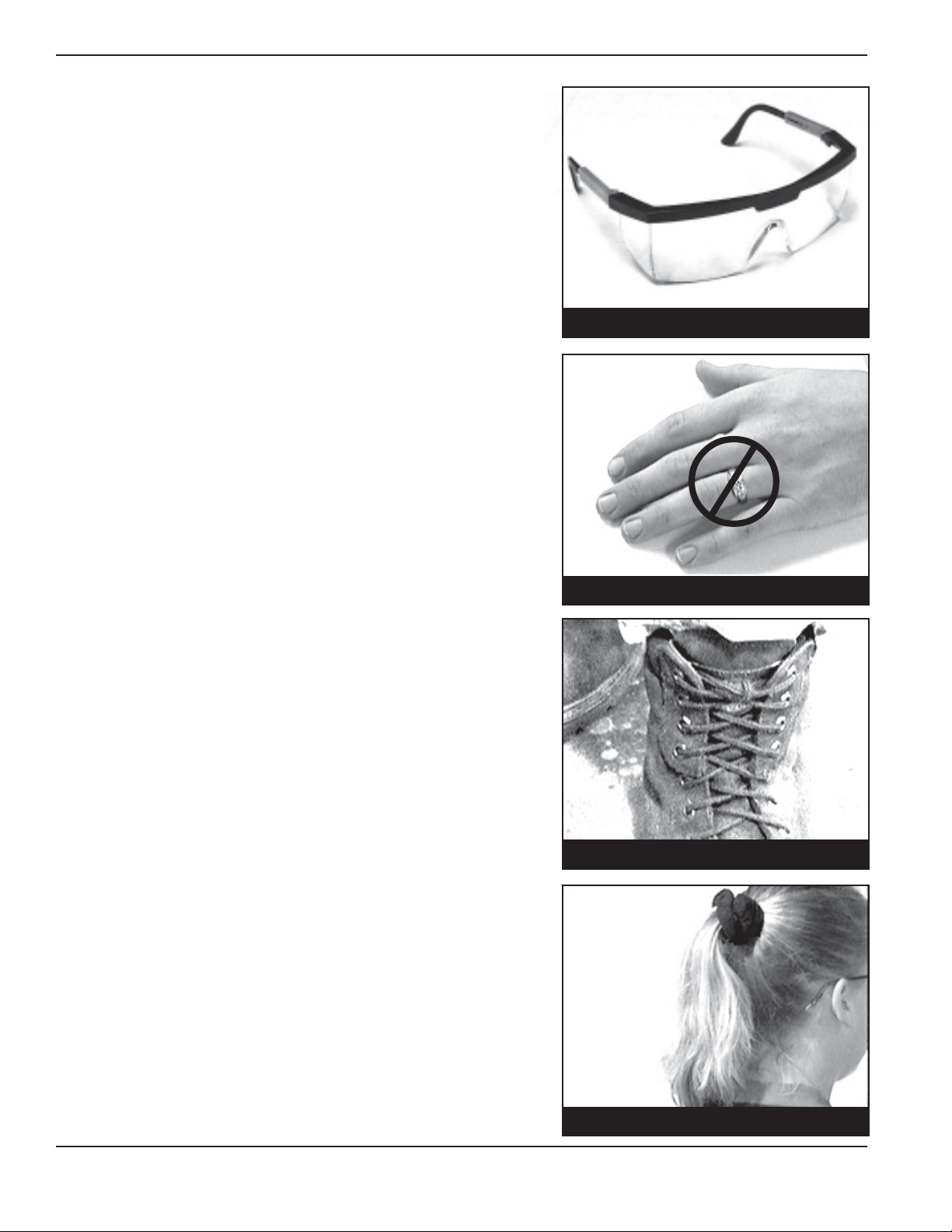

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Safety glasses should be worn at all times to

protect eyes from debris.

Wear gloves to protect your hands from sharp

edges on plastic or steel parts.

A respirator may be needed to help prevent

breathing potentially toxic fumes and dust.

Wear hard hat and steel toe boots to help

protect your head and toes from falling debris.

Eye Protection

Gloves

Steel Toe

Boots

PREPARE FOR EMERGENCIES

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy .

Keep emergency numbers for doctors, ambu-

lance service, hospital, and fire department near

your telephone.

Respirator

Hard Hat

6 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 7

SAFETY GUIDELINES

1. General Safety Guidelines

A. DO NOT make any alterations to the equipment. Such alterations may produce a very dangerous situation,

where SERIOUS INJURY or DEATH may occur .

B. This equipment shall be installed in accordance with any regulations or installation codes that are required by

law. Authorities having jurisdiction should be consulted before inst allations are made.

C. Untrained operators subject themselves and others to SERIOUS INJURY or DEA TH. NEVER allow untrained

personnel to operate this equipment.

D. Keep children and other unqualified personnel out of the working area at ALL times.

E. NEVER start equipment until ALL persons are clear of the work area.

Safety

F. Be sure ALL operators are adequately rested and prepared to perform ALL functions of operating this equipment.

G . Keep hair, loose clothing, and shoestrings away from rotating and moving part s. NEVER wear loose fitting clothing

when working around augers.

H. NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate the equipment.

I. NEVER allow anyone inside a bin, truck, or wagon which is being unloaded by an auger or conveyor. Flowing

grain can trap and suffocate in seconds.

J. Make sure someone is nearby who is aware of the proper shutdown sequence in the event of an accident or

emergency .

K. NEVER work alone.

L. ALWAYS think before acting. NEVER act impulsively around the equipment.

M. Make sure ALL equipment is locked in position before operating.

N. Keep hands and feet away from the auger intake and other moving parts.

O. NEVER attempt to assist machinery operation or to remove trash from equipment while in operation.

P . Use ample overhead lighting after sunset to light the work area.

Q. ALWAYS lockout ALL power to the equipment when finished unloading.

R. Keep area around intake free of obstacles such as electrical cords, blocks, etc. that might trip workers.

12" & 14" Commercial Bin Sweep Augers PNEG-1050

7

Page 8

Safety

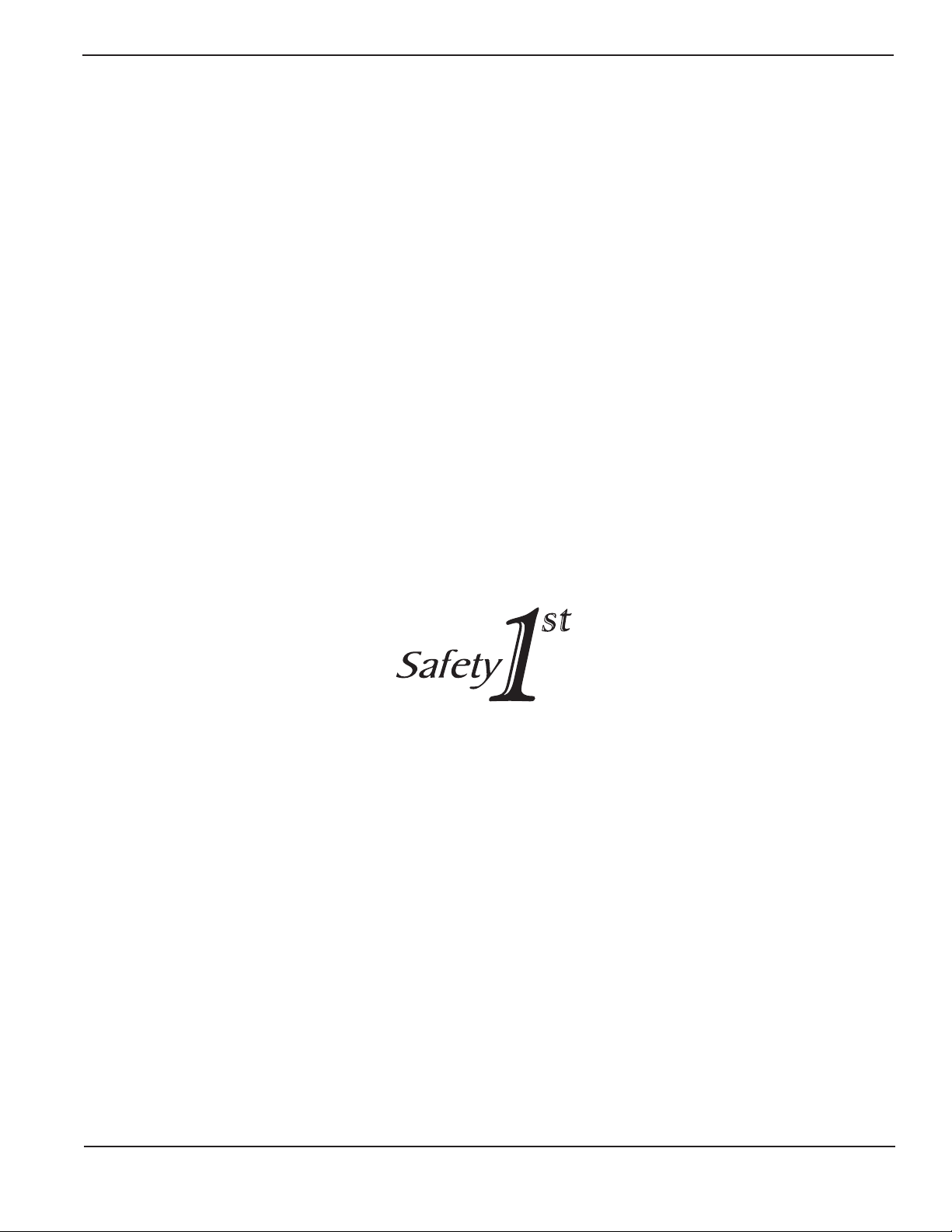

2. Personal Protective Equipment

A. The proper personal protective equipment should be

worn at ALL times by anyone in the work area.

B. ALWA YS wear safety glasses when in the work area.

C. The operator should NEVER wear jewelry.

2-B

2-C

D. Loose clothing should not be worn. Any clothing that

becomes loosened should be tucked in tightly .

E. Loose or dangling shoe strings should be tucked in.

F. Long hair should be tied up and/or back.

8 12" & 14" Commercial Bin Sweep Augers PNEG-1050

2-D, E

2-F

Page 9

3. In an Emergency, Shutdown the Power Source.

4. Hazards

A. Keep clear of all augers. DO NOT ENTER the bin!

B. If you must enter this bin:

1. Shut off and lock out all power .

2. Use safety harness and safety line.

3. Station another person out side the bin.

4. A void the center of the bin.

5. Wear proper breathing equipment or respirator.

C. Failure to heed these warnings will result in serious injury or death.

D. Be aware of Pinch Points. A Pinch Point is a narrow area between two surfaces that is likely to trap

or catch objects and so is a potential safety hazard.

E. Components of this equipment have sharp edges which can scrape and/or cut an operator.

F. A moving auger can sever appendages possibly resulting in death.

5. Shields and Guards

Safety

A. ALWAYS keep ALL shields and guards in place during operation.

We will replace any missing shields or guards free of charge!

See (page vi) for more information on our Safety First program.

6. Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who works

with or around augers must have good common sense in order to be qualified. These persons must also

know and meet all other qualifications, such as:

1. Any person who has not read and/or does not understand all operation and safety procedures is not

qualified to operate any auger systems.

2. Certain regulations apply to personnel operating power machinery. Personnel under the age of 18

years may not operate power machinery , including augers. It is your responsibility , as owner and/or

supervisor, to know what these regulations are in your area or situation.

3. Unqualified or incompetent persons are to remain out of the work area.

4. O.S.H.A. (Occupational Safety & Health Administration) regulations state: "At the time of initial assignment and at least annually thereafter , the employer shall instruct every employee in the safe operation

and servicing of all equipment with which the employee is, or will be involved." (Federal Occupational

Safety & Health Standards for Agriculture. Subpart D, Section 19287.57 (a) (6).

12" & 14" Commercial Bin Sweep Augers PNEG-1050

9

Page 10

Safety

6. Operator Qualifications (cont.)

B. As a requirement of OSHA, it is necessary for the employer to train the employee in the safe operating and

safety procedures for this auger . We included this sign-off sheet for your convenience and personal record

keeping. All unqualified persons are to st ay out of the work area at all times. It is strongly recommended

that another qualified person who knows the shutdown procedure is in the area in the event of an emergency .

A person who has not read this manual and understands all operating and safety instructions is not qualified

to operate the machine.

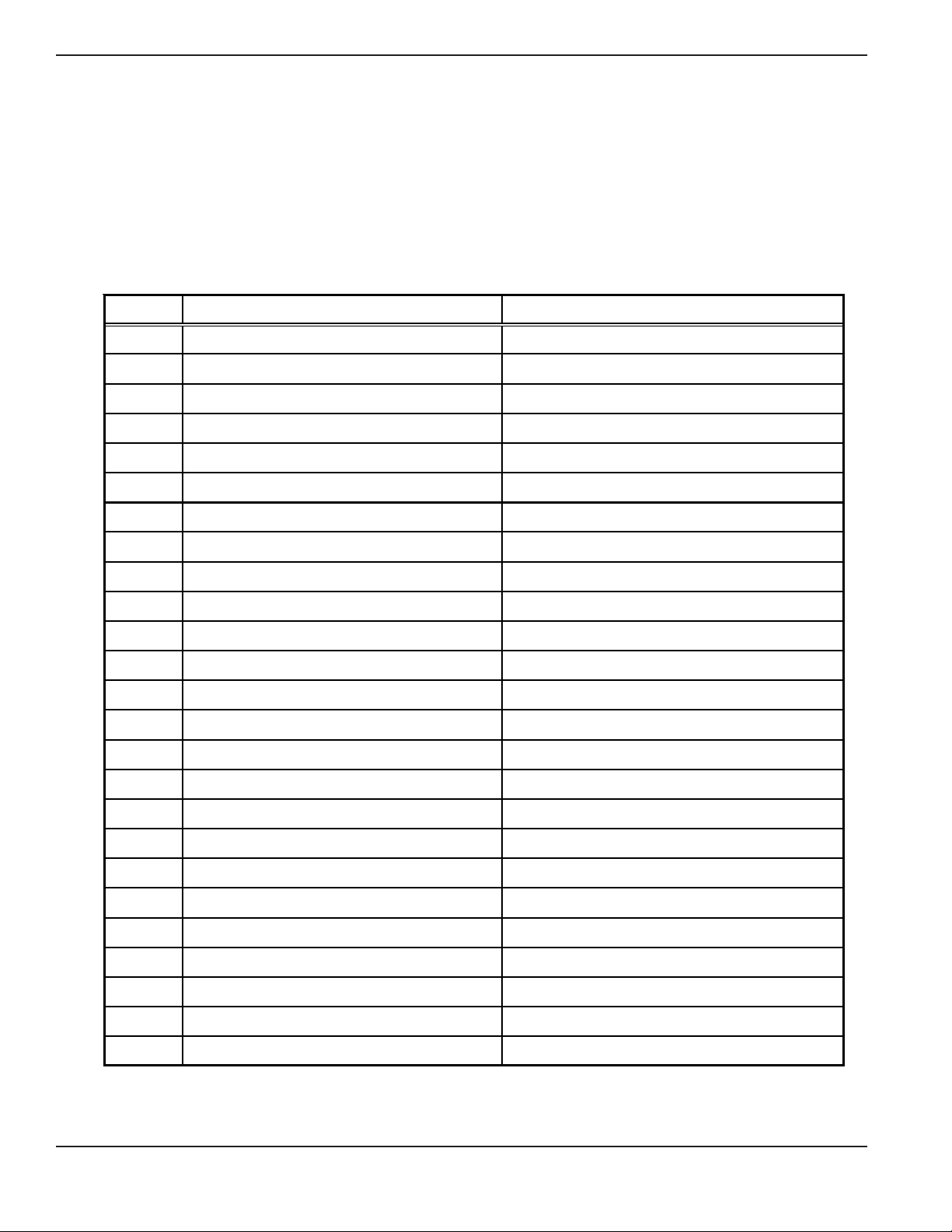

DATE EMPLOYER'S SIGNATURE EMPLOYEE'S SIGNATURE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

10 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 11

Safety

Our equipment is built to provide

many years of dependable service to

our customers through durable

craftsmanship.

One of the most important aspects of our engineering is SAFETY 1

st

design throughout all

product lines. At our company - safety is NO

ACCIDENT!

That is why we have implemented a SAFETY 1

program. Should you ever need guards,

shields, safety decals or owner/operator manuals, simply contact us or your local dealer , and

we will supply you with them FREE OF

CHARGE!

While it is our main goal for our

company to be a world leader in manufacturing,

it is always our first priority to keep our customers safe.

We replace missing guards and shields

FREE OF CHARGE!

st

If you need any of the above listed safety items or have any safety questions, please contact

the manufacturer or your local dealer.

12" & 14" Commercial Bin Sweep Augers PNEG-1050

11

Page 12

Safety

1. General Information

A. We reserve the right to improve our product whenever possible and practical to do so. We reserve the right to

change, improve, and modify products at any time without obligation to make changes, improvements, and

modifications on equipment sold previously.

B. The Commercial Bin Sweep Augers have been designed and manufactured to give years of dependable service.

The care and maintenance of this machine will affect the satisfaction and service obtained. By observing the

instructions and suggestions we have recommended, the owner should receive competent service for many

years. If additional information or assistance should be required, please contact the factory or your local dealer .

C.

Receiving Merchandise and Filing Claims

1. When receiving merchandise, it is important to check both the quantity of parts and their descriptions

with the packing list enclosed within each package. All claims for freight damage or short age must be

made by the consignee within ten (10) days from the date of the occurrence of freight damage. The

consignee should accept the shipment after noting the damage or loss.

For Claims Contact:

The GSI Group Inc.

1004 East Illinois Street

Assumption, IL 62510

Tele: (217) 226-4421

Fax: (217) 226-4420

12 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 13

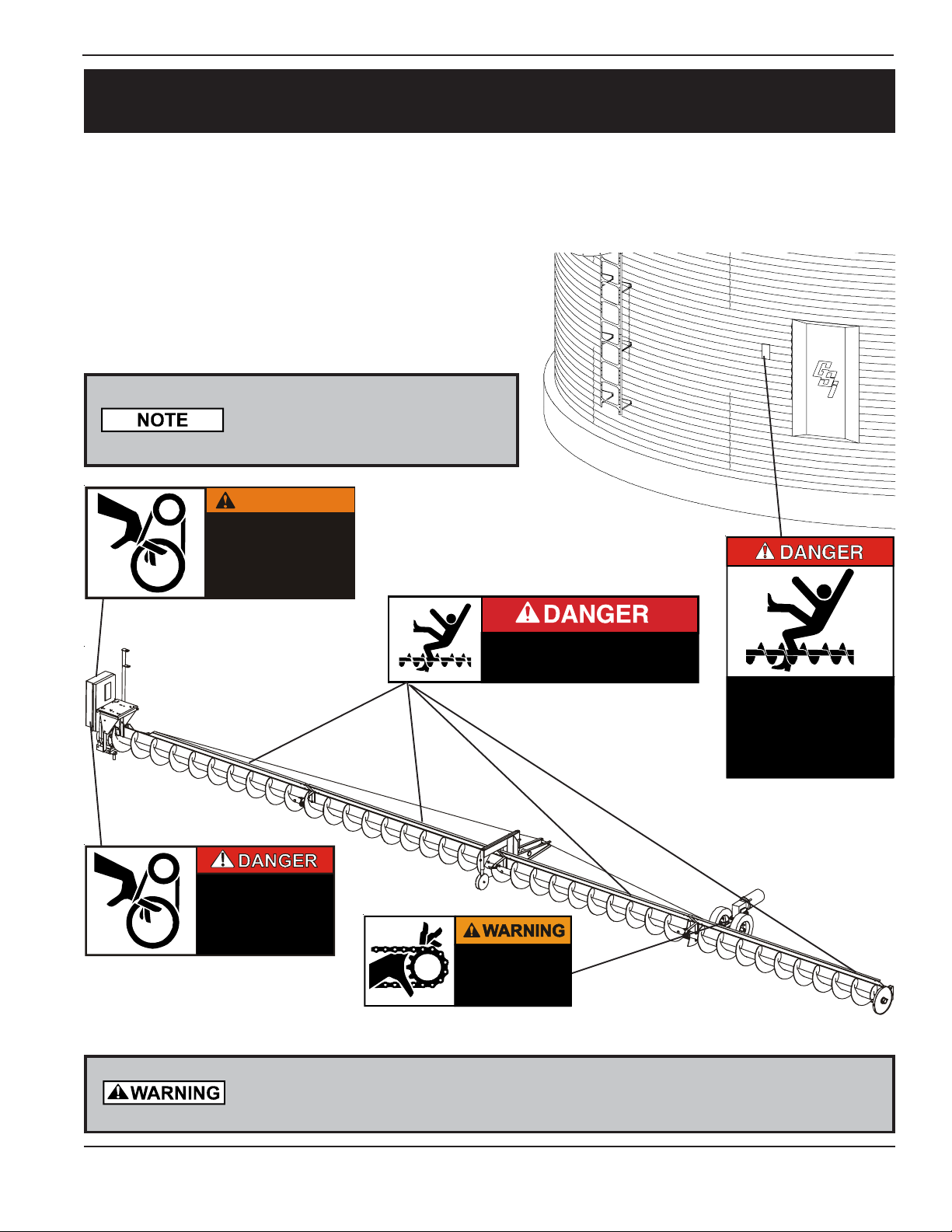

Decal

W

SAFETY DECALS

Check components shown below to insure that the safety decals are in place and in good condition. If a decal cannot be

easily read for any reason or has been painted over , replace it immediately . Contact your dealer or the manufacturer to

order a replacement decal free of charge.

DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign should be applied

to the side of the bin near the bin opening, so it will be viewed

by people entering into the bin storage building.

Do not cover any safety signs or any other signs that are

already there.

Please remember, safety signs

provide important safety information

for people working near bin unloading equipment that is in operation.

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

Located on Outside of Belt Guard

DC-995

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

Located Inside Belt Guard

DC-994

ARNING

DC-995

DC-994

KEEP OUT OF BIN WHILE SWEEP IS IN OPERATION

RAPIDLY TRAVELING SWEEP AUGER

FAILURE TO HEED WILL RESULT IN

SERIOUS INJURY OR DEATH

Located on Shield

DC-1384

SHEAR POINT

Moving parts can

crush and cut. Keep

hands clear of

sprocket and chain.

DC-13 86

Located on Tractor Drive Chain Guards

DC-1386

DC-1384

ROTATING FLIGHTING!

THIS BIN IS EQUIPPED WITH GRAIN AUGERS

WHICH CAN KILL OR DISMEMBER.

KEEP CLEAR OF ALL AUGERS AND NEVER ENTER

THIS BIN UNLESS ALL POWER IS

DISCONNECTED AND LOCKED OUT.

FAILURE TO DO SO WILL RESULT IN

SERIOUS INJURY OR DEATH!

DC-1395

Located Outside Bin Door

DC-1395

If the Safety Sign cannot be easily read for any reason or has been painted over,

replace it immediately. Additional Safety Signs may be obtained free of charge from

your dealer , distributor, or ordered from the factory .

12" & 14" Commercial Bin Sweep Augers PNEG-1050

13

Page 14

Assembly

1. CHAIN REDUCER DRIVE (For 36' thru 78' Diameter Bins)

A. Motor Mount Assembly Instructions’

(See Fig. 2 on page 15.)

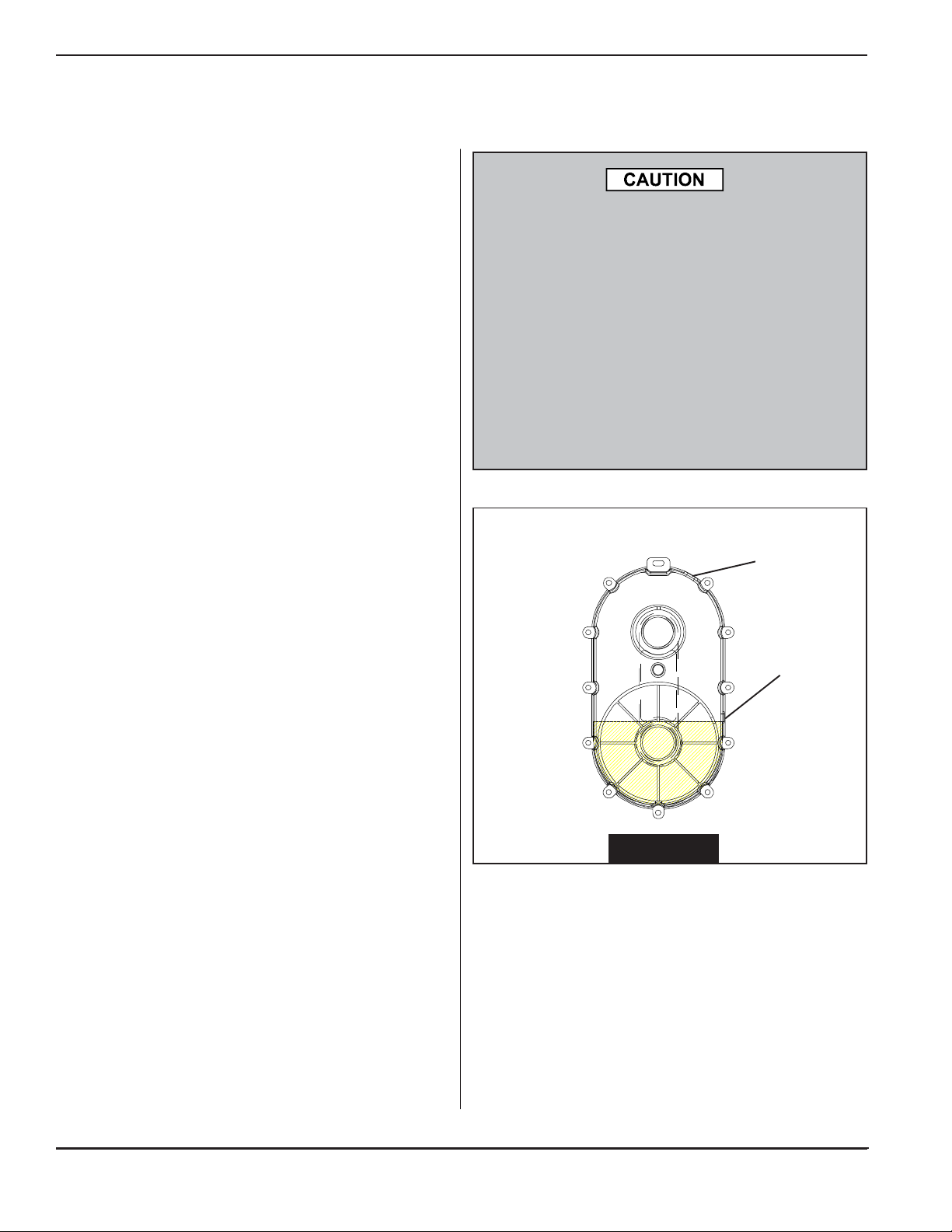

1. First, fill the chain reducer drive with oil by removing

the vented fill plug and pouring 48 oz. of oil into drive.

Oil level can be checked by removing the check plug.

Oil should not be over the check plug. (See Fig. 1)

2. Install Pivot Bracket (1) to bottom of motor mount

frame (2) using a 3/4" x 1 1" long (grade 5) hex head

capscrew and nylon locknut.

3. Attach the electric cord support stand (3) and one side

of the motor mount support plate (4) to the motor

mount frame (2) using two 1/2" x 1-1/2" long (grade 5)

hex head capscrews with lock washers and hex nuts.

Attach the other side of the motor mount support plate

(4) to the motor mount frame (2) using two 1/2" x

1-1/4" long capscrews with lockwashers and nuts.

4. Mount the chain reducer drive (6) to the mounting ring

on the motor mount frame (2) with four 3/8" x 1" long

(grade 5) hex head capscrews and nylon locknuts.

5. Screw the 3/4" threaded adjusting rod (7) down through

the nut welded to the top of the motor mount support

plate (4). Leave the adjusting rod (7) an inch or two

above the top surface of the motor mount support

plate (4). The adjusting rod will be adjusted later after

the drive belts are installed.

Oil must be added before assembly. The chain

reducer is shipped without oil.

Do NOT add more oil than recommended. Additional oil may damage the seals or be forced out

through the vented fill plug.

For lubrication in normal operating temperature

between 40° F to 120° F, we recommend the use

of non foaming, multi purpose gear oil, SAE 90

weight. For temperatures below 40° F, use a SAE

80 weight oil. Use grade commercially available

for automotive differentials. Extra pressure

additives may be of value in severe applications.

Enclosed Drive

Fill Plug

Check Plug

6. Thread a 3/4" hex nut onto the bottom end of the

adjusting rod (7) underneath the motor mount support

plate (4). This nut is for locking the adjusting rod in

place after adjusting it to the required position to

tighten the drive belts. DO NOT tighten this nut

against the motor mount support plate until the belts

have been installed and tightened.

7. Align the pivot holes (10) of the motor mount plate (4)

with those in the motor mount support plate (4) and

slide the pivot rod (9) through the holes. Insert a 3/16"

cotter pin into the holes in each end of the pivot rod (9)

to keep it in place.

14 12" & 14" Commercial Bin Sweep Augers PNEG-1050

FIG . 1

Page 15

1. CHAIN REDUCER DRIVE (cont.)

Assembly

(7) Adjusting Rod

(4) Motor Mount Support Plate

1/2" x 1-1/4" HHCS,

Lockwashers, and Nuts

(8) Motor Mount Plate

(10) Pivot Holes

(3) Electrical Cord

Support Sta nd

(9) Pivot Rod

1/2" x 1-1/2" HHCS

with Lock Washers

and Nut

(6) Chain Reducer Drive

3/8" x 1" HHCS Bolt

3/4" x 11" HHCS with

Locknut

(5) Shield Mount Plate

(2) Motor Mount Frame

(1) Pivot Bracket

1" Flat Washers

Pivot Tube in Center of Bin

FIG . 2

12" & 14" Commercial Bin Sweep Augers PNEG-1050

15

Page 16

Assembly

1. CHAIN REDUCER DRIVE (cont.) (Refer to Fig. 3.)

8. Slide the mounting ring of the belt guard (10) over the

mounting ring of the chain reducer drive (15).

9. Fasten the bottom of the belt guard (10) to the motor

mount frame (2) using two 3/8" x 1- 1/4" long (grade 5)

hex head capscrews, eight 1/16" thick flat washers

and two nylon locknuts. Position the flat washers

between the inside of the motor mount frame (2) and

the outside of the belt guard (10).

10.Use two 1/4" x 5" long hex head capscrews, belt guard

spacer tubes (1 1) and nylon locknuts to connect the

upper portion of the belt guard (10) to the motor mount

frame (2).

1 1 . Install electric motor on the motor mount plate (8).

(NOTE: The motor and motor mounting hardware are

not furnished.) (See Fig. 4 on page 17 for motor size

and bolt hole locations.)

FIG . 3

(8) Motor Mount

Plate

12.Install motor pulley on motor shaft and secure with

drive key . (NOTE: Motor pulley and drive key are not

furnished.) (See page 34 for pulley size.)

13. Slide 12" O.D. pulley (12) onto the input shaft of the

chain reducer (6). Using 1/4" square key (13) and

setscrew to secure pulley in place. Align motor pulley

with 12" O.D. pulley .

14. Install drive belts (14) on pulleys and tighten. Using a

wrench, turn the adjusting rod (7) ( installed in S tep 5

on page 14) so that it pushes against the bottom of

the motor mount plate (8). When the belts are tight,

screw the hex nut on the bottom side of the adjusting

rod tightly up against the nut welded to the bottom of

the motor mount support plate.

15. Bolt the belt guard door (10) closed with two 3/8" x

3/4" long (grade 5) hex head capscrews and nylon

locknuts.

(15) Chain

Reducer

Drive

(2)Motor

Mount

Frame

3/8" x 1-1/4" HHCS

3/8" x 1" HHCS &

Nylon Locknuts

(6) Input Shaft

(1 1) Belt Guard Spacer Tubes

(10) Belt Guard

1/16" Flat Washers

3/8" x 3/4" HHCS & Nylon Locknut

1/4" x 5" HHCS & Nylock Nut

(12) 12" O.D. Driven Pulley

(14) Drive Belt

(13) Square Key

16 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 17

1. CHAIN REDUCER DRIVE (Cont.)

B. Motor Mount Hole Locations

Use the charts & illustration below to determine the location of the holes

where you need to install your motor .

Assembly

BIN DIA.

36' - 39' 7 -1/2 213T 3/8" * * * *

40' - 49' 10 215T 3/8" * * * *

BIN DIA.

54' - 78' 15 254T 1/2" ****

80' - 105' 20 256T 1/2" ****

113' - 120' 25 284T 1/2" * * * *

MOTOR

SIZE HP

MOTOR

SIZE HP

MOTOR

FRAME

SIZE

MOTOR

FRAME

SIZE

BOLT DIA.

REQUIRED

BOLT DIA.

REQUIRED

B10

B3

A5

MO UNT IN HOLES

MARKED (*)

A1 A2 A3 A4 A5 A6

MOUNT IN HOLES MARKED (*)

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11

B7

B9

B1

B5

A1

12" & 14" Commercial Bin Sweep Augers PNEG-1050

A3

Fig. 4

A2

B6

B2

A6

A4

B4

B11

B8

17

Page 18

Assembly

2. ELECTRICAL CORD SUPPORT STAND (Refer to Fig. 5.)

1. Fasten electrical cord support stand (1) to the side of

the motor mount support (2) with two 1/2" x 1-1/2" hex

head capscrews, flat washers, and locknuts.

2. Install electrical cord clamp (3) into plate (4) on

support stand. Secure in place with the jam nut (7)

provided with the clamp.

Route Cord Through

Ring on Top of

Support St and

(4) Plate

(7) Jam Nut for

(8) Motor

Cord Clamp

3. Route the electrical cord (5) from the electrical junction

box (6) through the electrical cord clamp (3) on the

support stand then through the ring on the top of the

support stand.

4. Leave a small loop of electrical cord between the cord

clamp (3) on the support stand and the electrical

junction box (6) on the outside of the motor (8).

Tighten the clamp on the electrical cord clamp to

secure the cord to the support stand.

(3) Electrical Cord

Clamp

(1) Electrical Cord

Support Sta nd

Motor

Mount

Plate

(2) Motor Mount

Support

1/2" x 1-1/2"

HHCS, Flat

Washers, &

Locknuts

Output Shaft for

Connection to

Flight Shaft

SIDE VIEW

(5) Electrical Cord

Leave a Small Loop of

Cord Between Clamp

and Junction Box

(6) Motor Junction Box

Belt Guard

FIG . 5

END VIEW

18 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 19

3. FLIGHT & SHIELD ASSEMBLY

Assembly

A Commercial Bin Sweep can be made up of several

sections of flighting and back shields. The quantity and

lengths of the sweep flight and back shield sections will

vary depending on the bin size. Use the chart below for the

number and length of sections for your size of bin.

The sweep flight with a cut back must connect to the drive

assembly . The remaining sections should be assembled in

the order shown in the chart below. The section furthest

from the drive has mounting holes for the sweep tractor .

The assembly instructions in this section cover assembling the complete Commercial Sweep. Refer to pages 3033 and read where use of only a part of the sweep auger

may be recommended when starting to sweep unload a

bin, particularly a large bin. You may choose to only

assemble one or two sections of sweep flight, back

shields, and bearing stands for initial sweep unloading.

Remember, any number of sweep sections can be used

together up to a maximum of six. If a sweep auger with

four or more sections was selected, a truss assembly is

included. The truss should be used when four or more

sections are assembled together. Refer to p age 24 for

truss assembly instructions. If the truss assembly you

have is for a greater number of sweep auger sections

than you are assembling, be sure to tie off the extra

cable length so it does not become entangled in the

sweep auger.

Sweep Fli ght and Back Shield Secti ons

1st Se cti o n

12" w / cutback 2nd S ecti o n 3r d Se ction 4th S ecti o n 5th Secti on 6th Sectio n

Catalog Bin attached to from from from from from

Number Dia me te r Drive unit Drive unit Drive unit Drive uni t Drive unit Drive unit

GCS14360 24' 9'- 9 3/4" 6' - 7 1/2"

GCS14370 37' 9'- 9 3/4" 7' - 1 1/2"

GCS14400 40' 9'- 9 3/4" 8' - 7 1/2"

GCS14420 42' 9'- 9 3/4" 9' - 3 1/2"

GCS14430 43' 9'- 9 3/4" 9' - 9 3/4"

GCS14480 48' 9'- 9 3/4" 7' - 1 1/2" 5'- 3 1/2"

GCS14490 49' 9'- 9 3/4" 8'- 10" 3' - 9 1/ 2"

GCS14540 54' 9'- 9 3/4" 8'- 10" 6' - 7 1/ 2"

GCS14550 55' 9'- 9 3/4" 8'- 10" 7' - 1 1/ 2"

GCS14590 59' 9'- 9 3/4" 9'- 3 1/2" 8' - 7 1/2"

GCS14600 60' 9'- 9 3/4" 9' - 9 3/4" 8' - 7 1/2"

GCS14620 62' 9'- 9 3/4" 9' - 3 1/2" 9'- 3 1/2"

GCS14680 68' 9'- 9 3/4" 6' - 7 1/2" 8'- 10" 6'- 7 1/2"

GCS14720 72' 9'- 9 3/4" 7' - 1 1/2" 9'- 9 3/4" 7'- 1 1/2"

GCS14750 75' 9'- 9 3/4" 7' - 1 1/2" 9'- 3 1/2" 9'- 3 1/2"

GCS14780 78' 9'- 9 3/4" 9' - 3 1/2" 9'- 3 1/2" 8' - 7 1/2"

GCS14800 80' 9'- 9 3/4" 9' - 9 3/4" 9'- 9 3/4" 8' - 7 1/2"

GCS14880 88' 9'- 9 3/4" 6' - 7 1/2" 8' - 10" 6' - 7 1/2" 9' - 9 3/4"

GCS14900 90' 9'- 9 3/4" 3' - 9 1/2" 9'- 9 3/4" 9' - 3 1/2" 9' - 9 3/ 4"

GCS14920 92' 9'- 9 3/4" 7' - 1 1/2" 8' - 10" 8' - 10" 8' - 10"

GCS14105 105' 9'- 9 3/4" 5' - 3 1/2" 9'- 9 3/4" 9' - 9 3/4" 9' - 9 3/4" 5' - 3 1/2"

GCS14113 113' 9'- 9 3/4" 8'- 10" 9'- 9 3/4" 8' - 10" 9' - 9 3/4" 6' - 7 1/2"

GCS14120 120' 9'- 9 3/4" 9' - 3 1/2" 9'- 9 3/4" 9' - 9 3/4" 9' - 9 3/4" 8' - 7 1/2"

12" & 14" Commercial Bin Sweep Augers PNEG-1050

19

Page 20

Assembly

3. FLIGHT AND SHIELD ASSEMBLY (cont.)

FIG . 6

Sweep Flight Back Shield Layouts

Sweep Tractor

Drive Unit and Pivot Point

Drive Unit and

Pivot Point

(See Fig. 13 on pg. 25)

Drive Unit and

Pivot Point

Bearing Stand (2 Places)

Two Flight Section Units (36' - 43' Bin Dia.)

Bearing Stand (3 Places)

Three Flight Section Units (48' - 62' Bin Dia.)

Truss Cable

Sweep Carrier

Four Flight Section Units (68' - 80' Bin Dia.)

Sweep End Wheel

Sweep Tractor

Truss S tand

(See Fig. 14 on pg. 25)

Sweep End Wheel

Sweep Tractor

Sweep End Wheel

Bearing Stand (4 Places)

Truss Cable

(See Fig. 13 on pg. 25)

Drive Unit and

Pivot Point

Bearing Stand (6 Places)

Drive Unit and

Pivot Point

Sweep Carrier

Truss S tand

Truss S tand

Five Flight Section Units (88' - 92')

Sweep Carrier

Six Flight Units (105' - 120' Bin Dia.)

(See Fig. 14 on pg. 25)

Bearing Stand (5 Places)

Truss Cable

Truss S tand

Sweep Tractor

Sweep End

Wheel

(See Fig. 14 on pg. 25)(See Fig. 13 on pg. 25)

Sweep

Tractor

Sweep End Wheel

20 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 21

3. FLIGHT & SHIELD ASSEMBLY (cont.)

Sweep Back

Shield with Tractor

Mounting Holes

Truss Cable

Mounting Bracket

End Wheel

5/8" x 4" HHCS

with Locknut

Assembly

End Wheel

Eyebolt

(4) Truss Cable T ake-

Up Bracket

Truss S tand

(Two Used on 105' - 120' Dia. Bins)

Sweep Carrier Assembly

( T wo used on 105' - 120' Dia. Bins)

Truss Cable

Bearing Stand

3/8" x 1-1/4" HHCS with Flat

(6) Shield Mount Plate

Washer , Lock W asher and Nut

Bearing Stand

Large Shield

Splice Plate

(5) Sweep Back

Shield with Cutout

Assembly

Weld-In

Connecting

Small Shield

Splice Plate

Stub

5/8" x 4" HHCS

with Locknut

FIG . 7

Drive Unit

(Shown without Reducer Drive)

3/8" x 1-1/2" Long

HHCS with Flat

Washer , Lock

Washer , and Nut

12" & 14" Commercial Bin Sweep Augers PNEG-1050

(3) Sweep

Connect to

Reducer

Output

Shaft

Flight with

Cutback

21

Page 22

Assembly

3. FLIGHT & SHIELD ASSEMBLY (cont.)

1. Connecting Flight and Shield Sections

A. Bolt the sweep flight with the cutback (3) to the

reducer output shaft of the drive assembly . Use

two 5/8" x 4" long hex head capscrews and nylon

locknuts. (See Fig 8A.)

B. Attach the sweep back shield with cutout (5) to

the shield mount plate (6) on the drive assembly .

Use two 3/8" x 1-1/4" long hex head capscrews,

flat washers, lock washers, and nuts. (See Fig.

8A.)

C. Bolt the bearing holders (2) to the inside of the

bearing stands (1). Use a 7/16" x 1-1/2" long hex

head capscrew and nylon locknut to secure the

bearing holder (2) to the bearing stand (1).

(See Fig. 8B.)

D. Place the bearing stand (1) between the first

sweep back shield section and the next section

to be used. Bolt the sweep back shield sections

to the bearing stand (1) by using two 3/8" x 3"

long hex head capscrew , two flat washers, two

lock washers and two nuts. (See Fig 8B.)

On larger units that use four or more sections of flight

(68' to 120' Dia. Bins) a cable truss is provided for the

sweep back shields. On these units the truss cable

take-up bracket (4) must be attached to the back

shield mounting bracket with the same bolts that hold

the sweep back shield. The mounting bracket will be

sandwiched between the cable bracket and the back

shield. (See also Fig. 13 on page 25.) Use two 3/8" x

1-1/2" long hex head capscrews, flat washers, lock

washers and nuts to fasten the take-up bracket and

sweep back shield to the shield mount plate.

Fig. 8A

(6) Shield Mount Plate

3/8" x 1-1/4" HHCS,

flat washers, lock

washers, and nuts

(5) Sweep Back

Shield with Cutout

(3) Sweep Flight

with Cutback

3/8" x 3 Carriage Bolt

Hex Nut

Lock Washer

Flat Washer

7/16" x 1-1/2" Hex Head Cap

Screw with Locknut

Lower Back Shield

Splice Plate

22 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Bearing Stand Assembly

(2) Bearing Holder

Fig. 8B

(1) Bearing St and

Upper Back Shield

Splice Plate

Flat Washer

Lock Washer

Hex Nut

3/8" x 3" HHCS

Page 23

3. FLIGHT AND SHIELD ASSEMBLY (cont.)

Assembly

E. Attach sweep back shield splice plates (8 & 9) to

back side of the sweep back shield. Use eight 5/16" x

3/4" hex head capscrew and nylon locknuts for each

upper splice plate. Use four 5/16" x 3/4" long hex

head capscrews and nylon locknuts for each lower

splice plate. (See Fig. 9 & 10.)

F. Slide the flight connecting stub (10) through the

bronze bearing (1 1) and into the next flight section.

Connect the flight sections together using two 5/8" x

4" hex head capscrews and nylon locknuts.

(See Fig. 10 & 1 1.)

5/16" x 3/4"

HHCS &

Locknuts

Sweep Flight

(7) Bearing

Stand

Upper Portion

of Sweep Back

Shield

(8) Upper Back

Shield Splice

Plate

G . Repeat steps C-F for the other add-on sweep back

shield and flight sections. (NOTE: Units that use four

or more sections of flight include a sweep carrier

assembly that is used in conjunction with a truss

stand. (See Fig. 6 on page 20 for locations.) A cable

truss is also provided for the sweep back shields on

these units. The truss stand will fasten to the sweep

carrier assemblies. Fasten the truss stand to the

sweep carrier with 3/8" x 1" long hex head capscrews.

(See Fig. 12 on page 24.) Use 3/8" x 3-1/2" hex head

capscrews to connect the sweep carrier , sweep back

shield and bearing stand together.

5/8" x 4" HHCS

with Locknut

(1 1) Bronze

Bearing

5/16" Locknuts

(10) Connecting

Stub

(8)

(1 1) Bronze

Bearing

Lower Portion of Sweep

Back Shield

(9) Lower Back

Shield S plice Plate

FIG . 9

Splice Plate Side View

The sweep flights are indexed to achieve “timed”

connections ( A “timed” connection is where the

flight pitch does not change across the connection.)

When bolting timed flight sections together at the

bearing stand, position the flight ends so they are

open 90° to 180° to one another.

(9)

5/16" x 3/4"

HHCS with

Locknut

5/8" x 4" HHCS

with Locknut

FIG . 10

Splice Plate Angled View

Bearing

S tand

FIG . 1 1

5/16" x 3/4"

HHCS

Sweep Flight

12" & 14" Commercial Bin Sweep Augers PNEG-1050

23

Page 24

Assembly

4. SWEEP CARRIER WHEEL & TRUSS STAND ASSEMBLY

5/8" x 4"

HHCS with

Locknut

(3) Sweep

Back Shield

5/8" x 4"

HHCS with

Locknuts

(1) Sweep Carrier

Wheel Assembly

(4) Connecting Stub

(2)

Bearing

St and

(6) Truss

St and

(5) Flighting

3/8" x 3-1/2"

Carriage Bolt

with Flat Washer

and Locknut

FIG . 12

3/8" x 1"

HHCS with

Locknut

3/8" x 3-1/2"

HHCS with

Locknut

Cable

Cable

Top View

Cable goes

through this

tube on

truss stand.

End View

Sweep Carrier Wheel and Truss Stand Detail

A. Carrier Wheel Assembly (For bins with four or

more sections.) (Refer to Fig. 12.)

1. Place sweep carrier wheel assembly (1) over

bearing stand (2).

2. Connect carrier wheel (1) and bearing stand (2) to

sweep back shields (3) using a 3/8" x 3-1/2"

carriage bolt with flat washer, lock washer , and

locknut and a 3/8" x 3-1/2" HHCS with locknut.

3. Slide connecting stub (4) through bearing stand

(2) and connect to flighting (5) using four 5/8" x 4"

HHCS with locknuts.

B. Truss S tand

1. Attach truss stand (6) to sweep wheel carrier

assembly (1) using four 3/8" x 3-1/2" HHCS with

locknuts.

T o use a single section of auger flighting with back

shield (or just few sections) for gradual unloading, install

the sweep wheel at the end of the last section used.

On units that use four or more sections of flight, a cable

is provided for the sweep back shields. A truss cable

anchor will be attached to the bearing stand and shield

joint of the last section. (See Fig. 13 on page 25) Use

the same 3/8" bolts to connect the sweep back shield,

bracket, and truss cable anchor together.

24 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 25

5. SWEEP FLIGHT BACK SHIELD ASSEMBLY

C. T russ Cable Assembly . (For units without cable

truss, go to step D.)

Secure the clamp u-bolts against the loose end of

1. Install eyebolt (1) through anchor on cable take-up

bracket (4), using flat washer and two 5/8" hex nuts.

(See Fig. 13)

2. Install the cable anchor (5) to the outside of the back

shield using the existing hardware provided for the

shield. (See Fig. 14.)

3. Attach truss cable (3) to cable anchor (5) using two

cable clamps (6). (See Fig. 14)

4. Route the truss cable (3) through the small tube at the

end of the truss stand(s). (See Fig. 12 on page 24)

the cable. (See Fig. 13)

5. Attach truss cable (3) to eyebolt (1) using two cable

clamps (6). (See Fig. 13)

6. Using the eyebolt (1), tighten the truss cable (3) until

it is reasonably snug.

D. Inspect “DANGER” decal on back shield. If

decal cannot be easily read or is missing,

order a new one immediately from your

dealer or the manufacturer.

Assembly

Flat Washer

5/8" NonLocknuts

Shield

Mount

Plate

Drive Unit

(4) Cable

T ake -Up

Bracket

Reducer

Mount Plate

Sweep Back

Shield End

Plate

Flighting with

Cutback

(1) Eyebolt

(6) Saddle Portion

Of Cable Clamp

Truss Cable Tak e-Up Detail

(as viewed from the top)

(5) Cable Anchor

U-Bolt Portion

of Cable Clamp

Shield Mount Plate

FIG.13

(3) Truss

Cable

5/8" NonLocknuts

5/8" x 4" HHCS

with Locknut

3/8" x 1-1/2" HHCS with

Flat Washer and Locknut

Flat

Washer

(4) Cable

Take-Up

Bracket

Cable

Clamps

Eyebolt

U-Bolts

(3) Truss Cable

(6) Saddle Portion

of Cable Clamp

(6) U-Bolt Portion of

Cable Clamp

Bearing Stand

Truss Cable Anchor Detail

(as viewed from the top)

12" & 14" Commercial Bin Sweep Augers PNEG-1050

Sweep Tractor

Sweep Shield

(Farthest from Drive End)

FIG.14

25

Page 26

Assembly

6. END WHEEL ASSEMBLY (Refer to Fig. 15.)

1. Install stub (1) into sweep flight (2) using a 5/8" x 4"

long hex head capscrew and 5/8" nylon lock nut.

2. Slide bearing stand weldment (5) over stub (1) and bolt

it to the sweep shield (6) using a 3/8" x 3" hex head

capscrew , a 3/8" x 3" long carriage bolt and a

(6) Sweep Shield

flatwasher , lockwasher and non-lock nut. Use the

carriage bolt in the slotted hole of the bearing stand (5).

3. Slide end wheel (3) and collar (4) onto the stub (1). Bolt

the collar (4) in place with a 1/2 "x 3-1/4" long hex head

capscrew and 1/2" nylon lock nut.

(5) Bearing Stand W eldment

(2) Sweep Flight

(1) Stub

(3) End Wheel

(4) Collar

FIG . 15

26 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 27

Assembly

7. SWEEP TRACTOR TO BACK SHIELD ASSEMBLY (Refer to Fig. 16.)

1. Mount the sweep tractor (1) to the last shield section

(2) furthest from the drive end. There are six 7/16"

holes that have been pre-punched in the shield. Bolt

sweep tractor (1) to shield (2) using six 3/8" x 1" hex

Adjustment bolts for adjusting the

angle and height of the bracket

(3/8" x 1" HHCS with flat

washer’s Nylon Locknut)

head capscrews with flat washers and nylon locknuts.

2. Adjust bracket on sweep tractors as needed to get the

correct angle and height to match sweep.

Completed Tractor Assembly

12" & 14" Commercial Bin Sweep Augers PNEG-1050

Sweep Shield

FIG . 16

27

Page 28

Assembly

8. SWEEP TRACTOR ASSEMBLY (SEE FIG. 18)

1. Remove wheel hubs from axle. (Assembled for

shipping only.)

2. Bolt the adapter plate (2) to the gear motor (3) using

four 3/8" x 1" hex head capscrews with four 3/8"

lockwashers.

3. Install right side chain around the right side sprockets.

4. Slide right side chain guard (12) onto the axle.

5. Bolt the adpater plate (2) to the gear motor mount by

placing a 3/8" x 1-1/2" through the left side slots in the

adapter plate (2), four flat washers, gear motor mount

(4), one flat washer , the right side chain guard (12),

and finally , a hex nut. Repeat this with the left side

slots in the adapter plate (12), but replace the right

side chain guard with the left side chain guard mount

bracket (14). (See Fig. 17)

6. Attach the other right side chain guard flange &

support tube weldment (7) to the sweep tractor

assembly using (2) 1/2" x 4" hex head capscrews and

nuts.

7. Assemble 13 tooth sprocket (5) to gear motor shaft (6)

using a 1/4" key x 1" long. Align 13 tooth sprocket (5)

with 40 tooth sprocket (6) before tightening the

sprocket setscrews.

8. Install chain around the sprockets. Use slots in gear

motor mount to tighten the chain. Once chain is tight,

completely tighten bolts that hold gear motor to mount

from step 5.

9. Bolt the left side chain guard (12) to the mount

bracket (14) using (2) 3/8" x 1" HHCS & lock washers.

15. Attach the weight bracket (1 1) to the weight bracket

weldment (8) with a 3/4" hex nut. Tighten the nut so

the weight bracket is securely against the top of the

50 lb. weights (9).

16. Slide the weight clamps (10) out against the sides of

the 50 lb. weights (9) and tighten to secure the

weights in place.(See Fig. 17.)

17. Electric wiring for motor and controls shall be installed

by a qualified electrician and must meet the standards

set by the National Electrical Code and all local and a

state codes.

18. Run wiring for motor forward to the sweep shield along

sweep mount tube. Attach the wiring to the mount

sufficiently to keep wiring from contacting sweep

tractor wheels.

19. At the center of the bin the wiring for the tractor may

either be connected with the sweep flight motor wiring

or a separate wire may be run to the outside of the

bin. If the tractor wiring is connected to the wiring for

the sweep flight motor , then the tractor will turn on and

off with the sweep. If a separate wire is run to the

outside of the bin, then the tractor can be operated

independently .

(2)

Adapter

Plate

(4)

Gear

Motor

Mount

NOTE:

Motor not

shown for

clarity.

10. Replace wheel hubs onto the axle.

1 1. Assemble segmented rubber wheel (1) to hubs with

1/2" nylon locknuts (four for each wheel.)

12. Slide the weight bracket weldment (8) onto the

support tube weldment (7) and secure with a

3/16" x 1-1/2" cotter pin.

13. Place the 50 lb. weights (9) on the weight bracket

weldment (8).

14. Loosely attach the weight clamps (10) to the weight

bracket (1 1) using two 1/4" x 3/4" carriage bolts ,

1/4" lockwasher, & 1/4" flat washer. Do not tighten yet

to allow for adjustment later on.

28 12" & 14" Commercial Bin Sweep Augers PNEG-1050

(13) Left Side

Chain Guard

(4) Gear

Motor Mount

FIG . 17

(12) Right Side

Chain Guard

Page 29

8. SWEEP TRACTOR ASSEMBLY (Cont.)

Assembly

(1 1) Weight Bracket

(10) Weight Clamps

1/4" x 3/4" Carriage Bolts

(3) Gear Motor

3/8" x 1-1/2" HHCS

3/4" Hex Nut

(8) Weight

Bracket

Weldment

(9) 50 lb. Weights

3/16" x 1-1/2" Cotter Pin

(7) Support Tube

Weldment

1/2" x 4" HHCS

(6) Gear Motor Shaft

(5) 13 T ooth S procket

(2) Adapter Plate

3/8" x 1" HHCS

& Lockwashers

3/8" Flatwashers

(Use 4 between plates)

(4) Mount for Gear Motor

(12) Right Side

Chain Guard

Wheel Hub

(6) 40 T ooth

Sprocket

FIG . 18

1/4" Square Key

(14) Chain Guard Mount Bracket

(12) Left Side Chain Guard

Sweep Tractor

Assembly

3/8" x 1" HHCS Bolts

with Lockwashers

(1) Segmented

Rubber Wheel

1/2" Nylon Locknuts

Sweep Tractor Assembly

12" & 14" Commercial Bin Sweep Augers PNEG-1050

29

Page 30

Installation

9. INSTALLATION & UNLOAD PROCEDURES

A. Shut down and lock out the unloading unit before

entering the bin.

If the bin is not equipped with intermediate wells, the

Commercial Sweep Auger may be placed in the bin

after all the grain has been removed that will gravity

flow through the center well.

The grain remaining should appear as in Figure

21. DO NOT enter a bin if the grain has bridged or

flowed abnormally out of the bin as shown in

Figure 19 or Figure 20. Suffocation can occur if

grain suddenly breaks loose, burying persons

who are inside the bin.

Abnormal grain flow can easily fall and bury

a person, suffocating them. DO NOT enter a

Figure 19

bin with abnormal grain flow.

Keep clear of all augers.

DO NOT ENTER this bin!

If you must enter this bin:

1. Shut off and lock out all power.

2. Use safety harness and safety line.

3. Station another person outside the bin.

4. A void the center of the bin.

5. Wear proper breathing equipment

or respirator .

Failure to heed these warnings will

result in serious injury or death.

Figure 20

Bridged grain can easily break loose and

bury a person, suffocating them. DO NOT

enter a bin with bridged grain.

Figure 21

Grain should look similar to this. Always

shut down and lock out the power to all

devices before entering a bin.

30 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 31

9. INSTALLATION & UNLOAD PROCEDURES (cont.)

B. If the bin is equipped with intermediate bin wells, open

them after grain has stopped flowing into the center

well and before the sweep auger is placed in the bin.

Open the intermediate wells near the bin center first.

Then when grain flow stops, open the wells near the

bin wall. (See Fig. 22 and Fig. 23) The Commercial

Bin Sweep Auger can then be installed. Always shut

down the unloading equipment and lock out power

before entering the bin.

C. Place the sweep motor mount pivot pin into the pivot

tube of the center well. Lay the sweep auger assembly on the pile of sloping grain or in the area of the

intermediate wells where additional grain has been

removed.

Figure 22

Installation

KEEP OUT OF BIN WHILE SWEEP IS IN OPERA TION.

D. The Commercial Bin Sweep Augers are made with the

sweep auger and back shield in two or more sections.

One of the sections can be used first alone by attaching the section to the drive unit and mounting the

reduction wheel on that section. Then, after the center

portion of the bin has been emptied, another section of

sweep auger and back shield may be added and the

unloading process continued. (See Fig. 24, 25, and

26) If the sweep is equipped with a truss, be sure to

1st Sweep Section Added.

Figure 24 Figure 25 Figure 26

2nd Sweep Section Added.

Figure 23

3rd Sweep Section Added.

tie-off extra cable length so it does not become

entangled in the sweep auger . Always shut down the

unloading equipment and lock out power before

entering the bin.

Using the gradual method of unloading described

above helps to avoid situations where cascading grain

can bury the sweep causing high torque loads and

possible damage to the sweep assembly . This kind of

12" & 14" Commercial Bin Sweep Augers PNEG-1050

damage is not covered by the warranty .

This type of operation may also be used to prevent the

unloading of one side of the bin totally before any grain is

removed from the other side. T otal unloading of one side of

large diameter bins without some unloading from the other

side can cause structural damage to the bin. Check with

your grain bin dealer or the bin manufacturer for bin

unloading recommendations.

31

Page 32

Installation

10. INSTALLATION & UNLOAD PROCEDURES (cont.)

E. Attach suitable electric wiring to the motor in a

manner that will permit the sweep to rotate several

times about the bin. The motor starting controls must

be located outside of the bin. They must never be

installed on the sweep auger inside the bin. Locate

the motor starting controls outside the bin, but near

the door so the operator has full view of the operation

inside the bin. (See Fig 27.)

F. S tart the under floor bin unloading equipment before

starting the Commercial Bin Sweep Auger. The sweep

auger will work towards the floor at approximately a

NEVER enter the bin while the sweep auger is in operation!

EXTENSION CORD MUST BE SUPPORTED IN A

MANNER THA T WILL NOT ALLOW LOOP T O

GET INTO THE SWEEP FLIGHT.

45° angle and then empty the bin or center area of the

bin in one revolution after reaching the floor . As soon

as the bin or center area of the bin empties, the

sweep auger will rotate rapidly around the bin. Shut

down the sweep auger as soon as the bin or center

area of the bin is empty .

The height of the Commercial Bin Sweep back shield

above the bin floor can be adjusted at the motor mount

and at the bolted connection between back shields.

Be sure back shields will clear splices in metal

flooring or cracks in concrete floors.

IT IS RECOMMENDED THE

CORD BE A TT ACHED T O BIN

ABOVE DOORWAY.

MOTOR

DOORWAY

ELECTRICAL

BOX

BIN

SWEEP

FLOOR

FIG . 27

32 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 33

11. FINAL CLEAN-OUT

The following procedure is recommended for cleaning the

floor of the bin after the sweep auger has removed as

much grain as possible.

1. Lockout all power.

2. Clean (scoop and sweep by hand) the outer area of

the floor into a circular pile towards the center of the

bin. (See Fig. 28)

3. Get out of the bin.

4. After making sure everyone is outside the bin and

clear of the equipment, start the under floor unloader

and the sweep auger. In a short time, the circular pile

towards the center of the bin will have been removed.

BIN WALL

TOP VIEW OF BIN

Final Cleanout

5. Stop the equipment and lock out all power .

6. Scoop and sweep by hand the remaining floor area to

the center of the bin. (See Fig. 29)

7. Get out of the bin.

8. Repeat steps 3, 4, 5, and 6 until all grain has been

removed from the bin.

BIN WALL

SWEEP

AUGER

REMAINING GRAIN

BIN WELLS

CLEANED AREA

FIG . 28

DO NOT enter a grain bin unless all power driven equipment has been shut down and

locked out.

Keep out of bin while sweep is in operation! The sweep auger will move rapidly around

the bin when the bin is nearly empty.

FIG . 29

BIN WELLS

SWEEP

AUGER

12" & 14" Commercial Bin Sweep Augers PNEG-1050

33

Page 34

Power Source

12. POWER SOURCE

A. The horsepower recommendations are for augering reasonably dry grain. High moisture grain (above 15%) will

require greater power if maximum capacity is to be maintained. The maximum possible capacity will be less

with high moisture grain than with dry grain.

A main power disconnect switch capable of being locked only in the off position should be

used. The switch should be locked out whenever sweep is not in operation.

1. Electric motors and controls should be installed by a qualified electrician and must

meet the standards set by the National Electrical Code and all local and state codes.

2. A magnetic starter should be used to protect your motor when starting and stopping. It

should stop the motor in case of power interruption, conductor fault, low voltage,

circuit interruption or motor overload. Then the motor must be restarted manually.

Some motors have built-in thermal overload protection. If this type motor is used, use

only those with a manual reset.

3. The motor starting controls must be located outside the bin. They must never be

installed on the sweep auger inside the bin. Locate the motor starting controls outside

the bin, but near the bin door so the operator has full view of the operation inside

the bin.

4. Disconnect power before resetting motor overloads.

5. Reset and motor starting controls must be located so that the operator has full view of

the entire operation.

6. Make certain all electric motors are grounded.

7. Shut off power to adjust, service or clean.

Use the table below to determine the horsepower and electric motor pulley size your specific

sweep requires. Use an electric motor that operates at 1750 RPM (motor pulley not furnished).

HORSEPOWER REQUIREMENTS FOR POWER SWEEP WITH

9" DIAMETER FLIGHTING

Bin Diameter 24' - 37' 39' - 55' 60' - 75' 78' - 113'

H.P. (Electric) 3 H.P. 5 H.P. 7 1/2 H.P. 10 H.P.

Motor pulley for sweep when used with 12" unloading system - Chain Reducer Drives (oil bath)

5" O.D. motor pulley and 9.4 P .D. driven pulley for sweep auger speed of 196 RPM.

Motor pulley for sweep when used with 14" unloading system - Chain Reducer Drives (oil bath)

6" O.D. motor pulley and 9.4" P .D. driven pulley for sweep auger speed of 226 RPM.

34 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 35

Maintenance

13. BELT TENSION

A. Check the belt tension on electric drive. To tighten

belts, use the adjusting rod on the motor mount

assembly. DO NOT over tighten belts.

14. ENCLOSED DRIVE

LUBRICATION

A. The enclosed drive is located at the discharge

end of the auger housing and is shipped without

oil. Oil is to be added to the unit during field

assembly of the auger. Oil will dissip ate under

normal operating conditions, therefore the oil

level should be checked regularly . Add 90 EP

(non-foaming) oil until the oil level reaches the

check point.

B. For lubrication in normal operating temperature

between 40º F to 120º F , we recommend the

use of non-foaming, multi purpose gear oil. Use

SAE 90 weight for normal operating temperatures. For temperatures below 40º F , use SAE

80 weight oil. Use a grade of oil commercially

available for automotive differentials. Extra

pressure additives may be of value in severe

applications.

Enclosed Drive

Fill Plug

15. REDUCTION SWEEP WHEEL

A. Add two ounces of multi purpose gun grease to the

sweep wheel drive enclosure during assembly and

each time the bin has been emptied. Use the grease

zerk on the drive housing.

16. TROUBLE SHOOTING

A. LOW CAPACITY

Sweep capacity may vary as the angle of sloping grain

varies. Check the horsepower requirements on pages 34,

to determine correct operating speed and the motor pulley

size recommended for that speed. If a greater or lower

capacity is desired it may be possible to change the

motor pulley which will change the sweep flight speed. Do

not attempt operation at speeds greater than 50 to 100

RPM above standard recommended speed. Do not operate

a sweep that is overfeeding the unloading auger unit. The

slide gate in the center well should be left full open during

sweep operation.

B. SWEEP FLIGHT & BACK SHIELD NOT MOVING

DO NOT STORE SWEEPS IN THE BIN!

Sweeps are NOT designed to remain in a bin during filling,

storage, or bottom (gravity) unloading. A sweep left in a bin

during these operations may be serverly damaged. The

GSI Group, Inc. will not be responsible for such damages.

Check Plug

FIG. 30

DO NOT add more oil than recommended.

Additional oil may damage the seals or be forced

out through the vented plug.

12" & 14" Commercial Bin Sweep Augers PNEG-1050

The following action may reduce damages to a sweep

remaining in a bin: Lifting the sweep off the center pivot,

positioning it parallel to the intermediate wells (along side

of - not on top of) and fully supporting the sweep to the bin

floor. However , even with this procedure, The GSI group,

Inc. will not be responsible for any damges to the sweep.

Check clearance between back shield and the bin floor for

excessive drag. It may be possible to adjust the back

shield up by working the slotted connections between

back shields at bearing brackets.

The grain may have gone out of condition due to moisture

or insect activity and has become hard or caked. Stop the

sweep auger and lockout power before entering the bin to

correct this or any other difficulty . Make sure the grain

hasn’t flowed abnormally or bridged over. See p age 30 for

illustrations.

35

Page 36

Parts

CHAIN REDUCER DRIVE ASSEMBLY

Refer to page 37 for Reference Numbers.

12" Flight & Shield Bundles

Bundle # Ref # Part # Description

GK5580 -- --

2 GK5027 12" x 3' 9-1/2" Fligh t

5 GK5074 12" x 3' 9-1/2" Shield

GK5581 -- --

2 GK5028 12" x 5' 3-1/2" Fligh t

5 GK5075 12" x 5' 3-1/2" Shield

GK5582 -- --

2 GK5029 12" x 6' 7-1/2" Fligh t

5 GK5076 12" x 6' 7-1/2" Shield

GK5583 -- --

2 GK5030 12" x 7' 1-1/2" Fligh t

5 GK5077 12" x 7' 1-1/2" Shield

GK5584 -- --

2 GK5031 12" x 8' 7-1/2" Fligh t

5 GK5078 12" x 8' 7-1/2" Shield

GK5585 -- --

2 GK5032 12" x 8' 10" Flight

5 GK5079 12" x 8' 10" Shield

GK5586 -- --

2 GK5033 12" x 9' 3-1/2" Fligh t

5 GK5080 12" x 9' 3-1/2" Shield

GK5587 -- --

2 GK5034 12" x 9' 9-3/4" Fligh t

5 GK5081 12" x 9' 9-3/4" Shield

GK5588 -- --

2 GK5027 12" x 3' 9-1/2" Fligh t

5 GK5266 12" x 3' 9-1/2" Shield

GK5589 -- --

2 GK5028 12" x 5' 3-1/2" Fligh t

4 GK5267 12" x 5' 3-1/2" Shield f/ Tracto r

GK5590 -- --

2 GK5029 12" x 6' 7-1/2" Fligh t

4 GK5268 12" x 6' 7-1/2" Shield f/ Tracto r

GK5591 -- --

2 GK5030 12" x 7' 1-1/2" Fligh t

4 GK5269 12" x 7' 1-1/2" Shield f/ Tracto r

GK5592 -- --

2 GK5031 12" x 8' 7-1/2" Fligh t

4 GK5270 12" x 8' 7-1/2" Shield f/ Tracto r

GK5593 -- --

2 GK5032 12" x 8' 10" Flight

4 GK5271 12" x 8' 10" Shield f/ Tractor

GK5594 -- --

2 GK5033 12" x 9' 3-1/2" Fligh t

4 GK5272 12" x 9' 3-1/2" Shield f/ Tracto r

GK5595 -- --

2 GK5034 12" x 9' 9-3/4" Fligh t

4 GK5273 12" x 9' 9-3/4" Shield f/ Tracto r

GK5596 -- --

1 GK5026 12" x 9' 9-3/4" Fligh t w/ C ut back

3 GK5073 12" x 9' 9-3/4" Shield w/ Cutout

36 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 37

16

Parts

SHIELD & FLIGHT PARTS

15

18

3

1

7

3

1

22

6

9

13

5

10

2

8

2

6

5

11

14

17

4

19

12

2

20

21

22

7

2

12" Flight & Shield P a rts

Ref # Part # Description

6 GK2163 Upper Shield Splice Plate

7 GK2162 Lower Shield Splice Plate

8 GK2172 Bearing Bracket

9 GK5163 Sweep Carrier Body Weldment

10 GK5164 Sweep Carrier Leg Assembly

11 GK2163 Bearing Holder w/ Bronze Bushing

12 GK2010 2" I.D. Bronze Bushing

13 GK5119 Truss Stand Weldment

14 CAB LES

GK5285 5/16" x 34' 6" Cable Cut Roll f/ 68' - 78'

GK5286 5/16" x 43' Cable Cut Roll f/ 88' - 92'

GK5287 5/16" x 53' Cable Cut Roll f/ 105' - 120'

15 GK3107 5/8"-11 x 13" Grade 2 Zinc Eyebolt

16 GK2509 Cable Take-Up Plate Weldment

17 GK5120 Cabel Bracket Weldment

18 GK2760 5/16" Cable Clamp

19 GK4954 End Wheel

20 GK4952 Stub for End Wheel

21 GK4951 Stub Collar for End Wheel

22 GK2222 2" O.D. x 11-1/2" Connecting Stub

4

2

12" & 14" Commercial Bin Sweep Augers PNEG-1050

37

Page 38

Parts

MOTOR MOUNT PARTS

5

8

12

18

11

10

12" Reduc er Drive Parts

Ref # Part # Desc ript i on

1 GK 4949 M ot or Mount Frame

2 GK2159 Center P ivot Weldment

3 GK 4704 Chain Reduc er Drive (3 to 1)

4 GK 5114 M ot or Mount S upport W el dm ent

5 GK 5109 M ot or Mount P lat e

6 GK 4909 M ot or Mount A djus t m ent Rod

7 S-234 3/4" Nut for Adjustm ent

8 GK 5112 P i vot Pin

10 GK1335 12" O.D. P ulley 2B (for 36' - 37' Bi n Dia. )

10 GK2332 12" O.D. P ulley 3B (for 40' - 78' Bi n Dia. )

11 GK2349 B el t V B-54

12 GK2339 B elt Guard A ss em bly

13 GK5113 B elt Guard S pacer Tube

14 GK5111 Chord Holder Weldm ent

15 CH-1829 Cord Cl amp

16 S-248 Spacer W as her 1" O. D. x 1/ 4"

17 S-8259 3/4" x 11" Long Pi vot Bolt

18 S-8276 1/4" x 3" Drive Key

19 S-7111 1/4" x 6" Long Bol t

19

16

6

4

13

7

1

3

2

17

15

14

38 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 39

GK4704 - CHAIN REDUCER PARTS

GK4 7 0 4 - 3 TO 1 EN C LOSED CHAIN D RIVE

Ref # Part # Des cription

1 GK 2 363 Aluminu m Cast i n g Co ver (Inside )

2 GK 2 364 Aluminu m Cast i n g Co ver (Ou tside)

3 GK2383 1-1/4" Bearing Cup (Timken No. 15245)

4 GK5808 Stub Output Shaft (2" Turned Down to 1-1/2")

5 GK2369 1-1/2" Bore Sprocket - 27 Tooth

6 GK2384 1-1/2" Bearing Cup (Timken No. LM29710)

7 GK 2 371 Stu b Inpu t S ha f t - 1-1/4"

8 GK2368 1-1/2" Bearing Cone (Ti nk en No. LM29749)

9 GK2367 1-1/4" Bearing Cone (Ti mken No. 15123)

10 GK2373 Output Shaft S eal - 1-1/2"

11 GK2374 Input Shaft Seal - 1-1/4"

12 GK5350 Pipe B us hing, 1/8" x3/8" NPT

13 GK2376 Drain Plug - 3/8" NPT

14 DC-1512 Decal: Noti ce Oi l Level 3 Pint

15 DC-1760 Decal: 3.0 To 1.0 Ratio

16 S-8675 Nut, 5/16-18 Whiz Loc k

17 GK2697 Vent Pl ug, 1/ 8" NPT

18 GK2372 1 1/4" bore Sprocket - 9 Tooth

19 GC03540 Square Key 3/8" x 1"

20 GK2365 #80 Roller Chian - 36 Pitch

21 GK6781 Shim, .048" Thick , For 1.5" S haft

22 S-4276 Bolt, HHTB, 5/16-18 x 1-1/4" ZN GR5

23 S-4377 Pin, Grooved Spring, 5/16" x 2

24 S-4375 Pin, Grooved Spring, 5/16" x 2-1/2"

25 S-9168 Square Key 1/4" x 1"

26 GK6780 Mac hinery Bushing, 1.25" ID x . 048" Thick

27 GK7794 Shim, .020 Thk x 1.25ID x 1.75 OD

28 GK7734 Wave Spring

29 GK7812 Wave Spring

30 GK7516 Blue RTV Silicone Gasket Maker

Parts

12" & 14" Commercial Bin Sweep Augers PNEG-1050

39

Page 40

Parts

GK4995 - SWEEP TRACTOR PARTS

12" Tractor Drive Parts

Ref # Part # Desc ript i on

1 GK4967 Mount ing Brac ket for Gear Motor

2 GK 2344 S egm ent ed Rubber Wheel

3 GK 4975 S hi el d At t ac hm ent Brac ket

4 GK 1049 1" B ore Beari ng (2-Hole Flange)

5 GK4977 Wheel Shaft

6 GK 4979 S proc k et # 50 - 40 Tooth wit h 1" Bore

7 GK4974 Wheel Hub

8 GK 4978 S proc k et # 50 - 13 Tooth wit h 1-1/8" B ore

N\S GK5490 Chain RC-50 - 50 Pit ch w/ Connect ing Li nk

N\S GK4980 Chain RC-50 - 58 Pit ch w/ Connect ing Li nk

11 GK4950 A dapter Pl ate

12 GK4976 Gear Mot or Mount ing B rac k et

13 GK5412 Weight Support S tand

14 GK5416 Weight Clamp B ar

15 GK5417 Weight B racket Weldm ent

16 GK5418 Weight Clamp B rac k et

17 GK5432 50 l b. W ei ght Pai nted

18 S-8312 3/16" x 1-1/ 2" Zinc Cott er P in

19 GK5481 Gear Mot or (1/2 hp, 3P H, TEFC)-208 - 230/ 460V

GK4985 Gear Mot or (1/2 hp, 1P H, TEFC)-115/208 - 230V

GK6386 Gear Mot or (1/2 hp, 1P H, X-Proof)-115/208 - 230V

GK6387 Gear Mot or (1/2 hp, 3P H, X-Proof)-208 - 230/460V

GK6388 Gear Mot or (1/2 hp, 3P H, TEFC)-575V

GK4985 Gear Mot or (1/2 HP , s ingle phas e TEFC)

20 GK5509 Guard: Chain Mount B rac k et

21 GK6373 Tract or Drive Shield

22 GK6374 Tract or Chain Guard

23 GK2356 40 Tooth Sprocket Weldm ent #50 1-1/4" B ore

24 S-6297 13 Tooth S procket K eyed #50 1" Bore

40 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 41

GK4995 - SWEEP TRACTOR PARTS

14

Parts

16

19

15

17

18

13

2

11

24

7

12" & 14" Commercial Bin Sweep Augers PNEG-1050

1

23

22

12

21

8

20

6

4

5

3

41

Page 42

NOTES

42 12" & 14" Commercial Bin Sweep Augers PNEG-1050

Page 43

The GSI Group, Inc. Warranty

THE GSI GROUP, INC. (“GSI”) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE TO

REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORKMANSHIP.

ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S FACTORY WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE,

OR DESIGN OF SUCH PRODUCTS.

GSI SHALL NOT BE LIABLE FOR AN Y DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED

PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH

IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE

AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION DEFECTS

OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT MANUFACTURED.

MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN THE MANUAL

ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE PRODUCT

WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT

ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH

ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

12" & 14" Commercial Bin Sweep Augers PNEG-1050

43

Page 44

This Equipment shall be installed in accordance

with the cur rent installation codes and applicable

regulations which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installation occurs.

Copyright © 2006 by The GSI Group

Printed in the USA

1004 East Illinois Street

Assumption, IL 62510

Ph: 217-226-4421

Fax: 800-800-5329

Int’l T el: 1-217-226-4401

Int’l Fax: 1-217-226-3404

Internet: http://www .grainking.com

Loading...

Loading...