Page 1

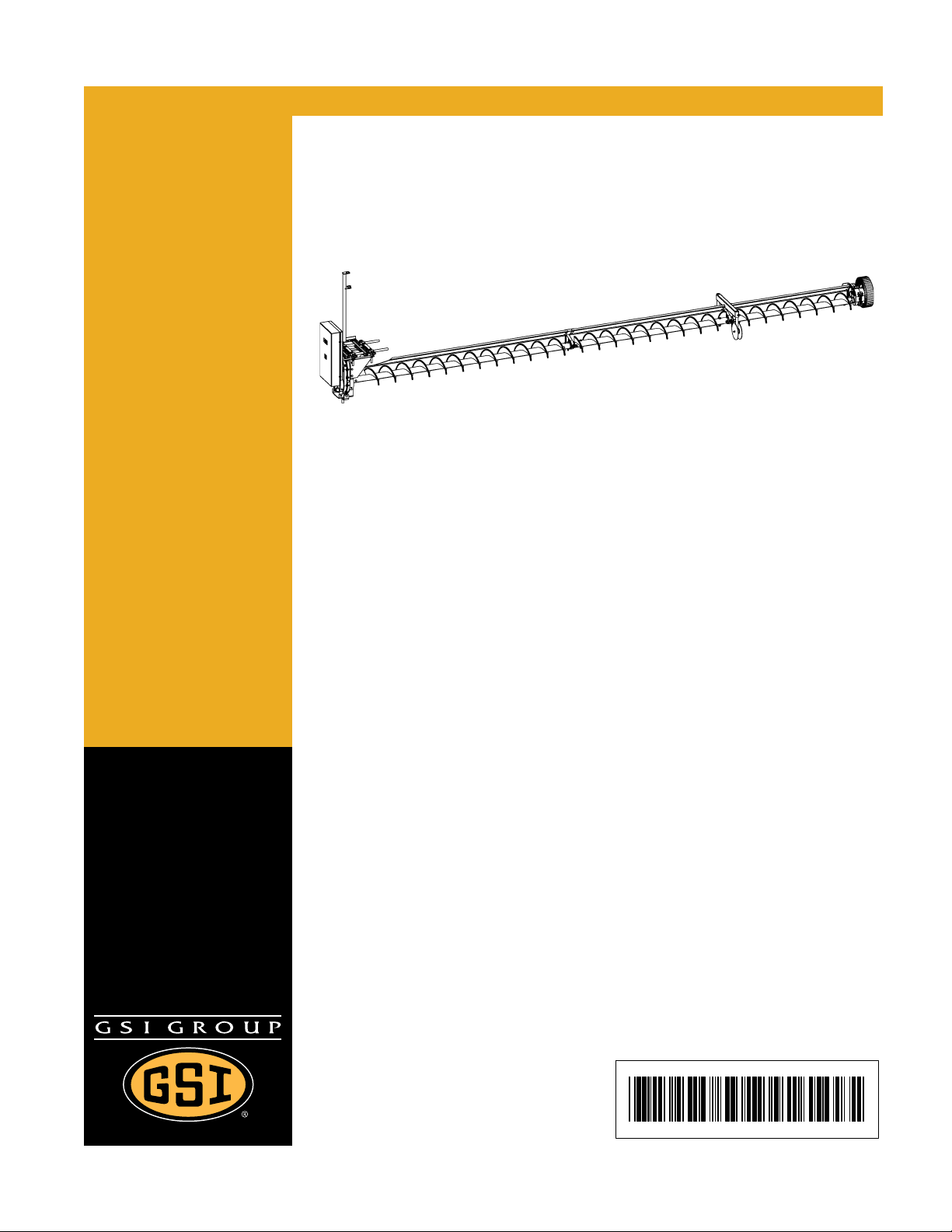

PNEG-1 04 9

10"-12" Commercial Bin

Sweep Augers

Assembly and Operation Manual

PNEG-1049

Date: 08-16-13

Page 2

Personnel operating or working around this equipment should read this manual. Th is manual

must be delivered with equipment to its owner. Failure to read this manual and its safety

instructions is a misuse of the equipmen t. Any misuse of the equipment may void the warranty.

2 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

General Information .............................................................................................................................. 4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 6

Operator Qualifications ....................................................................................... .... ... ... ... ................... 10

Chapter 3 Safety Decals ......................................................................................................................................11

Chapter 4 Assembly ............................................................................................................................................14

Chapter 5 Electrical Motor Drive Selection ................................................... ... ... .... ... ... ... .... ... ... .......................28

Chapter 6 Operation ............................................................................................................................................29

Chapter 7 Maintenance ........................................................................................................................................38

Storage ...................................... ................ ................ ................. ................ ......................................... 39

Chapter 8 Parts List .............................................................................................................................................41

Motor Rods to Drive ............................................................................................................................ 42

10"-12" Drive Assembly ...................................... ... ... .... ... ... ... .... ... ... ................................................... 44

3:1 Aluminum Enclosed Drive ............................................................................................................. 46

Motor Mount Frame Assembly ............................................................................................................ 48

Drive to Discharge Flight and Shield ............................. ................................................... ................... 49

Discharge Flight and Shield Bundles .................................................................................................. 49

Flight and Shield Joint w/o Carrier ...................................................................................................... 50

Intermediate Flight and Shield Bundles .............................................................................................. 51

Flight and Shield Joint w/ Carrier ........................................................................................................ 52

Flight and Shield to Segmented Wheel ............................................................................................... 53

Sweep Carrier Assembly ..................... ... ... ... .... .......................................... ... ... ... .... ... ... ...................... 54

Sweep Carrier Wheel Assembly ......................................................................................................... 55

Chapter 9 Configuration ......................................................................................................................................56

Flight and Shield Configuration ........ ... ... ... .......................................................................................... 56

Chapter 10 Warranty ............................................................................................................................................71

PNEG-1049 10"-12" Commercial Bin Sweep Augers 3

Page 4

1. Introduction

WARNING

DO NOT STORE SWEEPS IN THE BIN.

Sweeps are NOT designed to remain in a bin during filling, storage or gravity

unloading. A sweep left in a bin during these operations may be severely

damaged. The GSI Group will not be responsible for such damages.

General Information

1. We reserve the right to improve our product whenever possible and practical to do so. We reserve

the right to change, improve and modify products at any time without obligation to make changes,

improvements and modifications on equipment sold previously.

2. The commercial sweeps have been designed and manufactured to give years of dependable service.

The care and maintenance of this machine will affect the satisfaction and service obtained. By

observing the instructions and suggestions we have recommended, the owner should receive

competent service for many years. If additional information or assistance should be required, please

contact the local dealer.

Receiving Merchandise and Filing Claims

When receiving merchandise, it is important to check both the quantity of parts and their descriptions with

the packing list enclosed within each package. All claims for freight damage or shortage must be made by

the consignee within ten (10) days from the date of the occurrence of freight damage. The consignee

should accept the shipment after noting the damage or loss.

NOTE: The only way to prevent damage to the bin sweep, bin floor and wells is to completely remove the

bin sweep from the bin.

4 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 5

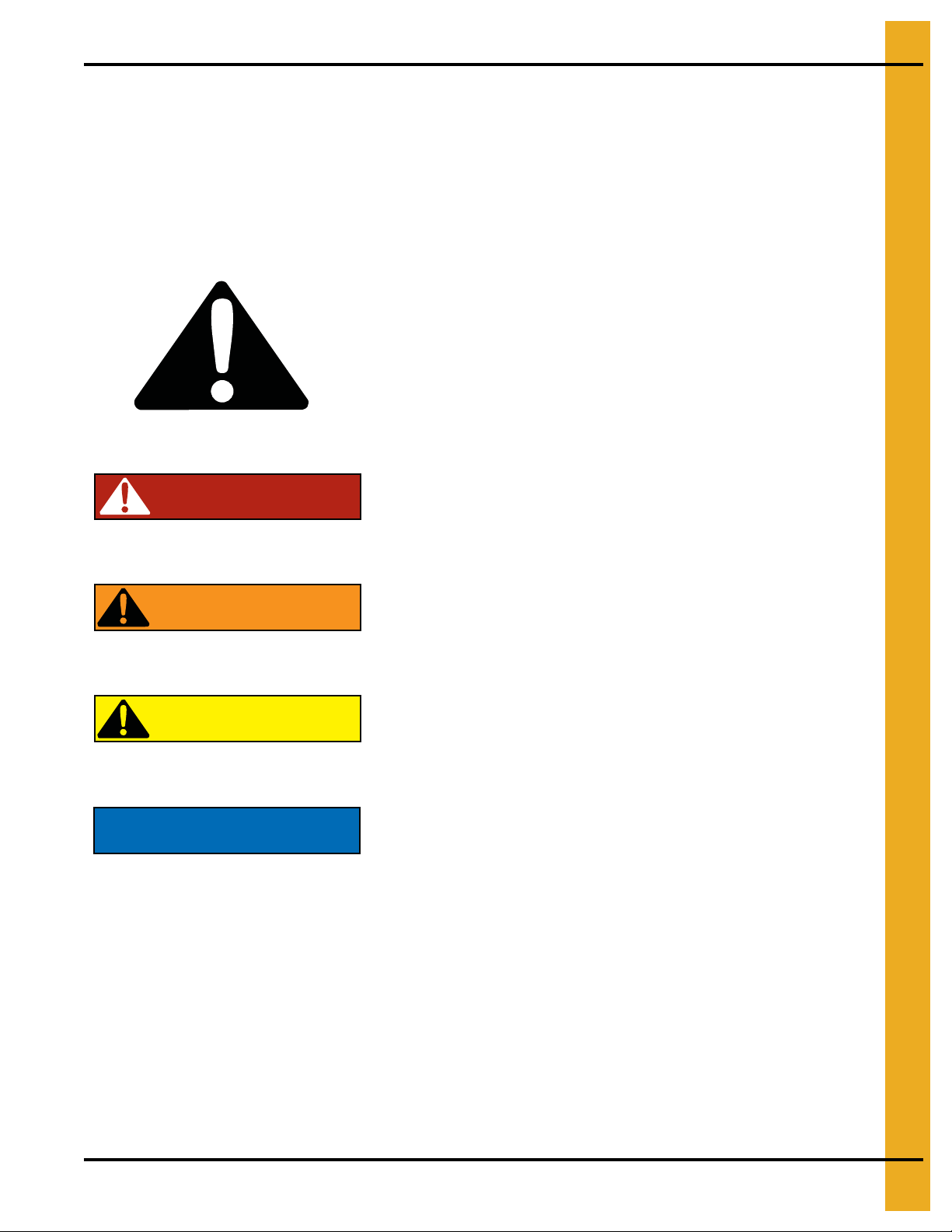

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 5

Page 6

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Keep Hands Away from Moving Parts

DO NOT put hand or arm in hopper. Rotating auger can

crush and dismember.

DO NOT put any kind of tool inside hopper to try and clear

debris while the auger is running. Damage to the equipment

will result.

ALWAYS turn off and lock out all power sources before

servicing equipment.

Keep all shields and covers in place during operation.

Rotating Auger

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 7

2. Safety

Operate Motor Properly

In an emergency, shut down the power source.

Turn OFF and lock out all power sources before performing

any maintenance.

Do not operate electric motor equipped units until motors are

properly grounded.

Disconnect power on electrical driven units before resetting

motor overloads.

Do not repetitively stop and start the drive in order to free a

plugged condition. Jogging the drive in this manner can damage

the equipment and/or drive components.

Electric Shock Hazard

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet, and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built-up grease, oil, and debris.

Maintain Equipment

and Work Area

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone

Keep Emergency Equipment

Quickly Accessible

PNEG-1049 10"-12" Commercial Bin Sweep Augers 7

Page 8

2. Safety

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on plastic

or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 9

Operate Unload Equipment Properly

• Untrained operators subject themselves and others to SERIOUS INJURY

or DEATH. NEVER allow untrained personnel to operate this equipment.

• NEVER work alone.

• Keep children and other unqualified personnel out of the working

area at ALL times. Refer to the Start-Up section of this manual for

diagrams of the work area.

• Make sure ALL equipment is locked in position before operating.

• NEVER start equipment until ALL persons are clear of the work area.

• Keep hands and feet away from the auger intake and other moving parts.

• NEVER attempt to assist machinery operation or to remove trash from equipment while

in operation.

• Be sure all operators are adequately rested and prepared to perform all functions of operating

this equipment.

• NEVER allow any person intoxicated or under the influence of alcohol or drugs to operate

the equipment.

• Make sure someone is nearby who is aware of the proper shut down sequence in the event of an

accident or emergency.

• ALWAYS think before acting. NEVER act impulsively around the equipment.

• NEVER allow anyone inside a bin, truck or wagon which is being unloaded by an auger or

conveyor. Flowing grain can trap and suffocate in seconds.

• Use ample overhead lighting after sunset to light the work area.

• Keep area around intake free of obstacles such as electrical cords, blocks, etc., that might

trip workers.

• NEVER drive, stand or walk under the equipment.

• Use caution not to hit the auger when positioning the load.

• ALWAYS lock out ALL power to the equipment when finished unloading a bin.

• Be aware of pinch points. A pinch point is a narrow area between two surfaces that is likely to trap or

catch objects and so is a potential safety hazard.

Operate Unload

Equipment Safely

2. Safety

PNEG-1049 10"-12" Commercial Bin Sweep Augers 9

Page 10

2. Safety

Operator Qualifications

A. The User/Operator must be competent and experienced to operate auger equipment. Anyone who

works with or around augers must have good common sense in order to be qu alified. These persons

must also know and meet all other qualifications, such as:

i. Any person who has not read and/or does not understand all operation and safety procedures

is not qualified to operate any auger systems.

ii. Certain regulations apply to personnel operating power machinery. Personnel under the age of

18 years may not operate power machinery, including augers. It is your responsibility, as owner

and/or supervisor, to know what these regulations are in your area or situation.

iii. Unqualified or incompetent persons are to remain out of the work area.

iv. O.S.H.A. (Occupational Safety and Health Administration) regulations state: “At the time of

initial assignment and at least annually thereafter, the employer shall instruct every employee

in the safe operation and servicing of all equipment with which the employee is, or will be

involved”. (Federal Occupational Safety and Health Standards for Agriculture. Subpart D,

Section 1928.57 (a) (6)).

B. As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe

operating and safety procedures for this auger. The sign-off sheet is provided for your convenience

and personal record keeping. All unqualified persons are to stay out of the work area at all times. It

is strongly recommended that another qualified person who knows the shut down procedure is in the

area in the event of an emergency.

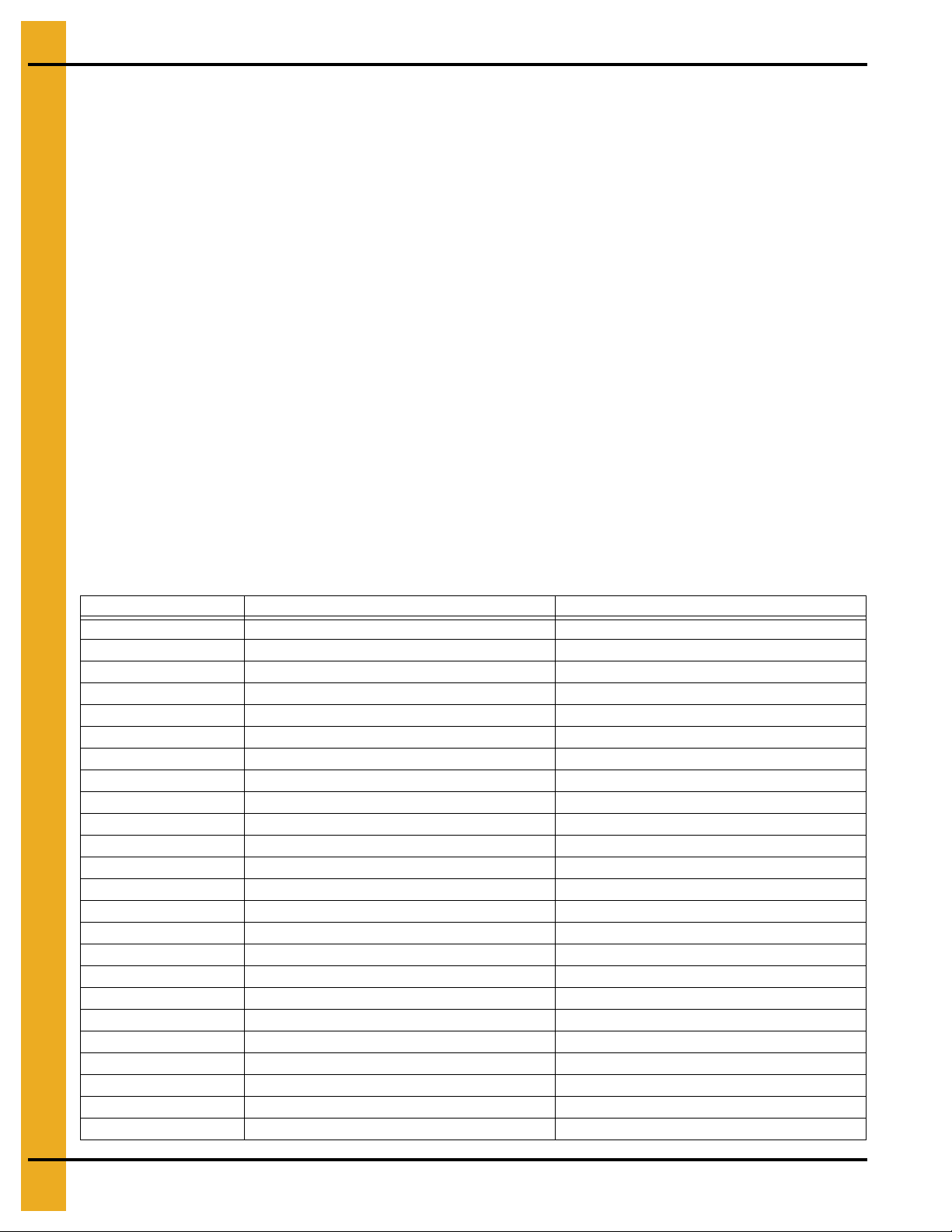

Date Employee Name Supervisor Name

10 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 11

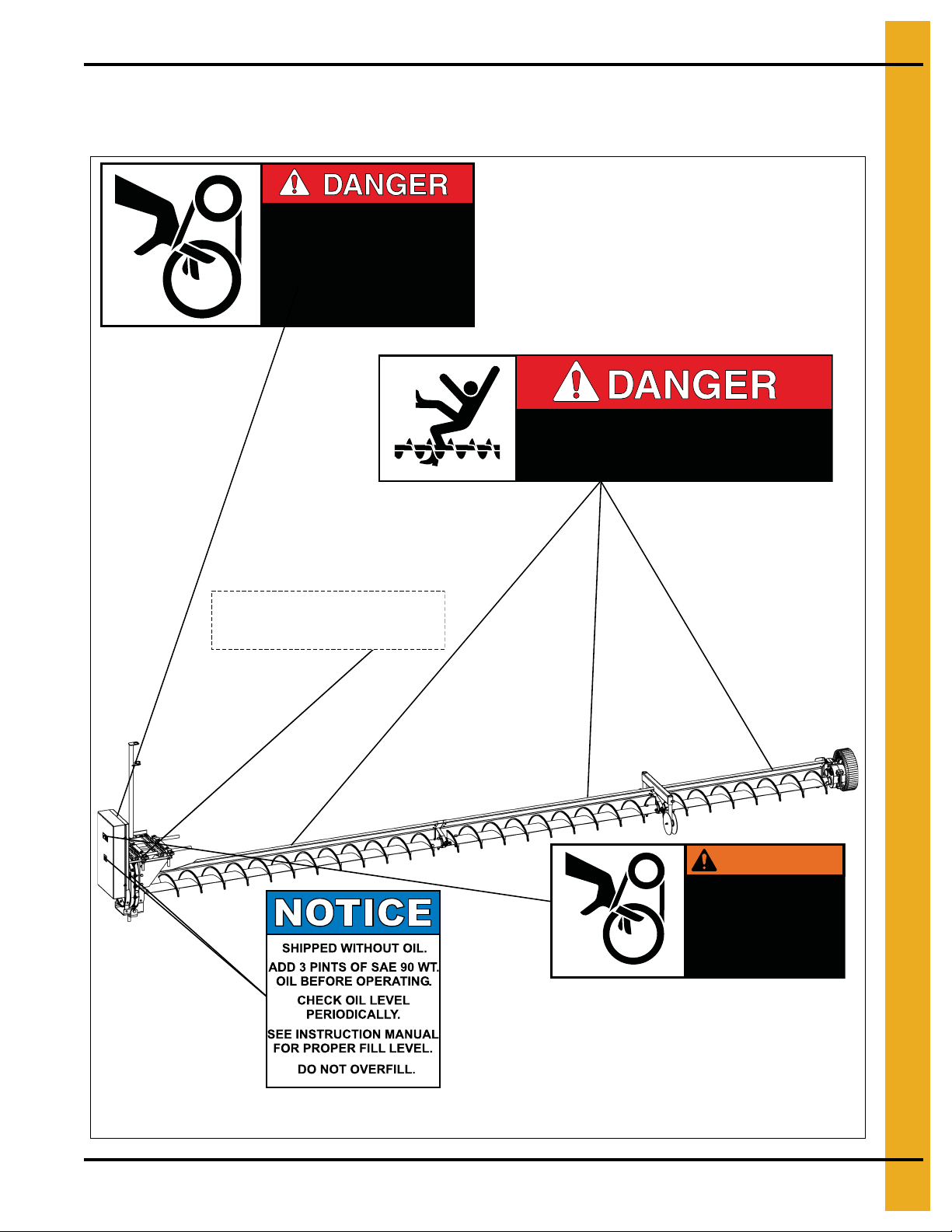

Check components shown below to ensure that the safety decals are in pla ce and in good condition. If a

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-994

SHEAR POINT

Keep hands clear of moving

parts. Do not operate with

guard removed. Disconnect

and lockout power before

servicing.

DC-995

WARNING

KEEP OUT OF BIN WHILE SWEEP IS IN OPERATION

RAPIDLY TRAVELING SWEEP AUGER

FAILURE TO HEED WILL RESULT IN

SERIOUS INJURY OR DEATH

DC-1384

DC-994

Located inside belt guard

DC-1384

Located on shield

DC-995

Located outside belt guard

DC-1512

DC-1760

Located on drive

3 TO 1 RATIO

DC-1760

DC-1512

Located on drive and on belt guard

decal cannot be easily read for any reason or has been painted over, replace it immediately. Contact your

dealer or the manufacturer to order a replacement decal free of charge.

3. Safety Decals

PNEG-1049 10"-12" Commercial Bin Sweep Augers 11

Page 12

3. Safety Decals

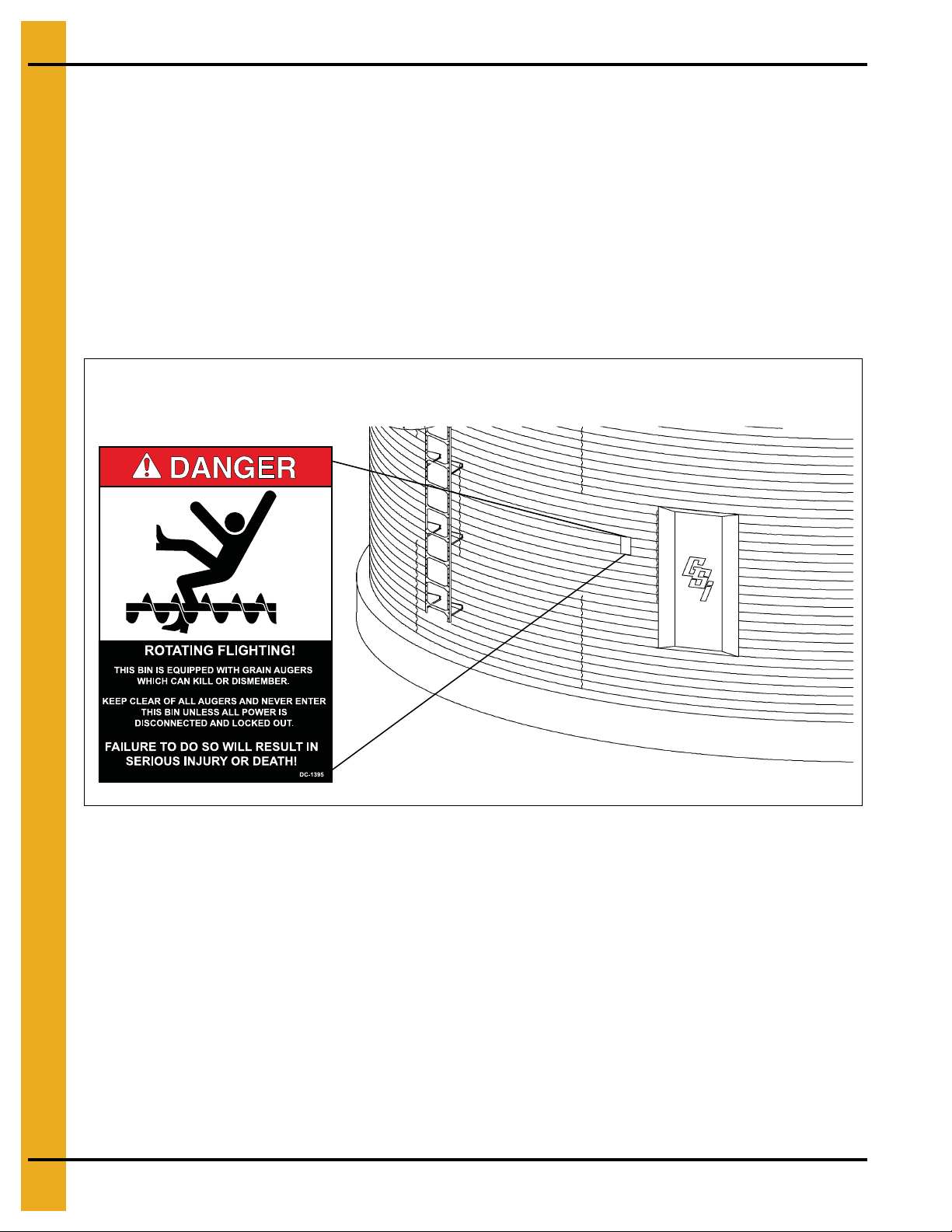

A. DANGER Sign No. DC-1395 was supplied with your bin unloading equipment. This safety sign

should be applied to the side of the bin near the bin opening, so it will be viewed by people

entering into the bin storage building. Do not cover any safety signs or any other signs that are

already there.

B. If the safety sign location suggested is not in full view because of equipment modifications, other

equipment in the area or any reason, then locate the safety sign in a more suitable location.

C. Be certain the surface is clean, dry and free of dirt and oil. Peel paper backing from decals and stick

into place. The adhesive backing will bond on contact.

NOTE: Please remember, safety signs provide important safety information for people working near bin

unloading equipment that is in operation.

NOTE: If the Safety Sign cannot be easily read for any reason or has been painted over, replace it

immediately. Additional Safety Signs may be obtained free of charge from your dealer, distributor

or ordered from the factory.

Order SAFETY SIGN NO. DC-1395

12 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 13

3. Safety Decals

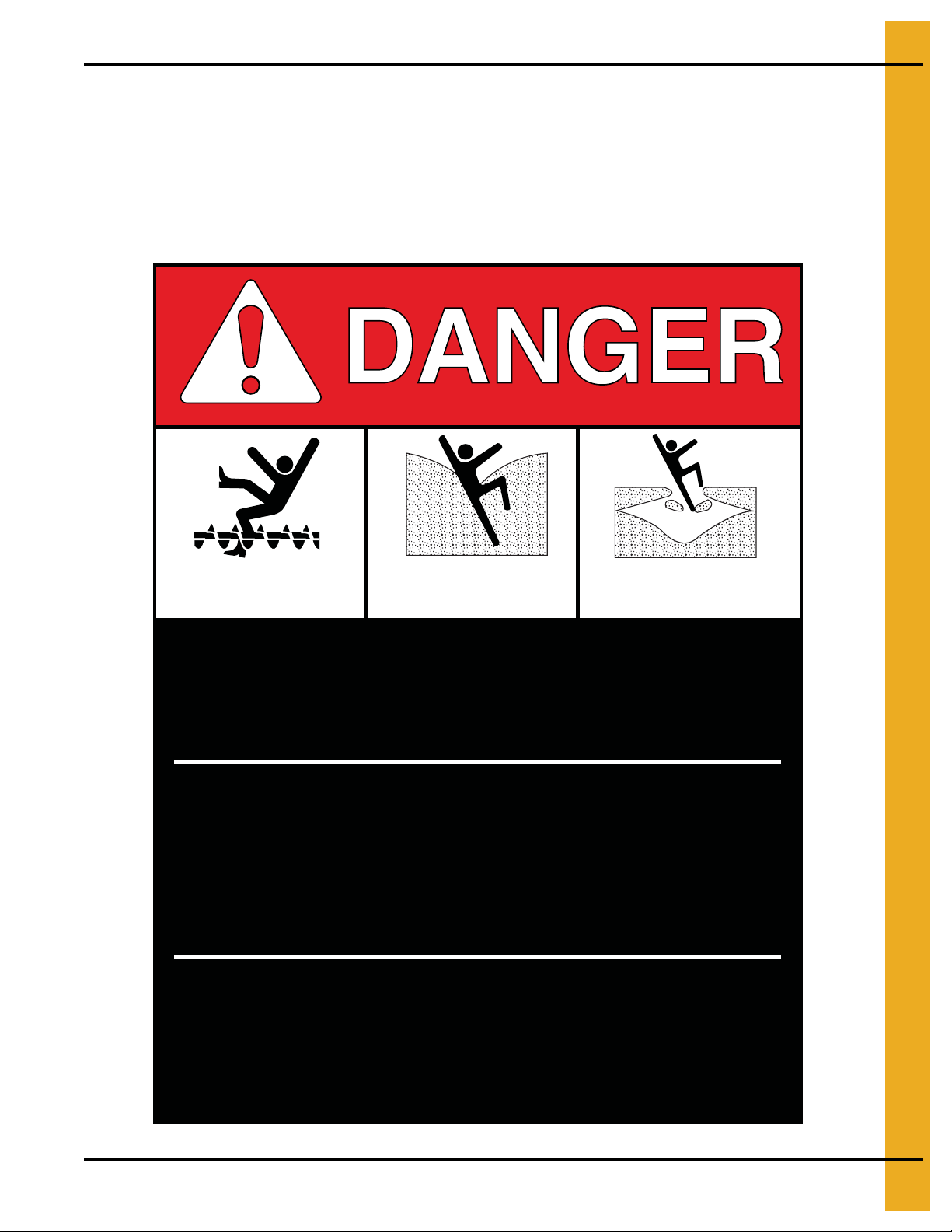

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring,

24" porthole door cover and the roof manway cover. If a decal has been damaged or is missing in any of

these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

Failure to heed these

warnings will result in

serious injury or death.

DC-GBC-1A

PNEG-1049 10"-12" Commercial Bin Sweep Augers 13

Page 14

4. Assembly

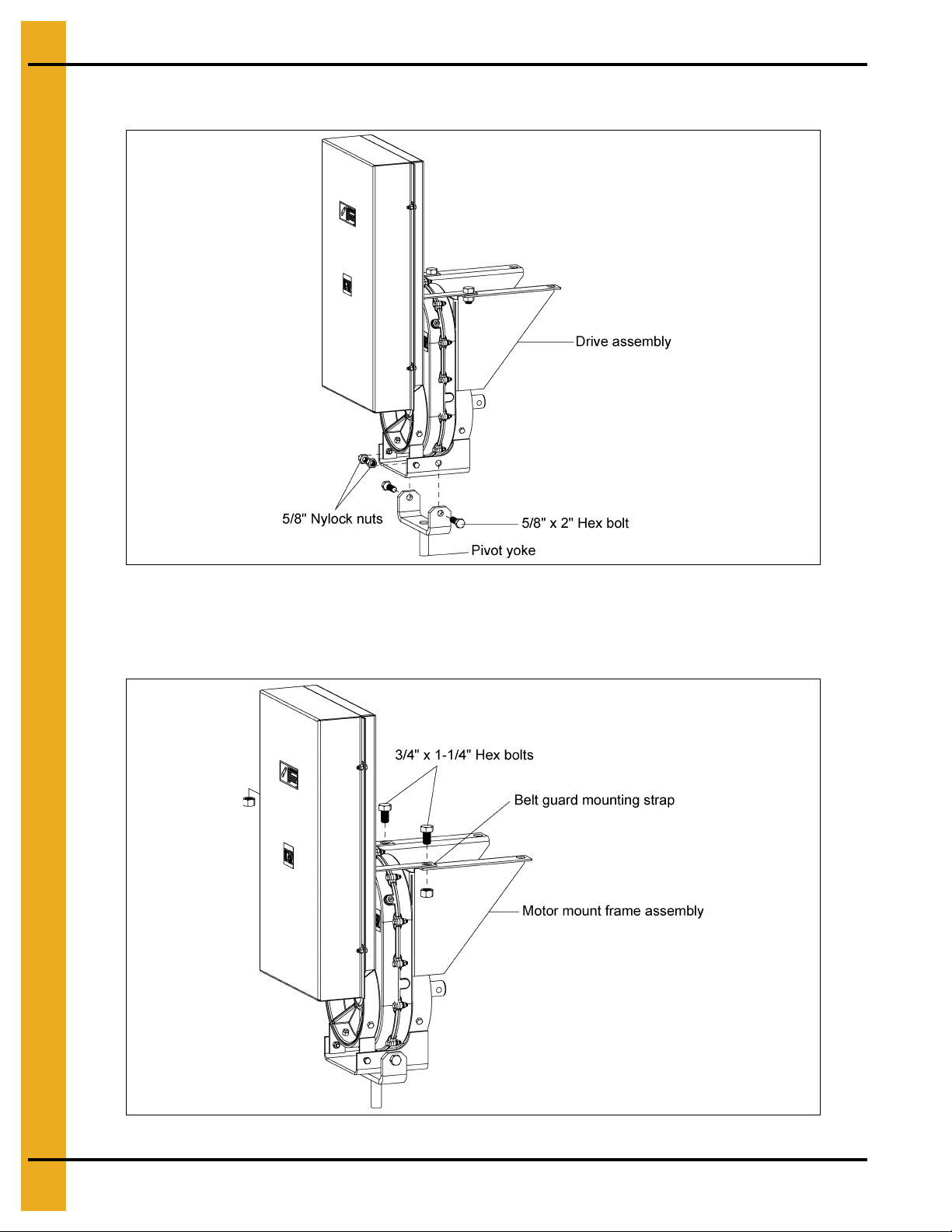

1. Attach the pivot yoke to the drive assembly with two (2) 5/8" x 2" grade 8 hex bolts and nylock nuts.

(See Figure 4A.)

Figure 4A Pivot to Drive Assembly

2. Remove the two (2) 3/4" x 1-1/4" grade 8 hex bolts and nuts that attach the belt guard mounting

strap to the motor mount frame assembly. These nuts will be reused in the Step 3 on Page 15.

(See Figure 4B.)

Figure 4B Remove Hardware

14 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 15

4. Assembly

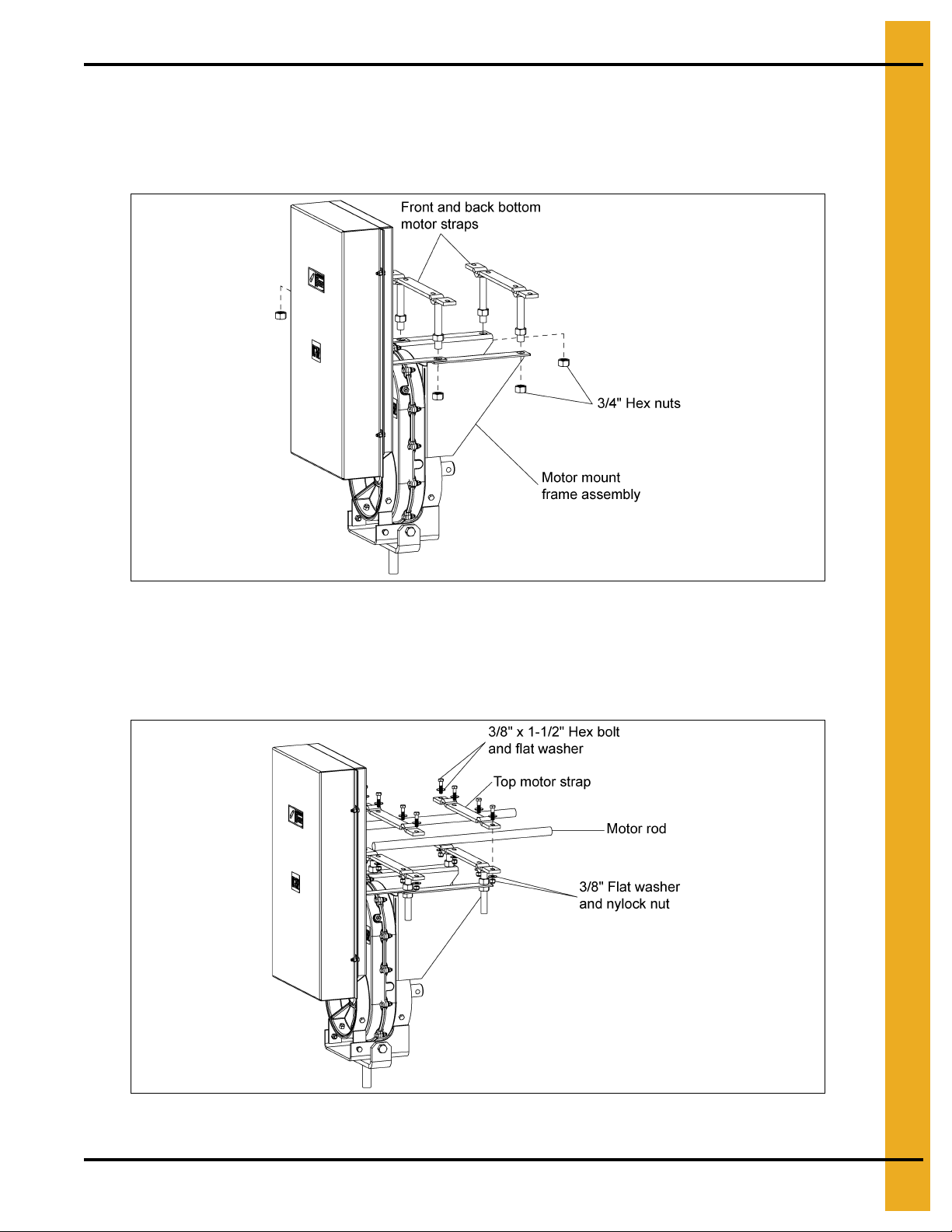

3. Thread one 3/4" hex nut onto each post of the bottom motor straps. Next, place the front bottom motor

strap through the belt guard mounting strap and the front hole of the motor mount frame assembly.

Place the back bottom motor strap thought the back hole of the motor mount frame assembly. Retain

the straps by threading one 3/4" hex nut onto each post. DO NOT TIGHTEN the nuts at this time.

They will need adjustment when the motor is installed. (See Figure 4C.)

Figure 4C Attach Bottom Motor Mount Strap

4. Place the motor rods into the indentations on the bottom motor straps. Secure the motor rods in place

by bolting the top motor straps to the bottom motor straps using eight (8) 3/8" x 1-1/2" grade 8 hex

bolts, sixteen (16) flat washers and eight (8) nylock nuts. DO NOT TIGHTEN the nuts at this time.

They will need adjustment when the motor is installed. (See Figure 4D.)

Figure 4D Attach Motor Rod and Top Motor Strap

PNEG-1049 10"-12" Commercial Bin Sweep Augers 15

Page 16

4. Assembly

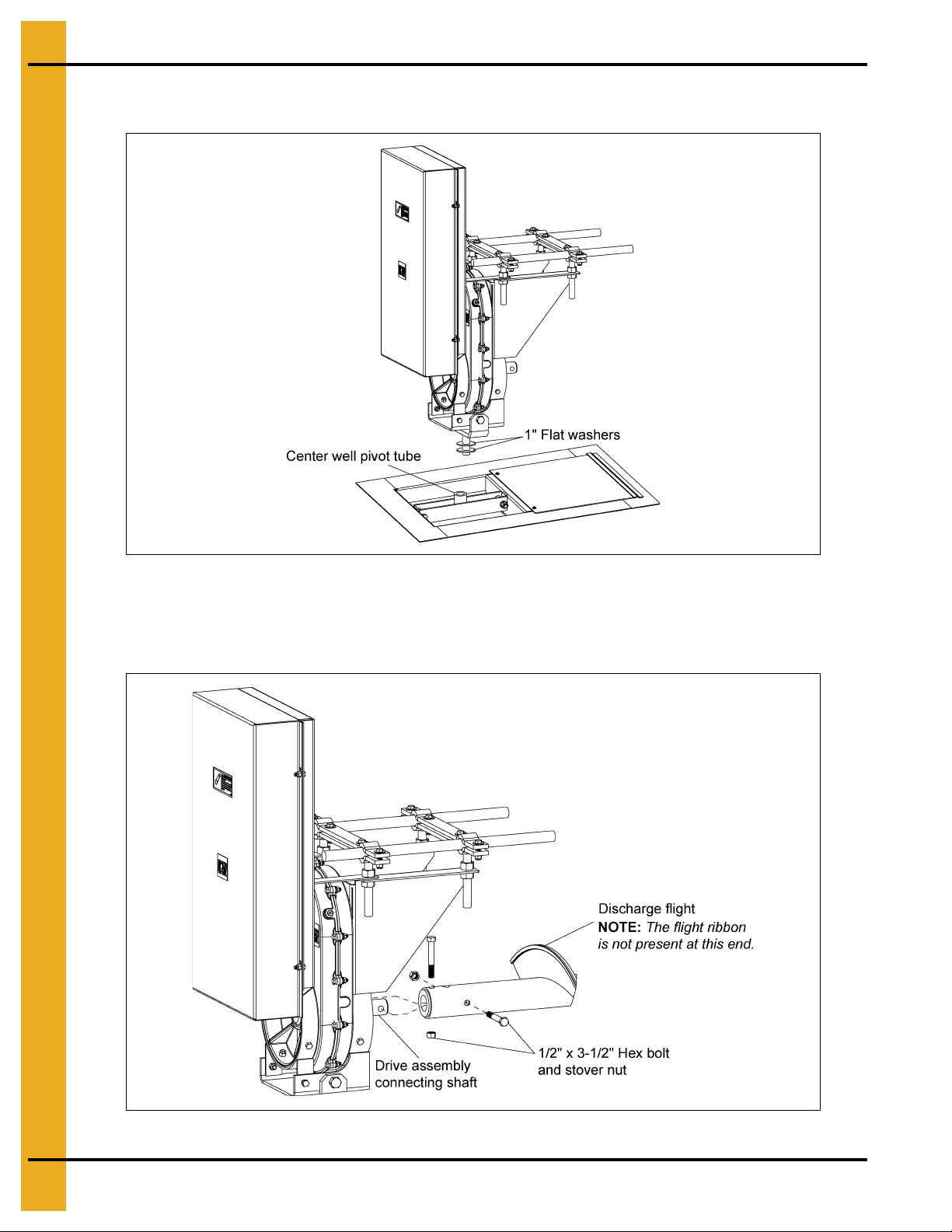

5. When installing the bin sweep in the bin, put two (2) 1" flat washers onto the post of the pivot yoke.

Place the drive assembly onto the center well pivot tube. (See Figure 4E.)

Figure 4E Drive Assembly to Center Pivot

6. Attach the discharge flight to the connecting shaft on the drive assembly using two (2) 1/2" x 3-1/2"

grade 8 hex bolts and stover nuts. The discharge flight is distinguished by the absence of flight ribbon

at one end. This end gets attached to the drive assembly. (See Figure 4F.)

Figure 4F Discharge Flight to Drive

16 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 17

4. Assembly

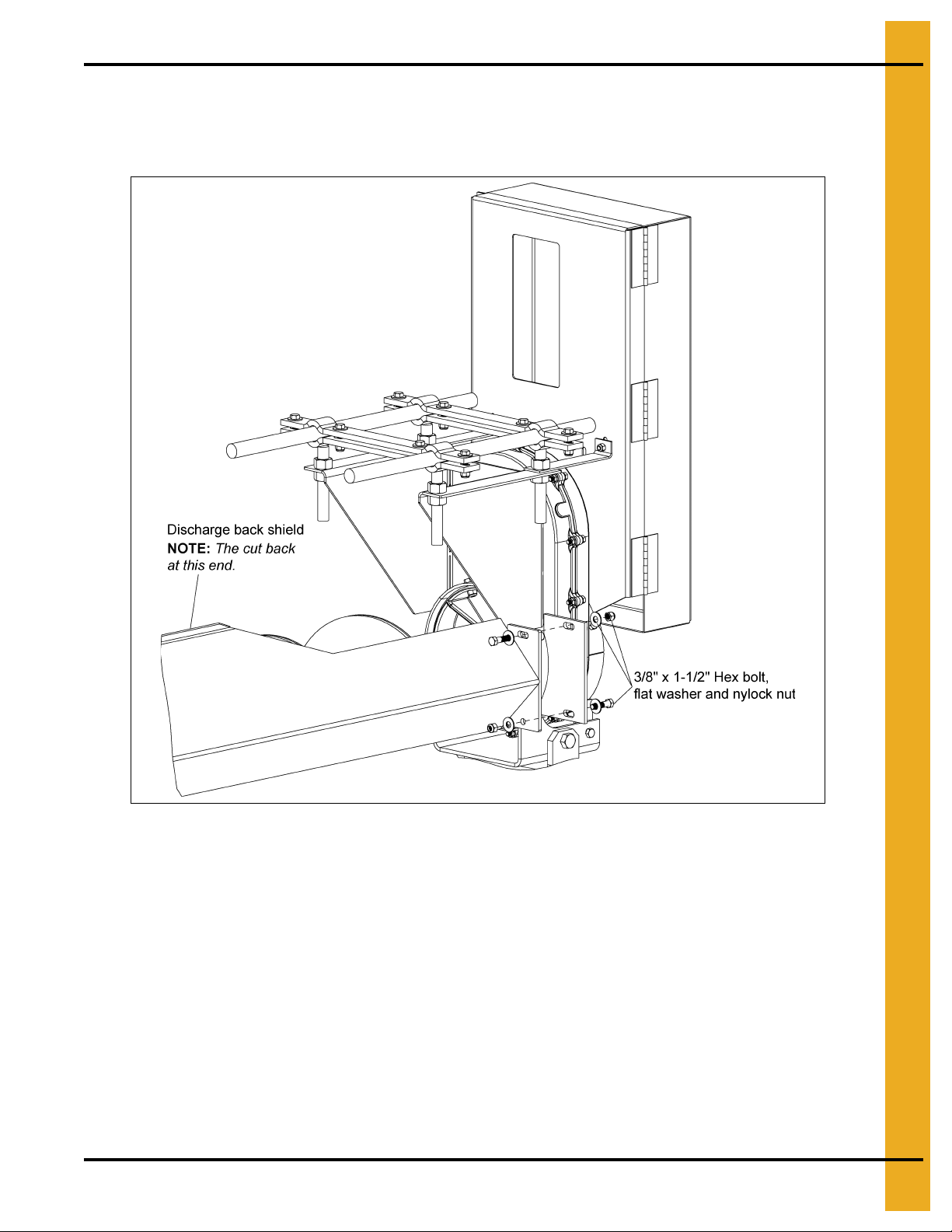

7. Attach the discharge back shield to the drive assembly using two (2) 3/8" x 1-1/2" grade 8 hex bolts,

four (4) flat washers and two (2) nylock nuts. The discharge back shield does not have the full

continuous high back shield. It is cut away at the discharge to allow more grain flow around the drive

assembly. This cut back end gets attached to the drive assembly. (See Figure 4G.)

Figure 4G Discharge Shield to Drive

NOTE: Bin sweeps containing more than two (2) sections of flight and back shield can have multiple

configurations. These configurations determine where the flight and back shield joints exist in

relation to the center of the bin.

Consider all configurations for the bin diameter before continuing. On bin sweeps with

three (3) or more sections of flight and back shield, a carrier wheel assembly is used every

two (2) sections.

Choose the configuration for the bin diameter to ensure that the(se) carrier wheel asse mbly(s)

do not interfere with the existing well positions.

Damage to the bin sweep and unload well or well grate could result from an incorrect

configuration of flight and back shield sections.

See the configuration section for the specific bin diameter on Page 56.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 17

Page 18

4. Assembly

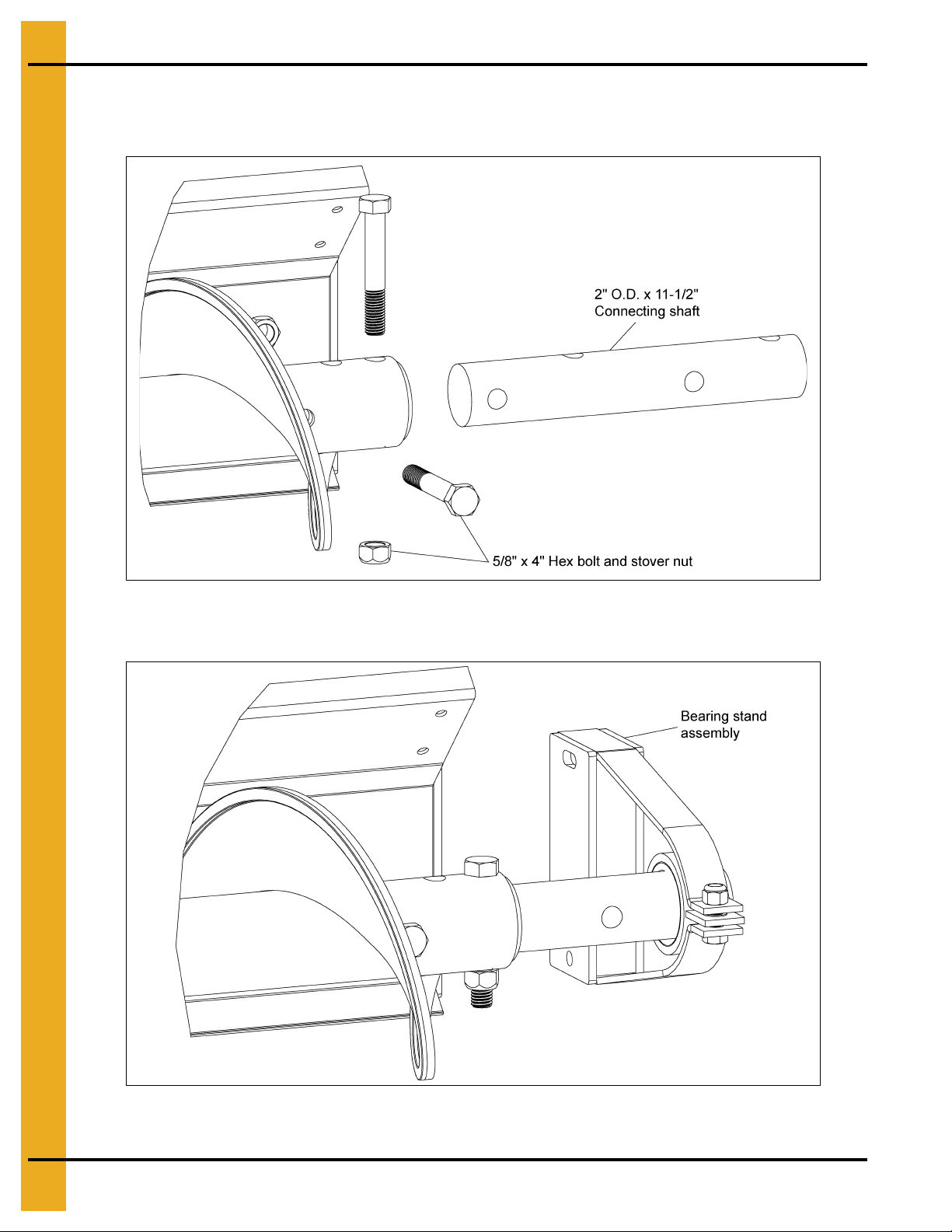

8. Place the 2" O.D. x 11-1/2" connecting shaft into the free end of the flight. Once the holes are aligned

properly, attach the shaft to the flight using two (2) 5/8" x 4" grade 8 hex bolts and stover nuts.

(See Figure 4H.)

Figure 4H Connecting Shaft to Flight

9. Place the bearing stand assembly onto the connecting shaft. (See Figure 4I.)

Figure 4I Bearing on Connecting Shaft

18 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 19

4. Assembly

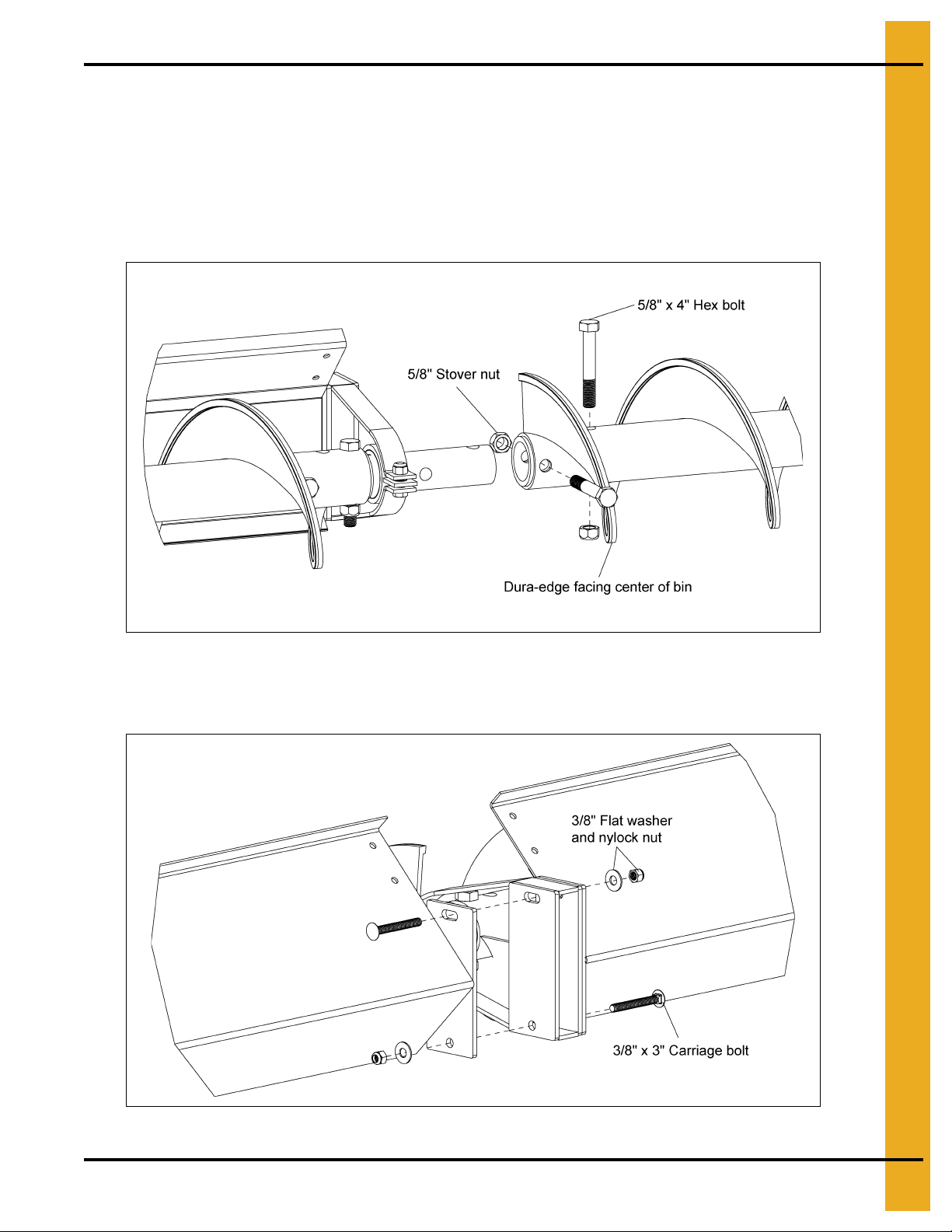

10. Align the next section of flight making sure that the Dura-Edge on both flights are as continuous

as possible, the angle between both faces being greater than 90° and less than 180° and

without overlapping.

NOTE: Overlapping the flights or having an angle between the ribbon faces be less than 90° or

greater than 180°, will result in reduced unload capacity.

11. Attach the next flight to the connecting shaft using two (2) 5/8" x 4" grade 8 hex bolts and

stover nuts. (See Figure 4J.)

Figure 4J Flight to Flight Via Connecting Shaft

12. Attach the matching section of back shield to the bearing stand assembly and the previous section

of back shield with two (2) 3/8" x 3" carriage bolts, flat washers and nylock nuts. (See Figure 4K.)

Figure 4K Shield to Shield through Bearing

PNEG-1049 10"-12" Commercial Bin Sweep Augers 19

Page 20

4. Assembly

13. Bolt the shield splice plate to complete the connection of the two (2) back shields. Use four (4)

5/16" x 3/4" hex bolts, flat washers and serrated flange nuts. (See Figure 4L.)

Figure 4L Shield to Shield through Splice Plate

14. Repeat Step 8 on Page 18 through Step 11 on Page 19.

NOTE: Bin sweeps with three (3) or more flight and shield sections use a carrier wheel assembly

after every two (2) sections. The first carrier wheel assembly should be installed after the first

two (2) sections of flight and shield.

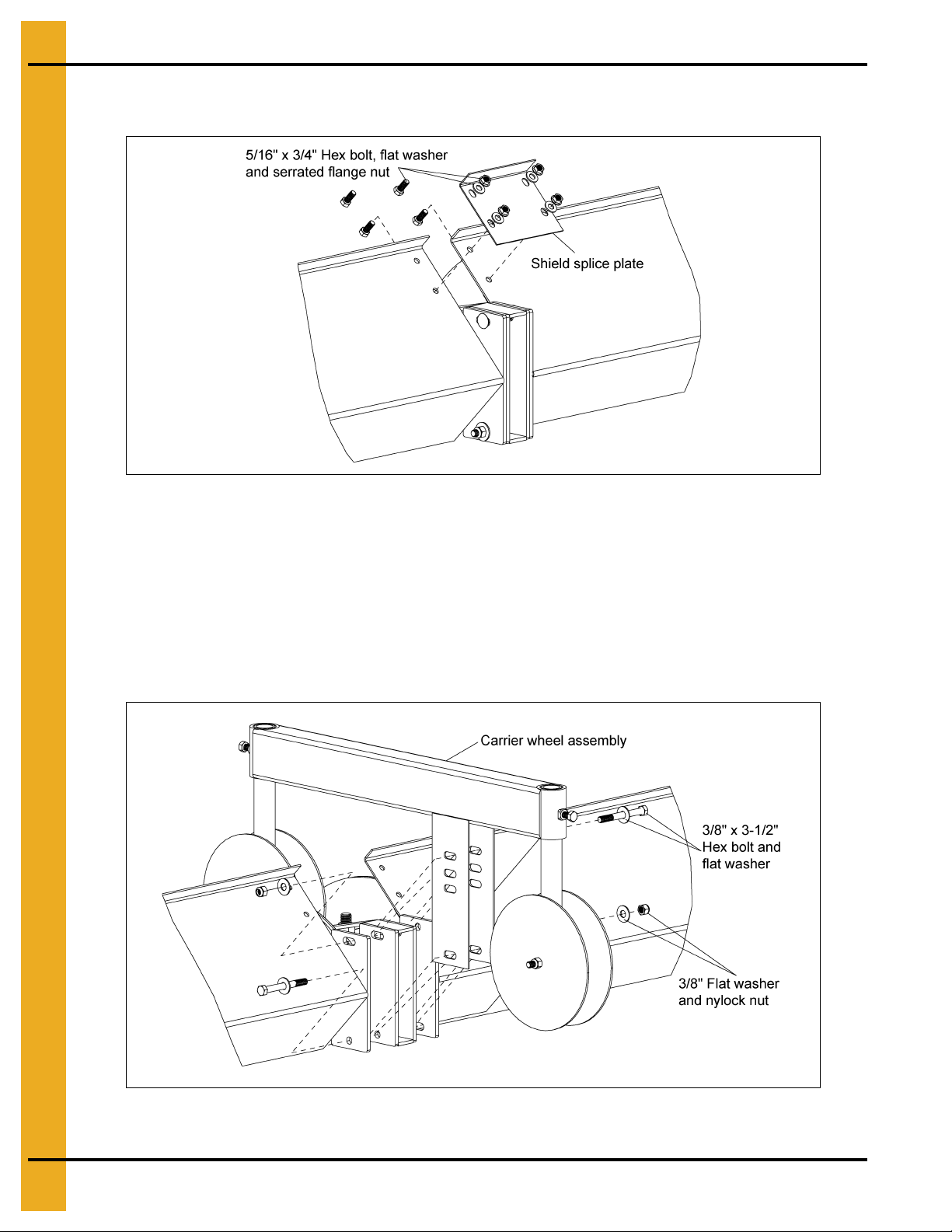

15. Place the carrier wheel assembly over the bearing stand assembly. Attach the previous and next

sections of back shield to the carrier and bearing stand assembly using two (2) 3/8" x 3-1/2" hex bolts,

four (4) flat washers and two (2) nylock nuts. (See Figure 4M.)

Figure 4M Shield to Shield through Carrier and Bearing

20 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 21

4. Assembly

16. Repeat Step 8 on Page 18 through Step 15 on Page 20 until all flight and shield sections

are assembled.

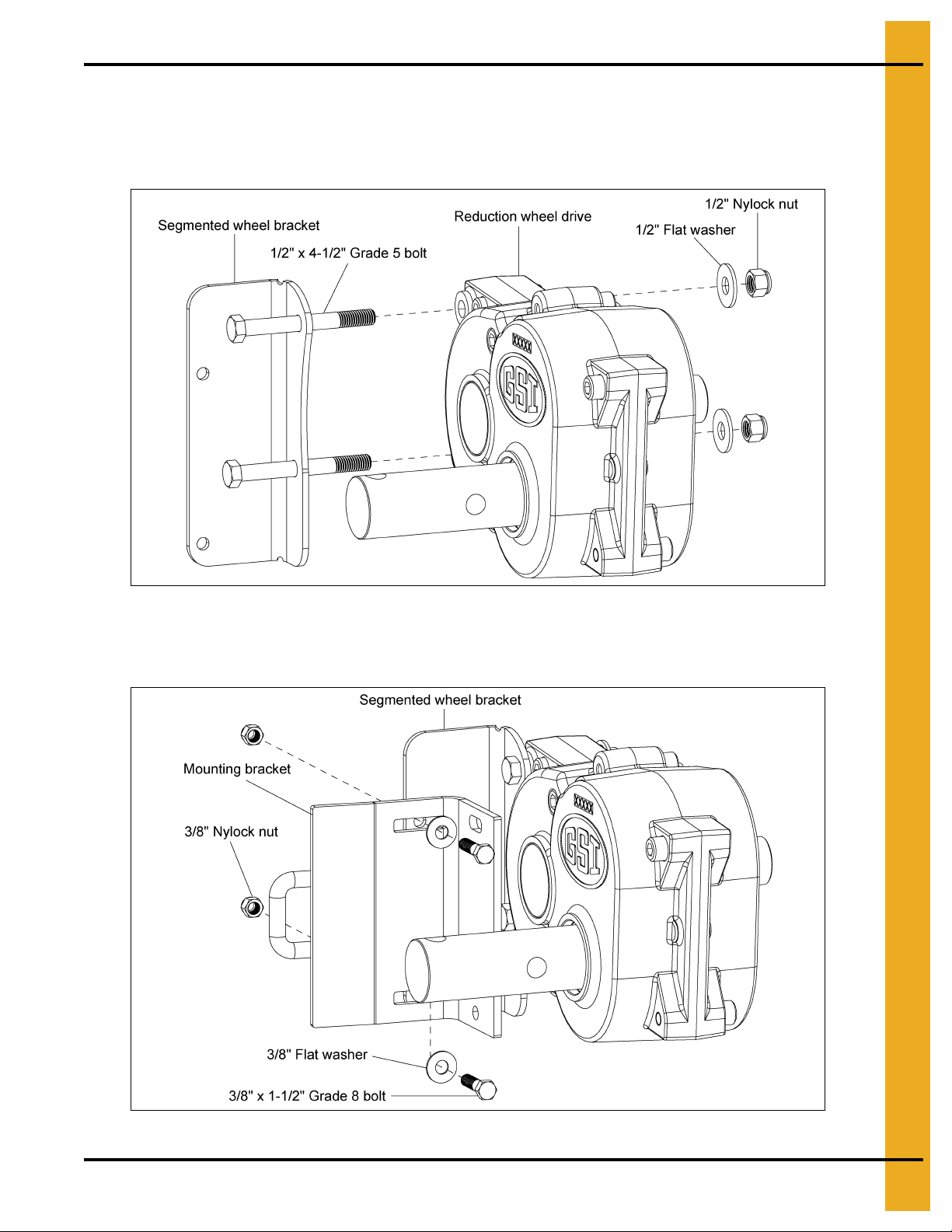

17. Join the segmented wheel bracket to the reduction wheel drive with two (2) 1/2" x 4-1/2" grade 5 bolts,

flat washers and nylock nuts. (See Figure 4N.)

Figure 4N Segmented Wheel Bracket to Reduction Wheel Drive

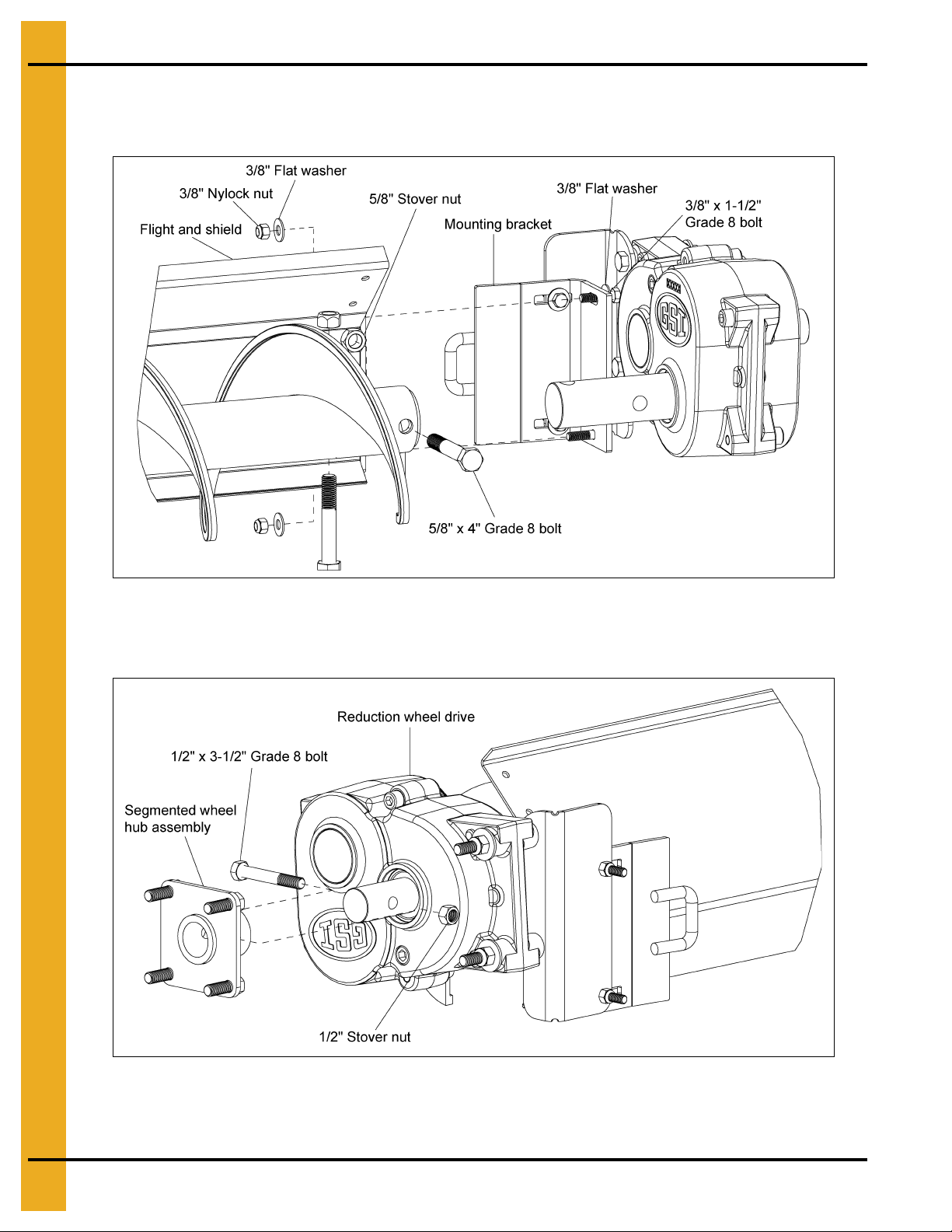

18. Join the mounting bracket and the segmented wheel bracket together with two (2) 3/8" x 1-1/2"

grade 8 hex bolts, two (2) flat washers and two (2) nylock nuts. (See Figure 4O.)

Figure 4O Segmented Wheel Bracket to Mounting Bracket

PNEG-1049 10"-12" Commercial Bin Sweep Augers 21

Page 22

4. Assembly

19. Attach the mounting bracket to the final back shield with two (2) 3/8" x 1-1/2" grade 8 hex bolts,

four (4) flat washers and two (2) nylock nuts. Attach the input shaft of the reduction wheel drive to

the final flight with two (2) 5/8" x 4" grade 8 bolts and stover nuts. (See Figure 4P.)

Figure 4P Mounting Bracket Assembly to Shield

20. Attach the segmented wheel hub assembly to the reduction wheel drive with one 1/2" x 3-1/2"

grade 8 bolt and stover nut. (See Figure 4Q.)

Figure 4Q Hub Assembly to Reduction Wheel Drive

22 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 23

4. Assembly

CAUTION

Oil must be added prior to running the bin sweep. The 3:1 aluminum enclosed

drive is shipped WITHOUT oil.

Do NOT add more oil than is recommended. Additional oil may damage the seals

or be forced out through the vented fill plug.

For lubrication in normal operating temperature between 40°F and 120°F, we

recommend the use of non-foaming, multi-purpose gear oil, SAE 90 weight. For

temperatures below 40°F, use SAE 80 weight oil. Use grade commercially

available for automotive differentials. Extra pressure additives may be of value in

severe applications.

21. Bolt the segmented rubber wheel to the segmented wheel hub assembly with four (4) 1/2" nylock

nuts. (See Figure 4R.)

Figure 4R Wheel to Enclosed Chain Drive

22. Make final adjustments to the back shields and mounting brackets and tighten all hardware. Adjust

the carrier wheel assemblies if provided. The carrier wheel assembly should NOT be adjusted to

support the full weight of the flight and shield sections. The carrier wheel assembly should be

adjusted so that it ONLY keeps the flight and back shield from contacting the floor.

NOTE: Failure to properly adjust the carrier wheel assembly as described above can result in

damage to the bin floor and the bin sweep.

23. Inspect the “DANGER” decals on the back shields to ensure legibility. If the decal cannot easily be

read or is missing, order a new decal immediately from the dealer.

24. Fill the 3:1 aluminum enclosed drive with oil. This is accomplished by removing the vented fill plug

and pouring 48 ounces of oil into the drive. The oil level can be checked by removing the check plug

on the opposite side of the drive. The oil level should not be over the check plug.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 23

Page 24

4. Assembly

25. Sandwich the front top and bottom motor clip onto the motor rods using two (2) 3/8" x 3" carriage

bolts and nylock nuts. Sandwich the back top and bottom motor clip onto the motor rods using

two (2) 3/8" x 3" carriage bolts and nylock nuts. DO NOT TIGHTEN the nuts at this time. They will

need adjustment when the motor is installed. (See Figure 4S.)

Figure 4S Motor Clips to Motor Rod

26. Attach the electrical cord support stand to the top motor clips using two (2) 7/16" x 1-1/4" hex bolts,

four (4) flat washers and two (2) nylock nuts. (See Figure 4T.)

Figure 4T Electrical Stand to Clip

24 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 25

4. Assembly

27. Remove the two (2) 5/16" x 3/4" hex bolts and nylock nuts from the front of the belt guard. This will

allow access to the sheave and belts. (See Figure 4U.)

Figure 4U Remove Belt Guard Hardware

28. Place the 1/4" square key on the keyway of the 3:1 aluminum enclosed drive input shaft. Place the

12" sheave onto the input shaft and key. The set screws of the sheave should be away from the

enclosed drive. Do NOT tighten the set screws. These will be adjusted after the motor and motor

sheave is in place. (See Figure 4V.)

Figure 4V Sheave to Drive Assembly

29. Attach the motor (not supplied) to the top motor clips with the appropriate hardware (not supplied.)

30. Attach the motor sheave to the motor.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 25

Page 26

4. Assembly

31. Adjust the position of the motor clips, motor sheave and the aluminum enclosed drive sheave to

achieve proper alignment. Tighten all set screws.

32. Place the two (2) belts over the sheaves. (See Figure 4W.)

Figure 4W Belts to Sheave

33. Adjust the position of the bottom motor straps to provide adequate tension on the drive belts.

The belts should allow 1/64" of deflection for every 1" of center distance between the two (2) shafts.

34. Close the front of the belt guard. Attach the front to the back with the two (2) 5/16" x 3/4" hex bolts

and nylock nuts that were previously removed. (See Figure 4X.)

Figure 4X Close Belt Guard

26 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 27

4. Assembly

35. Route the power cord for the motor through the electrical cord support stand top ring and the

3/4" electrical clamp. Leave a small loop of electrical cord between the clamp and the electrical

junction box on the outside of the motor. Tighten the clamp to secure the cord. (See Figure 4Y.)

Figure 4Y Electrical Cable Clamp

PNEG-1049 10"-12" Commercial Bin Sweep Augers 27

Page 28

5. Electrical Motor Drive Selection

DANGER

A main power disconnect switch capable of being locked only in the OFF

position should be used. The switch should be locked out whenever sweep is

not in operation.

1. Electric motors and controls should be installed by a qualified electrician and

must meet the standards set by the National Electrical Code and all local and

state codes.

2. A magnetic starter should be used to protect the motor when starting and

stopping. It should stop the motor in case of power interruption, conductor fault,

low voltage, circuit interruption or motor overload. Then the motor must be

restarted manually.

3. Some motors have built-in thermal overload protection. If this type motor is

used, use only those with a manual reset.

4. The motor starting controls must be located outside the bin. They must never

be installed on the bin sweep. Locate the motor starting controls outside the

bin, but near the bin door so the operator has full view of the operation inside

the bin.

5. Disconnect power before resetting motor overloads.

6. Reset and motor starting controls must be located so that the operator has full

view of the entire operation.

7. Make certain all electric motors are grounded.

8. Shut off power to adjust, service or clean.

The horsepower recommendations are for moving reasonably dry grain. High moisture grain (above 15%)

will require greater power if maximum capacity is to be maintained. The maximum possible capacity will

be less with high moisture grain than with dry grain.

Use the Table below to determine the horsepower required for the bin sweep and the motor sheave

diameter. Use an electric motor that operates at 1750 RPM. The motor and the motor sheave are

not furnished.

Bin Diameter

Horsepower 3 5 7-1/2 10 15

24'-37' 38'-55' 56'-75' 76'-113' 114'-120'

Motor sheave for the bin sweep when used with a 10" unloading system: 5" O.D. motor sheave, re sults in

speed of 250 RPM.

Motor sheave for the bin sweep when used with a 12" unloading system: 6" O.D. motor sheave, re sults in

speed of 290 RPM.

28 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 29

6. Operation

1. Abnormal grain flow can easily fall and bury a person, suffocating them. DO NOT enter a bin with

abnormal grain flow. (See Figure 6A.)

Figure 6A

2. Bridged grain can easily break loose and bury a person, suffocating them. DO NOT enter a bin with

bridged grain. (See Figure 6B.)

Figure 6B

PNEG-1049 10"-12" Commercial Bin Sweep Augers 29

Page 30

6. Operation

CAUTION

Failure to perform any and all of these pre-start checks may cause damage to the

equipment and could cause SERIOUS INJURY or DEATH to those in the work

area. A failure to perform any and all of these pre-start checks may also be a

misuse of the equipment, which may void the warranty.

DANGER

ALWAYS keep ALL guard(s) and sh ield(s) in place until all the power is disconnected

and locked out.

Make certain that ONLY trained operators are in the work area before operating or

moving the equipment. Two (2) people must always be in a position where the

operation of the equipment can be monitored.

CAUTION

DO NOT start or stop the auger while it is under load, this may cause the auger

to “jam”.

CAUTION

Failures may occur in the auger is run full before it has been polished by the

grain, during the break-in period. The auger should run at a partial capacity until

it becomes polished and smooth. Several hundred bushels of grain should be

run before operating at full capacity.

CAUTION

Be aware of any unusual vibration or noises during the initial start-up and

break-in. If anything unusual is detected, immediately shut down the auger,

disconnect and lock out the power supply before servicing. Visually inspect the

auger periodically during the operation.

ALWAYS shut down, lock out and disconnect the power supply before adjusting,

servicing or cleaning the equipment.

NEVER unload the bin from the intermediate wells before unloading the grain

from the center well FIRST. This situation could result in structural damage to the

grain bin.

3. Make sure that ALL belt(s) are tensioned properly on the unload system.

4. Make sure that ALL shield(s) are in place and that the belt(s) and pulley(s) are able to move freely.

5. Inspect the drive unit for any problems or potential problems.

6. Be aware of ALL emergency shut down procedures. Two (2) people must always be in a position

where the operation of the equipment can be monitored.

WARNING

DANGER

7. Start the unloading auger. The motor is located on the drive unit outside the bin, attached to the

unload tube.

8. Gravity unload the bin, through the center well first.

WARNING

9. Always close the well gates and allow the unload auger to clean out before stopping the

unload auger.

30 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 31

6. Operation

10. When the grain flow stops from the center well, close the ce nter well gate. The rem aining grain sho uld

look like

Figure 6C.

Figure 6C

11. Gradually open the center well and inside intermediate wells u ntil the desired flow has been established.

DO NOT excessively open the gates, as the flow of grain into the inside intermediate wells and

occasional grain flow into the center we ll will be at a higher rate than what the u n load system can

remove. This will cause the auger to plug or “jam”.

12. Always close the well gates and allow the unload auger to clean out before stopping the unload auger.

13. When the grain flow stops from the cen ter well and inside interm ediate wells, close the center well and

intermediate well gates. The remaining grain should look like

Figure 6D.

Figure 6D

PNEG-1049 10"-12" Commercial Bin Sweep Augers 31

Page 32

6. Operation

All power should be disconnected and locked out before entering the bin.

DO NOT enter a grain bin unless all power driven equipment has been shut down

and locked out.

The center well gate must be FULLY open during the bin sweep operation.

14. Gradually open the center well, inside intermediate wells and outside intermediate wells until the

desired flow has been established. DO NOT excessively open the gates, as the flow of grain into the

inside intermediate wells and occasional grain flow into the center well will be at a higher rate than

what the unload system can remove. This will cause the auger to plug or “jam”.

15. Always close the well gates and allow the unload auger t o clean out before stopping the unload auger.

16. When the grain flow stops from the center well, inside intermediate wells and the outside intermediate

wells, close the center well and intermediate well gates. The remaining grain sho uld look like

Figure 6E.

Figure 6E

DANGER

DANGER

CAUTION

17. Assemble the bin sweep and place the pivot onto the center well pivot tube. See installation

Step 5 on Page 16.

32 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 33

6. Operation

DANGER

DO NOT enter a grain bin unless all power driven equipment has been shut down

and locked out.

Figure 6F

18. Attach suitable electric wiring to the motor in a manner that will permit the bin sweep to rotate several

times around the bin. The motor starting controls must be located outside of the bin. They must

NEVER be installed on the bin sweep itself. Locate the motor starting controls outside the bin, but

near the bin door so the operator has full view of the operation inside the bin. (See Figure 6G.)

Figure 6G

19. Restore power and start the unload auger motor. Activate the bin sweep. Each time the bin sweep is

stopped, it may be necessary to adjust the sweep carrier wheel assembly up or down, so that the arm

is allowed to feed into the grain pile, but also not come into contact with the floor. Follow proper safety

procedures before entering the bin to adjust the carrier wheel assembly.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 33

Page 34

6. Operation

DO NOT enter a grain bin unless all power driven equipment has been shut down

and locked out.

20. The bin sweep will clear most of the remaining grain in one pass. A second pass will clean out

additional grain, before final clean out.

DANGER

21. After the bin sweep has made two (2) passes removing most of the grain, it will be necessary to clean

the floor. (See Figure 6H, Figure 6I below and Figure 6J on Page 35.)

NOTE: The bin sweep is composed of several sections of flight and back shields. The bin can be

emptied using just the discharge section of flight and back shield and attaching the wheel

assembly to the free end. After the center of the bin has been swept, the next section of light

and back shield can be attached to the discharge section, with the wheel assembly at the end

of the second section. After the bin has been swept with two (2) sections more the process

can be repeated until the bin is completely empty.

Figure 6H

Figure 6I

34 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 35

6. Operation

Cleaned area

Remaining grain

Bin wall

Bin sweep

Bin wells

Figure 6J

22. With all power disconnected and locked out, enter the grain bin. Sweep or scoop the remaining

grain from the outer area of the floor and move it to a circular pile towards the center of the bin.

(See Figure 6K below and Figure 6L on Page 36.)

Figure 6K

PNEG-1049 10"-12" Commercial Bin Sweep Augers 35

Page 36

6. Operation

Cleaned area

Remaining grain

Bin wall

Bin sweep

Bin wells

Figure 6L

23. Check the sweep carrier wheel assembly. If necessary, adjust the height so that the sweep arm

assembly is close to the floor, but will not contact the floor, intermediate well top flanges or the

floor screws.

24. Exit the grain bin.

25. Make sure everyone is outside of the bin and clear of the equipment.

26. Start the unload auger and then the bin sweep. Shortly, the swept pile will have been removed by the

bin sweep.

27. Disconnect and lock out all power to the bin sweep and unload auger.

28. Repeat Step 20 on Page 34, moving the grain into a smaller circular pile, as shown in Figure 6L.

29. Repeat Step 21 on Page 34.

30. Exit the grain bin.

31. Make sure everyone is outside of the bin and clear of the equipment.

32. Start the unload auger and then the bin sweep. Shortly, the swept pile will have been removed by the

bin sweep.

36 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 37

6. Operation

ALWAYS shut down, lock out and disconnect the power supply before adjusting,

servicing or cleaning the equipment.

Keep out of the bin while the bin sweep is in operation. The bin sweep travels

rapidly around the bin. As the bin empties, the bin sweep travels around the

bin faster.

Stay clear of the unload auger under the floor at the bin wells. The unload auger

could be exposed at these locations.

DO NOT STORE SWEEPS IN THE BIN.

Sweeps are NOT designed to remain in a bin during filling, storage or gravity

unloading. A sweep left in a bin during these operations may be severely

damaged. The GSI Group will not be responsible for such damages.

DANGER

DANGER

DANGER

33. Disconnect and lock out all power the bin sweep and unlock auger.

34. Disconnect the sweep auger wiring and remove the sweep from the bin. Disassemble the

sweep as necessary to remove it safety from the bin. See storage section for more details.

(See Figure 6M.)

Figure 6M

WARNING

NOTE: The only way to prevent damage to the bin sweep, bin floor and wells is to completely remo ve the

bin sweep from the bin.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 37

Page 38

7. Maintenance

ALWAYS shut down, lock out and disconnect the power supply before adjusting,

servicing or cleaning the equipment.

CAUTION

Do NOT add more oil than is recommended. Additional oil may damage the seals

or be forced out through the vented fill plug.

DANGER

1. Always stop and disconnect the power source whenever the operator must leave the work area or

for maintenance of the machinery.

2. Make sure no one can operate the unload auger while the operator is not in the work area.

3. Use caution when repairing or replacing equipment parts.

4. Make sure ALL decals are legible and tightly attached to the auger. If necessary, replace them FREE

OF CHARGE by contacting the dealer or the manufacturer.

5. Ensure that ALL electric motors, etc., are operating at the proper speed.

6. Maintain proper adjustments on the belts. To tighten the belts, adjust the nuts on the bottom

motor straps. The belts should allow 1/64" of deflection for every 1" of center distance between the

two (2) shafts. DO NOT over tighten the belts.

7. Mount controls for any electric motors at a safe distance from the machine and in a location

accessible in case of an emergency.

8. Make sure ALL electrical wiring is not damaged and that it meets proper wiring codes.

9. Make sure ALL components are in good working condition before use.

10. Check the auger flight to make sure it is in good working condition.

11. The 3:1 aluminum enclosed drive is shipped without oil. Oil is to be added during field assembly of

the bin sweep, assembly Step 24 on Page 23. Oil will dissipate under normal operating conditions.

Check the oil level regularly. Add non-foaming oil to the unit the check point is reached.

12. For lubrication in normal operating temperature between 40°F and 120°F, we recommend the use of

non-foaming, multi-purpose gear oil, SAE 90 weight. For temperatures below 40°F, use SAE 80

weight oil. Use grade commercially available for automotive differentials. Extra pressure additives

may be of value in severe applications.

38 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 39

7. Maintenance

DO NOT STORE SWEEPS IN THE BIN.

Sweeps are NOT designed to remain in a bin during filling, storage or gravity

unloading. A sweep left in a bin during these operations may be severely

damaged. The GSI Group will not be responsible for such damages.

Storage

1. Close all wells to discharge auger.

2. Be sure the unload tube is empty.

3. Shut down the bin sweep first and then the unload auger.

4. Make sure power source for both are locked out and disconnected.

WARNING

NOTE: The only way to prevent damage to the bin sweep, bin floor and wells is to completely remove

the bin sweep from the bin.

5. Adjust the motor straps to remove tension from the belts.

6. Open the belt guard and remove the belts.

7. Remove the motor sheave from the motor.

8. Disconnect the electrical cord from the motor.

9. Remove the motor from the drive unit by removing the top motor straps. The motor should still be

attached to the top and bottom motor clips.

10. Remove the motor from the bin.

11. Remove the drive assembly from the flight and back shields.

12. Remove the drive assembly and the flight and back shields from the bin.

PNEG-1049 10"-12" Commercial Bin Sweep Augers 39

Page 40

NOTES

40 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 41

1. Motor Rods to Drive - (See Pages 42-43.)

2. 10"-12" Drive Assembly - (See Pages 44-45.)

3. 3:1 Aluminum Enclosed Drive - (See Pages 46-47.)

4. Motor Mount Frame Assembly - (See Page 48.)

5. Drive to Discharge Flight and Shield - (See Page 49.)

6. Discharge Flight and Shield Bundles - (See Page 49.)

7. Flight and Shield Joint w/o Carrier - (See Page 50.)

8. Intermediate Flight and Shield Bundles - (See Page 51.)

9. Flight and Shield Joint w/ Carrier - (See Page 52.)

8. Parts List

10. Flight and Shield to Segmented Wheel - (See Page 53.)

11. Sweep Carrier Assembly - (See Page 54.)

12. Sweep Carrier Wheel Assembly - (See Page 55.)

PNEG-1049 10"-12" Commercial Bin Sweep Augers 41

Page 42

8. Parts List

Motor Rods to Drive

42 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 43

Motor Rods to Drive Parts List

Ref # Part # Description

1 GK6973 10"-12" Drive Assembly

2 GK2338 Drive Pivot Yoke

3 GK1335 2 Groove Sheave, 12" x 1-1/4"

4 GK1346 V-Belt, B57

5 GK1900 Motor Strap - Bottom

6 GK1893 Motor Rod

7 GK1901 Motor Strap - Top

8 GK1342 Motor Clip - Top

9 GK1341 Motor Clip - Bottom

10 GK4203 Electric Cord Support Stand

11 S-4329 5/8"-11 x 2" HHCS YDP Grade 8

12 S-8349 5/8"-11 Nylock Nut Zinc Grade 2

8. Parts List

13 S-7835 1" Flat Washer Zinc

14 S-8276 1/4" x 3" Square Key

15 S-234 3/4"-10 Hex Nut Zinc Grade 5

16 S-248 3/8" Flat Washer YDP Grade 2

17 S-2086 3/8"-16 x 1-1/2" HHCS Zinc Grade 8

18 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

19 S-8055 3/8"-16 x 3" Carriage Bolt Zinc Grade 5

20 S-8320 7/16" Flat Washer Zinc

21 S-3886 7/16"-14 x 1-1/4" HHCS Zinc Grade 5

22 S-8234 7/16"-14 Nylock Nut Zinc Grade 2

23 CH-1829 3/4" Clamp, Non-metallic Cable, 2 Screw

PNEG-1049 10"-12" Commercial Bin Sweep Augers 43

Page 44

8. Parts List

10"-12" Drive Assembly

44 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 45

10"-12" Drive Assembly Parts List

Ref # Part # Description

1 GK2341 3:1 Aluminum Enclosed Drive

2 GK2339 Belt Guard Assembly w/ Mounting Ring

3 S-2071 3/8"-16 x 1-1/4" HHCS Zinc Grade 5

4 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

5 S-8072 5/16"-18 x 3/4" HHCS Zinc Grade 2

6 S-7382 5/16"-18 Nylock Nut Zinc Grade 5

7 GK80083 Motor Mount Frame Assembly

8 GK2343 Belt Guard Mounting Strap

9 S-1937 5/16" Flat Washer Zinc Grade 2

10 S-4552 3/4"-10 x 1-1/4" HHCS YDP Grade 5

11 S-234 3/4"-10 Hex Nut Zinc Grade 5

8. Parts List

12 DC-1512 Oil Level Decal

PNEG-1049 10"-12" Commercial Bin Sweep Augers 45

Page 46

8. Parts List

3:1 Aluminum Enclosed Drive

46 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 47

3:1 Aluminum Enclosed Drive Parts List

Ref # Part # Description

1 GK2364 Cast Aluminum Cover - Output

2 GK2363 Cast Aluminum Cover - Input

3 GK2383 1-1/4" Tapered Roller Bearing Cup - Cup Only

4 GK2367 1-1/4" Tapered Roller Bearing Cone - Cone Only

5 GK2371 1-1/4" x 7-7/8" Input Drive Shaft

6 GK2374 2-1/4" O.D. x 1-1/4" I.D. x 0.252" Oil Seal

7 GK2372 Sprocket, #80, 9 Teeth - Hardened, 1-1/4" Bore, “C” Hub

8 S-4377 5/16" x 2" Slotted Rolled Sprin g Pin

9 GK7794 1-3/4" O.D. x 1-1/4" I.D. x 0.020" Shim

10 GK7734 Wave Spring, Single Turn, 1-5/8" x 1.310"

11 GK6780 1-3/4" O.D. x 1-1/4" I.D. x 0.048" Shim

8. Parts List

12 S-9168 1/4" x 1" Square Key

13 GK2384 1-1/2" Tapered Roller Bearing Cup - Cup Only

14 GK2368 1-1/2" Tapered Roller Bearing Cone - Cone Only

15 GK2370 1-1/2" x 8-9/16" Output Connecting Shaft

16 GK2369 Sprocket, #80, 27 Teeth - Hardened, 1-1/2" Bore, “C” Hub

17 GC03540 3/8" x 1" Square Key

18 GK2365 #80 Chai n, 36P

19 S-4375 5/16" x 2-1/2" Slotted Rolled Spring Pin

20 GK6781 2-1/8" O.D. x 1-1/2" I.D. x 0.048" Shim

21 GK7812 Wave Spring, Single Turn, 1-7/8" x 1.560"

22 GK2373 2-1/8" O.D. x 1-1/2" I.D. x 0.315" Oil Seal

23 TCR-GEN-0320 Loctite 518 Sealant

24 GK5350 1/8"-27 x 3/8"-18 NPT Pipe Adapter Bushing Brass

25 GK2697 1/8"-27 NPT Vent Plug - 7-1/2 - 15 PSI

26 GK2376 3/8"-18 NPT Hex Socket Plug Zinc

27 S-4276 5/16"-18 x 1-1/4" HHCS Zinc Grade 5

28 S-3611 5/16"-18 Serrated Flange Nut YDP Grade 2

29 DC-1512 Oil Level Decal

30 DC-1760 Enclosed Drive Reduction Ratio Decal

PNEG-1049 10"-12" Commercial Bin Sweep Augers 47

Page 48

8. Parts List

Motor Mount Frame Assembly

Motor Mount Frame Assembly Parts List

Ref # Part # Description

1 GK2337 Motor Mount Frame

2 GK80082 Motor Mount Side Plate

3 S-7534 1/2"-13 x 1-1/4" HHCS Zinc Grade 5

4 S-8260 1/2"-13 Nylock Nut Zinc Grade 5

48 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 49

Drive to Discharge Flight and Shield

8. Parts List

Drive to Discharge Flight and Shield Parts List

Ref # Part # Description

1 Flight and Shield Bundle Discharge Flight and Shield Bundle

2 GK6973 10"-12" Drive Assembly

3 S-8314 1/2"-13 x 3-1/2" HHCS YDP Grade 8

4 S-8315 1/2"-13 Stover Nut Zinc Grade C

5 S-248 3/8" Flat Washer YDP Grade 2

6 S-2086 3/8"-16 x 1-1/2" HHCS Zinc Grade 8

7 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

Discharge Flight and Shield Bundles

Discharge Flight and Shield Bundles

Bundle Flight Shield Length

GK5372 GK5047 GK5064 82-1/4"

GK5373 GK5048 GK5065 100-1/4"

GK5374 GK5049 GK5066 118-1/2"

GK80021 GK80019 GK80020 109-1/4"

PNEG-1049 10"-12" Commercial Bin Sweep Augers 49

Page 50

8. Parts List

Flight and Shield Joint w/o Carrier

Flight and Shield Joint w/o Carrier Parts List

Ref # Part # Description

1 Flight and Shield Bundle Discharge or Intermediate Flight and Shield Bundle

2 GK2047 Bearing Stand Assembly

3 GK2222 Connecting Shaft 2" O.D. x 11-1/2"

4 Flight and Shield Bundle Intermediate Flight and Shield Bundle

5 GK5615 Shield Splice Plate

6 S-7893 5/8"-11 x 4" HHCS Zinc Grade 8

7 S-8606 5/8"-11 Stover Nut Zinc Grade C

8 S-4275 5/16"-18 x 3/4" HHTB Zinc Grade 5

9 S-1937 5/16" Flat Washer Zinc Grade 2

10 S-3611 5/16"-18 Serrated Flange Nut YDP Grade 2

11 S-8055 3/8"-16 x 3" Carriage Bolt Zinc Grade 5

12 S-248 3/8" Flat Washer YDP Grade 2

13 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

50 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 51

Intermediate Flight and Shield Bundles

Intermediate Flight and Shield Bundles

8. Parts List

Bundle Flight Shield Length

GK5375 GK2053 GK2052 46"

GK5376 GK2280 GK2279 64"

GK5377 GK2055 GK2054 70-1/2"

GK5378 GK2294 GK2293 82"

GK5379 GK2299 GK2298 100"

GK5380 GK2284 GK2283 106-1/2"

GK5381 GK2296 GK2295 112"

GK5382 GK2289 GK2288 118-1/4"

PNEG-1049 10"-12" Commercial Bin Sweep Augers 51

Page 52

8. Parts List

Flight and Shield Joint w/ Carrier

Flight and Shield Joint w/ Carrier Parts List

Ref # Part # Description

1 Flight and Shield Bundle Discharge or Intermediate Flight and Shield Bundle

2 GK2078 Carrier Wheel Assembly

3 GK2047 Bearing Stand Assembly

4 GK2222 Connecting Shaft 2" O.D. x 11-1/2"

5 Flight and Shield Bundle Intermediate Flight and Shield Bundle

6 GK5615 Shield Splice Plate

7 S-7893 5/8"-11 x 4" HHCS Zinc Grade 8

8 S-8606 5/8"-11 Stove r Nut Zinc Grade C

9 S-4275 5/16"-18 x 3/4" HHTB Zinc Grade 5

10 S-1937 5/16" Flat Washer Zinc Grade 2

11 S-3611 5/16"-18 Serrated Flange Nut YDP Grade 2

12 S-248 3/8" Flat Washer YDP Grade 2

13 S-8676 3/8"-16 x 3-1/2" HHCS Zinc Grade 5

14 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

52 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 53

Flight and Shield to Segmented Wheel

8. Parts List

Flight and Shield to Segmented Wheel Parts List

Ref # Part # Description

1 Flight and Shield Bundle Discharge or Intermediate Flight and Shield Bundle

2 GK2347 Mounting Bracket with Anchor Loop

3 GK80022 Gear Driven Reduction Wheel Drive, 9.92:1

4 GK80049 Segmented Wheel Bracket

5 GK80048 Segmented Wheel Hub Assembly

6 GK2344 Segmented Rubber Wheel

7 S-7893 5/8"-11 x 4" HHCS Zinc Grade 8

8 S-8606 5/8"-11 Stover Nut Zinc Grade C

9 S-8232 1/2"-13 x 4-1/2" HHCS Zinc Grade 5

10 S-2121 1/2" Flat Washer Plated

11 S-8260 1/2"-13 Nylock Nut Zinc Grade 5

12 S-248 3/8" Flat Washer YDP Grade 2

13 S-2086 3/8"-16 x 1-1/2" HHCS Zinc Grade 8

14 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

15 S-8314 1/2"-13 x 3-1/2" HHCS YDP Grade 8

16 S-8315 1/2"-13 Stover Nut Zinc Grade C

PNEG-1049 10"-12" Commercial Bin Sweep Augers 53

Page 54

8. Parts List

Sweep Carrier Assembly

Sweep Carrier Assembly Parts List

Ref # Part # Description

1 GK2082 Sweep Carrier Body

2 GK2083 Sweep Carrier Leg Assembly

3 S-7469 3/8"-16 x 1" HHCS Zinc Grade 5

54 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 55

Sweep Carrier Wheel Assembly

8. Parts List

Sweep Carrier Wheel Assembly Parts List

Ref # Part # Description

1 GC08887 Sweep Carrier Wheel Leg

2 GC09726 Sweep Carrier Wheel Bushing

3 GK2085 Sweep Wheel Disc

4 S-7249 3/8"-16 x 3" HHCS Zinc Grade 5

5 S-7383 3/8"-16 Nylock Nut Zinc Grade 5

PNEG-1049 10"-12" Commercial Bin Sweep Augers 55

Page 56

9. Configuration

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish St art Finish S tart Finish Start Finish St art Finish S tart Finish Start Finish Start Finish

0.00 X.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX. XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX XXX.XX

XXX.XX XXX.XX XXX.XX XXX.XX

Start Finish Start Finish

Center of Bin

Wheel Disc Area

Wheel Disc Area

End Wheel

Assembly Area

From Center of Bi n

to Start of Fli ght

and Shield

Yellow Group Distance

Orange Group Distance

Brown Group Distance

XXX.XX

XXX.XX

XXX.XX

Carrier Wheels

Carrier Wheels

Wheel Assembly

GKXXXX

GKXXXX

GKXXXX

GKXXXX

GKXXXX

GKXXXX

Carrier

Fourth Ext Section

Bearing

Fifth Ext Section

Carrier

Second Ext Section

Bearing

Third Ext Section

Specific Fl ight and

Shield Bundle

Drive

Discharge Section

Bearing

First Ext Section

Specific Fl ight and

Shield Bundle

Specific Fl ight and

Shield Bundle

Configuration #

Group in between Drive and F irst Carrier Wheel Assembly

Group in between First Carrier W heel Assembly and

Second Carrier Wheel Assembly **Listed in numeri cal

order, not by length - See Step 4 a nd 6**

Group in between Second Carrier W heel Assembly and End

Wheel Assembly **Li sted in numerical or der, not by length -

See Step 4 and 6**

Specific Fl ight and

Shield Bundle

{

{

{

1. All care should be taken to ensure that the wheel discs on the carrier wheel assemblies do not conflict with known well positions.

Choose the applicable configuration that accomplishes this.

a. If multiple configurations exist that satisfy the above criteria, choose the configuration that makes the yellow, orange and brown

groups as equal as possible.

2. Install the longest group (yellow, orange or brown) closest to the center well. The discharge section must be installed to the drive.

3. Install the first carrier wheel assembly.

4. Install the shortest group (yellow, orange or brown) next. Assemble the shorter of the two (2) sections to the installed carrier wheel

assembly from the Step 3.

5. Install the second carrier wheel assembly.

6. Install the last group (yellow, orange or brown) next. Assemble the shorter of the two (2) sections to the installed carrier wheel

assembly from the Step 5.

7. Install the end wheel assembly.

All Distances Stated in Inches

Flight and Shield Configuration

56 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 57

Flight and Shield Configuration (Continued)

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 132.32 132.32 142.33

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 150.32 150.32 160.33

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 111.57 111.57 113.32 113.32 159.32 159.32 169.33

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 186.32 186.32 196.33

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 192.82 192.82 202.83

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.07 84.07 85.82 85.82 197.32 197.32 207.75

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 102.57 102.57 104.32 104.32 210.82 210.82 220.83

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 102.57 102.57 104.32 104.32 222.57 222.57 232.58

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 229.07 229.07 239.08

Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 234.57 234.57 244.58

130.00

GK5372

GK5375

Wheel Assembly

First Ext Section

Discharge Section

Drive

Bearing

24' Bin

27' Bin

Drive

Bearing

148.00

GK5372

GK5376

Wheel Assembly

First Ext Section

Discharge Section

30' Bin

Drive

Bearing

157.00

GK80021

GK5375

Wheel Assembly

First Ext Section

Discharge Section

33' Bin

184.00

Wheel Assembly

Drive

Bearing

GK5372

GK5379

First Ext Section

Discharge Section

34' Bin

Drive

Bearing

190.50

GK5372

GK5380

Wheel Assembly

First Ext Section

Discharge Section

36' Bin

Drive

Bearing

195.00

GK5372

GK5381

Wheel Assembly

First Ext Section

Discharge Section

37' Bin

Drive

Bearing

208.50

GK5373

GK5380

Wheel Assembly

First Ext Section

Discharge Section

39' Bin

220.25

Wheel Assembly

Drive

Bearing

GK5373

GK5382

First Ext Section

Discharge Section

Drive

Bearing

GK5374

GK5380

First Ext Section

Drive

Bearing

GK5374

GK5381

First Ext Section

Discharge Section

Discharge Section

42' Bin

232.25

Wheel Assembly

40' Bin

226.75

Wheel Assembly

9. Configuration

PNEG-1049 10"-12" Commercial Bin Sweep Augers 57

Page 58

9. Configuration

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 168.57 168.57 170.78 170.78 252.78 252.78 262.79

163.41 173.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 204.57 204.57 206.78 206.78 252.78 252.78 262.79

199.41 209.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 186.57 186.57 188.78 188.78 270.78 270.78 280.79

181.41 191.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 204.57 204.57 206.78 206.78 270.78 270.78 280.79

199.41 209.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 193.07 193.07 195.28 195.28 277.28 277.28 287.29

187.91 198.24

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 204.57 204.57 206.78 206.78 277.28 277.28 287.29

199.41 209.74

Start Finish

Start Finish Start Finish Start Finish Start Finish

Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 186.57 186.57 188.78 188.78 295.28 295.28 305.29

181.41 191.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 229.07 229.07 231.28 231.28 295.28 295.28 305.29

223.91 234.24

Start Finish

1

Drive

Bearing

GK5374

GK5376

GK5380

Carrier

Wheel Assembl y

Carrier Wheels

226.75

GK5374

Discharge Section

Wheel Assembl y

Carrier Wheels

First Ext Section

Second Ext Section

184.25

106.50

64.00

First Ext Section

Second Ext Section

Discharge Section

52' Bin

52' Bin

2

Drive

Bearing

GK5380

GK5376

Carrier

1

Drive

Bearing

GK5374

GK5377

GK5378

Carrier

Wheel Assembl y

Carrier Wheels

202.25

GK5374

Discharge Section

Wheel Assembl y

Carrier Wheels

First Ext Section

Second Ext Section

190.75

82.00

70.50

First Ext Section

Second Ext Section

Discharge Section

49' Bin

49' Bin

2

Drive

Bearing

GK5378

GK5377

Carrier

1

Drive

Bearing

GK5374

GK5376

GK5378

Carrier

Wheel Assembl y

Carrier Wheels

202.25

GK5374

Discharge Section

Wheel Assembl y

Carrier Wheels

First Ext Section

Second Ext Section

184.25

82.00

64.00

First Ext Section

Second Ext Section

Discharge Section

48' Bin

48' Bin

2

Drive

Bearing

GK5378

GK5376

Carrier

46.00

Wheel Assembl y

45' Bin

45' Bin

Wheel Assembl y

Carrier Wheels

Carrier Wheels

Second Ext Section

202.25

GK5374

GK5378

GK5375

Carrier2Drive

Discharge Section

First Ext Section

Bearing

1

Drive

Bearing

166.25

GK5374

GK5375

GK5378

Carrier

82.00

First Ext Section

Second Ext Section

Discharge Section

Flight and Shield Configuration (Continued)

58 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 59

Flight and Shield Configuration (Continued)

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 186.57 186.57 188.78 188.78 307.03 307.03 317.04

181.41 191.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 240.82 240.82 243.03 243.03 307.03 307.03 317.04

235.66 245.99

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 193.07 193.07 195.28 195.28 313.53 313.53 323.54

187.91 198.24

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 240.82 240.82 243.03 243.03 313.53 313.53 323.54

235.66 245.99

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 222.57 222.57 224.78 224.78 331.28 331.28 341.29

217.41 227.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 229.07 229.07 231.28 231.28 331.28 331.28 341.29

223.91 234.24

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 222.57 222.57 224.78 224.78 341.28 341.28 351.29

217.41 227.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 239.07 239.07 241.28 241.28 341.28 341.28 351.29

233.91 244.24

Start Finish

1

Drive

Bearing

GK5374

GK5379

GK80205

Carrier

Wheel Assembly

Carrier Wheels

236.75

GK5374

Discharge Section

Wheel Assembly

Carrier Wheels

First Ext Section

Second Ext Secti on

220.25

116.50

100.00

First Ext Section

Second Ext Secti on

Discharge Section

60' Bin

60' Bin

2

Drive

Bearing

GK80205

GK5379

Carrier

1

Drive

Bearing

GK5374

GK5379

GK5380

Carrier

Wheel Assembly

Carrier Wheels

226.75

GK5374

Discharge Section

Wheel Assembly

Carrier Wheels

First Ext Section

Second Ext Secti on

220.25

106.50

100.00

First Ext Section

Second Ext Secti on

Discharge Section

58' Bin

58' Bin

2

Drive

Bearing

GK5380

GK5379

Carrier

1

Drive

Bearing

GK5374

GK5377

GK5382

Carrier

Wheel Assembly

Carrier Wheels

238.50

GK5374

Discharge Section

Wheel Assembly

Carrier Wheels

First Ext Section

Second Ext Secti on

190.75

118.25

70.50

First Ext Section

Second Ext Secti on

Discharge Section

55' Bin

55' Bin

2

Drive

Bearing

GK5382

GK5377

Carrier

1

Drive

Bearing

GK5374

GK5376

GK5382

Carrier

Wheel Assembly

Carrier Wheels

238.50

GK5374

Discharge Section

Wheel Assembly

Carrier Wheels

First Ext Section

Second Ext Secti on

184.25

118.25

64.00

First Ext Section

Second Ext Secti on

Discharge Section

54' Bin

54' Bin

2

Drive

Bearing

GK5382

GK5376

Carrier

9. Configuration

PNEG-1049 10"-12" Commercial Bin Sweep Augers 59

Page 60

9. Configuration

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 186.57 186.57 188.78 188.78 259.28 259.28 261.03 261.03 361.03 361.03 371.04

181.41 191.74

Start Finish

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 193.07 193.07 195.28 195.28 259.28 259.28 261.03 261.03 361.03 361.03 371.04

187.91 198.24

Start Finish

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 222.57 222.57 224.78 224.78 288.78 288.78 290.53 290.53 361.03 361.03 371.04

217.41 227.74

Start Finish

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 156.82 156.82 159. 03 159.03 277.28 277.28 279.03 279.03 397. 28 397.28 407.29

151.66 161.99

Start Finish

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 204.57 204.57 206. 78 206.78 277.28 277.28 279.03 279.03 397. 28 397.28 407.29

199.41 209.74

Start Finish

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 156.82 156.82 159. 03 159.03 277.28 277.28 279.03 279.03 397. 28 397.28 407.29

151.66 161.99

Start Finish

Start Finish Start Finish Start Finish Start Fini sh Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 84.57 84.57 86.32 86.32 204.57 204.57 206. 78 206.78 277.28 277.28 279.03 279.03 397. 28 397.28 407.29

199.41 209.74

Start Finish

1

Drive

Discharge Section

Bearing

First Ext Section

Carrier

Second Ext Section

Bearing

Third Ext Section

Wheel Assembly

GK5372

GK5377

GK5382

GK5382

154.50

238.25

Carrier Wheel s

2

Drive

Discharge Section

Bearing

First Ext Section

Carrier

Second Ext Section

Bearing

Third Ext Section

69' Bin

69' Bin

202.25

190.50

Carrier Wheel s

Wheel Assembly

GK5372

GK5382

GK5377

GK5382

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

154.50

GK5372

GK5377

GK5382

Carrier

238.25

First Ext Section

Second Ext Section

Discharge Section

1

Drive

Bearing

GK5382

Discharge Section

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

GK5377

Carrier

190.50

First Ext Section

Second Ext Section

68' Bin

2

Drive

Bearing

GK5382

202.25

GK5372

GK5382

63' Bin

63' Bin

63' Bin

68' Bin

3

Drive

Bearing

GK5377

220.25

GK5374

GK5379

GK5376

Carrier

136.25

First Ext Section

Second Ext Section

Discharge Section

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

2

Drive

Bearing

GK5379

190.75

GK5374

GK5377

GK5376

Carrier

165.75

First Ext Section

Second Ext Section

Discharge Section

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

1

Drive

Bearing

GK5379

184.25

GK5374

GK5376

GK5377

Carrier

172.25

First Ext Section

Second Ext Section

Discharge Section

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

Flight and Shield Configuration (Continued)

60 PNEG-1049 10"-12" Commercial Bin Sweep Augers

Page 61

Flight and Shield Configuration (Continued)

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 193.07 193.07 195.28 195.28 295.28 295.28 297.03 297.03 403.53 403.53 413.54

187.91 198.24

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 222.57 222.57 224.78 224.78 295.28 295.28 297.03 297.03 403.53 403.53 413.54

217.41 227.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 229.07 229.07 231.28 231.28 301.78 301.78 303.53 303.53 403.53 403.53 413.54

223.91 234.24

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 193.07 193.07 195.28 195.28 313.53 313.53 315.28 315.28 433.53 433.53 443.54

187.91 198.24

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 240.82 240.82 243.03 243.03 313.53 313.53 315.28 315.28 433.53 433.53 443.54

235.66 245.99

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 222.57 222.57 224.78 224.78 324.78 324.78 326.53 326.53 433.03 433.03 443.04

217.41 227.74

Start Finish

Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish Start Finish

0.00 2.32 2.32 120.82 120.82 122.57 122.57 229.07 229.07 231.28 231.28 331.28 331.28 333.03 333.03 433.03 433.03 443.04

223.91 234.24

Start Finish

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

220.25

GK5374

GK5379

GK5379

Carrier

208.25

First Ext Section

Second Ext Section

Discharge Section

1

Drive

Bearing

GK5380

Discharge Section

Wheel Assembly

Carrier Wheel s

Third Ext Section

Bearing

GK5380

GK5379

Carrier

201.75

First Ext Section

Second Ext Section

75' Bin

75' Bin