Page 1

Instructions

PNEG-1040

6", 8" and 10" Truss Kit Assembly

1004 East Illinois Street • Assumption, IL 62510 • 1-217-226-4421

This handout is to be used for the installation of the truss kit only. For installation of, or problems

with equipment other than truss kits, refer to the manual(s) pertaining to that product.

This truss kit is designed to provide support for auger sections up to 30' in length.

NOTE: Augers over 30' long should use a permanent rigid type of support system to help minimize

auger vibration.

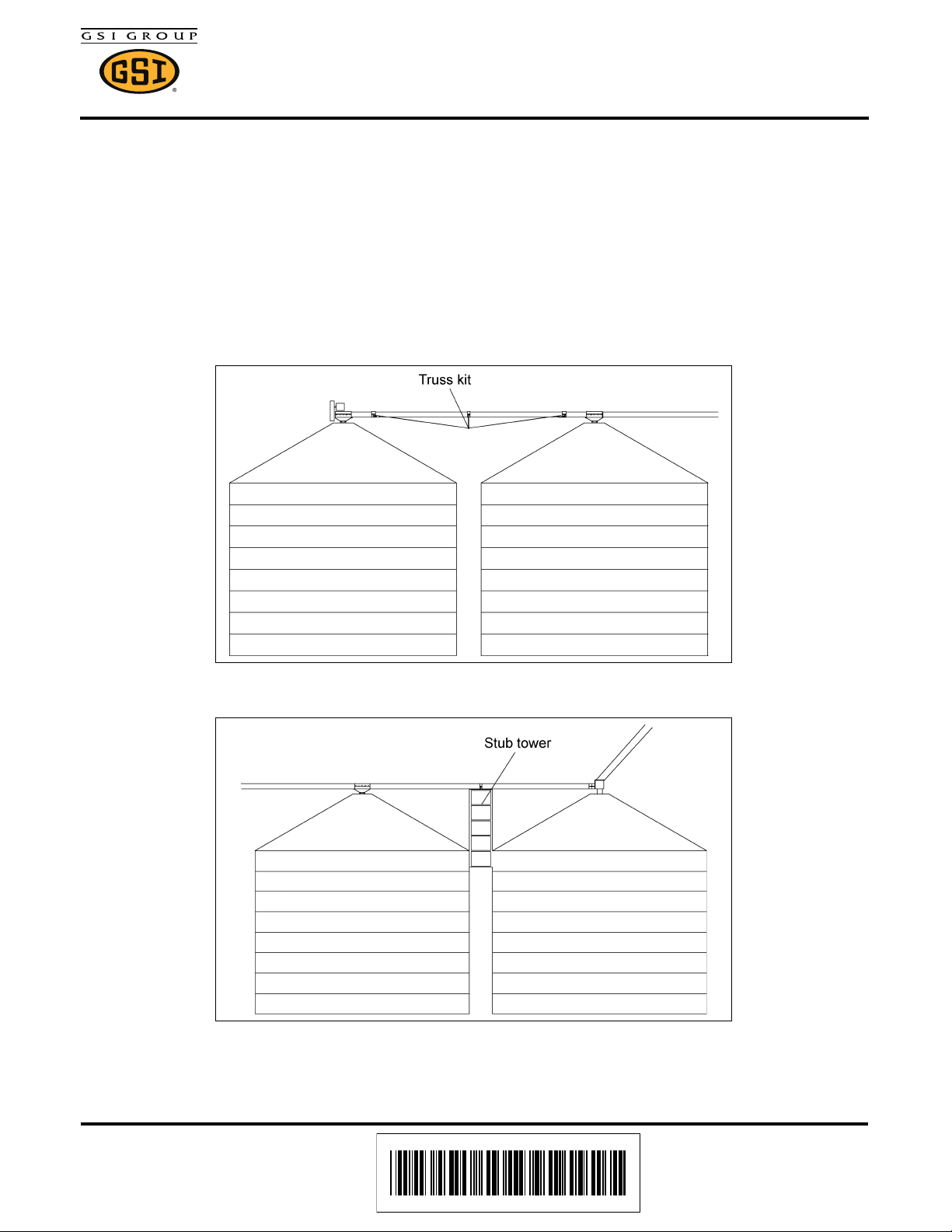

Figure 1 shows a cable truss kit as it may appear at a bin site where small diameter bins are used.

Figure 2 shows an alternative rigid system of support that uses a “stub tower” that bolts to the bin sides

and attaches to the auger tubing with halfbands. A stub tower may originate from the ground and is usually

used on larger size bins.

for 20' and 30' Spans

Figure 1

Figure 2

On most bins, the solid attach points are at the fill ring and sidewall. Use these when supporting overhead

weight whenever possible.

Date: 03-31-10 PNEG-1040

Printed in the U.S.A.

Copyright © 2010 by GSI Group

www.gsiag.com

Page 1 of 4

Page 2

6", 8" and 10" Truss Kit Assembly for 20' and 30' Spans

Assembly Instructions (See Figures on Pages 3 and 4.)

Step 1: Place the truss mount in the center of the tube that is to be trussed. Fasten the truss mount

on the underside of tube using a plain 4" halfband and four (4) 3/8" x 1-1/2" long (grade 5)

hex head cap screws and nylon lock nuts.

Step 2: Connect the vertical truss sides to the right and left sides of the truss mount using a

1/2" x 1-1/2" long (grade 5) hex head cap screw and nylon lock nut for each truss side.

Step 3: Connect the truss crossbrace between the right and left truss sides using two (2)

3/8" x 1-1/4" long (grade 5) hex head cap screws and nylon lock nuts.

Step 4: Position the halfbands with the truss cable anchors the same distance from the truss mount

on opposite sides as close to the ends without interfering with other equipment. Attach the

halfbands with the truss cable anchors to the underside of the tube using a plain 6" wide

halfband and six (6) 3/8" x 1-1/2" long (grade 5) hex head cap screws and nylon lock nut per

each clamp.

NOTE: Truss cable anchors should be skip welded to the tube to prevent slipping.

Step 5: Install the eye bolts through ears located on the bottom of one of the halfbands. Make sure

the eye is pointing towards the truss assembly. Install one flat washer and two (2) non-lock

nuts onto the end of each eye bolt. (See Figure 5 on Page 3.)

Step 6: Run cables through the cable anchor loops that are located on the bottom of one of the

halfbands. Fasten cables using two (2) cable clamps per each cable.

NOTE:

Step 7: Run the cables to the truss assembly and attach them to the truss sides using 3/8" cable

clamps. (See Figure 4 on Page 3.) DO NOT tighten 3/8" cables clamps down at this time.

Step 8: Loop cables through eyes in eye bolts and fasten together using two (2) cable clamps per

each cable.

NOTE:

Step 9: Using the eye bolts, tighten the cables to remove slack until cables are tight. Tighten both

cables so they have the same amount of tension. DO NOT overtighten. Sight down the tube

to make sure all sections are straight.

Step 10: Go back and tighten the 3/8" cable clamps that hold the cables to truss sides.

Secure the U-bolt clamps against the loose end of the cable.

Secure the U-bolt clamps against the loose end of the cable.

(See Figure 6 on Page 4.)

(See Figure 5 on Page 3.)

Page 2 of 4 PNEG-1040

Page 3

6", 8" and 10" Truss Kit Assembly for 20' and 30' Spans

Figure 3 Exploded Assembly

Figure 4 Truss and Cable Clamp Detail Figure 5 Eye Bolt Anchor Detail

PNEG-1040 Page 3 of 4

Page 4

6", 8" and 10" Truss Kit Assembly for 20' and 30' Spans

Figure 6 Loop Anchor Detail

6", 8" and 10" Truss Kit Parts List

Ref # Part # Description

GK4854 Band-On Truss Mount for 6" Tube

1

2

3

4

5

6

7

8

9 GK4749 1/2" Eye Bolt

10 S-4693 1/4" Cable Clamp

11 GK2759 3/8" Cable Clamp

GK1397 Band-On Truss Mount for 8" Tube

GK1403 Band-On Truss Mount for 10" Tube

GK1185 4" Wide Half Clamp for 6" Tube

GK2616 4" Wide Half Clamp for 8" Tube

GK1407 4" Wide Half Clamp for 10" Tube

GK4856 6" Vertical Truss Straps

GK1552 8" and 10" Vertical Truss Straps

GK4855 6" Crossbrace

GK1568 8" Crossbrace

GK1499 10" Crossbrace

GK4836 6" Band-On Truss Cable Anchor (with Cable Loops)

GK1183 8" Band-On Truss Cable Anchor (with Cable Loops)

GK3528 10" Band-On Truss Cable Anchor (with Cable Loops)

GK4835 6" Band-On Truss Cable Anchor (with Eye Bolt Ears)

GK1030 8" Band-On Truss Cable Anchor (with Eye Bolt Ears)

GK1458 10" Band-On Truss Cable Anchor (with Eye Bolt Ears)

GK1185 6" Wide Half Clamp for 6" Tube

GK1326 6" Wide Half Clamp for 8" Tube

GK1509 6" Wide Half Clamp for 10" Tube

GK4887 Truss Cable for 20' Span (1/4" x 24' Long)

GK4725 Truss Cable for 30' Span (1/4" x 33' Long)

Page 4 of 4 PNEG-1040

Loading...

Loading...