Page 1

WIRE GRILL GUARD ROOF VENT

PNEG-104

Wire Grill Guard Roof Vent Assembly & Installation Instructions

The following instructions are for assembling and installing the Wire Grill Guard Roof Vent. First,

check the packing list to ensure all components have been shipped. The unit is easiest assembled in

the upside down position as shown in the instructions. Roof vent location should be as shown on

the reverse page.

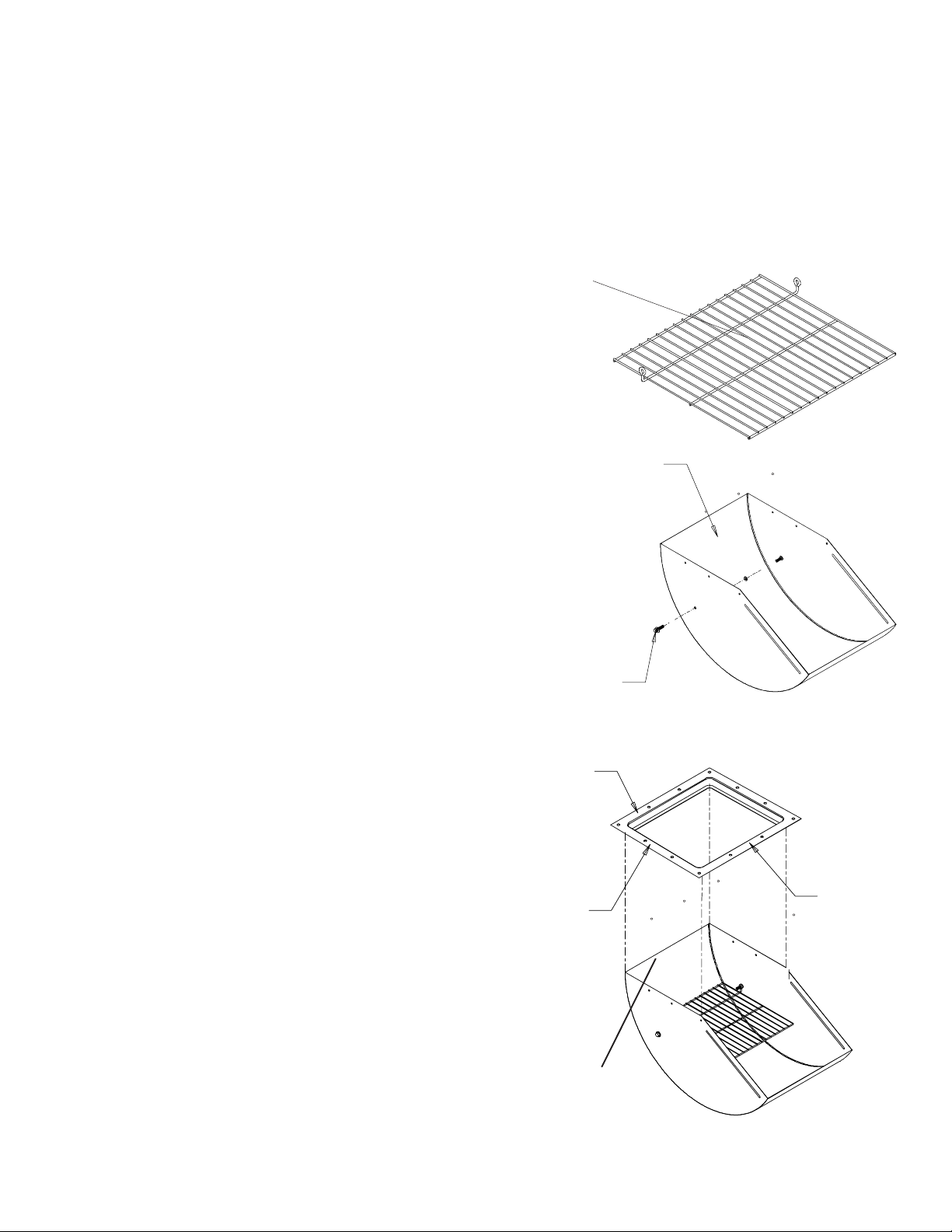

Grill Guard

(MIS-6766)

ASSEMBLY

1. T ake all parts out of the shipping box and check

if all parts are present.

2. Turn one (1) roof vent housing (MIS-6778) upside down. (See Figure #1)

3. Insert 5/16" x 1.1/4" bin bolt with neoprene

washer through hole in the side of the roof vent.

Place jamb nut onto the bolt and tighten. (See Figure #1).

Vent Housing Assembly

(MIS-6778)

4. Slide on eyelet of Grill Guard onto the 5/16" bin

bolt.

5. Insert 5/16" x 1.1/4" bin bolt with neoprene

washer through the other side of the roof vent,

through jamb nut and other eyelet of Grill Guard.

Tighten nut against vent housing side.)

6. Apply a bead of tube caulking around three(3)

housing sides of the roof vent where it meets the

holddown angle.

7. Place holddown angle (MIS-4404) on the assembled roof vent. The wide end of the hole-down

angle must face vent discharge. Once aligned, screw

nine (9) #10 self drilling (S-280) screws through the

roof housing and into the holddown angle. (See Figure #2).

5/16" x 1.1/4"

Nuts & Bolts

Short Side

Approx.

15.3/8"

Hold-Down

Angle

(MIS-4404)

Figure #1

Long Side

Approx.

15.7/8"

Caulk with tube caulking

(Three sides of vent housing)

Figure #2

Page 2

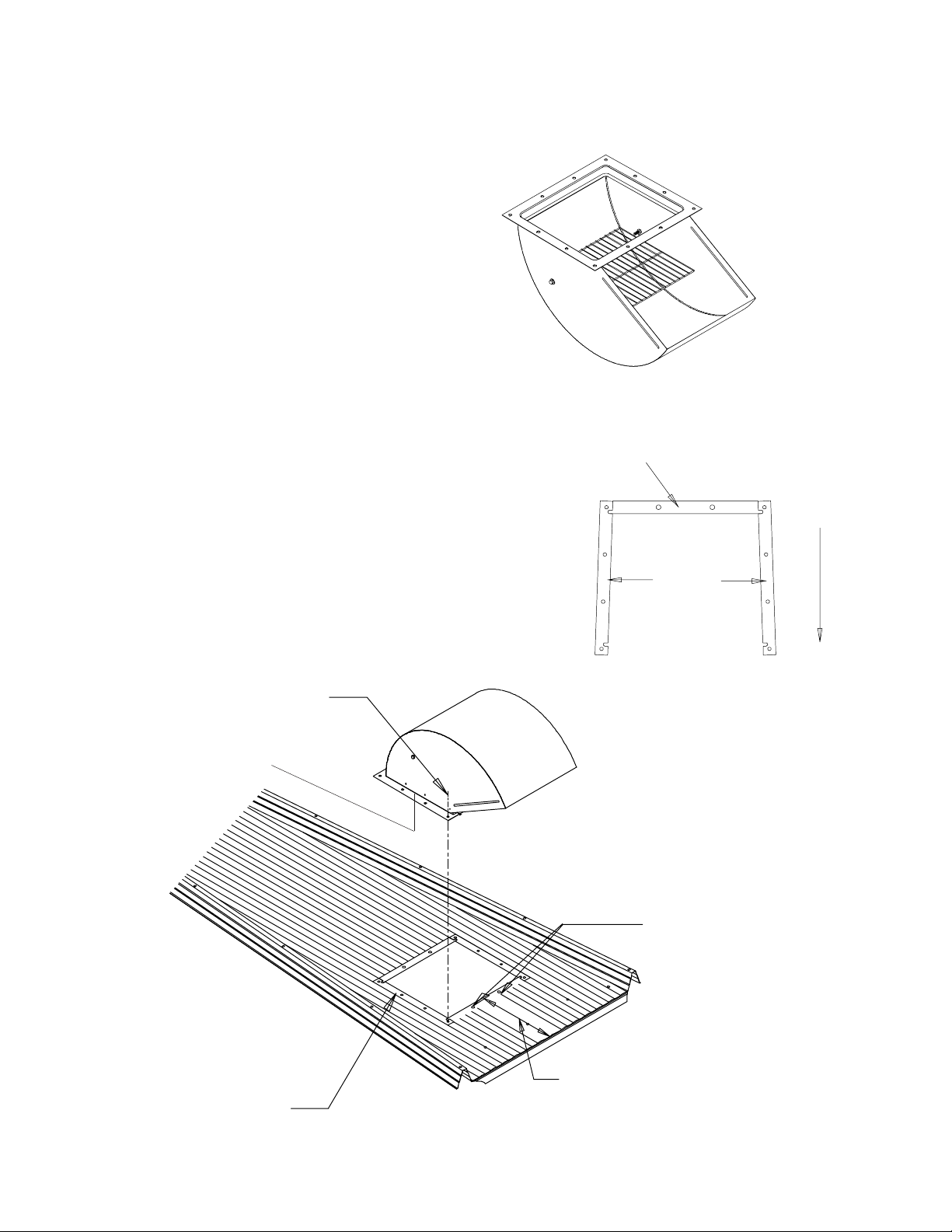

Wire Grill Guard Roof Vent Installation

Installation

8. If the roof sheet does not have a prepunched

hole for the roof vent, a hole must be cut. The cut

hole should match the roof vent. The hole inside

edge should be approximately fifteen (15) inches

from the eave. (See Figure #5)

9. Place the three (3) foam strips on roof sheet, as

shown in Figure #4. Position roof vent over foam

strips and bolt down using 5/16" x 3/4" bin bolts and

nuts. (Note: See instructions below for lower two

(2) bolts of vent).

Figure #3

5/16" x 3/4" Nuts & Bolts

(12 Required)

Caulk with tube caulking

(Three sides of vent housing)

Top Strip

(MIS-6780)

Approx. 15.7/8"

Short Side

Approx. 15.3/8"

Side Strips

(MIS-6781)

Roof Eave

Long Side

Figure #4

Foam Strips

(1) Top (MIS-6780)

(2) Sides (MIS-6781)

NOTE: Install bolts for these

two (2) holes with the bolt

head and neoprene washer to

the underneath side of the

roof sheet and the nut against

the vent holddown angle.

Caulk holes.

Approx. 15"

Figure #5

Loading...

Loading...