Page 1

PLC Controller

PNEG-2170

Installation and Operation Manual

PNEG-2170

Version: 1.0

Date: 12-07-17

Page 2

All information, illustrations, photos, and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

2 PNEG-2170 PLC Controller

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................5

General Safety Statements ................................................................................................................... 5

Scope ..................................... ............................................................................................................... 6

Ordering Parts ....................................................................................................................................... 6

Replacement Parts ....................... .... ... ... ... ... .... .......................................... ... ... ... .... ... ... ........................ 6

Chapter 2 General Information .............................................................................................................................7

System Description .......................................................... ... ... .......................................... ..................... 7

Optional Features ................... ... ... .... .......................................... ... ... ... .................................................. 7

Chapter 3 Safety .....................................................................................................................................................8

Safety Guidelines .................................................................................................................................. 8

Cautionary Symbol Definitions ............................................... .... ... ... ... ... .... ... ... ..................................... 9

Safety Cautions ................................... ... ... .......................................... ... .... ... ...................................... 10

Safety Sign-Off Sheet ......................................................................................................................... 13

Chapter 4 Installation ..........................................................................................................................................14

Receiving Inspection . ... ... .................................................................................................................... 14

Pre-Installation Preparation .................................... .................... ................... ................... ................... 14

Controller Location .............................................................................................................................. 14

System Wiring ..................................................... ... ... .... ... ... ... ............................................................. 14

Chapter 5 Operations and Adjustments ............................................................................................................15

Control Components and their Functions ............................................................................................ 15

Chapter 6 Operations Mode and Description ............................. ...................................................... .................20

Operation Modes .................... ... ... .... ... .......................................... ... ... ... ............................................. 20

Chapter 7 PLC Settings for PS, PS-XP and HD-PP Sampler Operation ..........................................................24

Sampler Operation Description ........................................................................................................... 24

PS, PS-XP and HD-PP Sampler Operating Components ................................................................... 24

PS, PS-XP and HD-PP Sampler Program Mode ................................................................................ 24

PS, PS-XP and HD-PP Sampler Timer Settings ................................................................................. 25

Chapter 8 PLC Settings for PT, PTG, LF, GS, GP and PDP Sampler Operation ............................................26

Sampler Operation Description ........................................................................................................... 26

PT, PTG, LF, GS, GP and PDP Sampler Operating Components ...... ....................... ................... ...... 26

PT, PTG, LF, GS, GP and PDP Sampler Main Fuse (Refer to Certified Drawing) ............................. 26

PT, PTG, LF, GS, GP and PDP Sampler Program Mode ................................................................... 26

PT, PTG, LF, GS, GP and PDP Sampler Timer Settings ........... ................... ................... ................... 27

Chapter 9 PLC Settings for GSS and GSS-U Sampler Operation .......................... ............................. .............28

Sampler Operation Description ........................................................................................................... 28

GSS and GSS-U Sampler Operating Components ............................................................................. 28

GSS and GSS-U Sampler Main Fuse (Refer to Certified Drawing) .................................................... 28

GSS and GSS-U Sampler Program Mode .......................................................................................... 28

GSS and GSS-U Sampler Timer Settings ........................................................................................... 29

Chapter 10 PLC Settings for GT, GRES and RS Sampler Operation ....................... ... ... .... ... ... ... ... .... ... ..........30

Sampler Operation Description ......................................................................................................... 30

GT, GRES and RS Sampler Operating Components ........................................................................ 30

GT, GRES and RS Sampler Main Fuse (Refer to Certified Drawings) .............................................. 30

GT, GRES and RS Sampler Program Mode ..................................................................................... 30

PNEG-2170 PLC Controller 3

Page 4

Table of Contents

Chapter 11 PLC Settings for PRT and HD-PRT Sampler Operation ................................................................31

Sampler Operation Description ....................................... ... ... .... ... ... ... ... .... ... ... ... ............................... 31

PRT and HD-PRT Sampler Operating Components ......................................................................... 31

PRT and HD-PRT Sampler Main Fuse (Refer to Certified Drawing) ................................................. 31

PRT and HD-PRT Sampler Program Mode and Solenoid Timer ....................................................... 31

Chapter 12 PLC Settings for GRA and GCA Sampler Operation (550804) .....................................................33

Sampler Operation Description ....................................... ... ... .... ... ... ... ... .... ... ... ... ............................... 33

GRA and GCA Sampler Operating Components .............................................................................. 33

GRA and GCA Sampler Main Fuse (Refer to Certified Drawing) ...................................................... 33

GRA and GCA Sampler Program Mode ............. ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ........................ 33

Chapter 13 PLC Settings for GPE Sampler Operation (550804) ......................................................................34

Sampler Operation Description ....................................... ... ... .... ... ... ... ... .... ... ... ... ............................... 34

GPE Sampler Operating Components .............................................................................................. 34

GPE Sampler Program Mode ............................................................................................................ 34

Chapter 14 PLC Settings for Index Cabinet and Other Options ................................ ... ... .... ... ... ... ... .... ... ... ......35

Setting Controller to Operate Index Cabinet and Setting Up Index Cabinet ...................................... 35

Index Cabinet Delay Before Indexing ................................................................................................ 35

Sample Purge Option ........................................................................................................................ 36

Remote Enable .................................................................................................................................. 37

Chapter 15 Maintenance and Repair ..................................................................................................................38

General Maintenance ........................................................................................................................ 38

Periodic Inspection ............................................................................................................................ 38

Chapter 16 Troubleshooting ...............................................................................................................................39

PLC Control Troubleshooting ................ ... ... .... ... ... ... .... ... ... ... .... ......................................... .... ........... 39

Chapter 17 Warranty ............................................................................................................................................41

4 PNEG-2170 PLC Controller

Page 5

1. Introduction

This equipment is to be obtained only on the voltage designated on the certified

electrical drawings. Fire or explosion may result, which can cause death, serious

injury and extensive damage to equipment. Do not connect to voltages other than

designated.

Compressed air can cause severe injury. Shut off and lock out compressed air

source to the sampler and bleed off any and all present compressed air within the

sampler pneumatics before attempting any service on this sampler.

This manual covers the installation and operation for the PLC Con troller. This manual provides guidelines

for installing the product. You must retain a qualified contractor to provide on-site expertise.

INTERSYSTEMS IS NOT RESPONSIBLE FOR THE INSTALLATION OF THIS PRODUCT.

InterSystems reserves the right to improve its product whenever possible and practical to do so. We

reserve the right to change, improve and modify products at any time without obligation to ma ke changes,

improvements and modifications on equipment sold previously.

General Safety Statements

1. The PLC Controller is designed and manufactured with operator safety in mind. However, residual

hazards remain due to the nature of material handling, and specific material hazards. Use extreme

caution at all times.

2. Modifications to equipment may cause extremely dangerous situations that could result in damage

to the equipment as well as serious injury or death. Never modify the equipment.

3. Intersystems recommends that you contact the local power company to have a representative survey

the installation to ensure wiring is compatible with their system and adequate power is supplied to

the unit.

4. Consult Intersystems before making any changes to the sampler or its operating environment.

Careless changes could result in death or serious injury to people and reduce the performance and

service life of the equipment.

5. Never perform any service on this equipment or any powered equipment until all power has been

shut off and locked out so that it cannot be restored without the consent and knowledge of the person

who interrupted power. Power includes electrical, fluid, mechanical or pneumatic energy.

6. Never perform any service on this equipment without utilizing the required PPE (Personal Protective

Equipment). Refer to the MSDS (s) (Material Safety Data Sheet (s)), on all products to which this

equipment is in contact to determine what PPE is required.

PNEG-2170 PLC Controller 5

Page 6

1. Introduction

Scope

The certified drawings list the non-standard components that have been incorporated into the equipment.

InterSystems, Inc. normally stocks non-fabricated parts and non-custom OEM parts. Replacement parts

for any other components, including fabricated parts and custom OEM components can be supplied

upon request.

Ordering Parts

Direct parts orders or requests for technical assistance to your sales representative or to:

InterSystems, Inc.

9575 No 109

Omaha, NE 68142

Phone: (402) 330-1500

FAX: (402) 330-3350

Please have available the MODEL NUMBER, SERIAL NUMBER and CUSTOMER ORDER NUMBER of

the equipment in question as well as the location where the sampler is INSTALLED.

th

Ave

Replacement Parts

The InterSystems, Inc. sampler is a quality built piece of machinery. As with any machine, parts do wear

out and fail. It is InterSystem’s recommendation that a small supply of spare parts be kept on hand to cover

any minor breakdowns. A separate priced spare parts list will be sent identifying the suggested spare

parts. It is also necessary to check the certified drawings, which will list a ny special or custom components

utilized on this equipment.

6 PNEG-2170 PLC Controller

Page 7

2. General Information

System Description

The PLC control is an Allen Bradley Micologix 10 point processor interfaced with a PanelView 300

operator display designed to control one sampler at a time. The control can handle the addition of a

collection cabinet at installation or at a later date without replacing or upgrading the control. The controller

was design with the intent to be user friendly using a minimum number of key strokes.

Sampler start-up, setting and operator interaction are easily navigated through the menu screens on the

PanelView screen. Once the control is set-up and the desired timer values entered, the control can be set

to run in automatic or manual operation. When in automatic mode, the control will upon initial power up

wait 30 seconds before beginning the automatic sequence. This is designed to allow the operator time to

decide if they want automatic or manual operation. If the control has been ON and the remote enable

signal is use the 30 second delay is not used. When the control is in automatic, the delay between samples

timer will start to time down, upon reaching 0 the control will begin the desired sampling sequence. When

the control is set for manual operation, the delay between samples timer is ignored and upon press the

“F1” key, the sampler will begin the sampling sequence.

Optional Features

The certified drawings indicate which, if any, optional features are included with a sampler control. Some

of the more frequently specified optional features are briefly described in the following list.

1. Controller arranged to initiate a sampling cycle based on quantity or volume of material passing

through conveying line rather than upon elapsed time periods.

2. Explosion Proof Controller. There are several major differences in an explosion-proof control as

compared to a standard control. An explosion proof control will typically have the following features.

The explosion proof sampler control is available in two enclosure classifications.

a. The NEMA 9 control with the rating of:

Class 2, Groups E, F and G, Division 1 and 2

b. The NEMA 7 control with the rating of:

Class 1, Groups C and D, Division 1 and 2

Class 2, Groups E, F and G, Division 1 and 2

3. Enclosure components of special materials, such as 304 stainless steel.

PNEG-2170 PLC Controller 7

Page 8

3. Safety

ST-0001-3

Safety Guidelines

Safety guidelines are general-to-specific safety rules that must be followed at all times. This manual is

written to help you understand safe operating procedures and problems that can be encountered by the

operator and other personnel when using this equipment. Save these safety guidelines for future

reference.

As owner or operator, you are responsible for understanding the requirements, hazards, and precautions

that exist and to inform others as required. Unqualified persons must stay out of the work area at all times.

Alterations must not be made to the equipment. Alterations can produce dangerous situations resulting in

SERIOUS INJURY or DEATH.

This equipment must be installed in accordance with the current installation codes and applicable

regulations, which must be carefully followed in all cases. Authorities having jurisdiction must be consulted

before installations are made.

When necessary, you must consider the installation location relative to electrical, fuel and water utilities.

Personnel operating or working around equipment must read this manual. This manual must be delivered

with equipment to its owner. Failure to read this manual and its safety instructions is a misuse of the

equipment.

8 PNEG-2170 PLC Controller

Page 9

3. Safety

This symbol indicates an imminently hazardous situation

which, if not avoided, will result in serious injury or death.

This symbol indicates a potentially hazardous situation

which, if not avoided, can result in serious injury or death.

This symbol indicates a potentially hazardous situation which,

if not avoided, can result in minor or moderate injury.

This symbol is used to address practices not related to

personal injury.

This symbol indicates a general hazard.

This symbol indicates a prohibited activity.

This symbol indicates a mandatory action.

ST-0005-2

Cautionary Symbol Definitions

Cautionary symbols appear in this manual and on product decals. The symbols alert the user of potentia l

safety hazards, prohibited activities and mandatory actions. To help you recognize this information, we

use the symbols that are defined below.

DANGER

WARNING

CAUTION

NOTICE

PNEG-2170 PLC Controller 9

Page 10

3. Safety

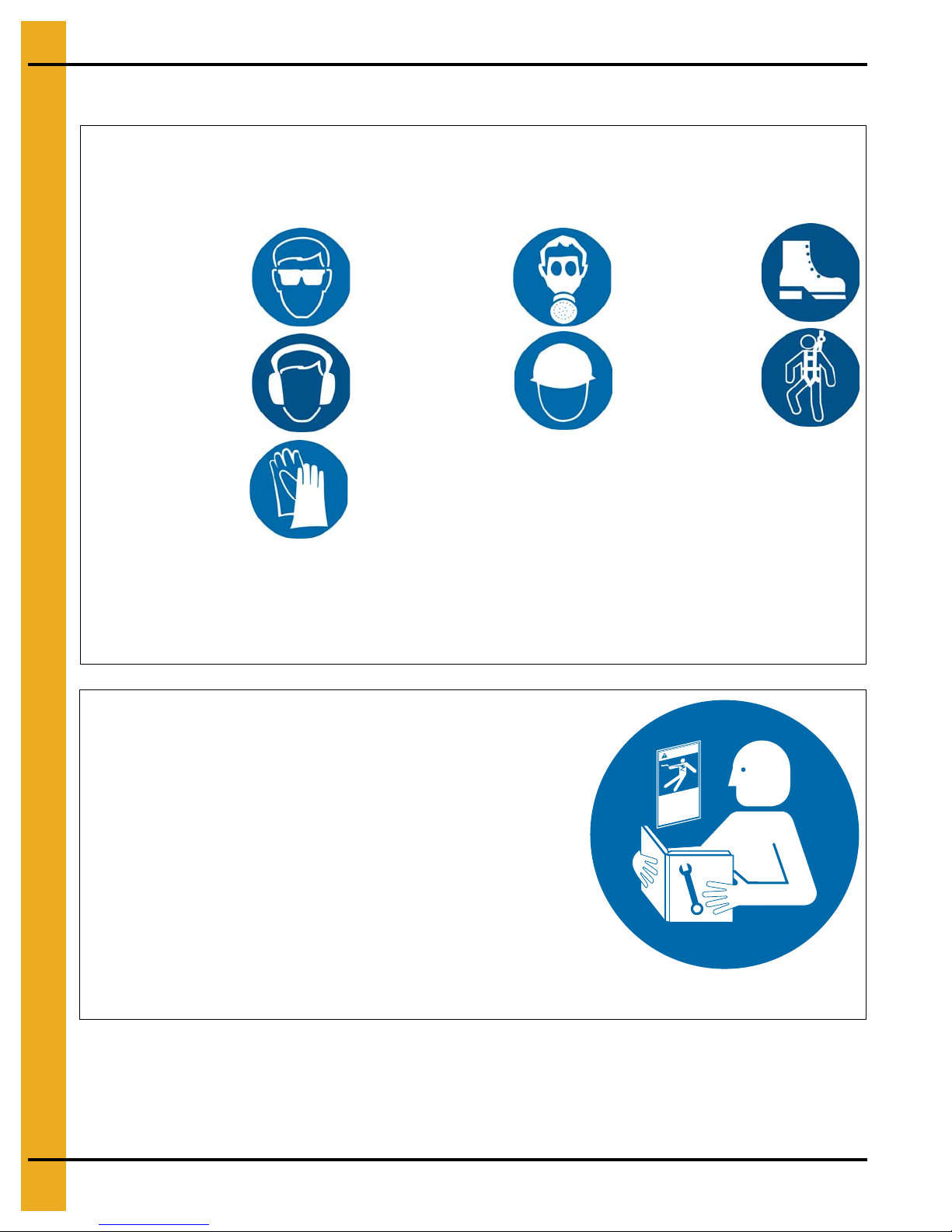

Use Personal Protective Equipment

Eye

Protection

Hearing

Protection

Hand

Protection

Head

Protection

Respiratory

Protection

Foot

Protection

Fall

Protection

• Use appropriate personal protective equipment:

• Wear clothing appropriate to the job.

• Remove all jewelry.

• Tie long hair up and back.

ST-0004-1

Follow Safety Instructions

• Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts

include the current safety signs. Replacement safety

signs are available from the manufacturer.

• Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction.

• If you do not understand any part of this manual or

need assistance, contact your dealer.

ST-0002-1

Safety Cautions

10 PNEG-2170 PLC Controller

Page 11

3. Safety

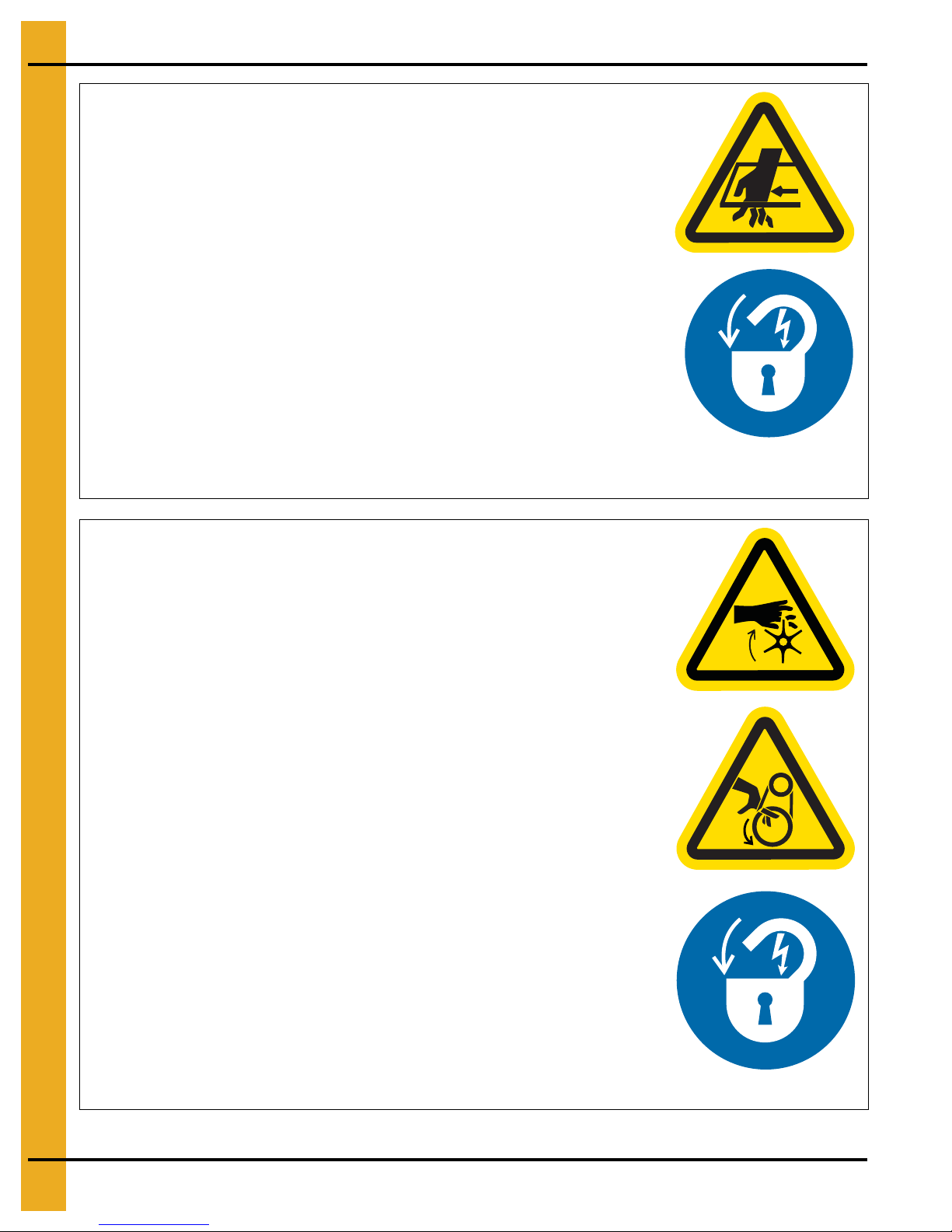

Maintain Equipment and Work Area

• Understand service procedures before doing work. Keep area

clean and dry.

• Never service equipment while it is operating. Keep hands, feet,

and clothing away from moving parts

• Keep your equipment in proper working condition. Replace worn

or broken parts immediately.

ST-0003-1

Stay Clear of Hoisted Equipment

• Always use proper lifting or hoisting equipment when assembling

or disassembling equipment.

• Do not walk or stand under hoisted equipment.

• Always use sturdy and stable supports when needed for

installation. Not following these safety precautions creates the

risk of falling equipment, which could crush personnel and cause

serious injury or death.

ST-0047-1

Sharp Edge Hazard

• This product has sharp edges, which can cause serious injury.

• To avoid injury, handle sharp edges with caution and always use

proper protective clothing and equipment

ST-0036-2

Install and Operate Electrical Equipment Properly

• Electrical controls must be installed by a qualified electrician and

must meet the standards set by applicable local codes (National

Electrical Code for the US, Canadian Electric Code, or EN60204

along with applicable European Directives for Europe).

• Lock-out power source before making adjustments, cleaning, or

maintaining equipment.

• Make sure all equipment is properly grounded.

ST-0027-4

PNEG-2170 PLC Controller 11

Page 12

3. Safety

Stay Clear of Moving Parts

• Stay clear - machine can start without warning.

• Entanglement in gate will cause serious injury.

• Keep all shields and covers in place at all times.

• Lock-out power source before making adjustments, cleaning, or

maintaining equipment.

ST-0070-1

Stay Clear of Rotating Parts

• Do not service equipment while it is in operation.

• Entanglement in rotating parts or exposed belts will cause serious

injury or death.

• Keep all shields and covers in place at all times.

• Lock-out power source before making adjustments, cleaning,

or maintaining equipment.

ST-0072-1

12 PNEG-2170 PLC Controller

Page 13

3. Safety

Flying Material and High Pressure Air Hazard

• Flying material and/or high pressure air can cause

severe eye injury or blindness.

• Wear safety glasses around operating equipment.

ST-0071-1

Safety Sign-Off Sheet

Below is a sign-off sheet that can be used to verify that all person nel have read and understood the safety

instructions. This sign-off sheet is provided for your convenience and personal record keeping.

Date Employee Name Supervisor Name

PNEG-2170 PLC Controller 13

ST-0007

Page 14

4. Installation

Receiving Inspection

Carefully inspect the sampler control for damage as soon as it is received. Also, verify that the quantity of

parts or packages actually received corresponds to the quantity shown on the packing slip. Report any

damage or shortage to the delivering carrier as soon as possible. InterSystem’s responsibility for the

equipment ended with acceptance by the delivering carrier. Refer to the bill of lading.

Pre-Installation Preparation

NOTE: Before starting the sampling system installation, study this manual, the certified drawing(s)

furnished with the system and other applicable documents (including, but not limited to OSHA

regulations, the National Electrical Code and all other applicable federal, state and local codes

and regulations).

Controller Location

1. Use vibration isolation pads when mounting the control enclosure or mount the controller in a

vibration free location.

2. Unless ordered for severe duty, locate controller so it is protected from water and dust.

3. Unless an explosion-proof rated controller was specifically ordered, DO NOT locate the controlle r in

a hazardous area.

4. Most applications require that the sampler be in easy view of the controller.

System Wiring

Refer to the certified electrical drawing(s) for specific wiring requirements. The 19-position barrier

terminal strip located inside the bottom right corner of the control enclosure is the connection point for

ALL external circuitry.

The controller was completely assembled and tested with the sampler before it left the factory. The

electrical installation must comply with OSHA Regulations, the National Electrical Code and all other

applicable federal, state and local codes and regulations.

If wiring between the controller and the sampler unit is run through rigid conduit, use a short length of

flexible conduit to connect wiring to the sampler. This will isolate the rigid conduit from any vibration

originating in the product conveying line and sampler.

Controller Electrical Power Requirements

110/120 VAC 50/60 Hz, Single Phase, 20 Amp Maximum Service.

Optional - 220/240 VAC 50/60 Hz, Single Phase, 10 Amp Service.

Refer to the certified electrical drawing(s) for specific wiring requirements. InterSystems strongly

recommends that electrical service to the sampling system be an isolated line. Voltage fluctuations and

line noise can affect the controller, thus causing the sampler to malfunction.

14 PNEG-2170 PLC Controller

Page 15

Control Components and their Functions

5. Operations and Adjustments

Figure 5A Standard Nema 4 Control Panel Detail

Refer to the certified electrical drawing(s) for dimensions on control panels with optional features.

PNEG-2170 PLC Controller 15

Page 16

5. Operations and Adjustments

This machine starts without warning. Moving parts can cause severe

injury. Clear area prior to controller start-up.

Power OFF/ON Switch S-1

The Power OFF/ON switch controls all electrical power to the controller and the sampler unit.

Power Pilot Light

This light is illuminated as long as power is available to the controller and the POWER switch (S-1) is set

to ON.

Sampling Pilot Light

This light will illuminate when a sampling cycle has been initiated and will stay lit until CR-1 has been

turned OFF for controller series 550800. On control series 550803 the sampling lights are associated

with the traverse direction of the pelican. The light will stay illuminated until the solenoid has been

de-engerized.

PanelView 300 Operator Interface

The operator interface is the source of all input necessary to operate the control. The operator PanelView

is setup using linked menus to step through the operation of the control. The following flow chart depicts

the layout of the operator menus. (See chart on Page 17.)

16 PNEG-2170 PLC Controller

Page 17

5. Operations and Adjustments

PNEG-2170 PLC Controller 17

Figure 5B Operator PanelView Flow Chart

Page 18

5. Operations and Adjustments

F1 MANUAL SAMPLE

F2 MANUAL INDEX

F3 IN MANUAL

F4 SETTINGS

F1 VIEW SETTINGS

F2 SAMPLER TIMER

F3 SAMPLE SELECTION

F4 MAIN SCREEN

F1 PROGRAM MODE

F2 OPTION SETTINGS

F4 MAIN SCREEN

F1 OPERAT ION MODE

F2 INDEXER SETUP

F3 PURGE OFF

F4 PASSWORD SCREEN

Description of Operator Screens

Function keys F1, F2, F3 and F4

Up/Down arrow keys

Left/right arrow keys Used to change numeric number position.

F1 MANUAL SAMPLE

F2 MANUAL INDEX

F3 IN MANUAL

F4 SETTINGS Allows user to select other control options.

F1 VIEW SETTINGS

Used to select desired control function or

parameters.

Used to enter numeric numbers by incrementing

digits.

Enter key

Used to initial a manual sample cycle when in

manual mode.

Used to initial a manual index of sample cabinet in

manual mode when a cabinet is connected to the

control.

F3 toggles between manual mode and automatic

mode.

Used to view sample duration timer.

F1 TIME BETWEEN SAMPLES

F2 SAMPLES DONE

F3 CURRENT JAR

F4 INPUT STATUS and TURN OUTPUT ON

F2 SAMPLE TIMER

F3 SAMPLE SELECTION

F1 PROGRAM MODE

F2 OPTION SETTINGS

F1 OPERATION MODE

F2 INDEXER SETUP

F3 PURGE OFF Turns sample purge ON/OFF.

Password required for changing time between

samples.

Allows operator to select program mode and option

settings.

Changes between the different sampler programs

in the controller.

F1 toggles through sampler programs.

F2 sets timer values for that specific sampler.

Allows operator to change mode of operation, turn

ON and set-up index cabinet and turn on sample

purge.

Changes control operation from timer based to

counter and timer/counter.

Also contains the Timer Settings to allow for the

adjustment of the specific sampler timer values.

Used to turn the indexer ON or OFF, enter the total

number of jars per cabinet and enter the number of

samples per jar.

18 PNEG-2170 PLC Controller

Page 19

5. Operations and Adjustments

This control is to be operated only on the voltage designated on the certified

electrical drawing. Fire or explosion may result, which can cause death, serious

injury and extensive damage to equipment.

Terminal Strip

This 19-position barrier terminal strip is located inside along the bottom right corner of the control

enclosure. It serves as the controller’s interface and connection point for all external circuits and for the

components mounted in the enclosure. Refer to the certified electrical drawing(s).

Power Transformer

The control is equipped with a transformer which converts 120/240 volt incoming power to 24 VDC f or the

operation of the PLC, PanelView, display lights, input signals and operation of the control relays. Refer to

the certified electrical drawing(s). The transformer is internally protected against overloads.

Control Relays

The control is equipped with four control relays, which are driven by the PLC output signals. Each relay

has a mechanical flag indicator showing the relay is energized. The relay coil is operated using 24 VDC

while the relay contacts are wired for 120/240 volts. Refer to the certified electrical drawing(s).

Main Fuse F1

This fuse is located along the top edge of the control next to the base of the ON/OFF switch. The fuse

rating will change depending on the type of sampler being used. This fuse protects the controller and

sampler components against overloads and short circuits.

For 120/240 VAC, 1 PH operation use ONLY a Buss Type FNM, 250 Volt Slo-Blo fuse or equal.

Microview PLC

The PLC for the control is a 10 point Allen Bradley Microview controller. The PLC operates on 24 VDC and

is pre-wired to the proper terminal strip inputs and outputs. The processor program is protected to prevent

any alterations to the existing program. This control is design only to run InterSystems equipment.

PNEG-2170 PLC Controller 19

Page 20

6. Operations Mode and Description

Operation Modes

The PLC control can operate under three different operation modes: Timer, Counter, Counter/Counter,

Timer/Counter. Operation mode determines when the sampler starts a sample cycle when in the

automatic mode. The controls are factory set in the Timer operation mode.

Counter Mode

When in the COUNTER mode the sampler is looking for pulses from external equipment (i.e. bagging line).

When the sampler reaches the desired counts a sample cycle will be initiated. To set the control to operate

in COUNTER mode:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F2 for Option Settings.

8. Press F1 for Operation Mode.

9. Press F1 to toggle through to counter.

10. Press F2 to change the number of counts between samples.

11. Enter desired value using the Up/Down arrow keys on the right side to adjust number values and the

Right/Left arrow keys on the left side to change position. Then press the Enter key .

12. Press F4 to return to Main Screen.

To initiate the input pulse the factory installed REMOTE ENABLE jumper needs to be removed. In its

place, install a normally open contact. The normally open contact should be a dry contact rated for

120 VAC 0.5 Amps. This contact needs to be driven by the customer’s process (i.e. bagging line). When

the contact closes the sampler PLC will register a count. They will count up until the desired count value

is reached. When the count value is reached the sampling cycle will begin.

Signal Start-Multiple Cycle Mode

When in the Signal Start-Multiple Cycle mode the sampler is lookin g for a pulse from exte rnal equ ipment

(i.e. bagging line). When the enable signal is initiated the sampler will cycle for a pre-determined nu mber

of cycles. To set the control to operate in Signal Start-Multiple Cycle mode:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

20 PNEG-2170 PLC Controller

Page 21

6. Operations Mode and Description

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F2 for Option Settings.

8. Press F1 for Operation Mode.

9. Press F1 to toggle through to Enable/X samples.

10. Press F2 to change the number of sample counts required.

11. Enter desired value using the Up/Down arrow keys on the right side to adjust number values and the

Right/Left arrow keys on the left side to change position. Then press the Enter key .

12. Press F3 to change the time between samples (in seconds).

13. Enter desired value using the Up/Down arrow keys on the right side to adjust number values and the

Right/Left arrow keys on the left side to change position. Then press the Enter key .

14. Press F4 to return to Main.

To initiate the input pulse, remove the factory installed REMOTE ENABLE jumper. In its place, install a

normally open dry contact rated for 120 VAC 0.5 Amps that is driven by the customer’s process

(i.e: bagging line). When the contact closes the sampler PLC will start the sampling cycle. When the

sample cycles are complete, the control will require another input pulse to start the cycle over.

Timer Mode

When in the Timer mode the sampler will time down in hours, minutes or seconds. Wh en the timer reaches

0 the sampling cycle will begin. To set the control to operate in TIMER mode:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F2 for Option Settings.

8. Press F1 for Operation Mode.

9. Press F1 to toggle through to Timer.

10. Press F4 to return to Main Screen.

When in automatic mode, the REMOTE ENABLE jumper needs to be installed. NOTE: When in manual

mode, the sampler will only take one sample per incident.

PNEG-2170 PLC Controller 21

Page 22

6. Operations Mode and Description

Changing the sampling frequency between sampler cycles is accomplished by following the instructions

below. This time value can be set for the maximum time of 9999 hours, 59 minutes and 59 seconds. To

change the program mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F2 for Sample Timer.

4. Press F3 for Change Time.

5. Press F1 for Hours.

6. Press F2 for Minutes.

7. Press F3 for Seconds.

8. Using the Up/Down and Right/Left arrow keys to set the correct Time. Once the correct time value

has been entered, press the enter key .

9. Press F4 to return to Previous Screen.

10. Press F4 for Main Screen.

Timer/Counter Mode

When in the Timer/Counter mode the sampler will time down in hours, minutes or seconds. When the timer

reaches 0 the sampling cycle will take the number of samples entered into the counter. To set the control

to operate in TIMER/COUNTER mode:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F2 for Option Settings.

8. Press F1 for Operation Mode.

9. Press F1 to toggle through to Time/X samples.

10. Press F2 to change the number of sample counts required.

11. Enter desired value using the Up/Down arrow keys on the right side to adjust number values and the

Right/Left arrow keys on the left side to change position. Then press the Enter key .

12. Press F3 to change the time between samples (in seconds).

13. Enter desired value using the Up/Down arrow keys on the right side to adjust number values and the

Right/Left arrow keys on the left side to change position. Then press the Enter key .

14. Press F4 to return to Main.

22 PNEG-2170 PLC Controller

Page 23

6. Operations Mode and Description

Changing the sampling frequency between sampler cycles is accomplished by following the instructions

below. This time value can be set for the maximum time of 999 hours, 59 minutes and 59 seconds.

To change the program mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F2 for Sample Timer.

4. Press F3 for Change Time.

5. Press F1 for Hours.

6. Press F2 for Minutes.

7. Press F3 for Seconds.

8. Using the Up/Down and Right/Left arrow keys to set the correct Time. Once the correct time value

has been entered, press the enter key .

9. Press F4 to return to Previous Screen.

10. Press F4 for Main Screen.

When in automatic mode, the REMOTE ENABLE jumper needs to be installed. NOTE: When in manual

mode, the sampler will only take one sampler per incident.

PNEG-2170 PLC Controller 23

Page 24

7. PLC Settings for PS, PS-XP and HD-PP Sampler Operation

Sampler Operation Description

The PS style sampler when operated in the timing mode and Automatic operates as follows. When the

illuminated display reads all zeroes (000), the timer has “timed out” and initiates a sampling cycle. The

sample probe extends and delays to collect a sample until T1 times out, the probe then retracts and

actuates the limit switch LS-1. After the limit switch close and a delay of 1/2 second (to allow the bevel

gears to mesh) the auger motor is energized for the time setting of T2. After timer T2 times out, the motor

will stop and the timer display resets to the preset value and another timing interval is initiated. If the

controller is shut off or the mode switched from AUTO to MANUAL, the timing cycle is te rmin ated. When

power is restored or the AUTO mode is again selected, the display is reset to the preset value and another

cycle begins. NOTE: A new timing cycle can be initiated ONLY after the sampling cycle has completed.

PS, PS-XP and HD-PP Sampler Operating Components

The PS, PS-XP and HD-PP style samplers have three main operating components: solenoid valve to

extend the sample probe, limit switch to ensure proper gear mesh and the auger motor. Refer to the

certified drawing(s).

PS Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 5 Amp, 250 volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 3 Amp, 250 volt Slo-Blo fuse or equal.

PS-XP Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 15 Amp, 250 volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 8 Amp, 250 volt Slo-Blo fuse or equal.

HD-PP Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 15 Amp, 250 volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 8 Amp, 250 volt Slo-Blo fuse or equal.

PS, PS-XP and HD-PP Sampler Program Mode

The PS, PS-XP and HD-PP style sampler must be set to run on Program Mode 0 only. To change the

program mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

24 PNEG-2170 PLC Controller

Page 25

7. PLC Settings for PS, PS-XP and HD-PP Sampler Operation

8. Press F1 for Mode (the current sampler mode sho uld be showing). To change samp ler mode, press

F1 until a 0 is showing on this line.

9. Press F2 to change the sampler timer settings. (Extend timer and auger run timer.) The current value

should be showing on the right side of this line. See PS and PS-XP and HD-PP chart for correct timer

settings.

10. Press F1 to change the Solenoid time in seconds.

11. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. See PS and PS-XP

and HD-PP chart for the correct timer setting. Once the correct time value has been entered, press

the enter key .

12. Press F2 to change the Auger run time in seconds. The current value should be showing on the right

side of this line. See PS and PS-XP and HD-PP chart for correct timer setting.

13. Using the Up/Down and Right/Left arrow keys to set the correct auge r time. See PS and PS-XP and

HD-PP chart for the correct timer setting. Once the correct time value has been entered, press the

enter key .

14. Press F4 to return to Password Screen.

15. Press F4 to return to Main Screen.

PS, PS-XP and HD-PP Sampler Timer Settings

The PS, PS-XP and HD-PP style sampler has two timer setting which must be set for proper operation.

The two timers are solenoid extend time (T1) and auger motor run timer (T2). See PS and PS-XP and

HD-PP chart for recommended settings.

PS and PS-XP

Sampler Size PS-4 PS-6 PS-8 PS-10 PS-12 PS-14 PS-16

Solenoid Time (Seconds) T1 2 3 3 3 4 4 4

Motor Time (Seconds) T2 8 8 10 12 14 14 16

HD-PP

Sampler Size HD-PP-6 HD-PP-8 HD-PP-10 HD-PP-12 HD-PP-14 HD-PP-16

Solenoid Time (Seconds) T1 3 3 4 4 5 5

Motor Time (Seconds) T2 8 10 12 14 14 16

NOTE: Solenoid valve time is to be adjusted so that the sample tube e xtends into the product stream only

long enough to allow a representative sample to be collected. Extending the sample tube into the

product stream for excessively

and can result in clogging of product flowing through the conveying line.

long periods of time can result in unnecessary sample tube wear

NOTE: Motor run time is to be adjusted to allow the auger to clean out the sa mple tube at the end of each

cycle. Minimum run time will depend on the characteristics of the ma terial being sampled and may

well require re-adjustment if the product being sampled changes.

PNEG-2170 PLC Controller 25

Page 26

8. PLC Settings for PT, PTG, LF, GS, GP and PDP Sampler Operation

Sampler Operation Description

The PT style sampler when operated in the timing mode and Automatic operates as follows. When the

AUTO mode is selected, the timer begins timing down. When the illuminated display reads all zeroes

(000), the timer has “timed out” and initiates a sampling cycle. The sample probe extends and delays to

collect a sample until T1 times out, the probe then retracts. The timer display resets to the preset value

and another timing interval is initiated. If the controller is shut off or the mode switched from AUTO to

MANUAL, the timing cycle is terminated. When power is restored or the AUTO mode is again selected,

the display is reset to the preset value and another cycle begins. NOTE: A new timing cycle can be initiated

ONLY after the sampling cycle has completed.

PT, PTG, LF, GS, GP and PDP Sampler Operating Components

The PT, PTG, LF, GS, GP style sampler has one main operating component, the solenoid valve to extend

the sample probe. Refer to the certified drawing(s).

PT, PTG, LF, GS, GP and PDP Sampler Main Fuse (Refer to

Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 2 Amp, 250 volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 1 Amp, 250 volt Slo-Blo fuse or equal.

PT, PTG, LF, GS, GP and PDP Sampler Program Mode

The PT, PTG, LF, GS, GP style sampler must be set to run on Program Mode 1 only. To change the

program mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

8. Press F1 for Mode (the current sampler mode should be showing). To change sampler mode, pre ss

F1 until a 1 is showing on this line.

9. Press F2 to change the sampler timer setting. (Extend timer.) The current value should be showing

on the right side of this line. See chart on Page 27 for correct timer settings.

10. Press F1 to change the Solenoid time in seconds.

11. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. See chart on Page 27

for the correct timer setting. Once the correct time value has been entered, press the enter key

.

26 PNEG-2170 PLC Controller

Page 27

8. PLC Settings for PT, PTG, LF, GS, GP and PDP Sampler Operation

12. Press F4 to return to Password Screen.

13. Press F4 to return to Main Screen.

PT, PTG, LF, GS, GP and PDP Sampler Timer Settings

The PT, PTG, LF, GS, GP style sampler has one timer setting which must be set f or proper operation. The

timer setting is for the solenoid extend time (T1). See Chart for recommended settings.

Sampler Size PDP PT PTG LF GP GS

Solenoid Time (Seconds) T1 3 3 3 3 3 3

NOTE: Solenoid valve time is to be adjusted so that the sample tube e xtends into the product stream only

long enough to allow a representative sample to be collected and the desired sample size.

Extending the sample tube into the product stream for excessively

long periods of time can result

in unnecessary sample tube wear and can result in clogging of product flowing through the

conveying line and excessive sample size.

PNEG-2170 PLC Controller 27

Page 28

9. PLC Settings for GSS and GSS-U Sampler Operation

Sampler Operation Description

The GSS style sampler when operated in the timing mode and Automatic operates as follows. When the

AUTO mode is selected, the timer begins timing down. When the illuminated display reads all zeroes

(000), the timer has “timed out” and initiates a sampling cycle. The sample cycle begins when an electric

motor operating through a right angle gear reducer rotates the drive housing input shaft. Timer T1 is set

for the total time the motor will run. The clutch solenoid energizes at the same time allowing the auger tube

in the product line to rotate through one revolution to collect a sample. Timer T-2 is set long enough to

complete on revolution of the auger tube. As the auger tube rotates the sample auger also is turning and

continues to auger material out of the auger tube for a period of time after the auger tube stops rotating

and T1 times out. The timer display resets to the preset value and another timing interval is initiated. If the

controller is shut off or the mode switched from AUTO to MANUAL, the timing cycle is te rmin ated. When

power is restored or the AUTO mode is again selected, the display is reset to the preset value and another

cycle begins. NOTE: A new timing cycle can be initiated ONLY after the sampling cycle has completed.

GSS and GSS-U Sampler Operating Components

The GSS and GSS-U style sampler has three main operating components: the clutch solenoid to rotate

the auger tube, the sampler motor to rotate the sample auger and auger tube and a limit switch to stop the

tube rotation. Refer to the certified drawing(s).

GSS and GSS-U Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 10 Amp, 250 volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 5 Amp, 250 volt Slo-Blo fuse or equal.

GSS and GSS-U Sampler Program Mode

The GSS and GSS-U style sampler must be set to run on Program Mode 2 only. To change the program

mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters, press F3 for OK.

7. Press F1 for Program Mode.

8. Press F1 for Mode (the current sampler mode should be showing). To change sampler mode, pre ss

F1 until a 2 is showing on this line.

9. Press F2 to change the sampler timer setting. (Solenoid timer and Motor run timer.) The current value

should be showing on the right side of this line. See Chart on Page 29 for correct timer settings.

10. Press F1 to change the Solenoid time in seconds.

28 PNEG-2170 PLC Controller

Page 29

9. PLC Settings for GSS and GSS-U Sampler Operation

11. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. See Chart for the

correct timer setting. Once the correct time value has been entered, press the enter key .

12. Press F2 to change the Motor run time in seconds. The current value should be showing on the right

side of this line. See Chart for correct timer setting.

13. Using the Up/Down and Right/Left arrow keys to set the correct auger time. See Chart for the correct

timer setting. Once the correct time value has been entered, press the enter key .

14. Press F4 to return to Password Screen.

15. Press F4 to return to Main Screen.

GSS and GSS-U Sampler Timer Settings

The GSS and GSS-U style sampler has two timer setting which must be set for proper operation.

The timer setting is for the solenoid clutch time (T1) and the motor time (T2). See Chart for recommended

settings.

Sampler Size Clutch Solenoid (T1) Motor Time (T2)

GSS and GGS-U Settings 4 25

NOTE: Clutch solenoid time is to be adjusted so that the auger tube makes one revolution. When this

timer times out the solenoid will stay energized until the limit switch is activated. The activation of

the limit switch will de-engergize the clutch solenoid stopping the auger tube. If additional

revolutions are desired, add 6 seconds to the clutch solenoid and motor timer settings for each

additional revolution.

PNEG-2170 PLC Controller 29

Page 30

10. PLC Settings for GT, GRES and RS Sampler Operation

Sampler Operation Description

The RS style sampler when operated in the timing mode and Automatic operates as follows. When the

AUTO mode is selected, the timer begins timing down. When the illuminated display reads all zeroes

(000), the timer has “timed out” and initiates a sampling cycle. An internal none adjustable timer starts the

sample cycle until the sampler limit switch contacts are closed. The sample cutter will make one complete

revolution to collect a sample until the limit switch contacts open, stopping the cycle. The timer display

resets to the preset value and another timing interval is initiated. If the controller is shut off or the mode

switched from AUTO to MANUAL, the timing cycle is terminated. When power is restored or the AUTO

mode is again selected, the display is reset to the preset value and another cycle begins. NOTE: A new

timing cycle can be initiated ONLY after the sampling cycle has completed.

GT, GRES and RS Sampler Operating Components

The GT, GRES and RS consist of three components. A limit switch to stop the sampler, a motor for turning

the cutter and a brake for accurate positioning of the cutter. The GT, GRES and RS style sampler only

have one timer value which is not changeable in the PLC. This timer is to hold the starter contacts in until

the limit switch has come off of the cam. When this timer has timed out the control will then look for the

next limit switch opening. Refer to the certified drawing(s).

GT, GRES and RS Sampler Main Fuse (Refer to Certified Drawings)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 3 Amp, 250 Volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 2 Amp, 250 Volt Slo-Blo fuse or equal.

GT, GRES and RS Sampler Program Mode

The GT, GRES, RS style sampler must be set to run on Program Mode 3 only. To change the program

mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the UP/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

8. Press F1 for Mode (the current sampler mode should be showing). To change sampler mode press

F1 until a 3 is showing on this line.

9. Press F2 to change the sampler timer setting. (Extend timer.) The current value should be showing

on the right side of this line. See chart for correct timer settings.

10. Press F1 to change the the Off Limit Switch Timer in milliseconds.

11. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. See chart for the

correct timer setting. Once the correct time value has been entered, press the enter key .

12. Press F4 to return to Password Screen.

13. Press F4 to return to Main Screen.

30 PNEG-2170 PLC Controller

Page 31

11. PLC Settings for PRT and HD-PRT Sampler Operation

Sampler Operation Description

The PRT style sampler when operated in the timing mode and Automatic operates as follows. When the

AUTO mode is selected, the timer begins timing down. When the illuminated display reads all zeroes

(000), the timer has “timed out” and initiates a sampling cycle. The sample cycle begins by actuating a

double solenoid valve (V1A) to extend a pair of double a cting cylinders moving the probe into the product

stream. When fully extended LS-1 is closed. Next another set of double solenoid valves (V-2A) then rotate

a rotary actuator and probe clockwise (view from actuator end) through a 270° arc, exposing the sample

probe opening to the product stream. When fully rotated LS-4 closes, the first valve set (V-1B) energizes

to retract the double acting cylinders and probe from the product stream, isolating the sample and sample

probe cavity from the product stream. Once fully retracted LS-2 closes and the second valve set (V2B)

energizes to rotate the rotary actuator counterclockwise through the 270° arc to discharge the collected

sample. When fully rotated LS-3 closes. If the controller is shut off or the mode switched from AUTO to

MANUAL, the timing cycle is terminated. When power is restored or the AUTO mode is again selected,

the display is reset to the preset value and another cycle begins. NOTE: A new timing cycle can be initiated

ONLY after the sampling cycle has completed.

Sampler is programmed that if the probe does not make the retract cycle it will extend out and dump

material. Then rotate to collect more sample and try to retract. If the sampler does not successfully

complete the retract 3 times sampler will fault and will need to be manually reset.

PRT and HD-PRT Sampler Operating Components

The PRT and HD-PRT style sampler has six main operating components. Two Double soleno id valves to

extend, retract and rotate the sample probe. The other four components are the extend, retract, sample

and dump limit switches. Refer to the certified drawing(s).

PRT and HD-PRT Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 4 Amp, 250 Volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 2 Amp, 250 Volt Slo-Blo fuse or equal.

PRT and HD-PRT Sampler Program Mode and Solenoid Timer

The PRT and HD-PRT style sampler must be set to run on Program Mode 5 only. To change the program

mode follow the instructions below:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

8. Press F1 for Mode (the current sampler mode should be showing). To change sampler mode press

F1 until a 5 is showing on this line.

PNEG-2170 PLC Controller 31

Page 32

11. PLC Settings for PRT and HD-PRT Sampler Operation

9. Press F2 to change the sampler timer settings. (Solenoid timer and Motor run timer). The current

value should be showing on the right side of this line. See chart for correct timer settings.

10. Press F1 to change the Sample rotate timer in seconds.

11. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. See chart for the

correct timer setting. Once the correct time value has been entered, press the enter key .

12. Press F2 to change the Retract probe time in seconds. The curre nt value should be showing on the

right side of this line. See the following chart for correct timer setting.

13. Using the Up/Down and Right/Left arrow keys to set the correct auger time. See chart for the correct

timer setting. Once the correct time value has been entered, press the enter key .

14. Press F3 to change the Dump rotate timer in seconds.

15. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. See chart for the

correct timer setting. Once the correct time value has been entered, press the enter key .

16. Press F4 to return to Password Screen.

17. Press F4 to return to Main Screen.

32 PNEG-2170 PLC Controller

Page 33

12. PLC Settings for GRA and GCA Sampler Operation (550804)

Sampler Operation Description

The GRA style sampler when operated in the timing mode and Automatic operates as follows. When the

AUTO mode is selected, the timer begins timing down. When the illuminated display reads all zeroes

(000), the timer has “timed out” and initiates a sampling cycle. The sample pelican traverses from one side

to the other. The timer display resets to the preset value and another timing interval is initiated, note the

cycle will keep repeating. If the controller is shut off or the mode switched from AUTO to MANUAL, the

timing cycle is terminated. When power is restored or the AUTO mode is again selected, the display is

reset to the preset value and another cycle begins. NOTE: A new timing cycle can be initiated ONLY after

the sampling cycle has completed.

GRA and GCA Sampler Operating Components

The GRA and GCA style sampler has a distinctive operating sequence, which can not be adjusted. The

sampler is operated using a dual solenoid 4-way control valve. Refer to the certified drawing(s).

GRA and GCA Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 4 Amp, 250 Volt Slo-Blo fuse or equal.

For 220/240 VAC, 1 PH operation use ONLY a Buss Type FNM 2 Amp, 250 Volt Slo-Blo fuse or equal.

GRA and GCA Sampler Program Mode

The GRA, GCA sampler must be set to run on mode 1 if sampler has limit switches or mode 2 if the

sampler does not have limit switches. To change program mode, please follow the instructions below.

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

8. Press F1 for Mode (the current sampler mode should be showing). To change sampler mode press

F1 until a 1 is showing on this line. Or a 2 if the sampler does not have limit switches.

9. Press F4 to return to Password Screen.

10. Press F4 to return to Main Screen.

The GRA/GCA sampler operational parameters can be changed as outlined below:

1. Check to see sampler is in mode 1 or 2. Refer to above instructions.

2. Press F2 key for Timer Settings

3. Press F1 for Off limit switch timer. This is the amount of time the sampler needs to complete a

single traverse.

4. Press F2 positive seal is the time allowed to raise the positive seal before the sampler cycles.

5. Press F3 to delay the index of the sample cabinet after a sample has been taken.

PNEG-2170 PLC Controller 33

Page 34

13. PLC Settings for GPE Sampler Operation (550804)

Sampler Operation Description

The GPE style sampler when operated in the timing mode and automatic operates as follows. When the

AUTO mode is selected, the timer begins timing down. When the illuminated display reads all zeroes

(000), the timer has “timed out” and initiates a sampling cycle. The sample probe extends into the product

stream, the probe will extend and stay extended until the extend timer has timed out. Once the extend

timer has timed out, the sample probe will retract to home position. The timer display resets to the preset

value and another timing interval is initiated, note the cycle will keep repeating. If the controller is shut off

or the mode switched from AUTO to MANUAL, the timing cycle is terminated. When power is restored or

the AUTO mode is again selected, the display is reset to the preset value and another cycle begins.

NOTE: A new timing cycle can be initiated ONLY after the sampling cycle has completed.

GPE Sampler Operating Components

The GPE sampler has a distinctive operating sequence, which can not be adjusted. The sampler is

operated using an electric actuator to extend/retract the sample probe. Refer to the certified drawing(s).

GPE Sampler Main Fuse (Refer to Certified Drawing)

For 110/120 VAC, 1 PH operation use ONLY a Buss Type FNM 5 Amp, 250 Volt Slo-Blo fuse or equal.

GPE Sampler Program Mode

The GPE sampler must be set to run on mode 4. To change program mode, please follow the instructions

below.

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

8. Press F1 for Mode (the current sampler mode should be showing). To change sampler mode press

F1 until a 4 is showing on this line.

9. Press F4 to return to Password Screen.

10. Press F4 to return to Main Screen.

The GPE sampler operational parameters can be changed as outlined below:

1. Check to see sampler is in mode 4. See above instructions.

2. Press F2 key for Timer Settings.

3. Press F1 for Extend timer.

4. Using the arrow keys adjust the Extend time require value in seconds. Then press the enter .

5. Repeat for the additional timer settings. The retract timer should be set longer than the extend timer.

F3 Purge is to allow purging of the sample probe after the probe retracts.

34 PNEG-2170 PLC Controller

Page 35

14. PLC Settings for Index Cabinet and Other Options

Setting Controller to Operate Index Cabinet and Setting Up

Index Cabinet

The PLC controller has the ability to operate a standard index cabinet with all samplers except the PRT

and HD-PRT. If an index cabinet is to be used with a PRT or HD-PRT sampler a special control with more

inputs and outputs are required. Due to the different sizes and styles of index cabinets, it is necessary to

enter in specific information of how many jars per cabinet and how many samples per jar are required.

Refer to the certified drawing(s). To add an index cabinet to the sampler control and enter these values:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F2 for Option Settings.

8. Press F2 for Indexer Setup.

9. Press F1 to toggle indexer OFF or ON.

10. Press F2 to change the total number of jars in cabinet. The current value should be showing on the

right side of this line.

11. Using the Up/Down and Right/Left arrow keys to set the change the number of jars in the cabinet.

Once the correct number of jars has been entered, press the enter key .

12. Press F3 to change the Number of samples per jar. The current value should be showin g on the right

side of this line.

13. Using the Up/Down and Right/Left arrow keys to set the correct solenoid time. Once the correct

number of samples per jar has been entered, press the enter key .

14. Press F4 to return to Password Screen.

15. Press F4 to return to Main Screen.

Index Cabinet Delay Before Indexing

The controller can be adjusted to accommodated for different distances between the sampler and index

cabinet. Timer T7 is used to delay the index cabinet before it indexes, allowing the sample to travel from

the sampler to the index cabinet. This delay is set in seconds the range of delay is 2-9999 seconds. To

change this value:

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

PNEG-2170 PLC Controller 35

Page 36

14. PLC Settings for Index Cabinet and Other Options

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F1 for Program Mode.

8. Press F2 for Timer Settings.

9. Press F3 for Index Delay timer. The current value should be showing on the right side of this line.

10. Using the Up/Down and Right/Left arrow keys to set the change the number of jars in the cabinet.

Once the correct number of jars has been entered, press the enter key .

11. Press F4 to return to Password Screen.

12. Press F4 to return to Main Screen.

Sample Purge Option

For the PS, PS-XP, HD-PP, PT, PTG, LF, GS and GP style samplers a sample purge option is available.

1. Turn power ON.

2. Press F4 key for Settings.

3. Press F3 for Sample Selection.

4. If prompted for the User enter 1 followed by enter key .

5. Enter Password screen will appear. Using the Up/Down arrow keys on the right side to adjust number

values and the Left/Right arrow keys on the left side to change position enter 1500 followed by the

enter key .

6. Caution Changing Sampler Parameters press F3 for OK.

7. Press F2 for Option Settings.

8. Press F3 for Purge Off. Press F3 to toggle the purge ON and OFF.

9. Press F4 to return to Password Screen.

10. Press F4 to return to Main Screen.

The sample purge for a PS style sampler is ON for the length of the auger run time T2. On the PT style

samplers, the sample purge timer will turn ON when the T1 times out add will stay on for the time set in

T2. Timer T2 is set in seconds, use only enough time to purge the system as necessary. To change the

time length of the a purge cycle:

1. Turn power ON.

2. Press MENU key.

3. Press 2 for settings.

4. Press 2 for change settings.

5. Press 2 for system values.

6. Press 1 for start-up set.

7. Enter in the above time value for T2 then press the NEXT key or the enter key .

8. Press MENU key to return to the starting menu.

36 PNEG-2170 PLC Controller

Page 37

14. PLC Settings for Index Cabinet and Other Options

Remote Enable

Each control is shipped with a jumper wire installed in the remote enable terminal strip (TB 1 and 2). The

remote enable signal allows the end user when in automatic to start and stop the sampler in conjunction

with the process system (i.e. conveyor, gate, etc). This prevents the sampler from operating when it is not

required. If remote enable is not required, the jumper wire must be installed unless the system is set-up

for counting. If the controller is set-up for counting the remote enable contacts are used for the input pulse

from an outside source. See counter mode on Page 20 for further information.

PNEG-2170 PLC Controller 37

Page 38

15. Maintenance and Repair

Failure to observe all safety rules, written and implied and those suggested by

common sense, can result in death, serious injury and/or equipment damage.

Lock out power before performing any maintenance.

General Maintenance

A good maintenance program involves thorough general housekeeping and inspection and replace worn

or damaged components.

Periodic Inspection

At regularly scheduled intervals, while observing all safety precautions, observe the sampler and control

as it operates. Inspect for:

1. Loose or missing hardware

2. Noisy motor or motor/reducer bearings

3. Overheated motor or reducer

4. Adequate lubricant in lubricator

5. Structural damage

6. Rust or corrosion

7. Damaged wiring and conduit, exposed conductors and connections

8. Damaged airlines or pneumatic components

9. Make sure that all guards are in place and that all warning labels are in place and legible.

See Page 9, GENERAL SAFETY INFORMATION, explains the purpose and intended location

of the warning signs. Warning signs are an important part of any safety program, replace any missing

signs IMMEDIATELY.

38 PNEG-2170 PLC Controller

Page 39

PLC Control Troubleshooting

Symptom Possible Cause Corrective Action

16. Troubleshooting

Motor fuse blows continuously.

Main power light does not turn

ON.

No input or output lights turn

ON.

Output light turns ON no

sampler function.

Motor wired improperly.

Motor jammed. Inspect and replace.

Auger seized up in sampler.

Sampler wired incorrectly. Verify wiring. Refer to certified print.

Fuse 1 is bad. Check fuse. Replace if bad.

Light burned out. Check light. Replace if bad.

Fuse 2 is bad. Check fuse. Replace if bad.

Sampler wired wrong. Verify wiring. Refer to certified print.

Control not in correct mode. Verify mode and mode setting.

Sampler wire wrong. Verify wiring. Refer to certified print.

Control relay bad.

Correct. Refer to the certified

electrical schematic.

Inspect and replace. Refer to Sampler

Manual.

Check relay to see if indicator flag

shows up on relay when energized.

Replace relay if bad.

Control works in MANUAL but

not AUTOMATIC

When index cabinet in

activated, index cabinet motor

does not stop.

Main power light ON, but LED

screen does not light up.

LED display shows “WAITING

FOR ENABLE”.

Remote enable not ON.

Index cabinet turned ON but not

wired to control

Index cabinet limit switch wired

wrong.

Cable loose between keypad and

PLC.

The remote enable contact

terminals 1 and 2 is not closed.

Check Remote enable signal. Input

0 should be ON. If not check wiring.

Turn index cabinet option OFF. Then

cycle power to reset control.

Verify limit switch wiring. Refer to

certified print.

Check both ends of cable to ensure

they are properly seated.

Install remote enable jumper or

verify the customer supplied dry

contact is functioning properly.

PNEG-2170 PLC Controller 39

Page 40

NOTES

40 PNEG-2170 PLC Controller

Page 41

17. Warranty

InterSystems, Inc. reserves the right to make changes in design or in construction of equipment and components without

obligation to incorporate such changes in equipment and components previously ordered.

WARRANTY, LIMITATION OF LIABILITY, DISCLAIMER OF IMPLIED WARRANTIES: InterSystems, Inc. manufactured

equipment and components are guaranteed against defects in workmanship or materials for one year from date of

shipment. The obligation of InterSystems, Inc. with respect to any goods is limited to replacement or repair of defective

parts and equipment provided those parts are returned, shipping costs prepaid, to InterSystems' factory and provided the

product has not been subject to misuse, negligence, or accident, or repaired or altered outside of our factory, or other than

by an Authorized Service Representative. This warranty does not cover the replacement of parts inoperative because of

wear occasioned by use, the cost of replacing parts by a person other than an InterSystems employee or an Authorized

Service Representative, or the adjustment of a product where the product was improperly adjusted by the purchaser. In

addition, this warranty does not cover components manufactured by others such as motors, drives, clutches, cylinders,

valves, blowers, and the like. On those components the standard Manufacturers' warranty applies. In any event, liability is

limited to the purchase price paid, and InterSystems, Inc. will, under no circumstances, be responsible for special or

consequential damages, or for incidental damages.

INTERSYSTEMS, INC. NEITHER MAKES NOR AUTHORIZES ANY WARRANTY OTHER THAN AS HEREIN