Page 1

MAGNA3

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

MAGNA3

Table of contents

English (US)

Installation and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Español (MX)

Instrucciones de instalación y funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Français (CA)

Notice d'installation et de fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2

Page 3

English (US) Installation and operating instructions

Original installation and operating instructions.

CONTENTS

1. Limited warranty

2. Symbols used in this document

3. General information

3.1 Applications

3.2 Pumped liquids

3.3 Operating conditions

3.4 Frost protection

3.5 Insulating shells

3.6 Non-return valve

3.7 Nameplate

3.8 Radio communication

3.9 Tools

4. Mechanical installation

4.1 Installing the pump

4.2 Positioning

4.3 Control box positions

4.4 Pump head position

4.5 Changing the control box position

5. Electrical installation

5.1 Supply voltage

5.2 Connection to the power supply (models 40-XX,

50-XX, 65-XX, 80-XX, 100-XX)

5.3 Connection to the power supply (models 32-XX)

5.4 Connection diagram

5.5 Input/output communication

5.6 Analog input for external sensor

5.7 Electrical connection for external sensor

5.8 Priority of settings

6. First start-up

7. Settings

7.1 Overview of settings

8. Menu overview

9. Control panel

10. Menu structure

11. "Home" menu

12. "Status" menu

13. "Settings" menu

13.1 Setpoint

13.2 Operating mode

13.3 Control mode

13.4 FLOW

13.5 Automatic Night Setback

13.6 Relay outputs

13.7 Setpoint influence

13.8 Bus communication

13.9 General settings

14. "Assist" menu

14.1 Assisted pump setup

14.2 Setting of date and time

14.3 Multi-pump setup

14.4 Setup, analog input

14.5 Description of control mode

14.6 Assisted fault advice

14.7 Wireless GENIair

14.8 Multi-pump function

LIMIT

Page

10

11

12

12

13

14

16

18

19

19

20

21

21

22

23

23

23

24

24

24

25

25

29

29

30

30

31

31

35

35

35

35

35

35

35

35

35

15. Selection of control mode

16. Fault finding

16.1 Grundfos Eye operating indications

16.2 Signalling communication with remote control

4

4

5

5

5

6

6

6

6

7

8

8

8

8

9

9

9

16.3 Fault finding

17. Sensor

17.1 Sensor specifications

18. Accessories

18.1 Grundfos GO Remote

18.2 Communication

18.3 Fitting the CIM module

19. Technical data

20. Disposal

Warnin g

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warnin g

The use of this product requires experience with

and knowledge of the product.

Persons with reduced physical, sensory or

mental capabilities must not use this product,

unless they are under supervision or have been

instructed in the use of the product by a person

responsible for their safety.

Children must not use or play with this product.

36

38

38

38

39

40

40

41

41

41

44

45

45

English (US)

3

Page 4

English (US)

Caution

Note

Note

1. Limited warranty

Products manufactured by GRUNDFOS PUMPS CORPORATION

(Grundfos) are warranted to the original user only to be free of

defects in material and workmanship for a period of 24 months

from date of installation, but not more than 30 months from date

of manufacture. Grundfos' liability under this warranty shall be

limited to repairing or replacing at Grundfos' option, without

charge, F.O.B. Grundfos' factory or authorized service station,

any product of Grundfos' manufacture. Grundfos will not be liable

for any costs of removal, installation, transportation, or any other

charges which may arise in connection with a warranty claim.

Products which are sold but not manufactured by Grundfos are

subject to the warranty provided by the manufacturer of said

products and not by Grundfos' warranty. Grundfos will not be

liable for damage or wear to products caused by abnormal

operating conditions, accident, abuse, misuse, unauthorized

alteration or repair, or if the product was not installed in

accordance with Grundfos' printed installation and operating

instructions.

To obtain service under this warranty, the defective product must

be returned to the distributor or dealer of Grundfos' products from

which it was purchased together with proof of purchase and

installation date, failure date, and supporting installation data.

Unless otherwise provided, the distributor or dealer will contact

Grundfos or an authorized service station for instructions.

Any defective product to be returned to Grundfos or a service

station must be sent freight prepaid; documentation supporting

the warranty claim and/or a Return Material Authorization must

be included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES

ARISING FROM INSTALLATION, USE, OR ANY OTHER

CAUSES. THERE ARE NO EXPRESS OR IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND

THOSE WARRANTIES DESCRIBED OR REFERRED TO

ABOVE.

Some jurisdictions do not allow the exclusion or limitation of

incidental or consequential damages and some jurisdictions do

not allow limit actions on how long implied warranties may last.

Therefore, the above limitations or exclusions may not apply to

you. This warranty gives you specific legal rights and you may

also have other rights which vary from jurisdiction to jurisdiction.

2. Symbols used in this document

Warnin g

If these safety instructions are not observed,

it may result in personal injury.

Warnin g

If these instructions are not observed, it may lead

to electric shock with consequent risk of serious

personal injury or death.

Warnin g

The surface of the product may be so hot that

it may cause burns or personal injury.

Warnin g

Risk of dropping objects which may cause

personal injury.

Warnin g

Escaping vapor involves the risk of personal

injury.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

Notes or instructions that make the job easier

and ensure safe operation.

4

Page 5

3. General information

Note

Note

Max. 95 % RH

Enclosure Type 2

The Grundfos MAGNA3 is a complete range of circulator pumps

with integrated controller enabling adjustment of pump

performance to the actual system requirements. In many

systems, this will reduce the power consumption considerably,

reduce noise from thermostatic radiator valves and similar fittings

and improve the control of the system.

The desired head can be set on the pump control panel.

3.1 Applications

The Grundfos MAGNA3 is designed for circulating liquids in the

following systems:

• heating systems

• domestic hot-water systems

• air-conditioning and cooling systems.

The pump can also be used in the following systems:

• ground source heat pump systems

• solar-heating systems.

3.2 Pumped liquids

The pump is suitable for thin, clean, non-aggressive and

non-explosive liquids, not containing solid particles or fibers that

may attack the pump mechanically or chemically.

In heating systems, the water should meet the requirements of

accepted standards on water quality in heating systems.

In domestic hot-water systems, we recommend to use MAGNA3

pumps only for water with a degree of hardness lower than

approx. 14 °dH.

In domestic hot-water systems, we recommend to keep the liquid

temperature below 150 °F (+65 °C) to eliminate the risk of lime

precipitation.

Warnin g

Do not use the pump for flammable liquids, such

as diesel oil and gasoline.

Warnin g

Do not use the pump for aggressive liquids, such

as acids and sea water.

English (US)

TM05 2857 0612

Fig. 1 Pumped liquids

3.2.1 Glycol

The pump can be used for pumping water/glycol mixtures up to

50 %.

Example of a water/ethylene glycol mixture:

Maximum viscosity: 50 cSt ~ 50 % water / 50 % ethylene glycol

mixture at +14 °F (-10 °C).

The pump has a power-limiting function that protects against

overload.

The pumping of glycol mixtures will affect the max. curve and

reduce the performance, depending on the water/ethylene glycol

mixture and the liquid temperature.

To prevent the ethylene glycol mixture from degrading, avoid

temperatures exceeding the rated liquid temperature and

minimize the operating time at high temperatures.

It is important to clean and flush the system before the ethylene

glycol mixture is added.

To prevent corrosion or lime precipitation, check and maintain the

ethylene glycol mixture regularly. If further dilution of the supplied

ethylene glycol is required, follow the glycol supplier's

instructions.

Additives with a density and/or kinematic

viscosity higher than those/that of water will

reduce the hydraulic performance.

5

Page 6

English (US)

Caution

Note

Note

Min./Max. +14 °F - 230 °F

(-10 °C - +110 °C)

175 psi (12 bar)

1

2

3

4

+32 to +104 °F

(0 to +40 °C)

< 43 dB(A)

Note

Note

Caution

3.3 Operating conditions

Fig. 2 Operating conditions

3.3.1 Liquid temperature

See fig. 2, pos. 1.

Continuously: +14 °F to +230 °F (-10 °C to +110 °C).

Domestic hot-water systems:

• Up to +150 °F (+65 °C).

3.3.2 System pressure

See fig. 2, pos. 2.

The maximum permissible system pressure is stated on the pump

nameplate.

3.3.3 Ambient temperature

See fig. 2, pos. 3.

+32 °F to +104 °F (0 °C to +40 °C).

The control box is air-cooled. Therefore, it is important that the

maximum permissible ambient temperature is not exceeded

during operation.

During transport: -40 °F to +158 °F (-40 °C to +70 °C).

3.3.4 Sound pressure level

See fig. 2, pos. 4.

The sound pressure level of the pump is lower than 43 dB(A).

3.3.5 Approvals

• Conforms to ANSI/UL Standard 778.

• Certified to CAN/CSA Standard C22.2 No. 108.

• The protective earth (ground) symbol identifies any

terminal which is intended for connection to an external

conductor for protection against electric shock in case of a

fault, or the terminal of a protective earth (ground) electrode.

3.5 Insulating shells

Insulating shells are available for single-head pumps only.

Limit the heat loss from the pump housing and

pipework.

The heat loss from the pump and pipework can be reduced by

insulating the pump housing and the pipework. See fig. 3 and

fig. 13.

• Insulating shells for pumps in heating systems are supplied

with the pump; see fig. 3.

• For pumps in air-conditioning and cooling systems (down to

+14 ° (-10 °C)) it is required to apply a silicon sealant to the

internal contours of the shell in order to eliminate any air gaps

and prevent condensation between the insulation shell and

pump housing. Alternatively, the pump can also be insulated

manually in accordance with standard insulating requirements

for heating and cooling systems (fig. 13).

The fitting of insulating shells will increase the pump dimensions.

TM05 7662 1413

TM05 2859 0612

Fig. 3 Fitting insulating shells to the pump

Do not insulate the control box or cover the

control panel.

3.6 Non-return valve

If a non-return valve is fitted in the pipe system (fig. 4), it must be

ensured that the set minimum discharge pressure of the pump is

always higher than the closing pressure of the valve. This is

especially important in proportional-pressure control mode

(reduced head at low flow). The closing pressure of a single

non-return valve is accounted for in the pump settings as the

minimum head delivered is 5 ft (1.5 m).

3.4 Frost protection

6

If the pump is not used during periods of frost,

necessary steps must be taken to prevent frost

bursts.

Additives with a density and/or kinematic

viscosity higher than those/that of water will

reduce the hydraulic performance.

TM05 3055 0912

Fig. 4 Non-return valve

Page 7

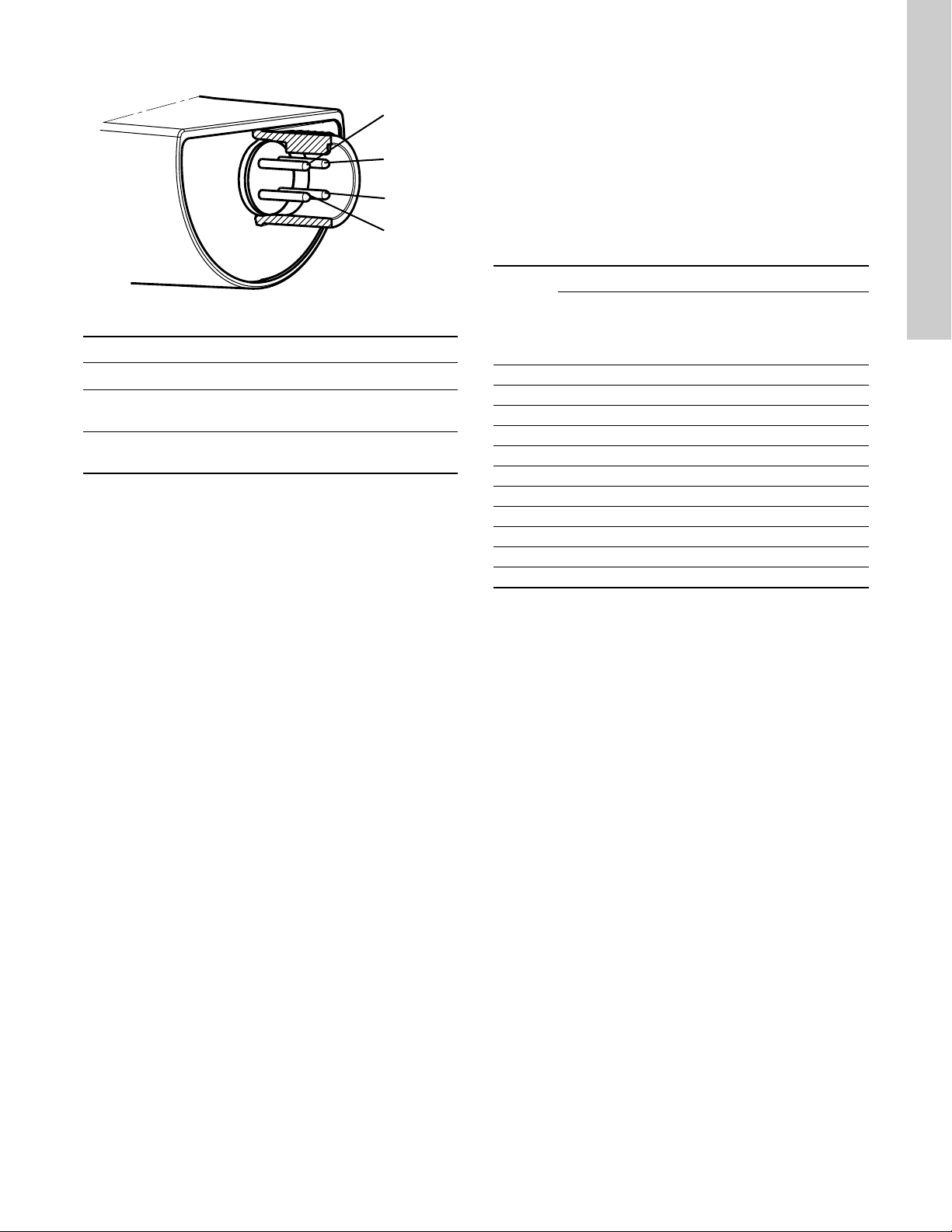

3.7 Nameplate

RISQUE DE CHOC ELECTRIQUE. HORS DES EQUIPEMENT AVANT ENLEVEMENT DE LA COUVERTURE ET D’ENTRENTIEN. POUR

LE RECCORDEMENT D’ALIMENTATION, EMPLOYEZ DES FILS QUI RESISTENT AU MOINS A 90 °C UTILISEZ UNIQUEMENT DES

CONDUCTEURS DE CUIVRE. POUR RE’DUIRE LES RISQUES DE CHOC E’LECTRIQUE, CONSULTES LE MANUEL D’INSTRUCTIONS

POUR UNE INSTALLATION CORRECTE. EMPLOYER UNIQUEMENT A L’INTERIEUR.

TYPE 2

BOITIER DE TYPE 2

THERMALLY PROTECTED

Nonsubmersible Pump

RISK OF ELECTRIC SHOCK. DE-ENERGIZE EQUIPMENT BEFORE REMOVAL OF COVER & SERVICING. FOR SUPPLY

CONNECTION USE COPPER WIRE SUITABLE FOR 90 °C OR EQUIVALENT. THIS PUMP HAS NOT BEEN INVESTIGATED FOR USE

IN SWIMMING POOL OR MARINE AREAS. TO REDUCE THE RISK OF ELECTRIC SHOCK, SEE INSTRUCTION MANUAL FOR

PROPER INSTALLATION; ACCEPTABLE FOR INDOOR USE ONLY.

PSI

For use with maximum 230° F water

Contains FCC ID: OG3-RADIOM01-2G4

The pump nameplate provides the following information:

Fig. 5 Example of nameplate

Pos. Description

1 Product name

2 Model

3 Production code (year and week)

4 Serial number

5 Product number

6 Enclosure type

7 Energy Efficiency Index (EEI)

8 Part (according to EEI)

9 TF-class

10 Minimum current [A]

11 Maximum current [A]

12 Minimum power [W]

13 Maximum power [W]

14 Maximum pressure

15 Voltage [V] and frequency [Hz]

16 QR (Quick Response) code

17 Approvals (nameplate)

18 Assembled in USA

English (US)

TM05 6381 4612

7

Page 8

English (US)

1.2 x 8.0 TX200.6 x 3.5 5.0

1

2

3

4

5

6

7

3.8 Radio communication

The wireless radio in this product is class B.

Intended use

This product incorporates a radio for remote control.

The product can communicate with Grundfos Go Remote and

with other MAGNA3 pumps of the same type via the built-in radio.

Only Grundfos-approved external antennae may be connected to

this product, and only by a Grundfos-approved installer.

3.9 Tools

4. Mechanical installation

4.1 Installing the pump

MAGNA3 is designed for indoor installation.

The pump must be installed in such a way that it is not stressed

by the pipework.

The pump may be suspended direct in the pipes, provided that

the pipework can support the pump.

Twin-head pumps are prepared for installation on a mounting

bracket or base plate.

To ensure adequate cooling of motor and electronics, the

following must be observed:

• Position the pump in such a way that sufficient cooling is

ensured.

• The temperature of the ambient air must not exceed +104 °F

(+40 °C).

Warnin g

Observe local regulations setting limits for

manual lifting or handling.

Fig. 6 Recommended tools

Pos. Tool Size

1 Screwdriver, straight slot 1.2 x 8.0 mm

2 Screwdriver, straight slot 0.6 x 3.5 mm

3 Screwdriver, torx bit TX20

4 Hexagon key 5.0 mm

5 Open-end wrench

6 Wire cutter

Depending on flange bolt

size

7Pipe wrench

Step Action Illustration

Arrows on the pump housing

indicate the liquid flow direction

through the pump. The liquid

1

flow direction can be horizontal

or vertical, depending on the

control box position.

TM05 6472 4712

TM05 2862 0612

Close the isolating valves and

make sure that the system is not

2

pressurized during the

installation of the pump.

TM05 2863 0612

Mount the pump with gaskets in

3

the pipework.

TM05 2864 0612

Fit bolts and nuts. Use the right

4

size of bolts according to system

pressure.

TM05 2865 0612

8

Page 9

4.2 Positioning

A

B

CD

Always install the pump with horizontal motor shaft.

• Pump installed correctly in a vertical pipe. See fig. 7, pos. A.

• Pump installed correctly in a horizontal pipe. See fig. 7, pos. B.

• Do not install the pump with vertical motor shaft. See fig. 7,

pos. C and D.

If the pump head is removed before the pump is installed in the

pipework, pay special attention when fitting the pump head to the

pump housing:

1. Gently lower the pump head with rotor shaft and impeller into

the pump housing.

2. Make sure that the contact face of the pump housing and that

of the pump head are in contact before the clamp is tightened.

See fig. 9.

English (US)

Fig. 7 Pump installed with horizontal motor shaft

4.3 Control box positions

To ensure adequate cooling, the control box must be in horizontal

position with the Grundfos logo in vertical position. See fig. 8.

TM05 2866 0712TM05 2915 0612

Fig. 9 Fitting the pump head to the pump housing

4.4 Pump head position

If the pump head is removed before the pump is installed in the

pipework, pay special attention when fitting the pump head to the

pump housing:

3. Visually check that the floating ring in the sealing system is

centered. See figs. 10 and 11.

4. Gently lower the pump head with rotor shaft and impeller into

the pump housing.

5. Make sure that the contact face of the pump housing and that

of the pump head are in contact before the clamp is tightened.

See fig. 12.

TM05 5837 4112TM05 6650 5012

Fig. 8 Pump with control box in horizontal position

Fig. 10 Correctly centered sealing system

9

Page 10

English (US)

Caution

Fig. 11 Incorrectly centered sealing system

Observe the position of the clamp before the

clamp is tightened. Incorrect position of the

clamp will cause leakage from the pump and

damage the hydraulic parts in the pump head.

See fig. 12.

4.5 Changing the control box position

Warnin g

The warning symbol on the clamp holding the

pump head and pump housing together indicates

that there is a risk of personal injury. S ee specific

warnings below.

Warnin g

When loosening the clamp, do not drop the pump

head.

Warning

Risk of escaping vapor.

Step Action Illustration

TM05 6651 5012

Loosen the screw in the clamp

holding the pump head and pump

housing together.

Warning: If the screw is loosened

1

too much, the pump head will be

completely disconnected from the

pump housing.

Carefully rotate the pump head to

the desired position.

If the pump head is stuck, loosen it

2

with a light blow of a rubber

mallet.

TM05 2867 0612

TM05 2868 0612

Fig. 12 Fitting the pump head to the pump housing

Position the control box in

horizontal position so that the

Grundfos logo is in vertical

3

position. The motor shaft must be

horizontal.

TM05 2869 0612

TM05 5837 4112

Due to the drain hole in the stator

housing, position the gap of the

4

clamp as shown in step 4a, 4b, 4c

or 4d.

TM05 2870 0612

Single-head pump.

Position the clamp so that the gap

4a

points towards the arrow.

It can be in position 3 or 9 o'clock.

TM05 2918 0612 - TM05 2871 0612

10

Page 11

Caution

Step Action Illustration

Note

Note

Single-head pump.

Note: The gap of the clamp can

also be in position 6 o'clock for the

following pump sizes:

4b

• MAGNA3 65-XX

• MAGNA3 80-XX

• MAGNA3 100-XX.

Twin-head pump.

Position the clamps so that the

gaps point towards the arrows.

4c

They can be in position 3 or

9o'clock.

Twin-head pump.

Note: The gap of the clamp can

also be in position 6 o'clock for the

following pump sizes:

4d

• MAGNA3 65-XX

• MAGNA3 80-XX

• MAGNA3 100-XX.

Fit and tighten the screw holding

6

the clamp to minimum

6 ± 0.7 ft-lbs (8 ± 1 Nm).

Fit the insulating shells.

Note: For air conditioning and

cooling systems a silicone sealant

must be applied inside the

insulation shell to eliminate all air

gaps and prevent condensation

7

between the pump housing and

insulation shell. Alternatively, the

pump may be insulated manually

in accordance with standard

insulation practices for cooling

applications.

5. Electrical installation

Carry out the electrical connection and protection according to

TM05 2899 1912

local regulations.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

Warnin g

Never make any connections in the pump control

box unless the power supply has been switched

off for at least 5 minutes.

Warnin g

TM05 2917 0612 - TM05 2873 0612

TM05 2897 1912

• If rigid conduit is to be used, the hub must be connected to the

conduit system before it is connected to the terminal box of the

TM05 2872 0612

pump.

• The pump must be connected to an external mains switch.

• The pump requires no external motor protection.

• The motor incorporates thermal protection against slow

overloading and blocking.

• When switched on via the power supply, the pump will start

pumping after approx. 5 seconds.

TM05 2874 0412

The pump must be connected to an external

mains switch with a contact separation of at least

1/8 inch (3 mm) in each pole.

The ground terminal of the pump must be

connected to ground. Grounding or

neutralization can be used for protection against

indirect contact.

If the pump is connected to an electric

installation where a Ground Fault Circuit

Interrupter (GFCI) is used as additional

protection, this circuit interrupter must trip out

when ground fault currents with DC content

(pulsating DC) occur.

The number of starts and stops via the power

supply must not exceed four times per hour.

English (US)

If insulating the pump manually, do not insulate

the control box or cover the control panel.

TM05 5549 3812

Fig. 13 Insulation of pump housing and pipework

11

Page 12

English (US)

5.1 Supply voltage

1 x 115 V ± 10 %, 50/60 Hz, PE.

1 x 208-230 V ± 10 %, 50/60 Hz, PE.

See pump nameplate for rated supply voltage

The voltage tolerances are intended for mains voltage variations.

They should not be used for running pumps at other voltages than

those stated on the nameplate.

5.2 Connection to the power supply (models 40-XX, 50-XX, 65-XX, 80-XX, 100-XX)

Step Action Illustration

Connect the cable

conductors to the

power supply plug.

6

L - L or L1

Ground - Ground

N - N or L2

Step Action Illustration

Remove the front

1

cover from the

control box.

Locate the power

supply plug and

conduit adapter in

2

the box supplied

with the pump.

Connect the

3

conduit adapter to

the control box.

TM05 2880 0612

Insert the power

supply plug into

the male plug in

TM05 2875 0612

7

the pump control

box.

TM05 2881 0612

TM05 2876 0612

Tighten the

conduit adapter.

8

Refit the front

cover.

TM05 2882 0612

Pull the power

supply cable

4

through the

conduit adapter.

Strip the cable

5

conductors as

illustrated.

TM05 2877 0612

TM05 2878 0612

TM05 5534 3812

12

Page 13

5.3 Connection to the power supply (models 32-XX)

L (L1) N (L2)

Step Action Illustration

Remove two

screws.

Remove the front

cover from the

1

control box and

access the power

connection.

Locate the power

2

plug inside.

Connect the

conduit to the

control box.

3

Pull the power

supply cable

through the

conduit.

Step Action Illustration

Refit the front

7

cover.

TM06 1102 1614

TM06 1103 1614

English (US)

TM06 1107 1614

Strip the cable as

illustrated.

Connect the cable

5

conductors to the

power supply plug.

L - L or L1

Ground - Ground

N - N or L2

Insert the power

plug into its mating

connector.

6

Tighten the

conduit.

TM06 1104 1614

TM06 1105 1614

TM06 1106 1614

13

Page 14

English (US)

External switch

Fuse

(min. 10 A, time lag)

GFCI

Note

Note

NC NO C NC NO C

NL

S/S

M

I

M

A

signal

sensor

Vcc

24V

IN

Mains

connection

Alarm

Operation

Start/

stop

On/off timer

Analog input

Note

Note

5.4 Connection diagram

TM03 2397 0312

Fig. 14 Example of typical connection, 1 x 230 V ± 10 %, 50/60 Hz

All cables used must be connected in accordance with local regulations.

5.4.1 Connection to external controllers

Fig. 15 Example of connections in the control box

Warnin g

Wires connected to supply terminals, outputs

NC, NO, C and start/stop input must be separated

from each other and from the supply by

reinforced insulation.

Concerning demands on signal wires and signal transmitters, see

section 19. Technical data.

Use screened cables for external on/off switch, digital input,

sensor and setpoint signals.

All cables used must be heat-resistant up to

+185 °F (+85 °C).

14

TM05 2673 3812

Page 15

Note

Note

Fig. 16 Wiring diagram, 32-XX versions

English (US)

TM05 8539 2413

The connection terminals of 32-XX versions differ from those of

terminal-connected versions, but they have the same function

and connection options.

Use screened cables for external on/off switch, digital input,

sensor and setpoint signals.

Connect screened cables to the ground connection as follows:

• Terminal-connected versions:

Connect the cable screen to ground via the digital-input

terminal (earth).

• Plug-connected versions:

Connect the cable screen to ground via cable clamp.

Warnin g

Wires connected to supply terminals, outputs

NC, NO, C and start/stop input must be separated

from each other and from the supply by

reinforced insulation.

All cables used must be heat-resistant up to

+85 °C.

All cables used must be installed in accordance

with EN 60204-1 and EN 50174-2:2000.

15

Page 16

English (US)

NC NO C NC NO C

Alarm

Operation

Relay 1 Relay 2

132

NC NO C

132

NC NO C

12 3

NC NO C

132

NC NO C

132

NC NO C

12 3

NC NO C

132

NC NO C

132

NC NO C

12 3

NC NO C

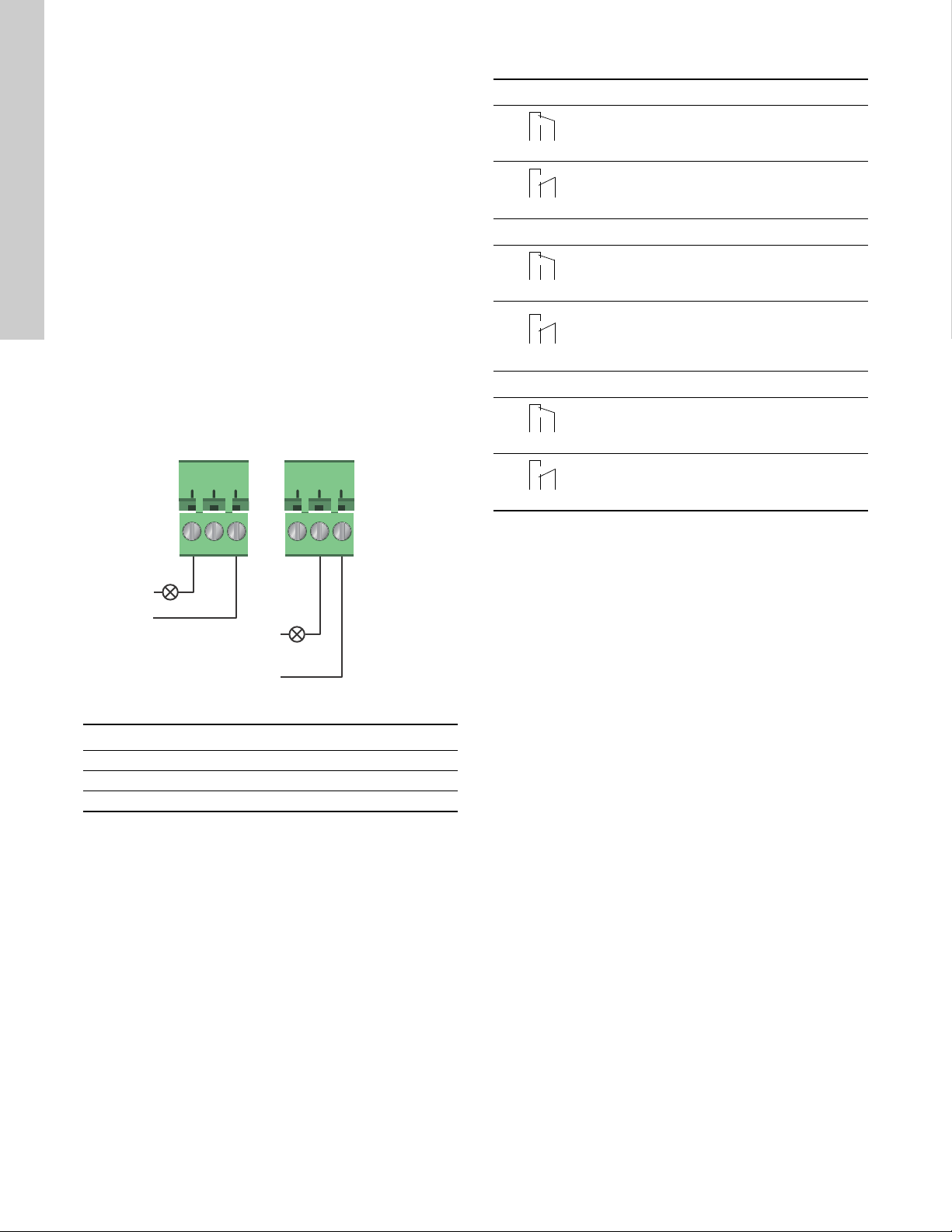

5.5 Input/output communication

• Relay outputs

Alarm, ready and operating indication via signal relay.

• Digital input

– Start/Stop (S/S)

– Min. curve (MI)

– Max. curve (MA).

• Analog input

0-10 V or 4-20 mA control signal.

To be used for external control of the pump or as sensor input

for the control of the external setpoint.

The 24 V supply from pump to sensor is optional and is

normally used when an external supply is not available.

5.5.1 Relay outputs

See fig. 15, pos. 1.

The pump incorporates two signal relays with a potential-free

changeover contact for external fault indication.

The function of the signal relay can be set to "Alarm", "Ready" or

"Operation" on the pump control panel or with Grundfos GO

Remote.

The relays can be used for outputs up to 250 V and 2 A.

The functions of the signal relays appear from the table below:

Signal relay Alarm signal

Not activated:

• The power supply has been switched off.

• The pump has not registered a fault.

Activated:

• The pump has registered a fault.

Signal relay Ready signal

Not activated:

• The pump has registered a fault and is

unable to run.

Activated:

• The pump has been set to stop, but is ready

to run.

• The pump is running.

Signal relay Operating signal

Not activated:

• The pump is not running.

Activated:

• The pump is running.

Fig. 17 Relay output

Contact symbol Function

NC Normally closed

NO Normally open

C Common

TM05 3338 1212

16

Page 17

5.5.2 Digital inputs

S/S

M

I

M

A

On/off timer

Start/stop

S/S

S/S

M

A

M

A

Q

H

M

I

M

I

Q

H

See fig. 15, pos. 2.

The digital input can be used for external control of start/stop or

forced max. or min. curve.

If no external on/off switch is connected, the jumper between

terminals Start/Stop (S/S) and frame ( ) should be maintained.

This connection is the factory setting.

External forced max. or min. curve

The pump can be forced to operate on the max. or min. curve via

the digital input.

Max. curve

H

Normal duty

Q

Max. curve

Min. curve

H

Normal duty

Q

Min. curve

Select the function of the digital input on the pump control panel

or with Grundfos GO Remote.

English (US)

Fig. 18 Digital input

Contact symbol Function

M

A

M

I

S/S Start/Stop

External start/stop

The pump can be started or stopped via the digital input.

Start/stop

H

Q

H

Q

Max. curve

100 % speed

Min. curve

25 % speed

Frame connection

Normal duty

Note: Factory setting with

jumper between S/S and .

Stop

TM05 3339 1212

17

Page 18

English (US)

signal

sensor

Vcc

24V

I

N

-+

Sensor

Sensor

24V

IN

Vcc

Signal

1

2

24V

BMS

PLC

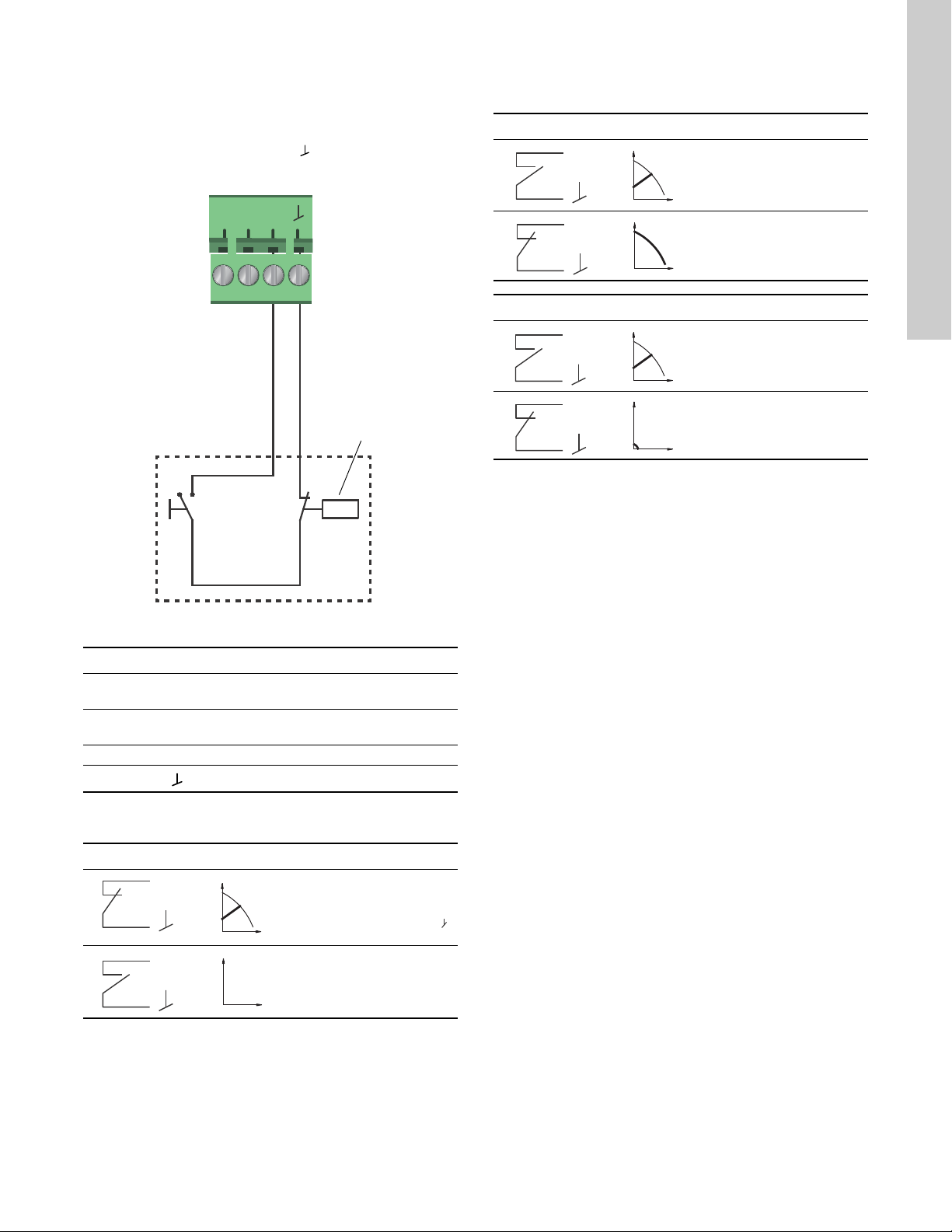

5.6 Analog input for external sensor

The analog input can be used for the connection of an external

sensor for measuring temperature or pressure.

The analog input can also be used for an external signal for the

control from a BMS system or similar control system.

The electrical signal for the input can be 0-10 VDC or 4-20 mA.

The selection of electrical signal (0-10 V or 4-20 mA) can be

changed on the control panel or with Grundfos GO Remote.

Fig. 19 Analog input for external sensor or control

In order to optimize the pump performance, external sensors can

advantageously be used in the following cases:

Function/control mode Sensor type

Heat energy meter Temperature sensor

Constant temperature Temperature sensor

Differential pressure Pressure sensor

Fig. 20 Wiring, analog input

PIN Description Load

IN Analog input

150 Ω (4-20 mA signal)

78 kΩ (0-10 V signal)

24 V 24 V supply to external sensor Max. 22 mA

TM05 3221 1112

Fig. 21 Examples of external sensors

Pos. Sensor type

Differential pressure transmitter,

1

Grundfos type DPI V.2

1/2" connection and 4-20 mA signal.

Relative pressure transmitter,

combined pressure and temperature sensor,

2

Grundfos type RPI/T G 1/2" connection and 4-20 mA

signal.

For further details, visit WebCAPS and reference Magna3 Data

booklet 98439208.

TM06 0882 1114

Fig. 22 Example of external signal for the control via BMS or

PLC

TM05 2947 1212

TM05 2888 0612

18

Ground for external sensor

Page 19

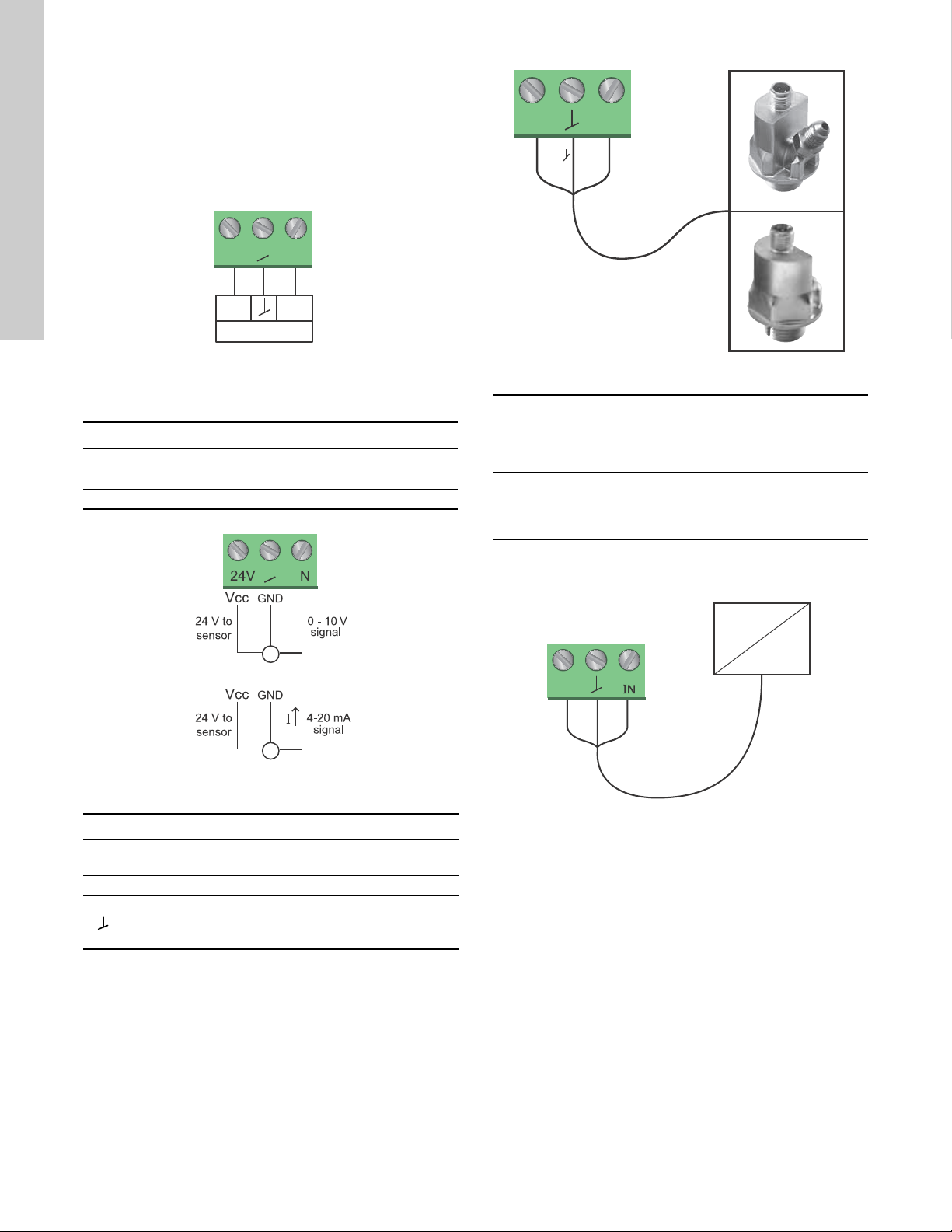

5.7 Electrical connection for external sensor

1

3

4

2

5.8 Priority of settings

The external forced-control signals will influence the settings

available on the pump control panel or with Grundfos GO

Remote. However, the pump can always be set to max. curve

duty or to stop on the pump control panel or with Grundfos GO

Remote.

If two or more functions are enabled at the same time, the pump

will operate according to the setting with the highest priority.

The priority of the settings is as shown in the table below.

Example: If the pump has been forced to stop via an external

signal, the pump control panel or Grundfos GO Remote can only

set the pump to max. curve.

English (US)

Fig. 23 Example electrical connections for external sensor

PIN 1 2 3 4

Wire color Brown Grey Blue Black

Output

4 to 20 mA

Output

2 x 0 to 10 V

* Common ground for both pressure and temperature signal.

* Power supply (screened cable): SELV or PELV.

+ not used - not used

Pressure

+

signal

-*

Temperature

signal

TM04 7156 1610

Priority

1 Stop

2 Max. curve

3Stop

4Stop

5Max. curve

6Min. curve

7Start

8Max. curve

9Min. curve

10 Min. curve

11 Star t

As illustrated in the table, the pump does not react to external

signals (max. curve and min. curve) when it is controlled via bus.

For further details, please contact Grundfos.

Pump control

panel or

Grundfos GO

Remote

Possible settings

External

signals

Bus signal

19

Page 20

English (US)

6. First start-up

Do not start the pump until the system has been filled with liquid

and vented. Furthermore, the required minimum inlet pressure

must be available at the pump inlet. See section 19. Technical

data.

The system cannot be vented through the pump. The pump is

self-venting.

Step Action Illustration

Switch on the power supply to the pump.

1

2

Note: When switched on, the pump will start in

AUTO

after approx. 5 seconds.

ADAPT

Pump display at first start-up.

After a few seconds, the pump display will change to the

start-up guide.

TM05 2884 0612

TM05 2885 0612

The start-up guide will guide you through the general

settings of the pump, such as language, date and time.

3

If the buttons on the pump control panel are not touched

for 15 minutes, the display will go into sleep mode.

When a button is touched, the "Home" display will appear.

TM05 2886 0612

When the general settings have been made, select the

4

desired control mode or let the pump run in AUTO

For additional settings, see section 7.

Settings

.

ADAPT

.

TM05 2887 0612

20

Page 21

7. Settings

7.1 Overview of settings

All settings can be made on the pump control panel or with Grundfos GO Remote.

Menu Submenu Further information

English (US)

Setpoint See section 13.1

Operating mode See section 13.2

• Normal

• Stop

• Min.

• Max.

Control mode See section 13.3

•AUTO

•FLOW

• Prop. press. See section 13.3.3 Proportional pressure.

• Const. press. See section 13.3.4 Constant pressure.

• Const. temp. See section 13.3.5 Constant temperature.

• Differential temperature See section 13.3.6 Differential temperature.

• Constant curve See section 13.3.7 Constant curve.

FLOW

LIMIT

• Set FLOW

Automatic Night Setback See section 13.5

• Not active

• Active

Relay outputs See section 13.6

• Relay output 1

• Relay output 2

Setpoint influence See section 13.7

• External setpoint function See section 13.7.1

• Temperature influence See section 13.7.2

Bus communication See section 13.8

• Pump number See section 13.8.1

General settings See section 13.9

• Language See section 13.9.1

• Set date and time See section 13.9.2

• Units See section 13.9.3

• Enable/disable settings See section 13.9.4

• Delete history See section 13.9.5

• Define Home display See section 13.9.6

• Display brightness See section 13.9.7

• Return to factory settings See section 13.9.8

• Run start-up guide See section 13.9.9

ADAPT

ADAPT

LIMIT

See section 13.3.1 AUTO

See section 13.3.2 FLOW

See section 13.4 FLOW

Setpoint

Operating mode

Control mode

.

ADAPT

ADAPT

LIMIT

.

.

.

.

.

Automatic Night Setback

Relay outputs

Setpoint influence

.

.

External setpoint function

Temperature influence

Bus communication

Pump number

General settings

Language

Set date and time

Units

.

.

.

.

.

.

Enable/disable settings

Delete history

.

Define Home display

Display brightness

.

Return to factory settings

Run start-up guide

.

.

.

.

.

.

.

21

Page 22

English (US)

8. Menu overview

Status Settings Assist

Operating status Setpoint Assisted pump setup

Operating mode, from Operating mode Setting of pump

Control mode Control mode Setting of date and time

Pump performance FLOW

Max. curve and duty point Enable FLOW

Resulting setpoint Set FLOW

LIMIT

LIMIT

function Date only

LIMIT

Liquid temperature Automatic Night Setback Multi-pump setup

Speed Relay outputs Setup, analog input

Operating hours Relay output 1 Description of control mode

Power and energy consumption Relay output 2 AUTO

Power consumption Not active FLOW

Energy consumption Ready Prop. press.

Warning and alarm Alarm Const. press.

Actual warning or alarm Operation Const. temp.

Warning log Setpoint influence Differential temperature

Warning log 1 to 5 External setpoint function Constant curve

Alarm log Temperature influence Assisted fault advice

Alarm log 1 to 5 Bus communication Blocked pump

Heat energy meter Pump number Pump communication fault

Heat power General settings Internal fault

Heat energy Language Internal sensor fault

Flow rate Set date and time Dry running

Volume Select date format Forced pumping

Hours counter Set date Undervoltage

Temperature 1 Select time format Overvoltage

Temperature 2 Set time External sensor fault

Differential temp. Units

Work log SI or US units

Operating hours Customized units

Trend data Pressure

Duty point over time Differential pressure

3D showing (Q, H, t) Head

3D showing (Q, T, t) Level

3D showing (Q, P, t) Flow rate

3D showing (T, P, t) Volume

Fitted modules Temperature

Date and time Differential temp.

Date Power

Time Energy

Pump identification Enable/disable settings

Multi-pump system Delete history

Operating status Delete work log

Operating mode, from Delete heat energy data

Control mode Delete energy consumption

System performance Define Home display

Duty point Select Home display type

Resulting setpoint List of data

System identification Graphical illustration

Power and energy consumption Define Home display contents

Power consumption List of data

Energy consumption Graphical illustration

Other pump 1, multi-pump sys. Display brightness

Brightness

Return to factory settings

Run start-up guide

Date format, date and time

Time only

ADAPT

ADAPT

22

Page 23

9. Control panel

Note

Note

Warnin g

At high liquid temperatures, the pump housing

may be very hot. In that case, only touch the

control panel.

10. Menu structure

The pump incorporates a start-up guide which is started at the

first start-up. After the start-up guide, the four main menus will

appear in the display. See section 6. First start-up.

1. Home

This menu shows up to four user-defined parameters with

shortcuts or a graphical illustration of a Q/H performance curve.

See section 11. "

2. Status

This menu shows the status of the pump and system as well as

warnings and alarms. See section 12. "

3. Settings

This menu gives access to all setting parameters. A detailed

setting of the pump can be made in this menu.

See section 13. "

4. Assist

This menu enables assisted pump setup, provides a short

description of the control modes and offers fault advice.

See section 14. "

Home

" menu.

Status

" menu.

No settings can be made in this menu.

Settings

Assist

" menu.

" menu.

11. "Home" menu

English (US)

Fig. 24 Control panel

Button Function

Goes to the "Home" menu.

Returns to the previous action.

Navigates between main menus, displays and

digits.

When the menu is changed, the display will always

show the top display of the new menu.

Navigates between submenus.

Saves changed values, resets alarms and expands

the value field.

TM05 7642 1313

Navigation

Home

Press to go to the "Home" menu.

"Home" menu (factory setting)

• Shortcut to control mode settings

• Shortcut to setpoint settings

• Flow rate

• Head.

Navigate in the display with or and change between the two

shortcuts with or .

The "Home" display can be defined by the user.

See section 13.9.6

Define Home display

.

TM05 7929 1613

23

Page 24

English (US)

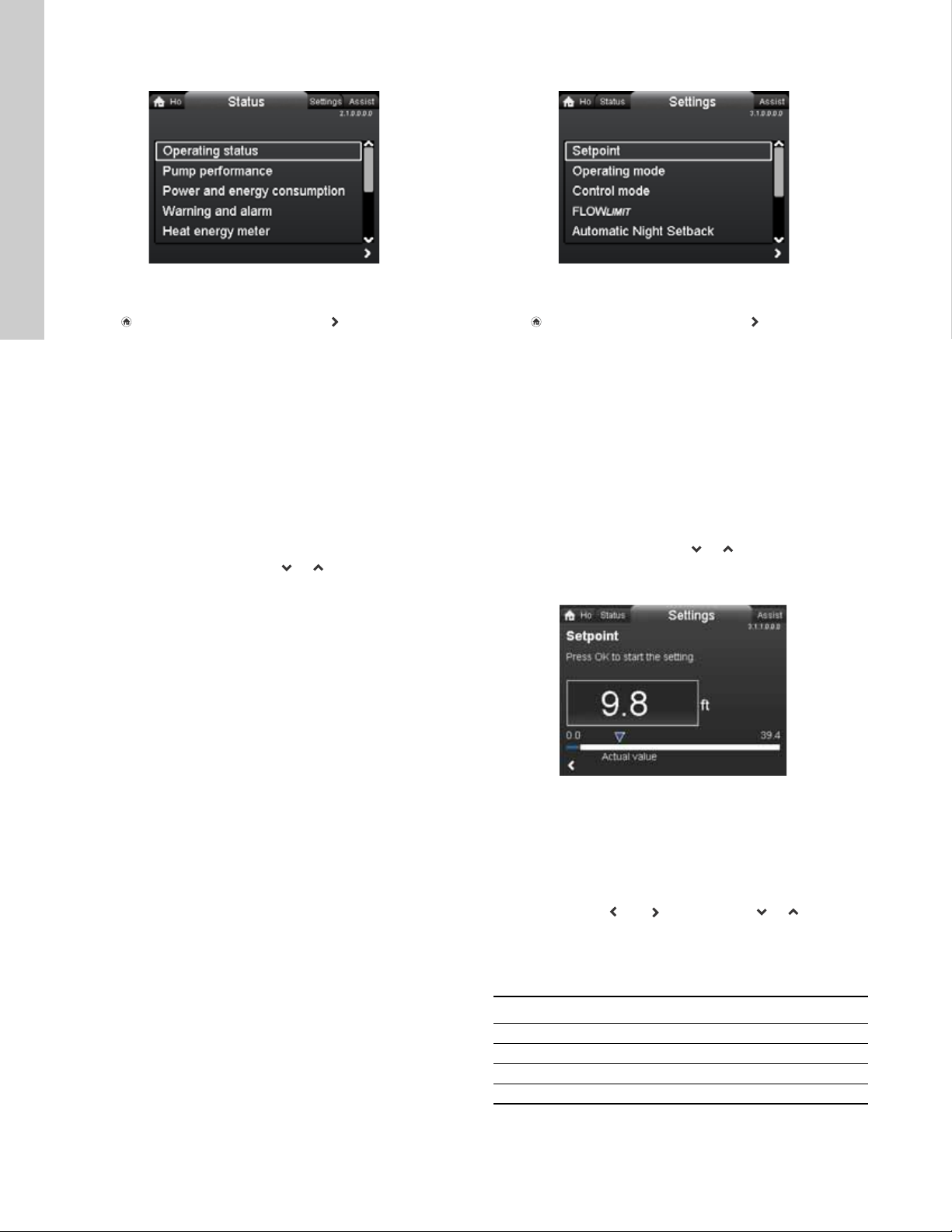

12. "Status" menu

13. "Settings" menu

Navigation

Home > Status

Press and go to the "Status" menu with .

"Status" menu

This menu offers the following status information:

• Operating status

• Pump performance

• Power and energy consumption

• Warning and alarm

• Heat energy meter

• Work log

• Fitted modules

• Date and time

• Pump identification

• Multi-pump system.

Navigate between submenus with or .

2.1.0.0.0.0 Status

Navigation

Home > Settings

Press and go to the "Settings" menu with .

"Settings" menu

This menu offers the following setting options:

• Setpoint

• Operating mode

• Control mode

•FLOW

• Automatic Night Setback

• Relay outputs

• Setpoint influence

• Bus communication

• General settings.

Navigate between submenus with or .

LIMIT

13.1 Setpoint

3.1.0.0.0.0 Settings

24

TM05 7925 1613

Navigation

Home > Settings > Setpoint

Setpoint

Set the setpoint so that it matches the system.

Setting:

1. Press [OK] to start the setting.

2. Select digit with and and adjust with or .

3. Press [OK] to save.

A too high setting may result in noise in the system whereas a too

low setting may result in insufficient heating or cooling in the

system.

Control mode Measuring unit

Proportional pressure m, ft

Constant pressure m, ft

Constant temperature °C, °F, K

Constant curve %

Page 25

13.2 Operating mode

H

Q

Max.

Min.

Note

Note

13.3 Control mode

English (US)

Navigation

Home > Settings > Operating mode

Operating mode

• Normal (control mode)

• Stop

• Min. (min. curve)

• Max. (max. curve).

Setting:

1. Select operating mode with or .

2. Press [OK] to save.

The pump can be set to operate according to the max. or min.

curve, like an uncontrolled pump. See fig. 25.

Fig. 25 Max. and min. curves

3.1.2.0.0.0 Operating mode

Navigation

Home > Settings > Control mode

Control mode

•AUTO

•FLOW

ADAPT

ADAPT

• Prop. press. (proportional pressure)

• Const. press. (constant pressure)

• Const. temp.(constant temperature)

• Constant curve.

The operating mode must be set to "

before a control mode can be enabled.

Setting:

1. Select control mode with or .

2. Press [OK] to enable.

The setpoint for all control modes, except AUTO

FLOW

"Settings" when the desired control mode has been selected.

, can be changed in the "Setpoint" submenu under

ADAPT

ADAPT

All control modes, except "Constant curve", can be combined with

Automatic Night Setback. See section 13.5

Setback

.

The FLOW

control modes mentioned above. See section 13.4 FLOW

TM05 2446 5111

function can also be combined with the last five

LIMIT

Automatic Night

Normal

and

"

LIMIT

3.1.3.0.0.0 Control mode

.

• Normal: The pump runs according to the selected control

mode.

• Stop: The pump stops.

• Min.: The min. curve mode can be used in periods in which a

minimum flow is required.

This operating mode is for instance suitable for manual night

setback if Automatic Night Setback is not desired.

• Max.: The max. curve mode can be used in periods in which a

maximum flow is required.

This operating mode is for instance suitable for hot-water

priority.

25

Page 26

English (US)

Note

Note

H

Q

H

auto_min

H

fac

A

1

A

3

A

2

H

set1

H

set2

H

Q

Q

max

90 %

H

auto_min

H

fac

Q

fac

Setting range

H

Q

H

set

H

set

2

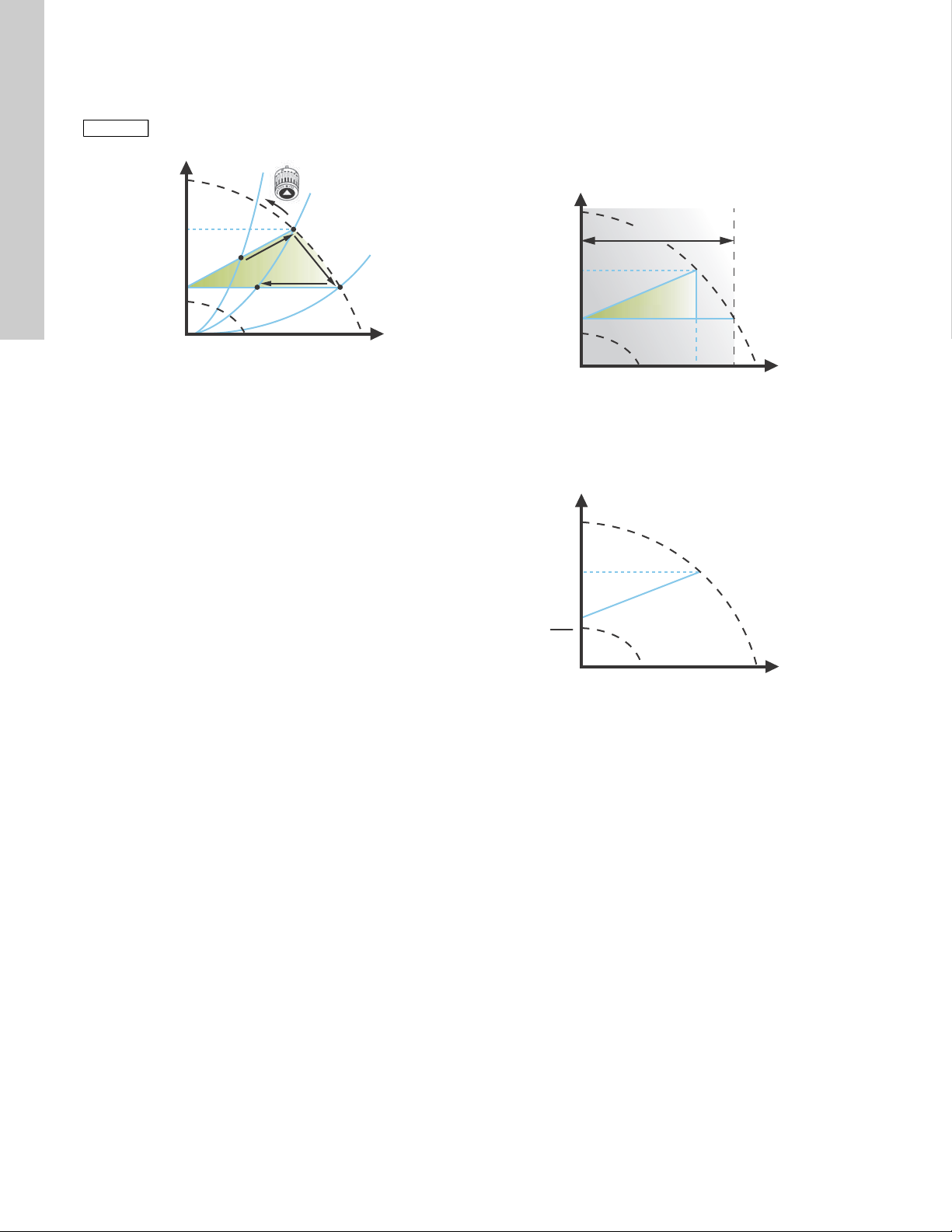

13.3.1 AUTO

The AUTO

performance according to the actual system characteristic.

ADAPT

control mode continuously adapts the pump

ADAPT

Manual setting of the setpoint is not possible.

Fig. 26 AUTO

When the AUTO

will start with the factory setting, H

ADAPT

control mode has been enabled, the pump

ADAPT

fac

= H

, corresponding to

set1

approx. 55 % of its maximum head, and then adjust its

performance to A

When the pump registers a lower head on the max. curve, A

AUTO

ADAPT

lower control curve, H

pump will adjust its performance to A

. See fig. 26.

1

function will automatically select a correspondingly

. If the valves in the system close, the

set2

.

3

, the

2

A1: Original duty point.

: Lower registered head on the max. curve.

A

2

: New duty point after AUTO

A

3

: Original setpoint setting.

H

set1

: New setpoint after AUTO

H

set2

: MAGNA3 xx-60: 11.4 ft (3.5 m)

H

fac.

ADAPT

ADAPT

control.

control.

MAGNA3 xx-80: 14.7 ft (4.5 m)

MAGNA3 xx-100: 18 ft (5.5 m)

MAGNA3 xx-120: 21.3 ft (6.5 m)

MAGNA3 xx-150: 26.2 ft (8.0 m)

MAGNA3 xx-180: 31.1 ft (9.5 m).

H

The AUTO

control where the control curves have a fixed origin, H

The AUTO

for heating systems and is not recommended for air-conditioning

: A fixed value of 4.9 ft (1.5 m).

auto_min

control mode is a form of proportional-pressure

ADAPT

control mode has been developed specifically

ADAPT

auto_min

.

and cooling systems.

To r e s et A U TO

settings

.

, see section 13.9.8

ADAPT

Return to factory

13.3.2 FLOW

When FLOW

ensure that the flow never exceeds the entered FLOW

The setting range for the FLOW

the pump.

The factory setting of the FLOW

AUTO

TM05 2452 1312

Fig. 27 FLOW

ADAPT

is selected, the pump will run AUTO

ADAPT

is 25 to 90 % of the Q

LIMIT

is the flow where the

factory setting meets the max. curve. See fig. 27.

ADAPT

ADAPT

LIMIT

13.3.3 Proportional pressure

The pump head is reduced at decreasing water demand and

increased at rising water demand. See fig. 28.

Fig. 28 Proportional pressure

ADAPT

LIMIT

and

value.

of

max

TM05 3334 1212 TM05 2448 1212

26

Page 27

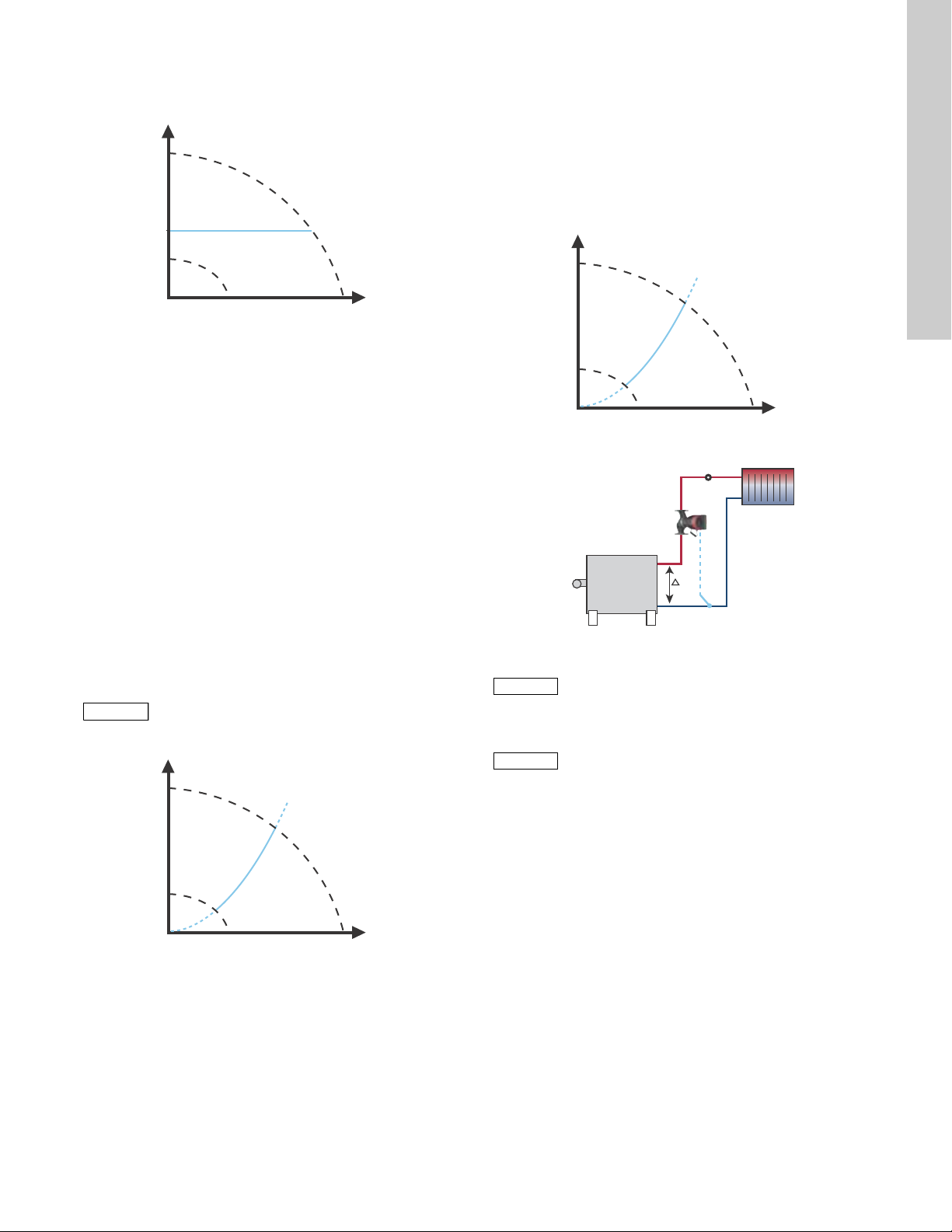

13.3.4 Constant pressure

Note

Note

H

Q

H

Q

Note

Note

Note

Note

H

Q

Δt

t

The pump maintains a constant pressure, irrespective of water

demand. See fig. 29.

Fig. 29 Constant pressure

13.3.5 Constant temperature

This control mode ensures a constant temperature.

Constant temperature is a comfort control mode that can be used

in domestic hot-water systems to control the flow to maintain a

fixed temperature in the system. See fig. 30. When this control

mode is used, no balancing valves must be installed in the

system.

If the pump is installed in the return pipe of the system, the

internal temperature sensor can be used. In this case, the pump

must be installed as close as possible to the consumer (radiator,

heat exchanger, etc.).

If the pump is installed in the flow pipe, an external temperature

sensor must be installed in the return pipe of the system.

The sensor must be installed as close as possible to the

consumer (radiator, heat exchanger, etc.).

The constant-temperature control mode also reduces the risk of

bacterial growth (for example Legionella) in the system.

It is possible to set the sensor range:

• min. +14 °F (-10 °C)

• max. +266 °F (+130 °C).

To ensure that the pump is able to control, we

recommend to set the sensor range between

+3 °F and +257 °F (-5 and +125 °C).

13.3.6 Differential temperature

This control mode ensures a constant differential temperature

drop across a heating system.

The pump should be installed in the flow pipe so the built-in

sensor measures the liquid temperature going out to the load.

An external temperature sensor must be installed in the system to

measure the liquid temperature returning from the heating load.

In this mode, the pump will maintain a constant temperature.

See figs 31 and 32, differential between the pump and the

external sensor.

TM05 2449 0312

Fig. 31 Differential temperature

Fig. 32 Differential temperature

Changing Kp and Ti values are only possible with

Grundfos GO.

Changing the Kp and Ti values will affect all

control modes. If the control mode is to be

changed back to another mode you must set the

K

and Ti values back to default values. For all

p

other modes the default values are K

T

= 0.5.

i

= 0.5,

p

English (US)

TM05 2451 5111TM05 8236 2113

TM05 2451 5111

Fig. 30 Constant temperature

27

Page 28

English (US)

t

L

2

[m]

Δt

L

2

[m]

L2 [m]

t

Note

Note

H

Q

H [%]

Q [m

3

/h]

100 %

Max. curve

Limited

max. curve

Actual duty point

See table, fig. 33.

The table shows the suggested controller settings:

K

p

System/application

Heating

system

1)

Cooling

system

2)

13.3.7 Constant curve

The pump can be set to operate according to a constant curve,

like an uncontrolled pump. See fig. 34.

The desired speed can be set in % of maximum speed in the

T

i

range from 25 to 100 %.

0.5 - 0.5 10 + 5L

-0.5 10 + 5L

0.5 - 0.5 30 + 5L

2

2

2

Fig. 33 Suggested controller settings

1)

Heating systems are systems in which an increase in pump

performance will result in a rise in temperature at the sensor.

2)

Cooling systems are systems in which an increase in pump

performance will result in a drop in temperature at the sensor.

L

= Distance in [m] between heat exchanger and sensor.

2

Proceed as follows:

1. Increase the gain (K

Instability can be seen by observing if the measured value

) until the motor becomes unstable.

p

starts to fluctuate. Furthermore, instability is audible as the

motor starts hunting up and down.

Some systems, such as temperature controls, are

slow-reacting, meaning that it may be several minutes before

the motor becomes unstable.

2. Set the gain (K

motor unstable. This is the correct setting of the gain.

3. Reduce the integral time (T

unstable.

4. Set the integral time (T

) to half the value of the value which made the

p

) until the motor becomes

i

) to twice the value which made the

i

motor unstable. This is the correct setting of the integral time.

General rules of thumb:

• If the controller is too slow-reacting, increase K

.

p

• If the controller is hunting or unstable, dampen the system by

reducing K

or increasing Ti.

p

TM05 2446 0312

Fig. 34 Constant curve

Depending on the system characteristic and the

duty point, the 100 % setting may be slightly

smaller than the pump's actual max. curve even

though the display shows 100 %. This is due to

power and pressure limitations built into the

pump. The deviation varies according to pump

type and pressure loss in the pipes.

TM05 3041 1212

Fig. 35 Power and pressure limitations influencing the max.

curve

28

Page 29

13.4 FLOW

H

Q

Q

max

Q

limit

90 %

Setting range

Note

Note

LIMIT

13.5 Automatic Night Setback

English (US)

LIMIT

Navigation

Home > Settings > FLOW

FLOW

LIMIT

• Enable FLOW

• Set FLOW

LIMIT

LIMIT

LIMIT

function

.

Setting:

1. To enable the function, select "Active" with or and press

[OK].

2. To set the FLOW

, press [OK] to start the setting.

LIMIT

3. Select digit with and and adjust with or .

4. Press [OK] to save.

Fig. 36 FLOW

The FLOW

control modes:

LIMIT

function can be combined with the following

LIMIT

• Prop. press.

• Const. press.

• Const. temp.

• Constant curve.

A flow-limiting function ensures that the flow never exceeds the

entered FLOW

The setting range for FLOW

LIMIT

value.

is 25 to 90 % of the Q

LIMIT

max

of the

pump.

The factory setting of the FLOW

AUTO

factory setting meets the max. curve. See fig. 27.

ADAPT

is the flow where the

LIMIT

3.1.5.0.0.0 FLOW

Navigation

Home > Settings > Automatic Night Setback

Automatic Night Setback

To enable the function, select "Active" with or and press

[OK].

Once Automatic Night Setback has been enabled, the pump

automatically changes between normal duty and night setback

(duty at low performance).

Changeover between normal duty and night setback depends on

the flow-pipe temperature.

The pump automatically changes over to night setback when the

built-in sensor registers a flow-pipe temperature drop of more

than +18 to +27 °F (-8 to -3 °C) within approx. two hours.

The temperature drop must be at least 0.18 °F/min (0.1 °C/min).

Changeover to normal duty takes place without a time lag when

the temperature has increased by approx. +18 °F (-8 °C).

Automatic Night Setback cannot be enabled

when the pump is in constant-curve mode.

TM05 2445 1212

3.1.6.0.0.0 Automatic Night Setback

29

Page 30

English (US)

Note

Note

rpm

V

Min.

02

Max.

10

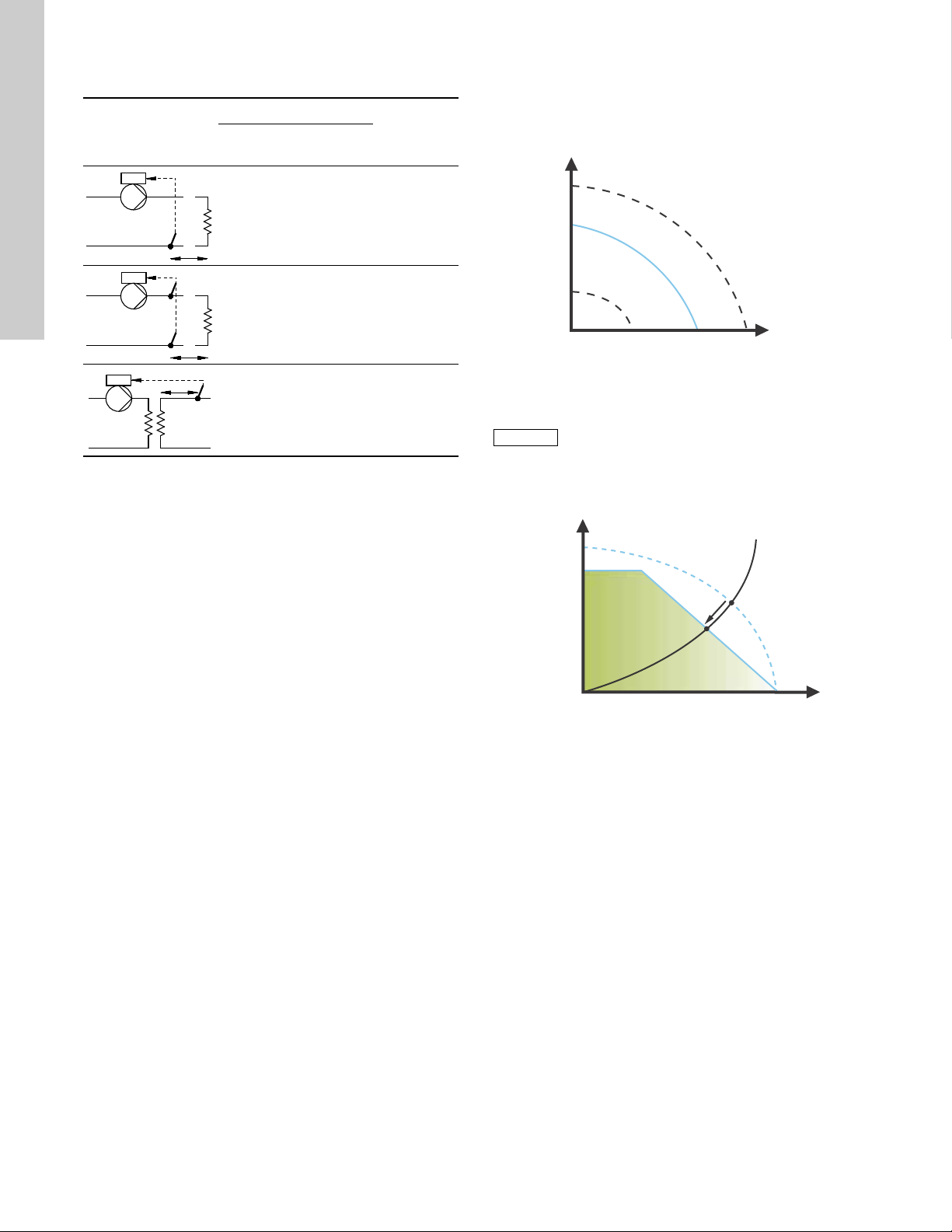

13.6 Relay outputs

13.7 Setpoint influence

Navigation

Home > Settings > Relay outputs

Relay outputs

• Relay output 1

• Relay output 2.

The relay outputs can be set to the following:

• Not active

• Ready

• Alarm

• Operation.

The pump incorporates two signal relays, terminals 1, 2 and 3, for

a potential-free alarm signal, ready signal and operating signal.

For further information, see section 5.5.1 Relay outputs.

Set the function of the signal relays, alarm signal (factory setting),

ready signal and operating signal, on the pump control panel.

The output, terminals 1, 2 and 3, is electrically separated from the

rest of the controller.

The signal relay is operated as follows:

• Not active

The signal relay is deactivated.

• Ready

The signal relay is active when the pump is running or has

been set to stop, but is ready to run.

• Alarm

The signal relay is activated together with the red indicator

light on the pump.

• Operation

The signal relay is activated together with the green indicator

light on the pump.

3.1.12.0.0.0 Relay outputs

Navigation

Home > Settings > Setpoint influence

Setpoint influence

• External setpoint function

• Temperature influence.

13.7.1 External setpoint function

Range

4-20 mA [0-100 %]

0-10 V [0-100 %]

Control

0-20 % (e.g. 0-2 V) Setpoint = Min.

20-100 % (e.g. 2-10 V) Setpoint = Min. ↔ setpoint

The external setpoint function is an external 0-10 V or 4-20 mA

signal that will control the pump speed in a range from 0 to 100 %

in a linear function. See fig. 37.

Before the "

External setpoint function

" can be

enabled, the analog input must be set to "

setpoint influence

" via the "

Assist

" menu.

See section 5.6 Analog input for external sensor.

3.1.15.0.0.0 Setpoint influence

External

30

TM05 3219 1212

Fig. 37 External setpoint function, 0-10 V

Page 31

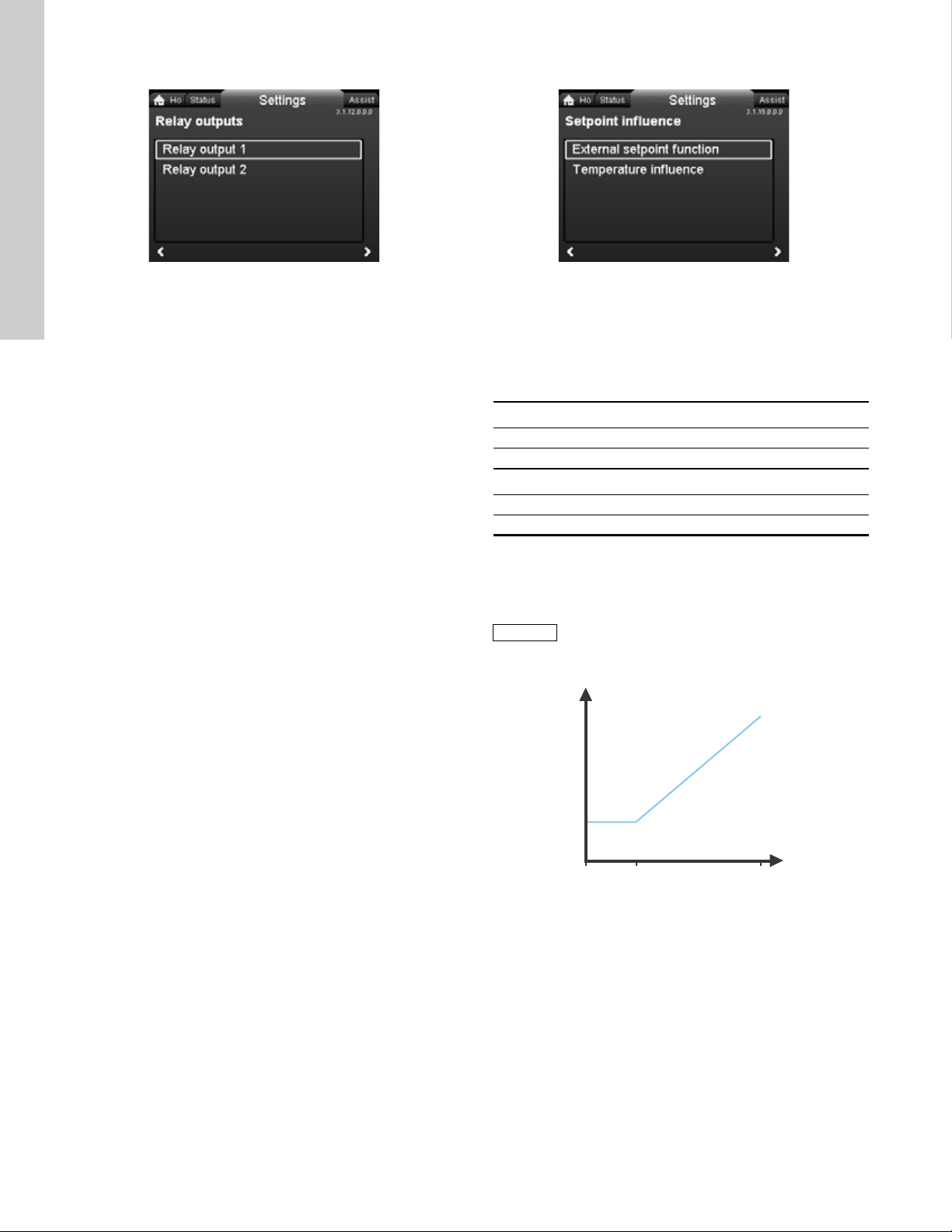

13.7.2 Temperature influence

Note

Note

H

T [°F]

30 %

68 122 176

T [°C]

20 50 80

100 %

H

actual

T

actual

H

Q

When this function is enabled in proportional- or

constant-pressure control mode, the setpoint for head will be

reduced according to the liquid temperature.

Temperature influence can be set to function at liquid

temperatures below +176 °F or +122 °F (80 °C or 50 °C).

These temperature limits are called T

reduced in relation to the head set (= 100 %) according to the

. The setpoint is

max.

characteristics below.

Fig. 38 Temperature influence

13.8 Bus communication

13.8.1 Pump number

Navigation

Home > Settings > Bus communication > Pump number

Pump number

A unique number can be allocated to the pump. This makes it

possible to distinguish between pumps in connection with bus

communication.

13.9 General settings

TM05 7946 1613

13.9.1 Language

English (US)

3.1.18.1.0.0 Pump number

In the above example, T

= +176 °F (+80 °C) has been

max.

selected.

The actual liquid temperature T

to be reduced from 100 % to H

causes the setpoint for head

actual

.

actual

The temperature influence function requires the following:

• Proportional-pressure, constant-pressure or constant-curve

control mode.

• Pump installed in flow pipe.

• System with flow-pipe temperature control.

Temperature influence is suitable for the following systems:

• Systems with variable flows (for example two-pipe heating

systems) in which the enabling of the temperature influence

function will ensure a further reduction of the pump

performance in periods with small heating demands and

consequently a reduced flow-pipe temperature.

• Systems with almost constant flows (for example one-pipe

heating systems and underfloor heating systems), in which

variable heating demands cannot be registered as changes in

the head as is the case with two-pipe heating systems. In such

systems, the pump performance can only be adjusted by

enabling the temperature influence function.

Selection of T

max.

In systems with a dimensioned flow-pipe temperature of:

• up to and including +131 °F (+55 °C), select T

(+50 °C)

• above +131 °F (+55 °C), select T

= +176 °F (80 °C).

max.

max.

= +122 °F

The temperature influence function cannot be

used in air-conditioning and cooling systems.

TM05 7947 1613

Navigation

Home > Settings > General settings > Language

Language

The display can be shown in any of the following languages:

GB, BG, CZ, DK, DE, EE, GR, ES, FR, HR, IT, LV, LT, HU, NL,

UA, PL, PT, RU, RO, SK, SI, RS, FI, SE, TR, CN, JP or KO.

Measuring units are automatically changed according to selected

language.

Setting:

1. Select language with and .

2. Press [OK] to enable.

31

Page 32

English (US)

13.9.2 Set date and time

13.9.3 Units

Navigation

Home > Settings > General settings > Set date and time

Set date and time

• Select date format

• Set date

• Select time format

• Set time.

Set the real-time clock in this menu.

Select date format

• YYYY-MM-DD

• DD-MM-YYYY

• MM-DD-YYYY.

Setting:

1. Select "Set date".

2. Press [OK] to start the setting.

3. Select digit with and and adjust with or .

4. Press [OK] to save.

Select time format

• HH:MM 24-hour clock

• HH:MM am/pm 12-hour clock.

Setting:

1. Select "Set time".

2. Press [OK] to start the setting.

3. Select digit with and and adjust with or .

4. Press [OK] to save.

3.1.19.2.0.0 Set date and time

Navigation

Home > Settings > General settings > Units

Units

• SI or US units

• Customized units.

Select whether the display should shows SI or US units or select

the desired units for the parameters below.

• Pressure

• Differential pressure

• Head

• Level

• Flow rate

• Volume

• Temperature

• Differential temp.

• Power

• Energy.

Setting:

1. Select parameter and press [OK].

2. Select unit with or .

3. Press [OK] to enable.

If "SI or US units" is selected, the customized units will be reset.

3.1.19.3.0.0 Units

32

Page 33

13.9.4 Enable/disable settings

13.9.6 Define Home display

English (US)

Navigation

Home > Settings > General settings > Enable/disable settings

Enable/disable settings

In this display, the possibility of making settings can be disabled

for protective reasons.

Select "Disable" with or and press [OK].

The pump will now be locked for settings. Only the "Home"

display will be available.

To unlock the pump and allow settings, press and

simultaneously for at least 5 seconds.

13.9.5 Delete history

Navigation

Home > Settings > General settings > Delete history

Delete history

• Delete work log

• Delete heat energy data

• Delete energy consumption.

It is possible to delete data from the pump, for example if the

pump is moved to another system or if new data are required due

to changes to the system.

Setting:

1. Select the relevant submenu and press [OK].

2. Select "Yes" with or and press [OK] or press to

cancel.

3.1.19.4.0.0 Enable/disable settings3.1.19.5.0.0 Delete history

Navigation

Home > Settings > General settings > Define Home display

Define Home display

• Select Home display type

• Define Home display contents.

The "Home" display can be set to show up to four user-defined

parameters or a graphical illustration of a performance curve.

Select Home display type

1. Select "List of data" or "Graphical illustration" with or .

2. Press [OK] to save.

To specify the contents, go to "Define Home display contents".

Define Home display contents

1. To set "List of data", press [OK] to start the setting.

A list of parameters will appear in the display.

2. Select or deselect with [OK].

Up to four parameters can be selected.

The selected parameters will be shown as illustrated below.

The arrow icon indicates that the parameter links to the "Settings"

menu and works as a shortcut for quick settings.

1. To set "Graphical illustration", press [OK] to start the setting.

2. Select the desired curve and press [OK] to save.

3.1.19.6.0.0 Define Home display

TM05 7929 1613

33

Page 34

English (US)

13.9.7 Display brightness

13.9.9 Run start-up guide

Navigation

Home > Settings > General settings > Display brightness

Brightness

1. Press [OK] to start the setting.

2. Set brightness with and .

3. Press [OK] to save.

13.9.8 Return to factory settings

Navigation

Home > Settings > General settings > Return to factory settings

Return to factory settings

It is possible to recall the factory settings and overwrite the

current settings. All user settings in the "Settings" and "Assist"

menus will be set back to the factory settings. This also includes

language, units, possible setup of analog input, multi-pump

function, etc.

To overwrite the current settings with the factory settings, select

"Yes" with or and press [OK].

3.1.19.7.1.0 Brightness3.1.19.10.1.0 Return to factory settings

Navigation

Home > Settings > General settings > Run start-up guide

Run start-up guide

It is possible to run the start-up guide again. The start-up guide

will guide the user through the general settings of the pump, such

as language, date and time.

To run the start-up guide, select "Yes" with or and press

[OK].

3.1.19.11.0.0 Run start-up guide

34

Page 35

14. "Assist" menu

Navigation

Home > Assist

Press and go to the "Assist" menu with .

"Assist" menu

This menu offers the following:

• Assisted pump setup

• Setting of date and time

• Multi-pump setup

• Setup, analog input

• Description of control mode

• Assisted fault advice.

The "Assist" menu guides the user through the setting of the

pump. In each submenu, the user is presented with a guide that

helps throughout the setting.

14.1 Assisted pump setup

This submenu is a step-by-step guide to complete pump setup,

starting with a presentation of the control modes and ending with

the setpoint setting.

14.2 Setting of date and time

See section 13.9.2

14.3 Multi-pump setup

This submenu assists the user in setting up a multi-pump system.

See section 14.8 M ulti-pump function.

14.4 Setup, analog input

This submenu assists the user in setting up the analog input.

14.5 Description of control mode

This submenu gives a short description of each control mode.

14.6 Assisted fault advice

This submenu provides information about faults and corrective

actions.

Set date and time

.

14.7 Wireless GENIair

The pump is designed for multi-pump connection via the wireless

GENIair connection or wired via a bus system (Building

Management System).

The built-in wireless GENIair module enables communication

between pumps and with Grundfos Go Remote without the use of

add-on modules:

• Multi-pump function.

See section 14.8 M ulti-pump function.

• Grundfos GO Remote.

See section 18.1 Grundfos GO Remote.

14.8 Multi-pump function

Assist

The multi-pump function enables the control of single-head

pumps connected in parallel and twin-head pumps without the

use of external controllers. The pumps in a multi-pump system

communicate with each other via the wireless GENIair

connection.

A multi-pump system is set up via a selected pump, i.e. the

master pump (first selected pump). All Grundfos pumps with a

wireless GENIair connection can be connected to the multi-pump

system.

The multi-pump functions are described in the following sections.

14.8.1 Alternating operation

Only one pump is operating at a time. The change from one pump

to the other depends on time or energy. If a pump fails, the other

pump will take over automatically.

Pump system:

• Twin-head pump.

• Two single-head pumps connected in parallel. The pumps

must be of same type and size. Each pump requires a

non-return valve in series with the pump.

14.8.2 Back-up operation

One pump is operating continuously. The back-up pump is

operated at intervals to prevent seizing up. If the duty pump stops

due to a fault, the back-up pump will start automatically.

Pump system:

• Twin-head pump.

• Two single-head pumps connected in parallel. The pumps

must be of same type and size. Each pump requires a

non-return valve in series with the pump.

14.8.3 Cascade operation

Cascade operation ensures that the pump performance is

automatically adapted to the consumption by switching pumps on

or off. The system thus runs as energy-efficiently as possible with

a constant pressure and a limited number of pumps.

All pumps in operation will run at equal speed. Pump changeover

is automatic and depends on energy, operating hours and fault.

Pump system:

• Twin-head pump.

• Two single-head pumps connected in parallel. The pumps

must be of same type and size. Each pump requires a

non-return valve in series with the pump.

• The control mode must be set to "Const. press." or "Constant

curve".

English (US)

35

Page 36

English (US)

H

Q

H

Q

H

Q

H

set

H

set

2

H

Q

15. Selection of control mode

System application

Recommended for most heating systems, especially in systems with relatively large pressure losses in the

distribution pipes. See description under proportional pressure.

In replacement situations where the proportional-pressure duty point is unknown.

The duty point has to be within the AUTO

makes the necessary adjustment to the actual system characteristic.

operating range. During operation, the pump automatically

ADAPT

This setting ensures minimum energy consumption and noise level from valves, which reduces operating costs

and increases comfort.

The FLOW

This control mode is suitable for systems where a maximum flow limit, FLOW

continuously monitors and adjusts the flow, thus ensuring that the selected FLOW

Main pumps in boiler applications where a steady flow through the boiler is required. No extra energy is used for

control mode is a combination of AUTO

ADAPT

ADAPT

and FLOW

.

LIMIT

, is desired. The pump

LIMIT

is not exceeded.

LIMIT

pumping too much liquid into the system.

In systems with mixing loops, the control mode can be used to control the flow in each loop.

Benefits:

• Enough water for all loops at peak load conditions if each loop has been set to the right maximum flow.

• The dimensioned flow for each zone (required heat energy) is determined by the flow from the pump.

This value can be set precisely in the FLOW

control mode without the use of pump throttling valves.

ADAPT

• When the flow is set lower than the balancing valve setting, the pump will ramp down instead of losing energy

by pumping against a balancing valve.

• Cooling surfaces in air-conditioning systems can operate at high pressure and low flow.

In systems with relatively large pressure losses in the distribution pipes and in air-conditioning and cooling systems.

• Two-pipe heating systems with thermostatic valves and

– a dimensioned pump head higher than 13 ft (4 meters)

– very long distribution pipes

– strongly throttled pipe balancing valves

– differential-pressure regulators

– large pressure losses in those parts of the system through which the total quantity of water flows (for

example boiler, heat exchanger and distribution pipe up to the first branching).

• Primary circuit pumps in systems with large pressure losses in the primary circuit.

• Air-conditioning systems with

– heat exchangers (fan coils)

– cooling ceilings

– cooling surfaces.

In systems with relatively small pressure losses in the distribution pipes.

• Two-pipe heating systems with thermostatic valves and

– a dimensioned pump head lower than 6.5 ft (2 meters)

– dimensioned for natural circulation

– small pressure losses in those parts of the system through which the total quantity of water flows (for

example boiler, heat exchanger and distribution pipe up to the first branching) or

– modified to a high differential temperature between flow pipe and return pipe (for example district heating).

• Underfloor heating systems with thermostatic valves.

• One-pipe heating systems with thermostatic valves or pipe balancing valves.

• Primary circuit pumps in systems with small pressure losses in the primary circuit.

Select this control

mode

AUTO

ADAPT

FLOW

ADAPT

Proportional

pressure

Constant pressure

36

Page 37

System application

H

Q

H

Q

ΔT

H

Q

In heating systems with a fixed system characteristic, for example domestic hot-water systems, the control of the

pump according to a constant return-pipe temperature may be relevant.

FLOW

can be used with advantage to control the maximum circulation flow.

LIMIT