Page 1

? IMPORTANT INFORMATION ? KEEP FOR OPERATOR ? IMPORTANT INFORMATION ?

OPERATOR MANUAL OM-NEB/1

Part Number 121012 DOMESTIC

Model: NEB/1

Steam Boilers

Electrically Heated

24, 36 or 48 Kilowatts

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

WARNING

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

Page 2

OM-NEB/1

IMPORTANT — READ FIRST — IMPORTANT

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: UNIT WEIGHS 620 LB (282 KG) FOR SAFE HANDLING, INSTALLER SHOULD

OBTAIN HELP, OR EMPLOY APPROPRIATE MATERIALS HANDLING

EQUIPMENT (FORKLIFT, DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO ITS PLACE OF INSTALLATION..

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITRY AND PLUMBING. IMPROPER INSTALLATION

COULD RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

CAUTION: DRAIN MUST BE RATED FOR STEAM AND BOILING WATER. DO NOT USE

PLASTIC PIPE.

WARNING: DO NOT CONNECT THE BOILER DRAIN DIRECTLY TO A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN MAY BE HAZARDOUS.

IMPORTANT: Improper drain connection will void warranty.

WARNING: ALLOW COOKING CHAMBERS TO COOL BEFORE CLEANING.

WARNING: CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE

LABEL OF EACH CLEANING AGENT. USE SAFETY GLASSES AND RUBBER

GLOVES AS RECOMMENDED BY DELIMING AGENT MANUFACTURER.

WARNING: DO NOT MIX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI) IN THE

STEAM GENERATOR OR ON THE COOKING CHAMBER WALLS.

NOTICE: Do not use a cleaning or de-liming agent that contains any sulfamic acid or

any chloride, including hydrochloric acid (HCl). If the chloride content of any

product is unclear, consult the manufacturer. Do not use a de-greaser that

contains potassium hydroxide or sodium hydroxide or that is highly alkaline.

WARNING: USE OF REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN

OR AUTHORIZED DISTRIBUTORS VOIDS ALL WARRANTIES AND CAN CAUSE

BODILY INJURY TO THE OPERATOR AND DAMAGE THE EQUIPMENT.

SERVICE PERFORMED BY OTHER THAN FACTORY-AUTHORIZED

PERSONNEL WILL VOID ALL WARRANTIES.

WARNING: HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT

FROM BRANCH BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN

SERIOUS INJURY OR DEATH.

WARNING: DO NOT EXPOSE SKIN TO ESCAPING STEAM. SEVERE BURNS CAN RESULT.

2

Page 3

OM-NEB/1

Table of Contents

OPERATOR WARNINGS .................................................................... 2

EQUIPMENT DESCRIPTION ................................................................. 4

INSPECTION AND UNPACKING .............................................................. 4

WATER CONDITIONING REQUIREMENTS ..................................................... 5

INSTALLATION INSTRUCTIONS .............................................................. 5

INITIAL START-UP ......................................................................... 7

OPERATING INSTRUCTIONS ................................................................ 8

SEQUENCE OF OPERATION ................................................................. 8

CLEANING ................................................................................ 9

MAINTENANCE ........................................................................... 11

TROUBLESHOOTING ...................................................................... 12

PARTS LIST .............................................................................. 14

SCHEMATICS ............................................................................ 17

REFERENCES ............................................................................ 20

SERVICE LOG ............................................................................ 21

NOTES .................................................................................. 22

WARRANTY PROTECTION ................................................................. 23

[SEE OM-HY-6CAV FOR STEAMER CAVITY OPERATION AND/OR OM-TD FOR KETTLE OPERATION.]

The NEB-1 Boiler may be used for a variety of applications in a variety of combinations.

3

Page 4

OM-NEB/1

Equipment Description

The Groen NEB/1 steam boiler generates low

pressure steam for use with HyPlus cabinet-mounted

steamers and steam jacketed kettles.

The boiler is housed in a stainless steel cabinet.

Various combinations of steam-operated kettles and

steamers can be mounted on the top. The boiler is

small enough to fit in a 24-1/8” (613 mm) wide by

34-3/16" (868 mm) deep by 29-3/16" (741 mm) tall

(maximum) cabinet.

The boiler is constructed of 1/4" thick steel, which is

certified by the American Society of Mechanical

Engineers (ASME) for pressure vessels. All welds

are hydrostatically tested.

Inspection and Unpacking

The unit will arrive completely assembled, wrapped

in protective plastic and in a heavy-duty carton on a

skid. Immediately on receipt examine the carton and

unit for shipping damage. Report any damage or

incorrect shipments to the delivery agent.

Write down the model number, serial number and

installation date of your unit, and keep this

information for future reference. Space for these

entires is provided at the top of the Service Log on

Page 21 of this manual.

The boiler is also equipped with all required

instruments, fittings, and controls.

Heating elements with low watt density ensure longer

life for the unit. The boiler is available for three

phase 60 Hertz service in the following voltage and

power combinations:

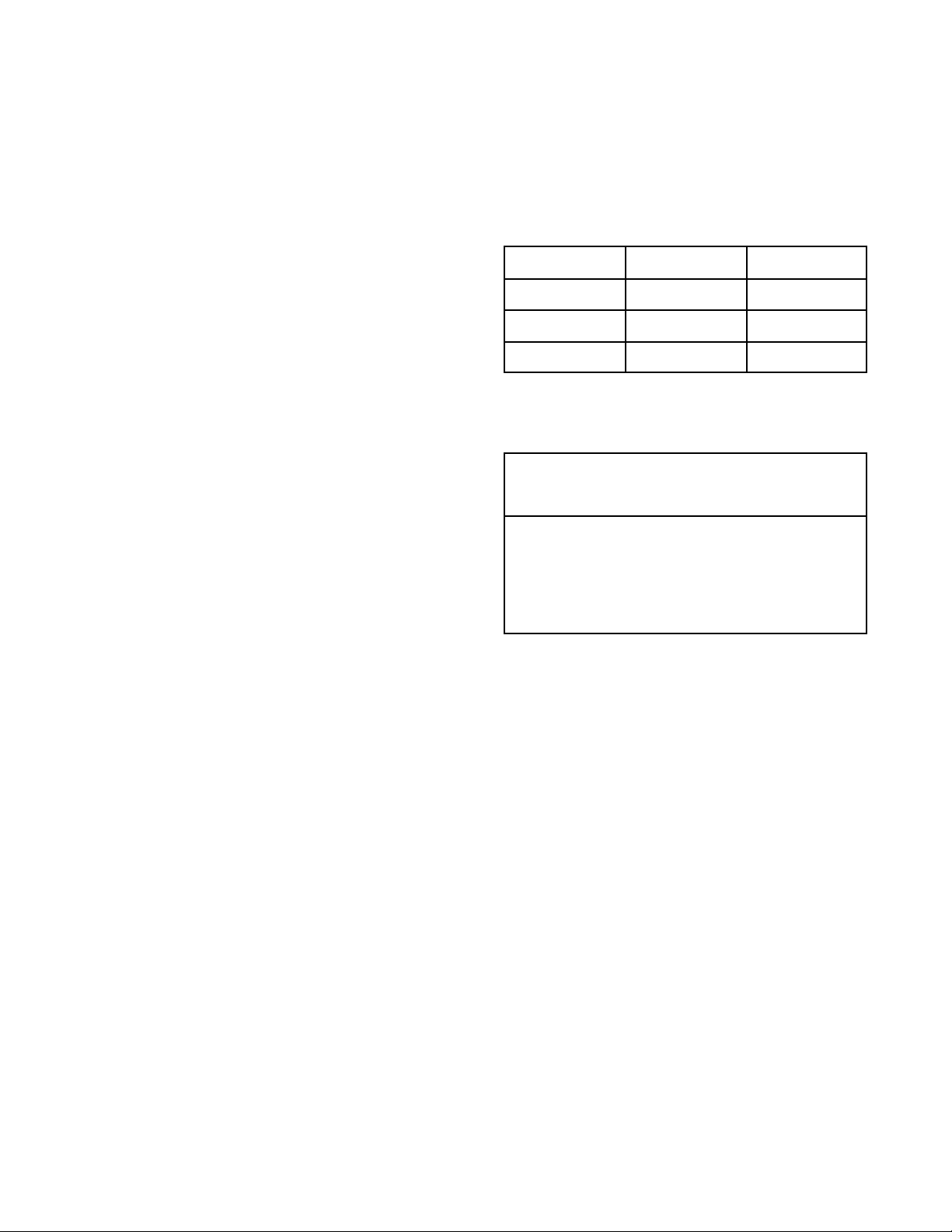

208 Volts 240 Volts 480 Volts

24 Kilowatt 24 Kilowatt 24 Kilowatt

36 Kilowatt 36 Kilowatt 36 Kilowatt

48 Kilowatt 48 Kilowatt 48 Kilowatt

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND

CAN SNAP BACK WHEN CUT.

UNIT WEIGHS 620 LB (282 KG) OR MORE.

FOR SAFE HANDLING OBTAIN HELP, OR USE

MATERIALS HANDLING EQUIPMENT (FORK

LIFT, DOLLY OR PALLET JACK) TO REMOVE

THE UNIT FROM THE SKID AND MOVE IT TO

ITS PLACE OF INSTALLATION.

When installation is to start, cut the straps and lift the

unit straight up off the skid.

Unit will arrive in a heavy carton,

mounted on a skid.

Beneath the heavy carton, the unit

will be wrapped in protective

plastic on a heavy skid.

4

Page 5

Water Conditioning

OM-NEB/1

It is essential that the boiler be supplied with water

that will not form scale at an unacceptable rate. The

boiler was engineered to minimize scale, but its

formation depends on water hardness and how

much the unit is used.

In some areas of the United States the water is low

enough in mineral content to avoid scale build-up.

However, most water supplies carry heavy loads of

minerals. This will form scale on the boiler, reduce

its steam output, and possibly cause premature

component failure.

Your water utility can tell you about the minerals in

your water. The water going to the steam generator

should have between 1 and 30 parts per million total

dissolved solids (TDS) and should have a pH (acidity

rating) of 7.0 or higher.

Please follow these simple precautions:

1. Do not rely on unproven water treatment

equipment which is sold for scale prevention or

scale removal. It frequently won’t work. The

best way to prevent scale is to supply the purest

possible water.

3. Installing a water meter between the softener

and the steamer will provide an accurate gauge

of water use, and will help determine when to

exchange cartridges or regenerate the softener.

Using a water softener will provide longer

generator life, higher steam capacity, and reduce

maintenance requirements.

4. If you notice a slowdown in steam production,

check the boiler for scale build-up. Heavy scale

reduces the unit’s ability to boil water, and can

even cause heating elements in the steam

generator to overheat and burn out.

5. Groen gas and electric pressure boilers are also

available with two separate water intakes:

one for the boiler (soft water)

one for the spray condenser (untreated water).

The steam generator only uses 14 to 31% of a

steamer’s water. Since softener systems are

typically sized by total GPH (gallons per hour),

the second intake could reduce treatment

requirements by up to 80%, resulting in

significant savings.

2. If your water contains scale-forming minerals, as

most water does, use a well-maintained water

softener. Whether an exchangeable softener

cartridge or a regenerating system is chosen, a

regular exchange system is essential.

Reduce scale problems by using and

maintaining a water softener for your

steamer!

Installation

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT.

Getting Started

WHEN THE UNIT IS RECEIVED, IMMEDIATELY

INSPECT IT FOR EXTERNAL OR INTERNAL

DAMAGE. REPORT ANY DAMAGE TO THE

FREIGHT CARRIER.

NOTE: A RETROFIT KIT IS AVAILABLE FROM

THE FACTORY FOR THOSE LOCALITIES IN

WHICH COMPLIANCE WITH CSD-1 STANDARDS

IS REQUIRED.

*In order to service the unit properly, access with

at least 24 inches clearance is needed on the

right side.

Level the unit front to rear and left to right by

adjusting its legs. Levelness may be checked by

using a spirit level on top of the cabinet.

Right Side — Two inches*

Left Side — Four inches

Rear — Six inches

After inspection, keep the unit in its shipping

container until it is installed. It can be installed on

combustible and non-combustible floors. Minimum

clearances are:

CAUTION

MAKING ANY ELECTRICAL OR MECHANICAL

CHANGE IN THE UNIT WITHOUT PRIOR GROEN

APPROVAL WILL VOID ALL WARRANTIES.

5

Page 6

OM-NEB/1

1. Electrical Supply Connection

Provide the proper voltage (60 Hz, Three Phase) as

specified on the electrical information plate attached

to the unit. The current draw and minimum

recommended wire size and insulation temperature

ratings are shown in the table below. Use only

copper wire. Local codes and/or the National

Electrical Code should be followed (ANSI/NFPA-701987 - or latest edition).

AN ELECTRICAL GROUND IS REQUIRED. The

ground terminal is located next to the supply terminal

block in the electrical enclosure. The main supply

knockout hole is sized for a 1½” conduit fitting. The

auxiliary supply knockout is sized for a ¾” conduit

fitting. Copies of the electrical schematic are located

in the electrical enclosure on the equipment and in

this manual. In Canada, electrical service must

comply with the Canadian Electrical Code, CSA

C22.1, Part 1, and/or local codes.

Voltage

208 24 67 2 6.5 8 3.3 90oC

208 36 100 2/0 9.3 6 4.1 90oC

208 48 100 (Main)

240 24 58 3 5.8 8 3.3 90oC

240 36 87 1 7.3 8 3.3 90oC

240 48 87 (Main)

480 24 29 3

480 36 44 1/0

480 48 58 2/0

Power Rating

(Kilowatt)

Current Draw

(Ampere)

34 (Auxiliary)

29 Auxiliary)

2. Water Connection

a. Cold water is supplied via a ½" NPT pipe

connection at the rear of the unit. A check valve

(back siphonage device) must be installed in

accord with local plumbing codes.

a. Water pressure should be between 30 and 60

PSI (215 and 420 kPa). If it is over 60 PSI (420

kPa), a pressure regulator is required. A strainer

screen at the connection is also recommended,

to trap any debris before it can enter the system.

c. The NEB/1 boiler uses water at the maximum

rate per hour shown below.

Maximum Water Consumption

Unit Gallons/Hour Liters/Hour

NEB/1 (24 KW) 8.2 31

NEB/1 (36 KW) 12.5 47.3

NEB/1 (48 KW) 16.9 64

Piping should be sized to handle total water

consumption.

Supply Wire Ground Wire

AWG mm AWG mm

2/0

6

1

8

8

6

3

9.3

4.1

7.3

3.3

5.8

3.3

8.3

4.1

9.3

5.8

6

10

6

10

10

10

10

10

8

8

4.1

2.6

4.1

2.6

2.6

2.6

2.6

2.6

3.3

3.3

3. Drain Connection

a. The drain connection is made at the rear of the

unit with 1¼" NPT pipe. DO NOT USE PLASTIC

PIPE. DRAIN PIPING MUST WITHSTAND

STEAM AND BOILING WATER. Extend the

drain piping to a nearby floor drain. Piping of

1¼" NPT (or 1½" NPT) is acceptable for

distances of six feet (2 m) or less. If the

distance to the drain is further than six feet (2

m), use 2" NPT piping.

b. The drain line must have a constant downward

pitch. Do not permit water traps in the line. DO

NOT CONNECT THE LINE DIRECTLY TO ANY

BUILDING DRAIN. There must be a vertical air

gap of at least two inches (5 cm) between the

drain line and the building drain unless otherwise

specified by local plumbing codes.

CAUTION

DO NOT LOCATE THE BOILER CABINET

DIRECTLY OVER A FLOOR DRAIN OR FLOOR

SINK. HUMIDITY OR WATER FROM A DRAIN

WILL DAMAGE ELECTRICAL PARTS.

IMPORTANT: Improper drain connection will

void warranty.

Rating

90oC

90oC

90oC

90oC

75oC

90oC

75oC

90oC

75oC

90oC

6

Page 7

4. Safety Valve

b. allows complete drainage of both the

Ensure that the safety valve (see picture, Page 11) is

vented properly. The following Installation Instruction

WARNING is quoted from the safety valve

manufacturer:

“During operation this valve may discharge large

amounts of steam and/or hot water. Therefore,

to reduce the potential for bodily injury and

property damage, a discharge line MUST be

installed that:

a. is connected from the valve outlet to a

safe point of discharge with no

intervening valve.

valve and the discharge line.

c. is independently supported and securely

anchored so as to avoid applied stress

on the valve.

d. is as short and straight as possible.

e. terminates freely to atmosphere where

any discharge will be clearly visible and

is at no risk of freezing.

f. terminates with a plain end which is not

threaded.

g. is constructed of a material suitable for

exposure to temperatures of 375oF or

greater

h. is, over its entire length, of a pipe size

equal to or greater than the valve outlet.”

Initial Start-Up

WARNING

ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE TRAINED IN SAFE AND CORRECT

OPERATING PROCEDURES.

OM-NEB/1

After the unit has been installed, test it to ensure that

it is operating properly.

1. Remove literature and packing material from the

interior and exterior of the unit.

2. Make certain the water supply is turned on.

3. Turn on electrical power to the unit.

4. Turn the ON/OFF switch on the cabinet front

panel to the “ON” position.

• The boiler drain valve will close and the unit

will fill with water.

• When the water level reaches the “mid”

probe, the red RESET light will come on.

• Push the START switch.

• The green light in the switch will come on

and the RESET light will go out. The heater

element contactors will close.

• When the water level reaches the “hi” probe,

the water supply to the boiler will shut off.

5. After about 15 minutes, the gauge pressure will

rise. When the pressure reaches 12 PSI (83

kPa), the main burner will turn off. Thereafter, as

pressure decreases, the contactors will close to

maintain the 12 PSI (83 kPa) level.

6. To shut the unit down, turn the ON/OFF switch to

OFF. When it has cooled to approximately

130oF, the unit will automatically drain.

If the unit functions as described above, it is ready

for use. If it does not, contact your authorized Groen

Service Agent.

7

Page 8

OM-NEB/1

Operation

WARNING

BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING INSTRUCTIONS,

CAUTIONS AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

1. Controls

Operating controls are located on the front panel of

the unit.

a. The on/off switch starts the boiler or shuts it

off.

b. The RESET indicator lights to show that the

boiler has filled with water and that the

heater elements can close.

c. The start switch (momentary) closes the

heater element contactors. It also restarts

the unit if electrical power is interrupted, or if

a low water condition in the boiler disables

the unit.

2. Operating Procedure

a. Turn on the water supply to the unit.

b. Turn on electrical power to the unit.

c. Turn the ON/OFF switch on the front of the

cabinet to “ON.”

1) The boiler drain valve will close and the

unit will fill with water.

3) When the water reaches the “mid”

probe, the red RESET light will come on.

4) Press the start switch.

5) The green light in the switch will come

on, the RESET light will go off, and the

heater element contactors will close.

6) When the water level reaches the “hi”

probe, the water supply to the boiler will

shut off.

d. After about 15 minutes, the pressure gauge

will indicate that the pressure is rising.

When it reaches 12 PSI (83 kPa), the heater

contactors will open. Thereafter, the

contactors will close as the pressure

decreases to maintain the pressure at 12

PSI (83 kPa).

f. To shut down the unit, turn the ON/OFF

switch to “OFF.” The unit will drain

automatically after it has cooled to about

130oF.

See OM-HY-6CAV for steamer cavity operation

and/or OM-TD for kettle operation information.

Sequence of Operation

When electrical power is turned on to the unit, the

following happens:

• The drain valve closes

• The water fill valve opens

• The unit fills with water

As the boiler fills, the water is detected by two

probes. The first of these is the “mid” probe, which

activates the RESET light. The second (“hi” probe)

is reached when the boiler is full, and shuts off the

water supply. As the water supply drops below this

probe, the water supply opens until it is again

reached.

A thermostatically-controlled air vent remains open

while the boiler fills. As steam develops, this vent

will close. Some steam may escape from the vent

before it is fully closed (at approximately 200oF)

(93oC).

Once the pressure has reached 12 PSI (kPa), the

operating pressure switch will open the heater

element contactors. As pressure decreases, the

heater element contactors close to maintain the

pressure at 12 PSI (83kPa).

If something causes the pressure to pass 14½PSI,

(100 kPa), a high-limit safety switch will electrically

shut down the boiler. If this happens, the unit should

not be re-started until the problem which caused the

shut-down has been corrected.

As an additional safety measure, the unit is equipped

with an A.S.M.E.-certified safety valve which will

open to relieve excess pressure at 15 PSI. The

ability of this valve to discharge steam pressure is

greater than the boiler’s ability to generate steam.

When the “ON/OFF” switch is turned “OFF,” a

thermostatic switch mounted on the boiler shell will

keep the drain valve closed until the temperature

drops to approximately 130oF (77oC). Then the

switch opens, and water drains from the boiler. A

vacuum breaker allows air to enter the boiler.

8

Page 9

Cleaning

OM-NEB/1

Whenever the boiler is turned off and allowed to cool

to about 130 oF, it drains automatically. This should

be done every day to minimize scale build-up inside

the boiler.

In addition to this draining, however, the following

cleaning procedure should be followed using a

regular schedule. This will prevent accumulation of

lime on the water level probes and interior surfaces

of the boiler. The actual time between these

scheduled cleanings depends on the water quality

and hours of operation. Minimally, Groen

recommends cleaning the boiler at least once each

month.

A. Suggested Tools

1. 1/2" hardened square wrench extension

2. Pipe Joint compound

3 32 oz. Groen Delimer Descaler (PN 114800),

Lime-A-Way or equivalent

4. Groen Spray Degreaser (PN 114801, or

equivalent

5. Nylon pad(s)

B. Procedure

WARNING

WATER AND VALVES MAY BE VERY HOT, AND

MAY CAUSE BURNS. ALLOW TIME TO COOL

AND PROTECT HANDS FROM HOT SURFACES

AND WATER.

1. Turn the boiler on/off switch to the OFF position.

2. Slowly open the manual drain valve to empty the

boiler. The valve is located under the boiler.

3. Close the manual drain valve.

4. Turn off water supply to the boiler.

5. Allow the boiler to cool. This takes several

hours, so it is recommended that you cool the

boiler overnight.

6. Turn on/off switch to “ON” to close the automatic

drain valve.

7. Using a 1/2" hardened square wrench extension,

remove one of the 1¼" NPT pipe plugs from the

front of the boiler.

The manual drain valve is located under the

boiler.

9

Page 10

OM-NEB/1

16. Completely wipe out steamer chambers using a

degreaser and nylon pad, if necessary. Rinse

thoroughly with clean water.

17. Replace fan baffle partitions.

USE SAFETY GLASSES AND RUBBER GLOVES

AS RECOMMENDED BY DE-LIMING AGENT

MANUFACTURER.

8. Pour 32 ounces of de-limer (Groen Delimer

Descaler - Part Number 114800), ECOLAB

Lime-a-Way or equivalent) into the boiler.

DO NOT USE A CLEANING OR DE-LIMING

AGENT THAT CONTAINS SULFAMIC ACID OR

ANY CHLORIDES, INCLUDING HYDROCHLORIC

ACID (HCL). IF THE CHLORIDE CONTENT OF

ANY PRODUCT IS UNCLEAR, CONSULT THE

MANUFACTURER.

9. Replace the pipe plug. Use pipe joint

compound, and tighten the plug securely.

10. Turn on water supply to allow water to fill the

boiler.

11. When the reset light appears, press the START

switch.

WARNING

®

CAUTION

18. Wait 10 minutes for the compartments to air dry,

then close the steamer doors.

19. Turn the on/off switch OFF, and slowly open the

manual drain valve.

WARNING

SOLUTION AND VALVES WILL BE VERY HOT,

AND MAY CAUSE BURNS. PROTECT HANDS

FROM HOT SURFACES AND CONTINUE TO USE

PROTECTIVE GLOVES.

20. When the boiler has drained completely, close

the manual drain valve and turn the on/off switch

to “ON” to fill the boiler with water.

21. After the RESET light comes on, press the start

switch.

22. Allow boiler pressure to develop

12. Allow boiler pressure to develop. Let it stand for

approximately 15 minutes after pressure has

built up. A badly limed unit may require more

than 15 minutes.

If there are no steamer cavities or compartments

with this boiler, proceed to step 19.

13. Turn on power to steamer cavities and set timers

for 10 minutes.

14. When steamer timers sound, turn them to OFF

and open the doors.

15. When the fans have stopped, remove fan baffle

partitions using protective gloves, and rinse

with clean water.

If steamers are not present, proceed to step 25.

23. Set steamer timers for 10 minutes.

24. When steamer signal sounds, turn timers off.

25. If the boiler is not to be used, it may be turned

off. It is ready for normal operation.

10

Page 11

Maintenance

Your Groen boiler is designed to minimize

maintenance, but certain parts may need to be

replaced after prolonged use. For the most part, no

user adjustments should be necessary. If a need for

service arises, only Groen personnel or Authorized

Groen Representatives should perform the work.

Among the most common problems is the build-up of

scale in the boiler. To avoid this, always supply

water that has a low mineral content, which meets

the standards described in the Water Conditioning

section of this manual.

WARNING

USE ONLY GROEN-SUPPLIED PARTS. USING

SUBSTITUTE, UNAUTHORIZED OR “GENERIC”

PARTS CAN CAUSE BODILY INJURY TO THE

OPERATOR AND DAMAGE THE EQUIPMENT.

1. Periodic Inspection

OM-NEB/1

WARNING

DO NOT EXPOSE SKIN TO ESCAPING STEAM.

SEVERE BURNS MAY RESULT.

At least twice each month, check the safety valve to

be sure it is working properly. (Ensure that the

safety valve is properly set up, as described in the

Installation Section of this manual (Page 7).

When pressure reaches five PSI on the gauge, lift

the lever to vent steam, then release it, allowing it to

snap back into place.

The unit should be inspected by a qualified service

technician at least once each year. The inspection

should include electrical wires and connections and

cleaning the inside of the control enclosure.

At the back of this manual (with the information

about our warranty) is a Maintenance and Service

Log. Each time maintenance is performed on the

unit, enter the date on which it was done, what was

done, and who did it.

In addition to yearly inspections by a qualified service

technician, a weekly check of the following will help

prevent down time and ensure continued efficient

operation.

1. Pressure gauge operation

2. Proper water level (gauge)

3. Strainer in water feed line (clear?)

4. Drain piping (free running? No blockage?)

The safety valve is located on the top left

rear of the boiler.

2. Component Replacement

The NEB/1 boiler is easy to service. The design is

simple, and controls are readily accessible.

Before replacing any part, COMPLETELY SHUT

OFF ELECTRICAL POWER TO THE UNIT.

11

Page 12

OM-NEB/1

Troubleshooting

Do not operate the unit if it malfunctions or has damaged or broken parts.

The NEB/1 steam boiler is designed to operate smoothly and efficiently when maintained properly. However, the

following is a list of checks to make if there is a problem. Electrical schematics are provided in this manual, and

inside the unit electrical enclosure. IF THE ITEM ON THE LIST IS MARKED WITH X, THE WORK SHOULD

ONLY BE DONE BY A FACTORY-AUTHORIZED SERVICE REPRESENTATIVE.

SYMPTOM WHO WHAT TO CHECK

Items marked with X should only be done by a factory-authorized service rep.

Boiler does not fill with water. User a. Is water supply connected and is water present?

b. Is water pressure low (less than 30 PSI)?

c. Is strainer screen (if used) clogged?

d. Is on/off switch in base cabinet turned on? Is the amber light in

the on/off switch “ON”?

e. Is the manual drain valve open?

Auth

Service

Rep Only

Boiler overfills with water. User a. Is the boiler level? Check levelness of unit with a spirit level.

Auth

Service

Rep Only

Boiler underfills with water User a. Is the boiler level? Check levelness of unit with a spirit level.

Water enters boiler slowly. User a. Is strainer screen (if used) clogged?

Auth

Service

Rep Only

RESET light does not come

on.

Heater(s) will not come on. Auth

Boiler does not build pressure

with heaters on.

Auth

Service

Rep Only

Service

Rep Only

User a. Is the steam power take-off valve open or leaking?

Auth

Service

Rep Only

f. Is the Water Level Control Board (PCB) defective? Check for

loose electrical connections on water fill solenoid. X

g. Is the water fill solenoid valve defective? X

h. Is the solenoid drain valve open or leaking? Check for loose

electrical connections on solenoid drain valve. X

b. Is the water pressure too high? (Greater than 60 PSI?)

c. Is the Water Level Control Board (PCB) defective? Check for

loose electrical connections on “hi” water fill solenoid. X

d. Is the water fill solenoid valve defective? X Check for debris on

valve seat.

e. Is the “hi” water probe sensing level? Clean water level probe

and probe well (located in boiler). X

b. Is the water pressure too low? (Less than 30 PSI)?

c. Is the water supply line too small?

d. Is the water fill solenoid defective? X

a. Is the Is the Water Level Control Board (PCB) defective? Check

for loose electrical connections on “mid” water fill solenoid. X

b. Is the “mid” water probe sensing level? Clean water level probe

and probe well (located in boiler). X

c. Is the indicator light defective? X

a. Are contactors defective? X

b. Is the heater burned out? Check voltage and amperage on

each line at each heater. X

c. Is the contactor control relay defective? Note: Relay controls all

contactor coils. X

b. Is the pressure gauge defective?

c. Is the air vent leaking steam? X

d. Is the solenoid or manual drain valve open or leaking? NOTE:

Excessive make-up water added to the boiler reduces steam

production. X

12

Page 13

Troubleshooting (Continued)

SYMPTOM WHO WHAT TO CHECK

Heater(s) does (do) not shut

off after reaching operating

pressure.

Boiler builds pressure but

shuts down. RESET light

comes on.

Safety relief valve opens. Auth

Boiler blows down

immediately when turned off.

Boiler does not drain. Auth

Auth

Service

Rep Only

User can

check

Auth

Service

Rep Only

Service

Rep Only

Auth

Service

Rep Only

Service

Rep Only

OM-NEB/1

Items marked with X should only be done by a factory-authorized service rep.

a. Is the pressure gauge defective? X

b. Is the operating pressure switch defective? No adjustment is

allowed. Replace the switch if defective. X

c. Are the contactors defective? X

d. Is the contactor control relay defective? X

a. Is the water level below the “mid” water level probe? Verify that

the water supply is sufficient to maintain the water level at or

above the “mid” water level probe.

b. Is the operating pressure switch defective? No adjustment is

allowed. Replace the switch if defective. NOTE: If the high-limit

pressure switch has shut down the unit, it should not be

restarted until the problem which caused the shut-down has

been corrected. X

c. Is the “mid” water level probe unable to detect water? Clean the

water level probe and probe well (located in the boiler). X

a. Are the operating pressure switch and/or high-limit pressure

switch defective? No adjustment is allowed. Replace defective

switches. X

b. Is the safety relief valve defective? Replace with ASME-

approved 15 PSI valve with “HV” marking. X

a. Is the thermostatic switch defective? Check for loose electrical

connections on switch. X

a. Is the thermostatic switch defective? X

b. Is the solenoid drain valve defective? X

c. Are the solenoid drain valve or hoses blocked? X

13

Page 14

OM-NEB/1

Parts List

Key Description Part No. Key Description Part No.

1 Main Power Distribution Block 099295 9 Relay 24VAC Coil 074842

2 Ground Lug 002863 10 Gasket 003494

3 Fuse Holder 096809 11 Blind Flange 003433

4 Fuse 20 AMP 071489 12A Heater Element 208 Volt (12KW) 051159

5 Auxilliary Power Distribution Block 003888 12B Heater Element 240 Volt (12KW) 051355

6 Contactor 102254 12C Heater Element 480 Volt (12KW) 051358

**7 Transformer 480V Primary 220V Secondary 099294 13 Wire Harness (Not Shown) 102223

**8 Fuse 3/10 AMP 086881

* Used on 208 Volt — 240 Volt 48 KW Units Only

** Used on 480 Volt Units Only

14

Page 15

Parts List

OM-NEB/1

Key Description Part No. Key Description Part No.

1 Boiler Weldment MS93747 11 Globe Valve 1/2" NPT 099255

2 Water Gauge Assy (Includes Sight Glass) 101401 12 Operating Pressure Switch (12 PSI) 099244

3 Sight Glass (5/8" Dia. X 4" Lg.) 070620 13 Hi-limit Pressure Switch (14-1/2 PSI) 099223

4 Safety Valve (15 PSI) 102297 14 Pressure Gauge 078000

5 Water Level Probe (3 Places) 014356 15 Solenoid Valve (Drain) 074594

6 Extension, Water Level Probe (3 Places) 041885 16 Ball Valve (3/4" NPT) 009883

7 Solenoid Valve (Water-in) 099220 17 Thermostatic Switch 077985

8 Check Valve 004187 18 Piping Kit 098263

9 Air Vent 084098 19 Union Elbow 061468

10 Vacuum Breaker 090787

15

Page 16

OM-NEB/1

Parts List

Key Description Part No. Key Description Part No.

1 Switch "On/off" 088876 8 Fuse, 3 Amp (Fast-blow) 077853

2 Switch "Start" (Momentary) 099290 9 Relay 24VAC Coil 074842

3 Indicator Light "Reset" 099289 10 Transformer 208/240V480V Pri-24V Sec. 099291

4 Circuit Board Supports (1/2" High) 099292 11 Fuse, 7 AMP 096798

5 Liquid Level Control Board 099246 12 Tie Anchor 102231

6 Circuit Board Supports (1/4" High) 102228 — Wire Harness (Not Shown) 102213

7 Fuse Board 102220

16

Page 17

Electrical Schematic

OM-NEB/1

208Volt/240Volt (24 KW and 36 KW)

17

Page 18

OM-NEB/1

Electrical Schematic

480Volt (24 KW, 36 KW and 48 KW)

18

Page 19

Electrical Schematic

OM-NEB/1

208Volt/240Volt (48 KW)

19

Page 20

OM-NEB/1

References

UNDERWRITERS LABORATORIES, INC.

333 Pfingsten Road

Northbrook, Illinois 60062

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March park

Quincy, Massachusetts 02269

NFPA/70 — The National Electrical Code

NOTE: A RETROFIT KIT IS AVAILABLE FROM THE FACTORY FOR THOSE

AREAS IN WHICH COMPLIANCE WITH CSD-1 STANDARDS IS REQUIRED.

20

Page 21

Service Log

OM-NEB/1

Model No.

Serial No.

Date Purchased

Purchase Order No.

Date Maintenance Performed Performed by

Purchased From

Location

Date Installed

For Service Call

21

Page 22

OM-NEB/1

NOTES

22

Page 23

OM-NEB/1

LIMITED WARRANTY TO

COMMERCIAL PURCHASERS*

(Continental U.S., Hawaii and Canadian Sales Only)

Groen Foodservice Equipment (“Groen Equipment”) has been skillfully manufactured, carefully inspected, and

packaged to meet rigid standards of excellence. Groen warrants its Equipment to be free from defects in

material and workmanship for (12) twelve months, with the following conditions and subject to the following

limitations.

This parts and labor warranty is limited to Groen Equipment sold to the original commercial

purchaser/users (but not original equipment manufacturers {O.E.M.}), at its original place of installation in

the continental United States, Hawaii and Canada.

Damage during shipment is to be reported to the carrier, is not covered under this warranty, and is the

sole responsibility of the purchaser/user.

Groen, or an authorized service representative, will repair or replace, at Groen’s sole election, any Groen

equipment, including but not limited to, drawoff valves, safety valves, gas and electric components, found

to be defective during the warranty period. As to warranty service in the territory described above, Groen

will absorb labor and portal to portal transportation costs (time and mileage) for the first twelve (12)

months from date of installation or fifteen (15) months from date of shipment from Groen.

This warranty does not cover boiler maintenance, calibration, periodic adjustments as specified in

operating instructions or manuals, and consumable parts such as scraper blades, gaskets, packings, etc.,

or labor costs incurred for removal of adjacent equipment or objects to gain access to Groen Equipment.

This warranty does not cover defects caused by improper installation, abuse, careless operation, or

improper maintenance of equipment. This warranty does not cover damage caused by poor water quality

or improper boiler maintenance.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE

REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL GROEN BE LIABLE

FOR SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN

PERFORMANCE OF THIS WARRANTY.

Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.) Manufacturer’s

equipment, or if used as a consumer product, such Equipment is sold AS IS and without any warranty.

*(Covers all Foodservice Equipment Ordered after October 1, 1995)

23

Page 24

1055 Mendell Davis Drive

Jackson, MS 39272

Telephone 601 372-3903

FAX 601 373-9587

OM-NEB/1 (Revised 3/98)

Part Number 121012

Loading...

Loading...