Page 1

Cooker/Mixer

Description

Cooker/Mixer Kettle shall be a Groen Model DHT-40 or

60, TA/3 (specify 40- or 60-gallon) stainless steel, self

contained 2/3 steam jacketed unit operating from a gasheated steam source contained within unit, complete with

console-mounted tilt-out twin shaft scraper mixer.

Construction

Kettle interior shall be of type 316 stainless steel, solid

one-piece welded construction. The control console and

kettle exterior shall be 304 stainless steel. The kettle

body shall be mounted on a heavy-duty stainless steel,

combination kettle support tilt trunnion, which, is supported by the polished stainless steel enclosed base. The

kettle shall be furnished with heavy-duty reinforced rim

with a butterfly-shaped pouring lip for maximum sanitation and ease of pouring. The base shall be provided with

stainless steel tubular legs with adjustable bullet feet.

The enclosed support base shall contain a self-locking

worm and gear tilt mechanism, controls, etc., and shall

be of sanitary, drip-proof construction with interior readily

accessible for installation or maintenance. Unit includes

2” TDO, 10-Gallon etch markings and double pantry

faucet.

Agitator Assembly

Enclosed transfer case to be cast aluminum with a 3- to-1

gear ratio. Gear motor to be completely enclosed-type,

cast iron housing, right angle shaft down, helical bevel

gearing, variable-speed motor driven through an electronic speed control. See table on back for minimum and

maximum agitator speeds.

Main agitator to be anchor type, shaped to the contour

of the kettle and provided with removable nylon finger

scrapers. The secondary counter-rotating bar type agitator shall be centrally-located between the center shaft

and the outside arms of the main agitator. Both agitators

are attached with bayonet connections for easy, quick

removal for cleaning or when kettle is to be used without

the mixing mechanism. Both agitators are 304 stainless

steel and either can be used alone.

Agitator and motor drive assembly can be manually tilted

to the right side of the kettle.

Finish

Kettle interior shall be polished to a 180 emery grit finish.

Kettle exterior shall be finished to a bright semi-delux finish, ensuring maximum ease in cleaning and maintaining

brilliant appearance.

ASME Code, and CSA Certification

Unit shall be ASME shop-inspected, stamped and registered with the National Board for operation up to a

maximum working pressure of 50 PSIG. Kettle shall be

design certified by CSA America for use with natural gas

or LP gas.

Sanitation

Unit shall be designed and constructed to be NSF listed,

meeting NSF requirements.

Self-Contained Steam Source

Kettle shall have an gas-heated (natural or propane), selfcontained steam source to provide kettle temperatures

models DHT-40 TA/3 & DHT-60 TA/3

Model DHT-60, TA/3 shown

of 150°F to approximately 295°F. Unit shall be factorycharged with water and rust inhibitors to ensure long life

and minimum maintenance.

Controls

Controls shall include a thermostat, pressure gauge, water

sight glass, a gas regulator valve and electronic ignition.

Power ON switch, power ON indicator light, low water

indicator light, agitator ON-OFF switch, motor speed control

and double-pantry faucet with bracket. Electronic ignition

to standing pilot is standard on all models.

Agitator to be of electronic, variable speed control-type

capable of operating at any RPM between minimum and

maximum settings.

Safety Features

Kettle shall have safety cut-off (turns off heat when tilted

to 10° and above), pressure relief valve, high limit pressure

switch and low water cut-off, 24Volt control system and

agitator safety tilt cut-off.

Options/Accessories

Disk Strainers (Not to be used with agitator)

240, 480 Volt Power Supply

Kettle Brush Kit

Pan Carrier

Gallon Master

Basket Insert

Lip strainers

Contour measuring strips

Installation Requirements

Specify natural or propane gas. Unit requires 1/2 “ NPT

gas line connection, 115Volt, 60Hz power for kettle and 208

Volt (3-phase only) power for agitator motor. No remote

steam source required.

Origin of Manufacture

Cooker/Mixer shall be designed and manufactured in the

United States.

Stainless Steel

2/3 Steam Jacketed

Cooker/Mixer

Floor-Mounted

Tilting,

Self-Contained,

Gas-Heated

40 or 60-Gallon

Capacity with Tilt-Out

Twin Shaft Agitator

Short Form

Groen Model DHT-40 or 60,

TA/3, (specify gallons) selfcontained, gas-heated, (specify natural or propane) tilting,

stainless steel, steam jacketed

cooker mixer, with twin shaft

tilt-out agitator scraper mixer.

Twin shaft agitator assembly

standard, with multiple scraping fingers and the second

agitator is counter rotating mixer. Base shall house

smooth-action positive lock,

manual-tilt assembly. 316

stainless steel kettle interior

has solid, one-piece, welded

construction with heavy-duty

reinforced rim and butterflyshaped pouring lip. Twin shaft

agitator mounted on console

with mechanically assisted

manual tilt-out and positive

quick-action rim lock and

latch. Unit is standard with

2” TDO valve and etch marks.

Kettle NSF-listed, ASME code

constructed for 50 PSI, Kettle

shall be CSA design certified

(natural and propane gas only).

1/2” NPT gas line, 115 Volt

electric service for kettle, 208

Volt, 1 or 3-phase for agitator

motor. Made in USA.

Applications

Meats

Soups

Stews

Sauces

Pie fillings

Pudding

Beans

Powdered mixes

Icings

Custards

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen Cooker/Mixer, Page 5

143942D

Revised 08/09

Page 2

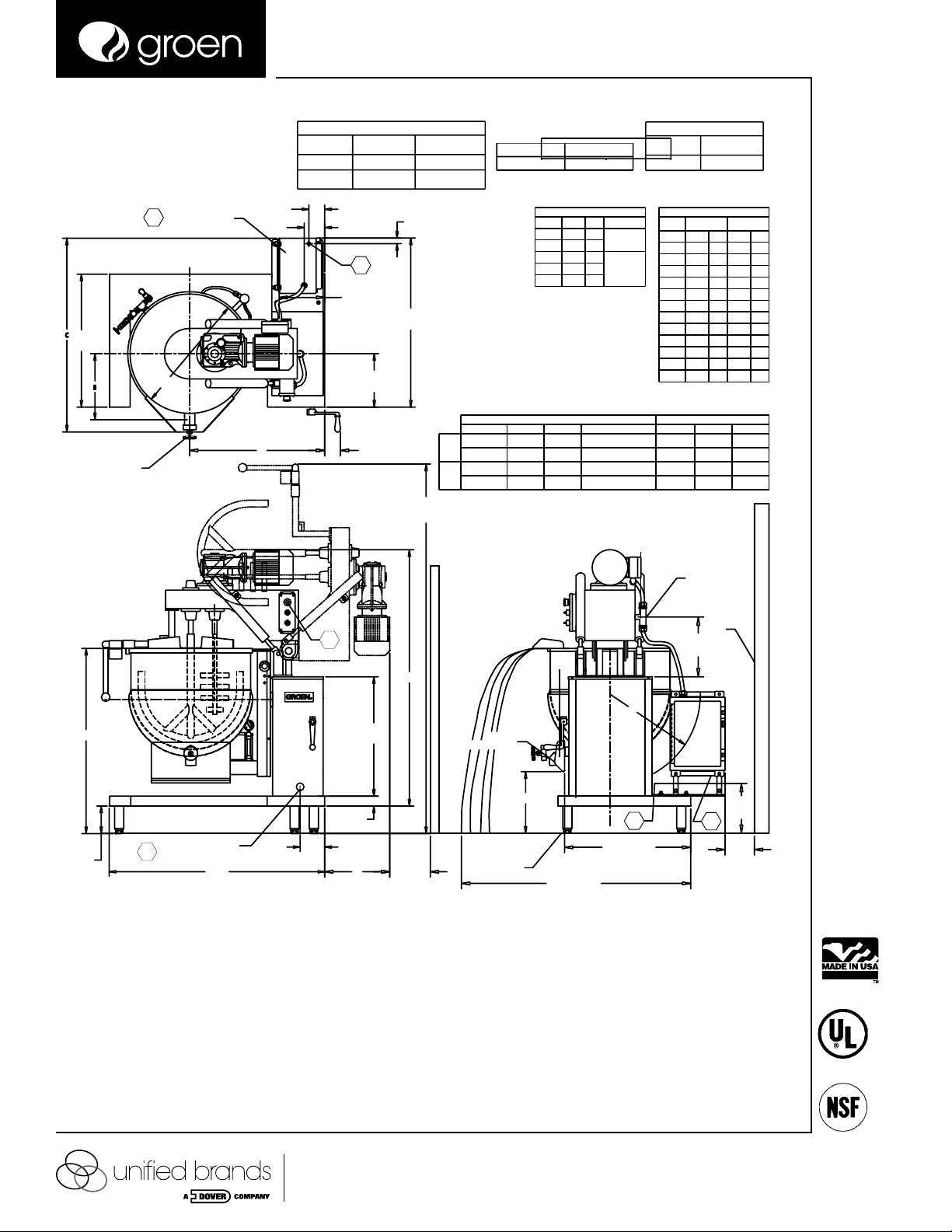

16-1/2

749

879

1025

387

546

1854

1613

1460

749

362

318

G

73

29-1/2

14-1/4

12-1/2

L

M

K

63-1/2

57-1/2

H

J

D

40-3/8

15-1/4

21-1/2

F

E

29-1/2

42-1/4

C

B

2070

81-1/2

31-1/2

12-3/8

314

419

800

68-3/4

61-1/2

1746

1562

1121

44-1/8

23-1/2

13-1/4

597

337

31

44-1/8

927

787

MM

660

DIM.

MODEL

40 GAL.

INCH

26A

TABLE OF DIMENSIONS

60 GAL.

INCH

30MM762

AGITATOR MOTOR DATA SPECIFICATIONS

27

54

RPM MAIN

MINIMUM

MAXIMUM

H.P.

1-1/2 150

75

RPM SECONDARY 240V 3PH

4.8 A

2.8 A

480V 3PH

2.4 A

1.4 A

23

462 120

60

6.2 A

3.6 A

3.1 A

1.8 A

MINIMUM

MAXIMUM

208V 3PH

5.3 A

3.1 A

6.9 A

4.0 A

ELEC. LOAD RATING

GAL

40

GAL

60

59 A

105 A

61 A

29 A480 V

3 PH

240 V

24 KW

LOAD

101 A

VOLTAGE PHASE

1 PH208 V

KETTLE POWER ELECTRICAL TABLE

POWER

21 KW

3 PH

1 PH

3 PH

47

(1194)

29

(737)

A ID

G

CLERANCE INCLUDING

HANDLE & LATCH DEVICE

6 MIN

(152)

7-1/2" MAX.

(191)

6-1/2

(165)

26

(257)

2-3/16

(165)

B

3-1/2

(89)

K

MIN. POUR PATH

KETTLE IN

TILTED POSITION

E

2"

TANGENT DRAWOFF

(OPTIONAL)

ELECTRICAL CONNECTION

FOR KETTLE 1" IPS

ADJUSTABLE FEET

J

MAX. POUR PATH

6 MIN (152)

REAR WALL

CLERANCE

WALL

6

(152)

ELECTRICAL

CONNECTION

FOR MIXERS

3/4" IPS

13 1/16

(332)

140906 REV. A

2

4

3

9-1/4

(235)

2

1

6 (152)

MIN.

SIDE WALL

CLERANCE

1

CONTROL BOX MAY BE

MOUNTED REMOTELY TO

AN ADJACENT WALL

(BY CUSTOMER)

C

11 5/8

(295)

36 7/8

(937)

F

4 1/2

(114)

3 1/2

(89)

1 1/4

(32)

Models DHT-40 TA/3 & DHT-60 TA/3

P/N 140906 REV A

INCOMING GAS PRESSURE TABLE

TYPE OF GAS

NATURAL

PROPANE

MIN.SUPPLY

GASPRESSURE

4.5 W.C.

11.0 W.C.

MAX.SUPPLY

GASPRESSURE

14.0 W.C.

14 W.C.

DH/1-40

DH/60

FIRING RATE (BTU/HR)

100,000

FOR BOTH NATURAL AND LP

150,000

OPERATING GAS PRESSURE

NATURAL

3.5W.C.

PROPANE

10.0W.C.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...