Groen DH-INA-2-100 Service Manual

? IMPORTANT INFORMATION ? KEEP FOR OPERATOR ? IMPORTANT INFORMATION?

OPERATOR MANUAL OM-DH/INA/2-100

Part Number 121018 DOMESTIC

Model: DH/INA/2-100

Steam Jacketed Kettle

Self-contained

Gas heated

Floor Mounted

Tilting

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND

AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS.

THIS INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR

LOCAL GAS SUPPLIER. AS A MINIMUM, TURN OFF THE GAS AND CALL

YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

OM-DH/INA/2-100

IMPORTANT — READ FIRST — IMPORTANT

WARNING: FAILURE TO DISCONNECT POWER BEFORE SERVICING COULD RESULT IN

ELECTROCUTION AND DEATH.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

WARNING: DO NOT PLACE HANDS, TOOLS OR HOSES IN KETTLE WHILE AGITATOR IS MOVING.

AGITATOR CAN BE JOGGED WHILE KETTLE IS TILTED.

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICABLE CODES.

WARNING: DO NOT ATTACH THE UNIT TO A TYPE “B” VENT. IT COULD CAUSE FIRE OR PROPERTY

DAMAGE.

WARNING: DO NOT CONNECT ANY PIPING TO THE SAFETY VALVE. IT MUST BE FREE TO VENT

STEAM AS NEEDED. TO AVOID BURNS FROM THE VENTED STEAM THE VALVE

DISCHARGE SHOULD POINT DOWNWARD.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO GROUND

THE UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

CAUTION: DO NOT OVERFILL THE KETTLE WHEN COOKING, HOLDING OR CLEANING. KEEP

LIQUIDS A MINIMUM OF 2-3" (5-8 CM) BELOW THE KETTLE BODY RIM TO ALLOW

CLEARANCE FOR STIRRING, BOILING AND SAFE TRANSFER OF PRODUCT.

CAUTION: KEEP FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY TO AVOID SLIPS OR FALLS.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND BURNERS. NEVER SPRAY OR

HOSE DOWN THE CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. TAKE PRECAUTIONS: WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD

AND PROTECTIVE CLOTHING. CAREFULLY READ WARNINGS AND FOLLOW

DIRECTIONS ON CLEANER LABELS .

NOTICE: NEVER LEAVE A SANITIZER IN CONTACT WITH STAINLESS STEEL SURFACES LONGER

THAN 10 MINUTES. LONGER CONTACT CAN CAUSE CORROSION.

WARNING: FAILURE TO PERIODICALLY CHECK SAFETY VALVE OPERATION COULD RESULT IN

PERSONAL INJURY AND/OR DAMAGE TO EQUIPMENT.

WARNING: WHEN TESTING, AVOID EXPOSURE TO THE STEAM BLOWING OUT OF THE SAFETY

VALVE. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: TO AVOID INJURY, READ AND FOLLOW ALL PRECAUTIONS STATED ON THE LABEL OF

THE WATER TREATMENT COMPOUND.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER

SUPPLY AND CLOSE THE MAIN GAS VALVE. ALLOW FIVE MINUTES FOR GAS TO VENT.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR

AUTHORIZED DISTRIBUTORS CAN CAUSE INJURY TO THE OPERATOR AND DAMAGE TO

THE EQUIPMENT AND WILL VOID ALL WARRANTIES.

Important: Service Performed by Other than Factory Authorized Personnel Will Void All Warranties.

WARNING: KEEP AREA AROUND KETTLE FREE AND CLEAR OF ALL COMBUSTIBLE MATERIALS.

FAILURE TO DO SO COULD RESULT IN FIRE OR PROPERTY DAMAGE.

WARNING: OPENING BOTTOM DROP VALVE EMPTIES KETTLE CONTENTS. CONTENTS MAY BE

HOT.

CAUTION: HEATING AN EMPTY KETTLE MAY CAUSE THE RELEASE OF STEAM FROM THE SAFETY

VALVE.

2

OM-DH/INA/2-100

Table of Contents

INSTALLER AND OPERATOR WARNINGS .....................................2

EQUIPMENT DESCRIPTION .................................................4

INSPECTION & UNPACKING ................................................ 5

INSTALLATION & START-UP ................................................ 7

OPERATION .............................................................9

CLEANING ..............................................................12

PREVENTIVE MAINTENANCE ..............................................15

SEQUENCE OF OPERATION ............................................... 16

MAINTENANCE .........................................................17

TROUBLESHOOTING (OPERATOR) .........................................18

PARTS LISTS & SCHEMATICS ..............................................20

REFERENCES ...........................................................37

SERVICE LOG ...........................................................38

WARRANTY .............................................................39

3

OM-DH/INA/2-100

Equipment Description

Groen Model DH/INA/2-100 is a stainless steel,

steam jacketed, floor mounted, tilting kettle with a

self-contained, gas heated steam source. The

Model DH/INA/2-100 is equipped with the INA/2

style inclined agitator/mixer. The kettle body is

welded into one piece and furnished with a

reinforced bar rim and welded “butterfly” pouring lip.

The interior of the kettle is polished to a 180 emery

grit finish and the exterior given a uniform Number 4

finish.

The unit is ASME shop-inspected and is registered

with the National Board for working pressures up to

50 PSI. Kettle supports mount directly to the floor by

use of lag bolts. A power tilt feature is standard.

Options available include: Air-operated bottom outlet

valve, 1½, two or three inch manual ball valve,

“Gallon Master” metering system, product outlet

strainer, and Honeywell DPR 100C Recorder.

The self-contained steam source is heated by either

propane or natural gas. The ignition system is spark

or standing pilot. The kettle is charged at the factory

with chemically pure water containing corrosion

inhibitors. The steam source provides kettle

temperatures of 150 to approximately 280 o F.

Controls for the unit include a thermostat, pressure

gauge, water level glass, safety valve, pressure limit

control, low water cutoff, gas regulator valve, and a

printed circuit board that monitors product

temperature. The gas supply shuts down

automatically when the kettle is tilted. The agitator

operates only in partial rotation mode when the

kettle is tilted.

The unit must be specified for use with natural or

propane gas. Service connections are required for

gas, electric, air (if the air-operated valve is

specified), water (if Gallon Master metering is

specified).

4

OM-DH/INA/2-100

KETTLE CHARACTERISTICS

Firing Rate, BTU / Hour

Model Ignition Natural Gas Propane Gas

DH-INA/2-100 Electronic 360,000 360,000

Dimensions

Kettle Capacity Kettle Diameter Overall Width

100 Gal (378.5 L) 34" (86 cm) 64¼” (163 cm) 54" (137 cm) 54¼” (138 cm)

Overall Front-to-

Back

Rim Height

Inspection & Unpacking

WARNING

THIS UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH ELECTRICITY

AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES.

The unit is delivered completely assembled, on a heavy

skid surrounded by a wooden crate.. Immediately upon

receipt, inspect the unit for damage. Report any shipping

damage or an incorrect shipment to the delivery agent.

Write down the model number, serial number, and

installation date of your unit, and keep this information

for future reference. Space for these entries is provided

at the top of the Service Log provided at the rear of this

manual. The unit is anchored to two metal shipping

channels (braces) which may be discarded after

installation. Carefully unbolt one side of shipping

channel. Position the kettle and remove second

shipping channel.

WARNING

SHIPPING CHANNELS (BRACES) ARE VERY

HEAVY. USE PROPER LIFTING AND HANDLING

EQUIPMENT FOR MOVEMENT

CAUTION

WATCH OUT FOR NAILS AND SPLINTERS

WHILE DISMANTLING THE SHIPPING CRATE.

The unit is delivered crated and bolted to a heavy

skid.

Two heavy shipping channels (braces) anchor

the unit for shipment.

5

OM-DH/INA/2-100

CAUTION

UNIT HAS AN APPROXIMATE SHIPPING WEIGHT OF

1750 LBS. (795 KG.). FOR SAFE HANDLING,

INSTALLER SHOULD OBTAIN PROFESSIONAL

RIGGING HELP AS NEEDED AND USE MATERIAL

HANDLING EQUIPMENT (SUCH AS A FORKLIFT,

OVERHEAD HOIST, OR PALLET JACKS) TO

REMOVE THE UNIT FROM THE SKID AND MOVE IT

TO ITS PLACE OF INSTALLATION.

When installation is to begin, unbolt the unit from the

skid, and lift the unit straight up and off the skid.

UTILITY REQUIREMENTS

1. Electrical Supply Connection-3 Phase Operation

Only

a. The panel must be removed to gain access to the

electrical supply connection. Open the wiring and

control panel by unscrewing the eight screws

which hold it in place. Grasp the panel by the

base at the bottom edge. While lifting the panel,

swing its bottom toward you. Set the panel aside.

b. Supply Voltage: The unit must operate at the

rated nameplate voltage, plus or minus 10

percent.

c. Wiring Information: Refer to the electrical

schematic for wiring information. A copy of the

schematic is found inside the control panel and at

the rear of this manual.

d. Terminal Block: The terminal block for incoming

power is located at the back of the control

compartment. The ground terminal is located next

to the terminal block. The unit must have a

separate ground wire for safe operation.

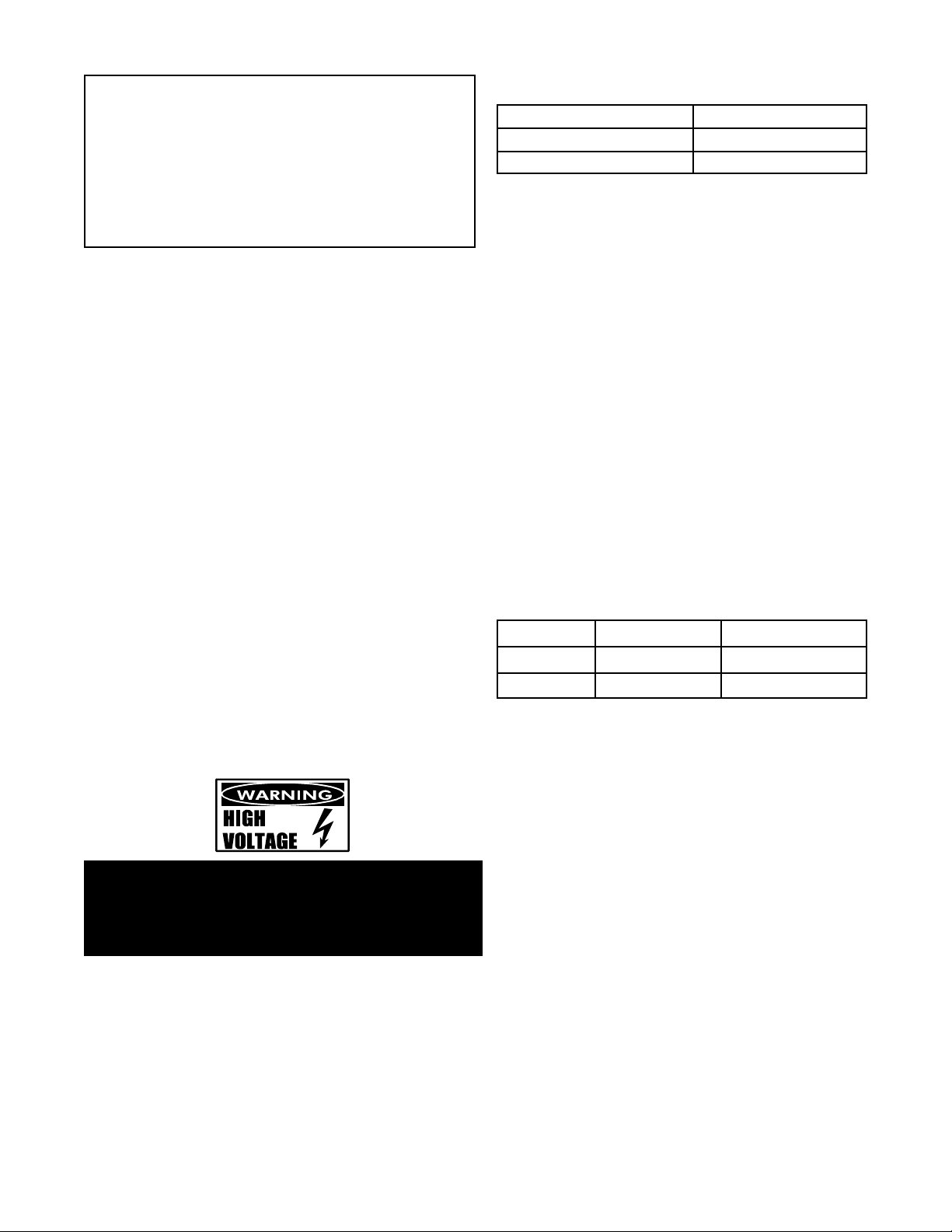

Maximum Voltage Three Phase Current, Per Line

208 7 AMP

240 7 AMP

480 3.5 AMP

2. Water Connection(s)

Install a check valve in the incoming cold water

line, if required by local plumbing codes. Water

pressure in the line should be between 30 and 60

PSIG (210 and 420 kPa).

A ¾ NPT connector is needed to attach the water

supply to the water inlet valve. The minimum

recommended water feed line diameter is ½ inch

(13mm).

Do not allow the connection to leak, no matter

how slowly. THE INSTALLER MUST PROVIDE

THE CHECK VALVE (ANTI-SYPHON DEVICE)

IF REQUIRED BY LOCAL CODES.

3. Air Connection.

Connect d NPT air line to the air connector.

4. Gas Connection

Connect 1 NPT gas line to the gas inlet valve on

the rear of the left stanchion. Be sure that the

gas supply meets the following criteria:

Natural Gas Propane

Minimum 7" W.C. 11" W.C.

Maximum 10" W.C. 14" W.C.

e. High Voltage safety

WARNING

TO AVOID DAMAGE OR INJURY, FOLLOW THE

ELECTRICAL SCHEMATIC EXACTLY WHEN

CONNECTING THE UNIT.

f. Branch Circuit Protection: Each conductor must

have over-current protection. Refer to the label

on the back of the unit for the proper wire type

and size. Connections to the unit must be

watertight.

We strongly recommend that the DH/INA/2-100

Kettle have its own branch circuit protection.

Current and power demands for the different

voltage units are as follows:

Gas, Water and Air Connections are on the

back of the left stanchion

6

OM-DH/INA/2-100

WARNING

THIS UNIT IS FOR COMMERCIAL USE. NEVER USE HOME OR RESIDENTIAL GRADE GAS CONNECTIONS.

THEY DO NOT MEET GAS CODES AND COULD BE HAZARDOUS.

Installation and Initial Start-Up

A. Installation

The unit should be installed in a well-ventilated room on

non-combustible flooring. Anything which might

obstruct or restrict the flow of air for combustion and

ventilation must be removed. The area directly around

the appliance must be free of combustible materials.

1. Installation requires connection with air, gas, water

and electric services. See items 8 to 14 for details.

2. To protect the unit from damage, leave it on the

shipping pallet until installation. When ready to start

installation, disassemble the shipping crate, unbolt the

stanchions, disconnect the shipping channels

(braces) and raise the unit straight up off the skid. Do

WARNING

DO NOT ATTACH THE UNIT TO A TYPE "B"

VENT. FAILURE COULD RESULT IN FIRE OR

PROPERTY DAMAGE.

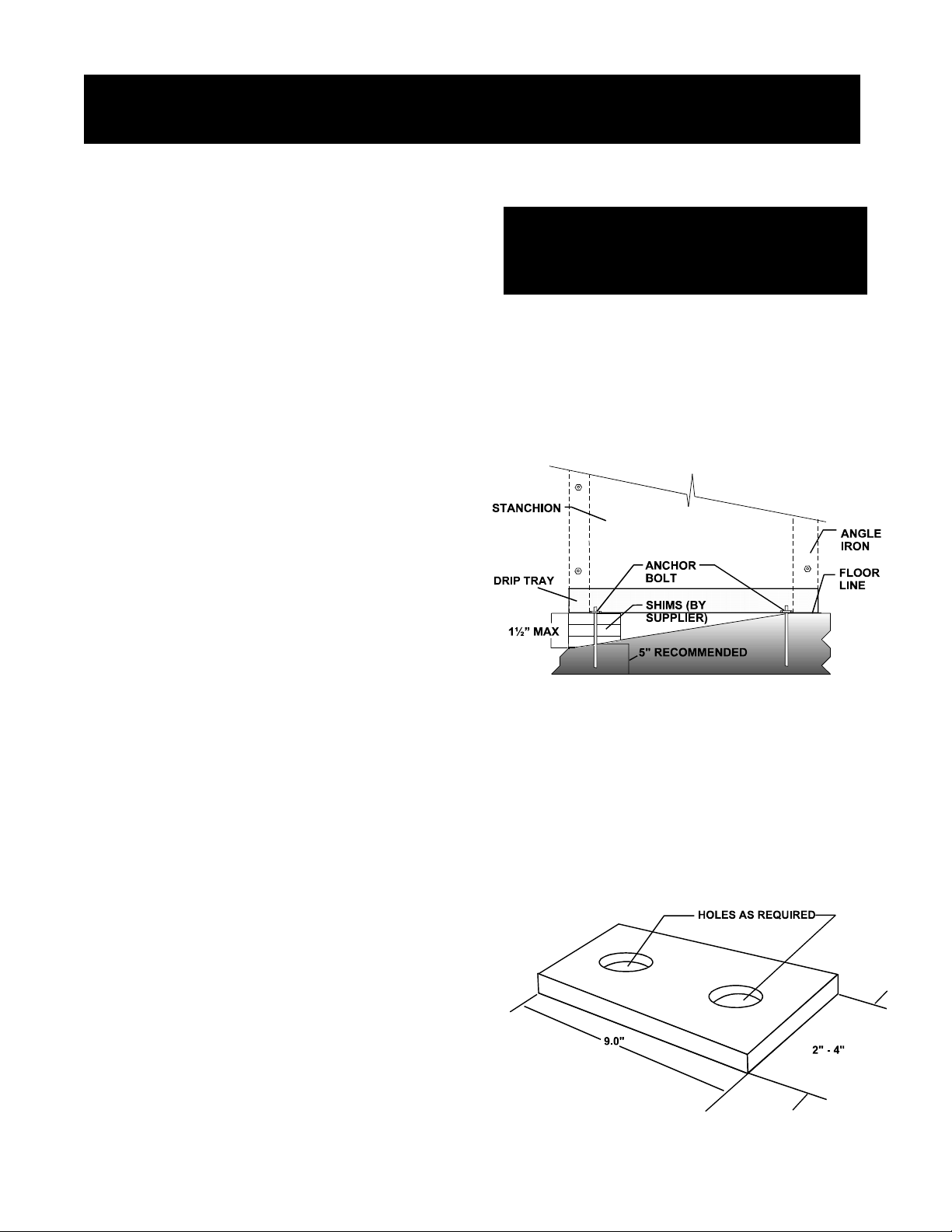

5. Level the unit as follows.

The stanchions are each supplied with a drip tray

in which the angle frame is placed. Steel

leveling shims (not included, supplied by

installer) are placed between the drip tray and

frame so that the drip tray will be flush with the

floor, as shown.

Lifting the kettle at the heat exchanger could damage

the unit.

not lift the kettle at the heat exchanger.

3. Install the unit with at least 22 inches clearance

from the back walls. Also leave enough room for

easy cleaning, maintenance, and service.

4. Do not alter the kettle in any way. Any mechanical,

electrical, or gas change must be approved by the

Groen Food Service Engineering Department.

Start with the right stanchion and level it as

shown in the sketch. Once the right stanchion is

levelled and properly anchored front to rear, level

the left stanchion front to rear and side to side.

Level the entire unit side to side by placing a four

foot carpenter’s level on the kettle rim. Once the

rim is level from side to side, rotate the level to

check front to back. Shim the left stanchion in

the same manner as the right, and anchor the

equipment firmly to the floor through the shims.

Recommended shim size is shown below.

7

OM-DH/INA/2-100

6. Make sure the jacket water level is correct by

confirming that it is between the marks on the gauge

glass. If the water level is low, follow the instructions

under "Jacket Filling" in the "Maintenance" Section of

this manual.

WARNING

DO NOT CONNECT ANY PIPING TO THE POP

SAFETY VALVE. IT MUST BE FREE TO VENT

STEAM AS NEEDED. THE ELBOW SHOULD

POINT DOWN TOWARD FLOOR. IMPROPER

INSTALLATION WILL VOID WARRANTY

7. To protect personnel from steam coming from the

safety valve, the open end of the elbow at the outlet

must be directed downward. If it is not, turn the

elbow to the correct position.

Requirements Section, Page 6. Use ½ inch

waterproof conduit and waterproof connections.

Observe local Codes and/or The National

Electrical Code in accordance with ANSI/NFPA 70

- latest edition. AN ELECTRICAL GROUND IS

REQUIRED. The electrical schematic is located on

the inside of the service panel. In Canada,

provide electrical service in accordance with the

Canadian Electrical code, CSA C22.1 Part 1

and/or local codes.

10. The internal gas lines of the unit were cleaned and

closed with a gas cock before the unit was shipped

from the factory. Ensure that external gas lines

are free of lint, dirt, metal chips, sealant, grease,

oil or other contaminants, before you connect the

line to the kettle.

11. Connect the kettle gas cock to the gas service

main using a 1" NPT gas connection.

12. Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z 223.1-1988 (or latest edition).

The unit should be installed in an well-ventilated

room with a provision for adequate air supply. The

best ventilation will use a vent hood and exhaust

fan with no direct connection between the vent

duct and the unit flue.

8. I nst

all a check valve in the incoming cold water line, if

required by local plumbing codes, as described in

Paragraph 2, page 6

DANGER

ELECTRICALLY GROUND THE UNIT AT THE

TERMINAL PROVIDED. FAILURE TO GROUND

UNIT COULD CAUSE ELECTROCUTION AND

DEATH.

9. Provide electrical service per Paragraph 1, Electrical

Supply Connecton in the Inspection and Unpacking,

Do NOT obstruct the flue or vent duct after

installation. In Canada, the installation must

conform with the CAN/CGA B149 Installation

Codes for Gas Burning Appliances and

Equipment and/or local codes.

13. Adequate space for proper service and operation

is required. Do NOT block any air intake spacings

to the combustion chamber or obstruct the air flow

by piling or stacking anything near the kettle.

14. After the kettle has been connected to the gas

supply, all gas line joints must be checked for

leaks. DO NOT USE A FLAME TO CHECK FOR

LEAKS. A thick soap solution or other suitable

leak detector should be used.

15. The appliance and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of ½ PSIG (3.48 kPa).

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any testing of the gas

system at pressures equal to or less than ½

PSIG (3.48 kPa).

16. Connect the kettle compressed air supply to a d”

NPT air line

8

17. Check the following to confirm that your kettle has

been installed properly:

’ Enough room between the kettle and nearby

objects for cleaning and service.

OM-DH/INA/2-100

B. Initial Start-Up

After the kettle has been installed, the installer should

test to ensure that the unit is operating correctly.

’ Minimum clearance of 24 inches from sides and

24 from back.

’ Unit vented to an exhaust hood.

’ Kettle level.

’ Correct amount of water in the jacket.

’ Safety valve outlet pointed down.

’ Connected with a waterproof electric power cable

in accordance with Paragraph 1 Electrical Supply

Connecton (above) and local electrical codes.

’ Gas lines cleaned before connection.

’ Gas connected with 1 NPT or larger.

’ Gas line joints checked for leaks.

’ No obstruction to air supply or venting.

’ Gas lines (1 NPT) connected to supply.

’ Water supply connection (¾") completed.

1. Remove all literature and packing materials from

the inside and outside of the unit. Clean out any

material that might clog or damage the product

outlet.

2. Put water into the kettle until the water is about 12

inches deep. Test operation of the product outlet

ball valve by opening it all the way then closing it

before all the water runs out.

3. Make sure the supplies of gas and electric power

are on.

4. Following "Start Kettle Heating" instructions in the

"Operating Instructions" section of this manual,

begin heating the water at the highest thermostat

setting. The pilot lamp should come on as soon as

you pull out the emergency stop and turn on

power. Heating should continue until the water

boils.

5. To turn off the unit, follow “To Stop Kettle Heating”

in “Operating Instructions,” below.

If the kettle functions as described, it is ready for use.

If the unit does not operate as designed, contact an

authorized Groen Service agent.

Operation

ANY POTENTIAL USER OF THE EQUIPMENT MUST BE TRAINED IN SAFE AND CORRECT OPERATING

PROCEDURES

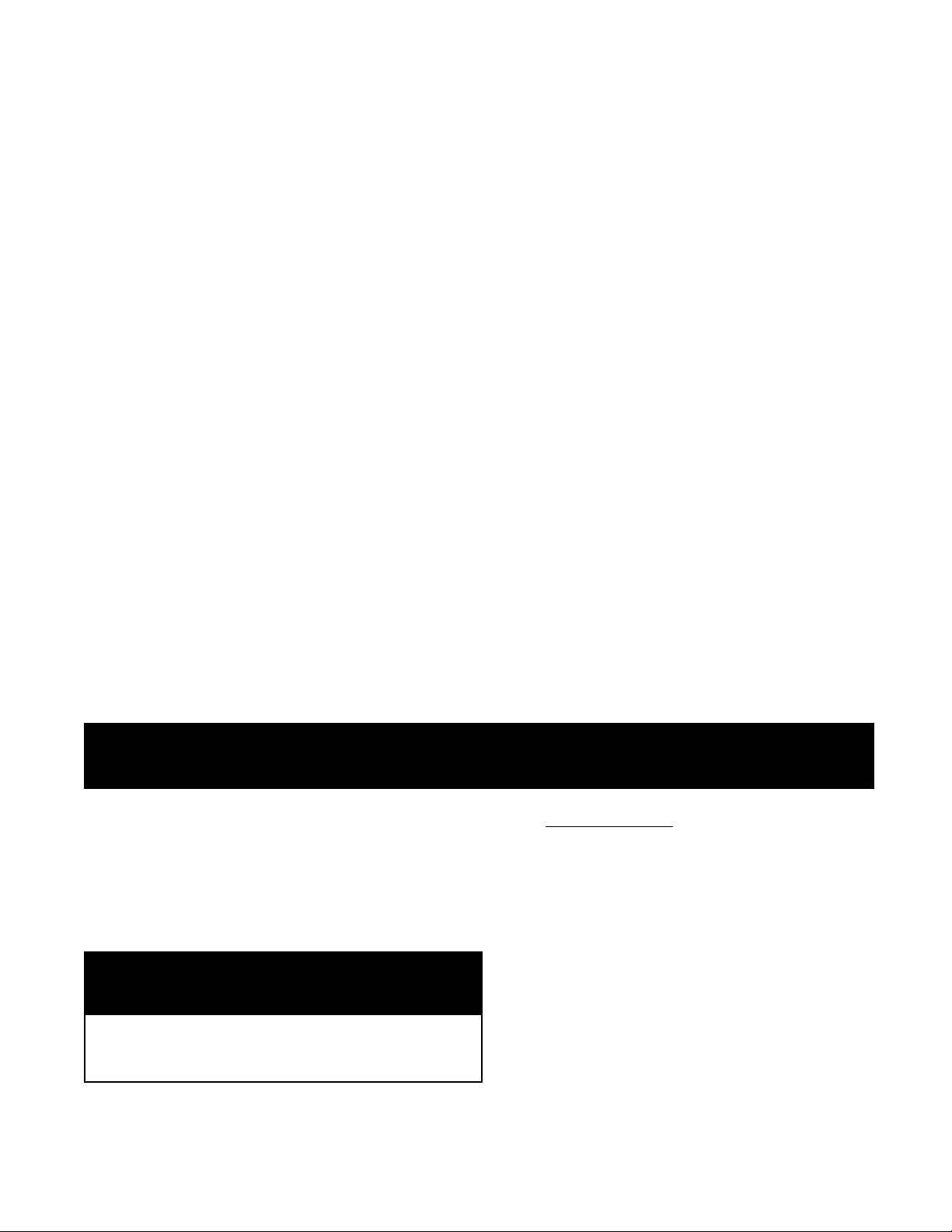

A. Controls

Refer to the drawing on the following page for

identification and function of kettle controls. Numbers in

parentheses in the operating instructions below

correspond to these controls.

B. Operating Instructions

WARNING

KEEP AREA AROUND KETTLE FREE AND CLEAR OF

ALL COMBUSTIBLE MATERIALS

CAUTION

HEATING AN EMPTY KETTLE MAY CAUSE THE

RELEASE OF STEAM FROM THE SAFETY VALVE.

WARNING

1. To Start Kettle

a. CHECK THE WATER LEVEL IN THE

JACKET EVERY DAY. The level must be

between the lines on the glass. If the level

is low, see “Jacket Filling” in the “Preventive

Maintenance” section of this manual.

b. With the kettle cold, check the pressure

gauge. If it does not show 20 or more

inches of vacuum (a reading of 20 to 30

below 0), see “Jacket Vacuum” in the

“Preventive Maintenance” section of this

manual.

9

OM-DH/INA/2-100

Right Stanchion Control Panel

10

Check water level and vacuum daily.

OM-DH/INA/2-100

WARNING

DO NOT PLACE HANDS, TOOLS, OR HOSES IN

KETTLE WHILE AGITATOR IS MOVING.

AGITATOR CAN BE JOGGED WHILE KETTLE IS

TILTED.

ENSURE AGITATOR AREA IS CLEAR BEFORE

RUNNING OR JOGGING THE AGITATOR.

SERIOUS INJURY CAN RESULT.

a. Ensure kettle is upright (tilt light must be off).

b. Place run/jog switch (7) in run position.

c. Set the agitator speed dial (6) to desired speed

(1 - 10 RPM).

d. Press the left (4) and right (8) agitator start

switches at the same time. This is for safety, to

avoid accidental start-up of the agitator.

c. Start Kettle Heating

1. Open main gas supply valve.

2. Pull out the emergency stop (9) and turn on

the control power on-off switch (10).

3. Ensure kettle is fully upright (tilt light (3)

must be off).

4. Pilot and pilot indicator lamp (near water

sight glass on front panel) will light

(DO NOT ATTEMPT TO LIGHT PILOT WITH

FLAME).

5. Fill kettle with water or product.

6. Turn heat switch (11) to on.

7. Select desired product temperature using

the temperature controller (13).

c. To Stop Kettle Heating

Turn heat switch (11) or control power (10) off.

d. To Relight Kettle

1. Close main gas supply valve.

CAUTION

KEEP FLOORS IN FRONT OF KETTLE WORK

AREA CLEAN AND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY TO AVOID THE DANGER

OF SLIPS OR FALLS

3. To Stop Agitator.

a. Press the red stop button (5) or

b. Press the emergency stop button (9).

4. To Jog Agitator

The operator can “jog” or partially rotate the

agitator to assist in shifting product, or to help

clean interior kettle and agitator surfaces. Do not

press the Jog button with any personnel near the

kettle agitator.

2. Set control power switch (10) to off.

3. Wait five minutes then start the kettle.

2. To Run Agitator

11

OM-DH/INA/2-100

b When the tilt indIcator (3) is lit, it indicates that

the kettle is not fully upright.

c. The kettle will not heat or agitate while tilted. It

WILL jog!

WARNING

AGITATOR WILL JOG WITH KETTLE IN ANY

POSITION. TO AVOID SERIOUS INJURY KEEP

CLEAR WHEN JOGGING AGITATOR.

a. Place run/jog switch (7) in the jog position.

b. Press and release the start / jog button (4) as

needed. (The jog speed is fixed.)

5. To Tilt Kettle

WARNING

DO NOT STAND IN FRONT OF KETTLE DURING

TILTING. PRODUCT IS HOT AND WILL CAUSE

BURNS.

To tilt kettle forward, rotate the tilt switch (3)

clockwise. Turn counter-clockwise to tilt back.

6. To Fill Kettle Automatically with Water

a. Select desired gallons by pressing the Gallons

Counter (2) keys. Do not set counter to a value

greater than the remaining capacity of the

kettle.

b. Move fill switch (1) to auto. Reset the gallons

counter (2) to zero (if needed).

c. After filling stops, turn the fill switch (1) to off.

The switch must be set to off before another fill

cycle can begin.

d. More water can be added by rotating the fill

switch (1) to manual.

e. The gallons counter (2) will show any added

water.

7. If Electric Power Fails

Do not attempt to operate the unit. The main

burner cannot be lit until power is restored.

A. KETTLE

1. Suggested Tools

a. Detergent and sanitizer, or a combination agent

such as Micro-Quat from ECOLAB.

b. Kettle brushes.

c. Bottle brush for cleaning the draw-off valve.

WARNING

KEEP WATER AND SOLUTIONS OUT OF

CONTROLS AND BURNERS. NEVER SPRAY OR

HOSE THE CONTROL CONSOLE, ELECTRICAL

CONNECTIONS, ETC.

Cleaning

2. Precautions

Before any cleaning operation:

a. Turn off the main burner by turning the heat

control dial to “OFF”.

b. Cut off electric power to the unit

3. Procedure

a. Clean food contact surfaces as soon as possible

after use, preferably while the kettle is still warm.

If the unit is in continuous use, clean and

sanitize inside and outside at least once every 12

hours.

b. Scrape and flush out large amounts of food

residues. Be careful not to scratch the kettle

with metal implements.

12

Loading...

Loading...