Page 1

SMARTSTEAM100 BOILERLESS STEAMER

PROJECT NAME:

LOCATION:

ITEM NO:

MODEL (2)SSB-5GF

Steamer shall be a Groen Model (2)SSB-5GF double-stacked SmartSteam100™ stainless steel, boilerless,

convection steamer. Each steamer shall have a self-contained atmospheric 58,000 BTU/hr gas steam

generating reservoir.

CONSTRUCTION: Steamer shall be constructed of

s/s with non-vented removable side panels for access to

the mechanical housing while impeding water migration

due to cleaning. Door shall be field reversible and equipped

with hands free door latch and a one piece easily removable

gasket. Interior shall be equipped with two s/s pan slide

racks and a steam reservoir cover all of which are easily

removable for cleaning. Each steamer door is accompanied

with a condensate tray positioned below each cavity opening.

FINISH: Cabinet exterior shall be a uniform #3 finish with

the interior being of high polished finish to aid in cleanability.

CERTIFICATIONS / LISTINGS: Steamer shall be

CSA certified and NSF listed.

PAN CAPACITY:

Pan Size Per Cavity Total

12 x 20 x 2 1/2” 5 10

12 x 20 x 4” 3 6

12 x 20 x 6” 2 4

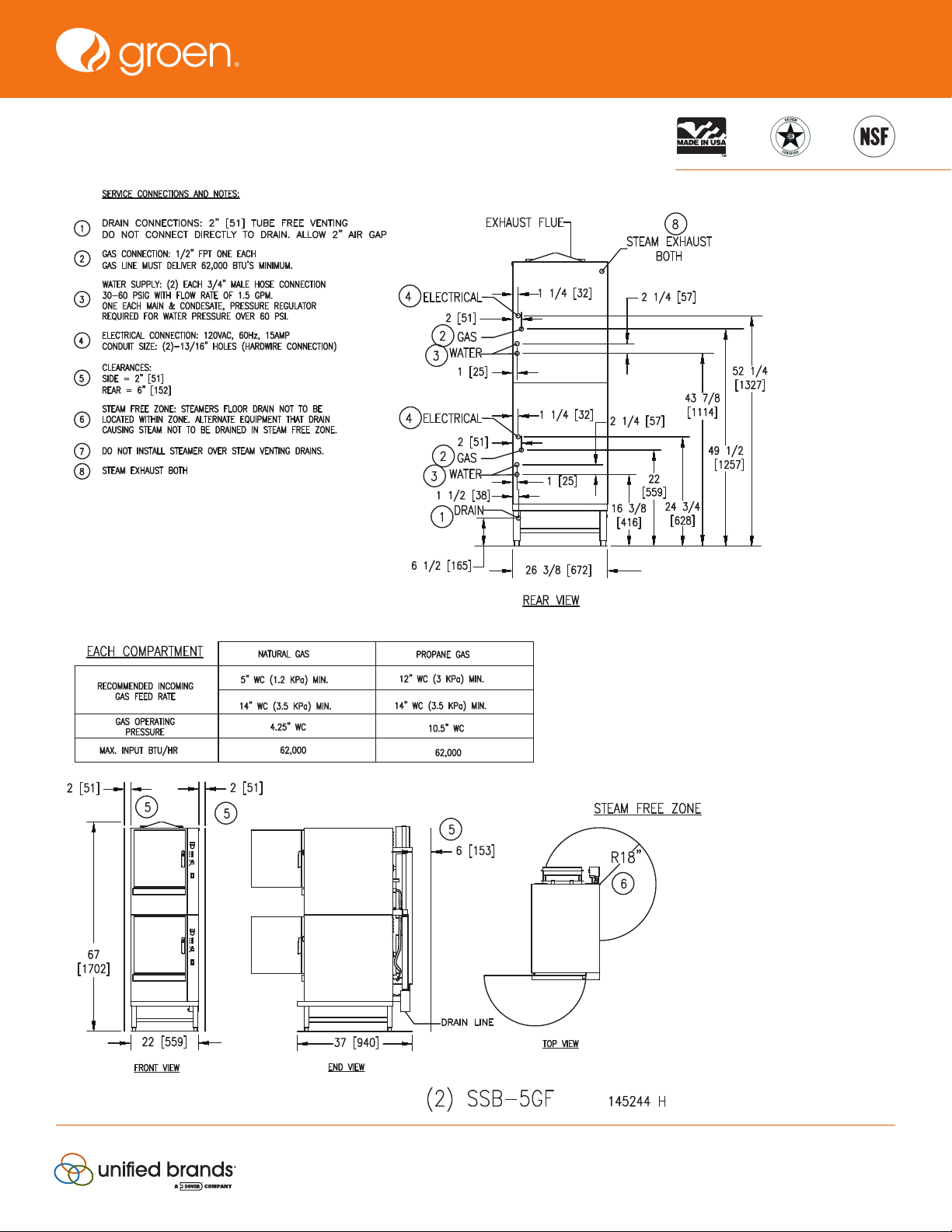

INSTALLATION: Each steamer shall require

natural or propane (specify) gas service via a 1/2

NPT gas supply line or approved equivalent. Each

cavity shall have (2) 3/4” NH cold water supply line

connections and a single 2-1/2” free venting drain

connection. Each steamer shall require 115 Volt,

single-phase electrical service.

QTY:

MODEL NO:

AIA NO:

SIS NO:

10-Pan Boilerless Convection

Steamer (5 pans per cavity), doublestacked, stand-mounted, stainless

steel, self-contained, gas heated.

(Model (2)SSB-5GF shown)

CONTROLS: Steamer shall have electronic controls

provided with continuous and timed steaming modes. The

steamer will have an audible alarm when completion of

timed steaming is met and will automatically switch to its

standby mode for energy savings. Controls are provided with

a self-diagnostic feature and visual code display for ease of

trouble shooting.

PERFORMANCE FEATURES: The steamer

cavities interior shall have a powerful convection fan to insure

even energy transfer throughout the entire cavity eliminating

temperature variations and ensuring uniform cooking. A

steam lid over the water reservoir will minimize energy

loss and provide fast recovery when adding and removing

food product. A hidden magnetic door switch will turn off

convection fan and reservoir generator when the door is

opened. Each steam generating reservoir is to be powered

by a 58,000 BTU infrared burner assembly providing an

approximant 212ºF cavity temperature atmospherically.

Initial start up to ready is typically 15 minutes or less with

operational recovery from ready to steam at typically (1)

minute. The water reservoir will auto fill and auto drain when

required with the water level maintained by a float system.

WATER SUPPLY REQUIREMENTS:

Steamer must be connected to an on-site water

supply. Water supply at 30 - 60 PSIG with flow at .75

- 1.5 GPM per cavity.

ORIGIN OF MANUFACTURE: Designed and

manufactured in the United States.

OPTIONS/ACCESSORIES:

Correctional Package

Field Drain Tempering Kit

½” Gas Quick Disconnect

Heat Shield

Caster Kit

SmartSteam Water

Treatment Kit

SmartSteam Water Treatment

Replacement Cartridge

High Altitude Kit

(above 2000’, specify)

SmartSteam100

144871 RevH

Revised 12/15

Page 2

P/N 145244 REV H

(2)SSB-5GF

888-994-7636, unifiedbrands.net

© 2015 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...