COLLET CLOSER

MODEL G4026

INSTRUCTION MANUAL

FOR USE WITH METAL CUTTING LATHE MODEL G4002/G4003

COPYRIGHT © MAY, 2003 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

PRINTED IN CHINA

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

METALWORKING EQUIPMENT

SAFETY INSTRUCTIONS

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words which are intended to convey the level

of importance of the safety messages. The progression of symbols is described below.

Remember that safety messages by themselves do not eliminate danger and are not a substitute

for proper accident prevention measures.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

This symbol is used to alert the user to useful information about

NOTICE

proper operation of the equipment or property damage hazards.

Safety Instructions For Metalworking Machines

1. READ AND UNDERSTAND MACHINE

OWNERS MANUAL FOR YOUR LATHE.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form a habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DO NOT USE IN DANGEROUS

ENVIRONMENT. DO NOT use power

tools in damp or wet locations, or where

any flammable or noxious fumes may

exist. Keep work area well lighted.

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be

kept at a safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DO NOT FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. DO NOT force tool or

attachment to do a job for which it was not

designed.

G4026 Collet Closer

Safety Instructions For Metalworking Tools

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause

a drop in line voltage resulting in loss of

power and overheating. Your extension

cord must also contain a ground wire and

plug pin. Always repair or replace extension cords if they become damaged.

Minimum Gauge for Extension Cords

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 16 16 16

7-10 16 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

10. WEAR PROPER APPAREL. DO NOT

wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which

may get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use properly secured

clamps or vises to hold work while performing the machining operation

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. On machines with magnetic

contact starting switches there is a risk of

starting if the machine is bumped or jarred.

Always disconnect from power source

before adjusting or servicing. Make sure

switch is in OFF position before reconnecting.

17. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its

operation. A guard or other part that is damaged should be properly repaired or

replaced.

18. NEVER LEAVE MACHINE RUNNING

UNATTENDED. TURN POWER OFF.

DO NOT leave machine until it comes to a

complete stop.

19. SOME COOLANTS USED FOR MACHINING

MAY CONTAIN HAZARDOUS CHEMICALS.

Read and understand all user information

on the coolant container and protect yourself accordingly.

20. NEVER OPERATE A MACHINE WHEN

TIRED, OR UNDER THE INFLUENCE OF

DRUGS OR ALCOHOL. Full mental alert-

ness is required at all times when running a

machine.

13. DO NOT OVER-REACH. Keep proper

footing and balance at all times.

14. MAINTAIN TOOLS AND MACHINERY

WITH CARE. Keep tools sharp and clean

for best and safest performance. Follow

instructions for lubricating and changing

accessories.

15. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

No list of safety guidelines can be complete. Every shop environment is different.

Always consider safety first, as it applies to

your individual working conditions. Use

this and other machinery with caution and

respect. Failure to do so could result in

serious personal injury, damage to equipment or poor work results.

-2-

INTRODUCTION

Commentary

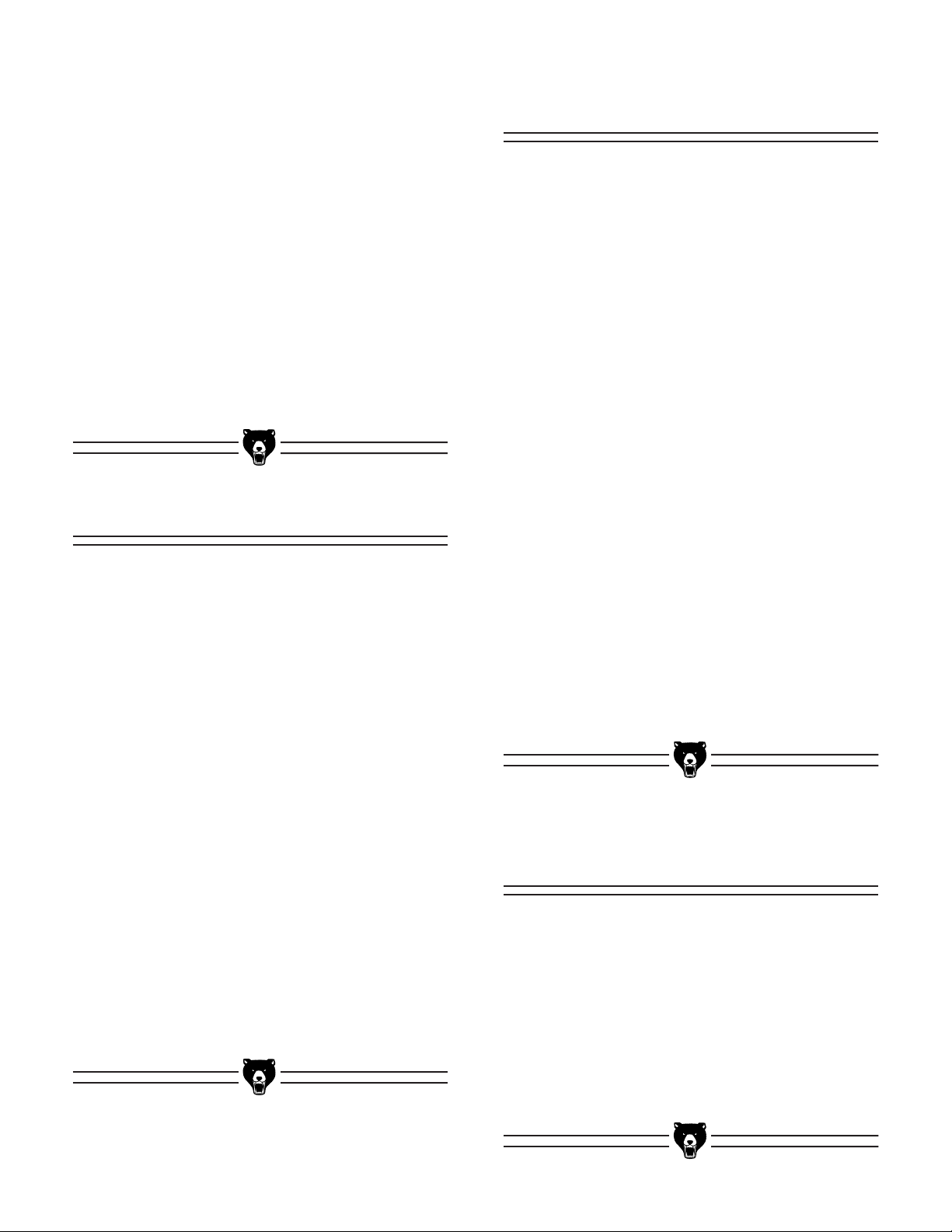

The Model G4026 Collet Closer allows you to

quickly interchange 5-C collets on your Model

G4002 or Model G4003 Metal-Cutting Lathe. The

positive-locking handle clamps standard 5-C collets safely and securely for precision turning.

Grizzly also offers an extensive line of precision-ground 5-C collets, ideal for use with the

Model G4026 Collet Closer. See the latest Grizzly

Catalog or visit our web site at www.grizzly.com

for price and ordering information.

Most importantly, we stand behind our tools. If

you have any service questions or parts requests,

please call or write us at the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901-Mail: support@grizzly.com

Site: http://www.grizzly.com

Cover Removal

Mounting the Model G4026 requires the use of a

few simple tools.

Tools Required:

— Adjustable wrench

— 3MM hex key

— 4MM hex key

To remove the lathe cover and the mounting

studs:

Remove the end cover from the lathe by unscrewing the cover knobs on the left end of the lathe.

The top cover knob removal is shown in Figure 1.

Disconnect power to your lathe before

beginning installation of the Model

G4026 Collet Closer.

To begin assembly, follow these initial safety

instructions.

1. Disconnect the lathe from the power

source!

2. Remove the chuck or any other device that is

mounted to the spindle. (Refer to your owner’s manual.)

3. Make sure the 5-C Collet/Morse Taper

Adapter (included in the kit) and the spindle

opening are clean and free of oil. Use a soft

cloth or rag to wipe up any contaminant.

G4026 Collet Closer

Figure 1. Lathe cover removal.

G4026 Collet Closer

Mounting Studs

Pivot Connector

To remove the mounting stud and install the

replacement stud:

1. Remove the upper mounting stud as shown

in Figure 2.

Figure 2. Mounting stud removal.

2. Install the replacement mounting stud as

shown in Figure 3.

To install the pivot connector:

Remove the pivoting rod connector from the draw

tube assembly and thread it onto the replacement

stud as shown in Figure 4. Make sure you have

replaced the lathe cover!

Figure 4. Installing the pivot connector.

This pivot will allow the locking yoke to be

secured to the lathe while providing a range of

motion to engage and disengage the locking

mechanism. The pivot connector should be

secured tightly to the stud and the pivot pin

should be in a horizontal position, allowing the

pivot to move up and down.

Figure 3. Replacement mounting

stud installed.

3. Replace the lathe cover and secure the bottom knob.

Hub Adapter

To install the hub adapter to the outboard

spindle:

1. Remove the hub adapter from the draw tube

assembly and unscrew the setscrews until

the ends are flush with the outer edge of the

hub.

2. Thread the hub adapter completely into the

outboard end of the lathe spindle. Secure the

hub adapter to the spindle by tightening the

setscrews shown in Figure 5

-4-

.

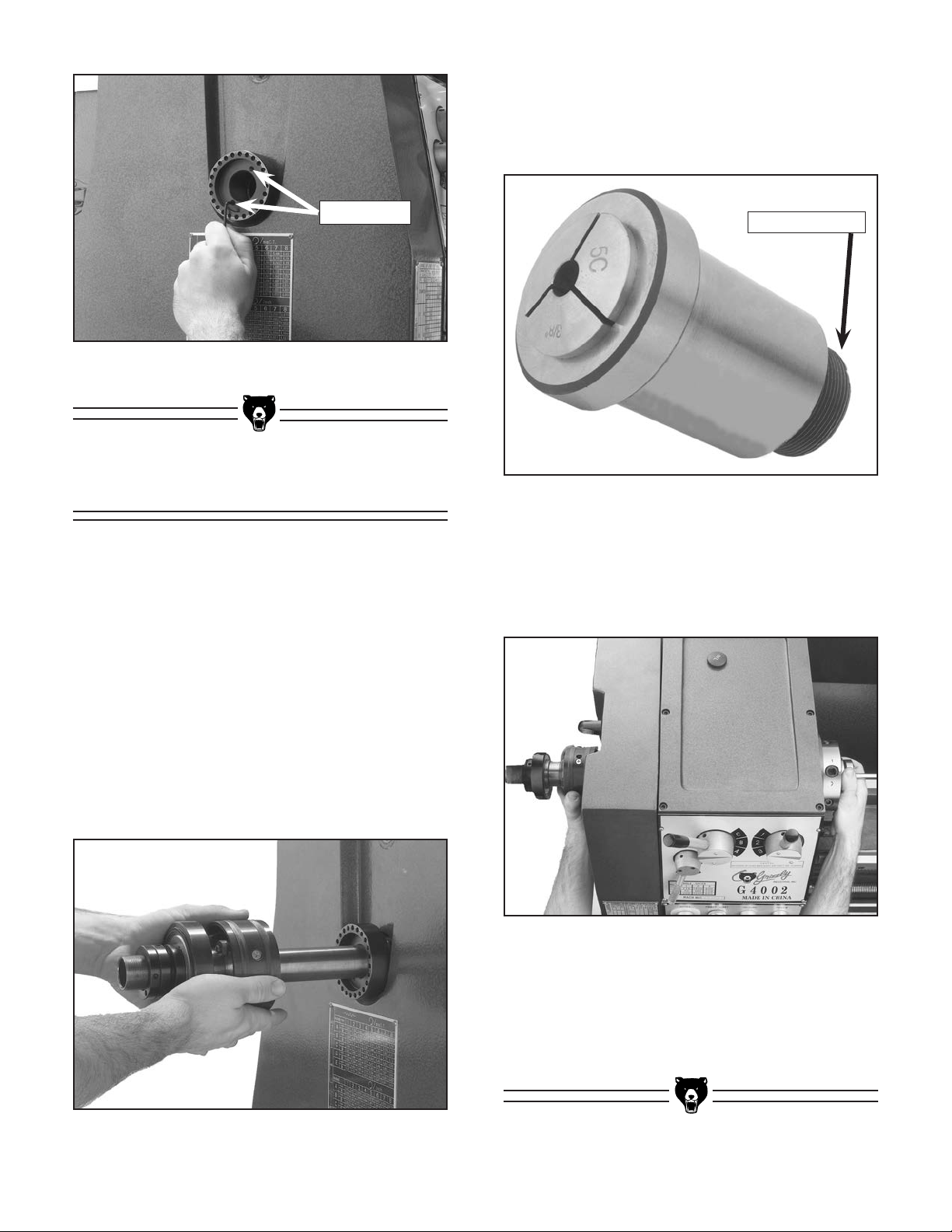

2. Place the collet in the collet adapter, so the

collet threads are exposed out of the back

end of the collet adapter as shown in Figure

7.

Setscrews

Figure 5. Installing hub adapter.

Tube Assembly

The draw tube assembly comes attached to the

locking yoke and connecting rod. Remove the

locking yoke and connecting rod by unscrewing

the setscrews that connect the locking yoke to the

bearing housing.

Collet Threads

Figure 7. Collet in collet adapter.

3. Hold the adjusting hub with your left hand

and thread the collet and adapter into the

front spindle with your right hand to engage

the draw tube, as shown in Figure 8.

To install the draw tube assembly into your

lathe:

1. Insert the draw tube assembly into the out-

board spindle as shown in Figure 6. Slide

the draw tube assembly all the way into the

outboard spindle until it engages around the

hub adapter.

Figure 8. Rotating collet in spindle to

engage with adjusting hub.

4. Turn the collet 4 to 5 complete revolutions.

Additional fine adjustments will be covered

later.

Figure 6. Inserting draw tube assembly.

G4026 Collet Closer

G4026 Collet Closer

Locking Yoke

To secure the locking yoke to your lathe:

4. Make sure the locking yoke and the rod con-

nector are secured to the mounting stud and

the pivoting rod connecter.

1. Thread the connecting rod and locking yoke

onto the pivoting rod connector as shown in

Figure 9.

Connecting

rod

Locking

yoke

Figure 9. Connecting rod and locking yoke

installed on pivot connector.

2. Please note that the rod connector is supplied with jam nuts. It may be necessary to

remove these nuts to allow for the proper fit

of the assembly on some lathes.

3. Install the handle to the yoke. Note—If you

have trouble positioning the locking yoke so

it is aligned with the draw tube in the next two

steps, adjust the length of the connecting rod

by threading it more or less into the pivot

connectors and try again.

5. Position the locking yoke back inline with the

setscrew holes on the draw tube assembly,

then secure the setscrews and the jam nuts

as shown in Figure 10.

Figure 10. Tightening yoke setscrews.

6. Thread the setscrews on both sides of the

locking yoke into the holes on either side of

the bearing housing. Make sure the setscrews are completely and evenly engaged

into the holes, without being tight.

7. The yoke should have

side, but still pivot freely. Tighten the jam

nuts.

8. The ideal locked position for the collet closer

is shown in the completed assembly diagram

in Figure 11.

no play from side-to-

-6-

Locking Pawls

Figure 11. Completed collet closer assembly.

Make sure proper turning clearance exists

between the bearing casing and the locking

yoke before operation. Serious personal

injury or damage to the lathe and collet

closer can occur if there is contact. Rotate

draw tube and check for clearance. DO NOT

make adjustments, remove workpiece or

open back cover of lathe while the machine

is in motion.

Locking Stroke

Figure 12. Locking pawls in locked position

on the cam lobe.

2. Secure the 38mm spanner nut against the

outboard side of the bearing housing and

then secure the 30mm spanner nuts against

the 38mm spanner nut as shown in Figure

13. Note—Be sure that the 30mm spanner

with the setscrew is on the outside, with the

setscrew accessible.

3. The two 30mm spanners define the stroke

distance. Secure the setscrew in the outer

30mm spanner nut to lock the stroke distance.

38mm spanner

To adjust the locking stroke on your collet

closer:

1. Position the locking pawls so they are in the

correct position on the cam as shown in

Figure 12.

G4026 Collet Closer

30mm spanners

Figure 13. Spanner nut positioning for locking

stroke adjustment.

G4026 Collet Closer

The mechanism that controls the stroke is depicted in detail in Figure 14.

3. Rotate the draw tube counter-clockwise at

the end of the collet closer, as shown in

Figure 16, to unthread the collet.

E

Figure 14. Stroke adjustment assembly.

Removal of 5-C

Collet

The draw tube threads may be sharp. To

avoid cutting your hands, use a clean rag

to rotate the draw tube.

4. Remove the collet from the collet adapter

and insert the new 5-C collet.

5. Rotate the draw tube clockwise at the end of

the collet closer to engage the new collet

threads.6. Engage the hub locking pin back

into place as shown in Figure 16.

To remove or replace your 5-C collet in the

collet closer assembly:

1. Choose a 5-C collet that is suitable for the

intended stock size to be turned.

2. Disengage the hub locking pin so the flat is

turned toward the outer rim of the hub adapter as shown in Figure 15.

Pin Disengaged

Pin

Engaged

Figure 15. Locking pin positions.

Figure 16. Location to rotate draw tube to

remove or replace 5-C collets.

Installing 5-C Collet

To adjust your 5-C collet in the collet closer

assembly:

1. Choose a 5-C collet that is suitable for the

intended stock size to be turned.

2. Line up the collet keyway with collet adapter

pin and insert the collet until it stops, then

gently rotate it for final alignment.

-8-

3. Gently push on the end of the draw tube until

it engages the collet threads in the spindle,

and rotate the adjusting hub in a clockwise

fashion (as viewed from the outboard end of

the lathe in Figure 8).

— If the draw tube fails to touch the collet,

remove the collet and look into the spindle to

see if the draw tube is accessible for proper

engagement. If the collet cannot touch the

draw tube when inserted into the spindle, see

the following section on “Rough Adjustment.”

If the collet does reach, try again to thread

the collet and adapter into the spindle by following the guidelines in the “Tube Assembly”

sub-section of this manual.

Rough Adjustment

Maintenance

The Model G4026 Collet Closer is essentially a maintenance free tool; however, some

things to keep in mind are:

1. Make sure that all the components of your

collet closer are assembled correctly, according to this manual.

2. Once the replacement stud and hub adapter

are installed, they will not need to be removed.

3. Ensure that your locking mechanism is working properly before you start any projects on

your lathe.

4. Check the locking stroke for proper placement of locking pawls on the cams.

If rough adjustments need to be made to the

collet closer assembly:

1. In the event that the above adjustments fail

to allow the collet to lock onto the material or

the draw tube fails to touch the collet, adjust

the adapter hub in or out.

2. Loosen the setscrews and turn the hub

adapter in a clockwise direction if the draw

tube does not contact the back of the collet.

3. Turn the hub adapter counter-clockwise if the

work material cannot be locked by the collet.

4. Tighten the setscrews.

The Model G4026 Collet Closer is adjusted properly when the 3 collet locking pawls are tight on

the cam and the workpiece will not twist in the

collet. Again, Figure 12 on page 7 shows the

proper locked position of the collet locking pawls

around the cam.

5. The bearings are non-serviceable. If you

have problems with your bearings, you must

order a new bearing pack.

6. The hub adapter must be removed in order

to change gears occasionally.

Aftermarket

Accessories

5-C collets do not come with the Model G4026

Collet Closer. However, they are available in the

current Grizzly Catalog:

• Model G1238 15 piece collet set ranging in

diameters from

1

⁄8" to 1".

G4026 Collet Closer

• Collets are also sold separately in individual

sizes.

G4026 Collet Closer

1

47

38

32

35

44

5

45

43

41

40

31

30

24

46

23

26V2

18

23A

4

29

22

48

27

G4026 Collet Closer

G4026 COLLET CLOSER

9

8

10

11

12

-10-

7

17

34V2

33V2

21

G4026 Collet Closer

REF

1 P4026001 COLLET ADAPTER

4 P4026004 DRAW TUBE

5 P4026005 HUB ADAPTER

7 P4026007 LOCKING YOKE

8 PN03M HEX NUT M8-1.25

9 P4026009 DOGPOINT SETSCREW M8-1.25 X 38

10 PN09M HEX NUT M12-1.75

11 P4026011 HANDLE ROD

12 P4026012 HANDLE

17 P4026017 PIVOT PIN

18 P4026018 ROD CONNECTOR

19 P4026019 THREADED ROD

21 PSS01M SETSCREW M6-1.0 X 10

22 P4026022 SPANNER NUT M38-1.25

23 P4026023 BEARING SUPPORT

23A P6208 CARTRIDGE BALL BEARING 6208ZZ

24 P4026024 CAM

25 P4026025 SET SCREW M4 X 5

26V2 P4026026V2 LOCKING PIN V2 01.08

27 P4026027 KNURLED KNOB M4-0.7

29 P4026029 SPRING

30 P4026030 COLLET LOCKING PAWL

31 P4026031 PIN

32 PSS14M SETSCREW M8-1.25 X 12

33V2 P4026033V2 SPANNER NUT M40-1.5 W/ SS V2.03.12

34V2 P4026034V2 SPANNER NUT M40-1.5 V2.03.12

35 P4026035 ROD CONNECTOR

37 P4026037 STUD ADAPTER

38 P4026038 MOUNTING STUD

39 P4026039 COVER KNOB M12-1.75 X 18

40 P4026040 SLIDING HUB SLEEVE

41 P4026041 HUB SLEEVE

43 P4026043 BRASS SUPPORT PIN

44 PFH07M FLAT HD SCR M5-.8 X 10

45 PSS03M SETSCREW M6-1.0 X 8

46 P4026046 THREADED STUD 12-1.75 X2.5

47 P4026047 COLLET ADAPTER PIN 3 X 6

48 PSS08M SET SCREW M4-.7 X 5

PART #

DESCRIPTION

G4026 Collet Closer

-11-

WARRANTY AND RETURNS

Grizzly Imports, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the

date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty and

any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent that

the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants. In

no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and any

legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special,

or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number,’’ which must be clearly posted on the outside as well as the inside of the

carton. We will not accept any item back without this number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

WARRANTY CARD

NAME_______________________________________________ PHONE NUMBER___________________

STREET________________________________________________________________________________

CITY_______________________________STATE_________ZIP ___________________________________

MODEL#

The following information is given on a voluntary basis. This information will be used for marketing purposes to help

Grizzly develop better products. Your name will be included in our mailing list only. It will not be sold to other companies. of course, all information is strictly confidential.

1. How did you find out about us?

__Advertisement __Friend __Website

__Catalog __Card deck __Other____________________

2. Do you think your machine represents good value? __YES __NO

3. Would you allow us to use your name as a reference for Grizzly customers in your area? __YES __NO

(Note: Your name will be used a maximum of three times.)

4. To which of the following publications do you subscribe? Check all that apply.

__Home Shop Machinist __Rifle Magazine Other ________________

__Projects in Metal __Hand Loader Magazine

__Modeltec __Precision Shooter

__Live Steam __RC Modeler

__Shotgun News __Model Airplane News

G4026 Collet Closer SERIAL#________________ INVOICE#_________________

5. What is your annual household income?

__$20,000-$30,000 __$50,001-$60,000 __$80,000-$90,000

__$30,001-$40,000 __$60,001-$70,000 __+$90,000

__$40,001-$50,000 __$70,001-$80,000

6. To which age group do you belong?

__20-30 __41-50 __61-70

__31-40 __51-60 __+70

7. Which of the following machines or accessories do you own? Check all that apply.

CUT ALONG DOTTED LINE

__Engine Lathe __Abrasive Cutoff __Sheet Metal Machine

__Band Saw (Metal) __Arc Welder __Other _____________________________

__Band Saw (Wood) __Oxy/Ac. Outfit

__Milling Machine __Air Compressor

__Bench Grinder __Drill Press

8. How many of the machines you checked in Question 7 are Grizzly machines? ______________________

9. Which of the following tooling and accessories do you own? Check all that apply.

__Milling Vises __Collet Closer __Digital Readout

__Indexing Head __Taper Attachment __Tool Post Grinder

__Rotary Table __Boring Head __Other _________________________________________

10. In the space below, list three tools you would like Grizzly to carry.

11. Of all the mail order metalworking company’s you have purchased from, how do you rate Grizzly in terms of overall

customer satisfaction?

__The best __Above average __Average

__Below average __The worst

12. Comments_______________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

________________________________________________________________________________________________

FOLD ALONG DOTTED LINE

Place

Stamp

Here

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

FOLD ALONG DOTTED LINE

Send a Grizzly Catalog to a friend:

Name_______________________________

Street_______________________________

City______________State______Zip______

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

G4026 Collet Closer

Loading...

Loading...