Page 1

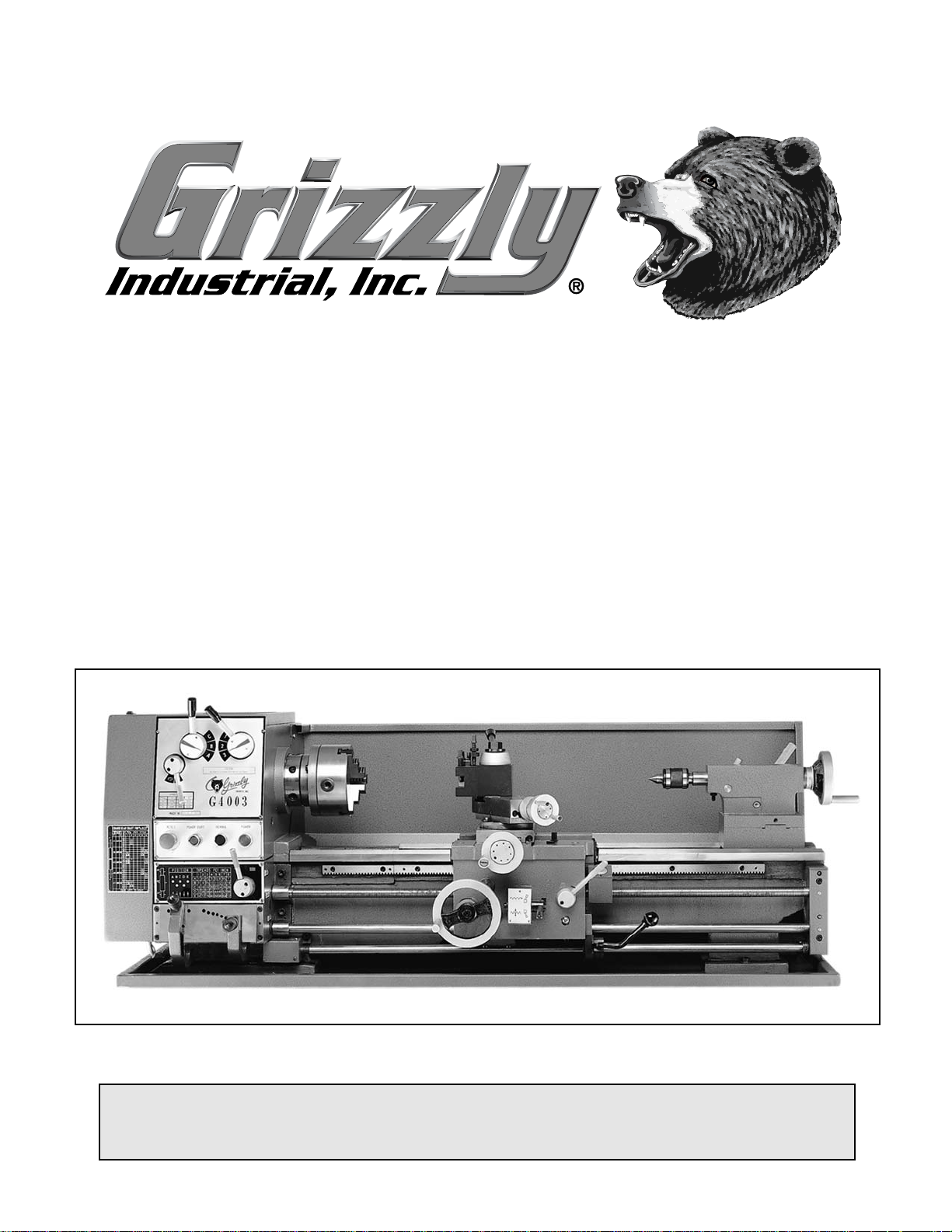

GEAR HEAD METAL LATHE

MODEL G4002 / G4003

INSTRUCTION MANUAL

COPYRIGHT © 2000 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

REVISED JANUARY, 2000 PRINTED IN CHINA

Page 2

Page 3

Table Of Contents

PAGE

1. SAFETY

SAFETY RULES FOR POWER TOOLS ..........................................................2-3

ADDITIONAL SAFETY INSTRUCTIONS FOR METAL LATHES ........................4

2. CIRCUIT REQUIREMENTS

220V OPERATION ..............................................................................................5

EXTENSION CORDS ..........................................................................................5

GROUNDING ......................................................................................................5

3. INTRODUCTION

COMMENTARY....................................................................................................6

UNPACKING ........................................................................................................7

PIECE INVENTORY ............................................................................................7

CLEAN UP............................................................................................................8

SITE CONSIDERATIONS ....................................................................................8

4. ASSEMBLY & SETUP

MOUNTING ..........................................................................................................9

LUBRICATION ....................................................................................................9

CHUCKS ........................................................................................................9-10

LIVE CENTER....................................................................................................10

STEADY REST ..................................................................................................11

FOLLOW REST..................................................................................................11

4-JAW CHUCK ASSEMBLY ..............................................................................12

5. CONTROLS

SPINDLE SPEEDS ............................................................................................13

FEED DIRECTION ............................................................................................14

SELECTING THE FEED ROD ..........................................................................14

QUICK CHANGE SELECTION ..........................................................................15

FEED RATE CHART..........................................................................................15

THREAD SELECTION ..................................................................................16-19

CARRIAGE CONTROLS....................................................................................20

TOOLPOST ........................................................................................................21

TAILSTOCK CONTROLS ..................................................................................21

TEST RUN..........................................................................................................22

6. ADJUSTMENTS

GIBS..............................................................................................................23-24

STEADY REST/FOLLOW REST........................................................................24

TAILSTOCK ..................................................................................................25-26

7. MAINTENANCE

LUBRICATION ..............................................................................................27-28

BEARING PRELOAD ........................................................................................28

8. CLOSURE................................................................................................................29

MACHINE DATA ..........................................................................................................30-31

PARTS BREAKDOWN AND PARTS LISTS ................................................................32-49

WARRANTY AND RETURNS ............................................................................................50

Page 4

-2- G4002/3 Gear Head' Lathes

Safety Instructions For Power Tools

SECTION 1: SAFETY

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be

kept a safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Develop a habit of checking

to see that keys and adjusting wrenches

are removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or where any flammable or

noxious fumes may exist. Keep work area

well lighted.

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

Indicates an imminently hazardous situation which, if not

avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, MAY

result in minor or moderate injury. It may also

be used to alert against unsafe practices.

This symbol is used to alert the user to useful information

about proper operation of the equipment.

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words which are intended to convey the level

of importance of the safety messages. The progression of symbols is described below.

Remember that safety messages by themselves do not eliminate danger and are not a substitute for proper accident prevention measures.

NOTICE

Page 5

G4002/3 Gear Head Lathes -3-

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause a

drop in line voltage resulting in loss of

power and overheating. Your extension

cord must also contain a ground wire and

plug pin. Always repair or replace extension cords if they become damaged.

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 18 16 16

7-10 18 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

Safety Instructions For Power Tools

13. DON’T OVERREACH. Keep proper foot-

ing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing

and changing accessories, such as blades,

bits, cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off

position before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

18. CHECK DAMAGED PARTS. Before fur-

ther use of the tool, a guard or other part

that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that

may affect its operation. A guard or other

part that is damaged should be properly

repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t

leave tool until it comes to a complete stop.

Page 6

-4- G4002/3 Gear Head Lathes

Additional Safety Instructions For The Lathe

Like all power tools, there is danger associated with the Model G4002/3 Metal Lathe.

Accidents are frequently caused by lack of

familiarity or failure to pay attention. Use

this tool with respect and caution to lessen

the possibility of operator injury. If normal

safety precautions are overlooked or

ignored, serious personal injury may

occur.

1. MAKE SURE ALL GUARDS are in place

and that the lathe sits on a flat, stable surface.

2. BEFORE STARTING THE MACHINE be

certain the workpiece has been properly

engaged in the chuck and tailstock center

(if in use) and that there is adequate

clearance for full rotation.

3. ADJUST TOOL HOLDER to provide prop-

er support for the turning tool you will be

using. Test tool holder clearance by rotating workpiece by hand before turning lathe

on.

4. SELECT THE TURNING SPEED which is

appropriate for the type of work and the

type of material. Allow the lathe to gain its

full speed before beginning turning.

5. NEVER CHANGE FEED RATE or spindle

speeds while the lathe is turning.

6. NEVER REVERSE MOTOR DIRECTION

while the lathe is running.

7. DO NOT STOP LATHE USING YOUR

HAND against the workpiece.

8. DO NOT LEAVE LATHE RUNNING

UNATTENDED for any reason.

9. NEVER OPERATE THE LATHE WITH

DAMAGED OR WORN PARTS. Maintain

your lathe in proper working condition.

Perform routine inspections and maintenance promptly when called for. Put away

adjustment tools after use.

10. MAKE SURE YOUR METAL LATHE IS

TURNED OFF, disconnected from its

power source and all moving parts have

come to a complete stop before starting

any inspection, adjustment, or maintenance procedure.

11. KEEP LOOSE CLOTHING ARTICLES

such as sleeves, belts or jewelry items

away from the lathe spindle.

12. ALWAYS USE THE PROPER CUTTING

TOOLS for the material you are turning,

make certain they are sharp and that they

are held firmly in the tool holder.

13. ALWAYS PLACE A BOARD OR PIECE

OF PLYWOOD ACROSS THE BEDWAY

when removing or installing chucks to

avoid the possibility of a finger pinch point

occurring between a loose chuck and the

edges of the bedway.

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to do so could result in serious personal injury, damage to equipment or poor

work results.

Page 7

G4002/3 Gear Head Lathes -5-

220V Operation

SECTION 2: CIRCUIT REQUIREMENTS

Figure 1. Typical 220V plug and outlet.

Grounding

In the event of an electrical short, grounding

reduces the risk of electric shock by providing a

path of least resistance to disperse electric current. This tool is equipped with a power cord hav-

ing an equipment-grounding conductor. See

Figure 1. The outlet must be properly installed

and grounded in accordance with all local codes

and ordinances.

The Model G4002/3 is wired for 220 volt, single

phase operation. The 2 HP motor will safely draw

9 amps at 220V. A 10-amp fuse or circuit breaker should be used when connecting this metal

lathe. Circuits rated any higher are not adequate

to protect the motor.

If you operate this lathe on any circuit that is

already close to its capacity, it might blow a fuse

or trip a circuit breaker. However, if an unusual

load does not exist and a power failure still

occurs, contact a qualified electrician or our service department.

Equipment returned to us for service that shows

evidence of being over-fused will be repaired or

replaced totally at the customer’s expense,

regardless of the present warranty status.

If you find it necessary to use an extension cord

with the Model G4002/3, make sure the cord is

rated Hard Service (grade S) or better. Refer to

the chart in the standard safety instructions to

determine the minimum gauge for the extension

cord. The extension cord must also contain a

ground wire and plug pin. Always repair or

replace extension cords when they become worn

or damaged.

Extension Cords

This equipment must be grounded. Verify

that any existing electrical outlet and circuit

you intend to plug into is actually grounded. If it is not, it will be necessary to run a

separate 12 A.W.G. copper grounding wire

from the outlet to a known ground. Under

no circumstances should the grounding pin

from any three-pronged plug be removed.

Serious injury may occur.

Page 8

-6- G4002/3 Gear Head Lathes

Commentary

We are proud to offer the Grizzly Model G4002 /

G4003 Gear Head Metal Lathe. The Model

G4002 / G4003 is part of a growing Grizzly family of fine metalworking machinery. When used

according to the guidelines set forth in this manual, you can expect years of trouble-free, enjoyable operation and proof of Grizzly’s

commitment to customer satisfaction.

The Model G4002/3 is a precision metalworking

lathe. It features cast iron construction, 24" or 36"

V-bed, a speed range of 70-1,400 RPM, 9-speed

gearbox and a complete electrical package. The

electrical package consists of a 2 H.P., 110V /

220V motor, electro-magnetic motor control and

overload protection. We also offer many accessories for this lathe. Please refer to the latest

Grizzly catalog for prices and information.

We are also pleased to provide this instructional

manual with the Model G4002 / G4003 Lathe.

This manual was written to guide you through

assembly, review safety considerations and

cover basic operating procedures. It represents

our latest effort to produce the best documentation possible. If you have any constructive criticisms or comments you feel we should include in

our next printing, please write us at the address

below.

Grizzly Industrial, Inc.

C

/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Most importantly, we stand behind our machines.

If you have any service questions or parts

requests, please call or write us at the location

listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G4002/3 as supplied when the manual was prepared. However, owing to Grizzly’s policy of continuous improvement, changes may be made at

any time with no obligation on the part of Grizzly.

Whenever possible, though, we send manual

updates to all owners of a particular tool or

machine. Should you receive one, we urge you to

insert the new information with the old and keep

it for reference.

To operate this, or any power tool, safely

and efficiently, it is essential to become as

familiar with its characteristics as possible.

The time you invest before you begin to use

your Model G4002/3 will be time well spent.

DO NOT operate this machine until you are

completely familiar with the contents of this

manual. Make sure you read and understand all of the safety procedures. If you do

not understand something, DO NOT operate

the machine.

SECTION 3: INTRODUCTION

Page 9

G4002/3 Gear Head Lathes -7-

Unpacking

This Metal Lathe is shipped from the manufacturer in a carefully packed crate. If you discover the

machine is damaged after you’ve signed for delivery, and the truck and driver are gone, you will

need to file a freight claim with the carrier. Save

the containers and all packing materials for possible inspection by the carrier or its agent.

Without the packing materials, filing a freight

claim can be difficult. If you need assistance

determining whether you need to file a freight

claim, or with the procedure to file one, please

contact our Customer Service.

When you are completely satisfied with the condition of your shipment, you should inventory its

parts.

The G4002 and G4003 are heavy machines

(1015 lbs. and 1040 lbs. shipping weight). DO

NOT over-exert yourself while unpacking or

moving your machine – get assistance. In the

event that your Metal Lathe must be moved up

or down a flight of stairs, be sure that the stairs

are capable of supporting the combined weight

of people and the machine. Serious personal

injury may occur.

Piece Inventory

The Model G4002/3 is, for the most part, preassembled at the factory. Inside the crate you’ll

find:

• The Model G4002/3 Metal Lathe

• 6" 3-jaw Chuck

• 8" 4-jaw Chuck

• Face Plate

• Steady Rest

• Follow Rest

• Quick Change Tool Post

• Tool Holder

• Toolbox

• Metric Allen

®

Wrenches

• Straight Blade Screwdriver

• Phillips

®

Screwdriver

• Oil can

• 26T Gear

• 27T Gear

• 35T Gear

• 2- 40T Gear

• 45T Gear

• 50T Gear

• Chuck wrenches (2)

• Reverse Jaws for the 3-Jaw Chuck

• Dead Center - MT #3

• Live Center - MT #3

In the event that any non-proprietary parts are

missing (e.g. a nut or a washer), we would be

glad to replace them, or, for the sake of expediency, replacements can be obtained at your local

hardware store.

Page 10

-8- G4002/3 Gear Head Lathes

Site Considerations

1. Floor Load: The Model G4002/3 can be

mounted on your existing workbench or on

an optional cabinet stand which is listed in

our current Grizzly catalog. If you choose to

use the stand, you will find the holes for bolting the G4002/3 to the stand are already in

place. If you are using your own bench,

ensure that it is strong enough to handle the

weight of the G4002/3 lathe. Keep in mind,

whichever way you choose to mount the

lathe, it’s essential that the mounting surface

be perfectly flat. Use an accurate carpenter’s

level to ensure that your bench is properly

leveled.

2. Working Clearances: Consider existing and

anticipated needs, size of material to be

processed through each machine, and

space for auxiliary stands, work tables or

other machinery when establishing a location for your lathe.

3. Lighting and Outlets: Lighting should be

bright enough to eliminate shadow and prevent eye strain. Electrical circuits should be

dedicated or large enough to handle amperage requirements. Outlets should be located

near each machine so power or extension

cords are clear of high-traffic areas. Observe

local electrical codes for proper installation

of new lighting, outlets, or circuits.

Clean Up

The unpainted surfaces are coated with a waxy

oil to protect them from corrosion during shipment. Remove this protective coating with a solvent cleaner or citrus-based degreaser, like

Grizzly’s G7895 Citrus Engine Degreaser. Avoid

chlorine-based solvents as they may damage

painted surfaces should they come in contact.

Always follow the usage instructions on the product you choose for clean up.

Many of the solvents commonly used to

clean machinery can be highly flammable,

and toxic when inhaled or ingested. Always

work in well-ventilated areas far from

potential ignition sources when dealing

with solvents. Use care when disposing of

waste rags and towels to be sure they do

not create fire or environmental hazards.

Keep children and animals safely away

when cleaning and assembling this

machine.

Do not use gasoline or other petroleumbased solvents to remove this protective

coating. These products generally have low

flash points which makes them extremely

flammable. A risk of explosion and burning

exists if these products are used. Serious

personal injury may occur.

All die-cut metal parts have a sharp edge

(called “flashing”) on them after they are

formed. This is generally removed at the

factory. Sometimes a bit of flashing might

escape inspection, and the sharp edge may

cause cuts or lacerations when handled.

Please examine the edges of all die-cut

metal parts and file or sand the edge to

remove the flashing before handling.

Make your shop “child safe”. Ensure that

your workplace is inaccessible to youngsters by closing and locking all entrances

when you are away. Never allow visitors in

your shop when assembling, adjusting or

operating equipment.

Page 11

G4002/3 Gear Head Lathes -9-

Chucks

The Model G4002/3 Metal Lathe comes equipped

with a 6'' 3-jaw chuck (already installed), a 8'' 4jaw chuck and a face plate.

The 3-jaw chuck is a scroll-type chuck, meaning

that all three jaws move in unison when adjustments are made. The 4-jaw chuck, on the other

hand, features independent jaws. The 4-jaw

chuck is used for square or unevenly-shaped

stock.

The 3 and 4-jaw chucks have a D-1 Camlock

mount. Please note that there are lines stamped

into the cam and on the chuck body. A chuck key

is used to turn the locking cams as in Figure 2.

Mounting

This lathe should be securely mounted to a stand

or bench top. An accessory stand is available

from Grizzly, please see our current catalog for

pricing. There are 2 holes in the base at the tailstock end of the lathe and four holes on the gearhead end which can be used to secure the

machine to a stand.

The lathe does not require a great deal of assembly. This section details the installation of the various accessory holding devices. The following

section will familiarize you with the controls for

your new lathe. After you have completed both of

these sections we will do a test run of the

machine. Do not attempt a test run until you have

become familiar with both of these sections.

SECTION 4: ASSEMBLY & SETUP

DO NOT attempt to start this machine until

you have completed all of the assembly and

control familiarization steps. When performing the assembly steps, ensure that

the switch is off and the power is disconnected. Failure to comply with this could

cause inadvertent starting of the machine

which can result in serious operator injury.

Lubrication

The G4002/3 is shipped from the factory prelubricated. However, it is recommended that you

go through the entire lubrication sequence before

operating the machine. Review Section 7:

Maintenance for lubrication instructions.

Lubrication must be completed before you

start your new lathe.

Figure 2. Key positioned to remove chuck.

ALWAYS place a piece of plywood over the

ways of the lathe before removing or

installing a chuck. This helps by covering

the sharp corners of the bed, protecting

your hands and fingers. Use extreme care

when removing or installing a chuck so

that your hands do not become trapped

between the chuck and the plywood.

Page 12

-10- G4002/3 Gear Head Lathes

To remove a chuck:

1. Place a piece of plywood across the lathe

bed and position it just under the chuck.

The board should be at least 8" wide and

10" long.

2. Turn a cam, with the chuck key, in the lathe

spindle in a counter-clockwise rotation until

the line on the cam is aligned with the line

going across the spindle housing as in

Figure 3.

Figure 3. Cam lines aligned to spindle line.

Never leave a chuck key in the chuck when

it is not in use. If the machine is accidentally started with this in place, it can

become a projectile and cause serious

injury.

The chuck is heavy and can be awkward to

handle. Be aware that when removing or

installing a chuck a finger pinch situation

exists.

3. Turn the other cams in the same way. Make

sure to support the chuck with one hand as

you align the last cam. The chuck may

come off at this point so it is important you

are ready to support its weight.

4. Remove the chuck key.

If the chuck is still tight on the spindle:

Tap the back of the chuck with a rubber or wooden mallet while supporting the bottom of the

chuck with your free hand. If the chuck does not

immediately come off, rotate the spindle approximately 60˚ and tap again. Make sure all the

marks on the cams and spindle are in proper

alignment.

To install a chuck:

1. Place a piece of plywood across the lathe

bed and position it just under the spindle.

2. Lift the chuck up to the spindle and align

the pins in the back with the holes on the

spindle’s face and insert the pins.

3. While supporting the weight of the chuck,

turn one cam with the chuck key until the

cam line is between the two vees on the

spindle. Do not tighten at this time.

4. Rotate the spindle and repeat step 3 on the

last two cams.

5. Return to the first cam and snug it up.

Repeat with the rest of the cams.

6. Finally, tighten all three cams.

Page 13

G4002/3 Gear Head Lathes -11-

Live Center

The live center is used to support stock which is

too long to be supported by the chuck alone.

Stock protruding more than three times its diameter should be supported by the live center.

Figure 4. Live center installed in tailstock.

Figure 5. Steady rest in place.

Steady Rest

The steady rest supports long, small diameter

stock that otherwise could not be turned. The

steady rest can also replace the tailstock to allow

for cutting tool access at the outboard end of your

workpiece.

To mount the steady rest:

1. Secure to bedway from below with the lock-

ing plate.

2. A single hex bolt, along with a nut and

washer, is used to hold the steady rest in

place. See Figure 5.

3. The bearing surfaces on the steady rest

should receive periodic lubrication while in

use to prevent premature wear.

The tailstock barrel and live center have a Morse

taper #3. Before assembling these, insure that

the mating surfaces are “white glove” clean.

These parts will last longer and remain accurate

when properly maintained. Morse tapers will not

interlock when oil is present on the mounting surfaces. Insert the end of the live center into the tailstock bore until it seats. The force of a mounted

workpiece will fully seat the taper.

When using a live center, the tailstock barrel

should protrude about

1

⁄2'' and not more than 3''.

See Figure 4.

To remove the live center, back the tailstock barrel all the way into the tailstock casting. The live

center will pop out. Be sure to catch it when it

comes out to avoid damaging the tip.

Page 14

-12- G4002/3 Gear Head Lathes

4-Jaw Chuck

The 4-jaw chuck supplied with the G4002/3 is not

mounted to the back plate. Assembly of the back

plate components is also required.

1. Make note of the reference lines on each

of the 3-jaw chuck studs. Thread each of

the 4-jaw chuck cam lock studs into the 4jaw chuck back plate to the exact same

depth as the 3-jaw studs. Screw in the

locking cap screws.

2. Mount the back plate on the spindle.

3. Accurately measure the inside of the back

relief bore on the 4-jaw chuck. This

dimension is critical, ± .001''.

4. Face the back plate to true it. Make pass-

es across the face until its entire surface

has been cut.

5. Turn a shoulder into the face

1

⁄8'' deep and

.001" to .002'' larger than the back relief

bore diameter. Chamfer the corner a

small amount.

6. Set the chuck on the back plate aligning

the shoulder with the relief bore. Use a

transfer punch to mark the back plate. If a

transfer punch is not available, a drill bit of

the same size as the mounting holes in

the chuck can be used. Lightly tap on the

bit, rotate it 90° and tap it again.

7. Remove the chuck from the back plate

and center punch the marks. Drill and tap

the holes for

3

⁄8''-16.

8. Set the chuck on the back plate. Line up

the mounting holes and thread in the cap

screws supplied. Remember that this is a

.001" to .002" press fit. Snug up the first

cap screw then alternate to the cap screw

across the chuck. Alternating the tightening process insures the chuck will go on

straight. This step should be repeated

until the back plate fits snugly against the

chuck. If the chuck fits loosely on the back

plate, or is crooked on the shoulder, it will

be necessary to face and shoulder the

back plate again.

The follow rest is normally used with small diameter stock to prevent the workpiece from “springing” under pressure from the turning tool. To

install the follow rest:

1. The follow rest is secured to the saddle with

two cap screws. See Figure 6.

2. The bearing surfaces on the follow rest are

similar to those on the steady rest, and

should be lubricated to prevent premature

wear.

Figure 6. Follow rest secured to saddle.

Follow Rest

Page 15

G4002/3 Gear Head Lathes -13-

Spindle Speeds

SECTION 5: CONTROLS

Figure 7. Speed shifting levers.

Figure 8. Speed chart.

Never change speeds while spindle or motor

is in motion.

The speed of the spindle is controlled by the

positions of the speed control knobs. See Figure

7. By positioning the knobs using the chart in

Figure 8, you can achieve all of these speed

ranges: 70, 200, 220, 270, 360, 600, 800, 1000

and 1400 RPM.

The chart above shows the various combinations

of knob positions for achieving a desired speed.

Example:

To select a spindle speed of 600 RPM, move the

left-hand selector knob until the indicator arrow

on its hub is pointing to the “C”. Move the righthand selector knob until its indicator arrow is

pointed at the “3”.

Page 16

Quick Change Selection

The two levers at the bottom of the headstock

change the feed rate, or the number of threadsper-inch. This section of the machine is commonly known as the Quick Change Gear Box.

See Figure 11. The left-hand lever can be

engaged in any of five different positions and are

listed on the charts as A, B, C, D, and E. The

right-hand lever has 8 positions and are listed on

the charts as 1 through 8.

The machine label describes some of the more

typical settings which might be used. Figure 12

shows the feed rate chart located on the gear

cover of the lathe. The chart is divided into metric feed rates and inch feed rates.

-14- G4002/3 Gear Head Lathes

Figure 9. Directional control lever.

Feed Direction

Selecting the Feed Rod

Never move selection levers while machine is

running.

The G4002/3 Metal Lathe can cut left or right while

feeding or threading and across both ways for facing operations. This feed direction is controlled by

the selection knob as shown in Figure 9.

When the selection knob is positioned as depict-

ed in Figure 9, the apron will move to the right

along the bed or the cross feed will travel away

from the operator. The cross feed and longitudinal feed selection is controlled on the apron and

will be discussed later.

To reverse the direction of the feeding or threading operation, rotate the selection knob to the

right. It should be noted that when the lever is

positioned in the middle, no direction is selected

and all of the drive mechanisms after this point

are in neutral.

Important:

Do not force any selection lever on the machine.

If the lever will not engage, rotate the chuck by

hand while keeping light pressure on the selec-

tor. As the chuck rotates it aligns the gears and

the selector will engage.

Figure 10. Feed rod selected.

The feed rod can be selected by rotating the han-

dle to the left as in Figure 10. Use this position for

all feeding operations. When the lever is positioned straight up, no drive device is selected and

the gear train is in neutral after this point.

Page 17

G4002/3 Gear Head Lathes -15-

Feed Rate Chart

Figure 11. Feed rate selector levers.

Figure 12. Feed rate selection.

This symbol indicates longitudinal feed.

This symbol indicates cross feed rates.

Important:

Do not force any selection lever on the machine. If

the lever will not engage, rotate the chuck by hand

while keeping light pressure on the selector. As the

chuck rotates, it aligns the gears and the selector

will engage.

To change the position of the feed selector, pull the

knurled handle. This disengages a pin which is

inserted into a selection hole. Position the lever in

the down position and slide to the right or left until

it is positioned below the desired selection hole.

Raise the lever with one hand while pulling the

handle with the other. The pin at the end of the

lever should align with the selection hole. If it does

not, rotate the feed rod or chuck by hand while

maintaining gentle pressure on the lever.

Feed Lever - Longitudinal and cross slide pow-

ered motions are controlled by the feed lever.

The lever pivots through two stops which require

moving the lever left and right as well as up and

down. Moving this lever upward activates the

automatic longitudinal feed. Moving the lever

down activates the cross slide. See Figure 13.

To perform a longitudinal cut in inches, use the

bottom portion of the chart. If the desired feed

rate is 0.0062"/revolution, look at the longitudinal

ranges. According to the chart we would put the

left-hand lever in the “C” position and the righthand lever in the “4” position. Metric calculations

would be done the same way. To perform a cross

feed cut with a feed rate of 0.0013" move the lefthand lever to the “D” position and the right-hand

lever to the “1” position.

Please note that when either of the two selector

levers are left in the down position, the drive train

after this point is in neutral.

Figure 13. Feed lever in neutral postition.

Feed lever

Page 18

-16- G4002/3 Gear Head Lathes

Figure 14. Selector positioned for threads.

Figure 15. Thread pitch chart.

Inch thread selection:

To cut threads with inch pitches, a selection must

be made for feed direction, pitch and lead screw.

Select the desired direction of cut as described in

the section titled Feed Direction.

Rotate the Feed/Lead Screw selection lever to

the position shown in Figure 14. If the lever does

not readily engage, rotate the lead screw or the

chuck by hand while maintaining gentle pressure

on the lever.

While other thread pitches may be achieved, the

G4002/3 comes with a chart that requires no gear

changes for cutting inch threads.

To achieve a desired thread pitch in inches, it is

necessary to determine the quick-change lever

positions. Refer to Figure 15 and find the desired

thread.

Thread Selection

Example:

The thread to be cut has 20 threads per inch

(TPI). Looking at the chart we find that the left

hand lever would be positioned at “C”. The right

hand lever would be positioned at “4”.

Page 19

-17-

G4002/3 Gear Head Lathes

Half Nut Lever - This lever compresses and

releases the half nut that engages the leadscrew.

See Figure 16. The lever is only engaged while

turning threads in stock. A lockout device featured in the lever mechanism engages when the

feed selector is used.

Threading Dial Indicator - The indicator tells

you when to engage the half nut to begin the

threading process. See Figure 16.

The Threading Dial Indicator has 8 lines and four

numbers printed on the dial. An indicator mark is

positioned near the rim of the dial. The dial is

mounted on a shaft that has a worm gear mounted at its opposite end.

Figure 16. Threading dial and half nut lever.

NOTICE

Do not simultaneously engage the feed lever

and the threading lever. Doing so will damage

the lathe.

NOTICE

The threading dial cannot be used when cutting metric threads. Once the half nut has been

engaged, it must remain engaged throughout

the threading process.

16b. Dial indicator chart.

Lever

Dial

These rest in a housing that pivots so that the

gear can be engaged or disengaged. An Allen

®

head cap screw is located on the side of the

housing. Loosen this screw to change the positioning of this housing.

When engaged, the dial will turn when the spindle is turning. If the dial does not turn, readjust

the housing.

When the half nut is engaged the dial stops turning. By carefully engaging the half nut as the

appropriate line or number passes by the indicator mark, a thread can be established and the

lead maintained through the multiple passes that

are required to cut a thread to the finished depth.

The chart listed in Figure 16b shows a system

for using the threading dial indicator while cutting

inch threads.

Example:

To cut 11 threads per inch engage the half nut

when the 1 or the 3 is on the indicator mark.

Determine the length of the thread to be cut.

Make a cut along the part and disengage the half

nut. Return the carriage to the beginning of the

cut. Watch the dial and when the 1 or the 3

comes around to the indicator mark engage the

half nut. Repeat this process until the desired

depth of cut has been achieved.

Page 20

-18- G4002/3 Gear Head Lathes

3. To the left of the desired pitch is a small

column with a letter. This letter indicates

placement of the left hand quick change

lever. Move the lever to the corresponding

location.

4. In the “Combination of Gears” column are 3

small columns. Please note the “F” and “G”

at the top. The numbers below F and G

represent the number of gear teeth of a

gear included with the lathe. Find the gears

that have the corresponding number of

teeth as stated in the chart to the left of the

desired pitch.

Example:

The desired metric pitch is 1.25 mm. Find this

number in the chart and find the number of teeth

of the two gears to the left. The F gear will need

to have 47 teeth and the G will need 60 teeth. A

diagram on the left side of the chart on the

machine tells us the 47 tooth gear goes on top of

the middle gear and the 60 tooth gear goes on

the bottom.

Metric thread selection:

The chart in Figure 17 lists 29 metric threads

that can be cut on the G4002/3. Five ranges are

used on the left hand quick change selector and

6 on the right hand quick change selector.

Additionally, 5 gear changes are necessary to

accomplish all of the available metric threads.

These gear changes take place on the left hand

end of the machine. See Figure 18.

The chart is divided into 3 main sections or

columns. Starting from the left: Gear diagram,

Combination of Gears and

m

/m Per Pitch.

To use the chart:

1.

Find the desired pitch in the chart.

2. Below the

m

/m Per Pitch label are numbers.

Find the corresponding number above the

desired pitch and change the right hand

quick change lever to that position.

Figure 17. Metric thread chart

Figure 18. Change gear bracket and gears.

Page 21

G4002/3 Gear Head Lathes -19-

Thread Selection Cont.

Metric threading requires 5 gear changes to

achieve all of the available pitches listed on the

chart. Refer to Figure 19 while reading the

instructions below.

To change gears:

1. Loosen the nut below the middle gear and

rotate the bracket so the middle gear

moves away from gear F.

2. Loosen the cap screw at the center of the

middle gear and slide it away from gear G.

3. Gear F can be removed by loosening the

cap screw in its middle. Gear G has a

setscrew in its rim. Loosen this screw and

pull the gear off of the shaft.

4. Replace these two gears with the gears

which will produce the desired pitch and

secure with screws provided.

Figure 19. Gear Placement

5. Slide the middle gear until it is in mesh with

the G Gear. Tighten the cap screw at the

center.

6. Pivot the bracket until the middle gear is in

mesh with gear F and tighten the nut below.

Page 22

-20- G4002/3 Gear Head Lathes

Figure 21. Spindle rotation control lever.

Spindle rotation control - The spindle rotation is

controlled from the lever on the right hand side of

the carriage. Moving the lever down causes the

spindle to rotate counter clockwise. Moving the

lever up causes the spindle to turn clockwise. The

middle position stops the motor and the lever is

considered to be in a neutral position. See Figure

21.

Figure 20. Handwheel locations.

Carriage Controls

The carriage handwheel allows the cutting tool to

move along the length of the lathe bed. The

cross slide allows the cutting tool to travel perpendicular to the bed. The carriage features a top

slide which allows linear movement of the cutting

tool at any preset angle. This section will review

the individual controls on the carriage and pro-

vide descriptions of their uses. See Figure 20.

Compound Slide Handwheel - The Top Slide

Handwheel controls the position of the cutting

tool relative to the workpiece. The top slide is

adjustable for any angle. The graduated dial is

adjustable using the same method as the dial on

the cross slide. Angle adjustment is controlled by

hex nuts on the base of the top slide.

Cross Slide Handwheel - The Cross Slide

Handwheel moves the top slide toward and away

from the work. Turning the dial clockwise moves

the slide toward the workpiece. The graduated

dial can be adjusted by holding the handwheel

with one hand and turning the dial with the other.

Carriage Handwheel - The Longitudinal

Handwheel moves the carriage left or right along

the bed. The control is helpful when setting up the

machine for turning or when manual movement is

desired during turning operations.

Carriage Handwheel

Cross Slide

Handwheel

Compound Slide

Handwheel

Page 23

G4002/3 Gear Head Lathes -21-

Figure 23. Detail of tailstock controls.

Tailstock Controls

Tool Post and Holder

The tailstock serves many functions. The primary use is for holding centers and drill chucks. The

barrel has a Morse taper

#

3 bore and is imprinted

with graduations in millimeters and inches.

Please refer to Figure 23.

Tailstock Handwheel - Turning the handwheel

advances or retracts the barrel in the tailstock.

The graduated dial on the handwheel is

adjustable.

Top Lock Lever - This lever locks the tailstock

barrel in place.

Side Lock Lever - This lever locks the tailstock

in place on the lathe bed.

Figure 22. Quick change tool post.

Tool post - A quick change tool post and 2 tool

holders are supplied with the Model G4002/3.

Figure 22 shows tool post and a holder with

optional bit. Cutting tools can be secured and

removed by tightening or loosening the clamping

screws in the top of the holder. A threaded stud

is mounted in the top of the holder and has a

knurled thumb wheel. Rotating the thumb wheel

allows for adjustment of the tool holder so the

cutting tool can be centered. The handle on the

tool post can be rotated to lock and unlock the

tool holder onto the dovetail ways. The tool post

may be rotated by loosening the nut at the top of

the tool post.

More styles of tool holders are available through

Grizzly Industrial, Inc. Consult the latest catalog

for styles, prices and ordering information.

Page 24

-22- G4002/3 Gear Head Lathes

Test Run

Now that the lathe is securely in place and

you’ve read the safety guidelines, it’s time to give

the machine a test run.

Before starting the machine:

1. Make sure the machine is properly ground-

ed, the Power Switch is in the “OFF” position

and the spindle control lever is in the neutral

position. See Figure 24.

2. Inspect the machine to ensure that all hand

tools are out of the way, guards are in place

and nothing is impeding the movement of

the chuck. Check this by rotating the chuck

by hand.

3. Rotate the stop switch, on the headstock of

the lathe, in the direction indicated by the

arrows imprinted on the button.

4. Lower the control lever on the apron. The

spindle should start turning in a counter

clockwise direction.

Figure 24. Carriage control lever in neutral.

Always make sure the power switch is in the

“OFF” position and the spindle control lever

is in the neutral position before plugging in

power cord.

If the direction is reversed, contact our service department for further instructions.

5. If the lathe is running correctly, lift the spindle con-

trol lever to the neutral position, wait for the

machine to come to a complete stop and take

some time to become familiar with the various

controls.

Page 25

G4002/3 Gear Head Lathes -23-

Compound Gib - The gib on the compound is

adjusted by the same method as the gibs on the

cross-slide, except the screw closest to the oper-

ator (when the compound slide is aligned with the

cross slide) must be loosened and the screw furthest from the operator tightened to make the gib

tighter. See Figure 26.

Figure 26. Tightening this screw tightens gib.

NOTICE

When adjusting gibs, keep in mind that the

goal of gib adjustment is to remove unnecessary sloppiness from the slide’s movement

without causing them to bind. Loose gibs may

cause poor finishes on the workpiece. Over

tightening may cause premature wear.

SECTION 6: ADJUSTMENTS

Figure 25.Adjusting the cross-slide gib.

There are three main gib adjustments for the

Model G4002/3. They are: the cross-slide gib, the

compound slide gib and the saddle gib.

Cross-slide Gib - The gib on the cross-slide is

adjusted by the two screws located at each end.

See Figure 25. To adjust, loosen the setscrew

located along the edge of the cross-slide.

This setscrew is provided for locking the slide for

certain operations. After making the adjustments

detailed below, tighten the setscrew until it just

touches the gib.

The gib is wedge shaped and by loosening the

screw closest to the operator and then tightening

the opposite screw, the slide will become looser.

Conversely, loosening the screw furthest away

from the operator and tightening the closer screw

will tighten the gib. Do not over tighten. Adjust the

gib so that it creates a slight drag when the slide

is in motion. Test the ease of motion with the gib

slightly loose. Begin tightening the gib and test

after making small adjustments. When a slight

drag is detected the gib is properly adjusted.

Gibs

Page 26

-24- G4002/3 Gear Head Lathes

Saddle Gib - The saddle is supplied with a

square head bolt on the front right hand side of

the slide. Before making adjustments to the saddle gib, ensure that this bolt is loose by turning it

counter clockwise. See Figure 26b.

It is important that the apron gib be properly

adjusted. A loose gib will cause finish problems

in a workpiece. A gib adjusted too tightly will

cause premature wear.

The gib for the saddle is located on the bottom

of the back edge of the slide. The tension on this

gib is maintained by four setscrews with jam

nuts. By loosening the jam nuts and tightening

the setscrews, the gib will tighten. Loosening the

setscrews will loosen the gib. The gib strip is

properly adjusted when a slight drag is detected

while moving the apron. Do not over tighten.

It is important the 4 setscrews are tightened

evenly. When tightening the jam nuts, hold the

setscrew’s position using an Allen

®

wrench.

Figure 27. Steady rest lock nuts.

Figure 26b. This bolt locks the apron in place.

Steady/Follow Rest

To adjust the Steady Rest:

1. Loosen the lock nuts. See Figure 27.

2. Open the sliding fingers by turning the

knurled screws until they fit around the

workpiece. Secure the steady rest in position.

3. Tighten the knurled screws so that the fin-

gers are snug, but not tight against the

workpiece. Tighten the setscrews and the

lock nuts.

4. Lubricate the brass points with machine oil.

The Follow Rest is setup in the same manner

except that the place of the third finger is taken up

by the tool bit. The follow rest prevents long,

small diameter pieces from flexing under the cutting pressure from the tool bit.

Lock Nuts

Square Head

Bolt

Page 27

G4002/3 Gear Head Lathes -25-

Figure 28. Finished dead center.

Tailstock

The tailstock on the Model G4002/3 is aligned at

the factory with the headstock. It is recommended that you take the time to ensure that the tailstock is aligned to your own desired tolerances.

To align the tailstock:

1. Center drill a 6'' long piece of bar stock on

both ends. Set it aside for use in step 4.

2. Make a dead center by turning a shoulder

to make a shank. Flip the piece over in the

chuck and turn a 60° point. See Figure 28.

As long as it remains in the chuck, the point

of your center will be accurate to your spindle’s axis. Keep in mind that the point will

have to be refinished whenever it is

removed and returned to the chuck.

Figure 29. Bar stock mounted on centers.

Figure 30. Adjusting for headstock end taper.

3. Place the live center in your tailstock.

4. Attach a lathe dog to the bar stock and

mount it between the centers. See Figure

29.

5. Turn approximately .010" off the diameter.

6. Measure the stock with a micrometer. If the

stock is fat at the tailstock end, the tailstock

needs to be moved toward you the amount

of the taper. See Figure 30.

TIP

Before making adjustments to the tailstock,

mount a dial indicator so that the dial’s plunger

is on the tailstock barrel. See Figure 30.

Viewed from above.

Page 28

-26- G4002/3 Gear Head Lathes

NOTICE

Do Not forget to lock down the tailstock after

each adjustment.

Figure 31. Adjusting for tailstock end taper.

Figure 32. Tailstock offset adjustment screw.

7. Loosen the tailstock mounting bolt. Adjust

the tailstock offset by the amount of the

taper by turning the adjustment setscrews.

See Figure 32. Turn another .010'' off of

the stock and check for taper. Repeat as

necessary until the desired amount of accuracy is achieved.

Adjustment Screw

Lock Screw

If the stock is thinner at the tailstock end, the

tailstock needs to be moved away from the

operator by at least the amount of the

taper. See Figure 31.

Page 29

G4002/3 Gear Head Lathes

-27-

SECTION 7: MAINTENANCE

Lubrication

Quick Change Gearbox - Lubrication for the

Gearbox is provided through 3 oil points, labeled

oil nipple. Add a squirt or two of oil after every

three-to-four hours of use. See Figure 35.

Motor - The bearings used in the motor are

shielded and lubricated for life.

Your Model G4002/3 will function best when it is

clean and well lubricated. Take the time to wipe

down and oil the machine after use. We recommend using ISO 68 or SAE 20W non-detergent

oil unless otherwise specified.

Apron - Apply lubrication to the apron through

the 2 ball fittings on the top face of the apron and

one near the apron handwheel. See Figure 33.

There is a level glass on the front of the apron

and a fill plug on top. Make sure the oil level is

between the 2 red marks on the glass before

using lathe.

External Gearing - Apply only a minimal amount

of oil to the teeth of the end gears. Avoid getting

oil on the belt or pulleys when lubricating.

Apply one squirt of oil into the port shown in

Figure 34.

Figure 33. Viewed from behind for clarity.

Figure 35. Gearbox lubrication points.

Figure 34. External gears and port.

ALWAYS disconnect the electric power to

the machine before servicing. NEVER lubricate your lathe while it is running.

Cross-Slide and Compound - These slides are

also supplied with ball fittings in their top surfaces

and should be oiled the same as the apron. See

Figure 33.

Oil Ports

Page 30

Bearing Preload

This lathe is shipped from the factory with the

bearing preload already set. If the preload

requires resetting for whatever reason, please

contact our service department for further

instructions.

Slides and Ways - Apply oil to the ways and

slides after each use. Wipe the ways with a clean

rag prior to lubrication to ensure that no grime is

carried along with your lubricant into friction-sensitive areas. Applying oil to the bedways and

other bare metal parts also protect the lathe from

rust and pitting.

Lead Screw and Feed Rod - Be sure to clean

and lubricate the leadscrew, feed rod and switch

control rod. The lead screw and feed rod have a

bearing on the tail stock end support that will

require one to two squirts of oil. See Figure 36.

Headstock Gearbox - The oil in the headstock

should be changed after the first 2 hours of use.

Then, every 6 months, depending on usage. It is

recommended that a light weight, non detergent

oil be used. Viscosity can range from 10W to

30W and may include multi-viscosity oil in this

same range.

Tailstock - The tailstock is fitted with one oiling

port. The tailstock barrel may be oiled directly.

Apply oil each week, or after every five uses

(depending on the frequency of operation). Be

sure to clean the slide ways for the tailstock and

lift the tailstock and squirt a few drops of oil on

the ways. It is a good idea to remove the tailstock

once a month and wipe the bottom thoroughly

and replace. See Figure 37.

Figure 36. Lead screw, feed rod and switch rod.

Figure 37. Tailstock oiling point.

Switch Control Rod

Feed Rod

Oil Ports

Lead Screw

-28- G4002/3 Gear Head Lathes

Page 31

-29-G4002/3 Gear Head Lathes

NOTICE

The Model G4002/3 was specifically designed

for turning operations. DO NOT MODIFY

AND/OR USE THIS LATHE FOR ANY

OTHER PURPOSE. Modifications or

improper use of this tool will void the warranty. If you are confused about any aspect of

this machine, DO NOT use it until you have

answered all your questions.

The following pages contain general machine

data, parts diagram, parts lists and Warranty/Return

information for your Model G4002/3.

If you need parts or help in assembling your

machine, or if you need operational information,

we encourage you to call our Service

Department. Our trained service technicians will

be glad to help you. If you have comments dealing specifically with this manual, please write to

our Bellingham, Washington location using the

address in the Introduction section of this manual.

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G4002/3 as supplied when the manual was prepared. However, due to Grizzly’s policy of continuous improvement, changes may be made at any

time with no obligation on the part of Grizzly.

Whenever possible, though, we send manual

updates to all owners of a particular tool or

machine. Should you receive one, add the new

information to this manual and keep it for reference.

We have included some important safety measures that are essential to this machine’s operation. While most safety measures are generally

universal, Grizzly reminds you that each work

shop is different and safety rules should be con-

sidered as they apply to your specific situation.

We recommend you keep a copy of our current

catalog for complete information regarding

Grizzly's warranty and return policy. If you need

additional technical information relating to this

machine, or if you need general assistance or

replacement parts, please contact the Service

Department listed in the General Information.

This machine is designed for highly-skilled individuals who have an understanding of metalworking. We realize there are numerous kinds of

cutters and specialized techniques used to turn

metals. To list all of the techniques necessary to

operate a metal lathe correctly for specific applications would require many volumes. Additional

information sources are necessary to realize the

full potential of this machine. Trade journals, metalworking magazines, and your local library are

good places to start.

SECTION 8: CLOSURE

As with all power tools, there is danger

associated with the Model G4002/3. Use the

tool with respect and caution to lessen the

possibility of mechanical damage or operator injury. If normal safety precautions are

overlooked or ignored, injury to the operator or others in the area is likely.

Page 32

-30- G4002/3 Gear Head Lathes

Design Type ......................................................................................................Floor Model

Overall Dimensions:

Overall Length ..........................................................................................................53"

Overall Width ............................................................................................................26"

Height With Optional Stand ..................................................................................52

1

⁄2"

Height Without Optional Stand ................................................................................23"

Bed Width ................................................................................................................7

1

⁄4"

Spindle Bore ..........................................................................................................1

7

⁄16''

Spindle Taper ......................................................................................#5 Morse Taper

Tailstock Taper ....................................................................................#3 Morse Taper

Tailstock Barrel Diameter ......................................................................................1

9

⁄16''

Weight (Net) ......................................................................................................913 lbs.

Weight (Shipping)............................................................................................1015 lbs.

Crate Size ..................................................................................59" L x 30" W x 29" H

Footprint ........................................................................................................53" x 23"

Construction:........................................................................................................Cast Iron

Capacity:

Swing Over Bed ......................................................................................................12''

Swing Over Gap ......................................................................................................17''

Swing Over Cross Slide ............................................................................................7''

Distance Between Centers ......................................................................................24''

Spindle..................................................................................................D1-4 Cam Lock

Compound Travel ....................................................................................................3

1

⁄4''

Cross Slide Travel ..................................................................................................6

1

⁄4''

Tailstock Barrel Travel................................................................................................4''

Spindle Speeds............................70, 200, 220, 270, 360, 600, 800, 1000, 1400 RPM

Feed Rate Range ..........................................................................40 @ .0011'' - .031''

Thread Range Inch ....................................................................40 @ 4 TPI - 112 TPI

Thread Range Metric ........................................................................29 @ .2 - 4.5 mm

Motor:

Type ............................................................................TEFC Capacitor Start Induction

Horsepower ..............................................................................................................1

1

⁄2

Phase ⁄ Hertz ................................................................................Single Phase ⁄ 60Hz

Voltage ..................................................................................................................220V

Amps............................................................................................................................9

RPM ......................................................................................................................1725

Bearings ....................................................................Shielded And Lubricated For Life

Features:

........................................................................6'' 3-Jaw Chuck With Two Set Of Jaws

..........................................................................8'' 4-Jaw Chuck With Reversible Jaws

............................................................Quick Change Tool Post With One Tool Holder

..........................................................................................................Extra Tool Holder

..................................................................................................................Steady Rest

....................................................................................................................Follow Rest

..............................................................................................................10'' Face Plate

....................................................................

1

⁄2'' Drill Chuck W⁄ # 3 Morse Taper Arbor

..................................................2- #3 Morse Taper Dead Centers (1 Carbide Tipped)

..........................................................................................#3 Morse Taper Live Center

..................................................................................................Set of 6 Change Gears

........................................................................................................................Tool Box

Specifications, while deemed accurate, are not guaranteed.

Customer Service #: (570) 326-3806 • To Order Call: (800) 523-4777 • Fax #: (800) 438-5901

GRIZZLY MODEL G4002 12" X 24" GEAR HEAD LATHE

MACHINE DATA

SHEET

Page 33

Design Type ......................................................................................................Floor Model

Overall Dimensions:

Overall Length ..........................................................................................................61"

Overall Width ............................................................................................................23"

Height With Optional Stand ..................................................................................54

1

⁄2"

Height W⁄O Optional Stand ......................................................................................23"

Bed Width ................................................................................................................7

1

⁄4"

Spindle Bore ..........................................................................................................1

7

⁄16''

Spindle Taper ......................................................................................#5 Morse Taper

Tailstock Taper ....................................................................................#3 Morse Taper

Weight (Net) ......................................................................................................917 lbs.

Weight (Shipping)............................................................................................1040 lbs.

Crate Size ..................................................................................66" L x 30" W x 28" H

Footprint ........................................................................................................61" x 23"

Construction:........................................................................................................Cast Iron

Capacity:

Swing Over Bed ......................................................................................................12''

Swing Over Gap ......................................................................................................17''

Swing Over Cross Slide ............................................................................................7''

Distance Between Centers ......................................................................................36''

Spindle..................................................................................................D1-4 Cam Lock

Compound Travel ....................................................................................................3

1

⁄4''

Cross Slide Travel ..................................................................................................6

1

⁄4''

Tailstock Barrel Travel................................................................................................4''

Spindle Speeds............................70, 200, 220, 270, 360, 600, 800, 1000, 1400 RPM

Feed Rate Range ..........................................................................40 @ .0011'' - .031''

Thread Range Inch ....................................................................40 @ 4 TPI - 112 TPI

Thread Range Metric ........................................................................29 @ .2 - 4.5 mm

Motor:

Type ............................................................................TEFC Capacitor Start Induction

Horsepower ..............................................................................................................1

1

⁄2

Phase ⁄ Hertz ................................................................................Single Phase ⁄ 60Hz

Voltage ..................................................................................................................220V

Amps............................................................................................................................9

RPM ......................................................................................................................1725

Bearings ....................................................................Shielded And Lubricated For Life

Features:

......................................................................6'' 3-Jaw Chuck With Two Sets Of Jaws

..........................................................................8'' 4-Jaw Chuck With Reversible Jaws

............................................................Quick Change Tool Post With One Tool Holder

..........................................................................................................Extra Tool Holder

..................................................................................................................Steady Rest

....................................................................................................................Follow Rest

..............................................................................................................10'' Face Plate

......................................................................

1

/

2'' Drill Chuck W/ #3 Morse Taper Arbor

................................................2- #3 Morse Taper Dead Centers (1 Carbide Tipped)

........................................................................................ #3 Morse Taper Live Center

..........................................................................................................................Oil Can

..............................................................................................Set Of Six Change Gears

........................................................................................................................Tool Box

Specifications, while deemed accurate, are not guaranteed.

G4002/3 Gear Head Lathes -31-

Customer Service #: (570) 326-3806 • To Order Call: (800) 523-4777 • Fax #: (800) 438-5901

GRIZZLY MODEL G4003 12" X 36" GEAR HEAD LATHE

MACHINE DATA

SHEET

Page 34

-32- G4002/3 Gear Head Lathes

Electrical Components

Page 35

-33-G4002/3 Gear Head Lathes

REF PART # DESCRIPTION

001 P4002001 START BUTTON

002 P4002002 INDICATOR LIGHT

003 P4002003 JOG BUTTON

004 P4002004 RESET BUTTON

050 P4002050 THERMAL PROT. BLOCK

051 P4002051 TRANSFORMER

052 P4002052 MAGNETIC CONTACTOR

053 P4002053 MAGNETIC CONTACTOR

054 P4002054 FUSE HOLDER

055 P4002055 CONTROL PANEL PLATE

933 P4002933 FUSE 2 AMP

Page 36

-34- G4002/3 Gear Head Lathes

Page 37

-35-G4002/3 Gear Head Lathes

REF PART # DESCRIPTION

101 P4002101 SCREW

102 P4002102 COVER

103 P4002103 OIL SEAL

104 P4002104 SPINDLE

105 P7212 BEARING D-7212

106 P4002106 KEY

107 P4002107 KEY

108 P4002108 SCREW

109 P4002109 GEAR

110 P4002110 GEAR

111 P4002111 GEAR

112 P4002112 NUT

113 P4002113 SCREW

114 P4002114 PIN

115 P4002115 COLLAR

116 P4002116 SCREW

117 P4002117 GEAR

118 P7211 BEARING D-7211

119 P4002119 NUT

120 P4002120 OIL SEAL

121 P4002121 COVER

122 P4002122 SCREW

123 P4002123 SCREW

124 P4002124 COVER

125 P4002125 OIL SEAL

126 P60304 BEARING 60304

127 P4002127 SHAFT

128 P4002128 KEY

129 P4002129 SCREW

130 P4002130 GEAR

131 P4002131 GEAR

132 P4002132 GEAR

133 P4002133 C-CUP

134 P4002134 GEAR

135 P4002135 GEAR

136 P4002136 GEAR

137 P6004 BALL BEARING 6004

138 P4002138 OIL SEAL

139 P4002139 COVER

REF PART # DESCRIPTION

140 P4002140 SCREW

141 P4002141 WASHER

142 P4002142 PULLEY

143 P4002143 SCREW

144 P4002144 COVER

145 P4002145 OIL SEAL

146 P4002146 GEAR

147 P4002147 GEAR

148 P4002148 GEAR

149 P4002149 SHAFT

150 P4002150 KEY

151 P4002151 KEY

152 P6004 BALL BEARING 6004

153 P4002153 SCREW

154 P4002154 WASHER

155 P4002155 GEAR

156 P4002156 KEY

157 P4002157 OIL SEAL 20 X 45 X 10

158 P4002158 C-CLIP

159 P4002159 C-CLIP

160 P6004 BALL BEARING 6004

161 P4002161 SCREW

162 P4002162 OIL SEAL

163 P4002163 COVER

164 P4002164 COLLAR

165 P4002165 SHAFT

166 P4002166 KEY

167 P4002167 GEAR

168 P4002168 SHAFT

169 P4002169 OIL SEAL

170 P4002170 SCREW

171 P4002171 C-CLIP

172 P4002172 C-CLIP

173 P6204 BALL BEARING 6204

174 P4002174 GEAR

175 P4002175 LOCK PIN

176 P4002176 SPRING

177 P4002177 SCREW

Page 38

-36- G4002/3 Gear Head Lathes

REF PART # DESCRIPTION

z178 P4002178 ECCENTRIC SHAFT

179 P4002179 GEAR

180 P4002180 SCREW

181 P4002181 PIN

182 P4002182 SHAFT

183 P4002183 OIL SEAL

184 P4002184 SHAFT ARM

185 P4002185 C-CLIP

186 P4002186 SCREW

187 P4002187 NUT

188 P4002188 SIGN BOARD

189 P4002189 SCREW

190 P4002190 SPRING

191 P4002191 BALL

192 P4002192 SCREW

193 P4002193 COVER

194 P4002194 SCREW

195 P4002195 SCREW

196 P4002196 OIL SEAL

197 P4002197 HEAD STOCK

198 P4002198 SHAFT

199 P4002199 COLLAR

1100 P40021100 SHIFTER ARM

1101 P40021101 SHIFTER

1102 P1183108 RIVET

1103 P40021103 SIGN BOARD

1104 P40021104 OIL WINDOW

1104B P40021104B O-RING

1105 P40021105 SCREW

1106 P40021106 OIL SEAL

1107 P40021107 SCREW

1108 P40021108 SCREW

1109 P40021109 HANDLE

1110 P40021110 BOSS

1111 P40021111 KEY

1112 P40021112 GEAR

1113 P40021113 SCREW

1114 P40021114 SCREW

1115 P40021115 BOSS

1116 P40021116 SHIFTER

1117 P40021117 COLLAR

Page 39

-37-G4002/3 Gear Head Lathes

REF PART # DESCRIPTION

201 PSB26M CAP SCREW M6-1 X 12

202 P4002202 WASHER

203 P4002203 GEAR

204 PK12M KEY 5 X 5 X 30

205 PSB26M CAP SCREW M6-1 X 12

206 P4002206 WASHER

207B P4002207B STEP GEAR 86-91T

208 P6202 BALL BEARING 6202

210 P4002210 QUADRANT

211 P4002211 SHAFT

212 P4002212 GEAR

213 PK12M KEY 5 X 5 X 30

Page 40

-38- G4002/3 Gear Head Lathes

Page 41

-39-G4002/3 Gear Head Lathes

REF PART # DESCRIPTION

301 P4002301 LEAD SCREW

302 P4002302 PIN

304 P8103 BEARING 8103

305 P4002305 SHAFT

306 PK19M KEY 5 X 5 X 14

308 P4002308 GEAR

309 PN09M HEX NUT M12-1.75

310 P4002310 WASHER

311 P4002311 SCREW

312 P4002312 COVER

313 PK12M KEY 5 X 5 X 30

314 PK06M KEY 5 X 5 X 10