NAIL GUNS & STAPLERS

MODEL G1847 / G1852 / G1861 / G3811

INSTRUCTION MANUAL

COPYRIGHT © 1990 BY GRIZZLY INDUSTRIAL, INC. TX 3 176 561

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

REVISED MARCH, 1999 PRINTED IN USA

DISCONTINUED MACHINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE LAST CONFIGURATION OF THE MACHINE BEFORE IT WAS DISCONTINUED.

MACHINE CONFIGURATIONS MAY HAVE CHANGED AS PRODUCT IMPROVEMENTS WERE INCORPORATED. IF YOU OWN AN EARLIER VER-

SION OF THE MACHINE, THIS MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY

QUESTIONS ABOUT DIFFERENCES. PREVIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

®

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -1-

Table Of Contents

PAGE

1. SAFETY ....................................................................................................................2

SAFETY RULES FOR ALL TOOLS ....................................................................2

ADDITIONAL SAFETY INSTRUCTIONS FOR NAILERS....................................3

2. INTRODUCTION ...................................................................................................... 4

3. OPERATIONS............................................................................................................5

UNPACKING ........................................................................................................5

CONNECTING TO AIR ........................................................................................5

LOADING BRADS................................................................................................6

LOADING STAPLES ............................................................................................7

TEST FIRE ..........................................................................................................8

AIR QUALITY ......................................................................................................8

4. MAINTENANCE ........................................................................................................9

GENERAL ............................................................................................................9

CLEANING & OILING ..........................................................................................9

JAMMING ..........................................................................................................10

ALIGNING NOSE PIECE ..................................................................................10

DRIVER REPLACEMENT..................................................................................11

O-RING ..............................................................................................................12

5. CLOSURE................................................................................................................13

G1847 PARTS DIAGRAM AND LIST ..........................................................14-15

G1852 PARTS DIAGRAM AND LIST ..........................................................16-17

G1861 PARTS DIAGRAM AND LIST ..........................................................18-19

G3811 PARTS DIAGRAM AND LIST ..........................................................20-21

MACHINE DATA ................................................................................................22

TROUBLESHOOTING GUIDE ..........................................................................23

WARRANTY AND RETURNS............................................................................24

-2- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

For Your Own Safety Read Instruction

Manual Before Operating Nailer

Safety Instructions For Power Tools

These safety rules cannot cover every situation in a work shop. Consider your conditions when setting

up or operating your nailer.

SECTION 1: SAFETY

DO NOT CONNECT nailer to the air hose until

you are in position and ready to operate the

nailer safely.

KEEP HANDS and other body parts away from

the nailer tip at all times.

NEVER MANUALLY DEPRESS the safety

nose and shoot fasteners for any reason.

DO NOT REST a pressurized nailer against

your body for any reason.

8. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

9. WEAR PROPER APPAREL Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering to contain long hair.

10. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if tool operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety

glasses.

11. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

12. DON’T OVERREACH. Keep proper footing

and balance at all times.

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see

that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or expose them to rain. Keep

work area well lighted.

5. KEEP CHILDREN AND VISITORS AWAY.

All children and visitors should be kept a

safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job bet-

ter and safer at the rate for which it was

designed.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -3-

Safety Instructions for Nail Guns

17. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function-check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its

operation. Damaged parts should be properly repaired or replaced immediately.

18. DIRECTION OF FEED. Feed work into a

blade or cutter against the direction of rotation of the blade or cutter only.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop.

7. Use only clean, dry, regulated, compressed

air. DO NOT connect this air tool to any pres-

surized gas other than compressed air.

8. Air compressors must comply with ANSI B

19.3 - 1981 (U.S.), “Safety Standard for

Compressors for Process Industries.”

9. DO NOT operate at a pressure higher than

90 PSI.

10. NEVER use this nailer for fastening alu-

minum, brass, metal, plastics, or any other

like material.

11. Air hose must be rated as having a minimum

working pressure of 150 p.s.i. or 150% of the

maximum pressure produced in the line,

whichever is greater. Inspect air hoses frequently.

12. All air tools exhaust compressed air. If work-

ing in an area where dust will become air-

borne due to exhausted air, WEAR RESPI-

RATORY PROTECTION.

1. Make sure the safety nose is functioning

properly before loading fasteners.

2. Make sure the magazine spring is set

before operating.

3. ALWAYS point nailer away from yourself

and others when loading or operating.

4. DO NOT carry nailer with your finger on

the trigger. Nailer will fire if safety nose is

accidentally depressed.

5. DO NOT place your free hand or feet near

the nailer tip to support the work. If you

cannot safely support the work without

placing body parts near the nailer tip, do

not use this nailer.

6. DO NOT operate the nailer if workpiece is

between you or someone else and the

nailer. Reposition yourself so you and others are behind the nailer.

13. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

14. DISCONNECT TOOLS before servicing

and changing accessories, such as blades,

bits, cutters, and the like.

15. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off posi-

tion before plugging in.

16. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

Safety Instructions For Power Tools

-4- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

Grizzly Industrial, Inc. is proud to offer its Model

G1847, G1852, G1861 and G3811 Pneumatic

Nailers and Staplers. These professional-quality

tools are part of Grizzly’s growing family of fine

woodworking machinery. When used according

to the guidelines set forth in this manual, you can

expect years of trouble-free, enjoyable operation,

and proof of Grizzly’s commitment to customer

satisfaction.

These nailers comprise a large part of our complete line of nail nailers covering most applications. The G1847 will shoot 18 Ga. staples

between

1

/2" and 7⁄8" long. The G3811 will shoot

18 Ga. staples between

7

⁄8" and 1 3⁄16" long. The

G1852 will shoot 18 Ga. brad nails between

3

⁄8"

and 1

3

⁄16" long. The G1861 will shoot 18 Ga. brad

nails between

5

⁄8" and 19⁄16". Each will handle up

to 100 fasteners.

We are also pleased to provide this manual with

your pneumatic nailer/stapler. It was written to

guide you through general operating procedures

and safety considerations. It represents our latest effort to produce the best documentation possible. If you have any criticisms that you feel we

should address in our next printing, please write

to us at the Bellingham, WA address at the end of

this section.

Most important, we stand behind our machines.

We have excellent service departments at your

disposal should the need arise. If you have any

service questions or parts requests, please call or

write to us at the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone:(570) 546-9663

Fax:(800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

To comment on this manual write to:

Grizzly Industrial, Inc.

C

⁄O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227

To operate this, or any tool, safely and efficiently,

it is essential to become as familiar with its characteristics as possible. Take as much time as

necessary to become acquainted with your pneumatic nailer. The time you invest before you begin

to use your tool will be time well spent. Also, read

all of the safety procedures. If you do not under-

stand them, DO NOT operate your nailer.

SECTION 2: GENERAL INFORMATION

The nailers and staplers described in this

manual are powerful, professional-quality

tools, each designed and built to provide

outstanding results when used cautiously

and with respect. Like any tools of their

type, they can be inherently dangerous.

Careless use could result in serious injury.

Please do not attempt to use these tools

without familiarizing yourself with their

instructions for assembly, adjustment, and

safe operation. Failure to do so could result

in serious personal injury, as well as property damage and damage to the tool.

ALWAYS wear ANSI-approved goggles or

safety glasses when operating these or any

other woodworking tool. Wearing hearing

protection is also strongly recommended.

Failure to wear proper safety gear could

result in serious personal injury.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -5-

SECTION 3: OPERATIONS

If the air fitting is not already screwed in, first be

sure the threads are wrapped with teflon tape and

then screw it in the back. Teflon tape is available

at most hardware stores.

To connect the air hose to the air nozzle at the

rear of the nailer:

1. Pull back on the female hose connector

sleeve.

2. Press the fitting onto the nailer air nozzle and

release the sleeve. The female fitting will

lock onto the male nailer fitting.

3. Listen for any air leaks. If no leaks are

detected, you are ready to test fire the nailer.

Air pressure should be set at the minimum

required to set the fastener and must not exceed

90 p.s.i.

Consistently operating at unnecessarily high

pressures will put excessive stress on internal

parts which will lead to premature nailer failure.

Connecting To Air

Unpacking

The pneumatic nailers/staplers are shipped from

the manufacturer in a carefully packed carton. If

you discover damaged after delivery, please call

Customer Service immediately for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise filing a claim can be difficult.

Carefully remove the items packed in the carton.

It may be a good idea to save the carton and

packing material in case it might be needed in the

future. Upon removal of all items from the package, you should have:

1. Nail Nailer

2. Allen Wrenches

3. Oil Bottle

4. Air Fitting

Be sure that your air compressor is properly grounded. If you are unsure of the quality

and condition of the circuit you intend to

use, have it inspected and repaired by a

qualified electrician. Failure to ensure proper grounding could result in serious injury

and/or equipment damage.

Please keep all packaging materials until

you are satisfied that the machine is in good

condition. Should you need to file a freight

claim, the carrier’s agent will require inspection of those materials. Settling a claim can

be difficult if packaging is not available.

NOTE

Figure 2. Inserting brads in magazine.

Figure 1. Releasing magazine latch.

-6- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

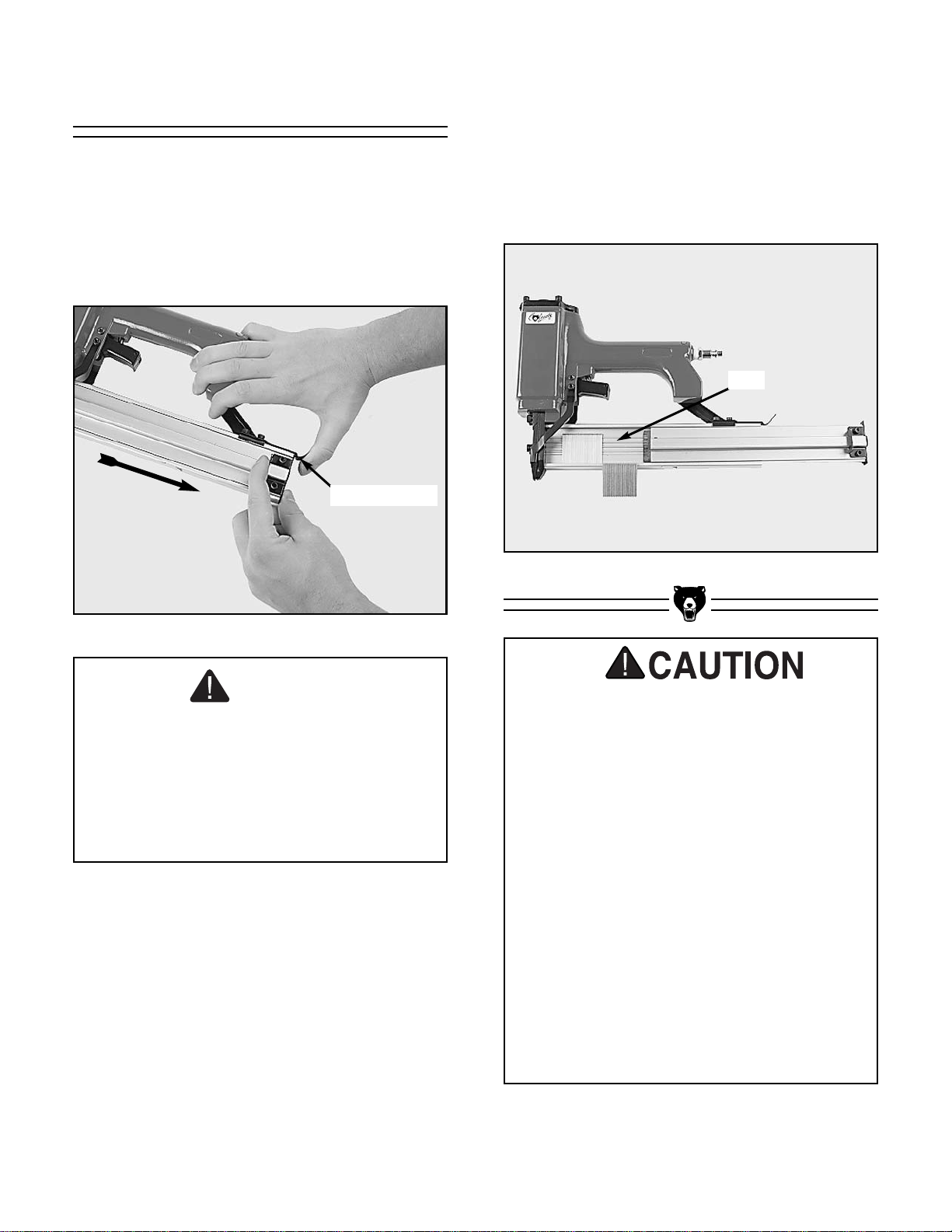

To load the nailer:

1. Disconnect the air hose if connected.

2. Lift the magazine latch that holds the maga-

zine in place. Figure 1.

3. Slide the magazine out and place the brads

into the nailer. Your nailer has slots in its

magazine to accommodate different size

brads. Figure 2.

4. Close the magazine. The latch will snap into

place if the brads are seated correctly.

Loading Brads

Magazine Latch

Slots

Be sure that brads are in good condition

before attempting to load them into the gun.

Rusty, corroded, bent, or damaged brads

should be discarded. Loading small, partial

bands of brads can also jam the gun. Also,

be sure that the brads you are using are the

correct size and style for the gun.

Do not force the magazine shut after loading. If the magazine seems stuck, or if it

requires more pressure than normal to slide

the magazine into it’s “firing” position, slide

it back out and remove the brads. Try sliding the magazine while empty. If the magazine slides easily, open again, reload, and

try to secure it.

If the magazine has difficulty closing when

empty, inspect for a loose brad or other foreign object that may be jammed between

the magazine slide and the frame of the gun.

CAUTION: Disconnect the gun from its air

source whenever you need to inspect or

service the gun. Failure to do so could

result in misfire and potential injury to the

operator or others in the work area.

NOTE

Figure 4. Staple placement.

Figure 3. Releasing the magazine.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -7-

To load the stapler:

1. Disconnect the air hose if connected.

2. Press down on the magazine latch that holds

the magazine in place. Figure 3.

3. Slide the magazine out and place the staples

into the nailer. The staples will seat over the

guide in the magazine. Figure 4.

4. Close the magazine. The magazine latch will

click into place if the staples are loaded correctly.

Loading Staples

Staples

Magazine Latch

DO NOT load or service any pneumatic nailer or stapler without first disconnecting it

from its air source. Failure to do so could

result in a misfire and possible serious

injury to the operator or others in the work

area.

DO NOT operate these pneumatic guns

without wearing ANSI-approved goggles or

safety glasses. Be sure that you are not

wearing loose-fitting clothing or jewelry that

could become entangled with the trigger

and cause misfires. Serious personal injury

could result. Never attempt to disconnect

the safety mechanisms on any of these

guns. In addition to voiding their warranties,

doing so could result in serious injury to the

operator or others in the work area.

Be sure that staples are in good condition

before attempting to load them into the gun.

Rusty, corroded, damaged, or incorrectlysized staples should not be used. Loading

small, partial bands of staples can also jam

the gun.

NOTE

-8- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

Whenever changing fastener size or composition

of material being fastened, the nailer should be

tested to ensure that the air pressure is set correctly and the nailer is working properly. To test

fire the nailer:

1. Firmly press the safety nose down against

the sample piece.

2. Pull trigger.

3. Inspect your results. If the nail is set too far

into the workpiece, reduce the regulated air

pressure. If the nail is not set or protrudes

above the work surface, increase the air

pressure. However, do not exceed the maximum air pressure recommended for the nailer or the hose (90 p.s.i. for the nailer).

4. Disconnect the air hose from the nailer when

finished.

Do not hold the nailer so that exhausted air is

blown into your face or someone else’s face.

Exhausted air will cause any dust near the operating nailer to become airborne; use a respirator

if using the nailer in a dusty environment.

Test Fire

This air nailer or stapler must be regularly oiled

and operated with treated or clean air. It is a precision tool with close internal tolerances designed

for repetitious use. Wet and/or dirty air lowers

performance and prematurely destroys internal

parts.

To ensure that the best quality air enters your

nailer:

1. Use an in-line system to automatically oil, fil-

ter, and dry compressed air. Grizzly offers an

in-line regulator/filter/water-separator/lubricator (G2304). Please refer to our catalog for

price and ordering information.

2. Keep your air filter clean. Replace periodi-

cally.

3. Drain compressor’s air tank(s) frequently;

more often in high humidity. This prevents

corrosion in the tanks, as well as damage to

your nailer or stapler.

4. Keep air hoses as clean as possible inter-

nally. Inspect nipples and couplers for any

dirt and moisture. Blow out prior to connecting the nailer.

Air Quality

Under no circumstances should you exceed

the recommended pressure limits for the

pneumatic gun or the air hose. In addition to

endangering the safety of the operator and

others in the work area, over-pressurizing

can cause damage to the gun and the hose.

Evidence of operation at pressures exceeding maximum recommended levels could

also void the gun’s warranty.

DO NOT operate this gun without wearing

ANSI-approved goggles or safety glasses.

Quality hearing protection is also strongly

recommended. Failure to wear proper safety gear could result in serious personal

injury and long-term damage to your sight

and hearing.

Make your workshop child-safe. Ensure that

idle machines have their safety keys

removed, sharp blades are stored safely

out of reach, and that your shop is securely

locked when your shop is not in use.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -9-

SECTION 4: MAINTENANCE

Maintenance requirements are minimal for these

nailers. The two most common problems with any

nailer are jamming and damaged drivers. In both

cases, the nailer will need to be partially disassembled to make the repairs.

The third most common problem is worn out Orings. Consult the Grizzly service staff for special

instructions if needed. Grizzly has replacement

parts and special O-ring rebuilding kits available

for these tools.

WARNING: All inspections and/or any maintenance is to be performed with the air supply

disconnected from the tool.

Inspect and maintain the following items

daily:

1. Check the air nailer for any loose bolts or air

leaks. Loose bolts should be retightened.

Make sure that all lock washers are in place.

Air leaks are an indication that internal seals

are worn or nicked and should be replaced.

2. Make sure the safety nose and trigger are

functioning properly. Repair as necessary.

Do not use the nailer with a broken or modified safety nose.

3. Inspect the automatic lubricating system if

applicable and fill as required. Inspect the inline air and water filters if applicable and

change or clean as necessary.

4. Inspect the compressor regulator and/or in-

line regulator to ensure that they are set correctly. Adjust accordingly.

General

CLEANING: Keep the nailer nose as clean as

possible. Dirt and debris have a tendency to work

their way into the nailer from the nose. Wipe off

any dirt that collects on the outside of the nailer

before connecting it to the air supply.

OILING: Keep the nailer oiled. Use special pneu-

matic tool oil to keep internal parts well lubricated. This tool oil is available through the Grizzly

Catalog (G2820).

If your air supply is not pre-lubricated, you must

add 2 drops of oil directly into the air nozzle at the

rear of the nailer each time the magazine is

loaded. NEVER USE any oil that will corrode the

rubber O-ring seals such as motor oil, detergent

oils, or oils that are used as solvents. Avoid overoiling.

IMPORTANT: When you first pick up an air activated nailer, ALWAYS ASSUME THAT IT IS

LOADED. Open the magazine and inspect for

any nails or staples before connecting it to the air

hose. Do not connect the air supply until you are

in position and ready to operate the nailer.

Cleaning & Oiling

DO NOT load or service any pneumatic nailer or stapler without first disconnecting it

from its air source. Failure to do so could

result in a misfire and possible injury.

Ensure that the safety mechanism is working properly each time you use this tool.

Under no circumstances should the safety

be modified or disabled. Serious injury

could occur.

-10- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

Aligning Nosepiece

The nosepiece may become misaligned if the

nailer has been dropped or otherwise mishandled. Misfiring and/or jamming will result if the

nosepiece is misaligned – but correcting the

problem is simple.

To align the nosepiece:

1. Remove the nosepiece cover.

2. Remove fasteners and visually inspect to

see if the nail slot in the nosepiece is aligned

with the nail slot in the magazine. If it is hard

to tell, put a nail in and see if it slides through

both slots easily.

3. If the nosepiece is misaligned, loosen the

cap screws that secure it to the magazine

and shift it until it lines up.

4. Re-assemble.

5. Do not put any fasteners into the magazine.

Connect the air hose.Check for any leaking

air. You will hear it hissing or feel it rushing

through the spaces.

6. If everything sounds normal, press the safe-

ty nose down on a piece of wood and pull the

trigger a couple of times. Air should be

exhausted normally each time.

Jamming

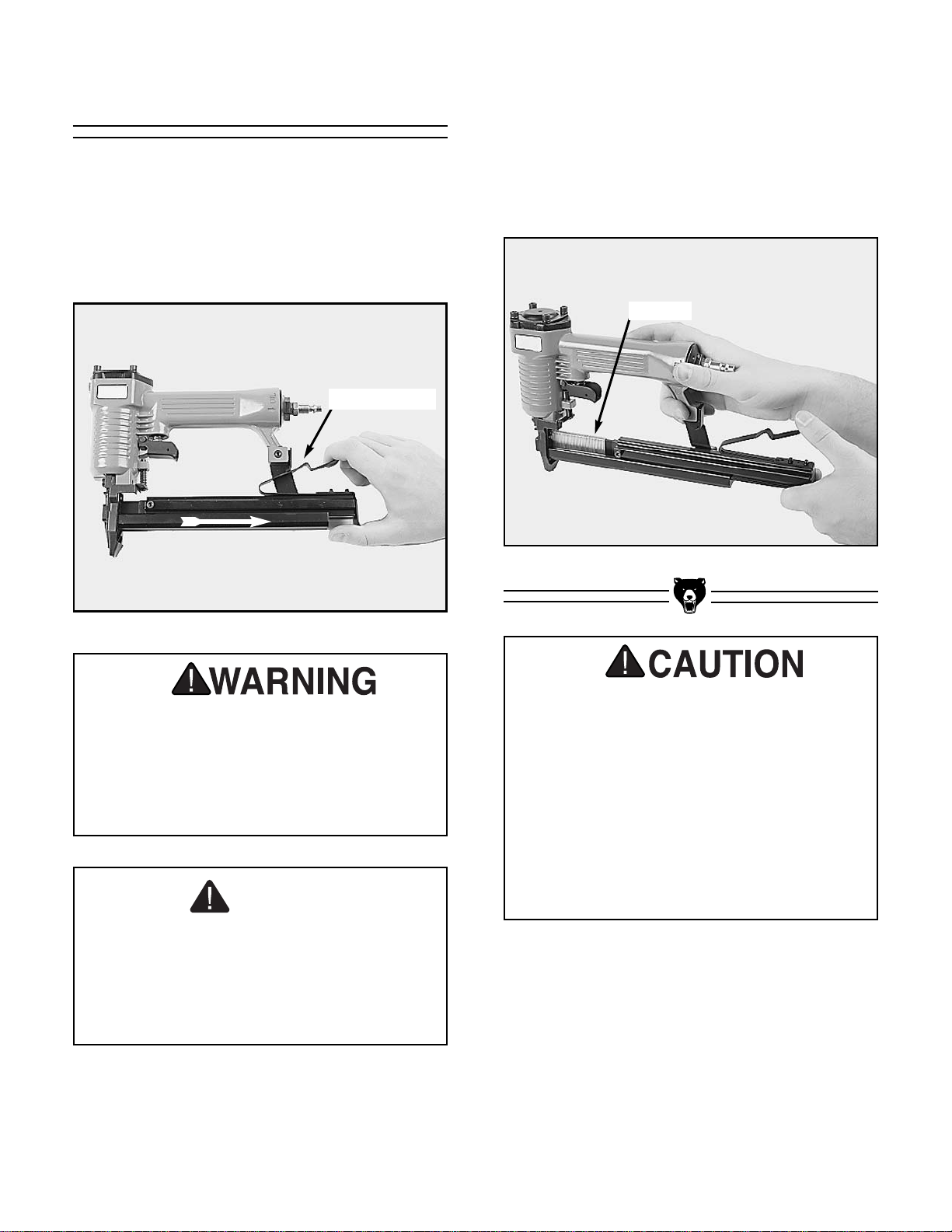

To repair a jam:

1. Remove any fasteners remaining in the gun.

2. Partially unscrew the cap screws that hold

the nosepiece cover in place. Slide the nose-

piece cover down and pull it off. Figure 5.

(G1861: Remove the safety tip before

removing the nosepiece cover.)

4. Remove any fasteners lodged in the nailer

nose.

5. Re-attach the nosepiece cover. Make sure it

lines up properly. G1861: Attach the safety

tip.

6. Load fasteners and connect the nailer to the

air supply.

7. Make sure the safety tip is functioning cor-

rectly and that it slides freely. Test fire into a

sample piece.

If jamming persists, make sure you are using fasteners within the size range of this nailer. If jamming is due to worn or broken parts, repair or

replace them before placing the nailer back into

service.

Jammed Brad

Nosepiece Cover

Cap Screw

Nosepiece

DO NOT attempt to repair or service this

gun without ensuring that all nails or staples have been removed and that the gun is

disconnected from its air source. Use

extreme care when testing after freeing

jams or after re-loading. Always wear

approved safety glasses or goggles and

quality hearing protection when operating

pneumatic guns or other woodworking

tools and machinery. Failure to do so could

result in serious personal injury.

Figure 6. Stapler driver assembly.

Figure 7. Brad driver assembly.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -11-

Driver Replacement

To remove the driver:

1. Disconnect the nailer from the air supply and

remove any fasteners from the magazine.

2. Sequentially loosen the 4 cap screws secur-

ing the nailer cap to the nailer body.

3. G1847/52: Remove the 4 cap screws,

deflector, cap, spring, and HD valve piston.

Place them to one side. Figure 6. G1861:

Remove the 4 cap screws, deflector, cap,

gasket set, and spring. Figure 7.

4. G1861 only: Remove the cap insert by plac-

ing one of your small Allen wrenches into the

hole, wedging, and then pulling. The cap

insert will work its way out. Figure 9.

5. Reach into the air cylinder with a pair of nee-

dle nose pliers, grasp the tip of the main piston unit, and pull it out. The driver is connected to the main piston unit.

6. Inspect driver condition and repair or replace

as necessary.

7. Re-assemble the nailer.

8. Do not put any fasteners into the magazine.

Connect the air hose. Check for any leaking

air. You will hear it hissing or feel it rushing

through the spaces.

9. If everything sounds normal, press the safe-

ty nose down on a piece of wood and pull the

trigger a couple of times. Air should be

exhausted normally each time.

Cap Screws

Driver

HD Valve

Piston

Cap

Main Piston

Deflector

Cap Screws

Deflector

Cap

HD Valve

Piston

Gasket Set

Main Piston

Driver

-12- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

O-Rings

Since the nailer is disassembled, inspect the condition of the visible O-rings. If the O-rings show

signs of wear and tear, they should be replaced.

Inspect the surfaces where the O-rings seal for

any possible rough spots which will erode the

new O-rings. When replacing the O-rings, make

sure that there is no dirt or grit in the groove

where the O-rings seat. Do not stretch the Orings or nick them on any sharp edges or burrs. If

cleaning parts with a solvent, do not use a solvent

that may deteriorate the O-rings.

To re-assemble the nailer:

1. Before replacing O-rings, lubricate them with

a light grease that is non corrosive to rubber.

2. IMPORTANT: Carefully position the driver

tip into the plastic driver insert from the top of

the nailer. You may have to wiggle the driver

so the main piston seats into the cylinder.

G1861: the driver has a T-shaped cross sec-

tion and will only fit one way. If the driver is

not seating, do not force it. Remove the driver unit, rotate 180°, and try to reinstall it.

3. Replace the parts in the same order they

were removed. See the parts diagrams if

necessary. Tighten the cap screws sequen-

tially. If the cap screws are not tightened

evenly, the cap will not seat correctly, air

will leak, and the nailer will not function.

Ensure that the washers are installed

under the cap screw heads.

4. Check all bolts to make sure they are tight

and test the nailer to ensure that it works

properly.

5. Do not put any fasteners into the magazine.

Connect the air hose. Check for any leaking

air. You will hear it hissing or feel it rushing

through the spaces.

6. If everything sounds normal, press the safe-

ty nose down on a piece of wood and pull the

trigger a couple of times. Air should be

exhausted normally each time.

Failure to repair or replace damaged or

worn parts could result in poor performance

and additional damage to other components of the gun. Take the time to make

repairs immediately, rather than nursing

along a damaged gun. Doing so will ensure

maximum performance and dependability.

DO NOT attempt to repair or service this

gun without ensuring that all nails or staples have been removed and that the gun is

disconnected from its air source. Use

extreme care when testing after freeing

jams or after re-loading. Always wear

approved safety glasses or goggles and

quality hearing protection when operating

pneumatic guns or other woodworking

tools and machinery. Failure to do so could

result in serious personal injury.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -13-

The following pages contain general specifications, a parts diagram and list, and index for your

Pneumatic Nailer.

If you need parts or help in assembling your nailer, or if you need operational information, we

encourage you to call our Service Department.

Our trained service technicians will be glad to

help you.

The specifications, drawings, and photographs

illustrated in this manual represent the Models

G1847 / G1852 / G1861 / G3811 as supplied

when the manual was prepared. But owing to

Grizzly’s policy of continuous improvement,

changes may occur at any time with no obligation

on the part of Grizzly. Should you receive a manual update, please insert it into the manual and

keep it for reference.

We have included some important safety measures that are essential to this tool’s operation.

While most safety measures are generally universal, Grizzly reminds you that each workshop is

different and safety rules should be considered

as they apply to your specific situation.

We recommend you keep a copy of our current

catalog for complete information regarding

Grizzly's warranty and return policy. If you need

additional technical information relating to this

machine, or if you need general assistance or

replacement parts, please contact the Service

Department listed in the General Information.

Additional information sources are necessary to

realize the full potential of of pneumatic nailers.

Trade journals, woodworking magazines, and

your local library are good places to start.

WARNING!

As with all power tools, there is danger associated with pneumatic nailers/staplers. Use the tool

with respect and caution to lessen the possibility

of mechanical damage or operator injury. If normal safety precautions are overlooked or ignored,

injury to the operator or others in the area is likely.

Your pneumatic nailer was specifically designed

for nailing or stapling operations. It must never be

modified and/or used for any application other

than that for which it was designed.

SECTION 5: CLOSURE

DO NOT MODIFY AND/OR USE THIS TOOL

FOR ANY OTHER PURPOSE. Modifications

or improper use of this tool will void the

warranty. If you are confused about any

aspect of this tool, DO NOT use it until you

have answered all your questions.

The nailers and staplers described in this

manual are powerful, professional-quality

tools, each designed and built to provide

outstanding results when used cautiously

and with respect. Like any tools of their

type, they can be inherently dangerous.

Careless use could result in serious injury.

Please do not attempt to use these tools

without familiarizing yourself with their

instructions for assembly, adjustment, and

safe operation. Failure to do so could result

in serious personal injury, as well as property damage and damage to the tool.

-14- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

G1847 PARTS DIAGRAM

416

304

303

302

419

427

214

423

215

207

208

422

209

421

424

425

201

202

203

417

204

205

418

206

415

414

408

413

411

210

410

409

406

120

121

112

122

113

301

116

117

216

217

118

218

429

119

123

403

407

402

401

405

404

101

102

103

104

105

106

107

108

109

110

111

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -15-

REF PART # DESCRIPTIONREF PART # DESCRIPTION

101 PSB15M CAP SCREW M5 - 0.8 x 20

102 PLW01M LOCK WASHER 5mm

103 P1847103 DEFLECTOR

104 P1847104 SPRING

105 P1847105 SEAL

106 P1847106 CAP

107 P1847107 O-RING

108 P1847108 O-RING

109 P1847109 HD VALVE PISTON

110 P1847110 O-RING

111 P1847111 O-RING

112 P1847112 COLLAR

113 P1847113 O-RING

116 P1847116 MAIN PISTON UNIT

117 P1847117 O-RING

118 P1847118 CYLINDER

119 P1847119 BUMPER

120 P1847120 O-RING

121 P1847121 TUBE

122 P1847122 O-RING

123 P1847123 JOINT GUIDE

201 P1847201 SEAL

202 P1847202 TRIGGER VALVE HEAD

203 P1847203 TRIGGER VALVE STEM

204 P1847204 O-RING

205 P1847205 O-RING

206 P1847206 TRIGGER VALVE GUIDE

207 PEC01M E-CLIP 3mm

208 P1847208 TRIGGER

209 P1847209 STEPPED PIN

210 P1847210 SPRING

214 PRP11M ROLL PIN 2.5 x 16mm

215 P1847215 SAFETY LEVER

216 P1847216 SHAFT

217 P1847217 SPRING

218 PEC02M E-CLIP 4mm

301 P1847301 NAILER BODY

302 P1847302 O-RING

303 P1847303 NIPPLE

304 G2308 AIR FITTING

401 PSB15M CAP SCREW M5 - 0.8 x 20

402 PLW01M LOCK WASHER 5mm

403 P1847403 DRIVER GUIDE COVER B

404 PSB17M CAP SCREW M4 - 0.7 x 10

405 P1847405 NOSEPIECE COVER

406 P1847406 NOSEPIECE

407 PSB41M CAP SCREW M4 - 0.7 x 14

408 P1847408 MAGAZINE UNIT A

409 P1847409 STOPPER

410 PSB18M CAP SCREW M4 - 0.7 x 8

411 P1847411 MAGAZINE UNIT B

413 PSB18M CAP SCREW M4 - 0.7 x 8

414 P1847414 PUSHER

415 P1847415 PUSHER PIN

416 P1847416 SPRING

417 P1847417 REAR PLATE

418 P1847418 MAGAZINE LATCH

419 PSB16M CAP SCREW M4 - 0.7 x 16

421 P1847421 STOPPER

422 P1847422 FIXED PLATE

423 PSB18M CAP SCREW M4 - 0.7 x 8

424 PLW02M LOCK WASHER 4mm

425 PSB17M CAP SCREW M4 - 0.7 x 10

427 PLN01M LOCK NUT M4 - 0.7

429 P1847429 SAFETY

430 P1847430 O-RING KIT

-16- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

G1852 PARTS DIAGRAM

421

414

416

415

304

120

303

121

302

423

122

424

419

427

214

420

215

207

422

208

209

201

202

203

204

216

205

217

206

218

210

409

425

413

412

411

410

408

418

417

426

404

301

405

403

119

110

106

117

107

108

118

109

112

101

113

102

103

116

104

105

123

111

402

401

407

406

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -17-

REF PART # DESCRIPTIONREF PART # DESCRIPTION

101 PSB15M CAP SCREW M5 - 0.8 x 20

102 PLW01M LOCK WASHER 5mm

103 P1847103 DEFLECTOR

104 P1847104 SPRING

105 P1847105 SEAL

106 P1847106 CAP

107 P1847107 O-RING

108 P1847108 O-RING

109 P1847109 HD VALVE PISTON

110 P1847110 O-RING

111 P1847111 O-RING

112 P1852112 COLLAR

113 P1847113 O-RING

116 P1852114 MAIN PISTON UNIT

117 P1847117 O-RING

118 P1847118 CYLINDER

119 P1847119 BUMPER

120 P1847120 O-RING

121 P1847121 TUBE

122 P1847122 O-RING

123 P1847123 JOINT GUIDE

201 P1847201 SEAL

202 P1847202 TRIGGER VALVE HEAD

203 P1847203 TRIGGER VALVE STEM

204 P1847204 O-RING

205 P1847205 O-RING

206 P1847206 TRIGGER VALVE GUIDE

207 PEC01M E-CLIP 3mm

208 P1847208 TRIGGER

209 P1847209 STEPPED PIN

210 P1847210 SPRING

214 PRP11M ROLL PIN 2.5 x 16mm

215 P1847215 SAFETY LEVER

216 P1847216 SHAFT

217 P1847217 SPRING

218 PEC02M E-CLIP 4mm

301 P1847301 NAILER BODY

302 P1847302 O-RING

303 P1847303 NIPPLE

304 G2308 AIR FITTING

401 PSB15M CAP SCREW M5 - 0.8 x 20

402 PLW01M LOCK WASHER 5mm

403 P1847403 DRIVER GUIDE COVER B

404 P1847404 NOSEPIECE

405 PSB41M CAP SCREW M4 - 0.7 x 14

406 PSB17M CAP SCREW M4 - 0.7 x 10

407 P1852407 NOSEPIECE COVER

408 P1852408 STOPPER

409 P1852409 MAGAZINE UNIT A

410 P1852410 STOPPER

411 PLW02M LOCK WASHER 4 mm

412 PSB17M CAP SCREW M4 - 0.7 x 10

413 P1852413 MAGAZINE UNIT B

414 P1852414 REAR PLATE

415 PLW02M LOCK WASHER 4mm

416 PSB18M CAP SCREW M4 - 0.7 x 8

417 P1852417 PUSHER

418 P1852418 SPRING

419 PSB18M CAP SCREW M4 - 0.7 x 8

420 P1852420 FIXED PLATE

421 P1852421 MAGAZINE LATCH

422 P1852422 STOPPER

423 PSB23M CAP SCREW M4 - 0.7 x 12

424 PLW02M LOCK WASHER 4mm

425 P1852425 SAFETY

426 P1852426 FLAT BAR

427 PLN01M LOCK NUT M4 - 0.7

428 P1847430 O-RING KIT

-18- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

A02

G1861 PARTS DIAGRAM

B54

B08

B53

B54

B07

B06

B52

B03

B05

A01

C52

A12

C57

A55

A11

A57

C02

C55

C01

A10

C03

C53

A57

C07

A09

A56

C54

B56

C06

B55

B02

B01

B51

C04

C56

C51

B09

B04

C05

C57

C52

A51

A59

A58

A16

A52

A13

A14

A54

A08

A03

A07

A55

A04

A54

A17

A06

A53

A05

REF PART # DESCRIPTIONREF PART # DESCRIPTION

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -19-

A01 P1861A01 NAILER BODY

A02 G2308 AIR FITTING

A03 P1861A03 CYLINDER

A04 P1861A04 BUMPER

A05 P1861A05 MAIN PISTON UNIT

A06 P1861A06 GASKET SET

A07 P1861A07 SPRING

A08 P1861A08 HD VALVE PISTON

A09 P1861A09 COPPER COVER

A10 P1861A10 SHAFT, VALVE

A11 P1861A11 SPRING

A12 P1861A12 COLLAR

A13 P1861A13 CAP

A14 P1861A14 INSERT OF CAP

A16 P1861A16 DEFLECTOR

A17 P1861A17 JOINT GUIDE

A51 P1861A51 O-RING

A52 P1861A52 O-RING

A53 P1861A53 O-RING

A54 P1861A54 O-RING

A55 P1861A55 O-RING

A56 P1861A56 O-RING

A57 P1861A57 O-RING

A58 PSB15M CAP SCREW M5 - 0.8 x 20

A59 PLW01M LOCK WASHER 5mm

A60 P1861A60 O-RING KIT

B01 P1861B01 NOSEPIECE

B02 P1861B02 MAGAZINE UNIT A

B03 P1861B03 MAGAZINE UNIT B

B04 P1861B04 PUSHER

B05 P1861B05 SPRING

B06 P1861B06 REAR PLATE

B07 P1861B07 FIXED PLATE

B08 P1861B08 MAGAZINE LATCH

B09 P1861B09 FLAT BAR

B51 PSB16M CAP SCREW M4 - 0.7 x 16

B52 PSB17M CAP SCREW M4 - 0.7 x 10

B53 PSB18M CAP SCREW M4 - 0.7 x 8

B54 PLW02M LOCK WASHER 4mm

B55 PSS22M SETSCREW M4 - 0.7 x 12

B56 P1861B56 SPECIAL BOLT

C01 P1861C01 TRIGGER

C02 P1861C02 SAFETY LEVER

C03 PRP02M ROLL PIN 3 x 16

C04 P1861C04 DRIVER GUIDE COVER B

C05 P1861C05 NOSEPIECE COVER

C06 P1861C06 SAFETY

C07 P1861C07 SPACER SLEEVE

C51 PSB07M CAP SCREW M6 - 1.0 x 30

C52 PSB20M CAP SCREW M5 - 0.8 x 14

C53 PSB21M CAP SCREW M4 - 0.7 x 30

C54 PSB22M CAP SCREW M4 - 0.7 x 35

C55 PLN01M LOCK NUT M4 - 0.7

C56 PLW03M LOCK WASHER 6mm

C57 PLW01M LOCK WASHER 5mm

-20- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

G3811 PARTS DIAGRAM

B51

A02

A01

C02

C01

B04

C03

C53

B03

B10

B53

C54

C06

B05

B08

B02

B09

B05

C57

B01

C61

B52

C08

C55

B51

C60

B07

C59

B06

C56

A53

A12

C07

A55

A55

A05

A11

A57

A57

A51

A10

A52

A57

A09

A03

A56

A56

C04

C58

A04

C05

C52

C51

A17

A59

A58

A16

A13

A14

A54

A08

A07

A55

A54

A54

A06

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -21-

REF PART # DESCRIPTION

B04 P3811B04 FIXED PIN

B05 P3811B05 SPRING STOPPER

B06 P3811B06 PUSHER

B07 P3811B07 FIXED PIN

B08 P3811B08 PUSHER SPRING

B09 P3811B09 FIXED PIN

B10 P3811B10 STOPPER

B51 P3811B51 E-CLIP

B52 PSB17M CAP SCREW M4 - 0.7 x 10

B53 P3811B53 HEX NUT

C01 P1861C01 TRIGGER

C02 P1861C02 SAFETY LEVER

C03 PRP02M ROLL PIN 3 x 16

C04 P3811C04 DRIVER GUIDE COVER B

C05 P3811C05 DRIVER GUIDE COVER A

C06 P3811C06 SAFETY

C07 P1861C07 SPACER SLEEVE

C08 P3811C08 ATTACHING PLATE

C51 PSB07M CAP SCREW M6 - 1.0 x 30

C52 PSB20M CAP SCREW M5 - 0.8 x 14

C53 PSB21M CAP SCREW M4 - 0.7 x 30

C54 PSB22M CAP SCREW M4 - 0.7 x 35

C55 P3811C55 CAP SCREW

C56 PLN01M LOCK NUT M4 - 0.7

C57 P3811C57 LOCK NUT

C58 PLW03M LOCK WASHER 6mm

C59 P3811C59 CAP SCREW

C60 P3811C60 LOCK WASHER

C61 P3811C61 LOCK WASHER

REF PART # DESCRIPTION

A01 P3811A01 NAILER BODY

A02 G2308 AIR FITTING

A03 P1861A03 CYLINDER

A04 P1861A04 BUMPER

A05 P3811A05 MAIN PISTON UNIT

A06 P1861A06 GASKET SET

A07 P1861A07 SPRING

A08 P1861A08 HD VALVE PISTON

A09 P1861A09 COPPER COVER

A10 P1861A10 SHAFT, VALVE

A11 P1861A11 SPRING

A12 P1861A12 COLLAR

A13 P1861A13 CAP

A14 P1861A14 INSERT OF CAP

A16 P1861A16 DEFLECTOR

A17 P3811A17 JOINT GUIDE

A51 P1861A51 O-RING

A52 P1861A52 O-RING

A53 P1861A53 O-RING

A54 P1861A54 O-RING

A55 P1861A55 O-RING

A56 P1861A56 O-RING

A57 P1861A57 O-RING

A58 PSB15M CAP SCREW M5 - 0.8 x 20

A59 PLW01M LOCK WASHER 5mm

A60 P1861A60 O-RING KIT

B01 P3811B01 DRIVER GUIDE

B02 P3811B02 COVER ASSEMBLY

B03 P3811B03 PLASTIC COVER

-22- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

MACHINE DATA

GRIZZLY MODEL G1847/G1852/G1861/G3811 PNEUMATIC NAILERS/STAPLERS

Operating Air Pressure: 65 to 90 P.S.I.

Fastener Length:

G1847 ........................................................................................................

1

⁄2" to 7⁄8" Crowned Staples

G1852........................................................................................................................

3

⁄8" to 13⁄16" Brads

G1861........................................................................................................................

5

⁄8" to 19⁄16" Brads

G3811......................................................................................................

7

⁄8" to 13⁄16" Crowned Staples

Gauge: ......................................................................................................................................18 Ga.

Magazine Capacity: ......................................................................................................................100

Construction: ............................................................................Cast Aluminum and Hardened Steel

Coupling System: ..................................................................................................................

1

⁄4" NPT

Recommended Lubricating Oil:..........................................................................Pneumatic Tool Oil

Nailer Weight:

G1847......................................................................................................................................3.10 lbs.

G1852......................................................................................................................................3.15 lbs.

G1861......................................................................................................................................4.20 lbs.

G3811......................................................................................................................................3.80 lbs.

Parts and Accessories:

A rebuilding kit is available from Grizzly and includes all O-rings. The rebuilding kit and other parts

can be individually ordered through our Service Department.

Grizzly also carries air hose,in-line regulator/filter/water-separator/lubricator, quick connect couplers

and a complete line of fasteners. Please refer to a current Grizzly catalog for price and ordering information.

Specifications, while accurate, are subject to change without notice.

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers -23-

TROUBLESHOOTING GUIDE

Symptom Cause Solution

Air leaking at trigger valve area. O-Rings in trigger valve housing are Replace and/or re-lubricate trigger

damaged or dry. system O-Rings.

Air leaking between body and nose. 1. O-Rings are damaged or dry. 1. Replace and/or re-lubricate O-Rings.

2. Loose screws. 2. Loosen all screws first, and then tighten

sequentially using

1

/2 turns.

3. Bumper is damaged. 3. Replace bumper.

Air leaking between body and cap. 1. O-Rings are damaged or dry. 1. Replace and/or re-lubricate O-Rings.

2. Loose screws. 2. Loosen all screws first, and then tighten

sequentially using

1

/2 turns.

Nailer won’t shoot even when loaded 1. Bumper is damaged. 1. Replace bumper

and under pressure. 2. Nose piece is dirty. 2. Clean nose piece.

3. Dirt or damage prevents the 3. Clean and inspect for damage.

fasteners or driver from moving

freely.

4. Damaged HD valve spring. 4. Replace spring.

5. Inadequate air pressure. 5. Adjust air pressure.

6. O-Rings are damaged or dry. 6. Replace and/or re-lubricate O-Rings.

7. Trigger is damaged. 7. Inspect trigger. Replace if necessary.

8. Air leaks. 8. Replace and/or re-lubricate O-Rings and/or

check for loose screws.

9. Nosepiece is misaligned. 9. Align nosepiece.

Nails don’t set properly and/or nailer 1. Nailer is inadequately lubricated. 1. Disassemble and re-lubricate.

does not recover quickly. 2. HD valve spring is broken. 2. Replace spring.

3. Exhaust port is blocked. 3. Clean exhaust port.

Jamming. 1. Driver guide is worn. 1. Replace guide.

2. Fasteners are incorrect size. 2. Use recommended fasteners.

3. Fasteners are bent. 3. Use straight fasteners.

4. Magazine or nose screws are 4. Tighten screws sequentially.

loose.

5. Driver is damaged. 5. Replace or recondition driver.

6. Nosepiece misaligned. 6. Align nosepiece.

Brads or staples are driven too far. 1. Air pressure is set too high. 1. Check air pressure.

2. Bumper is worn or broken. 2. Replace bumper.

O-Rings have been replaced and/or 1. Screws were not tightened 1. Loosen all screws first, and then tighten

re-lubricated, but air still leaks out. sequentially. sequentially using

1

⁄2 turns.

2. Not enough grease was used on 2. Remove O-Rings and re-lubricate.

O-Rings.

3. Wrong type of grease was used 3. Remove O-Rings and replace with new ones

that damaged O-Rings. Use grease that is safe for rubber.

4. Nailer lubrication oil is not 4. Completely disassemble nailer and clean

rubber-safe. Replace all O-Rings. Use rubber-safe

grease for new O-Rings and only use

Pneumatic Tool Oil in the future.

-24- G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number’’, which must be clearly posted on the outside as well as the inside of the carton. We will not accept any item back without this number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

WARRANTY AND RETURNS

10. Which benchtop tools do you own? Check all that apply.

___1" x 42" Belt Sander ___6" - 8" Grinder

___5" - 8" Drill Press ___Mini Lathe

___8" Table Saw ___10" - 12" Thickness Planer

___8" - 10" Bandsaw ___Scroll Saw

___Disc/Belt Sander ___Spindle/Belt Sander

___Mini Jointer

___Other__________________________________________________

11. How many of the machines checked above are Grizzly? ____________

12. Which portable/hand held power tools do you own? Check all that apply.

___Belt Sander ___Orbital Sander

___Biscuit Joiner ___Palm Sander

___Circular Saw ___Portable Planer

___Detail Sander ___Saber Saw

___Drill/Driver ___Reciprocating Saw

___Miter Saw ___Router

___Other__________________________________________________

13. What machines/supplies would you like Grizzly Industrial to carry?

___12" Table Saw ___Horizontal Boring Machine

___24" Planer ___Panel Saw

___Combination Planer/Jointer ___Radial Arm Saw

___Paint & Finishing Supplies ___Lumber

___Contractor’s Supplies ___Brass Hardware

___Other__________________________________________________

14. What new accessories would you like Grizzly Industrial to carry?

___Builders Hardware ___Hand Tools

___Fasteners ___Wood Components

___Other__________________________________________________

15. What other companies do you purchase your tools and supplies?

__________________________________________________________

__________________________________________________________

16. Do you think your purchase represents good value?

___Yes ___No

17. Would you recommend Grizzly Industrial to a friend?

___Yes ___No

18. Would you allow us to use your name as a reference for Grizzly customers

in your area? Note: We never use names more than three times.

___Yes ___No

19. Comments:_________________________________________________

__________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________

1. How did you learn about us?

___Advertisement ___Friend

___Catalog ___Card Deck

___World Wide Web

___Other__________________________________________________

2. Which of the following magazines do you subscribe to.

___American Woodworker ___Practical Homeowner

___Cabinetmaker ___Shop Notes

___Family Handyman ___Today’s Homeowner

___Fine Homebuilding ___WOOD

___Fine Woodworking ___Wooden Boat

___Home Handyman ___Woodshop News

___Journal of Light Construction ___Woodsmith

___Old House Journal ___Woodwork

___Popular Mechanics ___Woodworker

___Popular Science ___Woodworker’s Journal

___Popular Woodworking ___Workbench

___Other__________________________________________________

3. Which of the following woodworking/remodeling shows do you watch?

___Backyard America ___The New Yankee Workshop

___Home Time ___This Old House

___The American Woodworker ___Woodwright’s Shop

___Other__________________________________________________

4. What is your annual household income?

___$20,000-$29,999 ___$60,000-$69,999

___$30,000-$39,999 ___$70,000-$79,999

___$40,000-$49,999 ___$80,000-$89,999

___$50,000-$59,999 ___$90,000 +

5. What is your age group?

___20-29 ___50-59

___30-39 ___60-69

___40-49 ___70 +

6. How long have you been a woodworker?

___0 - 2 Years ___8 - 20 Years

___2 - 8 Years ___20+ Years

7. How would you rank your woodworking skills?

___Simple ___Advanced

___Intermediate ___Master Craftsman

8. What stationary woodworking tools do you own? Check all that apply.

___Air Compressor ___Panel Saw

___Band Saw ___Planer

___Drill Press ___Power Feeder

___Drum Sander ___Radial Arm Saw

___Dust Collector ___Shaper

___Horizontal Boring Machine ___Spindle Sander

___Jointer ___Table Saw

___Lathe ___Vacuum Veneer Press

___Mortiser ___Wide Belt Sander

___Other__________________________________________________

9. How many of your woodworking machines are Grizzly? _____________

Name ________________________________________________________Phone Number_________________

Street ____________________________________________________________________________________

City ______________________________________________________________State________Zip_________

MODEL # ______________________________Order #______________________________________________

The following information is given on a voluntary basis. It will be used for marketing purposes to help us develop better products and services. Of

course, all information is strictly confidential.

WARRANTY CARD

Cut along dotted line

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

Place

Stamp

Here

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Name_______________________________

Street_______________________________

City______________State______Zip______

Send a Grizzly Catalog to a friend:

Loading...

Loading...