Page 1

EYE INJURY HAZARD!

Always wear safety glasses

during use to prevent

serious personal injury.

10 PSI MAX

AIR PRESSURE!

Exceeding this PSI may

result in injury/tool damage.

RESPIRATORY HAZARD!

Sanding produces fine

dust. Wear the appropriate

protection during use!

MODEL G1600

PNEUMATIC SANDING

DRUM FOR MODEL G1495

INSTRUCTIONS

Specifications

Mounting Bore ..............................1" x 12 TPI LH

Length ...............................................................6"

Diameter ...........................................................4"

Air Inlet Type ...............................Schrader Valve

Maximum Pressure .................................. 10 PSI

Inflation Method .................... Manual Pump Only

Inventory

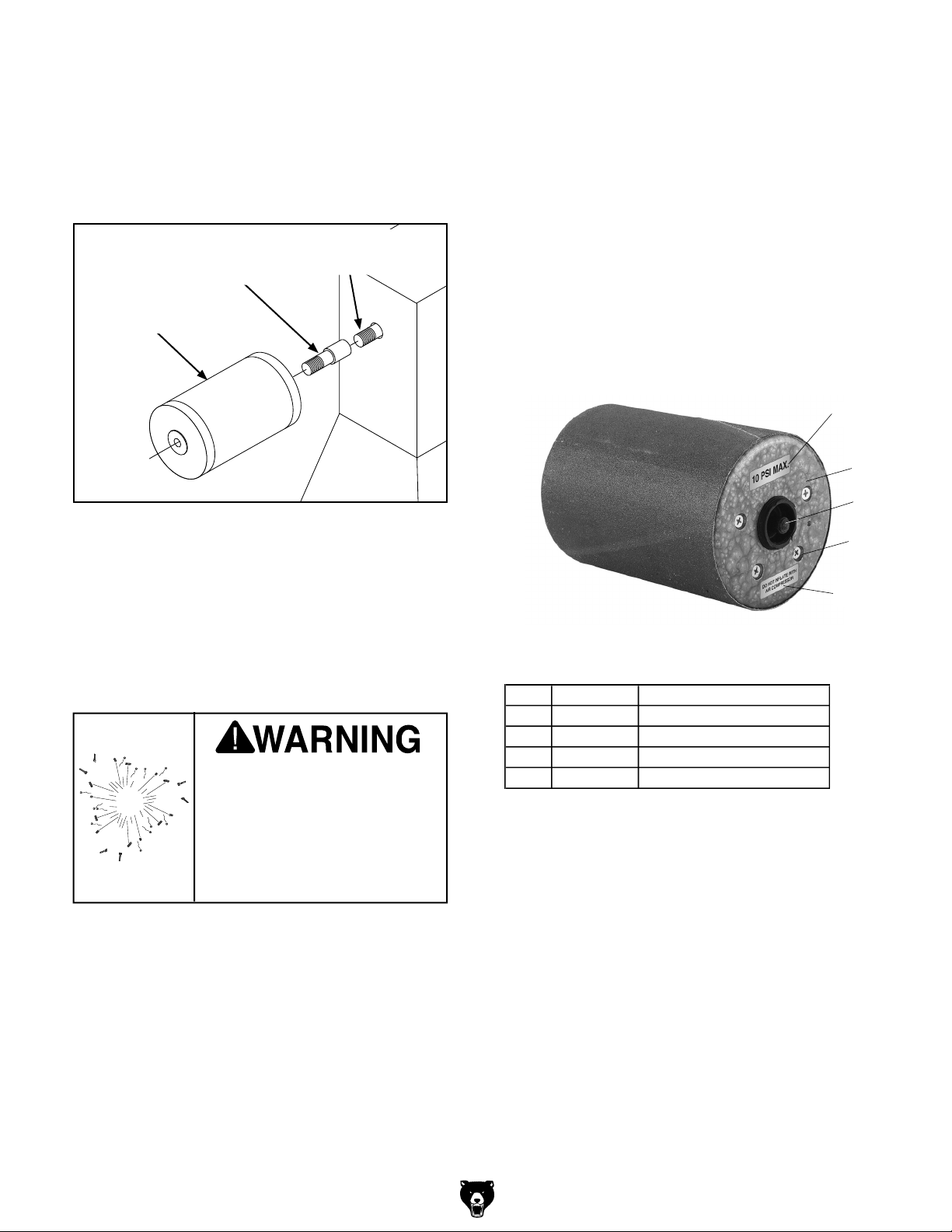

A. Pneumatic Sanding Drum .......................... 1

B. Sanding Sleeve .......................................... 1

Functional Overview

A pneumatic sanding drum mounted to a lathe

allows for easy and smooth sanding of contours

and curves.

The inflatable bladder provides for easy changes

of the replaceable sanding sleeve and also allows

for fine-tuning of the overall flexibility of the drum

for sanding compound curves and contoured sur

faces.

By increasing the pressure in the drum, a user

can create a more rigid surface for sanding shal

low contours. Similarly, by decreasing the pres

sure, a user can soften the surface of the drum,

allowing it to "wrap-around" workpieces with

tighter curves.

Completely releasing the pressure decreases the

diameter of the drum so the sanding sleeve can

be removed and replaced.

A

B

-

Figure 1. Model G1600.

-

-

Replacement Sanding Sleeves

G4387 4" x 6" x 60 Grit Silicon Carbide

G4388

G1975

G4389

G1976

4" x 6" x 80 Grit Silicon Carbide

4" x 6" x 100 Grit Silicon Carbide

4" x 6" x 120 Grit Silicon Carbide

4" x 6" x 150 Grit Silicon Carbide

COPYRIGHT © MARCH, 2008 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#JB10532 PRINTED IN TAIWAN

Page 2

Operation

REF PART # DESCRIPTION

2 P1600002 RUBBER DRUM 4"

3 P1600003 VALVE STEM

4 PWS002 WOOD SCREW #10 X 1/2

5 P1970004 10 PSI MAX. LABEL

6 P1970005 AIR COMPRESSOR LABEL

1. DISCONNECT LATHE FROM POWER!

2. Install the sanding drum on the lathe spindle

using the adapter included with the lathe

(Figure 2).

Lathe Outboard

Adapter

Sanding Drum

Spindle

Operation Tips

• Adjust the pressure in the drum to fine-tune

the firmness of the drum for sanding con

tours.

• Always hold the workpiece firmly—the soft

surface of the drum will exert more force

on the workpiece than a traditional sanding

drum.

• Deflate the drum when not in use.

Parts Breakdown & List

5

2

-

Figure 2. Mounting drum to shaft.

3. Slide the sanding sleeve over the sanding

drum.

4. Use a bicycle pump (or other manual pump)

to inflate the drum until the sanding sleeve is

secure. Do not exceed the 10 PSI maximum

rating.

EXPLOSION HAZARD!

Do not use an air compressor

to inflate the sanding drum!

Over-inflation will cause the

bladder to explode, resulting

in personal injury or tool

damage

3

4

6

If you need help with your new pneumatic tool,

call our Tech Support at: (570) 546-9663.

-2-

G1600 Pneumatic Sanding Drum For G1495

Loading...

Loading...