Page 1

Shuttle Brewer & Airpot/Shuttle Brew ers

Operation and Instruction Man u al

For Models P300E, P400E, P400ESHP, RAP300E,

RAP400E, RAPS300E, RAPS400E

Installation:

See rough-in drawings in this manual for di men sions and lo ca tions of

electric and water input.

Set-Up/Position

1) Remove the brewer from the packing material and attach its legs.

2) Position the brewer on a strong, stable table or counter. Check

the level front to back and side to side. Adjust the legs to the correct level.

IMPORTANT:

THE PERSON INSTALLING THIS APPLIANCE IS RESPONSIBLE

FOR ENSURING THAT ELECTRIC AND WATER CONNECTIONS

MEET THE RE QUIRE MENTS OF THE NATIONAL ELECTRIC

CODE, NATIONAL PLUMBING CODE, AND ANY LOCAL

ORDINANCES.

The electric and water hook-up locations are behind the front pan el.

Re move the four screws fastening this panel for access to these

con nec tions.

Table of Contents

Installation and Start-up ....................................... 1-2

Warning Labels ...........................................................3

Operation .......................................................... 4

Adjustments ........................................................ 5-8

Care and Cleaning ............................................... 9-10

Service ............................................................... 10-11

Troubleshooting

Filling Problems ....................................... 12

Heating Problems ................................. 13

Brewing Problems ................................ 14

Parts Illustrations

Models P300E & P400E ....................... 15

Model P400ESHP .....................................16

Model RAP400E ..................................... 17

Model RAPS400E ................................... 18

VSB-400................................................ 19

Shuttle CS-LL .......................................... 20

Rough-In Drawings

Model P300........................................................... 21

Model P400 & P400ESHP ...................... 22

Model RAP300 ......................................... 23

Model RAP400 ........................................ 24

Model RAPS300 ....................................... 25

Model RAPS400 ..................................... 26

VSB-300 .................................................. 27

VSB-400 ................................................ 28

Wiring Diagrams

P300E/P400E with 1 Batch Timer ......... 29

P300E/P400E with 2 Batch Timer........ 30

RAP300E/RAP400E................................31

RAPS300E/RAPS400E........................32

P400ESHP ...........................................33

Drawing #091-548 .................................34

Drawing #091-182 .....................................35

Water Hook-up

1) The water line may enter through holes on the rear or the bottom of the brewer. Use the right hand opening for water.

2) Use 3/8" copper or flexible water line to prevent strain. Do not use low temperature plastic tubing. The connection

to the fill valve is 3/8" flare.

3) Water line pressure must be from 30 to 70 psi.

4) Hot (up to 160°F) or cold water may be used. Hot water offers faster recovery between brews.

5) Install a shut-off valve near the brewer.

6) Installing a filtering system can improve the taste of brewed coffee and extend the life of the brewer. If your water

has high calcium (lime), chlorine, or iron content, this is especially important. The filter should be the lime inhibiting

type if cold water is used. Contact your local water treatment professional regarding the type of filter you should use

based on water quality and volume of water used.

© Grindmaster Corporation, 1998

PRINTED IN U.S.A.

0307 FORM # AM-309-08

Part # 090-077

Prior authorization must be obtained from Grindmaster Corporation for all warranty claims.

Grindmaster Corporation

4003 Collins Lane

Louisville, KY 40245 USA

(502) 425-4776

(800) 695-4500 (USA & Canada only)

(800) 568-5715 (Technical Service Only)

FAX (502) 425-4664

www.grindmaster.com

WARNING

ELECTRIC SHOCK HAZARD!

Installation of this appliance should be performed by

qualified service per son nel only. Improper installation

could result in elec tro cu tion.

Page 2

Page 2

Shuttle Brewers & Airpot/Shuttle Brewers

Installation (con't)

Electric Hook-up

1) The electric ratings for your brewer are printed on its nameplate. Typical electric ratings

are:

P300, P400, RAP300, RAP400

Optional 120/208V, 3.8kW, 18A or 120/240V 5.0kW, 21A, 1 phase

Standard 120/208V, 5.0kW, 24A or 120/240V 6.6kW, 28A, 1 phase

RAPS300, RAPS400

Standard 120/208V, 4.4KW, 21A or 120/240V, 5.6KW 24A, 1 phase

P400ESHP

Standard 440V, 12.5KW, 16.3A, 3 phase WYE

If the brewer includes the three heater tank option C21A, the ratings will be different. Always

see the nameplate for correct ratings.

2) The brewer should be connected to its own circuit with a fused disconnect switch or a

circuit breaker near the brewer.

3) Attach the appropriately sized cord to the brewer with a cord grip for the 1 1/2" electric input

opening. The cord may enter through the rear or bottom on the left side of the brewer. Use

an oil resistant cord such as type SO, SOO, SAO, STOO, SEO, SJO, SJOO, SJTO, SJTOO,

SJEO, HSO, HSOO, HSJO, or HSJOO. Alternatively, flexible conduit and type THHN wires

may be used. Use only copper conductors.

4) Standard connection is 1 phase 3 wire. Connect the two lines to L1 and L2 on the terminal

block. If the brewer is wired for three phase, a lug, L3, is provided on the terminal block. A

neutral line must be connected to the N terminal.

5) The body of the brewer must be grounded. A ground lug is provided for this purpose.

Start-up

1) Turn on the water supply to the brewer. Check for leaks.

2) Turn on the electric supply. The brewer will begin to fill.

3) Replace the front access panel.

4) Once the brewer is full, it will take 15 to 35 minutes to heat. The water hot light will turn on

when up to temperature.

5) Insert the brew baskets and place a shuttle or airpot under the baskets. Brew at least one

batch from each side. Check the level in the container to be sure the brew volume is correct.

Remember that when using coffee, the level will be lower. Do this for both batch sizes when

provided. The water must be hot to check the levels. If adjustments are needed, see the

adjustments section of this manual.

WARNING

Never use the ground conductor as a neutral. This could cause electrocution.

Page 3

Page 3

Shuttle Brewers & Airpot/Shuttle Brewers

Warning Labels

The following warning labels were on your dispenser when it was shipped from the factory. They should remain on your dispenser

in good, readable condition at all times. If one of your labels is missing or damaged, order a replacement label immediately.

Part # A546-445

Located on front splash panel and lid of machine.

Part # A546-213

Located on front splash panel.

Part # A71949

Located on brew baskets.

Part # A546-020 (P-300), A546-129 (P-400)

Located near warmer plates.

Part # A546-020 (P-300), A546-129 (P-400)

Located near water faucet.

CAUTION

Hot liquid in brew

basket could cause

burns.

Remove with care.

Page 4

Page 4

Shuttle Brewers & Airpot/Shuttle Brewers

Operation

1) RAPS Brewers require the accessory warmer base placed over the pegs on the brew

shelf before brewing into a shuttle. Plug the base into the receptacle on the side of the

brewer. The receptacle is only energized when a shuttle is in place.

2) Place an empty, warm shuttle or airpot on the shelf, counter, or accessory base (depending

on model) under the brew head. Turn on the warmer if a shuttle is used.

3) If the shuttle is not warm, allow the warmer to heat the shuttle. Only a short brew of water

will speed this. A cold shuttle will significantly lower the temperature of the brewed coffee.

4) Remove the filter basket and line with a filter paper. Paper size is 13 x 5 for the smaller

basket, BB1.5, and 14 x 5 for the larger, BB2.0.

5) Place ground coffee in the filter basket. Your coffee supplier can help you select the right

amount of coffee and grind. Coffee brewing experts recommend between 6.5 and 8 ounces

of coffee per gallon of water for most applications. A full shuttle is 1.4 gallons and a full

airpot is 0.80 gallon.

6) Slide the basket into the brewer making sure the spout lines up with the top of the shuttle

or airpot.

7) Check that the correct batch size is selected. Check the WATER HOT light. If lit, press start.

8) Brew time is about 4 minutes for a full shuttle, less for airpots and half batches. After the

brew, allow the coffee to drip for 1 to 2 minutes.

9) Dump the grounds from the basket and rinse for the next brew. Coffee is ready to serve.

10) The shuttle may be placed on remote warming stations. Use caution when moving a

full shuttle.

CAUTION

Coffee basket contains very hot water until the drip is completed. Early removal of a

dripping basket could result in burns.

CAUTION

HOT LIQUID HAZARD!

Water used for brewing coffee is very hot. Use caution when brewing, pouring, or

transporting coffee. Accidental spills may result in severe burns.

Page 5

Page 5

Shuttle Brewers & Airpot/Shuttle Brewers

Adjustments

All adjustable components are located under the top cover. To access these parts:

1) Shut off the electric line to the brewer or unplug the brewer.

2) Remove the single screw fastening the top cover. Remove the top cover.

3) Pull forward and lift off the top cover.

Brew Volume, Brew Timer

The brew volume of the brewer is controlled by its timer. The batch size is directly proportional to the

timer setting. The timer adjustment is located under the top cover. On twin brewers, there is one

timer for each brew head.

Depending on the model, American Metal Ware offers three types of timer adjustments. Look at the

instructions for the type of timer you have. There will always be a small variation (+

5%) in level from

batch to batch.

Note: Always adjust bypass before adjusting timer because bypass affects brew rate.

Before making the timer adjustment, do the following:

1) Brew a batch of water to determine where the level falls. Using a stop watch, determine

the current brew volume.

2) To determine the desired time setting, use the following formula:

desired brew volume

desired brew time = _________________ X current brew time

current brew volume

Adjusting the Timer

Standard single batch timer: RAP and P models without half

batch include this timer, (see Figure 1). This timer is adjustable

from 1 to 8 minutes. After removing the cover, do the following:

1) Use the timer label to make an approximate adjustment

of the timer. Figure 1

Single Batch Timer

2) After adjusting the timer, brew a batch of water to check

the volume. Repeat adjustment, tweaking the timer knob

until the volume is correct.

WARNING

Electrical Shock Hazard!

Dangerous electric voltages are present near adjustable components. All adjustments

should be performed by qualified service personnel only.

Page 6

Page 6

Shuttle Brewers & Airpot/Shuttle Brewers

Two Batch Timer with Knob Adjustment, See Figure 2:

This timer is adjustable from 15 seconds to 5 minutes.

Locate the adjustment knobs under the top cover.

Set this timer by adjusting the knob. The batch selector

switch picks the adjustment potentiometer which the

timer will see.

Figure 2

Two Batch Timer

Two Batch Timer with Counter Adjustment, See Figure 3:

The two batch size timer may also be used with optional

counter potentiometer to ease adjustments. Each batch

size is adjustable from 00 to 99. The timer settings for this

timer are tabulated on the table below. This chart is for

making an approximate setting. You may need to click up or

down to make fine adjustments to volume. Each number

is about 3 seconds.

Figure 3

Two Batch Timer

w/Counter Adjustment

Counter Settings for NCC Q4F-0300-341AM Timers

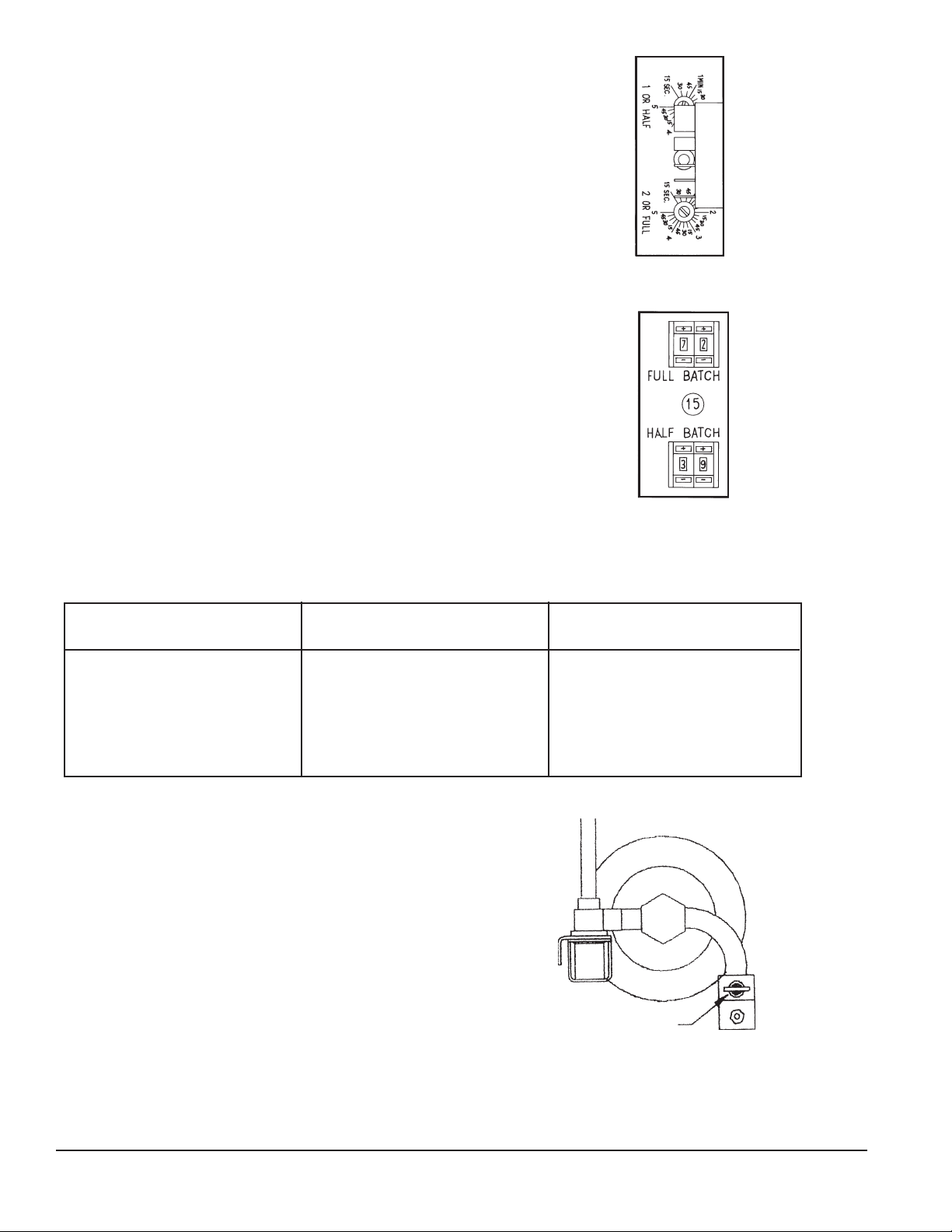

Bypass Adjustment

The bypass valve adjusts the amount of water which

bypasses coffee grounds and dilutes the final brew

(see Figure 4). The factory setting is no bypass.

Bitter coffee results when the amount of ground

coffee is too small. Therefore, if your coffee is

brewing too strong, it is better to adjust the bypass

valve instead of reducing the amount of coffee.

Figure 4

Bypass Valve

Counter Time

Setting (min:sec)

35 2:03

40 2:17

45 2:31

50 2:45

55 2:59

60 3:13

Counter Time

Setting (min:sec)

65 3:26

70 3:39

75 3:53

80 4:06

85 4:20

99 5:00

BYPASS VALVE

Counter Time

Setting (min:sec)

00 0:15

10 0:46

15 1:01

20 1:17

25 1:32

30 1:47

BYPASS VALVE

Page 7

Page 7

Shuttle Brewers & Airpot/Shuttle Brewers

To Adjust the Bypass:

1) Shut off and open brewer as described at the beginning of the adjustments section.

2) Locate the bypass valve for the brew head you wish to adjust. Valve is on the right and front

of the BREW valve.

3) Open the valve (counter clockwise) to the desired setting. Use the table below as a guide:

BYPASS SETTING BYPASS: % OF TOTAL BREW

closed 0

1 turn 8

2 turns 12

3 turns 22

4 turns 33

4) Measure the bypass setting:

a) Remove the brew basket.

b) Place an empty shuttle without its lid under the spray head.

c) Place a measuring cup under the bypass nozzle.

d) Press START and brew water for about thirty seconds or until measuring cup is almost

full. Press STOP.

e) Record the amount of water in the bypass measuring cup.

f) Add this to the water in the shuttle and record, measure the total amount of water.

g) The bypass percent is calculated as:

Bypass % = (Bypass Volume/Total Volume) X 100

5) Tweak the valve adjustment until the bypass is set as desired.

Note: The bypass is accurate to +

4%.

Thermostat Adjustment

The main thermostat adjusts the water temperature in the tank. Factory setting is 200°F. This

is the ideal temperature for brewing most coffee. Water should never boil in the tank. If water is

boiling, adjust the thermostat. There are two types of thermostats available. Mechanical is standard

and solid state is optional. See the adjustment instructions for the thermostat in your brewer.

Standard Mechanical Thermostat:

1) Shut off power and open cover.

2) Locate thermostat mounted on tank. See Figure 5.

3) Turn the shaft counter clockwise to decrease temperature,

opposite to increase temperature.

Figure 5

Mechanical Ther mo stat

Page 8

Page 8

Shuttle Brewers & Airpot/Shuttle Brewers

4) If the maximum temperature adjustment needs to be increased, insert a small flat screwdriver

into the shaft. Turn the calibration screw counter clockwise to increase the maximum

temperature.

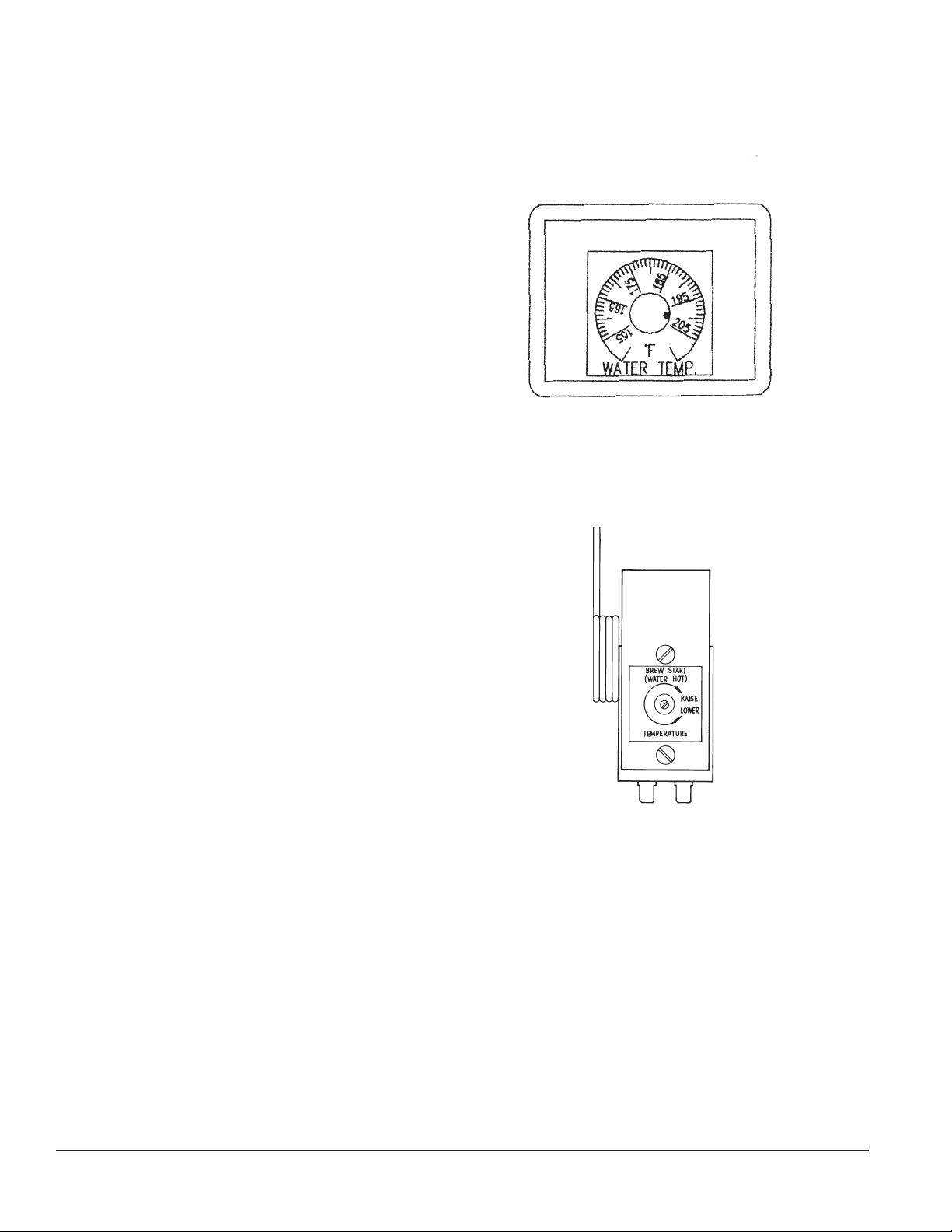

Optional Solid State Thermostat: This control maintains temperature within 3°F. The ad just able

range is from 155°F to 205°F.

See Figure 6.

1) Shut off power and open top cover.

2) Locate thermostat on bracket mounted

to front panel.

3) Adjust the knob to the temperature

desired. This control cannot be set

above 205°F.

Figure 6

Solid State Thermostat

Optional Brew Thermostat Adjustment: Your brewer may include the optional low temp/no brew

thermostat, (see Figure 7). This will not allow a brew unless the water is up to temperature. The

factory setting is 192°F. If you wish to adjust this, do the following:

1) Shut off power and remove top cover.

2) Locate the thermostat mounted on the

water tank.

3) To increase the set point, turn the shaft

clockwise. We do not recommend adjusting

this above 192°F which may cause

excessive delays between batches.

4) For accurate setting of the thermostat, remove

the bulb from the brewer and immerse in

water known to be 190°F. Adjust the

knob so the thermostat closes at this point.

Figure 7

Brew Thermostat

Page 9

Page 9

Shuttle Brewers & Airpot/Shuttle Brewers

Cleaning

After Each Brew:

1) Dispose of grounds and rinse brew basket.

2) Rinse shuttle or airpot containers before reuse.

Every Day:

1) Wash brew basket with warm soapy water. The wire basket is removable to aid

cleaning.

2) Remove spray head(s), located above brew basket(s), using gloves or a heavy towel.

Wash off coffee oils and clean any plugged holes.

3) Clean shuttles with warm soapy water and a brush or towel.

4) Clean airpots with warm soapy water and bottle brush. Be careful, glass interior

breaks easily. Use only a soft cloth and warm soapy water or stainless steel polish

on the outside to avoid scratches.

5) Wipe exterior of brewer with a damp cloth. Do not use abrasives which will scratch

surface.

6) If shuttles are to be left on warmer all night, fill with water to avoid coffee oil burn-in.

WARNING

Burn Hazard!

Hot liquids and surfaces are present in this equipment. To avoid burns use caution when

cleaning. Rinse hot parts with cold water before cleaning. Use gloves or a heavy cloth when

removing hot parts from brewer.

Page 10

Page 10

Shuttle Brewers & Airpot/Shuttle Brewers

Weekly or Bi-Weekly, Depending on Use

1) Fill shuttles with one gallon, 2/3 full, of hot water.

2) Pour into the shuttle liners the recommended concentration of urn cleaner (excessive amounts

of cleaner will attack the stainless steel).

Urn cleaners that have been used successfully:

DIP-IT, manufactured by Economics Laboratories, Inc.

4 Corporate Park Drive

White Plains, NY 10604

OXYLITE, manufactured by Avril, Inc., Syndet Division

601 N. Third Street

Reading, PA 19601

3) Scrub the liner interior with a plastic bristle brush.

4) Remove the knurled nut at the top of the gauge glass and clean the glass with a small

bottle brush.

5) Pour out the contents of the shuttle.

6) Remove the handle assembly of the shuttle faucet by unscrewing the plastic bonnet.

7) Gently wash the faucet seat cup with a soft cloth and warm soapy water.

8) Wash the faucet shank with a bottle brush.

9) Soak airpot pick-up tube assembly in hot soapy water. Urn cleaner may be used for

stronger cleaning.

10) Clean the warmer and bottom of shuttle surfaces. These surfaces must be clean for

proper heat transfer.

11) Polish the exterior of the brewer with stainless steel cleaner. Use the appropriate

cleaner for brass, copper, or vinyl if these optional finishes are provided.

Service

The rest of this manual contains information to aid the service person who is working on this equip ment.

This page has information on performing common service tasks. Following this is the Trou ble shoot ing

section which can help diagnose problems which are divided into three basic systems: filling, heating, and

brew ing.

Next is an illustrated parts breakdown which will help in the selection of repair parts. If further as sis tance

is needed, call our Technical Service Department at (502) 425-2776 or 800-695-4500 (USA & Canada

only) Monday - Friday between 8:00 am and 8:00 pm EST.

Wiring diagrams are also provided. Locate the basic diagram for the model you are working with. If

there are any options, see Diagram #091-548 (page 31 of this manual) which shows the wiring

alterations for Shuttle Brewer & Airpot/Shuttle Brewer options.

Page 11

Page 11

Shuttle Brewers & Airpot/Shuttle Brewers

Service (con't)

Drain Water Tank

Always empty the tank before shipping.

Note: Brewer may contain over 5 gallons of hot water.

1) Prepare a heat resistant container to drain tank water into.

2) Shut off power to the brewer.

3) Remove the front access panel.

4) Pinch or clamp the silicone hose connected to fill valve.

5) Disconnect hose from outlet barb on fill valve.

6) Place hose over drain and release clamp.

7) Allow the tank to drain completely.

NOTE: It may be necessary to pinch the hose and stop the water before container is full. Carefully

reinstall hose over fill valve outlet, then empty container. Repeat steps 4-7 completely to drain tank.

Remove Brew Valve

1) Disconnect electric power to machine.

2) Remove top cover and remove wires and small tube from valve.

3) Tilt inlet of valve down and pull sideways out of spray tee.

4) Clamp rubber tubing and disconnect valve from tubing.

Remove Heater

1) Disconnect power and remove top cover of brewer.

2) Disconnect wire leads to heater.

3) Remove tank cover by loosening retaining screw. Cover is lifted up with heater attached.

Heater is then removed.

4) Replace heater with sealing washers in same configuration. When tightening nuts, hold

element so it does not twist.

5) Replace tank cover ensuring O-ring seal is good.

6) Replace heater wires. Be sure all electrical connections are secure.

WARNING

Draining of tank should be performed by a qualified service technician. The tank contains

very hot water. May cause severe burns.

Page 12

Page 12

Shuttle Brewers & Airpot/Shuttle Brewers

Troubleshooting: Filling, Heating, and Brewing

Overfilling water

tank even when

power is off.

Fill valve not sealing

properly.

Fill valve installed

backwards.

Water entering tank

continuously, usually

slowly.

Look for direction of

arrow on valve body.

Disassemble valve and clean out

dirt. Valve may need new plunger

if seal is worn.

If arrow on valve is pointing toward

water inlet, remove valve and

install correctly.

Problem Possible Cause Service Check Remedy

Filling Problems

The filling system consists of the following components:

• Liquid Level Control, located behind the brewer front panel.

• Liquid Level Probes, located on the tank top, secured by wing nut, under the top cover.

• Fill Valve, located behind the front panel.

Overfilling water

tank only when

power is on.

High electrode

coated with lime or

faulty.

Missing or faulty connection of C terminal

on level control to metal

enclosure.

Jumper HI terminal on

level control to metal

enclosure stops fill.

Jumper from C

terminal to metal body

stops fill.

Check connections.

Jumper from HI to C

or metal enclosure

does not stop fill.

Remove electrode assembly and

clean both probes. If this does not

work, replace assembly.

Make secure connection of C to

metal body.

Connect black lead for valve to

FILL on level control.

Replace level control.

Tank does not

refill.

No power at

equipment.

No water at

equipment.

Water strainer

clogged.

No power to level

control.

Level control faulty.

Electrodes faulty.

Fill valve faulty.

Nothing operates.

Cracked water inlet

fitting.

Water pressure before

strainer but not after.

Check for 120V AC

across H and N terminals on level control.

Disconnect probe wire

to HI terminal on level

control. Check for

120V at FILL terminal.

Tank fills only when

probe wire is disconnected from HI terminal on level control.

120V is across FILL

and N on level control,

but no fill.

Check main switch or circuit

breaker, brewer's circuit breaker or

power switch if provided.

Make sure all water supply line

valves are open.

Remove and clean or replace

strainer's mesh.

If no voltage, check for loose or

broken wires.

If no 120V at FILL terminal,

replace level control.

Replace electrodes. If no remedy,

check for improper wiring or level

probe tip touching metal.

Disassemble valve and clean or

replace plunger if frozen. If plunger

is OK, coil may need replacement.

Fill valve connected

to heat terminal on

level control.

Liquid level control is

faulty.

Page 13

Page 13

Shuttle Brewers & Airpot/Shuttle Brewers

If you still need help, call our Technical Service Department at (502) 425-4776 or (800) 695-4500 (USA &

Canada only) Monday thru Friday 8 am - 8 pm EST or an authorized service center in your area. Please

have the model and serial numbers ready so that accurate information can be given. Prior authorization

must be obtained from Grindmaster Corporation’s Technical Service Department for all warranty claims.

Troubleshooting: Filling, Heating, and Brewing

Tank does not

heat.

Low electrode faulty

or covered w/lime.

Level control faulty.

Thermostat faulty or

out of calibration.

Heater relay coil

faulty. (electric heat)

Heater contactor

contacts faulty.

Heater faulty.

Jumper from XL terminal on level control

to metal body allows

heating.

Check for 120V between H and N terminals on level control.

If OK, jumper between

XL and metal body and

check for 120V

be tween HEAT and N

terminals.

Make sure thermostat

is turned on. Jumper

across thermostat

allows heating.

Check for 120V

across contactor coil.

Check for heater voltage between each

heater pole on con tactor, and different pole.

Check resistance

across elements with

wires disconnected.

Clean electrodes, check wiring. If

no remedy, replace electrodes.

If 120V is not at HEAT, replace level

control.

Recalibrate thermostat. If no remedy or thermostat does not cycle,

replace thermostat.

If correct voltage, but contactor not

closing, replace contactor.

If no continuity across contactor

when it is closed, replace contactor.

If resistance is much different than

10 to 15 ohms, replace heater.

Problem Possible Cause Service Check Remedy

Heating Problems

The heating system consists of the following components:

• Liquid Level Control, located behind the front enclosure panel.

• Liquid Level Probes, located on the tank top, secured by wing nut, under the top cover.

• Thermostat, located on the tank or on the front of top control panel under top cover.

• Heater Relay, located in top control section under top cover.

• Heating Elements, located on tank top under top cover.

Recovery time is

very long.

Heater faulty.

Low temp/no brew

thermostat set too

high.

See above.

Water is above 190

degrees F, but HOT

WATER light is off.

See above.

Turn down brew thermostat, see

adjustments.

Page 14

Page 14

Shuttle Brewers & Airpot/Shuttle Brewers

Troubleshooting: Filling, Heating, and Brewing

Brewing Problems

The brewing system consists of the following components:

• Start and Stop, switches located in the top control panel.

• Brew Timer, located in the top control section under the top cover.

• Brew Valve, located in the top control section under the top cover.

Brew volume too

large or too small.

Timer out of

adjustment.

Pressure not

ad e quate at urn.

Spray head clogged.

Brew valves clogged

with lime.

Timer faulty.

Compare timer setting to

factory setting chart.

Fill valve should cycle on

and off frequently during

brew cycle when all brew

heads are used.

Visual

Visual, inspect brew

valve.

Brew time does match

timer setting. Timer not

adjustable.

Adjust timer.

If fill valve does not cycle or takes

too long to refill, be sure water line

is 3/8" and pressure is uninterrupted

30psi.

Clean all holes.

Clean lime from valve. Seat cup or

entire valve may need replacement.

Replace timer.

Problem Possible Cause Service Check Remedy

Brew volume erratic.

(there is always some

small vari a tion from

batch to batch)

Timer faulty.

Pressure fluctuations

at urn.

Measure brew time for

inconsistencies.

Check pressure at urn

inlet.

If time is different from batch to

batch, replace timer.

Plumb water line so its pressure is

not influenced by other appliances.

Brew will not

start.

Circuit breaker

tripped or faulty.

Brew valve faulty.

Stop switch faulty.

Start switch faulty.

Low temp/no brew

thermostat set too

high.

Timer faulty.

If circuit breaker button

is out, breaker is tripped.

Check 120V across

brew valve.

Check for con ti nu ity

across stop switch

when not pressed.

Check 120V between

S.S. and N on timer

when start is pressed.

Water is above 190°F

(88°C), but HOT

WATER light is off.

Check 120V between H

and N on timer. If OK,

check for 120V between

BREW and N on timer

after pressing start.

If tripped, find cause and reset. If

faulty, replace.

If 120V is across brew valve, but brew

valve doesn't open, replace coil or

valve.

If no continuity, replace switch.

If start switch does not provide 120V

start signal, replace switch.

Turn down brew thermostat, see

adjustments.

If no 120V BREW output from timer,

replace timer.

Spray head will not

stop dripping water.

(spray heads normally

drip slightly after

brew)

Boiling tank.

Limed up brew valve.

If drip is from right

side, check for water

from overflow outlet at

top of tank.

Visual check of valve.

Turn down thermostat. If that doesn't

cure, check for faulty thermostat or

heater relay.

Clean valve. Valve seal or entire

valve may need replacement.

Page 15

Page 15

Shuttle Brewers & Airpot/Shuttle Brewers

Parts Illustration for Models P300E & P400E

Item Part # Description Item Part # Description

1 A545-034

LEG, 4” PLASTIC W/ SS FOOT

13 A725-081

BRASS SPRAY TEE W/ BYPASS TUBING

1 A545-015

LEG, 4” SS (OPTIONAL)

14 A530-009

BREW TIMER 0-8 MINUTES

2 A537-043

HOT WATER FAUCET W/ NUT

15 A585-021

SPRAY TUBING 3/8” ID X 5/8”OD X 6”LG

3 A531-035

TERMINAL BLOCK

16 A712-018

ELECTRODE ASSEMBLY

4 A531-026

TOGGLE SWITCH

17 A535-059

TANK HTR 6.6 KW @ 240V

5 A549-006

LIQUID LEVEL CONTROL BRD

18 A712-046

THERMOSTAT W/ GROMMET

6 APT400-105

SPRAY HEAD

19 A515027

DPST POWER RELAY

7 ACS-LL

SHUTTLE W/ LOCKING LID

20 A585-023

OVERFLOW TUBE 1/2”OD X 5/16”ID 7”LG

8 ABB1.5SS

BREW BASKET, SS

21 A515072

CIRCUIT BREAKER 10 AMP

9 A537-129

BREW VALVE

22 A718-111

BYPASS VALVE ASSEMBLY

10 A531-005

STOP SWITCH (before March 2000)

23 A718-198

FILL VALVE W/ FITTINGS (after 01-26-00)

10 A531-063

STOP SWITCH (after March 2000)

23 A537-154

FILL VALVE ONLY (after 01-26-00)

11 A531-004

START SWITCH (before March 2000)

23 A725-072

FILL VALVE RETROFIT KIT (before 01-26-00)

11 A531-062

START SWITCH (after March 2000)

24 A585-016

TUBING FILL 1.6’ LG & HOT WATER 1.5’ LG

12 A515016

PILOT LIGHT

25 A535-018

WARMER ELEMENT (below warmer shelf)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

TOP - (COVER REMOVED)

FRONT - (COVER REMOVED)

FRONT

NOTE: THIS DRAWING SHOWS PARTS FOR THE MODEL P400E.

ALL PARTS SHOWN ON THIS DRAWING APPLY TO THE MODEL

P300E, EXCEPT THE QUANTITIES MAY CHANGE. DEPENDING

ON THE OPTIONS INCLUDED, YOUR BREWER MAY HAVE

DIFFERENT PARTS

Page 16

Page 16

Shuttle Brewers & Airpot/Shuttle Brewers

Parts Illustration for Model P400ESHP

Item Part # Description Item Part # Description

1 A545-034

LEG, 4” PLASTIC W/ SS FOOT

15 A585-021

SPRAY TUBING 3/8” ID X 5/8”OD X 6”LG

1 A545-015

LEG, 4” SS (OPTIONAL)

16 A712-018

ELECTRODE ASSEMBLY

2 A537-043

HOT WATER FAUCET W/ NUT

17 A535-068

TANK HTR 3.7 KW @ 240V

3 A531-035

TERMINAL BLOCK

18 A712-046

THERMOSTAT W/ GROMMET

4 A531-026

TOGGLE SWITCH

19 A514005

CONTACTOR

5 A549-006

LIQUID LEVEL CONTROL BRD

20 A585-023

OVERFLOW TUBE 1/2”OD X 5/16”ID 7”LG

6 APT400-105

SPRAY HEAD

21 A515072

CIRCUIT BREAKER 10 AMP

7 ACS-LL

SHUTTLE W/ LOCKING LID

22 A718-111

BYPASS VALVE ASSEMBLY

8 ABB1.5SS

BREW BASKET, SS

23 A718-198

FILL VALVE W/ FITTINGS (after 01-26-00)

9 A537-129

BREW VALVE

23 A537-154

FILL VALVE ONLY (after 01-26-00)

10 A531-005

STOP SWITCH (before March 2000)

23 A725-072

FILL VALVE RETROFIT KIT (before 01-26-00)

10 A531-063

STOP SWITCH (after March 2000)

24 A585-016

TUBING FILL 1.6’ LG & HOT WATER 1.5’ LG

11 A531-004

START SWITCH (before March 2000)

25 A535-079

WARMER ELEMENT 240V

(below warmer shelf)

11 A531-062

START SWITCH (after March 2000)

not shown

A515027

WARMER RELAY

12 A515016

PILOT LIGHT

not shown

A532-001

FUSE HOLDER

13 A725-081

BRASS SPRAY TEE W/ BYPASS TUBING

not shown

A532-010

FUSE 1A

14 A530-009

BREW TIMER 0-8 MINUTES

not shown

A515043

TRASFORMER STEP DOWN

Page 17

Page 17

Shuttle Brewers & Airpot/Shuttle Brewers

Parts Illustration for Model RAP400E

Item Part # Description Item Part # Description

1 A548-072

LEG, RUBBER (RAP400)

11 A515016

PILOT LIGHT

1 A545-004

LEG, PLASTIC 4” (OPTIONAL RAP 400)

12 A725-082

SPRAY TEE KIT W/ BYPASS PLUG

1 A548-090

LEG, PLASTIC PLUG (RAP300)

13 A530-009

BREW TIMER 0-8 MINUTES

2 A531-035

TERMINAL BLOCK

14 A585-021

SILICONE TUBING 3/8”ID X 5/8”OD X 6”LG

3 A549-006

LIQUID LEVEL BOARD

15 A712-018

ELECTRODE ASSEMBLY

4 AAP-3

AIRPOT

16 A535-059

TANK HTR 6.6 KW @ 240V

5 APT400-105

SPRAY HEAD

17 A712-046

THERMOSTAT W/ GROMMET

6 ABB1.5P

BREW BASKET, PLASTIC

18 A515027

POWER RELAY

7 A537-129

BREW VALVE

19 A585-023

OVERFLOW TUBE 1/2”OD X 5’16ID X 7LG

8 A531-005

STOP SWITCH (before March 2000)

20 A515072

CIRCUIT BREAKER 10 AMP

8 A531-063

STOP SWITCH (after March 2000)

21 A718-198

FILL VALVE W/ FITTINGS (after 01-26-00)

9 A531-004

START SWITCH (before March 2000)

21 A537-154

FILL VALVE ONLY (after 01-26-00)

9 A531-062

START SWITCH (after March 2000)

21 A725-072

FILL VALVE RETROFIT KIT (before 01-26-00)

10 A537-043

HOT WATER FAUCET

22 A585-016

TUBING FILL 1.6’ LG & HOT WATER 3.75’ LG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

TOP - (COVER REMOVED)

FRONT - (COVER REMOVED)

FRONT

Page 18

Page 18

Shuttle Brewers & Airpot/Shuttle Brewers

Parts Illustration for Model RAPS400E

FRONT

Item Part # Description Item Part # Description

1 A545-034

LEG, 4” PLASTIC W/ SS FOOT

16 A725-081

BRASS SPRAY TEE W/ BYPASS TUBING

1 A545-015

LEG, 4” SS (OPTIONAL)

17 A585-021

SPRAY TUBING 3/8” ID X 5/8”OD X 6”LG

2 A537-043

HOT WATER FAUCET W/ NUT

18 A712-018

ELECTRODE ASSEMBLY

3 A531-035

TERMINAL BLOCK

19 A535-010

TANK HEATER 5KW @ 240V

4 AABW-R

ACCESSORY WARMER RIGHT

20 A712-046

THERMOSTAT W/ GROMMET

5 AAP-3

AIRPOT 3 LITER

21 A515027

DPST POWER RELAY

6 A549-006

LIQUID LEVEL CONTROL BOARD

22 A585-023

OVERFLOW TUBE 1/2”OD X 5/16”ID 7”LG

7 APT400-105

SPRAY HEAD

23 A515072

CIRCUIT BREAKER 10 AMP

8 ACS-LL

SHUTTLE W/ LOCKING LID

24 A530-016

1/2 BATCH CUBE TIMER

9 ABB1.5SS

BREW BASKET, STAINLESS STEEL

25 A718-111

BYPASS VALVE ASSEMBLY

10 A537-129

BREW VALVE

26 A531-025

MOMENTARY SWITCH

11 A531-005

STOP SWITCH (before March 2000)

27 A718-198

FILL VALVE W/ FITTINGS (after 01-26-00)

11 A531-063

STOP SWITCH (after March 2000)

27 A537-154

FILL VALVE ONLY (after 01-26-00)

12 A531-004

START SWITCH (before March 2000)

28 A515062

FUSE HOLDER

12 A531-062

START SWITCH (after March 2000)

29 A532-002

FUSE CLASS G 3 AMP

13 A550-159

BATCH SELECTOR SWITCH

30 A585-016

TUBING FILL 1.6’ LG & HOT WATER 1.5’ LG

14 A515016

PILOT LIGHT

31 A550-279

SINGLE RECEPTACLE NEMA 5-15R GFCI

15 A554-043

POTENTIOMETER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

FRONT - (COVER REMOVED)

TOP - (COVER REMOVED)

FRONT

Page 19

Page 19

Shuttle Brewers & Airpot/Shuttle Brewers

Parts Illustration for Model VSB-400

Item Part # Description Item Part # Description

1 A545-034

LEG, 4” PLASTIC W/ SS FOOT

12 A725-081

SPRAY TEE KIT W/ BYPASS TUBING

1 A545-015

LEG, 4” SS (OPTIONAL)

13 A530-009

BREW TIMER 0-8 MINUTES

2 A531-035

TERMINAL BLOCK

14 A585-021

SILICONE TUBING 3/8”ID X 5/8”OD X 6”LG

3 A549-006

LIQUID LEVEL BOARD

15 A712-018

ELECTRODE ASSEMBLY

4 AVS-1.5

SHUTTLE VACUUM

16 A535-059

TANK HEATER 6.6 KW @ 240V

5 APT400-105

SPRAY HEAD

17 A712-046

THERMOSTAT W/ GROMMET

6 ABB1.5P

BREW BASKET, PLASTIC

18 A515027

POWER RELAY

7 A537-129

BREW VALVE

19 A585-023

OVERFLOW TUBE 1/2”OD X 5/16”ID 7”LG

8 A531-005

STOP SWITCH (before March 2000)

20 A515072

CIRCUIT BREAKER 10AMP

8 A531-063

STOP SWITCH (after March 2000)

21 A718-111

BYPASS VALVE ASSEMBLY

9 A531-004

START SWITCH (before March 2000)

22 A718-198

FILL VALVE W/ FITTINGS (after 01-26-00)

9 A531-062

START SWITCH (after March 2000)

22 A537-154

FILL VALVE ONLY (after 01-26-00)

10 A537-043

HOT WATER FAUCET

22 A725-072

FILL VALVE RETROFIT KIT (before 01-26-00)

11 A515016

PILOT LIGHT

23 A585-016

TUBING FILL 1.6’ LG & HOT WATER 1.5’ LG

Page 20

Page 20

Shuttle Brewers & Airpot/Shuttle Brewers

Parts Illustration for Shuttle CS-LL

Item Part # Description

1 A537-053 FAUCET MODEL ES

2 A522078

SHANK W/ CHROME BONNET

3 A718-018 GAUGE ASSEMBLY

4 A725-092 KIT, SHUTTLE LID

A713-027

SS SHUTTLE COVER

(not shown)*

5 A548-142 LID RETAINING CLIP

6

A548-140

A61365

LID STOPPER W/ O-RING

* S.S. Cover used until August 2001

1

2

3

4

5

6

A537-049 UPPER

FAUCET ASSEMBLY

A537-055 HANDLE

A522132 BONNET NUT

A522120 SPRING

A537-047 PLASTIC STEM

A522102 SILICONE

SEAT CUP

Upper Faucet A537-049

Gauge Assembly A718-018

A318-119P TOP GAGE FITTING

A522026 WASHER UPPER GAGE

A555-001 GAGE SHIELD

A522031 GAGE GLASS

A522027 WASHER LOWER GAGE

AA-958 GAGE BASE

Page 21

Page 21

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model P-300

Page 22

Page 22

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model P-400 & P-400ESHP

Page 23

Page 23

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model RAP-300

Page 24

Page 24

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model RAP-400

Page 25

Page 25

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model RAPS-300

Page 26

Page 26

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model RAPS-400

Page 27

Page 27

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model VSB-300

W

W

W

W

WA TER

IMS

Page 28

Page 28

Shuttle Brewers & Airpot/Shuttle Brewers

Rough-In Drawing for Model VSB-400

Page 29

Page 29

Shuttle Brewers & Airpot/Shuttle Brewers

Wiring Diagram for P300E/P400E, with 1 Batch Timer

NOTE: THIS DRAWING SHOWS COMPONENTS ON

STANDARD MODEL ONLY. SEE 091-548 FOR WIRING

OF BREWER OPTIONS

Page 30

Shuttle Brewers & Airpot/Shuttle Brewers

Page 30

Wiring Diagram for P300E/P400E, with 2 Batch Timer

NOTE: THIS DRAWING SHOWS COMPONENTS ON

STANDARD MODEL ONLY. SEE 091-548 FOR WIRING

OF BREWER OPTIONS

Page 31

Page 31

Shuttle Brewers & Airpot/Shuttle Brewers

Wiring Diagram for RAP300E/400E

NOTE: THIS DRAWING SHOWS COMPONENTS ON

STANDARD MODEL ONLY. SEE 091-548 FOR WIRING

OF BREWER OPTIONS

Drawing #091-545

Page 32

Page 32

Shuttle Brewers & Airpot/Shuttle Brewers

Wiring Diagram for RAPS 300/400E

NOTE:

1) TWO SETS OF RECEPTACLE COMPONENTS ONLY

PROVIDED ON TWIN RAPS400E MODEL. DELETE

GROUP IN DASHED BOX FOR RAPS300E.

2) THIS DIAGRAM SHOWS COMPONENTS ON STAN DARD MODEL ONLY. SEE 091-548 FOR WIRING OF

BREWER OPTIONS.

Drawing #091-523

Page 33

Page 33

Shuttle Brewers & Airpot/Shuttle Brewers

Wiring Diagram for P-400ESHP

Page 34

Page 34

Shuttle Brewers & Airpot/Shuttle Brewers

Wiring Diagram #091-548

NOTE:

1) ONE GROUP OF WARMER COMPONENTS PER

BREW HEAD ON P AND RAPS MODELS.

2) TRANSFORMER MUST BE USED WHEN NEUTRAL

LINE IS NOT PROVIDED.

3) IF MODEL RAP, DELETE WARMER COMPONENTS.

4) IF MODEL IS RAPS, DELETE WARMER LIGHT AND

REPLACE WARMER ELEMENT WITH NEMA 6-15 RE CEP TA CLE.

NOTES:

1) IF PROVIDED WITH OPTION C21A, THREE HEATERS, SEE HEATER WIRING DIAGRAM 091-182.

2) WHEN PROVIDED WITH OPTION C14, AUTOMATIC WARMER SHUTOFF, SUBSTITUTE ACTIVATED SWITCH FOR

WARMER TOGGLE.

Page 35

Page 35

Shuttle Brewers & Airpot/Shuttle Brewers

Wiring Diagram #091-182

T3 T3 T3 1 1 T4 A

T2 T3 T3 T4 T4 T4 B

T2 T3 T3 1 1 T1 C

T3 T3 T3 T1 T1 T4 D

T2 T3 T3 T1 T1 T4 E

T2 T3 T3 T1 T1 T2 F

NOTE: USE WIRE NUT FOR 1 - 1 CONNECTION

5000 WATT / 240V HEATERS

* SEPARATE 120V REQUIRED FOR CONTROLS (3 AMP LOAD)

2.0 KW - 120/208V - 1 PH - 3 WIRE - 9 AMPS

2.5 KW - 120/240V - 1 PH - 3 WIRE - 11 AMPS

4.0 KW - 120/208V - 1 PH - 3 WIRE - 18 AMPS

5.0 KW - 120/240V - 1 PH - 3 WIRE - 21 AMPS

5.5 KW - 120/208V - 1 PH - 3 WIRE - 27 AMPS

7.5 KW - 120/240V - 1 PH - 3 WIRE - 31 AMPS

7.5 KW - 120/208V - 1 PH - 3 WIRE - 38 AMPS

10.0 KW - 120/240V - 1 PH - 3 WIRE - 42 AMPS

11.5 KW - 120/208V - 1 PH - 3 WIRE - 54 AMPS

15.0 KW - 120/240V - 1 PH - 3 WIRE - 63 AMPS

11.5 KW - 120/208V - 3 PH - 4 WIRE - 31 AMPS

15.0 KW - 240V - 3 PH - 3 WIRE - 36 AMPS *

A

B

C

D

E

F

WIRE PER FIG.FOR THIS HEAT AND ELECTRIC SERVICE

* FOR 3 PHASE WIRING

1. MOVE WIRE 6 FROM L1 TO L3

2. CONNECT HEATER ACCORDING TO FIG. F

ON CHART

3. FIG. F FOR 3 PH ONLY

WIRES 5 6 7 8 ARE 8 AWG, 105°C

1 2 3 4 ARE 10 AWG, 105°C

A

Page 36

Grindmaster® Coffee Grinders and Brewers • PrecisionBrew™ Brewing Systems • Espressimo® Espresso Machines

Crathco® Hot Beverage Dispensers • Crathco® Cold and Frozen Beverage Dispensers • AMW Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500 (USA & Canada only)

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

© Grindmaster Corporation, 1998

PRINTED IN USA

0307 Form # AM-309-08

Part # 090-077

Loading...

Loading...