Page 1

Grindmaster Corporation

4003 Collins Lane

Louisville, KY 40245 USA

Phone: (502) 425-4776

(800) 695-4500 (USA & Canada only)

Fax: (502) 425-4664

www.grindmaster.com • info@grindmaster.com

0608 Form# CC-399-05

Part# 90381

© Grindmaster Corporation, 2000

PRINTED IN THE USA

Crathco® Visual Granita Machine

Operation and Instruction Manual

for

G & MG Series Models

Prior authorization must be obtained from

Grindmaster Corporation for all warranty claims.

Models G23-2B, G235-2B, G236-2B,

MG23-2B, MG235-2B & MG236-2B

TABLE OF CONTENTS

Introduction and Warnings......................................2

Installation............................................................2-3

Connection To Power Supply..................................3

Preparing Product ..................................................4

Operating Panel......................................................4

Programming - G Series Electronic

Touchpad Model ..................................................4-6

Errors - G Series Electronic Touchpad Model ....6-7

Operating Panel Description-MG Series Traditional

Rocker Switch Model ..............................................7

Dispensing Product ................................................8

Adjustments ............................................................8

Cleaning & Sanitizing ........................................9-11

Maintenance ....................................................11-13

Crathco Granita Preventive

Maintenance Checklist ......................................14-15

Accessories ..........................................................16

Troubleshooting ..............................................17-18

Exploded View ................................................19-26

Crathco Granita G&MG Series Parts List ............27

Gear Motor Exploded View ..................................28

Refrigeration Diagrams....................................29-30

Electrical Diagrams..........................................31-33

Page 2

Page 2 G & MG Series Granita Machine

Introduction and Warnings

This instruction manual is an important part of this Granita machine and must be kept for future reference.

Carefully read the warnings contained in this instruction manual before installing and operating this Granita

machine.

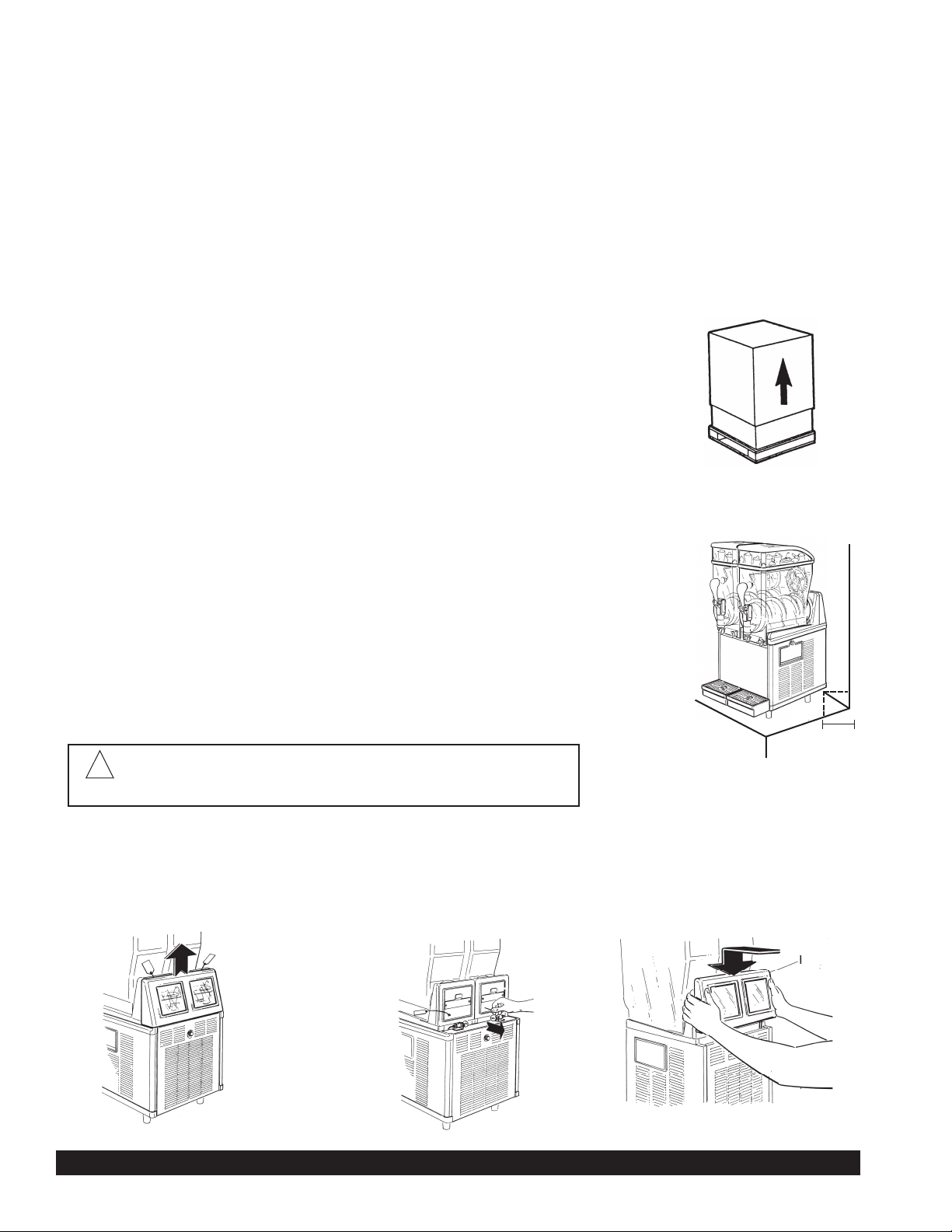

Instructions For Machine Transport

NOTE: Refrigeration equipment must remain upright to avoid damage to the compressor

In order to prevent the oil contained in the compressor from flowing into the cooling

circuit, it is necessary to always ship, carry, store and handle this Granita machine in

an upright position, following the instructions located on the packaging. Never ship,

carry, store or handle unit on its side.

Installation

1.) Cut banding straps from box and lift the box off the machine (see fig. A).

2.) Positioning the machine

• The machine must be well ventilated. Leave an 8” (20 cm) clearance on the

sides and back of the machine to allow proper ventilation. Installation of the

machine near a heat source should be avoided. Some heat sources you should

avoid locating this unit too close to are ovens, coffee machines, cold or frozen

beverage dispensers or ice machines (equipment with compressors that expel

hot air through its vents). Machines should also not be positioned near dust producing units such as a Powdered Cappuccino or Cocoa dispenser. A room temperature between 59°F (15°C) and 77°F (25°C) is recommended (see fig. B).

• The lit merchandising covers are reversible (front to back) depending upon the

needs of the operator (see fig. B).

3.) Remove Shipping Pin

• Lift up and remove rear back-lit merchandiser panel (see fig. C). NOTE: Some units may have dual rear

back-lit merchandiser panels, these function in the same manner as the single panel rear merchandisers.

• Pull out each pin attached to each tag (see fig. D)

• Replace rear back-lit merchandiser panel (see fig. E).

(Figure A)

(Figure B)

(Figure C)

(Figure D)

(Figure E)

Attention: Shipping pin attached to tag located behind

each bowl must be removed before starting machines.

!

8"

(20 cm)

Page 3

G & MG Series Granita Machine Page 3

Installation (cont.)

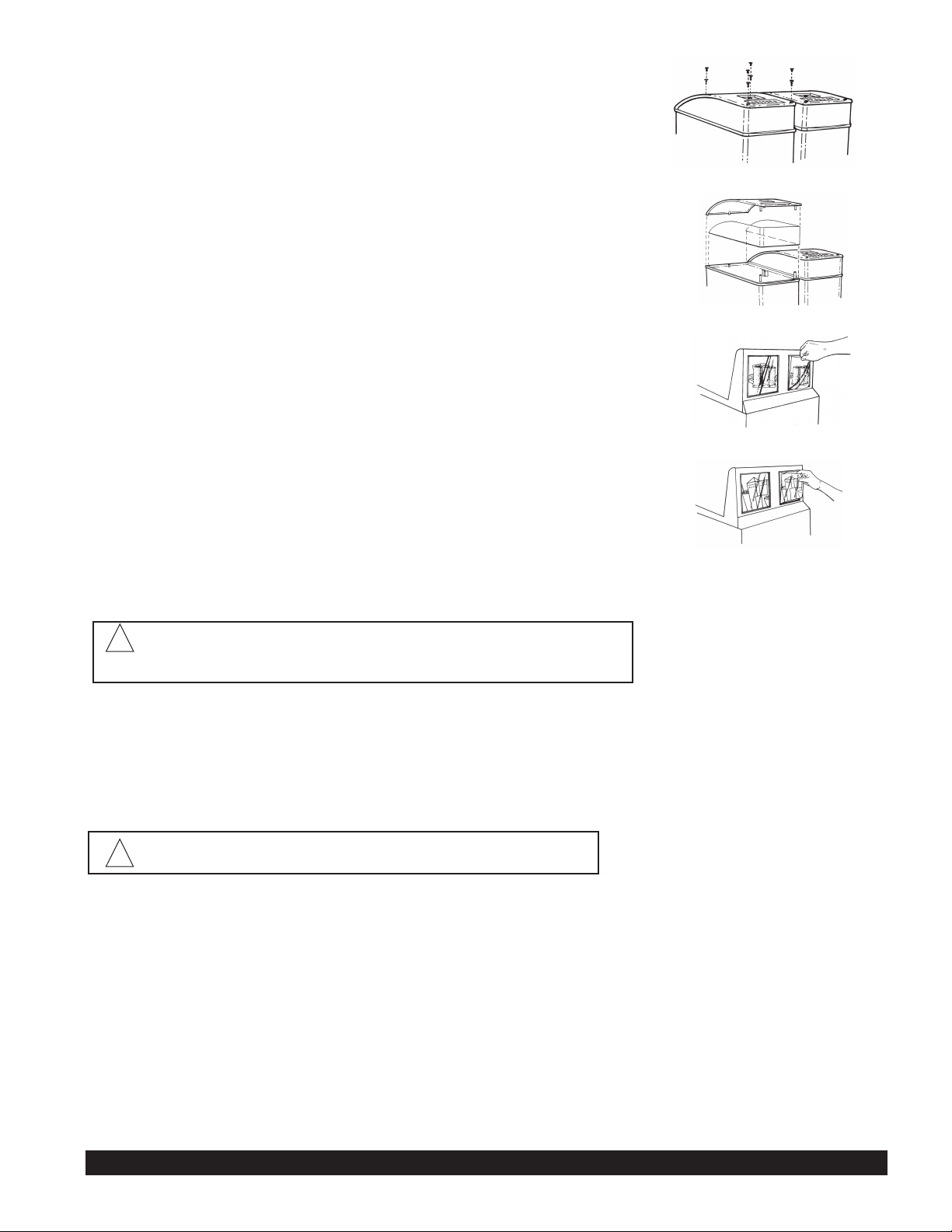

4.) Installing the Top Lid Merchandiser (requires Phillips head screwdriver)

• Unplug the cord to the lid and remove the lid from the machine.

• On top of the cover, remove the 4 hole plugs over the front (2) screws,

middle (near rocker switch) and back screws then remove these 4 screws

with a Phillips head screwdriver. Remove the black top part of the cover

from the clear plastic base. (see fig. E)

• Slide the merchandiser header around the outside edge of the lid’s clear

plastic base. Position bottom edge of header in grooved area. (see fig. F)

• Reassemble the black top cover onto the clear plastic base. The top edge of

header should slide into black top cover grooved area. (see fig. F) Replace

screws. Replace hole plugs (the angled plugs goes in the rear hole, and the

two large plugs go in the two front holes and the small plug goes in the

center hole by the rocker switches).

• Replace assembled lid on machine and reattach cord.

5. Installing the Rear Back-lit Merchandiser

• To remove any existing artwork, bend or pinch the middle of the back-lit

merchandiser and pull it from the rear merchandising display casing.

(see fig. G)

• To insert new art, slide the left corner edges into the left top and bottom

casing edges. (see fig. H)

• Slightly bend art and insert the right side of art into the right top and bottom

casing edges. (see fig. H)

• Smooth out art until all edges are properly inserted into the casing.

Connection To Main Power Supply

• The electrical safety of this Granita machine can only be achieved if the machine is properly connected

to an appropriate grounded, electrical receptacle that is in compliance with current national safety standards. Therefore, the manufacturer cannot be held responsible for damage and/or injury caused by failure to connect the unit to an appropriate source of power.

• For a safe and correct installation, connect the unit to a dedicated outlet.

• Do not alter the cord or plug in any way.

• The entire length of the power supply cord must not, in any way, be compressed (bent or bunched

together) nor may extension cords be used.

• Do not obstruct the ventilation and heat dispersion grill vents on the side and rear panels of the unit. An

insufficient ventilation process may reduce the efficiency of the machine, causing it to function inadequately, and cause serious damage to the machine. A minimum of eight inches (20cm) clearance is

necessary on each side and behind the unit.

Attention: Altering the cord or plug will void the warranty.

!

Attention: Before inserting the plug into the electrical

outlet, carefully read the following precautions.

!

(Figure E)

(Figure F)

(Figure G)

(Figure H)

Page 4

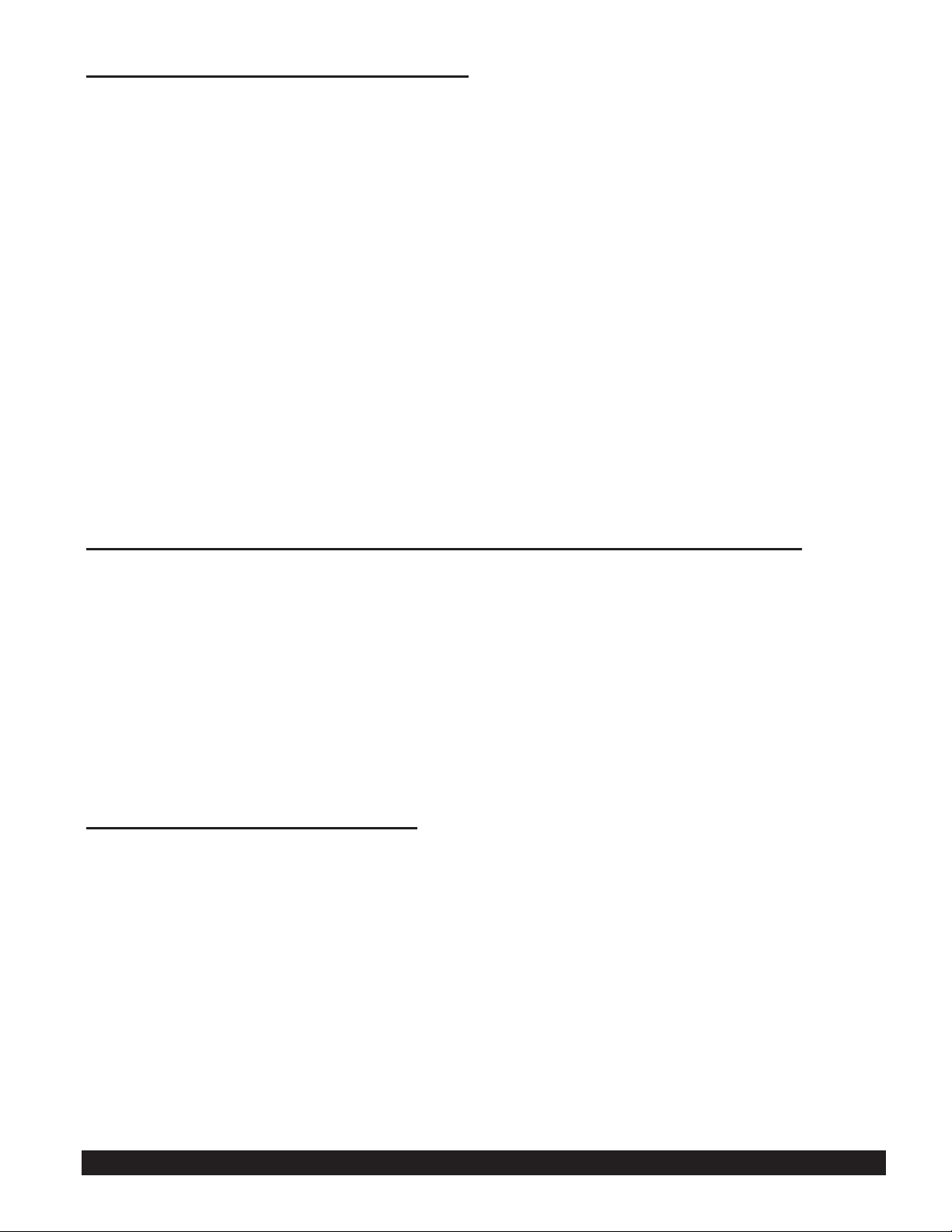

Operating Panel -Electronic Touchpad

Programming G Series Electronic Touchpad Models

Models G23-2B, G235-2B & G236-2B Electronic Touchpad:

Main Power Switch:

1.) Turns unit ON.

2.) Selects 12/24 time or FÞ/CÞ temperature display when turned ON while simultaneously depressing the auger

button.

3.) Sets current time when turned ON while simultaneously depressing the “Mode/Press To Select Function”

button.

Page 4 G & MG Series Granita Machine

(Figure L)

Auger ON/OFF

COLD

FROZEN

OFF

COLD

AUGER ON/OFF

PRESS TO SELECT

FUNCTION

FROZEN

OFF

Press To Select

Function

ON

AUTO TIMER

OFF

AUTO TIMER

Preparing Product

1.) If using product concentrate (instead of ready-to-use product), dilute and mix the product with water, according to the directions given by the manufacturer, in a separate

container (see fig. I). Never pour dry powder, crystals, or concentrate into a dry

bowl.

2.) Slide the merchandising lid either forward or toward the back of the bowl until the

“stops” reach the edge of the bowl. (It is not necessary to remove the merchandising cover.) When sliding lid back make sure that no droplets of water come off lid.

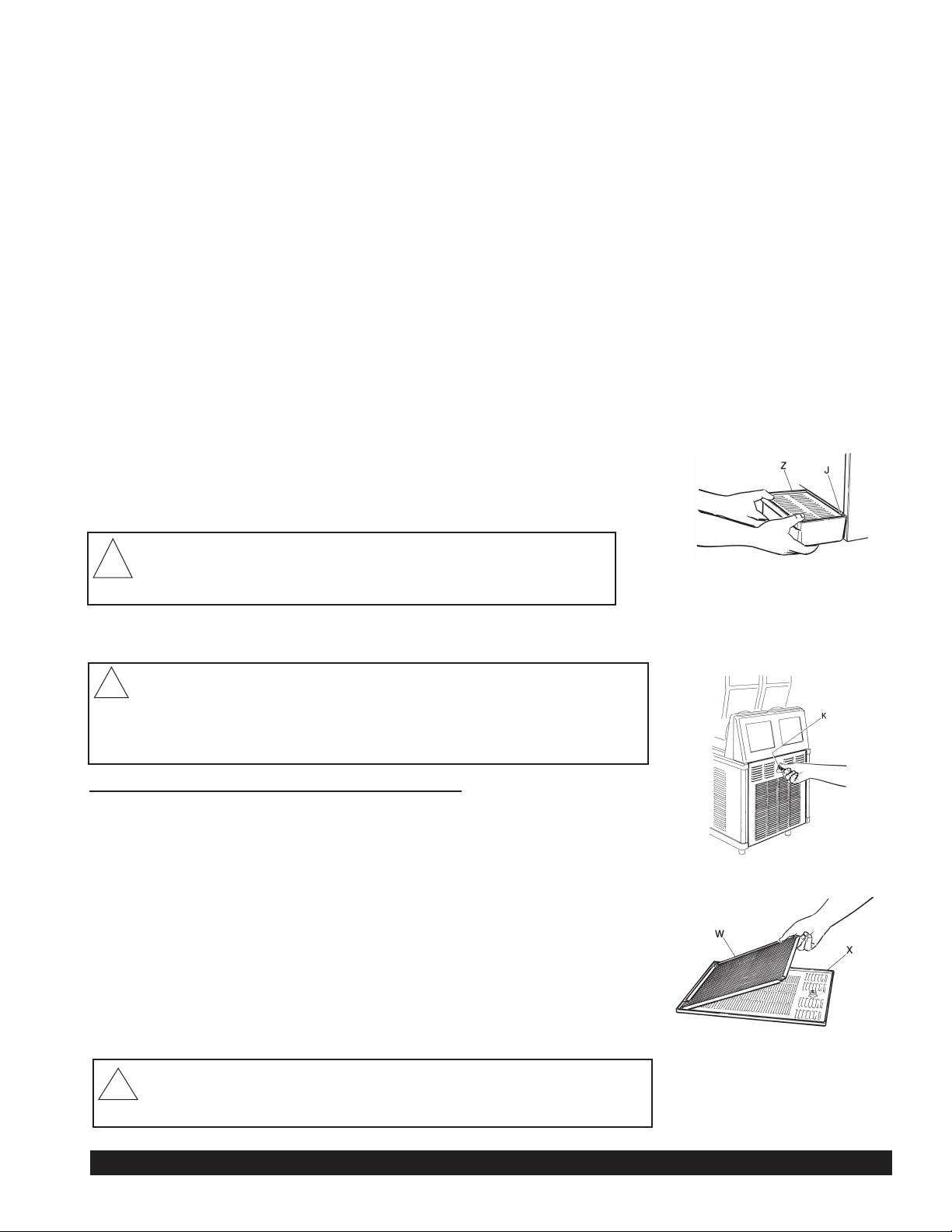

Pour the prepared product into the bowl (see fig. J). Do not spill any material on lid

or on bowl. There is a minimum and maximum fill line on the bowl. Do not overfill

or run the unit without enough product. Running unit with product below the minimum

full line may cause damage to the unit.

3.) Insert the plug into a dedicated electrical outlet.

Operating Panel

In order to access the operating panel, lower the cover (A) as shown

in figure K. To lower the cover use a coin or other object to turn the keyless lock to the horizontal position.

(Figure J)

(Figure I)

(Figure K)

Attention: Make sure that the mixture has a 13% minimum

Brix (sugar content). A lower concentrate could seriously damage

the mixing parts, as well as the gear motors. NEVER USE ONLY

WATER.

!

LED

Page 5

G & MG Series Granita Machine Page 5

Model G23-2B Electronic Touchpad (cont.):

Auger ON/OFF Button:

1.) Turns auger ON and OFF when main power switch is ON.

2.) Must be ON to permit defrost time to be reset.

3.) Must be ON to activate the “Mode/Press To Select Function” button to select manual “OFF”, “FREEZE” or

“COOLING” functions.

Mode/Press To Select Function Button:

1.) Used to manually select “OFF”, FREEZE” or “COOLING” functions when auger is turned ON.

2.) Accesses defrost timer reset mode when depressed for an extended period when auger is turned ON.

3.) Locks in hours, minutes and final time settings after they are reset using the “Auto Timer” button.

4.) Does not function when light on “Auto Timer” button is illuminated.

“Auto Timer” button

1.) Turns auto defrost mode ON or OFF (light on switch indicates when auto defrost mode is activated).

2.) Used to adjust the hours and minutes settings when readjusting current time or auto defrost timer.

Enter Time Programming on Initial Installation or in the Event of a Time Change:

1.) Turn OFF power switch.

2.) While pressing left “Press To Select Function” button, turn ON power switch while continuing to hold the “Press

To Select Function” button until the display illuminates (hour digits will start to blink).

3.) First set hour by pressing the “Auto Timer” clock button until the appropriate hour is shown (note: when using a

12 hour clock the time is P.M. when the dot at the bottom right corner of the LED is lit; when dot is not lit it is

A.M.)

4.) To set the minutes press the left “Press To Select Function” button, then press the “Auto Timer” clock button

until the appropriate minutes are set.

5.) To save your settings press the “Press To Select Function” button one more time.

Setting Defrost Timer (Night Setting):

1.) Turn power switch ON.

2.) Then press “Auger ON/OFF” button on for the side you are setting.

3.) Then press and hold the “Press To Select Function” button until you hear a long beep and the LED, “cold” and

the “Auto Timer” clock light begins to blink.

4.) Press the “Auto Timer” clock button to set the hour you want it to turn to refrigeration mode and then press the

“Press To Select Function” button to save the setting.

Page 6

Page 6 G & MG Series Granita Machine

Setting Defrost Timer (Night Setting) (cont.):

5.) Then press the “Auto Timer” clock button to set the minutes to complete time setting that you want it to turn to

refrigeration mode, (defrost mode). Then press the “Press To Select Function” button to save the setting.

6.) Proceed to setting the time you want the machine to turn to freezing mode by following steps 4 and above.

Then press the “Press To Select Function” button to save the time settings for freeze mode. Freeze light

should be blinking.

Note: Once the settings have been saved, the unit will save the settings, even when the power switch is turned OFF.

When the light on the “Auto Timer” clock button is “on”, the defrost timer is activated. To turn OFF the defrost timer,

press the “Auto Timer” clock button(s) until the light(s) on the clock button(s) turns off.

Operate in Automatic Mode (with Defrost Timer Activated):

1.) Turn power switch ON and wait for LED to light up.

2.) Press auger button “ON” for the side you are setting.

3.) To operate in defrost mode press the “Auto Timer” button until it is illuminated.

4.) When setting automatic times, please keep in mind it will take time for the frozen product to become liquid or

vice versa.

Operate in Manual Mode (without Defrost Timer Activated):

1.) Turn power switch ON and wait for LED to light up.

2.) Make sure clock button is OFF (LED light on clock button should not be lit up).

3.) First turn auger on by pressing “Auger ON/OFF” button until it beeps. (Note: The auger must be on before unit

will allow the cooling or freezing mode to activate)

4.) Then select refrigeration or freezing mode by pressing the “Press To Select Function” button until the light

under the selection you desire is lit up. (Note: In the cooling mode, the LED will read the actual temperature of

the product {The temperature setting is preset to NSF standards and is not adjustable.}) In the freezing mode

the LED will read the current time.

G SERIES MODELS - ERROR MESSAGES

1.) “FILTER CLEANING” ALARM

A filter cleaning alarm will activate when the unit is running hot due to insufficient internal air circulation.

When this occurs a “Filtr” message will appear on the touchpad LED readout and an intermittent audible tone

will also sound to alert the operator of this condition.

The “Filtr” message will appear when the alarm activates (a beeping sound every 4-5 seconds). To determine

the condition that caused the alarm and correct problem, see list of conditions below:

• Condition: The filter is dirty and needs to be cleaned. - Corrective Action: Clean and replace filter following

instructions on page 11 (Removing and Cleaning Filter).

• Condition: The unit is positioned too close to a wall or other object restricting air flow and causing the

machine to run at a higher temperature. - Corrective Action: Reposition unit to maximize ventilation space

(see page 2 - installation figures).

• Condition: The filter is not properly installed. - Corrective Action: Properly install filter see “Removing and

cleaning filter” page 11.

• Condition: The unit has been installed near a heat source, such as a coffee machine, ice maker or cold

beverage machine which expels hot air from its vents, causing the machine to run at a high temperature.

(Installation near a heat source should be avoided) - Corrective Action: Reposition unit to maximize ventilation space (see page 2 - installation figures).

Page 7

G & MG Series Granita Machine Page 7

G SERIES MODELS - ERROR MESSAGES (CONT.)

2.) “SYSTEM OVER TEMPERATURE” ALARM

• A system over temperature alarm will activate as a safety when the unit has overheated to protect the

compressor.

• The system automatically goes to “OFF” status where the compressor’s operations is stopped, while

augers will keep working to avoid forming ice blocks.

• When this occurs an “Err” message will appear on the touch pad LED readout accompanied by a continuous buzzer sound to alert the operator of this condition.

• When this alarm activates, turn off all switches. Then determine the condition. (See “Filter Cleaning” Alarm

Section for Conditions and Corrective Actions)

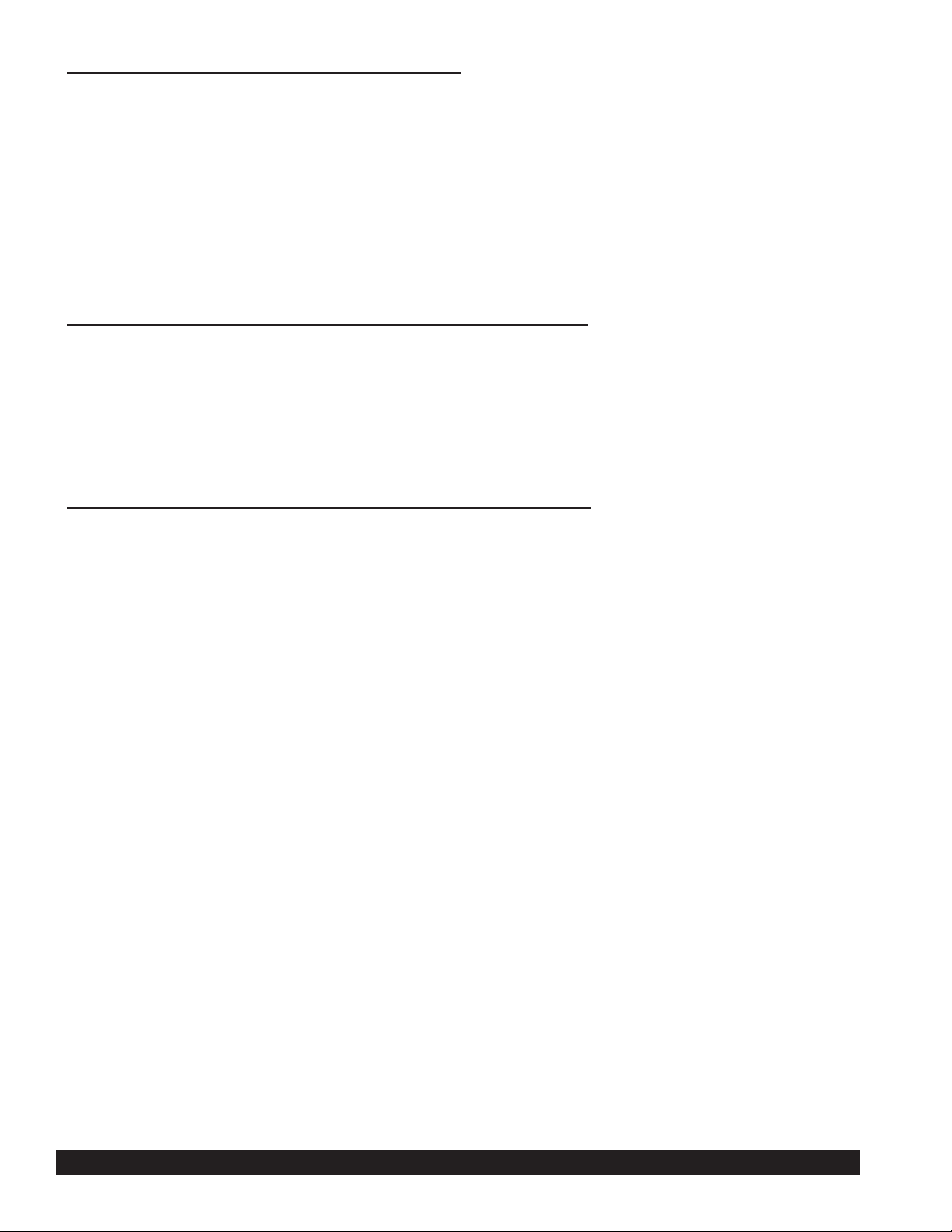

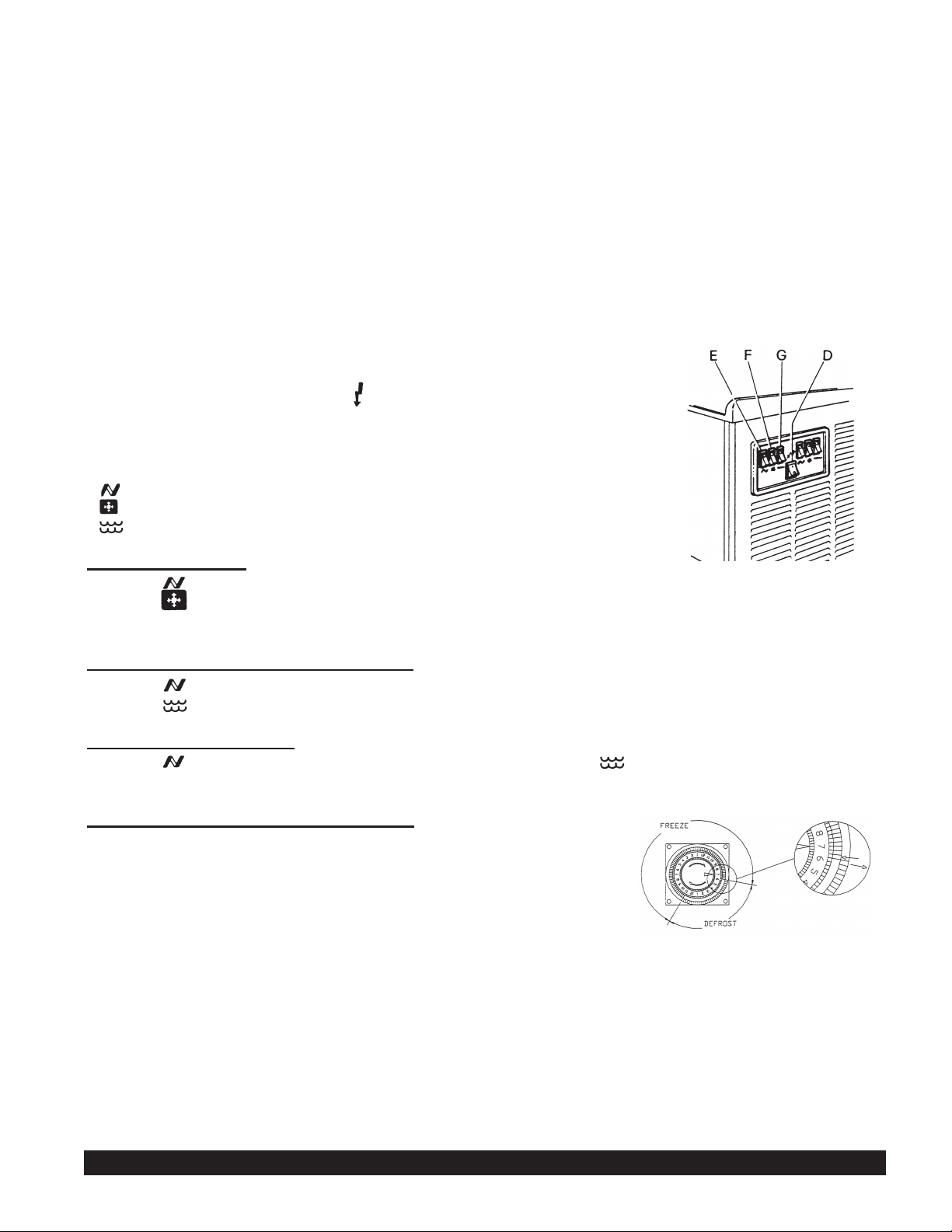

Operating Panel Description-MG Series Traditional

Rocker Switch Model

1.) Turn ON the main power switch (D) (see figure M)

2.) Description of the buttons (see figure cc):

Each bowl is controlled by three switches which have the following functions:

(E) activates the mixing parts/spiral auger

(F) activates the freezing of the product

(G) activates the refrigeration of the product (night/defrost setting)

To obtain a slush:

Select the (E) switch to activate the mixing parts/spiral auger and

select the (F) switch to activate the freeze mode.

Note: There is a 4 minute delay before the compressor will start.

To obtain cold (night/defrost) drinks:

Select the (E) switch to activate the mixing parts/spiral auger and

select the (G) switch to activate the refrigeration mode.

Stand-by mode setting:

Select the (E) switch to activate the mixing parts/spiral auger and the (G) switch to activate refrigeration

mode to keep the product(s) in bowl(s) overnight.

Defrost Timer Operating Instructions

1.) SETTING CURRENT TIME - Rotate the program disc, in the direction of

the arrows, to align the correct time of day with the time of day mark.

Figure H shows the timesetting of 7:00.

2.) SETTING DEFROST MODE - Set the defrost period by pushing the switch

actuator toward the outer edge of the program disc. Freeze time is set by pushing the

switch actuators toward the center of the time switch. Figure N shows a defrost time

from 11:00 to 6:15. The light and dark shaded areas of the program disc indicate day and night respectively.

Each actuator is equivalent to 15 minutes.

3) All switches (power, auger, refrigeration and freeze) must be “on” for defrost timer to properly function.

NOTE: The timer is battery backed. Do not remove power from the unit for greater than 2 weeks as doing so will

result in failure of the battery back-up feature. The battery is nickel cadmium and will last from 6 to 8 years if

properly charged. The battery is not replaceable upon failure.

(Figure N)

(Figure M)

Page 8

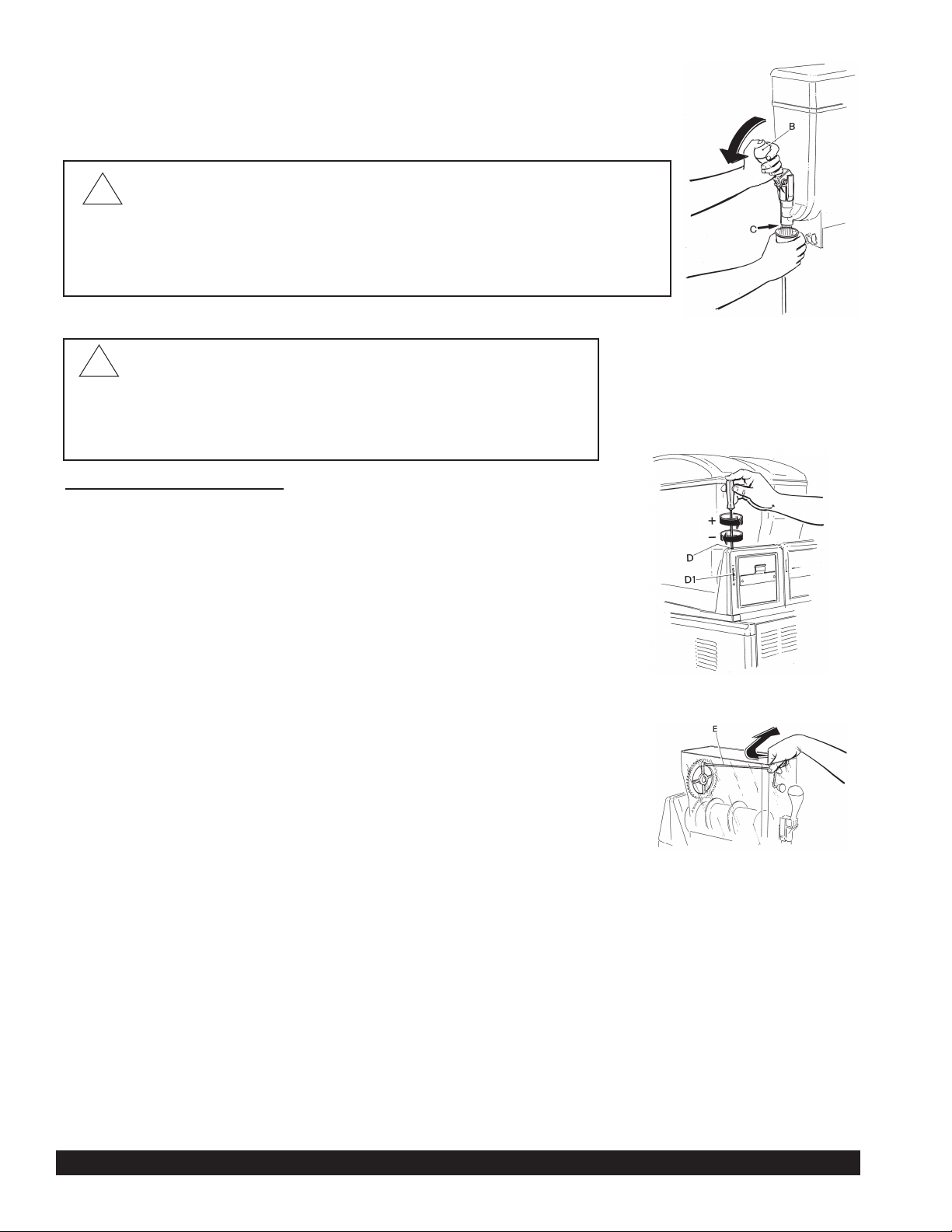

Dispensing Product

To dispense the product, position the cup under the dispensing valve (C)

and lower the dispensing lever (B) (see fig. O).

Adjustments

Consistency Adjustment

1.) Unplug the machine.

2.) Be sure that product in bowl is within proper fill range.(Above the minimum

fill line)

3.) Remove merchandiser.

4.) Change the thickness of the product by turning the screw (D) on the back of

the bowl, as shown on fig. P. Turn the screw clockwise for thinner product or

counterclockwise for thicker product. The indicator gauge (D1), located on

the back of the bowl, shows the degree of adjustment (+/-). (+) = thicker,

(-) = thinner

Note: This (D1) is an indicator gauge only. To adjust consistency, turn screw

on top (D).

Page 8 G & MG Series Granita Machine

(Figure Q)

(Figure P)

Attention: To prevent the product from becoming too thick,

it is necessary to push left “Press To Select Function” and right

“Press To Select Function” keys to cold drink position or to refill

the bowl when the level of the granita inside the bowl is below the

minimum fill line.

!

!

Attention: If the machine is turned off at night, with the bowls filled,

or just partially filled, a layer of solid ice may form on the surface due to the

natural separation of the unmixed (non-moving) product. In this case, before

turning the machine back on, remove the layer of superficial ice to prevent

damage to the mixing auger.

(Figure O)

Page 9

G & MG Series Granita Machine Page 9

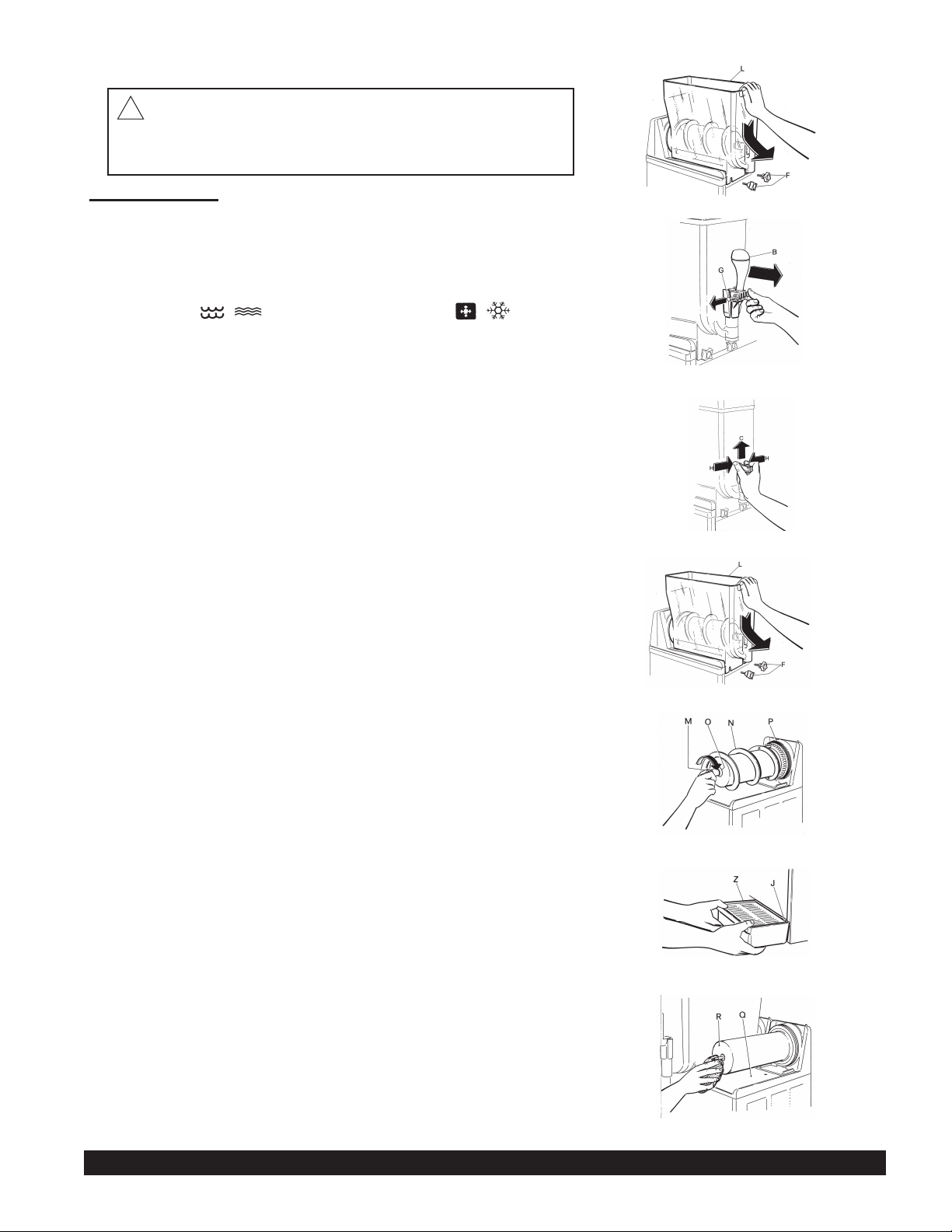

Cleaning and Sanitizing Procedures

Daily Cleaning

For the machine to function properly, it is important that

the cleaning procedures be carried out daily, according

to the following instructions:

1.) Turn off the / (G, fig. M) refrigeration and / (F, fig. M) freezing

switches and empty the bowl of its remaining product; after draining the product from the unit, you can fill the bowl with hot water (not boiling) to help melt

off any sugar deposits. Then drain the water prior to proceeding to step (2).

2.) Unplug the unit.

3) Pull out the mixing rod (E) by pushing it slightly backwards

to remove it from its position (see fig. Q on pg.8).

4.) Unscrew and remove the two knobs (F) then lower the bowl to

drain out any remaining product through the dispensing valve

(see fig. R).

5.) Remove and disassemble the dispensing valve:

• Remove the pin (G) as shown (see fig. S).

Then, remove the handle (B) sliding it from its seat.

• Simultaneously apply pressure to the two securing tabs (H) and

lift the dispensing valve (C) to pull it out of its position (see fig. T).

6.) Remove the bowl (L) by unscrewing the two knobs (F) and

pulling it downwards as shown in fig. U.

7.) Unscrew the securing bolt (M) clockwise. Pull off the auger (N)

and remove the shaft seal (O) and the bowl seal (P) (see fig. V).

8.) Remove the drain tray by lifting up on the front edge, while lowering the

rear edge, and then lift it off the unit (see fig. W).

9.) Thoroughly wash each part that has been removed in steps 1-8 and the base

(Q), as well as the freezing cylinder (R) with warm water and mild dishwashing detergent. Rinse well with clear water and allow to air dry (see

fig. X). Avoid the use of abrasive cleaners which can damage the finish.

Do not put in dishwasher. Dishwasher may damage some parts such as

the clear plastic auger gears and top mixing bar. Reassemble with clean

hands.

(Figure V)

(Figure W)

(Figure X)

(Figure U)

!

Warning Disconnect the unit from its power supply

prior to cleaning or sanitizing the unit. Failure to do so may

result in electric shock.

(Figure R)

(Figure S)

(Figure T)

Page 10

Page 10 G & MG Series Granita Machine

Cleaning and Sanitizing Procedures (con’t)

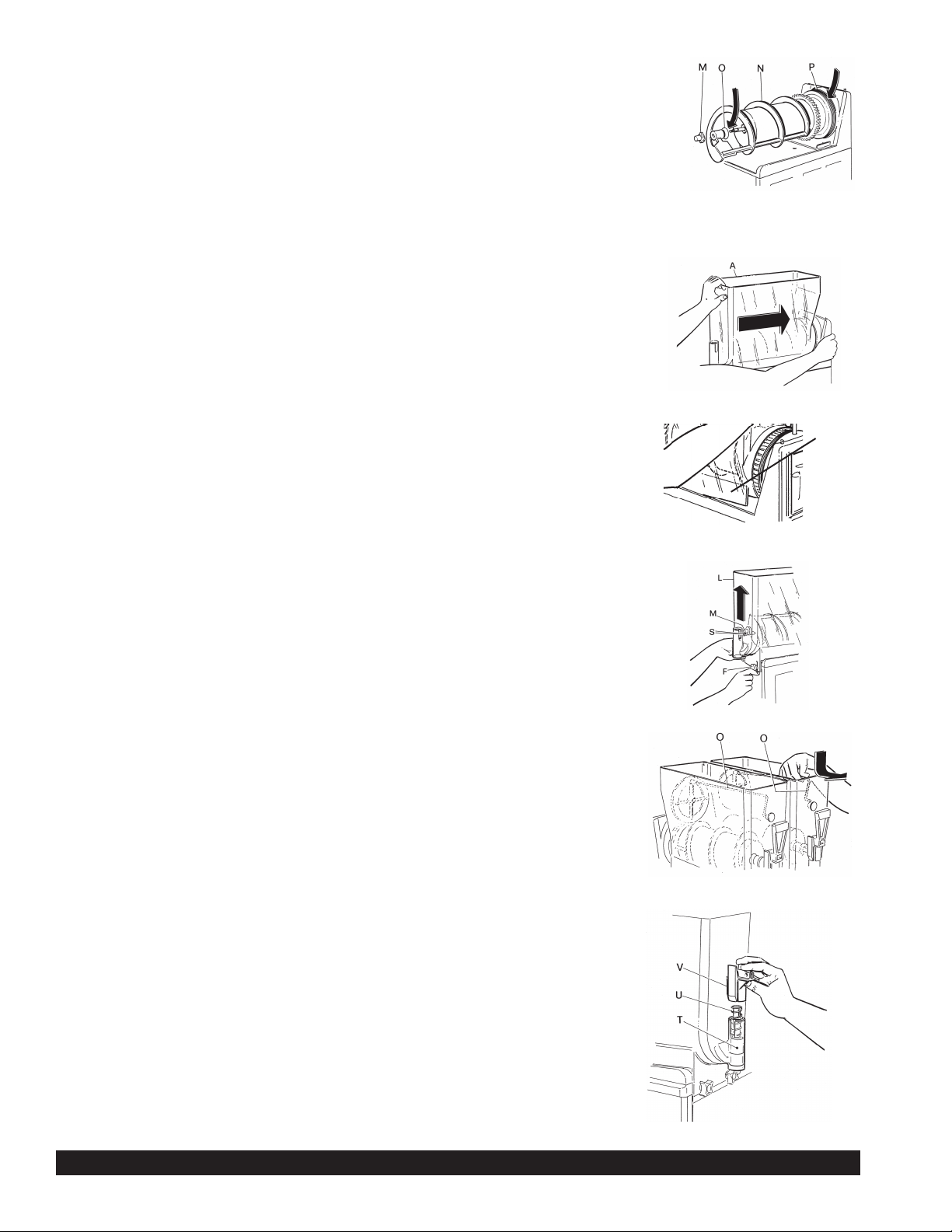

10.) Reassemble the mixing unit back together, according to the following

procedures (see fig. Y):

• Moisten the bowl seal (P) with water and slip it into place at the back of cylin-

der with ribs angled toward back of freezer.

• Apply food grade lubricant to the inside of the shaft seal (O) and put the shaft

seal (O) back on with the flared end of seal toward back of freezer.

• Put the auger assembly (N) back on the evaporator.

• Secure all the parts in place by screwing on the bolt (M) counterclockwise.

11.) Reassemble the bowl (L), positioning it into place. Make sure that the bowl fits

tightly to the bowl seal (see fig. Z). We also suggest that the rear part of the

bowl be moistened with water or lightly lubricated at the point where it fits

together with the seal to make it easier to install bowl.

11a.) The lower right and left bowl flanges should fit on the outside of each black tri-

angle edge (see fig. AA). The lid cover will not fit properly if this is not cor-

rectly positioned.

12.) Secure the bowl (L) by keeping it lifted until the bolt (M) is aligned with its hole

(S), then tightly screw on the knobs (F) without exerting excessive pressure to

avoid cracking the bowl (see fig. BB).

13.) Reassemble the mixing rod (O) so that its gears are aligned with the lower gear

ring. This will allow the front pin to fit perfectly in its position on the bowl (see fig.

CC).

14.) Reassemble in sequence the parts of the dispensing valve

as follows (see fig. DD).

• Make sure that the dispensing valve seat is properly

lubricated with food-grade lubricant (such as Haynes Lubrifilm).

• Put the dispensing valve body (T) in its seat.

• Insert the spring (U).

• Put the dispensing valve upper body (V) into its position

until it completely snaps into place.

• Reassemble the handle (B) and insert retaining pin (G)

following the same procedures in #5, fig. S.

15.) Reinstall the drain tray (fig. T). Make sure that the condensation

drainage tube (J) is reinserted into its correct fixed position, allowing it to

drain into the tray.

(Figure BB)

(Figure CC)

(Figure AA)

(Figure DD)

(Figure Z)

Bowl outside

corner must be

over the white

plastic edge.

(Figure Y)

Page 11

G & MG Series Granita Machine Page 11

Cleaning and Sanitizing Procedures (con’t)

16.) Plug the unit back into appropriate power supply.

17.) After the cleaning and reassembly of the mixing parts and bowl as per above instructions, fill the bowl with a

mix of water and an approved cleaning solution (example kay5), according to the measures specified.

18.) Start the mixing part of the machine for about 10 minutes to sanitize all parts. Follow the cleaning solution

specifications.

19.) Drain the cleaning solution as follows:

• Unscrew the two knobs (F) see fig. U);

• then lower the bowl to drain out any remaining product through the dispensing valve (C)

(as shown in fig. U).

20.) Screw again the knobs (F) to fix the bowls.

21.) With a clean cloth wash the underside of the lamp cover with warm water and a mild detergent. Allow this

part to air dry and then wipe it with a clean cloth which has been dipped in the sanitizing mixture.

Prepare a minimum of 4 gallons (15 liters) of sanitizing solution (Stera Green

Label or equivalent) following the manufacturer’s instructions.

Note: Add 4 ounces of Stera Sheen to 4 gallons (15 liters) of 120° Fahrenheit

(50° Centigrade) water to achieve a concentrate of 100 parts per million.

Warning: Lamp cover must be unplugged. Electric shock

could occur if cover or power cord come in contact with

solution.

Maintenance

Removing and cleaning the filter (Weekly)

This should be done weekly or more often if necessary.

In order to guarantee an efficient refrigerating system, it is essential that the

filter be properly cleaned, according to the following procedures:

1) Unplug the machine.

2) Unscrew the knob (K) in order to remove back panel (see fig. FF).

3) Remove the filter (W) held inside the back panel (X) and clean

it properly using water or vacuum (see fig. GG).

4) Place the cleaned filter back inside back panel and reinstall the back

panel on the machine by screwing in the knob (K).

(Figure FF)

(Figure GG)

Warning: Disconnect the unit from its power supply prior to

performing any maintenance procedures. Failure to do so could result in

electric shock, injury from hazardous moving parts or serious burns from

hot surfaces.

Attention: Failure to maintain a clean filter and condenser will

cause damage to the unit not covered by warranty.

!

(Figure EE)

!

!

Page 12

Page 12 G & MG Series Granita Machine

Maintenance (con’t)

Cleaning the Condenser (Monthly)

This cleaning should be done monthly or more often if necessary.

In order to guarantee an efficient refrigerating system, it is essential that the

condenser be properly cleaned at regular intervals, according to the following

procedures:

• Unplug the machine.

• Remove the back panel and filter. Using a dry brush or vacuum, remove the dust that

has accumulated between the fins of the condenser (see fig HH).

Replacing the Lightbulbs (As Needed)

• Unplug the machine.

Lid Lights

• Unplug the cord to the lid and remove the lid from the machine.

• In order to access the lightbulb in the merchandising cover, insert

a quarter in the slot on the small panel on the top of the cover (DA)

and rotate the quarter to pop the panel open (see fig. II).

• Holding the merchandising cover with the top open, carefully remove the

lightbulb (see fig. JJ).

• Insert the new bulb and replace the light cover.

• Place lid on machine and plug lid cord back into lid.

Rear Merchandiser Lights

• In order to access the lightbulb from the rear back-lit merchandiser (BB),

remove the rear merchandiser by sliding it upwards (see fig. KK).

NOTE: Some units may have dual rear backlit merchandiser panels, these

function in the same manner as the single panel rear merchandisers.

• Then remove the lightbulb(s) (BA) (see fig. LL).

• Insert the new bulb(s) (BA).

• Reassemble the rear back-lit merchandiser (AA) making sure that its slots

are inserted properly in the relevant brackets (CA) (see fig. LL).

• Plug machine into dedicated outlet.

(Figure II)

(Figure JJ)

(Figure KK)

(Figure LL)

(Figure HH)

Page 13

G & MG Series Granita Machine Page 13

Maintenance (con’t)

Seal Maintenance

Bell Shaped Seal

• Replace every 1 to 6 months depending on conditions of use and level of maintenance and lubrication.

This part should be lubricated during re-assembly after every cleaning.

Spindle Bushing Seal

• Replace every 6 to 12 months depending on conditions of use and level of maintenance.

Replacement of spindle bushing should ONLY be done by a qualified service technician.

To Replace Spindle Bushing:

Tools required: Power screwdriver, Rubber mallet, Replacement Kit #90104, spindle bushing extraction tool

#90544

Each PM kit # 90104 contains 2 bell shaped shaft seals, 2 spindle bushing seals, 4 dispense valve o-rings, 1 laminated care and cleaning card and one PM checklist.

1. Empty product bowl and disassemble as if for cleaning. Spindle bushing seals should be replaced every

6-12 months and bell-shaped shaft seals should be replaced once every 1-6

months depending on conditions of use and maintenance.

2. Slide the threaded metal cylinder on the drive shaft so that the flat surface meets

the face of the evaporator cylinder.

3. Thread the two tapping screws (max length 1 1/8”) through the holes in the tool

and into the spindle bushing seal. Use of a power screwdriver is suggested. (See

Figure MM)

4. Screw the outer cylinder of the extracting tool on to the metal cylinder by rotating

clockwise until it is fully connected.

5. Continue turning the outer cylinder clockwise until the spindle bushing seal is removed.

If necessary, apply higher torque by inserting a screwdriver in the holes of the outer

cylinder. (See Figure NN)

6. After extracting the old spindle bushing seal, position a new one in the evaporator

cylinder. The gasket (black side) should be facing the inside of the evaporator.

7. Position the inserting pipe so that it’s smaller diameter touches the spindle bushing

seal.

8. Push the spindle bushing seal in by tapping on the pipe with a rubber mallet. Be

sure the spindle bushing seal is completely

in place. (See Figure OO)

9. Reassemble bowl.

When replacing the spindle bushing be sure to check the condition of the driveshaft. If the

surface is not smooth and the driveshaft is not secure, then replace the driveshaft while replacing the spindle bushing. Replacement of a driveshaft should only be done by a qualified service technician using PM kit #90110.

Bowl Gasket (located at rear of bowl)

• Replace as necessary depending on the conditions of use and level of maintenance. This part should be

lubricated during re-assembly after every cleaning.

O-Ring Maintenance

•O-rings should be replaced every 6 to 12 months or as necessary where wear is apparent.

Figure MM

Figure NN

Figure OO

Page 14

Page 14 G & MG Series Granita Machine

Crathco Granita Preventive

Maintenance (PM)

Checklist for Kit 90566 Serial # 11259 and above

(and units with lower serial #’s that have been

converted to stainless steel shafts - units with

black stainless shafts will need to be converted

using PM Kit # 90110B)

A preventive maintenance visit should be performed every 6 months. In addition, air filter should be cleaned weekly,

and every three months the condenser should be cleaned, and the rubber shaped bell shaft seals should be

replaced. Failure to complete PM’s every 6 months is considered abuse of the machine, and therefore voids the

warranty. Proof of PM must be documented with Grindmaster Corporation to maintain warranty coverage. To document your PM, complete this form with signatures, place used/worn parts that were replaced during the PM inside

envelope, and mail to Grindmaster Corporation. Parts returned should include 2 evaporator seals, 2 rubber bell

shaped shaft seals, valve o-rings and shafts (if applicable). First PM on serial numbers 11259 to 12202 should also

include kit number 90225 (one per serial number).

The following procedures should be performed during a Preventative Maintenance visit, using PM kit # 90566

or 90110B.

Document model and serial number of equipment and record above.

Check product temperature and consistency for proper setting - adjust if necessary.

Insure product is being mixed properly and is within specification (check and document brix - most products

should be around 13% - refer to product manufacturer’s recommendations for exact recommended brix).

Record Brix reading here: Left Bowl _____ Right Bowl _____

Check for leaks at gaskets, o-rings, front shaft seal, etc.

Empty product from bowls and disassemble unit completely.

Clean and sanitize all disassembled parts.

Clean and sanitize top tray and freezing barrel.

Clean out condensation tube with sanitizer and long brush.

Check condition of all panels, bowls, lids - replace if necessary.

Check mixing rods and augers for wear, check mixing rod bearing for wear - replace if necessary.

Check for bowl knobs (two per bowl to lock down bowl in front) - replace if necessary.

Check operation of lights in lid and rear of unit (if equipped) - replace light bulbs if necessary.

Clean re-usable air filter. Check condition of filter and replace if necessary.

Clean condenser.

Check condition of bowl gaskets and replace if necessary.

Replace all o-rings on dispense valves and lubricate.

Check drive shaft. Replace if necessary, using PM kit #90110B in place of 90566 above.

Replace evaporator seal in front of evaporator. (use brass tool, included, to slide seal onto shaft, and use the

white tool to tap seal into place. Be sure to lubricate seal with food grade grease first)

Replace bell shaped rubber shaft seal on front of freezing barrel (generously lubricate inside seal)

Lubricate parts where appropriate (dispense valve o-rings, inside of shaft seal, inner rim of bowl where it meets

with the bowl seal)

Re-assemble unit and refill with product

Verify and document defrost timer setting and operation and time of day setting and adjust if necessary.

Check thermostat setting on MG models. Thermostat setting should be between 1-1/2 and 2.

Verify compressor operation and freezer controller operation.

Verify ventilation is adequate (8” on both sides and back)

Check electrical connections and wiring.

Check fan operation (1 condenser fan and 2 gear motor fans) and clean fan or blades if necessary.

Review proper periodic care and cleaning instructions (disassembly, cleaning, sanitizing, lubrication and

re-assembly) with store personnel. Review proper product mixing and handling instructions with store personnel

Demonstrate and train store personnel to follow proper procedures (stress importance of store level

maintenance such as lubrication and filter cleaning).

Make sure store personnel have appropriate supplies (lubricant and sanitizer) to care for machine.

Model # ___________________________

Serial # ____________________________

Date: ______________________________

PM by _____________________________

Of Company ________________________

Store Name/# _______________________

Address ___________________________

__________________________________

Store Mgr Name ____________________

Signature __________________________

Page 15

Crathco Granita Preventive

Maintenance (PM)

Checklist for Kit 90104 Serial # 11258 and below*

(If unit has been converted to unhardened

stainless shaft system, then use kit #90566

instead. )

A preventive maintenance visit should be performed every 3

months. Failure to complete PM’s every 3 months is considered abuse of the machine, and therefore voids the warranty. Proof of PM must be documented with Grindmaster Corporation to maintain warranty coverage. To document

your PM, complete this form with signatures, place used/worn parts that were replaced during the PM inside envelope, and mail to Grindmaster Corporation. Parts returned should include 2 spindle bushing evaporator seals, 2 rubber bell shaped shaft seals, valve o-rings and shafts (if applicable).

The following procedures should be performed during a Preventative Maintenance visit, using PM kit # 90104:

Document model and serial number of equipment and record above.

Check product temperature and consistency for proper setting - adjust if necessary.

Insure product is being mixed properly and is within specification (check and document brix - most products

should be around 13% - refer to product manufacturer’s recommendations for exact recommended brix).

Record Brix reading here: Left Bowl _____ Right Bowl _____

Check for leaks at gaskets, o-rings, front shaft seal, etc.

Empty product from bowls.

Disassemble unit completely.

Clean and sanitize all disassembled parts.

Clean and sanitize top tray and freezing barrel.

Clean out condensation tube with sanitizer and long brush.

Check condition of all panels, bowls, lids - replace if necessary.

Check mixing rods and augers for wear, check mixing rod bearing for wear - replace if necessary.

Check for bowl knobs (two per bowl to lock down bowl in front) - replace if necessary.

Check operation of lights in lid and rear of unit (if equipped) - replace light bulbs if necessary.

Clean re-usable air filter if so equipped (standard on G & MG models, optional on ID models). Check condition

of filter and replace if necessary.

Clean condenser.

Check condition of bowl gasket and replace if necessary.

Replace all o-rings on dispense valves and lubricate.

Check drive shaft. If surface is not smooth or the drive shaft is not secure (excessive movement in and out) use

PM kit #90110, or 90110B in place of 90104 above.

Replace spindle bushing seal in front of evaporator using extraction tool.

Replace bell shaped rubber shaft seal on front of freezing barrel (generously lubricate inside seal)

Lubricate parts where appropriate (dispense valve o-rings, inside of shaft seal, inner rim of bowl where it meets

with the bowl seal)

Re-assemble unit and refill with product

Verify and document defrost timer setting and operation and time of day setting and adjust if necessary.

Check thermostat setting on ID and MG models. Thermostat setting should be between 1-1/2 and 2.

Verify compressor operation and freezer controller operation.

Verify ventilation is adequate (8” on both sides and back).

Check electrical connections and wiring.

Check fan operation (1 condenser fan and 2 gear motor fans) and clean fan or blades if necessary.

Review proper periodic care and cleaning instructions (disassembly, cleaning, sanitizing, lubrication and

re-assembly) with store personnel. Review proper product mixing and handling instructions with store personnel.

Demonstrate and train store personnel to follow proper procedures (stress importance of store level

maintenance such as lubrication and filter cleaning).

Make sure store personnel have appropriate supplies (lubricant and sanitizer) to care for machine.

Model # ___________________________

Serial # ____________________________

Date: ______________________________

PM by _____________________________

Of Company ________________________

Store Name/# ______________________

Address ___________________________

__________________________________

Store Mgr Name ____________________

Signature __________________________

G & MG Series Granita Machine Page 15

Page 16

Page 16 G & MG Series Granita Machine

Accessories (not included)

Security Kit Installation (Part # 3468)

Installing Locking Clip

1. Pinhead must be located on righthand side of valve,

as shown.

2. The 0.125” slot, on the locking clip, lines up with

the horizontal shelf on the valve body.

3. Insert the locking clips as shown.

4. Attach padlock in hole provided on the locking clip.

Installing Security Straps

1. Hook straps under side edge of the bowl,

beginning at the front of the bowl.

2. Slide the straps back on the bowl until the

are firmly in place

3. Interlock straps above the bowl lid.

4. Attach the padlock.

Autofills

Attach liquid autofill systems to your granita dispenser.

Autofills minimize manual labor to mix and refill the unit, as well as maintain

the product bowl at an attractive level.

Contact your local Grindmaster Corporation representative or

Grindmaster Corporation customer service at (800) 695-4500

for more information on any of the above accessories.

PULL HANDLE

PIN HEAD

LOCKING CLIP IN

LOCK POSITION

LOCKING CLIP

HORIZONTAL

SHELF

HOLE FOR

PADLOCK

VALVE BODY

0.125”

SLOT

GRANITA BOWL

SECURITY STRAP

(Figure PP)

(Figure QQ)

(Figure RR)

BIB Product

Product Delivery

System

Water line

Product Filling

System

Page 17

G & MG Series Granita Machine Page 17

Troubleshooting Guide

The following procedures must be performed by a qualified service technician.

Problem Possible Cause Solution

The machine does not cool, or cools

only partially, but the compressors

are running

The machine does not cool or cools

only partially, but one or more of the

compressors are not running

The machine over-freezes, making

the auger movement slow or

stopped

The machine is noisy

The main power switch is “On”. The

unit is not running.

Product is leaking out of the bowl

• Allow at least 8” (20cm) between the

machine and anything next to it; keep

away from heat sources

• Return to freeze mode

• Remove the side panels. Using a

brush or compressed air clean the

condenser

• Check the fan motor’s electrical

connections and, if disconnected,

reconnect. If still not operating,

replace the motor

• Locate the leak, eliminate it and

recharge the system

• Replace the malfunctioning

components

• Check the contacts and correct those

that are incomplete

• Replace the compressor(s)

• Check the electrical connections to

the PC board as well as the

transformer feeding the PC board

and correct

• Check the product brix and correct

• Reset the screw toward the “-”

position to produce a thinner

consistency product

• Using pliers, straighten the limit switch

arm

• Add more product or turn the

refrigeration “Off”

• Replace the PC board

• Check and correct

• Replace the fuse(s)

• Clean the condenser or add

ventilation space around the machine

(the cutout switch reset is automatic

when the conditions are corrected)

• Check the contacts and correct those

that are incomplete

• Replace the switch

• Replace or reposition the seals

• The space around the machine is

inadequate for ventilation

• Freezer is in defrost

• The condenser fins are clogged with

airborne particles

• Fan motor is not running

• Refrigerant is leaking

• Electrical components of the

compressor(s) are not functioning

• Some electrical connections are not

complete

• One or more of the compressors are

malfunctioning

• No current is coming to the “compressor delay” PC board

• The product brix is too low

• The screw setting for the product

consistency control system is set too

far toward the “+” position

• The limit switch arm is bent away

from the gearmotor and prevents

contact

• The level of the product in the bowl is

too low, exposing the auger

• The compressor PC board contacts

don’t open

• The fan motor blades are hitting

internal components

• The fuse(s) are blown

• The pressure cutout switch has

activated

• Some electrical connections are not

complete

• The main power is not functioning

• One of the bowl seals is not in place

Page 18

Page 18 G & MG Series Granita Machine

Troubleshooting Guide (cont’d)

Problem Possible Cause Solution

If you still need help, call our service department at (800) 695-4500 (USA & Canada only) or (502) 425-4776 (Monday

through Friday, 8 am - 6 pm EST) or an authorized service center in your area. Please have the model and serial

numbers ready so that accurate information may be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all

warranty claims.

Product is leaking from the

dispensing valve

Product is flowing into drain tray

through drainage tube

The auger and/or the upper mixing

unit is not turning

The auger and/or the upper mixing

units are creating noises as they

rotate

There is no light in the

merchandising lid or rear

merchandising panel

The cover does not fit properly on

the bowl

“Filtr” or “Err” message appears on

the touchpad LED readout

• Reassemble and replace

• Clean and lubricate the valve and

valve cylinder with the lubricant provided with the machine

• Replace the o-rings

• Find the seal and put it back in place

• Replace the damaged/worn seal and

check the condition of the driveshaft.

• Turn auger on

• Check the contacts and correct the

ones that are incomplete

• Replace the gear motor(s)

• Check and correct

• Check the product brix and correct

• Replace or Clean and lubricate with

the lubricant provided with the

machine

• Check and correct

• Replace (See “Changing the lightbulb”

section in this manual)

• Replace

• Replace

• Remove bowl and position properly

• Clean and replace filter following

instructions on page 11 (Removing

and Cleaning Filter)

• Reposition unit to maximize ventilation

space (see page 2 - installation figures)

• Properly install filter see “Removing and

cleaning filter” page 11

• Reposition unit to maximize ventilation

space (see page 2 - installation figures)

• The dispensing valve has been incompletely or incorrectly replaced in its

position

• The free movement of the dispensing

valve is impeded

• Dispensing valve o-rings are damaged

• The bell shaped “shaft” seal between

the front of the cylinder and the auger

hub has not been reinstalled properly

• The bell shaped “shaft” seal or the

spindle bushing seal is damaged or

worn

• Auger not turned on

• Some electrical connections are not

complete

• The gear motor(s) are malfunctioning

• The large red bowl seal is not in

position, causing the gear teeth not to

mesh

• The product brix is incorrect

• The bell shaped “shaft” seal has been

replaced without lubrication or is damaged

• The auger has been incompletely or

incorrectly reassembled (ie the

auger’s gear pins are not properly

seated)

• The light bulb is burnt out

• The 5 Amp fuse between the transformer and the lamp is blown

• The transformer is blown

• The bowl is incorrectly positioned (the

lower, outside corner is not over the

lower, outside base piece)

• The filter is dirty and needs to be

cleaned

• The unit is positioned too close to a

wall or other object restricting air flow

and causing the machine to run at a

higher temperature

• The filter is not properly installed

• The unit has been installed near a

heat source, such as a coffee

machine, ice maker or cold beverage

machine which expels hot air from its

vents, causing the machine to run at a

high temperature. (Installation near a

heat source should be avoided)

Page 19

G & MG Series Granita Machine Page 19

Exploded View MG23-2B (115/60)

(for units up to serial number 8195)

Page 20

Page 20 G & MG Series Granita Machine

Exploded View G23-2B (115/60)

(for units up to serial number 8195)

Page 21

G & MG Series Granita Machine Page 21

Exploded View G23-2B (115/60)

(serial number 8195 and higher)

Page 22

Page 22 G & MG Series Granita Machine

Exploded View MG23-2B (115/60)

(serial number 8195 and higher)

Page 23

G & MG Series Granita Machine Page 23

Exploded View G235-2B (220/50)

Page 24

Page 24 G & MG Series Granita Machine

Exploded View MG235-2B (220/50)

Page 25

G & MG Series Granita Machine Page 25

Exploded View G236-2B (220/60)

Page 26

Page 26 G & MG Series Granita Machine

Exploded View MG236-2B (220/60)

Page 27

G & MG Series Granita Machine Page 27

2 90000 Supporting Foot

4 90002 Washer

5 90003 Nut

6 90004 Bushing for Cord

8 90006 Screw

10 90007 General Switch

12 90008 Function Switch (MG Series)

24 90015 Lid Light Switch

29 90391 Lid Merchandiser, city scene

30 90021 Bottom of Lid

31 90022 Bowl, standard

32 90023 Seal for Bowl

38 90027 Drain Tube

39 90028 Nut

40 90029 Screw

41 90030 Hex Head Nut Screw

43 90470 Screw

47 90033 Screw

48 90034 Screw

50 90036 Fuse Holder

51 90471 Fuse, 16 Amp (220V)

63 90046 Dispensing Valve O-ring

74 90048 Thermostat (MG Series)

75 90049 Gear Motor

76 90050 Consistency Control Spring

77 90051 Bushing Consistency Control Spring

78 90052 Nut

79 90053 Consistency Control Pin

80 90054 Limit Microswitch

81 90055 Screw

82 90056 Nut

83 90057 Bushing Spindle Connection

84 90058 Screw

89 90063 Washer for Front Bushing

90 90064 Evaporator

91 90065 Upper Mixing Unit

92 90066 Shaft Seal, Rubber Bell Shaped

94 90068 Securing Nut for Auger

95 90069 Spindle Bushing

97 90071 Drive Shaft

98 90072 Screw

101 90075 Hose Clamp

102 90076 O-ring

103 90077 Washer for Rear Bushing

106 90078 Accumalator

108 90080 Compressor (115/60)

109 90081 Compressor Electrical Parts (115/60)

110 90082 Condenser Fan Motor (115/60)

111 90083 Impeller (60Hz)

112 90084 Control Box Timer (MG Series)

115 90085 Gear Motor Fan (115/60)

116 90086 Screw

125 90102 Lid Socket

270 90464 Filter Drier

272 90129 High Pressure Cutout Switch

274 90005 Cord with Plug AWG14(20A)

277 90465 Filter drier, dual connection

350 90469A Dispensing Valve Handle Assy, Black

353 90404 Screw

354 90405 Nut,M5 DIN 934

355 90406 Transformer(IN 115V out 12) G&MG

356 90407 Washer 5X15X1.5

357 90408 Drip Tray Grid Black

358 90409 Black Drip Tray

359 90410 Black Lower Trim

360 90411 Stainless Steel Lower Front Panel

361 90412 Stainless Steel Upper Front Panel

362 90413 Stainless Steel Left Side Panel

363 90414 Black Upper Trim

364 90415 Black Merchandiser Cover

365 90142 Incandescent Light Bulb (BP1156CL)

366 90141 Incandescent Light Socket

367 90418 Center Screw Lid Plug

368 90419 Front Screw Lid Plug

369 90420 Rear Screw Lid Plug

370 90421 Wiring for Black Lid w/Cord

371 90422 Black Cover For Light Bulb

372 90423 Black Evaporator Support

373 90424 Black Cover for Evaporator Support

374 90425 Wiring,PC Control Board (G Series)

375 90426 Black Knob to Secure Bowl

376 90427 Control Board Mounting Plate

377 90428 PC Control Board, Electronic

378 90429 Filter Inlet Air

379 90430 Black Top Tray

380 90431 Screw

381 90432 Back-Lit Merchandiser Panel Bracket

382 90433 Knob Rear Panel

383 90434 O-ring Knob,Rear Panel

384 90435 SS Back Panel

385 90436 Painted Frame

386 90437 Stainless Steel Right Side Panel

387 90438 Screw

388 90439 Screw (Foot)

389 90440 Main Fuse 20A

390 90441 10A Fuse

391 90442 Screw

392 90443 10A Fuse Holder

393 90444 Auger, Granita One Piece

394 90445 Bulb Insulator, Rear Merchandiser

395 90446 Screw (Single Pc. Rear Merchandiser)

396 90447 Back-Lit Merchandiser Support (Single Pc.)

397 90448 Bulb Bracket, Rear Merchandiser

398 90449 Back-Lit Cover (Single Pc.)

399 90450 Screw

400 90451 Thermister (G Series)

401 90452 Fan Motor Cover

402 90453 Condenser

403 90454 Condenser Fan Motor Bracket

404 90455 Screw

405 90456 Compressor Mouting Plate

406 90457 Control Box Cover Black

407 90458 Screw

408 90459 Control Board Cover Lock

409 90460 Control Board Cover Key

410 90395 Complete Wiring (MG Series)

411 90132 Timer, Defrost (MG Series)

446 90472 Back-lit Merchandiser, Panel Bracket (Dual Pc.)

306 90392 Rear Merchandiser, City Scene (Single Pc.)

447 90397 Rear Merchandiser Graphic, City Scene (Dual Pc.)

448 90473 Transparent Surface (Dual Pc Rear Merchandiser)

449 90474 Cord with Plug (220V)

450 90475 Transformer (IN 230 OUT 12)

451 90476 Compressor (220/50)

452 90477 Compressor Electrical Parts (220/50)

453 90478 Condensor Fan Motor (220V)

454 90479 Impeller (220/50)

455 90480 Gear Motor Fan (220V)

456 90481 Compressor (220/60)

457 90482 Compressor Electrical Parts (220/60)

90566 Preventative Maintenance Kit

90106 Brush 1/4" Ceaning

90107 Brush, Valve 1" Cleaning

90110B Shaft Replacement Kit

W0470076 Food Grade Lubricant

90177 Bowl, 2-gallon

90178 Complete bowl cover G & MG Series

90381 Instruction Manual, G & MG Series

90386 Care & Cleaning Inst., Lam. Card

90468 Control Box Cover Assy. Blk

90469 Complete Dispensing Valve Black

90483 9 ltr. Max Bowl Label

Crathco Granita G & MG Series Parts List

ITEM PART DESCRIPTION ITEM PART DESCRIPTION

NO. NO NO. NO

Page 28

Page 28 G & MG Series Granita Machine

GEAR MOTOR EXPLODED VIEW

Item # Description Part No.

1 ROTOR WITH TWO BEARINGS 90174

4 ARMATURE 90169

6 DRIVE GEAR WITH BEARING 90165

7 IDLER GEAR WITH BEARING 90166

10 OUTPUT SHAFT AND GEAR 90171

13 OUTPUT SHAFT BEARING 90170

19 HOUSING GASKET 90167

41 OUTPUT SHAFT SEAL 90168

Page 29

G & MG Series Granita Machine Page 29

Item Description

CL

DL

CTL

EL

AL

CR

DR

CRT

ER

AR

C & CFM

REFRIGERATION DIAGRAM MODEL G SERIES (115V/220V)

COMPRESSOR LEFT

DRIER LEFT

CAPILLARY TUBE LEFT

EVAPORATOR LEFT

ACCUMULATOR LEFT

COMPRESSOR RIGHT

DRIVER RIGHT

CAPILLARY TUBE RIGHT

EVAPORATOR RIGHT

ACCUMULATOR RIGHT

CONDENSER AND CONDENSER FAN MOTOR

REFRIGERATION DIAGRAM MODEL MG SERIES (115V)

Item Description

CL

COL

DL

CTL

EL

AL

CR

COR

DR

CRT

ER

AR

C & CFM

COMPRESSOR LEFT

CUT-OUT LEFT

DRIER LEFT

CAPILLARY TUBE LEFT

EVAPORATOR LEFT

ACCUMULATOR LEFT

COMPRESSOR RIGHT

CUT-OUT RIGHT

DRIVER RIGHT

CAPILLARY TUBE RIGHT

EVAPORATOR RIGHT

ACCUMULATOR RIGHT

CONDENSER AND CONDENSER FAN MOTOR

Page 30

Page 30 G & MG Series Granita Machine

REFRIGERATION DIAGRAM MODEL MG SERIES (220V)

Item Description

CL

DL

CTL

EL

AL

CR

DR

CRT

ER

AR

C & CFM

COMPRESSOR LEFT

DRIER LEFT

CAPILLARY TUBE LEFT

EVAPORATOR LEFT

ACCUMULATOR LEFT

COMPRESSOR RIGHT

DRIVER RIGHT

CAPILLARY TUBE RIGHT

EVAPORATOR RIGHT

ACCUMULATOR RIGHT

CONDENSER AND CONDENSER FAN MOTOR

Page 31

G & MG Series Granita Machine Page 31

ELECTRICAL DIAGRAM MODEL - MG SERIES (115)

Page 32

Page 32 G & MG Series Granita Machine

Item Description Item Description

LB

RB

PS

DT

MASL

FSL

RSL

MASR

FSR

RSR

GML

GMFL

TL

GMR

GMFR

TR

CL

RL

SCL

OPL

CR

RR

SCR

OPR

TRANSF

CFM

LLL

LLR

MSL

MSR

TDB

BLL

BLR

LEFT BOWL

RIGHT BOWL

POWER SWITCH

DEFROST TIMER

MIXING AUGER SWITCH LEFT

FREEZING SWITCH LEFT

REFRIGERATING SWITCH LEFT

MIXING AUGER SWITCH RIGHT

FREEZING SWITCH RIGHT

REFRIGERATING SWITCH RIGHT

GEAR MOTOR LEFT

GEAR MOTOR FAN LEFT

THERMOSTAT LEFT

GEAR MOTOR RIGHT

GEAR MOTOR FAN RIGHT

THERMOSTAT RIGHT

COMPRESSOR LEFT

COMPRESSOR RELAY LEFT

STARTING CAPACITOR LEFT

OVERLOAD PROTECTOR LEFT

COMPRESSOR RIGHT

COMPRESSOR RELAY RIGHT

STARTING CAPACITOR RIGHT

OVERLOAD PROTECTOR RIGHT

TRANSFORMER

CONDENSER FAN MOTOR

LID LAMP LEFT

LID LAMP RIGHT

MICROSWITCH LEFT

MICROSWITCH RIGHT

TIME DELAY BOARD

BACK LAMP LEFT

BACK LAMP RIGHT

ELECTRICAL DIAGRAM MODEL - MG SERIES (220V)

Page 33

G & MG Series Granita Machine Page 33

ELECTRICAL DIAGRAM MODEL - G SERIES (115V/220V)

Page 34

Page 35

Page 36

Grindmaster® Coffee Grinders and Brewers • Espressimo® Espresso Machines • Crathco® Hot Beverage Dispensers

Crathco® Cold and Frozen Beverage Dispensers • American Metal Ware® Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

Loading...

Loading...