Page 1

Grindmaster Model FDD2500

Service Manual

for

Model FDD2500

Warning Labels.................................... 12

Installation .......................................... 13

Programming ...................................... 14

Start-up & Adjustments ...................... 17

Cleaning .............................................. 18

Shipping Preparation........................ 110

Replacing Controller ............................11

Replacing Components ........................11

Product Out Adjustment......................11

Troubleshooting Guide ........................12

Assembly Drawings ..............................14

Wiring Diagrams.................................. 28

Table of Contents

Prior authorization must be obtained from Grindmaster

Corporation for all warranty claims.

© Grindmaster Corporation, 2005 0905 Form # AM-342-02

PRINTED IN USA Part #63361

Grindmaster Corporation

4003 Collins Lane

Louisville, KY 40245 USA

(502) 425-4776

(800) 695-4500 (USA & Canada only)

FAX: (502) 425-4664

www.grindmaster.com

Model FDD2500-1-M-B

Model FDD2500-3-M-B

Model FDD2500-1-3A-B

Model FDD2500-3-3A-B

Page 2

Page 2 Model FDD2500

Warning Labels

The following warning labels were on your dispenser when it was shipped from the factory. They should remain on your dispenser

in good, readable condition at all times. If one of your labels is missing or damaged, order a replacement label immediately.

Part #71582

Located on machine cover and spout mounting bracket.

Part #63370

For FDD2500- -M-B models only

Located on front splash panel

Part #63371

Located next to center spout

Part #62981

Located on front splash panel

Part #63448

Located on tank drain hose

ADVERTENCIA

Contenidos pueden causar

quemadur as severas si el

uso es inadecuado .

AVERTISSEMENT

Contenu peut pr ovoquer

des brûlures grâves si il est

manipul é incorrectement.

WARNING

Contents can cause

severe burns if

handled impr oper ly.

PN# 62981

*

Page 3

Model FDD2500 Page 3

Installation

WATER INLET CONNECTION

The National Sanitation Foundation requires the following for an NSF approved water hook-up:

1. A quick disconnect water connection or enough coiled tubing so that the machine can be moved for cleaning

underneath.

2. An approved backflow prevention device, such as a double check valve to be installed between the machine and

water supply. On units plumbed to permanent water line, installation of a water filter/softener system is recommended

to prevent lime and scale build up in the machine. On units pumping from remote water container, filtered water

is recommended to prevent lime and scale buildup in the machine.

3. Water pipe connections and fixtures directly connected to potable water supply shall be sized, installed and maintained

in accordance with Federal, State, and Local codes.

WATER HOOK-UP

1. Install the 4" legs and hand tighten. Install the plastic drain tray onto the

drain tray bracket and install drain grid. (Note: The drain tray is provided with

a drill-out port to allow for plumbing to a drain.)

2. Remove front splash panel for access to water hook-up. (see Figure 1)

3. Ensure the 3/8" water supply hose has sufficient length to allow the machine

to be moved for cleaning or service. Supplying hot water to the machine will

greatly increase the capacity of the machine. The use of copper tubing is

required to prevent rupture when using a hot water supply. A maximum inlet

water temperature of 160°F (71°C) is recommended.

4. Flush the water line to purge any debris from the supply line.

5. Connect a 3/8" water line to the 3/8" male flare connection.

6. Ensure water supply to machine is within 20 to 100psi. Install a pressure

regulator if pressure is too high.

7. Turn on water supply and check for leaks.

WARNING: ELECTRIC SHOCK HAZARD

Only qualified service personnel should perform installation of this appliance.

Improper installation could result in serious injury or death.

WARNING: ELECTRIC SHOCK HAZARD

Always disconnect power to the machine before servicing or cleaning. Risk

of electric shock is present which can cause serious injury or death.

WARNING: ELECTRIC SHOCK HAZARD

Never use the ground conductor as a neutral conductor. Serious injury or

death could occur in the event of a fault condition.

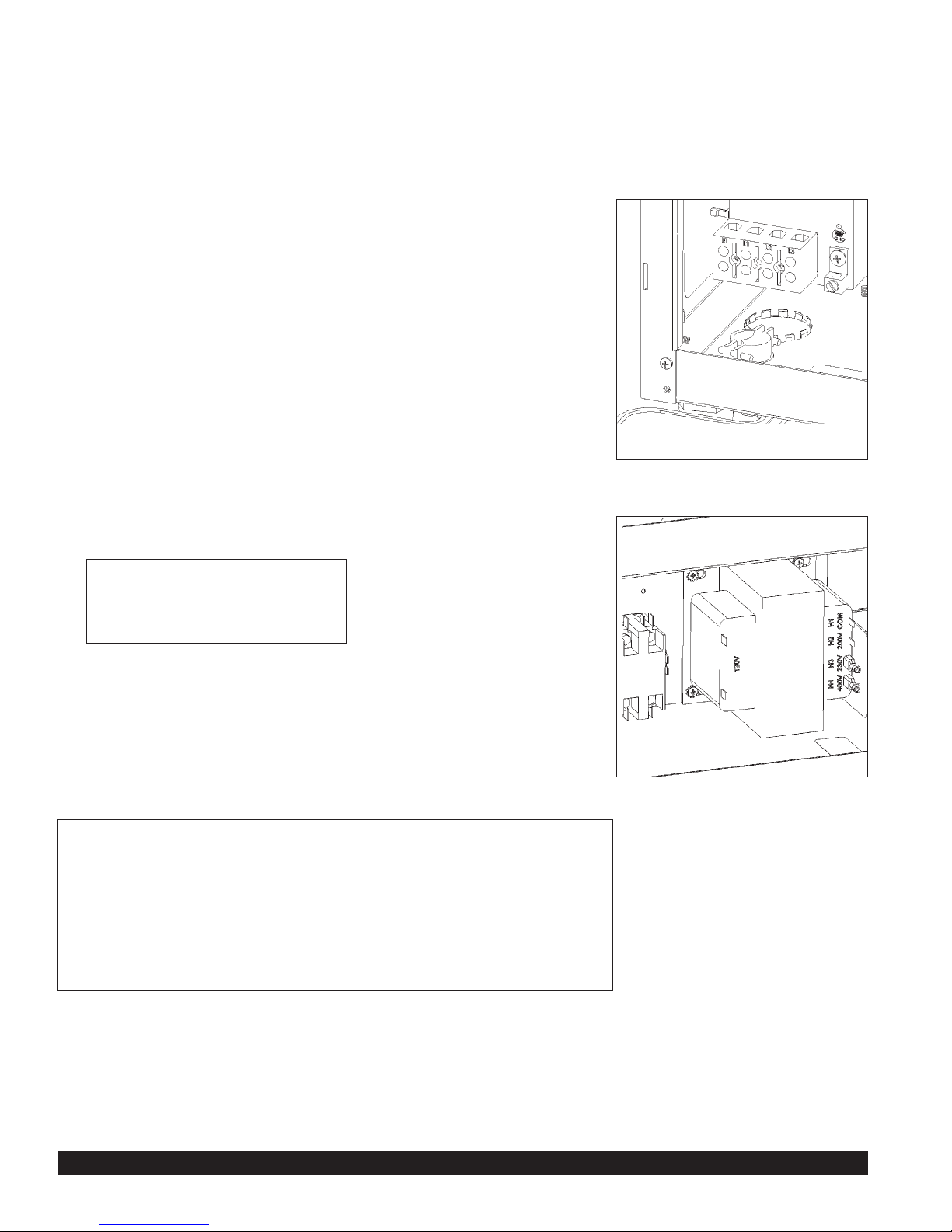

Figure 1

Page 4

Page 4 Model FDD2500

Installation (cont.)

ELECTRICAL HOOK-UP

Ensure water connection is made to machine before proceeding.

The electrical ratings for your dispenser are located on the serial plate on the outside cabinet and inside door.

For configuration of three heater models to optional wattages, refer to page 31 of service manual.

1. For cord connected models, plug the power cord into an appropriate grounded

and dedicated electrical outlet. Go to step 8.

2. For hard-wired models not supplied with an electrical cord, the dispenser

should be connected to a dedicated circuit with a fused disconnect switch or

a circuit breaker near the dispenser.

3. Strain relief is supplied under the machine chassis for power entry.

(see Figure 2)

• Electrical connections and wiring materials must conform to local

codes and/or be in compliance with the National Electric Code

• Use only copper conductors

4. Note: Wiring diagram is on inside of left side panel.

5. Connect the power supply conductors, neutral (optional) and ground wire to

the appropriate positions on the terminal block. The ground lug is separate

from the terminal block. Note: machine is equipped with a stepdown

transformer to provide the necessary 120 volt power supply for the control

circuits. Neutral will not be used.

6. Remove lid and left side panel. (see Figure 3)

7. Install the front splash panel.

8. Install the plastic drain tray into the drain tray rails then place drain grid onto

drain tray.

9. Flip power supply to machine “ON” at the branch supply disconnect.

10. Flip power switch to the “ON” position and allow the water tank to fill. The

machine will make a subtle hissing sound while filling. Allow 3-4 minutes for

fill time depending on water pressure.

Attention: This machine employs an interlock switch to disable

the dispense and fill circuits when the front door is open. Ensure

the front door is closed while installing or operating the machine.

A watchdog circuit also monitors the water level in the tank and

will disable the machine if the water level in the tank is not normal

within (5) minutes of fill time. The machine will require power to

be reset to clear the watchdog timeout.

11. After the water tank has completed the fill cycle, the display will read “Water Heating” signifying that the heating

element has been activated. Allow 10-45 minutes for the display to read “Ready” signifying the water tank has

reached operating temperature. (Note: Heatup time is dependent on water inlet temperature and input wattage

to the machine.)

Figure 2

Figure 3

Move red wire on transformer to:

• “H2” for 208V supply

• “H3” for 240V supply

Page 5

Model FDD2500 Page 5

Programming Machine from Touchpads

Tools Required: None

MACHINE PROGRAMMING: The machine operating parameters can be changed from the touchpad and LCD display

without opening up the machine. (See illustration below).

To enter Programming Mode:

Press and hold (>) and (+) at the same time for approximately 5 seconds.

Tip: Use the eraser end of two pencils to press the buttons if you are having difficulty entering programming mode.

To Exit programming mode at anytime:

• Wait 20 seconds without pressing a button.

• The display will prompt “Exit?”

• Press (+) or (-) to toggle between YES and NO.

• After selecting YES, you MUST press (>) to SAVE changes, or wait for ready message and machine

will exit without saving.

Tip: To verify changes successfully save, re-enter programming mode and check settings.

1) Press (>) to select Language. (1A)

Press (+) to choose English, Spanish, German, or French.

2) Press (>) to set the Time of day on the machine.

Press (+) or (-) to change the time.

3) If password is activated, enter password now.

a) Press (+) to enter first number.

b) Press (>), then (+) to enter second number.

c) Press (>), then (+) to enter third number.

NOTE: The default password is “111”. If the password has been changed and forgotten, press “I/O” and “+” at the

same time to proceed.

4) Press (>) to change Password settings. (2B)

Press (+) or (-) to toggle between ON (enable password) and OFF (disable password).

If ON is selected, press (>) to change password.

a) Press (>) to enter new password. (following steps 3 a, b, c)

b) Press (>) to confirm new password. (following steps 3 a, b, c)

5) Press (>) to program Dispense Settings. (to change Portion Sizes) (2E) (For FDD2500-**-3A models only)

a) Press (+) for message “Select Dispense Button”. (5A)

b) Press the dispense button for the dispense head you wish to adjust the settings. LCD will display L, M,

or R for left, middle, or right dispense head to acknowledge your selection.

c) Once the dispense head is selected, press (+) or (-) to change the amount of time (portion size) for the

beverage being dispensed.

6) Press (>) to change Whipper Settings. (5A1)

a) Press the dispense button for the dispense head you wish to adjust the settings. LCD will display L, M,

or R for left, middle, or right dispense head to acknowledge your selection.

b) Once the dispense head is selected, press (+) or (-) to toggle between ON (turn whipper ON) and OFF

(turn whipper OFF).

7) Press (>) to return to Dispense Settings. (2E)

Repeat steps 6 & 7 for remaining heads.

8) Press (>) to modify Drink Strength. (7A)

a) Press (>) to Select a Dispense Button. (7B)

b) Press the dispense button for the dispense head that you want to change the drink strength for.

c) Press (+) or (-) to modify the auger speed which changes the drink strength (0-100% of maximum auger

speed in 1% increments).

Note: A faster speed will result in a stronger drink and a slower speed will result in a weaker drink.

PROCEED

POWER ON/OFF

(STANDBY)

INCREMENT UP

INCREMENT DOWN

Page 6

Page 6 Model FDD2500

Programming Machine from Touchpads (cont.)

9) Press (>) to modify Auger Delay.

a) Press (>) and select dispense button.

b) Press the dispense button for the dispense head that you want to change the auger ON delay time.

c) Press (+) or (-) to modify the time in tenths of a second.

10) Press (>) to modify Auger Off Delay.

a) Press the dispense button for the dispense head that you want to change the auger OFF delay time.

b) Press (+) or (-) to modify the time in tenths of a second.

11) Press (>) to change Heater settings. (8A)

Press (+) or (-) to toggle between ON (water tank heater ON) and OFF (water tank heater OFF).

12) Press (>) to modify Water Tank Temperature. (7A)

Press (+) or (-) to increase or decrease water tank temperature.

13) Press (>) to modify Low Temp/No Brew settings. (7B)

Press (+) or (-) to toggle between ON (will not allow drinks to dispense if water temperature is below

programmed temperature) and OFF.

a) If turned ON press (>) to modify Minimum Dispensing Temp.

b) Press (+) or (-) to increase or decrease Minimum Dispensing Temp.

14) Press (>) to change Sleep Mode settings. (8A)

Press (+) or (-) to toggle between OFF and ON (forces the water tank temperature to a programmed temperature

after a programmed time of inactivity – used for energy savings).

a) If turned ON, press (>) to change Sleep Mode Settings.

b) Press (+) or (-) to increase or decrease the amount of time the unit is inactive before going into sleep mode.

c) Press (>) to change sleep mode water tank temperature setting.

d) Press (+) or (-) to increase or decrease the water tank temperature during sleep mode.

15) Press (>) to view Manual Dispense mode. (9A)

(Models with manual Free-Flow Tomlinson handles cannot be changed to portion control.)

16) Press (>) for Sales Mode. (14A) (This option for future use. “Free” is currently the default setting.)

17) Press (>) to retrieve Sales Data. (15A)

18) Press (>) to view Total Dispense data (number of drinks dispensed per head). (15B)

Press the dispense buttons that you want to retrieve information about.

After viewing each head’s data, proceed to next step.

19) Press (>) to view Total Brews data. (15E)

LCD will display total number of drinks dispensed by the unit.

20) Press (>) for Clear Data options. (16A)

Press (+) or (-) to toggle between YES (resets sales data counter to “0”) and NO.

Important: After selecting YES and then pressing (>) all data will be cleared immediately.

21) Press (>) to view Dispenser Type. (17A)

LCD will display type of dispenser.

22) Press (>) to display Date Code information. (18A)

LCD will display manufacture date.

23) Press (>) to display Software Version on controller. (19A)

Displays current software version stored in controller memory.

24) Press (>) to Retrieve Error Codes. (20A)

Press (+) or (-) to toggle through and review all error codes. The LCD will display the number of times each

error code has occurred. Error Codes:

SC1: No Water Pressure

SC2: Reset Power (Error has occurred that requires power to be reset).

SC3: Low Water Level (Inlet valve ON for more than 5 minutes.)

Page 7

Model FDD2500 Page 7

Programming Machine from Touchpads (cont.)

24) Press (>) to Retrieve Error Codes. (20A) (cont.)

SC4: Thermistor Failure (Temperature is out of range – less than 32°F or greater than 210°F.)

SC6: Check Heating (Tank is too hot.)

SC8: Overcooling

SC9: Overflow (Water level safety probe is tripped.)

SC10: Adjust Temperature (Temperature adjusted from touchpad.)

25) Press (>) for Clear Error Code options. (20B)

Press (+) or (-) to toggle between YES (clears all stored error codes from memory) and NO.

Important: After selecting YES and then pressing (>) all data will be cleared immediately.

26) Press (>) for EXIT option

Press (+) or (-) to toggle between YES and NO.

Important: After selecting YES, you MUST press (>) to SAVE changes, or wait for READY message and machine

will exit without saving.

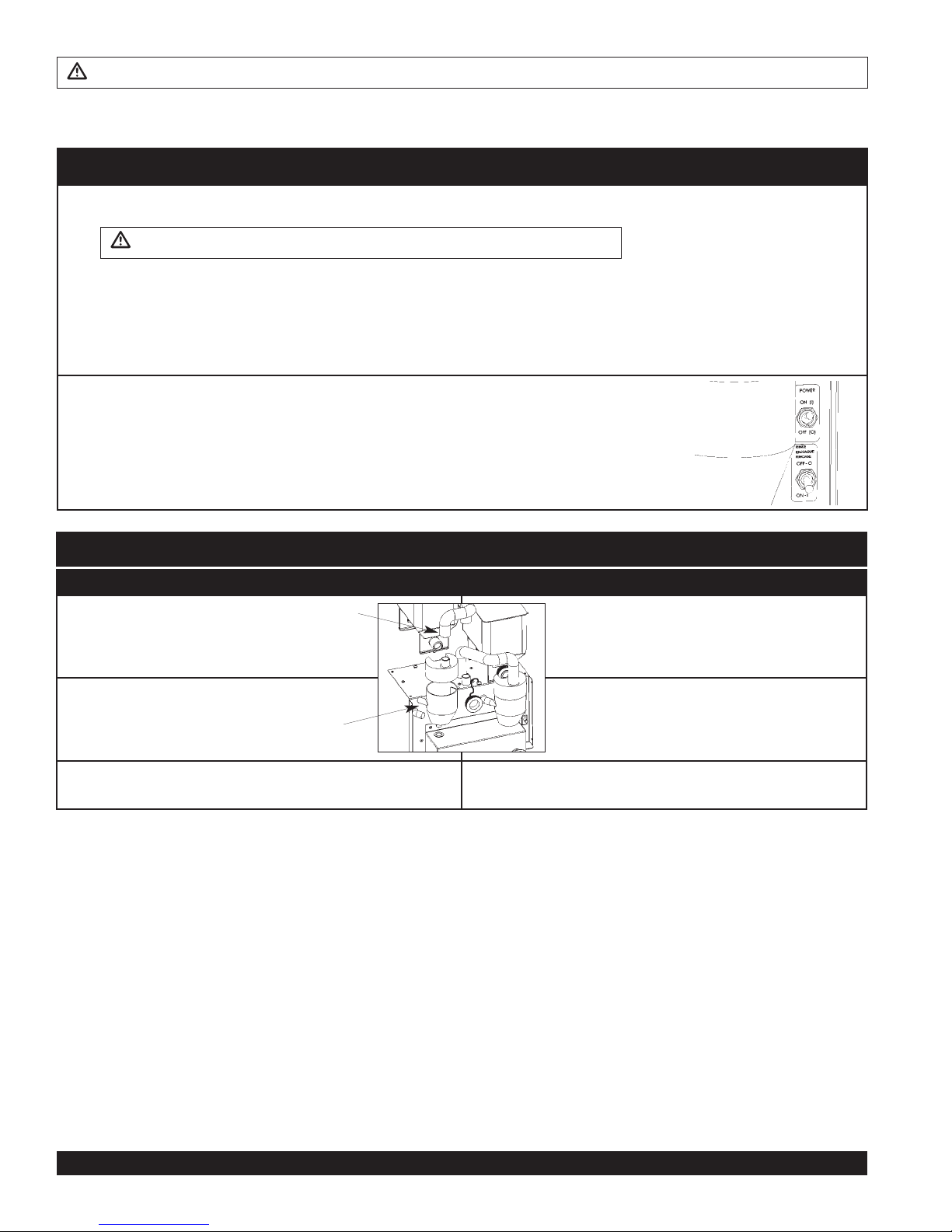

FILLING PRODUCT HOPPERS (see Figure 4)

1) Open door.

2) Lift hinged top.

3) Remove hopper lid.

4) Carefully pour product into hopper.

5) Replace hopper lid.

6) Lower hinged top.

7) Close door.

THERMOSTAT ADJUSTMENT

(See machine programming procedure: Water tank temperature)

Tools required: None

NOTE: The thermostat range is approximately 40°F to 205°F (4°C to 96°C). The water tank temperature is factory set

at 190°F (87°C), making the beverage temperature slightly lower than 190°F (87°C).

HOW TO DISPENSE A DRINK

Machine is equipped to dispense into cups, decanters, 1.3 L servers, 2.2 L airpots or hose connected to 5 gal. containers.

WARNING: Server must rest flat on tray with a 1/4" (6 mm) clearance between cup and spout. Contents can cause

severe burns if handled improperly.

For Manual Machines FDD2500-1-M-B and FDD2500-3-M-B:

1) Place a server under the selected drink dispense nozzle.

2) Pull dispense handle until cup is 2/3 full, then release handle.

For Automatic Machines FDD2500-1-3A-B and FDD2500-3-3A-B:

1) Place a server under the selected drink dispense nozzle.

2) Press and release desired dispense button.

NOTE: To stop a dispense, simply press-and-release any button.

Figure 4

WARNING: Disconnect power before servicing machine.

Page 8

Page 8 Model FDD2500

Weekly Cleaning

ylbmessaeR– lennuF eht gninaelCylbmessasiD – lennuF eht gninaelC

1.

Open the door and remove the large tube

from the funnel cover, then remove the

cover.

1.

Place funnel into position, then

connect hoses.

2.

Remove the mixing funnel by removing silicone tube at the side, then remove funnel.

2.

Place funnel cover on funnel and connect

large tube.

3.

PARTS IN CONTACT WITH FOOD MUST BE WASHED,

RINSED, SANITIZED, AND AIR DRIED.

Daily Cleaning

1.

CAUTION: When cleaning the unit, do not use cleansers, liquid bleach, powders or any other substance that contains

chlorine.These products promote corrosion of stainless steel and plastic parts. Use of these products will void the warranty.

Empty drip pan as needed and wash daily in a dish detergent.

Wipe down all surfaces of the dispense spouts, product storage cabinet, splash panel and drip tray areas with a clean

soft cloth using a mixture of one ounce Ivory liquid detergent (or equivalent) to one gallon of fresh water. Follow by

wiping down all surfaces of the dispense spouts, product storage cabinet, splash panel and drip tray areas with a clean

soft cloth moistened with fresh water and allow to air dry.

2.

Rinse out the funnel by placing the rinse switch (located to the right of the dispensing valves

when the door is open) in the ON position. Dispense one to two cupfuls until the water is clear.

Short bursts of dispensing may also help clean the chambers. When

complete, return the rinse switch to the OFF position.

WARNING: Disconnect power before servicing machine.

WARNING: Do not use a water jet to clean machine. Risk of electric shock.

Cleaning

Page 9

Model FDD2500 Page 9

Cleaning (cont.)

Weekly Cleaning (cont.)

Cleaning Hoppers – Disassembly Cleaning Hoppers – Reassembly

CAUTION: Do not wash hopper without first

disassembling.

IMPORTANT: All components must be completely dry prior

to reassembly.

1.

Open door, disconnect large hose from

funnel cover and then lift off funnel

cover.

1.

Place driveshaft bearing inside hopper

with threads going through hole in the

rear of the hopper.

2.

Lift off ring heater and set aside.

2.

Secure the bearing by attaching the palnut

to the bearing outside rear hopper opening. Use

one hand inside the hopper to push

the bearing outward while turning the

palnut clockwise.

3.

Lift open lid and remove coffee spill

pan.

4.

Remove the hopper from the cabinet.

3.

Install the auger spring driveshaft

and the auger spring by inserting the

flat end of the spring into the

5.

Remove the hopper

cover and empty

hopper contents.

4.

Insert assembly into lower front hopper

opening, making sure the threaded end of

the auger spring driveshaft completely

inserts into the plastic driveshaft bearing in

the rear of the hopper. The driveshaft

bearing threads should be accessible

6.

Remove the auger pinwheel by pulling it

forward while stretching out the sides of

the hopper.

5.

Place the washer over the driveshaft

bearing threads followed by securing

the drivelink onto the driveshaft bearing

by turning counterclockwise. Secure

the auger spring with one hand while

attaching the drivelink with the other.

7.

Remove the drivelink and washer at

the rear of the hopper by holding the

auger spring with one hand at the front

of the hopper while turning the drivelink

clockwise with the other hand.

6.

Replace the auger pinwheel making sure

the pins are securely positioned inside the

locator holes in the hopper.

8.

Remove the auger

spring and auger spring

driveshaft by pulling out

through the lower front opening of the hopper.

7.

Carefully fill

the hopper

with product

and replace

the cover.

9.

Remove the palnut at the

rear of the hopper by turning

it counterclockwise then remove

the driveshaft bearing from the

inside of the hopper.

8.

Reinstall hopper into the

machine, making sure it is

properly aligned.

10.

All parts in contact with food must be washed, rinsed,

sanitized, and air dried.

1

Install ring heater to front spout.

Open lid and install coffee

spill pan.

Driveshaft

Bearing

PULL

Auger Spring

Driveshaft

9.

10.

Install funnel cover with large

tube attached.

Page 10

Page 10 Model FDD2500

Prepare for Shipment

Important: Always completely empty water tank and PRODUCT HOPPERS prior to shipping unit. (See Draining

the Tank and Cleaning the Hoppers section).

NEVER SHIP UNIT WITH PRODUCT IN HOPPER OR WATER IN TANK –

THIS WILL CAUSE IRREPARABLE DAMAGE.

Draining the Tank

Always empty the tank before shipping.

WARNING: Draining of the tank should be performed by a qualified service technician. The tank contains

7.5 gallons (28.4L) of very hot water. May cause severe burns.

1.

Prepare a heat resistant container to drain 7.5 gallons

(28.4L) of hot water from the tank into.

5.

Pinch hose with fingers and

remove the hose clamp

and plug.

2.

Disconnect power to machine.

6.

Allow the tank to drain

completely.

NOTE: It may be necessary to pinch

the hose and stop the water before

container is full. Carefully re-install

plug, then empty container. Repeat

steps 4-6 to completely drain tank.

3.

Remove the drain tray and front access panel.

7.

Once the tank is empty, securely

replace the plug and clamp on

the end of the hose. Reposition

the drain hose.

4.

Locate the silicone drain hose.

Put the end of the drain hose

into the container. Secure the

end of the drain hose (i.e. with

tape) into the container.

8.

Reassemble the front access panel and drain tray.

Page 11

Model FDD2500 Page 11

REPLACING COMPONENTS

Tools Required: Phillips Head Screwdriver

1. Remove drain tray.

2. Remove 2 screws then remove front panel.

3. Remove 4 screws then remove lid.

4. Lift off side panels and/or rear panel.

5. Replace components as needed.

WARNING: Disconnect power before servicing machine.

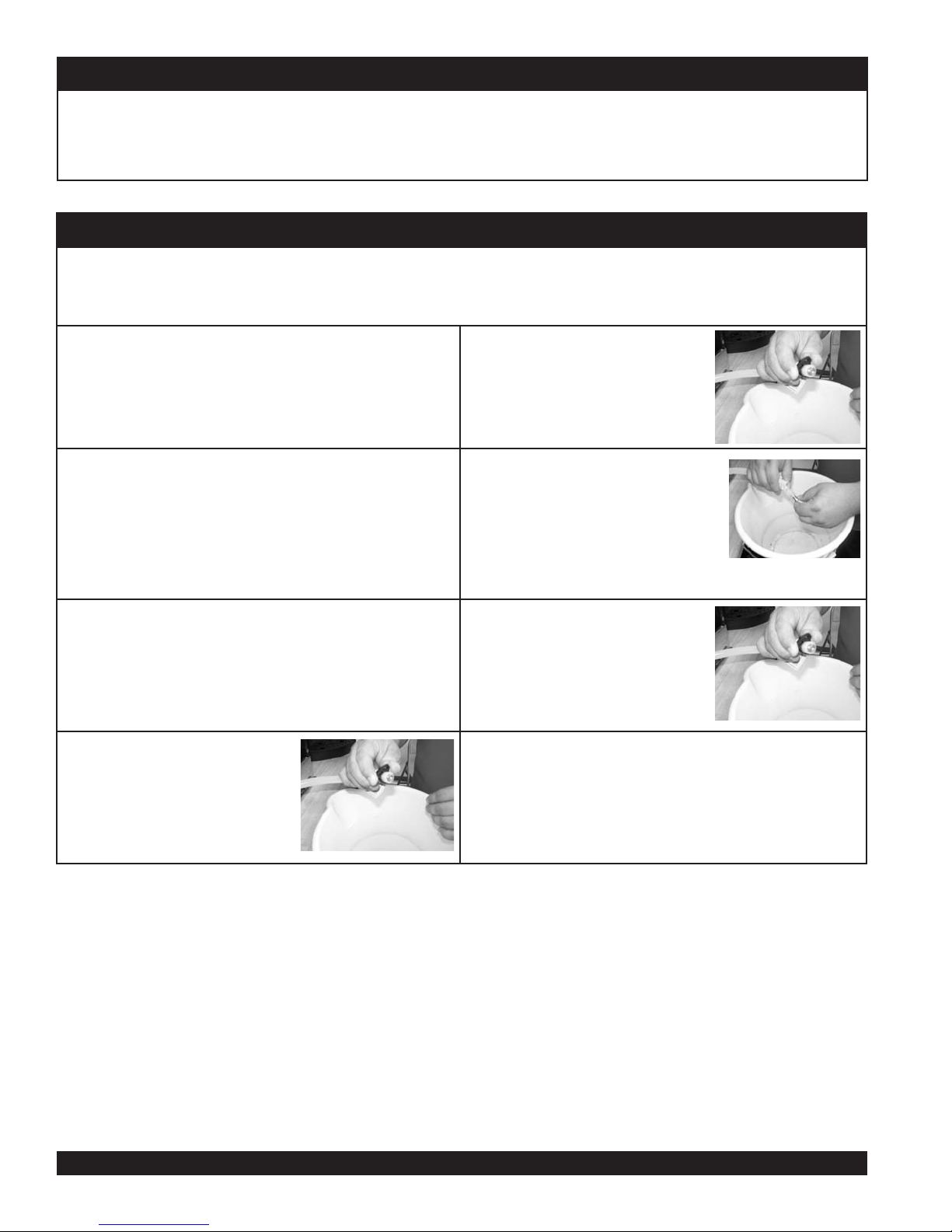

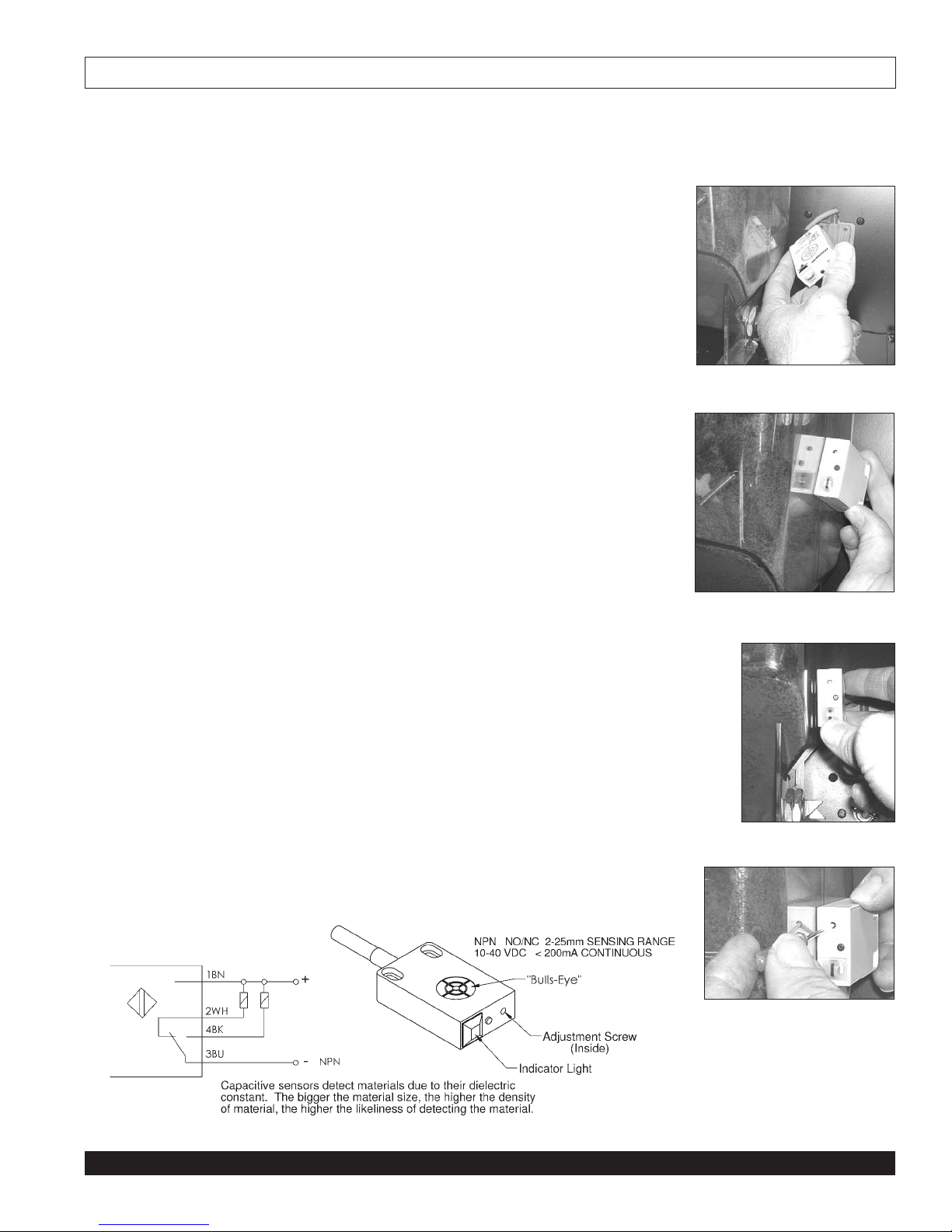

ADJUSTMENT TO “ADD PRODUCT” SENSORS

Capacitive Sensors might need to be adjusted if either situation occurs:

• Hoppers are full and display reads “ADD PRODUCT” when attempting a dispense.

• Hoppers are empty and display does NOT read “ADD PRODUCT” when attempting

a dispense.

Adjusting Capacitive Sensors:

1. Remove both hoppers.

2. Remove Sensor screws and gently pull sensor into cabinet. (see Figure 5)

3. Fill one hopper half full with product.

4. Hold sensor (“bulls-eye” side) flat against the full half of the hopper. (see Figure 6)

* Indicator light should be “ON”

5. Slowly move sensor away from the full half of the hopper.

* Indicator light should turn “OFF” 1/16” from hopper. (see Figure 7)

* If needed, adjust sensor with micro-screwdriver by gently turning adjustment screw.

(see Figure 8)

6. Hold sensor (“bulls-eye” side) flat against the empty half of the hopper. (see Figure 6)

* Indicator light should be “OFF”

* If indicator light is “ON”, adjust sensor with micro-screwdriver until light turns “OFF”.

7. Repeat steps 4 through 6 until no adjustment is needed.

Figure 5

Figure 6

Figure 7

Figure 8

REPLACING CONTROLLER

Tools Required: Phillips Head Screwdriver

1. Remove 4 screws and lift off lid.

2. Lift off right side panel.

3. Carefully disconnect each wiring connector from controller.

NOTE: Pull only on connectors. Do not pull on wires.

4. Carefully spring-back mounting clips and lift controller out of clips.

NOTE: Do not pull or press on sensitive controller components. Handle controller by

touching the edges.

NOTE: Reverse procedure to install controller. Make sure connector ramps and pins

are properly aligned before installing connectors.

Page 12

Page 12 Model FDD2500

Troubleshooting Guide

NOTE: The LCD display provides diagnostic feedback for determining the cause of fault or abnormal conditions. Error codes listed below are

stored in the controller memory and can be retrieved through the programming menu. Additional diagnostic LEDs are located on the controller

located behind the right side panel. See wiring schematics for LED locations and descriptions. Disconnect power before servicing machine.

Failure to do so can result in risk of electric shock.

Problem Possible Cause Solution

LCD display not illuminated

• Power switch turned “OFF”

• No power supplied to machine

• Ground Fault Circuit Interrupter (GFCI)

has tripped

• Machine control transformer circuit breaker

has tripped

• Fuse has blown.

• Faulty wiring connections

• Press and release “I/O” button located under the display.

• Turn power switch “ON”.

• Ensure machine is plugged in at wall socket.

• Reset GFCI (if applicable) at power outlet

• Check if green LED is illuminated on control board located behind

right panel. If LED is not illuminated, reset the control transformer

circuit breaker located next to the

control board.

NOTE: An overload condition can

reoccur. The overload

condition must be diagnosed and

corrected.

• Replace fuse. (see figure on right)

• Ensure all wiring connectors are

plugged into display board and

control board correctly. Check if any

wires have pulled loose from terminals.

LCD display shows error code (i.e. SC 1, 2, 3, etc.)

SC1: No Water Pressure

This feature is disabled and should not appear.

SC2: Reset Power • A fault condition described below has

occurred requiring power to be reset to

machine.

1) Water tank fill circuit has exceeded the

maximum run time (5 minutes)

2) A water tank overflow condition has

occurred

3) A water tank heating condition has

exceeded the water tank temperature set

point due to:

• Welded contacts on heater contactor

• For #1-3, turn power switch OFF for 5 seconds, then ON.

• Call Technical Service for assistance.

SC3: Low Water Level • Machine is filling the water tank

• Faulty water inlet valve electrical connections

• Faulty water inlet valve

• Insufficient water flow rate to machine (typically

during dispensing only).

• Allow machine to fill the water tank

• Ensure electrical leads are properly made to water inlet valve

• Check for power across water inlet valve terminals. If power is not

detected, replace water inlet valve.

• Allow water tank to fill. If problem continues, check for restrictions in

water line and check for proper water pressure (20-100 psi).

SC4: Thermistor Fail • Thermistor is disconnected

• Thermistor was subjected to sudden

temperature change (i.e. filling or

draining tank)

• Thermistor resistance valve is out of

“valid” range

• Check thermistor wiring connections

• Allow water temperature to stabilize, reset power to machine.

• Reset power first, if continues, check thermistor resistance (consult

factory for details), replace if necessary

SC6: Check Heating Water temperature has increased above set

point due to:

• Abnormal increase or decrease in water tank

temperature

• Welded contacts on heater contactor.

• Inlet water temperature must be below temperature set point

of water tank

• Check heater contactor for welded contacts, replace contactor if

necessary

SC9: Overflow condition • Water inlet valve weeping (leaking valve seal)

• Water inlet valve stuck open

• Loose water level probe connection

• Replace inlet valve

• Replace inlet valve

• Check connection to water level probe

Add Product • Hopper is empty

• Hopper is disengaged

• Capacitive sensor needs to be adjusted

• Fill hopper

• Make sure hopper is properly in place

• See “Add Product” Adjustment section on page 9.

Fuse

#63395

Page 13

Model FDD2500 Page 13

Problem Possible Cause Solution

LCD display shows “Standby” • Machine is in “STANDBY” mode • Press “I/O” on touchpad to activate machine. (Standby switch

acts as a power switch to the control module of the machine;

however, the machine is still powered up.)

No water or product is

dispensed

• Machine is in “STANDBY” mode

• Door is open

• Press “I/O” on touchpad to activate machine. (Standby switch

acts as a power switch to the control module of the machine;

however, the machine is still powered up.)

• A door interlock disables the dispense circuit when the door

is open. The door interlock switch is located behind the door

near the lower hinge and can be overridden by pulling the

switch plunger out. The switch will reset when the door is

closed.

No water is dispensed • Blockage in water delivery circuit • Check for kinked water delivery tubing, lime and scale blockage

to and from dump valve.

Powder not dispensing • Coffee dispense outlet clogged

• Hopper drive link not engaged with drive

motor

• Low or no product

• “Drink Strength” setting too low

• Clean hoppers according to cleaning procedure

• Remove and reinstall hopper to engage with drive motor

• Check product container for product

• Check “Drink Strength” setting (see programming guide for

setting Drink Strength)

Water overflows mixing funnel • Powder flow rate too fast – too much powder

to water ratio can prevent adequate mixing

resulting in blockage in mixing funnel

• Outlet is restricted

• Adjust powder flow rate to prevent blockage in mixing funnel

• Ensure mixing chamber outlets are free of blockage. Follow

rinse and cleaning procedure to prevent buildup of product in

mixing system.

Drink is too cold or hot • Check temperature set point and adjust as needed. (Refer to

Programming Guide for Thermostat Adjustment section)

Drink is too weak or strong • Check drink strength to desired taste. (Refer to Programming

Guide for Drink Strength Adjustment)

Water tanks boils water • Water temperature too high for elevation

of installation

• Adjust water temperature down. Refer to Thermostat

Adjustment section.

Troubleshooting Guide (cont.)

If you still need help, call our service department (Monday – Friday, 8 am – 6 pm EST) at (800) 695-4500 (USA and Canada

only) or (502) 425-4776 or an authorized service center in your area. Please have the model and serial numbers ready so

that accurate information may be given. Prior authorization must be obtained from Grindmaster Corporation’s Technical

Services Department for all warranty claims.

Page 14

Page 14 Model FDD2500

FDD2500 Assembly

5

2

38

33

4

20 63098 Logo "Grindmaster" PIC5/6

21 63446 Decal,Kraft Service

22 63358 Pad Top Foam FDD2500

23 63359 Pad Bottom Foam FDD2500

24 63357 Carton, FDD2500

25 63357A CARTON BOTTOM FDD2500

26 63360 Manual Installation FDD2500

27 63361 Manual Service FDD2500

28 100736 Decal,Flavor Strip Kraft Soluble

29 63451 Card Cleaning FDD2500

30 63450 Sheet Installation Check FDD2500

31 63427 Decal CDE for Box

32 92716 Warning Card Assy

33 61157 PLUG, HOLE 1/2 HEYCO #3065

34 71129 NUT, 8-32 KEPS SS

35 61303 Screw, #8 x 3/8 black trilobe

36 61186 Washer, #8 Int Lock

37 63402 Hose Adapter Asy FDD2500

18

12

ITEM NO. PART NO. DESCRIPTION

38 71676 Clamp,.671-.812,Nylon Hose

19

7

1

6

17

3

1 63200 Frame Assy FDD2500

2 63213 Tank Assy FDD2500

3 63211 Blower Assy FDD2500

4 63223 Panel Side Outer FDD2500

5 63224 Panel Rear Outer FDD2500

6 63225 Hopper Shelf Assy FDD2500

7 63238 Lid Assy FDD2500

8 63241 Splash Panel Assy FDD2500

9 63388 Decal Wiring Configs FDD

10 63245 Tray, Drain FDD2500

11 63246 Grid Drain FDD2500

12 63323 Control Brkt Assy FDD2500 Rt

13 63249 Contactor Brkt Asy FDD2500

14 63331 Door Assy FDD2500

15 61123-FDD-Left Hose 1-1/4 ID, 24"

16 61123-FDD-Right Hose 1-1/4 ID, 24"

17 62271 FDD Md Re Tube Silicone 1/2 x 3/4 X 8.75"

18 62271 FDD Rt Re Tube Silicone 1/2 x 3/4 X 6"

15

16

3

37

13

ITEM NO. PART NO. DESCRIPTION

8

FDD2500-1-M-B Shown

19 62271 FDD Lt Re Tube Silicone 1/2 x 3/4 X 8.75"

4

9

14

11

10

20

Page 15

Model FDD2500 Page 15

FDD2500 Frame Assembly

2

2

8

7

19

14

10

4

ITEM NO. PART NO. DESCRIPTION

1 63201 Shell Drawing for FDD2500

2 63202 Bracket Rear Corners FDD2500

9

9

3 63203 Bracket Front Left Corner FDD2500

4 63204 Bracket Front Right Corner FDD2500

13

18

5 63205 Bracket Hinge Top FDD2500

6 63206 Bracket Hinge Bottom FDD2500

12

7 63207 Bracket Upper Brace FDD2500

8 63208 Bracket Tank Cradle FDD2500

11

11

9 60380 RIVNUT, 3/8-16

10 63210 Panel Base Pan FDD2500

12

12

11 63119 Rail, Drain Tray PIC5/6

12 71256 Leg, 4" Plastic

13 62269 Fitting, 1/2" Barb SS

14 07920 Connector, 3/4 Conduit Metal Romex

15 61303 Screw, #8 x 3/8 black trilobe

16 61236 SCRW, 10-32X1/2 PH TR SS

17 61186 Washer, #8 Int Lock

18 63397 Plug, Hole, 1.75" Metal

19 63389 Decal, Field Wiring FDD

63200 - FRAME ASSEMBLY

12

5

5

6

3

Page 16

Page 16 Model FDD2500

FDD2500 Door Assembly

for models FDD2500-1-M-B

FDD2500-3-M-B

7

2

12

13

14

6

23

4

25

20

1

5

3

8

22

23

8

25

20

ITEM NO. PART NO. DESCRIPTION

ITEM NO. PART NO. DESCRIPTION

20 63384 Screw 1/4-20 x 1 SS Ph Hd

21 61303 Screw, #8 x 3/8 black trilobe

1 63332 Door Outer Plastic FDD2500

2 63253 Door Weldment FDD2500

22 63296 Harness Display-Switches FDD2500

23 W0611073 1/4-20 Nylon Lock-nut

3 63401 Display,LCD FDD2500

4 100117 Support,Circuit Board

24 71129 NUT, 8-32 KEPS SS

25 61334 Washer, Slinger

5 63255 Panel Access Rear Door FDD2500

6 100050-FDD Harness Cable Door FDD2500

26 63282 Switch Assy FDD

7 100068 Strain Relief,Heyco,SR5M-3

27 63283 Switch Assy FDD

28 63284 Switch Assy FDD

8 63281 Bracket Display Mtg FDD2500

9 62841 Touchpad, Adj only FDD

29 100736-C Label COFFEE (part of 100736)

30 63443 Label HOT WATER FDD

10 63258 Cover Display Plastic FDD2500

11 63286 Decal Display Cover FDD2500

31 100736-D Label DECAF (part of 100736)

12 62219 Spacer, Key Lock

13 100115 Latch,Thumb

19

14 62556 Cam,Straight,Hook,0.883

15 63289 Sight Gage Assy FDD2500

16 63287 Decal Shuttles FDD2500

17 63292 Decal Upper Door FDD2500

18 63288 Decal Brew Basket FDD2500

19 63298 Screw 1/4-20 x 1/2 SS Ph Hd

17

10

11

15

63331 - DOOR ASSEMBLY FDD2500

28

15

27

9

18

18

26

16

31

30

29

Page 17

Model FDD2500 Page 17

FDD2500 Door Assembly

for models FDD2500-1-3A-B

FDD2500-3-3A-B

12

13

14

31

7

2

6

5

3

22

ITEM NO. PART NO. DESCRIPTION

10

11

15

8

23

8

15

9

25

19

26

26 27

18

3-PORT

20

63434 - DOOR ASSEMBLY FDD2500

23

4

25

20

1

19 63298 Screw 1/4-20 x 1/2 SS Ph Hd

20 63384 Screw 1/4-20 x 1 SS Ph Hd

21 61303 Screw, #8 x 3/8 black trilobe

22 63438 Harness Switch 3-Port FDD2500

23 W0611073 1/4-20 Nylon Lock-nut

24 71129 NUT, 8-32 KEPS SS

25 61334 Washer, Slinger

26 63435 Touchpad Assy 3-Port FDD2500

27 63283 Switch Assy FDD

28 100736-C Label COFFEE (part of 100736)

29 63443 Label HOT WATER FDD

30 100736-D Label DECAF (part of 100736)

31 63452 Decal, Cleaning Door FDD

19

17

1 63332 Door Outer Plastic FDD2500

2 63253 Door Weldment FDD2500

3 63401 Display,LCD FDD2500

4 100117 Support,Circuit Board

5 63255 Panel Access Rear Door FDD2500

6 100050-FDD Harness Cable Door FDD2500

7 100068 Strain Relief,Heyco,SR5M-3

8 63281 Bracket Display Mtg FDD2500

9 62841 Touchpad, Adj only FDD

ITEM NO. PART NO. DESCRIPTION

10 63258 Cover Display Plastic FDD2500

11 63286 Decal Display Cover FDD2500

12 62219 Spacer, Key Lock

13 100115 Latch,Thumb

14 62556 Cam,Straight,Hook,0.883

15 63289 Sight Gage Assy FDD2500

16 63287 Decal Shuttles FDD2500

17 63292 Decal Upper Door FDD2500

18 63288 Decal Brew Basket FDD2500

18

16

30

29

28

Page 18

Page 18 Model FDD2500

FDD2500 Lid Assembly

FDD2500 Splash Panel Assembly

4

2

3

5

1

4

ITEM NO. PART NO. DESCRIPTION

1 63239 Panel, Lid, FDD2500

2 63322 Lid, Hinged Cover FDD2500

3 61792-flat HINGE, PWDR COATED SS 2 LEAF

6

4 61303 Screw, #8 x 3/8 black trilobe

5 61440 CAP, #8 SCREW SOFT

6 71582 Decal, Warning Disconnect

Page 19

FDD2500 Hopper Shelf Assembly

Model FDD2500 Page 19

37

37

25

3

43

46

43

9

40

10

2

17

33

42

42

15

19

21

36

23

11

11

51

11

38

27

31

51

24

16

15

20

36

1

29

30

6

6

63225 - HOPPER SHELF ASSEMBLY FDD2500

20

12

44

48

51

14

8

7

41 61303 Screw, #8 x 3/8 black trilobe

42 65131 HEATER RING ASSEMBLY

43 63383 Sleeve Hopr Nozzle FDD

44 63382 Fitting, Funnel Drop-in FDD

45 63229 Bracket Spout Mtg FDD2500

46 63393 Decal, "THIS SIDE UP"

47 07348-01 RIVET, POP MAXG 1/8 X 1/8 SS

48 63376 Diffuser, Flow FDD2500

49 63371 Decal, Caution Surfaces are Hot

50 71582 Decal, Warning Disconnect

51 71676 Clamp,.671-.812,Nylon Hose

52 70425 TERM, 1/4M INS QD 18-22 GA

10 63321 Bracket Dump Valve Mtg FDD2500

11 62251 Valve Dump Unvented Deltrol

53 61264 Plug, 3/16" Hole

12 62271 FDD Lt Fr Hose Silicone 1/2" x 3/4" x 4.25"

13 62271 FDD Md Fr Hose Silicone 1/2" x 3/4" x 6"

14 62271 FDD Rt Fr Hose Silicone 1/2" x 3/4" x 3.38"

15 61236 SCRW, 10-32X1/2 PH TR SS

16 63235 Spacer, Nylon,.194IDx.312ODx.125L

17 61228 Spacer, NYL HEY #334 SPU98

18 63068 NUT, 10-32 ESNA SS

19 61157 PLUG, HOLE 1/2 HEYCO #3065

20 100068 Strain Relief,Heyco,SR5M-3

21 100205 Fan,24VDC,60mm

22 63236 Cover Funnel FDD2500

ITEM NO. P ART NO. DESCRIPTION

1 63363 Bracket, Hopper Lower FDD

2 63362 Bracket, Hopper Upper FDD

3 63227 Hopper Asy .406P FDD2500

4 63228 Faucet Coffee/Water FDD2500

5 63318 Funnel Mixing FDD2500

6 63319 Fitting Plenum Hose FDD2500

7 63368 Lt 16 Tubing 1"ID PVC Flex Hose

8 63368 Rt 16 Tubing 1"ID PVC Flex Hose

ITEM NO. P ART NO. DESCRIPTION

9 61618 Motor,24VDC,Auger,145 RPM

23 63237 Bracket Fan Louver FDD2500

22

22

24 62218 Switch, Panel Mount Interlock

25 63268 Pan Coffee Catcher FDD2500

26 61440 CAP, #8 SCREW SOFT

27 61847 Switch,Toggle-Spst

28 61847-1 Nut, Switch, for 61847

29 61242 Label, Flush On/Off

5

30 61241 Label,Power

31 61466 Switch,Toggle 16 Amp Dpst

5

32 61466-1 Nut, Switch, for 61466

33 62286 Screw 6-32x1.25 PH PN SS (A601018)

44

45

34 61353 Screw,8-32 X 1/4" PH PN 18-8 SS

13

14

51

51

35 61250 Washer, #8 Split Lock

36 63266 Sensor Capacitive Carlo Gav

37 63267 Bracket Cap Sensor Mtg FDD2500

38 63317 Harness Hopr Brkt FDD

39 60145 6-32 x 3/4" SCREW, PH PN SS

40 71084 Screw 8-32 X 1/2 PH HD

51

51

4

4

4

Page 20

Page 20 Model FDD2500

FDD2500 Hopper Assembly

Page 21

20

Model FDD2500 Page 21

17

6

10

8

4

2

5

21

7

3

1

9

9

9

15

13

18

16

19

17

16

9

14

11

16

17

63213 - TANK ASSEMBLY,

ITEM NO. PART NO. DESCRIPTION

1 63214 Tank Weldment FDD2500

2 63355 Tank Gasket Tank 38"

3 63355 Baffle Gasket Baffle 20"

4 63220 Tank Lid Asy FDD2500

5 63222 Insulation Tank FDD2500

6 63294 Harness Htr 1-Ph FDD2500

12

7 62271 FDD Vent Tubing Silicone 1/2 x 3/4, 33"

8 70635 TERMINAL, 1/4-032 X 45DEG TAB

9 62269 Fitting, 1/2" Barb SS

10 63297 NUT, 10-24 ESNA SS

11 05826 FDD Short Tubing Silicone 3/8 x 5/8 x 5"

12 05826 FDD IValve Tubing Silicone 3/8 x 5/8 x 17"

13 61232 Plug,3/8 Barb

14 61152 Tee, 7/16" Barbed

15 63448 Decal,Tank Drain 5+ Gal

16 07327 Clamp,Hose,21/32ID,Heyco#2322

17 71676 Clamp,.671-.812,Nylon Hose

18 05826 FDD Drain Tubing Silicone 3/8 x 5/8 x 25"

19 62282 Gasket, Bulkhead

20 61353 Screw,8-32 X 1/4" PH PN 18-8 SS

21 60262,18 TAPE, ALUM HI-TEMP 18.25"

Page 22

Page 22 Model FDD2500

FDD2500 Tank Assembly – 3 Heater, 11.1kW

10

20

10

6

8

4

2

7

5

21

3

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 63214 Tank Weldment FDD2500

2 1 63355 Tank Gasket Tank 38"

3 1 63355 Baffle Gasket Baffle 20"

17

1

9

9

9

19

9

17

16

11

16

14

16

18

15

12

4 1 63261 Tank Lid Asy FDD2500

5 1 63222 Insulation Tank FDD2500

6 1 63295 Harness Heater 3-Ph FDD2500

7 1 62271 FDD Vent Tubing Silicone 1/2 x 3/4, 33"

8 1 70635 TERMINAL, 1/4-032 X 45DEG TAB

9 4 62269 Fitting, 1/2" Barb SS

10 3 63297 NUT, 10-24 ESNA SS

11 1 05826 FDD Short Tubing Silicone 3/8 x 5/8 x 5"

12 1 05826 FDD IValve Tubing Silicone 3/8 x 5/8 x 17"

13 1 61232 Plug,3/8 Barb

14 1 61152 Tee, 7/16" Barbed

15 1 63448 Decal,Tank Drain 5+ Gal

16 4 07327 Clamp,Hose,21/32ID,Heyco#2322

17 3 71676 Clamp,.671-.812,Nylon Hose

18 1 05826 FDD Drain Tubing Silicone 3/8 x 5/8 x 25"

19 4 62282 Gasket, Bulkhead

20 6 61353 Screw,8-32 X 1/4" PH PN 18-8 SS

21 1 60262,18 TAPE, ALUM HI-TEMP 18.25"

16

13

17

63263 - TANK ASSEMBLY FDD2500-3, 15kW

Page 23

4

3

2

2

5

2

10

11

8

8

6

7

1

11

9

ITEM NO. PART NO. DESCRIPTION

1 63221 Lid Tank FDD2500

2 71147 GROMMET, SILICONE WHT

3 61108 PROBE, PIC

4 61128 Probe,Thermistor,12"

5 100160 Probe,Safety

6 62305 T-STAT, HI TEMP LIMIT

7 62239 BRKT, T-STAT CE MODEL

8 61353 Screw,8-32 X 1/4" PH PN 18-8 SS

9 62265 Element 240V 6.6kW

10 71585 Elbow,1/2mptx5/8barb 90 brass

11 71586 Nut,Lock,1/2fpt brass

Model FDD2500 Page 23

Page 24

Page 24 Model FDD2500

FDD2500 Tank Lid Assembly – 3 Heater

4

7

7

5

1

6

10

2

10

3

2

8

9

9

ITEM NO. PART NO. DESCRIPTION

10

1 63262 Lid Tank FDD2500

2 71147 GROMMET, SILICONE WHT

3 61108 PROBE, PIC

4 61128 Probe,Thermistor,12"

5 62305 T-STAT, HI TEMP LIMIT

6 62239 BRKT, T-STAT CE MODEL

7 61353 Screw,8-32 X 1/4" PH PN 18-8 SS

8 71585 Elbow,1/2mptx5/8barb 90 brass

9 71586 Nut,Lock,1/2fpt brass

10 62403 Element,240V, 3.7kW

Page 25

FDD2500 Control Bracket Assembly

Model FDD2500 Page 25

10

5

5

5

8

1

5

5

5

63323 - CONTROL BRACKET ASSEMBLY RT FDD2500

ITEM NO. PART NO. DESCRIPTION

1 63324 Bracket Control Right FDD2500

2 63345 Valve Inlet 120V Brass

3 100045 TRANSFORMER, 100VA CHASSIS MOUNT

4 63400 Controller FDD2500

5 61266 STANDOFF, RVRS EDGEMOUNT

3

9

2

6 63346 Fitting 1/2barb x 3/8nptm

7 63347 Fitting 3/8mfl x 3/8nptm

8 71620 Bushing, Hole Heyco 1.094" 2166

9 61303 Screw, #8 x 3/8 black trilobe

10 63293 Harness Right FDD2500 Control

6

9

4

7

Page 26

Page 26 Model FDD2500

ITEM NO. PART NO. DESCRIPTION

9

12

6

10

3

11

13

2

1

7

63280 - CONTACTOR BRACKET ASSEMBLY FDD2500-3

5

9

4

17

8

8

17

18

17

16

17

14

15

18

19

9

20

ITEM NO. PART NO. DESCRIPTION

1 63329 Bracket Control Left FDD2500

2 61131 Relay,12 vdc Coil

3 62262 Terminal Block 4-pole

4 61998 Contactor 4-Pole

5 63373 Transformer StepD 200VA 200/230/460-120

6 63349 Harness Left Side FDD2500

7 63350 Harness Term to Contact 3-Ph FDD

8 62332 Fuseholder, 30A 600V pnl mt

9 63395 Fuse 2 Amp Time Delay

10 63396 Decal, 2 Amp Fuse

11 07921 Lug Ground

12 60394 Bushing,Snap-7/8"OD x 3/4"

13 10073 Label, Ground Symbol

14 62286 Screw 6-32x1.25 PH PN SS (A601018)

15 60746 10-24 x 5/16" SCREW, PH PN 18-8 SS

16 70426 TERM, 1/4F INS QD 18-22 GA

17 61303 Screw, #8 x 3/8 black trilobe

18 60758 WASHER, #10 LOCK EXT SS

19 61159-4 Seal, Closed Cell Foam 4"

20 63449 Decal, Step-Down Wiring

1 63329 Bracket Control Left FDD2500

2 61131 Relay,12 vdc Coil

3 62262 Terminal Block 4-pole

4 62261 Contactor DPST 30A 120V

5 63373 Transformer StepD 200VA 200/230/460-120

6 63349 Harness Left Side FDD2500

7 62457 Harness Htr LCD, FDD 1-ph

8 62332 Fuseholder, 30A 600V pnl mt

9 63395 Fuse 2 Amp Time Delay

10 63396 Decal, 2 Amp Fuse

11 07921 Lug Ground

12 60394 Bushing,Snap-7/8"OD x 3/4"

13 10073 Label, Ground Symbol

14 62286 Screw 6-32x1.25 PH PN SS (A601018)

15 60746 10-24 x 5/16" SCREW, PH PN 18-8 SS

16 70426 TERM, 1/4F INS QD 18-22 GA

17 61303 Screw, #8 x 3/8 black trilobe

18 60758 WASHER, #10 LOCK EXT SS

19 61159-4 Seal, Closed Cell Foam 4"

20 63449 Decal, Step-Down Wiring

1

2

12

17

18

17

4

17

16

17

18

17

5

18

63249 - CONTACTOR BRACKET ASSEMBLY FDD2500-1

6

9

19

10

9

17

8

9

9

8

1

13

18

15

7

3

11

14

20

Page 27

FDD2500 Switch Assembly

FDD2500

Sight Gauge Assembly

1 63285 Plate, Switch FDD2500

8 62270 Pin, Pull Switch A551-015

Item No. Part No. Description

1 63285 Plate, Switch FDD2500

2 62260 Bezel, pull switch (A1101-020)

3

62266 Handle, Pull Switch - Coffee

62267 Handle, Pull Switch - Hot Water

62268 Handle, Pull Switch - Decaf

4 62281 Spring, Pull Switch A522120

5 61887 Switch, Snap Action Micro

6 61883 Bracket, Pull Switch Activation

7 63385 Rod, Pull Switch Modified A1101-019

8 62270 Pin, Pull Switch A551-015

9 71127 Screw 4-40 x 5/8 PH HD SS

10 71128 Nut, 4-40 SS Hex

11 71261 Nut, 8-32 SS ESNA

12 63447 Plate Striker

Model FDD2500 Page 27

FDD2500

Touchpad Assembly

2

1

ITEM NO. PART NO. DESCRIPTION

1 63437 Plate, Switch FDD 3-Portion

2 63436 Touchpad 3-Port FDD2500

2 62260 Bezel, pull switch (A1101-020)

3 62266 Handle, Pull Switch

4 62281 Spring, Pull Switch A522120

5 61887 Switch, Snap Action Micro

6 61883 Bracket, Pullswitch Activation

7 63385 Rod Pull Sw Mod 62259/A1101-019

1

9 71127 Screw 6-32 x 9/16" SS

10 71128 Nut 6-32 Hex SS

11 71261 NUT, 8-32 ESNA SS

12 63447 Striker Pullswitch

10

5

10

12

7

4

11

3

2

8

6

9

9

Page 28

Page 28 Model FDD2500

FDD2500 Blower Assembly

FDD2500 Hose Adapter Assembly #63402

(Optional)

2

ITEM NO. PART NO. DESCRIPTION

1 61103 Fan, Blower 120V .25A

2 63212 Bracket Blower Mt FDD2500

3 63260 Insulation Strip Blower FDD

4 61303 Screw, #8 x 3/8 black trilobe

1

4

3

4

63211 - BLOWER ASSEMBLY FDD2500

Page 29

FDD2500 Wiring Schematic

for all models

Model FDD2500 Page 29

FDD2500 WIRING SCHEMATIC

ALL VOLTAGE SUPPLIES

FAN

FAN

120V

STEAM EXHAUST

THERMISTOR

AUGER

MOTORS

Blk

M

Blk

M

RINSE

Blk

NL1

POWER SUPPLY

120V

TRANSFORMER

Capacitive

Sensor

Right

Capacitive

Sensor

Left

Blk

Red

Yel

L3

L2

PUR/WHT

BLK

120

24 VAC

RED

BN +

BLK SIG

WHT SIG

BLU -

BN +

BLK SIG

WHT SIG

BLU -

DOOR

SWITCH

OR

OR

Blk

2143

Right 0-24vdc

Middle

Augers:

Left

Ground

RED

BLK

TERMINAL

BLOCK

WHT

6587109

2A FUSE

2A FUSE

WHT

COM

COM

YEL

TOUCHPAD

Adj/Rinse

B

l

k

B

l

k

15

12111413

CONTROLLER

12VDC

MASTER

POWER

16

RED

BLK

H1

COM

L2

L1

H2

H3

H4

COM

120V

120V

WHT

BLK

B/W

WHT

WATER TANK

GROUND

OVERFLOW

LEVEL

FDD2500-1 only

SEE SWITCH

WIRING SCHEMATIC

DISPLAY

123

Red

Grn

Blk

Wh

CONNECT RED TO:

CONNECT RED TO:

CONNECT RED TO:CONNECT RED TO:

H2 FOR 208V SUPPLY

H2 FOR 208V SUPPLY

H2 FOR 208V SUPPLYH2 FOR 208V SUPPLY

H3 FOR 240V SUPPLY

H3 FOR 240V SUPPLY

H3 FOR 240V SUPPLYH3 FOR 240V SUPPLY

STEP-DOWN

TRANSFORMER

4

R/Wh

Br/Wh

Or

+24VDC

SEE OTHER SHEETS FOR HEATER CONFIGS

L1

L2

L3

CONTACTOR

120V

WHT

HI-TEMP LIMIT

THERMOSTAT

t°

BRN BRN

HEATER RELAY

NC

C

BLK/WHT

120V

YEL

RED

24VAC

24VAC

NO

12VDC

PUR

PUR

COM

Red

GND

Blk

CABINET

FAN

FDD2500 Wiring All

MJB, 6/29/05

PUR

PUR

R/Blk

Blu/Blk

Y/Blk

Blk

Blk

Blu/W

120V INLET VALVE

120V LEFT DISP VAL VE

120V MIDDLE DISP VALVE

120V RIGHT DISP VALVE

Page 30

Page 30 Model FDD2500

1 Heater, 1 Phase, 60 Hz, 240/208 VAC Configuration

for models FDD2500-1-M-B

FDD2500-1-3A-B

(1) 6.6 kW 240 VAC ELEMENT

6.6 kW (28 AMPS) @ 240 VAC (2 WIRE + GND)

5.0 kW (24 AMPS @ 208 VAC (2 WIRE + GND)

6.6 kW (28 AMPS) @ 120/240 VAC (3 WIRE + GND)

5.0 kW (24 AMPS @ 120/208 VAC (3 WIRE + GND)

HE

ATER #

1

TOP VIEW OF WATER TANK

CONNECT RED WIRE TO:

CONNECT RED WIRE TO:

CONNECT RED WIRE TO:CONNECT RED WIRE TO:

"H2" FOR 208V SUPPLY

"H2" FOR 208V SUPPLY

"H2" FOR 208V SUPPLY"H2" FOR 208V SUPPLY

"H3" FOR 240V SUPPLY

"H3" FOR 240V SUPPLY

"H3" FOR 240V SUPPLY"H3" FOR 240V SUPPLY

460VH4230VH3200V

H2

STEP-DOWN

TRANSFORMER

120 VAC

TO CONTROL CIRCUIT

H1

COM

RED

BLACK

2A FUSE

2A FUSE

N

N

L1L3L2

L2

L1

TERMINAL

BLOCK

L3

T2

T1

CONTACTOR

L2L1

FDD Manual Wiring 1-Ph

Page 31

Three Heater Option Configuration Hookup Diagram

for models FDD2500-3-M-B

FDD2500-3-3A-B

Model FDD2500 Page 31

H

EATER #3

FDD2500-3

3-HEATER WIRING HOOK-UP

3

NOTE: MACHINE IS EQUIPPED WITH

(3) 3.7kW 240 VAC ELEMENTS WHICH

CAN BE CONFIGURED TO ACHIEVE

VARIOUS WATTAGE OUTPUTS PER

THE CHART BELOW DEPENDING ON

POWER SOURCE AVAILABLE.

CONNECT RED WIRE TO:

"H2" FOR 208V SUPPLY

"H3" FOR 240V SUPPLY

H4 H3

460V

H2

230V

200V

STEP-DOWN

TRANSFORMER

H

EATER #2

H

EATER #1

TOP VIEW OF WATER TANK

#10 AWG BLACK HEATER WIRES

ARE CONNECTED TO CONTACTOR

CONNECTIONS "T1,T2,T3,T4"

PER THE CHART BELOW TO

ACHIEVE THE SERIAL PLATE

VOLTAGE AND WATTAGE

CONFIGURATION

2A FUSE

2A FUSE

H1

COM

RED

BLACK

3

2

2

1

1

N

L1

NL1

L2

L3

L2

L3

1

1

T2

T1

CONTACTOR

L2

L1

TERMINAL

BLOCK

3

2

2

3

T4

T3

L4

L3

# OF ELEMENTS

UTILIZED

SINGLE PHASE

0.5

1

1.5

2

0.5

1

1.5

2

THREE PHASE (DELTA CONFIGURATION)

3

3

VOLTAGE

208

208

208

208

240

240

240

240

208

240

120 VAC

TO CONTROL CIRCUIT

AMPSWATTS

1390

2780

4140

5560

1850

3700

5550

7400 30.9 1,2

8340

11100

6.7

13.4

19.9

26.8

7.7

15.5

23

23.2

26.8

CONNECT NUMBERED HEATER WIRES TO

CONTACTOR TERMINALS PER CHART BELOW

1,2

1,2

1,2

1,2

1,2

T1

T2

1

1

1

1

2

1

1,3

1,2

2

1

1,3

1,2

1,3

1,3

T3

1,2

2,2

2,3

3,3

1,2

2,2

2,3

3,3

2,3

2,3

T4

3,3

3,3

-

-

3,3

3,3

-

-

-

-

FDD2500 Wiring 3-Ph

Page 32

Page 32 Model FDD2500

Wiring Schematic within Door

for models FDD2500-1-M-B

FDD2500-3-M-B

Page 33

Model FDD2500 Page 33

Wiring Schematic within Door

for models FDD2500-1-3A-B

FDD2500-3-3A-B

W/R

header 2

BLK

TOUCHPAD

W/R

W/ORG

W/BLU

PUR/W

M

N/O

W/ORG6BLK/W

W/ORG

23

45

LEFT

BRN/W

PINK

TOUCHPAD

32

L

S

132

RIGHT

TOUCHPAD

I/O

">"

"+"

324 3

768

9

S

M

21

PUR

4

14

BLU/W

2610

GRN

12

"-"

16 20

5437891513 1917

header 1

2422 26

W/ORG

30

11

header 2

211 25272931

28

header 1

L

6

5

18

2 x 16 backlit LCD display

RED

3412

WH

GRN

WHT

GRY

TO MAIN

ORG

BLK

R/W

W/BLU

COM

W/R

BOARD

WHT

BRN

ORG/W

W/R

SETTINGS

W/BLU

FDD2500-WIRING DISP 3A

FDD2500-*-3A-B

3-PORTION COFFEE & DECAF

MANUAL HOT WATER

SCHEMATIC WITHIN DOOR

CENTER SWITCH

MANUAL FREE-FLOW

CAP THIS TERM.

GRY/WHT

Page 34

Page 34 Model FDD2500

Page 35

Model FDD2500 Page 35

Page 36

Grindmaster® Coffee Grinders and Brewers • Espressimo® Espresso Machines • Crathco® Hot Beverage Dispensers

Crathco® Cold and Frozen Beverage Dispensers • American Metal Ware® Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

© Grindmaster Corporation, 2005 0705 Form # AM-342-02

PRINTED IN USA Part #63361

Loading...

Loading...