Page 1

Crathco Cold Powdered Beverage Dispensers

Service Manual

For

Models CP3, CP3A, CP33A,

CP3E, CP3AE, CP33AE

Table of Contents

Warning Labels

Installation and moving

Cleaning of unit

Dispensing

Portion and Drink Strength Adjustment

Prepare for shipment

Refrigeration System Maintenance

Preventative Maintenance Checklist

Troubleshooting

Replaceable parts Illustration

Controller and Refrigeration Info

Exploded Views

Wiring Diagrams

Page 3

Page 4-5

Page 6-7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14-15

Page 16-17

Page 18-34

Page 35-37

©Grindmaster Corporation, 2007 0807 Form CC-352-03

Printed in USA

Grindmaster Corporation

4003 Collins Lane

Louisville, KY 40245

(800) 695-4500 (US & Canada only)

Fax (502) 425-4776

www.grindmaster.com

USA

Page 2

Page 3

Warning Labels

r

Part # 71582 – Warning label located on the lower right hand corner of the lower

front panel. “Disconnect power before servicing unit”

Part # 61848 – Warning label located on plenum cover under hoppers on inner

front tray. “Do not pour liquids into tray. Failure to comply will damage the

dispenser and void the warranty” It is also written in French and Spanish as well.

Part # 65288 – Warning label on upper front panel. “Important to prevent

overflow, release button when cup is 2/3’s full. This will produce a full cup”

Crathco Cold Powdered Beverage Dispense

PAGE 3

Page 4

Installation

Installation Notice

A water filter is recommended for the water supply to the dispenser, especially in areas where water contains a

high level of minerals such as calcium or other solids. Over long periods of time, calcium deposits build on

heat-exchanger coils and will lower the cooling capacity of the system. Calcium build-up will also occur on the

strainers enclosed in the inlet of the water valves as well as in the inlet of the dispensing valve.

The cooling system is provided with copper coils, designed to last the life of the dispenser. However, some

chemicals in treated or non-treated water, specifically chlorine and sulfur (sulfide) may shorten the life of the

coils. The initial investment in the filtering system will pay for itself in product quality and by ensuring a longer

life for the machine.

Water Inlet Connection

The National Sanitation Foundation requires the following for an NSF approved water hook-up:

1. A quick disconnect water connection or enough coiled tubing so the machine can be moved for cleaning

underneath without the water being disconnected from the machine.

2. An approved backflow prevention device, such as a double check valveis to be installed between the

machine and water supply.

3. Water pipe connections and fixtures directly connected to potable water supply shall be sized, installed, and

maintained in accordance with applicable codes.

Unpacking

To remove the machine from the box:

1. Remove staples from the top of the box.

2. Remove top padding from the top of box.

3. Using a utility knife, cut the box vertically from the top to the bottom starting at the top rear corner.

4. Cut the box in the front corners.

5. Remove the machine.

If you intend to keep the box:

1. Tilt the box with the machine 45° and remove staples from the bottom - bring the bottom box flaps up.

2. Tilt the box to the opposite side and remove remaining staples - bring the bottom box flaps up.

3. Set the box to normal position and slide the box upward.

4. Remove drip tray accessories from the bottom pad.

5. Remove the machine from the pad.

Start-up Procedure

1. Install drain tray in front of machine.

2. Flush the water line to purge any debris from the supply line.

3. Connect the 1/4” male flare adapter (provided) to the inlet valve on the back of the

machine.

4. Connect the water line to the connection and turn the water supply on.

a. Minimum water pressure to the machine: 20 psi (1.3 bar))

b. Maximum water pressure to the machine: 100 psi (6.8 bar)

5. Plug the power cord into the proper electrical outlet (either 115V 60 Hz or 220V, 50 Hz).

115 Volt power requirements are as follows 115Volt, 60 Hertz 518 watts , 4.6 amperes.

Note : Take precautions to insure the electrical circuit is not overloaded. It is advised

that this unit be installed on a dedicated electrical circuit.

6. Turn the power switch to the “ON” position and allow the water tank to fill. The machine will make a subtle

hissing sound when this occurs. Allow 1-3 minutes for fill time depending on inlet water pressure.

Page 4 Crathco Cold Powdered Beverage Dispensers

Page 5

Installation (cont.)

7. After the water tank has filled, allow 90-150 minutes to build ice-bank depending on ambient temperature

and the initial water temperature. (Green ready light will illuminate when compressor stops and the

machine has reached full cooling capacity.)

8. Remove the powder hoppers, rotate the dispense elbow to the “UP” position and fill with desired powder

product. IMPORTANT: Make sure that the auger inside inside the hopper is correctly installed prior to

filling. Reinstall powder hoppers. Turn dispense elbow down toward the mixing funnel to rest at a 7 o’clock

position.

9. Peel protective film off the merchandiser cover and install graphic. Install flavor decals as needed.

NOTE: If water supply is allowed to run dry, watchdog timer circuit may disable fill circuit. Ensure adequate

water supply for machine, then reset machine by turning power switch “OFF” for 3 seconds and then turning

the power switch back “ON”.

MOVING MACHINE, TANK DRAINING INSTRUCTIONS

Turn the power switch off first.

1. If the CP3 machine needs to be moved, tank draining instructions are as follows.

Indentify the right hand side panel and remove it. Locate the ice bank tank drain hose. Pull the

hose out to allow it to drain into a bucket

Remove blank off plug from hose. The tank will drain all liquid out into the bucket (about 2

gallons of liquid).

The ice bank (about 1.5 quarts) will remain in the tank, to remove proceed as follows.

Place blank off plug back into drain line. Turn power switch on and allow the tank to

refill with water.

Turn off the power switch off and repeat the draining procedurell and drain the tank at

least 3 times to insure all ice is melted away from coils

2. If machine will be exposed to temperatures below 32 degrees F (less than 0 degrees C) all of the water

from the machine must be removed to avoid water freeze-up and damage to the valves.

Follow above procedure for draining the ice bank tank and in addition.

Turn off water supply and remove water supply line from the water inlet valve.

Power up machine.

Apply pressurized air to the inlet valve and at the same time push dispensing button. Repeat

this for each dispensing head. Some water will splash at the dispensing funnel and nozzle.

Air pressure should not exceed 4.1 bar (60 psi).

Crathco Cold Powdered Beverage Dispensers Page 5

Page 6

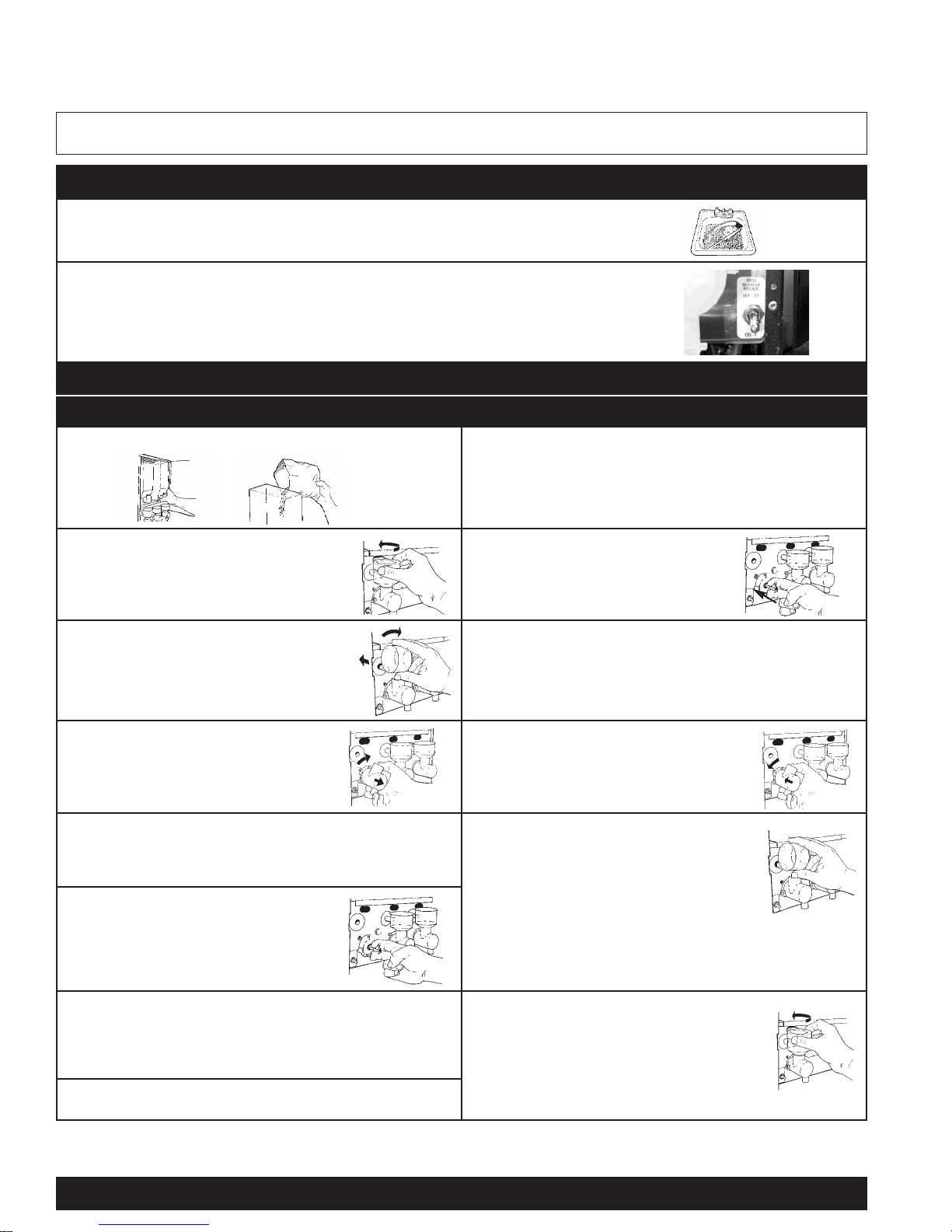

Daily Cleaning (2 times per day)

Empty drip pan as needed and wash in a solution of dish detergent.

Rinse out the whipper chambers by placing the rinse switch (located on the right of the

dispensing valves when the door is open) in the “ON” position. Dispense one to two cups until

the water is clean. Short bursts of dispensing may also help clean the chambers more

effectively. When completed, return the rinse switch to the “OFF” position.

Daily Cleaning (once at the end of the day)

Cleaning the Chambers - Disassembly Cleaning the Chambers - Reassembly

Remove the hoppers and refill with product.

Replace the o-ring onto the whipper shaft.

Open the door and remove the mixing

funnel shroud by pulling forward while

turning 1/4 turn to the right. Lift off and

remove.

Replace the whipper blade by

aligning the flat side inside the blade

with the flat side of the motor shaft.

Push blade firmly onto shaft up to the

end of the flat.

Remove the mixing funnel by lifting the

neck of the funnel out of the whipper

chamber, then tilt clockwise. With one

hand on the water inlet fitting on the back

panel, pull the funnel out of the white ring.

Press dispense nozzle onto whipper

chamber.

Remove the whipper chamber by

rotating it 1/8 of a turn clockwise,

then pull to remove.

Put whipper chamber over whipper

blade and whipper base and turn

counterclockwise until it locks into place.

Remove the dispense nozzle from

the whipper chamber by pulling it

apart.

Replace the mixing funnel by positioning

the large opening up and tilting it slightly

counterclockwise. Lubricate the o-ring on the

water inlet with a film of food grade approved

lubricant. Insert the water inlet into the water

inlet fitting on the back panel then rotate the

funnel to the right until the neck of the funnel seats inside the

whipper chamber opening.

Remove the whipper blade by

grasping the whipper blade with two

fingers and firmly pulling to remove.

Remove the o-ring from the whipper

shaft near the whipper base and wipe

the motor shaft with a clean, damp towel.

Wash o-ring in running water.

Replace the shroud by placing it on the

mixing funnel with the opening to the right.

Turn the shroud to the left until the opening

in the shroud rests inside the opening in the

back panel. If shroud doesn’t rest inside the

opening on the front panel, push in or lift up on

the funnel.

PARTS IN CONTACT WITH FOOD MUST BE WASHED,

RINSED, SANITIZED, AND AIR DRIED.

1.

2.

2.

3.

4.

6.

7.

2.

4.

5.

6.

1.

5.

1.

3.

8.

CAUTION: When cleaning the unit, do not use cleansers, liquid bleach, powders or any other substance that contains chlorine.

These products promote corrosion of stainless steel and plastic parts. Use of these products voids the warranty.

Cleaning

Page 6 Crathco Cold Powdered Beverage Dispensers

Page 7

Weekly Cleaning (cont.)

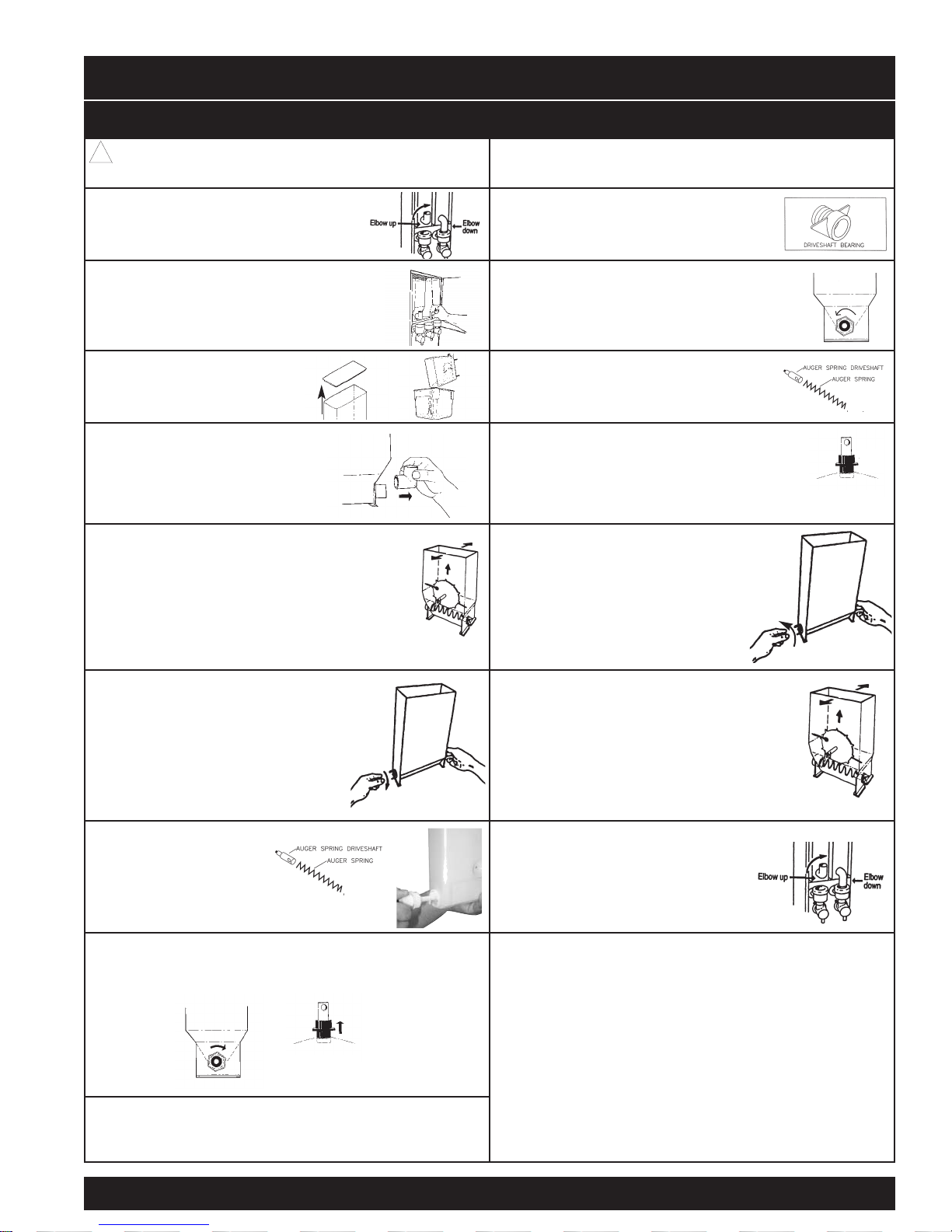

Cleaning Hoppers - Disassembly Cleaning Hoppers - Reassembly

CAUTION: Do not wash hopper without first

disassembling.

IMPORTANT: All components must be completely dry

prior to reassembly.

Open door and rotate elbow on hopper

to the UP position to prevent spillage.

Place driveshaft bearing inside hopper

with threads going through the hole in

the rear of the hopper.

Remove the hopper from the cabinet.

Secure the bearing by attaching the palnut

to the bearing at the outside rear hopper

opening. Tighten using fingers only. Use one hand

inside the hopper to push the bearing outward while

turning the palnut counterclockwise.

Remove the hopper cover

and empty hopper

contents.

Install the auger spring driveshaft and

the auger spring by inserting the flat end

of the spring into the hole in the auger

spring driveshaft.

Pull off the elbow.

Insert assembly into lower front opening,

making sure the threaded end of the auger

spring driveshaft completely inserts into the

driveshaft bearing in the rear of the hopper.

Remove the auger pinwheel by pulling it

forward while stretching out the sides

of the hopper.

Place the washer over the

driveshaft bearing threads followed

by securing the drivelink onto the driveshaft bearing by turning counterclockwise. Secure the auger spring with one

hand while attaching the drivelink with

the other.

Remove the drivelink and washer at

the rear of the hopper by holding the

auger spring with one hand at the front of

the hopper while turning the drivelink

clockwise with the other hand.

Replace the auger pinwheel making sure the

pins are securely positioned inside the notches

under the hopper.

Remove the auger spring and auger spring

driveshaft by pulling out

through the lower front

opening of the hopper.

Turn the elbow DOWN toward the mixing

funnel. Stop when the elbow is at

the 7 o’clock position.

Remove the palnut at the rear of the hopper by turning it

clockwise then remove the driveshaft bearing from

the inside of the hopper.

All parts in contact with food must be washed, rinsed,

sanitized, and air dried.

!

1.

2.

3.

4.

5.

1.

2.

3.

4.

6.

9.

8.

7.

5.

6.

7.

PULL

Driveshaft

Bearing

PULL

Driveshaft

Bearing

Crathco Cold Powdered Beverage Dispensers Page 7

Page 8

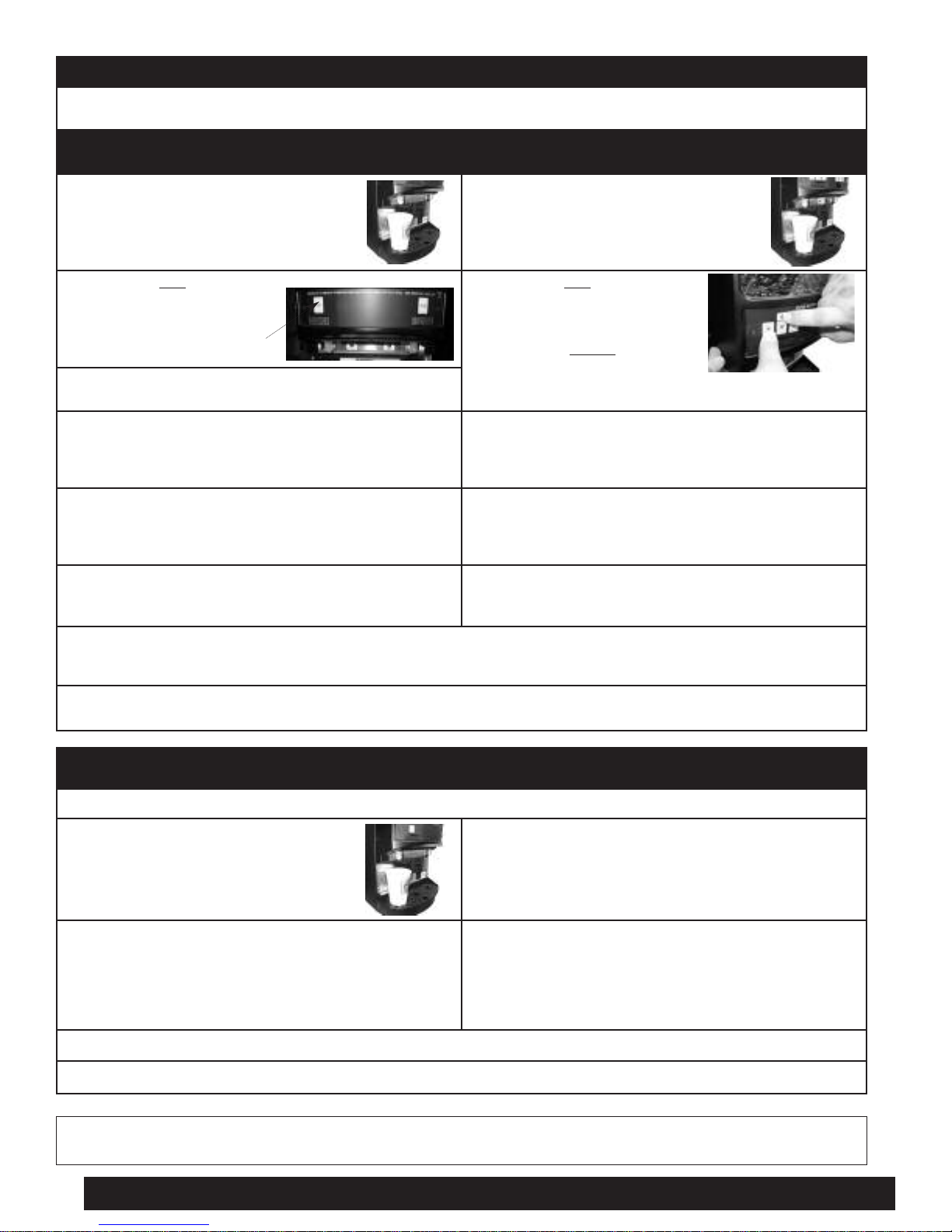

How to Dispense a Cup of Beverage

Models with Manual Dispense Switches

(Refer to serial tag to verify model number of your machine)

Place cup under the selected

1.

drink dispense nozzle.

Push and hold the appropriate

2.

switch on the touchpad until

cup is 2/3 full and then

release switch.

ispense Switch

D

NOTE: Portion may be cancelled by “push and release” of the switch during dispensing.

CAUTION: Cup must rest flat on tray with a 1/4” (6 mm) clearance between cup and spout.

Models with Portion Control

(Single portion or 3 portion per head)

Place cup under the selected

1.

drink dispense nozzle.

Push appropriate switch on

2.

the touchpad, then release

to dispense one preset serving.

(See Portion Control Adjustment

to set portion size)

ispense Switch

D

Changing the Merchandiser Lightbulb

WARNING: Disconnect machine from branch electrical supply before changing the lightbulb.

NOTE: The machine uses a F8T5 12” 8 watt replacement bulb.

Remove the front merchandiser photo

1.

and cover by grasping the edges of the

merchandiser.

Remove the old lightbulb by gently

2.

turning the lightbulb 1/4 turn to the left

and pulling the bulb from the socket.

Install the new bulb by lining up the pins

3.

on either end of the bulb parallel with the

socket opening.

Gently insert both ends of the bulb into

4.

the socket and turn the bulb 1/4 turn to

the right until the bulb locks into place.

Replace the merchandiser photo and

5.

cover.

Page 8 Crathco Cold Powdered Beverage Dispensers

Page 9

Portion Adjustment

If machine is a manual dispense, there are no portion control adjustments to be made. (Please refer to serial tag to

reference model number.

Setting Single Portion Control Setting Three Portion Sizes Per Head

Place a cup under the selected drink

1.

dispense nozzle.

Press and hold the dispense

2.

switch for 10 seconds.

ispense Switch

D

After a 10 second time delay, the machine is triggered into

3.

program mode and will begin dispensing.

Continue pressing the button until cup is approximately

4.

2/3 full, then release the switch to prevent overfill. The

elapsed portion dispense time is saved to memory and

will remain until the dispense switch is reprogrammed.

Check the portion size by placing an empty cup under the

5.

desired dispense nozzle, the press and release the

dispense switch. The machine will dispense the

preprogrammed portion size.

If the portion size is incorrect, repeat above steps until the

6.

desired portion size is achieved. Each dispense switch

needs to be set separately.

Place a cup under the selected drink

1.

dispense nozzle.

Press and hold one of the size

2.

buttons (S, M or L) on the touch

pad. (Hold button throughout entire

procedure).

Then press and release

(top-off) button ( ) . After 10 seconds,

while still depressing portion button, programming sequence

will start.

Continue pressing the size button until cup is approxi-

3.

mately 2/3 full, then release the switch to prevent overfill.

The elapsed portion dispense time is saved to memory

and will remain until the dispense switch is reprogrammed.

Check the portion size by placing an empty cup under the

4.

desired dispense nozzle, then press and release the

dispense switch. The machine will dispense the

preprogrammed portion size.

If the portion size is incorrect, repeat above steps until the

5.

desired portion size is achieved. Each portion size for

each head needs to be set separately.

*

the manual

CAUTION: After button release, there will be 50 ml (1.7 fl. oz.) of water added to the cup. Each dispense includes a 1 second

delay for powder at start and 1 second run-on for water and whipper at end of dispense. This allows for extra rinsing inside the

whipper chamber.

NOTE: Each “S” button on touch pad is pre-set to dispense 150 ml (5 fl. oz.) of water. “M” and “L” settings are not pre-set for

any specified volume unless requested.

Drink Strength Adjustment

Tools Required: Small, Flat Screwdriver

Dispense a drink to determine if drink is

1.

too strong or too weak.

Remove drip tray. Dispense a drink to determine if drink strength is

2.

NOTE: Clockwise rotation will result in a stronger drink and counterclockwise will result in a weaker drink.

NOTE: Water flow rate is factory preset at approximately 24 mL (0.80 ounces) per second.

Using a flat head screwdriver, adjust individual dispense

3.

heads by rotating appropriate adjustment knob.

Clockwise rotation will result in a stronger drink and

counterclockwise will result in a weaker drink.

4.

acceptable, repeat adjustment steps until desired drink

strength is achieved.

NOTE: Machines are factory set in cooling mode to control drinking water temperature between 2.2°C (36°F) and

5.5°C (42°F) and it cannot be adjusted.

Crathco Cold Powdered Beverage Dispensers Page 9

Page 10

Prepare for Shipment

Important: Always completely empty ice bank water tank and POWDER HOPPERS prior to shipping unit. (See

Draining the Tank and Cleaning the Hoppers section).

NEVER SHIP UNIT WITH POWDER IN HOPPER OR WATER IN TANK - THIS MAY CAUSE

IRREPARABLE DAMAGE.

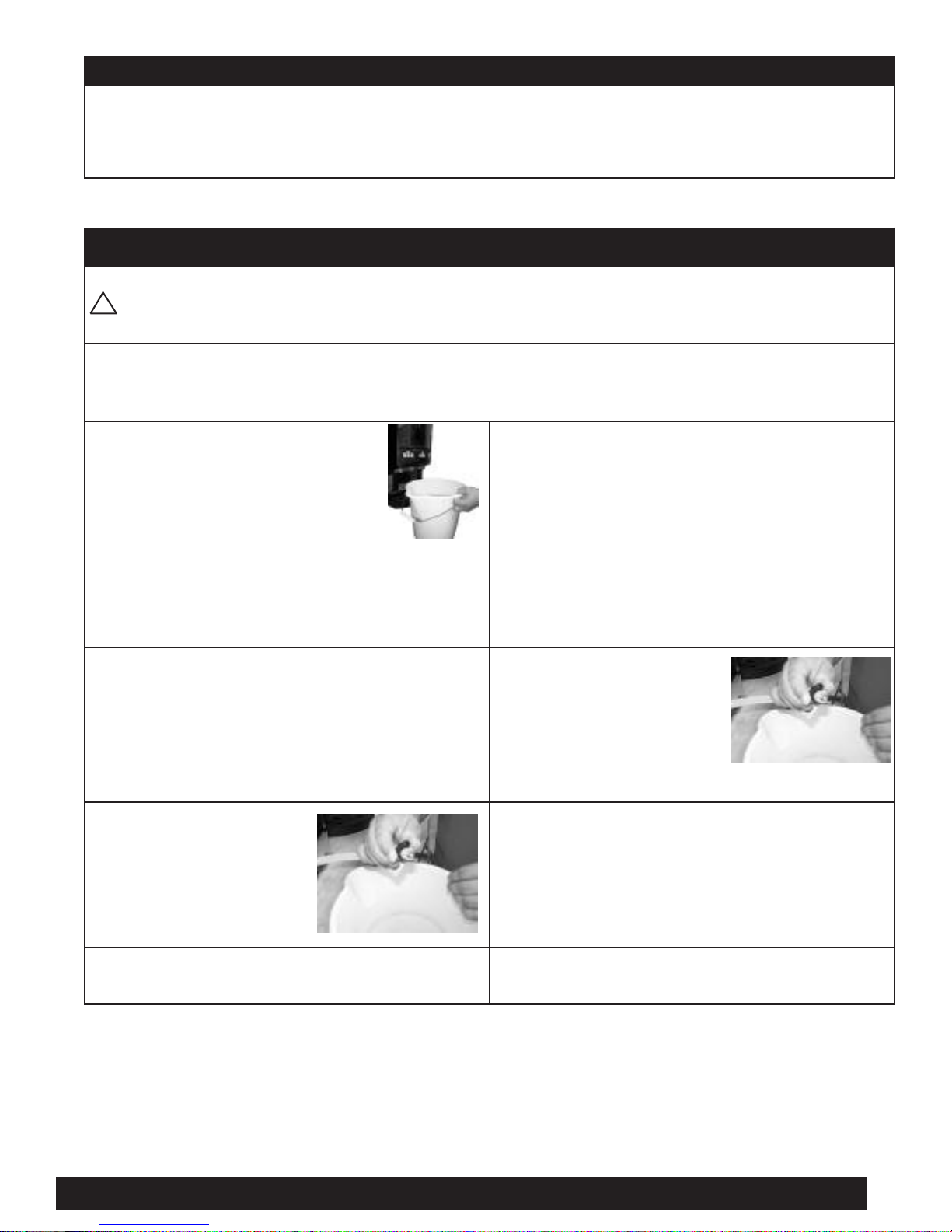

Draining the Tank

Always empty the tank before shipping.

WARNING: Draining of the tank should be performed by a qualified service technician.

!

NOTE: CP3 ice bank tank contains 7.5 L (2 gallons) of water if no ice is present in the tank.

Prepare a container to drain the

1.

tank water into. The container

must hold at least 10 L

(2.6 gallons).

Remove right side louver panel. Drain hose is right behind

2.

the panel routed down and then up to lean against back

wall - The hose is insulated.

Locate the silicone drain hose

3.

end. Put the end of the drain

hose into the container.

Allow the tank to drain completely.

5.

NOTE: It is likely that there will be approximately 4.5 lb

(2 kg) of ice around the evaporator. This ice needs to be

melted and the water drained from the machine:

a) Plug the drain hose

b) Power up the machine

c) Allow to fill the tank.

d) When the compressor starts (fan blade will turn)

turn the machine OFF.

e) Drain the tank.

f) Repeat this cycle three times beginning step (a).

To drain remaining water from

6.

the bottom of the tank, tilt the

dispenser 30° to the right. Once

the tank is empty, securely

replace the plug and

clamp on the end of the hose.

Reposition the drain hose inside

the hose clip.

Replace the louver panel.

7.

Pinch hose with fingers and remove the hose clamp

4.

and plug.

Page 10 Crathco Cold Powdered Beverage Dispensers

Page 11

Refrigeration System Maintenance

Ice Bank Tank Cleaning

NOTE: This procedure may need to be performed once every other year depending on water quality.

If time to make the ice bank or recover the ice bank from the dispensing period is becoming excessively long (e.g. twice as long

as it should take compared to the experience noted in the same ambient conditions) it is likely that there is too much mineral

deposit on the evaporator coil and/or the heat exchanger. The layer of minerals insulates the coil from the water or ice therefore

cooling time increases. To correct the problem, the ice bank tank assembly needs to be cleaned. Proceed as follows:

Turn the power OFF and unplug the machine from the

1.

power receptacle.

Drain the tank (see instructions on page 5). Drain the ice bank tank (see instructions on page 5).

2.

Remove agitator motor from the ice bank tank and clean

3.

any visible mineral deposits from the motor shaft, bottom

of the motor and the propeller.

Through the opening in the lid of the ice bank, add to the

4.

tank a mixture of 1 liter (34 fl. oz.) of distilled vinegar

(clear) and 5 liters (1.3 gallons) of lukewarm water.

Replace the agitator motor.

Disconnect water inlet valve. (Pull the brown wire).

Valve is located on the left side of the machine at the

back.

Turn the machine ON. Replace side panel. The tank and the coils now should

5.

Run the machine for 15 minutes. Turn the machine ON.

6.

Turn the machine OFF.

7.

8.

When water will stop flowing tilt the machine to the right

about 30° to remove remaining water.

Reconnect water inlet valve (brown wire).

Plug the drain hose and start the machine.

9.

When the compressor starts, turn the machine OFF

10.

and repeat this process beginning with step #8 twice.

11.

be free of mineral deposits.

12.

Remove the service panel located under the hoppers.

1.

Remove the dark gray foam filter from plenum.

2.

Bring the filter under running water.

3.

Under the running water, squeeze the filter a couple of

4.

times, by hand, to wash the powder from it.

Squeeze the filter one more time to remove the water

5.

from the foam.

Shake the filter vigorously a couple of times to dry it.

6.

Roll the foam sheet as a tube 1” (25.4 mm) diameter.

7.

Insert the foam into the plenum.

8.

Replace the service access panel.

9.

Install the hopper back into the machine.

10.

Crathco Cold Powdered Beverage Dispensers Page 11

Filter Cleaning

Filter location

Page 12

CP3 Preventative Maintenance Checklist (Every 6 to 12 months)

A preventative maintenance visit should be performed every 6 to 12 months, depending on usage. The following procedures should be

performed during a preventative maintenance visit.

Parts Required: One PM parts kit (Part # 60933).

Tools Required: 11/32 nut driver, needle nose pliers, phillips head screwdriver, food grade lubricant.

The following procedures should be performed by a qualified service technician.

!

WARNING - Risk of electric shock. Disconnect power before servicing.

1. Document model and serial number of equipment above.

2. Disconnect unit from power supply and turn power switch off. Then remove all access panels.

3. Shut off the water supply valve to the machine.

4. Open front door of unit and remove product hoppers. Clean hoppers following procedures on the decal on panel behind

hoppers or as stated in instruction manual.

5. Remove the plenum chamber access panel and filter. Wipe out exposed plenum.

6. Locate the tank drain hose. It is located behind the right side access panel. It is a white silicone tubing that has a 3/8” stainless

steel barb plug and a black 5/8” hose clamp on it.

7. Prepare a container to drain the tank water into. Locate the silicone drain hose on the left side wall. Put the end of the drain

hose into the container. Secure the end of the drain hose

(i.e. with tape) into the container. Pinch hose with fingers and remove the hose clamp and plug. Allow tank to drain completely.

Note: It may be necessary to pinch the hose and stop the water before container is full. Carefully re-install plug, then empty

container. Repeat process until tank is drained completely. Once the tank is empty, securely replace the plug and clamp on the

end of the hose. Refer to Draining the Tank section on page 5.

8. Remove the mixing funnel shroud and mixing funnel from each chamber. Remove and discard the o-ring on the mixing funnel.

Set the shroud and funnel aside.

9. Remove each whipper chamber and whipper blade and discard. Then remove and discard the small whipper shaft o-rings from

each dispense head.

10. Remove the two screws from each whipper base and save the screws. Clean the whipper motor shaft and clean all dried

product in this area under where the whipper base was located. Discard the old whipper base and slinger washer, and

replace with the new parts in the PM kit.

11. Install the new slinger washer onto the whipper motor shaft.

12. Lubricate inside of whipper base with a food grade lubricant. Then install whipper base over the whipper motor shaft and

tighten mounting screws.

13. Check whipper motor shaft to ensure it can turn freely using fingers. If shaft is hard to turn, remove screws, rotate base

180°, and then re-tighten the mounting screws. If the motor shaft is still hard to turn, replace the motor.

14. Install the new, red, small o-rings, along with the new whipper blades, and new whipper chambers. Clean the funnel shrouds

and funnels. Install the new funnel o-ring and lubricate. Install funnel and shroud.

15. Remove plenum through side access opening and remove the plenum hose(s) from the blower to the plenum chamber. Clean

the plenum and either clean or replace the hose. Clean the air filter (see instructions on page 6). If the blower fan is clogged

with powder product clean it by taking apart the blower shroud and blower blade. Re-install clean parts.

16. Turn on water supply, and verify adequate water flow.

17. Plug the power cord back into outlet. Turn main power switch to “on”.

18. Verify water tank is filling. .

19. Allow unit to fill and shut off. Check around valves and any tubing for signs of water leaks. Verify the cooling cycle has started

20. Replace all access panels and reinstall hoppers inside the unit. Verify nut on back of hopper is secure.

21. Verify each dispense head is operating properly and that the settings are correct. Adjust if necessary.

22. Check for proper product temperature and check mix ratio for proper setting, and adjust if necessary.

23. Review proper care, cleaning and maintenance procedures with store personnel.

Page 12 Crathco Cold Powdered Beverage Dispensers

Page 13

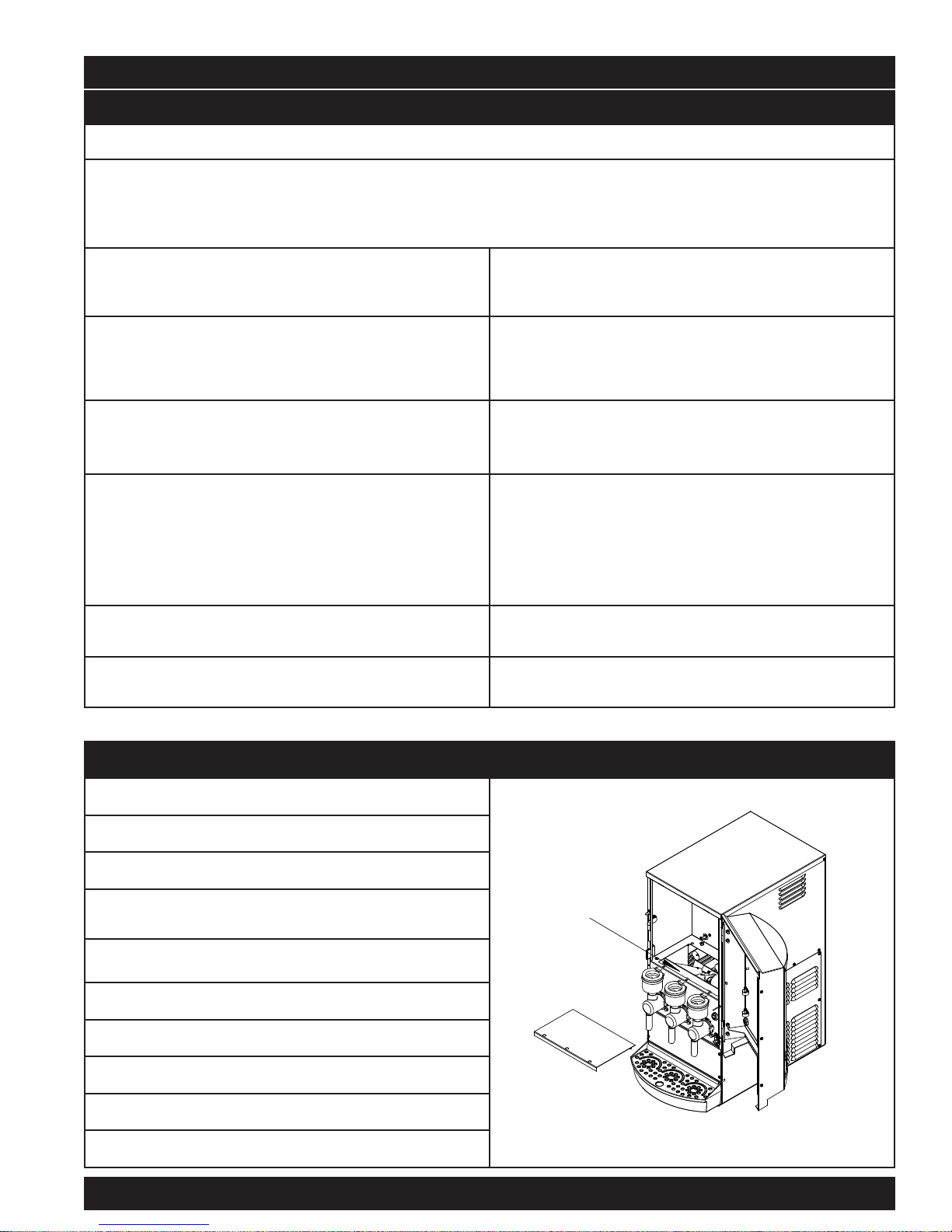

Troubleshooting Guide

Only a qualified service technician should perform electrical and mechanical adjustments or repairs.

Always disconnect power before attempting any maintenance procedures.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Powder is not dispensing • Rinse switch turned to “RINSE ON” position

Machine is not dispensing • Power turned “OFF” to machine

Product not whipping • Whipper blade broken or missing

Water overflows mixing funnel • Water flow too fast

Drink is too weak or strong Refer to Drink Strength Adjustment section (page 4)

No cold water from

dispense head

REFRIGERATION TROUBLESHOOTING

Compressor will not start • No power

Compressor will not start hums but trips on overload

Compressor starts but start

relay does not switch off.

Compressor starts but short

cycles on overload protector

Unit operates long or

continuously

• Powder hopper dispense outlet clogged

• No or low powder level in hopper

• Hopper drivelink not engaged with motor

• Hopper elbow is not directed into the mixing funnel

• Dispense cycle watchdog timer has tripped

• Faulty transformer

• Faulty control board

• Faulty whipper motor speed control

• Faulty whipper motor

• Whipper chamber outlet restricted

• Whipper blade broken or missing

• Water level in tank is below water probe

• Faulty compressor relay

• Tube from dispensing valve is kinked

• Water shorting out probe connections

• Faulty Ice Bank Agitator Motor (ice bank frozen)

• Faulty dispensing triple valve

• Compressor power relay failed (located on

controller board)

• Controller board or water inlet valve failure

• Wiring improper/loose

• Compressor improperly wired

• Low voltage to the unit

• Compressor relay failing to close

• Compressor failure

• Improperly wired

• Low voltage to unit

• Relay failing to open

• Low voltage to the unit

• Overload protector defective

• Excessive discharge pressure

• Compressor is too hot, return gas line (suction is hot)

• Compressor motor has windings shorted

• Frequent dispensing cycle

• Dirty condenser

• Unit is low on refrigerant

• Flip rinse switch to “RINSE OFF” position

• Clean hoppers

• Refill hoppers

• Remove and reinstall hopper. Ensure engagement

with motor

• Turn down dispense elbow; align with mixing funnel

• Ensure power switch is in “ON” position, machine is

plugged in and water is turned on

• Reset machine by flipping power switch “OFF” then “ON”

once

• Contact factory for assistance with faulty components

• Verify blade is in place. Replace if broken or missing

• Reset speed control. If cannot reset speed control replace it.

• Contact factory for assistance

• Remove obstruction in mixing chamber or nozzle

• Verify blade is in place. Replace if broken or missing

• Ensure water supply is on to machine and reset power

• Replace relay

• Check tubing for obstructions

• Dry connections on tank

• Thaw out ice bank, replace the motor

• Replace the valve

• Trace power input

• Replace relay

• Check power light is ON

Check if ice bank has sufficient water level (compressor

will not start unless ice bank has correct water level)

• Check wiring against wiring diagram (compressor

electrical box, water inlet valve or compressor power relay)

• Check wiring in compressor electrical box

• Determine reason and correct

• Replace relay (compressor electrical box)

• Replace compressor

• Correct wiring

• Determine reason and correct

• Replace relay

• Determine reason and correct

• Replace overload protector

• Check air flow across condenser (dirty condenser),

restrictions in the refrigeration system

• Check for leaks, low charge

• Replace compressor

• Normal operation

• Clean condenser (removecondenser fan shroud and rear

panel)

• Check for refrigerant leaks and repair then recharge unit.

Suction line frosted • Refrigerant charge too high • Correct the charge (169 grams or 5.91 ounces of R134a)

Liquid line frosted or sweating • Restriction in filter drier (dehydrator)

(more likely end of capillary tube)

If you still need help, call our service department at (800) 695-4500 (USA & Canada only) or (502) 425-4776 Monday - Friday, 8 am - 6 pm EST) or an authorized

service center in your area. Please have the model and serial numbers ready so that accurate information may be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all warranty claims.

Crathco Cold Powdered Beverage Dispensers Page 13

• Replace the filter drier

Page 14

Replaceable Parts

Part # Description Part # Description

PIC 3 Cold

120V/60z

PIC 3E Cold

230V/50z

PIC 3 Cold

120V/60z

PIC 3E Cold

230V/50z

61490 61490 62395 62395

ssy, Hopper 5#, Auger .718

A

Sugarbased, 2 pinwheel

62925 62925 61221 61221

Assy, Hopper 5#, Auger .406

non-sugar, 2 pinwheel

61442 61442 61127 61127

Assy, Hopper 5#, Auger .718

ugarbased, 1 pinwheel

S

62926 62926 60741 60741

Assy, Hopper 5#, Auger .406

non-sugar, 1 pinwheel

Chamber, Whipper

Funnel, Whipper Mixing

-Ring, Funnel

O

O-RIng, Whipper Shaft

61302 61302 65014 65014

Spring, Auger .718 Pitch

Sugarbased Product

61278 61278 61539 61539

Spring, Auger .406 Pitch

Non-sugar Product

61223 61223 100174 100175

Elbow, 3/4 x 3/4 Hopper

61523 61523 61118 61118

Whipper Base Assembly

61458 61458 05096 70271

Controller

Remote Board

100174

Compressor

Lamp, Fluorescent F8T5 8 Watts

100175

Blade, Whipper (4 Blade)

Page 14 Crathco Cold Powdered Beverage Dispensers

Lamp, Red

Page 15

Replaceable Parts

Part # Description Part # Description

PIC 3 Cold

120V/60z

PIC 3E Cold

230V/50z

PIC 3 Cold

120V/60z

PIC 3E Cold

230V/50z

62436 61125 61847 61466

ight, Indicator Green

L

61103 61111 61847 61847

Motor, Fan

65045 65045 62432 62432

Motor Gear, Auger Dispenser

20 rpm for Sugarbased Product

2

65057 65057 62415 62415

Motor Gear, Auger Dispenser

30 rpm for Non-sugar Product

61847

Switch, Power

Switch, Rinse

ouch Pad - Single Portion

T

Touch Pad - Three Portions

61466

61116-01 61117-01 61481 61470

Motor, Whipper

61131 61131 61198 61198

Relay

61194 61194 61892 61892

Starter, FS-5

61196 61468 65062 65020

Ballast

65399

Kraft

restrictor

65399

Kraft

restrictor

65066 65034

61481

Transformer

Tray, Drain

Grid, Drain

Valve Dispensing, Triple Outlet

Valve Inlet, Dual Outlet

61470

Crathco Cold Powdered Beverage Dispensers Page 15

Page 16

Controller Information

Jumper settings

The controller has (5) 3-pin jumpers along side

the left hand side of the controller. The top pin is

number one, the center is number two and the

bottom pin is number three.

See Figure 1

1

O

2

O

3

Cleaning indicator

The J6 jumper is in on the upper left hand corner J6

This controls the cleaning or rinse reminder LED on the front touch

pad. If the jumper is between terminal 1 and 2 the reminder LED is

enabled. If the jumper is between the 2 and 3 terminal the reminder

LED is off. The timing sequence is every 23 hours the reminder will

illuminate the led. To reset: turn the unit to the rinse mode and rinse

each flavor. This will then reset the timer for the next 23 hour

period.

Dispense Function configuration

The J1 jumper is on the left hand side towards the center J1

This is the dispense function configuration. The default is between

pin 1 and 2 (automatic mode) Do not place the pin between the 2

and 3 pin as the unit will not function.

Cleaning indicator reset – Rinse switch reset circuit

The J2 jumper is just below the J1 on the left side center

This has a connector that hold two wires that goes to the rinse

switch. When the rinse switch is turned on, terminals 2 and 3 are

jumped together resetting the cleaning LED.

Speed Control Configuration

The lower left hand side contains three jumpers

These three jumpers will set the controller to

recognize the onboard auger speed controllers.

Set the jumper between 2 and 3 pin for onboard control (shown)

Set the jumper between 1 and 2 pin for remote controllers (front

panel)

Page 16 Crathco Cold Powdered Beverage Dispensers

Figure 1

J2

J5 left

J4 middle

J3 right

Auger speed controllers

These control the speed of the DC auger motors

Page 17

CP-3 Refrigeration System Part Numbers

Filter Drier (65013) Compressor 115 V (100174)

Condenser Shroud (100169)

Condenser Fan (65064) Condenser (100168)

Refrigeration System information;

Refrigerant R-134A Amount 169 Grams (5.91 Ounces)

The refrigeration system builds and maintains a thickness of ice inside and at the bottom of the water tank. The remaining tank

water is in constant motion via the agitator propeller. The dispensing water travels through a heat exchanger coil also inside the

water tank. Therefore the dispensing water is not in direct contact with the tank water but travels through it and is chilled to the

desired temperature. The water level inside the tank is maintained by the control board to a preset level. The refrigeration system

Is sealed and the system is charged with a very precise amount of refrigerant. No gauge access is provided.

C

Crathco Cold Beverage Dispensers

Page 17

Page 18

CP3 Ice Bank Assembly

Page 18 Crathco Cold Powdered Beverage Dispensers

Page 19

CP3 Lower Panel Assembly

Crathco Cold Powdered Beverage Dispensers Page 19

Page 20

CP3 Condenser Assembly

Page 20 Crathco Cold Powdered Beverage Dispensers

Page 21

CP3 Agitator Motor Assembly

Crathco Cold Powdered Beverage Dispensers Page 21

Page 22

CP3 Controller Panel

Page 22 Crathco Cold Powdered Beverage Dispensers

Page 23

CP3 Hopper Shelf Assembly - 120V

65045

65057

Crathco Cold Powdered Beverage Dispensers Page 23

Page 24

CP3 Hopper Shelf Assembly - 220V

Page 24 Crathco Cold Powdered Beverage Dispensers

Page 25

CP3 Hopper Assembly

Crathco Cold Powdered Beverage Dispensers Page 25

Page 26

CP-3 Controller

P-

Controller part number 65014

Page 26 Crathco Cold Powdered Beverage Dispensers

Page 27

CP3 Drink Strength & Portion Control Adjustment

CP3 Auger Speed Adjustment

Crathco Cold Powdered Beverage Dispensers Page 27

Page 28

CP3 Hot Flush Final Assembly

Page 28 Crathco Cold Powdered Beverage Dispensers

Page 29

CP3 Hot Flush Assembly

Crathco Cold Powdered Beverage Dispensers Page 29

Page 30

CP3 Hot Flush Tank Assembly

Page 30 Crathco Cold Powdered Beverage Dispensers

Page 31

CP3 Hot Flush Shelf Assembly

Crathco Cold Powdered Beverage Dispensers Page 31

Page 32

CP-3 Refrigeration and Water System

Page 32

Crathco Cold Powered Beverage Dispensers

Page 33

CP-3 Door Assembly - single portion

Crathco Cold Powdered Beverage Dispensers

Page 33

Page 34

CP-3 Door assembly - three portion

r

Page 34

Crathco Cold Powdered Beverage Dispense

Page 35

CP-3 Wiring Diagram 120 VAC

Crathco Cold Powdered Beverage Dispensers Page 35

Page 36

CP-3 Pictorial Wiring Diagram 120 VAC

Page 36 Crathco Cold Powdered Beverage Dispensers

Page 37

CP-3AE Wiring Diagram with all options shown

Crathco Cold Powdered Beverage Dispenser Page 37

Page 38

Notes and Comment page

Page 38 Crathco Cold Beverage Dispenser

Page 39

Page 40

© Grindmaster Corporation, 2003

PRINTED IN USA

0405 Form # CC-352-01

Part #

Grindmaster® Coffee Grinders and Brewers • Espressimo® Espresso Machines • Crathco® Hot Beverage Dispensers

Crathco® Cold and Frozen Beverage Dispensers • American Metal Ware® Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500 (USA & Canada only)

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

Loading...

Loading...