Grindmaster Brew-11, Brew-10H, Brew-10Q, Brew-10HQ, Brew-11H Operation And Instruction Manual

...Page 1

Table of Contents

Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warning Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Water Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Electrical Hook-up & Start-up Procedure . . . . . . . .5

Operating the Touchpad . . . . . . . . . . . . . . . . . . . . .5

Brewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Setting Throw Weights and Water Portion . . . . . . .6

Timer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Setting the Grind . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Shear Plate Replacement . . . . . . . . . . . . . . . . . . . .8

Water Solenoid Valve Replacement . . . . . . . . . . . .8

Control Board Settings . . . . . . . . . . . . . . . . . . . . . .9

Troubleshooting Guide . . . . . . . . . . . . . . . . . . .10-11

Exploded Views . . . . . . . . . . . . . . . . . . . . . . . .12-16

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . .17

Grindmaster Corporation

4003 Collins Lane

Louisville, KY 40245 USA

(502) 425-4776 (800) 695-4500

(800) 568-5715 (Technical Service Only)

FAX (502) 425-4664

www.grindmaster.com

© Grindmaster Corporation, 1997

PRINTED IN USA

Patents Pending

0505 Form # BW-350-11

Part #70661

Grind’n Brew Coffee Systems™

Operation and Instruction Manual

for

Models: -

11, -21, -10, -20 including H, HQ versions

TABLE OF CONTENTS

Prior authorization must be obtained from

Grindmaster Corporation for all

warranty claims.

Model Grind’n Brew-10

Model Grind’n Brew-20H

Model Grind’n Brew-21

Model Grind’n Brew-11H

Page 2

Warning Labels

Page 2 Grind’n Brew Coffee Systems™

! WARNING:

USE ONLY ON A CIRCUIT THAT IS PROPERLY PROTECTED AND CAPABLE OF THE

RATED LOAD.

! WARNING:

ELECTRONICALLY GROUND THE CHASSIS.

! WARNING:

DO NOT DEFORM PLUG OR CORD.

! WARNING:

FOLLOW NATIONAL AND LOCAL ELECTRICAL CODES.

! WARNING:

WATER CONNECTIONS SHALL COMPLY WITH THE PLUMBING CODE OF BOCA & THE

FOOD SERVICE SANITATION MANUAL OF THE FDA

! WARNING:

DO NOT USE NEAR COMBUSTIBLES.

! WARNING:

FAILURE TO COMPLY RISKS PERSONAL INJURY, DAMAGE TO EQUIPMENT, FIRE OR

SHOCK HAZARD.

! WARNING:

READ THE ENTIRE OPERATING MANUAL INCLUDING THE LIMIT OF WARRANTY AND

LIABILITY BEFORE BUYING OR USING THIS PRODUCT.

! WARNING:

ALWAYS UNPLUG UNIT FROM POWER SUPPLY BEFORE SERVICING.

Page 3

x

x

x

x

x

x

x

x

1810

1810

208

3660

1710

1710

2674 3560 1810 1810 2749 3660

120

120

208/240 120 120 208/240 208/240208/240

1710

1710

2674 3560 1810 1810 2749 3660

120

120

208/240 120 120 208/240 208/240208/240

Page 3 Grind’n Brew Coffee Systems™

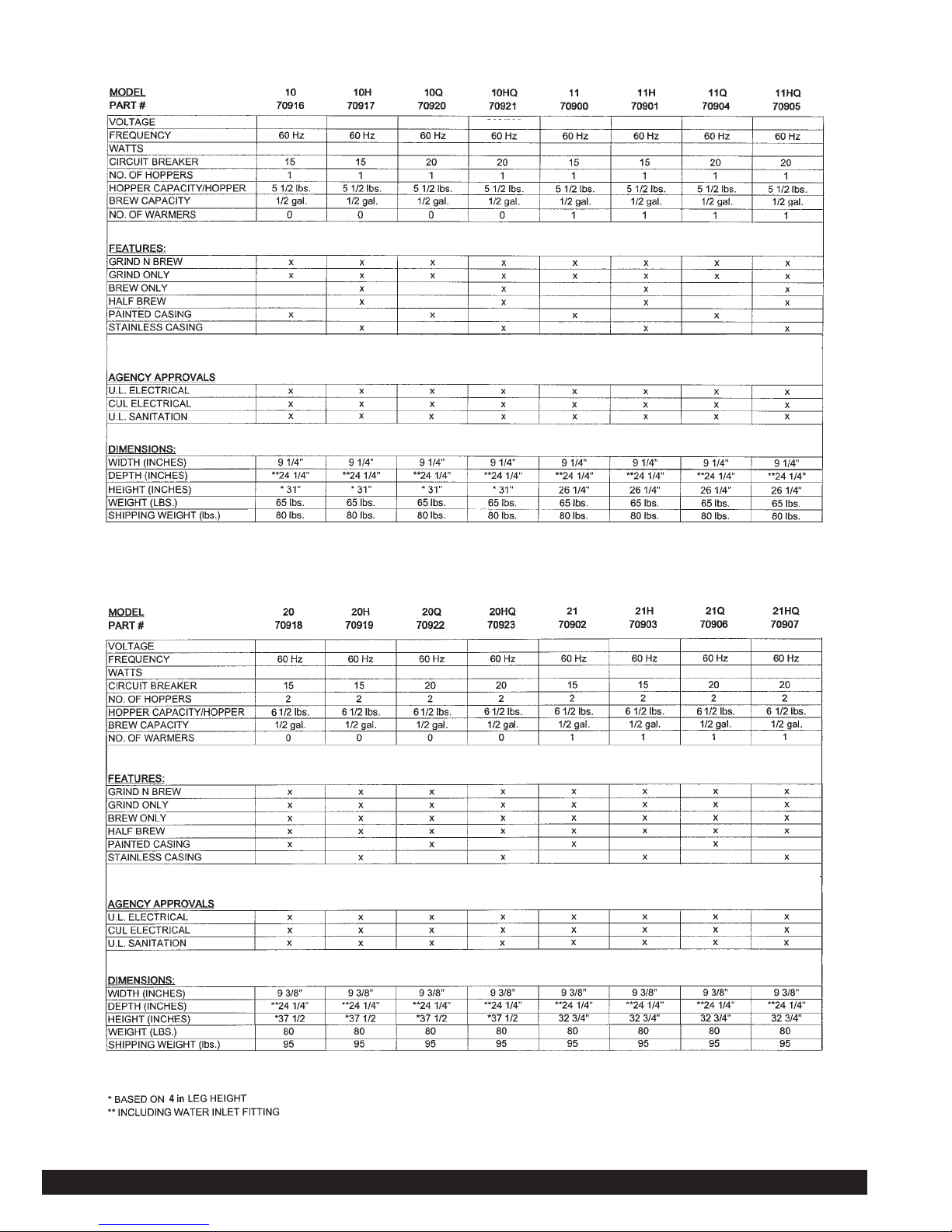

Technical Data - Single Bean Domestic Models

Technical Data - Dual Bean Domestic Models

Page 4

Unit Installation

IMPORTANT: This brewer should be installed by a knowledgeable and experienced commercial

equipment installer.

Brewer Contents

Your brewer package should include the following:

1 Grinderbrewer (either single or dual bean)

1 Operation and Instruction Manual (this manual)

1 Hose to 1/4" flare fitting (part # 61237)

Tools Required for Installation

#2 Phillips screwdriver

9/16" wrench

5/8" wrench

(or crescent wrench)

6" level

NOTE: Other tools may be needed depending on the type of water supply tubing and location.

1. Inspect unit to see if any damage occurred in shipment.

2. Position brewer on counter. Place on sturdy permanent counter top. If you have an airpot brewer, install the 4"

plastic legs (included) at the bottom of the brewer. Lean the brewer towards its side to expose screwholes underneath for legs. Adjust the leg height to suit the size of airpots you will use. IMPORTANT: Adjust the feet to

level the brewer.

With bubble level, check to see that the brewer is level on countertop.

Water Hook-up (All Models) (Refer to Figure A)

IMPORTANT: This equipment must be installed in compliance with applicable Federal, State and/or

Local plumbing codes having jurisdiction. Incoming water pressure should be greater

than 20 psi and not more than 100 psi.

1. The incoming water supply should have a shut-off valve connected in-line. The end should have a female 1/4"

flare fitting. Water supply should be a 1/4" I.D. dedicated line branched off a 1" or larger supply line.

2. Prior to installing the brewer, flush out the water line by running approximately 1 gal. of water into a pail.

This will insure no sediment from a new installation can get in the brewer.

3. Make sure your source water is turned off. Connect the water line’s 1/4" female flare fitting (1) to the 1/4" male fitting on the hose connector (2).

4. Make sure Grind’n Brew is unplugged. Connect the water line to the brewer with the hose connector (2).

5. Turn the water valve on, sending water to the brewer. If there are any leaks, tighten connections to stop leakage.

Figure A

Grind’n Brew Coffee Systems™ Page 4

Page 5

Electrical Hook-up and Start-up Procedure (All Models)

IMPORTANT: Do not plug the unit in yet.

IMPORTANT: This equipment must be installed in compliance with applicable Federal, State and/or

Local electrical codes having jurisdiction. Do not use extension cords. Make sure that

the outlet the brewer plugs into is grounded.

IMPORTANT: Make sure that the Main Power Switch in the back of the unit is in the Off position before

plugging in the brewer.

IMPORTANT: Domestic Q models at 208/230V must have a 4 wire electrical connection. The circuit must

have 2 hots, 1 ground and 1 neutral wire. Failure to install with a 4 wire connection will void

the manufacturer’s warranty. 208/230 Volt Grind’n Brew units require a 20 Amp circuit.

1. Plug the brewer into an electrical outlet (or run power to unit for hardwire applications).

2. Make sure the brew basket is inserted in the brew rails.

3. Reach to the back of the brewer and press the white Main Power Switch to the On position. The front control lights

will go on, and water will enter the brewer. The tank will fill in 2-3 minutes from the moment the Main Power Switch is

turned on.

4. Once the tank is full, it will take 10-15 minutes to heat the water to the brewing temperature. (Cut that time in half for

the 230V “Q” models.) Once the Ready light is lit, you are ready to brew.

Page 5 Grind’n Brew Coffee Systems™

IMPORTANT: Brewers are factory set for throw weight and water portion. Please check that installation

is correct before making adjustment. No adjustments should be necessary for normal

installation.

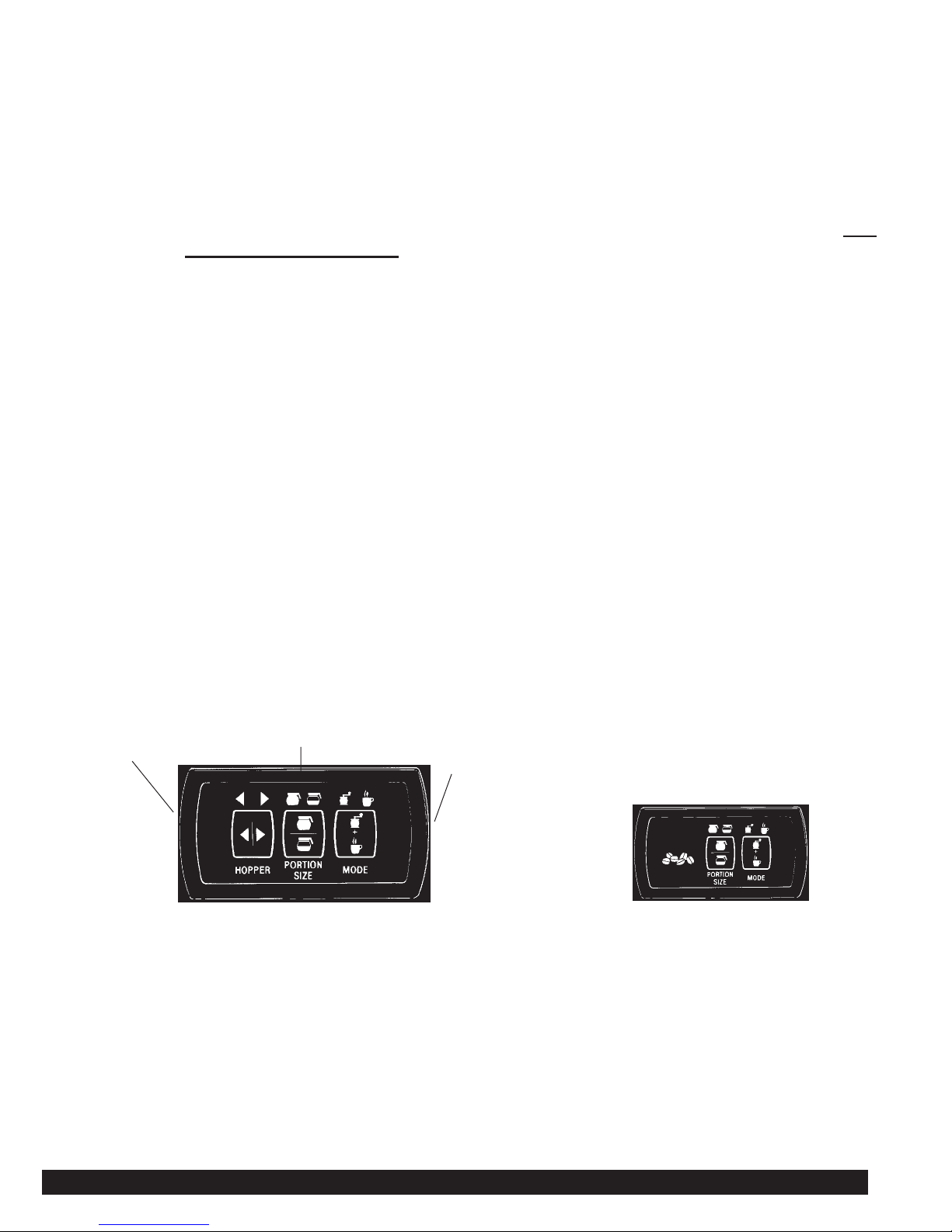

Operating the Touchpad (Refer to Figure B)

1. To select the appropriate bean hopper, press the hopper button until the desired indicator arrow is illuminated.

NOTE: This step only applies to dual bean hoppers.

2. To select a portion size, press the center of the Portion Size button until the half pot or full pot symbol (depending

on your need) is illuminated.

3. The Mode button allows you to select either the “Brew Only”, “Grind Only” or “Grind and Brew” feature.

a) To grind only, press the center of the Mode button until the grinder symbol is illuminated.

b) To brew only, press the center of the Mode button until the coffee cup symbol is illuminated.

c) To grind and brew, press the Mode button until both symbols are illuminated together.

Figure B

(Dual Bean Model)

(Single Bean Model)

Half or Full PotBean Selector

(Dual Bean Models Only)

Grind only

Brew only

Grind and Brew Option

Page 6

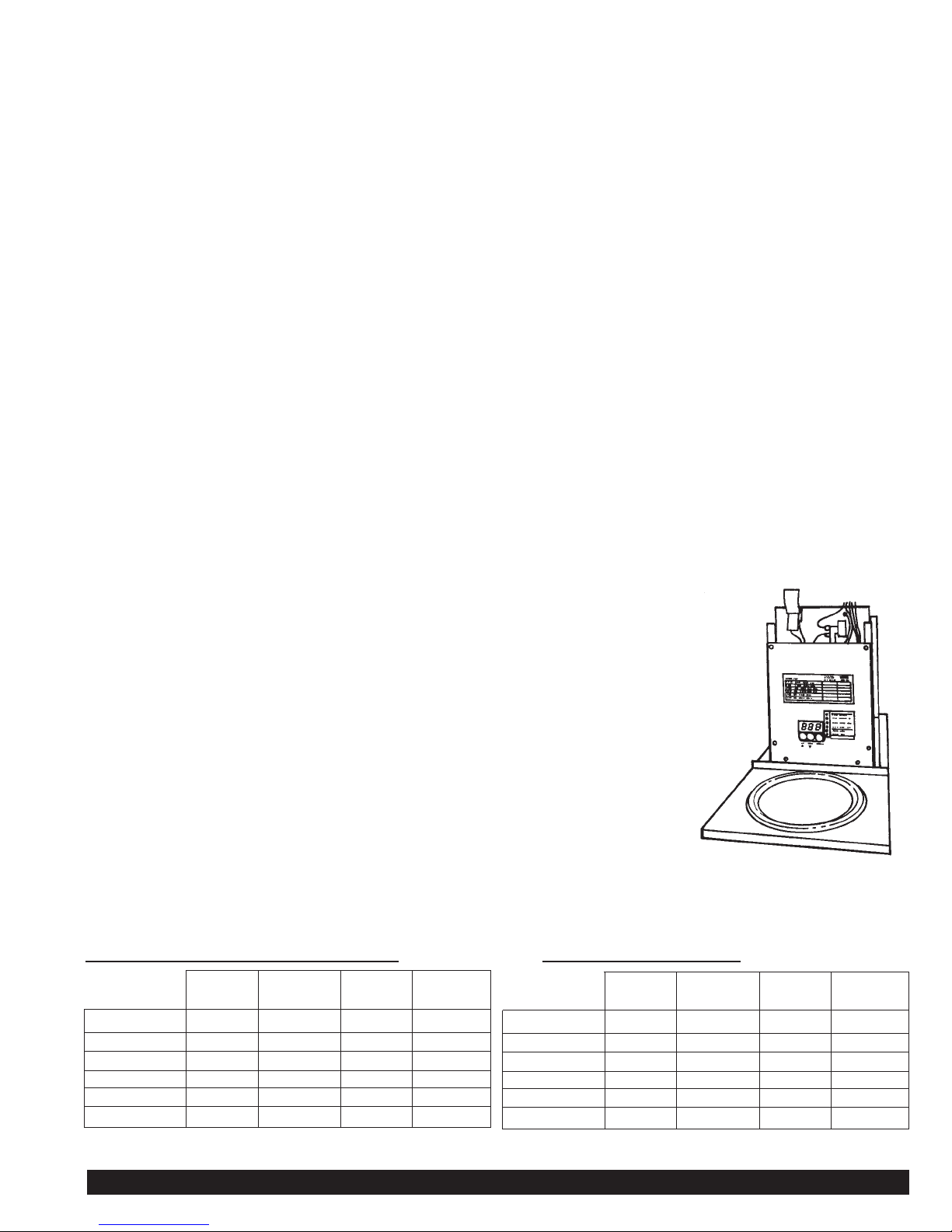

Timer Settings

A standard 64 oz. bottle Grind’n Brew All Airpot Grind’n Brews

• Increase of 1 sec. to timer setting equates to an increase in fluid volume by 1/2 oz.

• Decrease of 1 sec. to timer setting equates to a decrease in fluid volume by 1/2 oz.

Figure C

Setting Throw Weights and Water Portion (Refer to Figure C)

Tools Required: #2 Phillips screwdriver

1. Remove lower front access panel to expose digital timer. Refer to chart to

determine timer setting for the amount of coffee/water you wish to dispense.

2. Use the Select button to toggle to the setting available on your unit.

3. Use the up and down buttons to make your adjustments to the settings, then

press the Select button again to store your new settings. The display will flash

to indicate your settings have been stored. Scroll through the settings to confirm

that the timer setting gives the desired dispense volume.

a.) Brew a pot to confirm that the timer setting produces the desired

dispense volume.

b.) Record your new timer values on the customer settings chart

located on the time face.

4. After a few seconds, the display will shut itself off. The access panel may

be re-installed.

Setting Approx. Setting Approx.

Single Bean yield Dual Bean yield

Single/Left Full Pot 4.2 sec. 2 oz. 5.7 sec. 2 oz.

Right Full Pot - - 5.7 sec. 2 oz.

Single/Left Half Pot 2.4 sec. 1.25 oz. 3.0 sec. 1.25 oz.

Right Full Pot - - 3.0 sec. 1.25 oz.

Full Pot 112-125 sec. 62 fl oz. 112-125 sec. 62 fl oz.

Half Pot 56-63 sec. 31 fl oz. 56-63 sec. 31 fl oz.

Setting Approx. Setting Approx.

Single Bean yield Dual Bean yield

Single/Left Full Pot 4.5 sec. 2.3 oz. 6.2 sec. 2.3 oz.

Right Full Pot - - 6.2 sec. 2.3 oz.

Single/Left Half Pot 2.7 sec. 1.4 oz. 3.7 sec. 1.4 oz.

Right Full Pot - - 3.7 sec. 1.4 oz.

Full Pot 140-153 sec. 72 fl oz. 140-153 sec. 72 fl oz.

Half Pot 70-77 sec. 36 fl oz. 70-77 sec. 36 fl oz.

Grind’n Brew Coffee Systems™ Page 6

Brewing

IMPORTANT: Brewers are factory set for the correct grind and brew times for average situations. You

should not need to make adjustments in the field.

1. Make sure that a new paper filter is in the brew basket and the brew basket is in place in the brewer.

2. Place beans in the hopper.

3. Choose to “Grind and Brew”. Press the far right touchpad so “Grind and Brew” lights are lit.

4. Choose the Portion Size. Press the middle touchpad until desired volume is lit.

5. Choose Decaf or Regular coffee (only applicable to dual bean Grind’n Brews). Press left touchpad.

Arrow will either point left or right for Decaf or Regular.

6. Place a decanter or airpot under the brew basket, depending on the model.

7. Press Start. You will see the coffee bean level go down slightly. You will hear the coffee grind. Coffee is automatical-

ly ground, portioned and placed in brew basket. Then ground coffee is automatically brewed. The Ready light will

now blink, indicating that grinding and brewing are in progress. This will take 3-4 minutes for a 1/2 gal. pot. Portions

are factory set. A stop function is added to the start switch. When this switch is depressed, it allows the unit to stop

during the selected grind, brew or grind and brew functions.

After brewing a pot, the tank must reheat. Reheat time is 5 1/2 - 8 minutes for 120V brewers and half that time

for 230V machines. Remember that the brewer will not function (although the grinder will) until the Ready light is

on, indicating that the water is hot enough to brew. A flashing green light indicates that the brewer is reheating or

that there is a cycle in progress. Do not remove the brew basket while the light is flashing. The brew basket must

be removed before a new brew can be initiated. This feature ensures that the operator discards the old coffee

grounds and installs a new coffee filter.

Page 7

Figure D

Figure E

Setting the Grind (Refer to Figure D)

Tools Required: #2 Phillips screwdriver, 7/8" box wrench, large flat blade screwdriver

1. Remove front decal panel by removing screw on underside of

panel and 2 screws on both sides of panel.

2. Loosen adjusting screw lock nut by turning counter clockwise.

3. Turn slotted adjusting screw clockwise to make the grind coarser

or counter clockwise to make the grind finer.

Generally, a 1/8 to 1/4 turn will provide the desired adjustment.

4. After adjustment has been made, re-tighten the adjusting

screw lock nut.

5. Visually inspect the grind adjustment with a small portion of coffee and

readjust if necessary.

6. Reinstall the front decal panel.

Maintenance

Daily Cleaning

Cabinet: The outside of the machine can be cleaned with a damp cloth, a household dusting

spray or a stainless steel cleaner. Do not use any abrasive such as Scotchbrite or

Brillo pads. These may mar the finish.

Wipe the underside of the cabinet hood with a clean cloth. Be especially careful

when using soap or detergent around the sprayhead. Any soap left on the deflector

may give an unpleasant taste to the first brews.

Warmers: The warmer plate is easy to clean and will maintain its appearance longer if cleaned

regularly. Coffee stains can be wiped off with a damp cloth. Use detergent or

sanitizer for heavy deposits, but refrain from using abrasives.

Weekly Cleaning (Refer to Figure E)

Slide Valve: The slide valve behind the spray deflec-

tor under the cabinet hood should be wiped off with

a clean, dry cloth. Using the finger tab open the slide

valve and wipe the ground coffee from inside of the

spout, seal and slide valve.

NOTE: When the machine is not in use, the finger

tab will automatically activate every 60 minutes

to keep clear.

Brew Basket, Airpots and Decanters: Use com-

mercial grade urn cleaner (as directed by manufacturer) and rinse thoroughly.

Page 7 Grind’n Brew Coffee Systems™

Page 8

Shear Plate Replacement (Refer to Figure F)

Tools Required: #2 Phillips screwdriver, large flat blade screwdriver

1. Unplug the machine.

2. Remove the front panel. Shut off the bean flow to the grinder. Single bean units require you to pull the

bean shut-off valve forward. Dual bean units require you to push the bean shut-off valve back into the

slots in the hopper.

3. Remove the hopper cradle. There are 5 screws (2 in front and 3

across the back) holding the hopper cradle in place.

4. Remove the spray head. First remove the spray deflector by

spinning it clockwise. Second, pull the spray nozzle away

from the mounting sheet.

5. Remove the grind cap by loosening the 2 screws and rotating

the grind cap away from the screws.

6. Pull out the revolving burr and feedworm assembly. The

sweeps on the revolving burr and feedworm assembly. The

sweeps on the revolving burr must line up with the cut outs

on the grind head.

7. Remove the shear cap and broken shear plate.

8. Slide the rotating burr onto the motor shaft, aligning up the

sweeps with the cutouts on the grind head. Rotate the burr

so that the burr is held back into the burr pocket by the sweeps on the grind head lip. Slide the

drive coupler into place. Rotate the slot on the drive coupler with the feedworm. Insert a new

shear plate.

9. Reassemble the remaining components in reverse order of disassembly.

Water Solenoid Valve Replacement (Refer to Figure G)

Tools Required: #2 Phillips screwdriver, pliers, 1/4" sockets

NOTE: The water solenoid valve is accessible from the rear

of the unit. This water valve contains a flow washer which

delivers a constant water flow rate of 0.29 gal. per minute.

1. Unplug the machine.

2. Remove the 2 lower screws from the access panel.

3. Pivot the panel and pull it away from the machine.

4. Disconnect the electrical connections and water line from the

water valve. The water line is removed by sliding the

sleeve on the elbow fitting into the fitting and pulling

the hose out of the fitting.

5. Disassemble the water valve and de-lime.

6. Reassemble in reverse order of disassembly.

NOTE: After reinstallation, make sure that the tubing

from the valve to the top of the tank is not kinked.

Grind’n Brew Coffee Systems™ Page 8

Figure F

Figure G

Page 9

Control Board Settings (Refer to Figure H)

J1 Jumper should remain on pin 1 & 2

J2 Jumper Controls

- No pin connected with jumper - No minimum brewing temperature.

- Jumper connecting 2 & 3 - Low temperature no brew. The brewing cycle will wait until

temperature of water (factory setting) is ready before continuing.

- Jumper connecting 1 & 2 - Disables thermistor. Unit must use a thermostat to operate

properly (not normally used).

Figure H

Page 9 Grind’n Brew Coffee Systems™

Page 10

• Set to portion more coffee.

• Readjust grind to a finer grind.

• Check spray temp, should be greater

than 185°F.

• Adjust brew time at the controller.

• Spray deflector broken or missing. Replace.

• Readjust coffee portion.

• Coarsen grind setting.

• Use proper filter.

• Use no more than 3 1/2 oz. of coffee.

• Coarsen grind.

• You must dump old coffee and use fresh

new filter for each brew.

• Clean, sanitize (de-lime).

• Refer to Regular Maintenance section.

• Remove basket, replace filter, reinstall.

• Turn main power switch, on located on

back of unit (left side from front) on.

• Check outlet with lamp or radio to verify

outlet has power.

• Ensure basket is in position.

• Reset circuit breaker (located on back of

unit) by pushing the reset button in until

you hear a click.

• Remove basket, replace filter, reinstall.

• Replace shear disc. See Shear Disc

Replacement section.

• Remove hopper and clear obstruction.

• Remove hopper and clean obstruction.

• Check for free operation of slide valve.

Adjust solenoid mount or slide valve

mount as required. Make sure white slide

valve gasket is not touching moving

parts.

• Check for blown fuse and replace with

5 Amp fuse.

• Check the length of time grinder runs

with watch.

• Remove upper assembly and clean

obstruction.

• Check for free operation of slide valve.

Adjust solenoid mount or slide valve

mount as required. Make sure white slide

valve gasket is not touching moving

parts.

!

CAUTION: Unplug power cord from outlet before cleaning or servicing the unit.

Troubleshooting Guide

The following procedures must be performed by a qualified service technician.

Weak coffee

Strong coffee

Bitter coffee

Grounds in coffee

Brew basket overflowed

Unpleasant taste

Brewer will not brew

Grinder will not start when

start button is pushed

Grinder runs or hums but

no coffee is dispensed

Quantity of coffee dispensed each throw is not

the same

Problem Possible Cause Remedy

• Not enough coffee used

• Grind is too coarse

• Water not hot enough

• Too much water used (half brews)

• Coffee bed has dry areas

• Too much coffee used

• Grind is too fine

• Paper filter collapsed during

brewing

• Too much coffee

• Coffee ground too finely

• Double batching

• Water tank or brew basket needs

cleaning

• Basket has not been changed

• Main power switch turned off

• No power to outlet

• Basket out

• Circuit breaker has tripped

• Basket has not been changed

• Shear disc is broken

• Obstruction in opening of

auger assembly (on dual bean units)

• Obstruction in opening to

grinding chamber

• Slide valve is bending

• Blown fuse on controller

board (Dual bean only)

• Defective timer in controller

• Slide valve is binding

Grind’n Brew Coffee Systems™ Page 10

Page 11

Troubleshooting Guide (cont.)

Circuit breaker continuously

trips

Basket Out light flashing

w/ 1 sec. on/off pulse

(Control board displays “ER1”)

Basket Out light flashing w/ 0.2

sec. on/off pulse w/ 1 sec. pause

(Control board displays “ER2”)

Water not hot enough

Water boiling (or steaming)

Start switch not working

(Basket Out light illuminated)

No lights are on

(Including Warmer light)

No touch pad lights

(other lights o.k.)

Too much or not enough water

in decanter

Spray head dripping

Hot water spigot dripping

Hot water spigot not dispensing

Warmer Failure

Auger motor, water solenoid,

shutter not working

Basket Out or Brew Cycle

indicators will not light up

• Plug unit directly into outlet. Do not

use extension cord.

• Designate single line for unit. Do not

use multi outlet box.

• Clean or replace water fill valve.

• Turn water supply on.

• Replace if defective.

• Adjust potentiometer.

• Adjust potentiometer.

• Replace Thermistor.

• Replace basket.

• Turn power on.

• Turn switch on.

• Reconnect touch pad.

• Readjust.

• Delime unit.

• Replace seal.

• Delime tank and drain tube.

• Replace seat.

• Check power source.

• Perform continuity test. Replace

defective component.

º

• Replace 5 Amp bus fuse.

• Connect black wire to + terminal of

LED.

• Replace LED.

Problem Possible Cause Remedy

• Insufficient current due to use of

extension cord

• Insufficient current due to

overloaded line

• Water fill valve on too long

• Water supply turned off

• Problem with Thermistor

• Thermistor not set high enough

• Thermistor set too high

• Defective Thermistor

• Brew basket out of place

• No power to brewer

• Power switch turned Off

• Touch pad disconnected

• Water time adjustment

• Lime build up in dump valve

• Faulty seal

• Drain tube limed-up

• Defective valve seat

• Loss of power

• Defective warmer switch or

warmer heater

• Bus fuse on controller board is

blown

• Polarity reversed

• LED burned out

If you still need help, call our Technical Service Department at 800-568-5715 or 502-425-4776, Monday through Friday,

8:00 AM - 6:00 PM Eastern Standard Time or an authorized service center in your area. Please have the model and serial number ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all warranty claims.

Page 11 Grind’n Brew Coffee Systems™

Page 12

Exploded View Grind’n Brew Assembly

Grind’n Brew Coffee Systems™ Page 12

Page 13

Mounting Sheet Assembly

Warmer Assembly

Basket Arm Assembly

Page 13 Grind’n Brew Coffee Systems™

Page 14

Exploded View Hot Water Tank Assembly

Grind’n Brew Coffee Systems™ Page 14

1 61762 PLUG, 5/8" HOLE

2 61128 PROBE, THERMISTOR 12" LG.

3 71147 GROMMET, PROBE

4 61773 COVER, TANK PIC 1

5 70635 FASTON TAB, 1/4" X 0.032"

6 71129 NUT, 8-32 KEPS S/S

7 82116 BRACKET, TANK

8 71084 SCREW, 8-32 X 1/2" S/S

9 71166 NUT, TINNERMAN 8-32 S/S

10

61626 ELEMENT, HEATING 1650 W/ 120V

71375 ELEMENT, HEATING 3500 W/ 240V

11 70824 THERMODISC, BRACKET

12 70410 THERMODISC

13 61317 FITTING 1/8" NPT MF 3/8" BARB

14 61143 NUT, PIPE JAM 1/8" NPT

15 07327 CLAMP, HOSE 5/8"

16 05826 TUBING, 3/8" I.D X 20" LG. SILICONE

17 71148 VENT TUBE SUPPORT

18 61108 WATER LEVEL PROBE

19 70821 GASKET, WATER TANK

20 61700 TANK 16" WATER

21 61243 GROMMET, DUMP VALVE

22 61229 GROMMET, PLUG

23 71155 TUBING, 5/16" I.D X 2" LG. SILICONE

24 71258 SPRAY TUBE S/S

25 70341 FITTING, 90 DEGREE ELBOW-SILICONE

26 12152 SIPHON TUBE

27 71093 TUBE SPLICE

28 71155 TUBING, 5/16" I.D X 9 1/2" LG. SILICONE

29 61237 FITTING, HOSE TO 1/4" FLARE SWIVEL

30 71155 TUBING, 5/16" I.D X 1" LG. SILICONE

31 61104 WATER FILL VALVE 120 VAC

32 71129 NUT, 8-32 KEPS S/S

33 05826 TUBING, 3/8" I.D X 7 1/2" LG. SILICONE

34 61152 TEE, 7/16" X 7/16" X 7/16" BARBED

35 05826 TUBING, 3/8" I.D X 11" LG. SILICONE

36 61232 PLUG, 3/8" BARBED DRAIN

37 05826 TUBING, 3/8" I.D X 16" LG. SILICONE

38 82119 PANEL, SERVICE

39 61102 DUMP VALVE - 120 VAC

Page 15

Exploded View Hot Water Tank Assembly

(Export Units)

Page 15 Grind’n Brew Coffee Systems™

Page 16

Single Bean Upper Assembly

Dual Bean Upper Assembly

Grind’n Brew Coffee Systems™ Page 16

Page 17

Wiring Diagram 115/230V, 60Hz

Page 17 Grind’n Brew Coffee Systems™

Loading...

Loading...