Greenheck SWB 100 User Manual

0

Document 455308

Centrifugal Utility Fans

®

Model SWB - Series 100, 200 and 300

Models SFB and SFD

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Model SWB

Series 300

Series 30

Model SFB

Model SWB

Series 200

Model SWB

Series 100

Table of Contents

Motor and Drive Installation

(Units Shipped from Stock) ................ 2

Installation ............................... 3

Affect of Installation on Performance ......... 3

UL/cUL 762 - Restaurant Exhaust ............ 4

Pre-Starting Checks ......................4-5

Belt Drive Fan Maintenance ................. 6

Bearing Lubrication Schedule ............... 6

Motor Maintenance (Belt and Direct Drive) ..... 6

Parts List ................................ 7

Model SFD

®

Troubleshooting Chart ..................... 8

Centrifugal Utility Fans

1

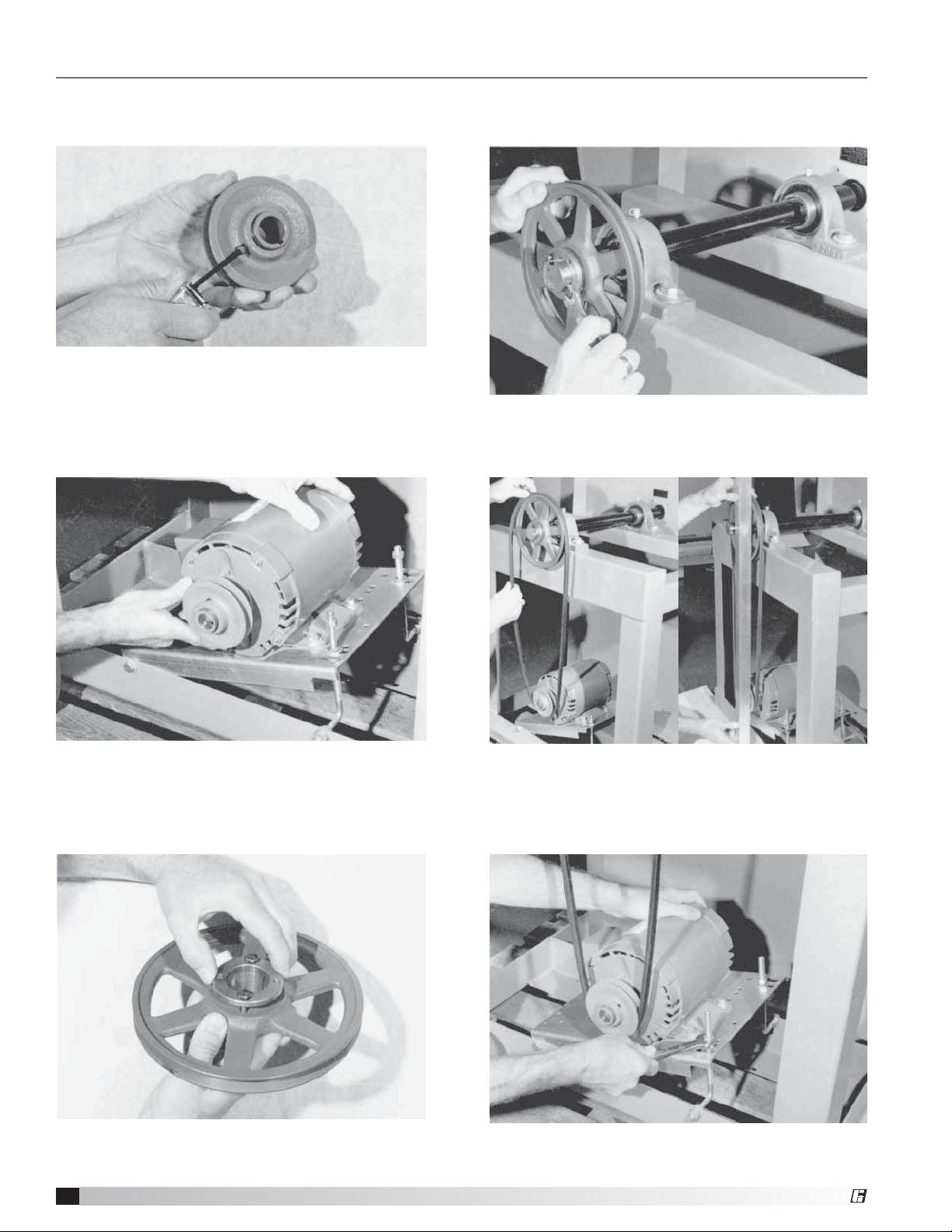

Motor and Drive Installation Instructions

Model SWB units are shipped from stock without motors or drives.

1. Adjust motor pulley to its closed position for

maximum fan speed or increments of 1/2 turn

open (maximum of 5 turns open) for reduced fan

speed. Tighten set screw on flat area only.

4. Install shaft pulley to fan shaft.

2. Install motor pulley to the motor shaft and install

motor to the motor plate. Pre-punched holes are

provided for most common motor frame sizes.

3. If supplied, install taperlock bushing into

shaft pulley.

Centrifugal Utility Fans

2

5. Install drive belt(s). Belts should not be forced

over pulleys. Align motor and shaft pulleys with a

straight edge. Tighten all set screws.

6. Adjust belt tension.

See page 6 for belt tensioning instructions.

®

Installation

Affect of Installation on Performance

Inspect the unit for any damage and report it to

the shipper immediately. Also, check to see that all

accessory items are accounted for.

Move the fan to the desired location and fasten

securely through mounting holes provided in the base

angles. The unit must be set level (shimming may be

necessary). Flexible duct connections and vibration

isolators should be used where noise is a factor.

The motor voltage and ampere rating must be

checked for compatibility with the electrical supply

prior to final electrical connection. Supply wiring to the

fan must be properly fused, and conform to local and

national electrical codes.

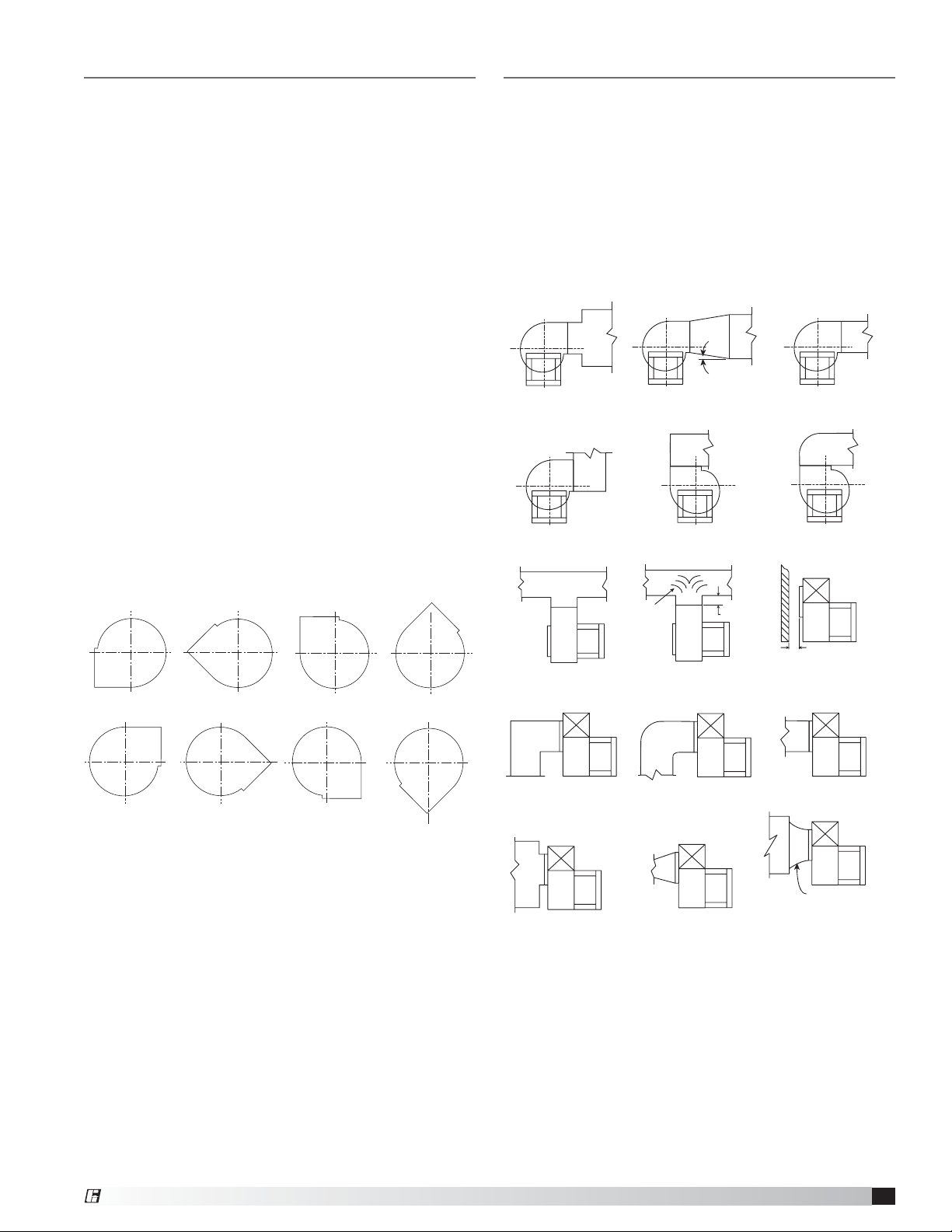

The discharge is factory set as specified by customer

order, however, it can be rotated to other discharge

positions in the field if necessary. Removal of the

housing bolts allows the discharge to be rotated to

the clockwise positions below. For TAD, BD and BAD

discharge positions, a portion of the frame angle must

be removed.

Clockwise rotation shown. Counterclockwise

discharge positions are a mirror image of those

shown. Fan rotation is always specified from the

drive side of the housing.

Restricted or unstable flow at the fan inlet can cause

pre-rotation of incoming air or uneven loading of the

fan wheel, yielding large system losses, increased

sound levels and structural failure of the fan wheel.

Free discharge or turbulent flow in the discharge

ductwork will also result in system effect losses.

The examples below show the system layout and

inlet and discharge configurations which can affect

fan performance.

Discharge Configurations

7o MAX.

POOR

POOR

FAIR

POOR

GOOD

FAIR

Discharge Positions

CW BH CW BAU CW TAUCW UB

CW TH CW TAD

CW DB

CW BAD

POOR

POOR

POOR

Turning

Varies

FAIR

FAIR

POOR

One

Impeller

Dia.

Should be at least

1/2 Impeller Dia.

GOOD

GOOD

Not Greater than

o

60

Including Angle

FAIR

®

Centrifugal Utility Fans

3

Loading...

Loading...