Greenheck SMD-302 User Manual

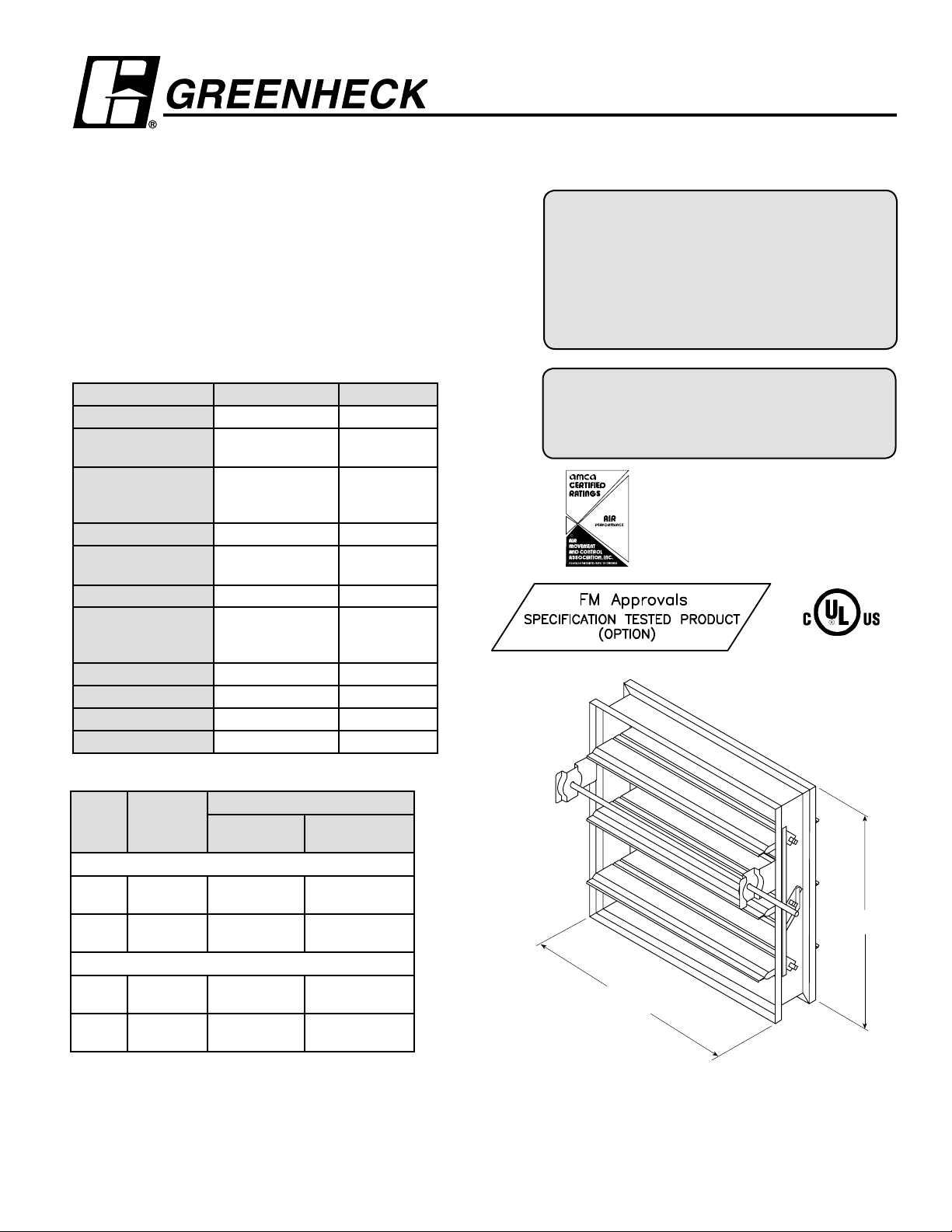

SMD-302

H*

W*

Application

Model SMD-302 is a leakage rated smoke damper with extremely low

leakage. The SMD-302 serves the function of both a control damper and

smoke damper. High strength airfoil blades insure lowest resistance to

airflow in HVAC systems with velocities to 4000 fpm (20.3m/s) and 4 in.

wg (1.0 kPa) Model SMD-302 may be installed vertically (with blades

running horizontal) or horizontally and is rated for airflow and leakage in

either direction.

UL555S Leakage Rating

Leakage Class: II

Operational Rating

Maximum Velocity: 4000 fpm (20.3m/s)

Maximum Pressure: 4 in. wg (1 kPa)

Maximum Temperature: 350ºF (177ºC) depending on the actuator

Construction Standard Optional

Frame Material Galvanized Steel -

Frame Material

Thickness

Frame Type

Blade Material Galvanized Steel -

Blade Material

Thickness

Blade Type Double Skin Airfoil -

Linkage

Axle Bearings Bronze 304SS

Axle Material Plated Steel -

Blade Seals Silicone -

Jamb Seals 304SS -

16 ga. (1.5mm) -

5 in. x 1in.

(127mm x 25mm)

hat channel

14 ga. (2mm)

Equivalent

Plated Steel Out

of Airstream,

Concealed in Jamb

Double Flange

-

-

Smoke Dampers

Steel Airfoil Blades

UL 555S Leakage Class II

Model SMD-302 meets the requirements for smoke

dampers established by:

National Fire Protection Association

NFPA Standards 92A, 92B, 101 & 105

IBC International Building Codes

New York City (MEA listing #260-91-M)

CSFM California State Fire Marshal

Leakage (Smoke) Damper Listing (#2330-0981:104)

“UL CLASSIFIED (see complete marking on

product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standard 555S (Listing #R13317)

Greenheck Fan Corporation certifies that the

model SMD-302 shown herein is licensed to bear

the AMCA Seal. The ratings shown are based on

tests and procedures performed in accordance

R

with AMCA Publication 511 and comply with

the requirements of the AMCA Certified Ratings

Programs. The AMCA Certified Ratings Seal

applies to air performance ratings only.

Size Limitations

W x H

Minimum

Size

2000 fpm (10.3 m/s)

Inches 8 x 6

mm 203 x 152

4000 fpm (20.3 ms/)

Inches 8 x 6

mm 203 x 152

Features:

• Frames are constructed with reinforced corners. Low

profile head and sill are used on sizes less than 17 in.

high (432mm).

• Blades are double skin airfoil shape of galvanized steel

with full length structural reinforcement

• Actuators: 120V, 24V, 230V, Pneumatic

Maximum Size

Single

Section

32 x 50 or

36 x 48

813 x 1270 or

914 x 1219

32 x 50 or

36 x 48

813 x 1270 or

914 x 1219

Multiple Section

128 x 100 or

256 x 50

3251 x 2540 or

6502 x 1270

128 x 50

3251 x 1270

LH

RH

*W&H dimensions furnished approximately 1/4 in. (6mm) undersize.

Right hand drive is shown. Left hand drive is available upon request.

Damper also may be rotated 180° in the field for opposite side drive.

(Add sleeve thickness for overall sleeved damper dimension)

Installation instructions available at www.greenheck.com

5D 6D

5D

D

4 (W) (H)

3.14

5D 6D

Options & Pressure Drop Data SMD-302

Options for SMD-302:

• Factory mounted accessories

- Retaining angles

- Quick connect breakaway connections

- S & drive connections

- Access doors

• Greenheck test switches (GTS-3 & GTS-4)

• Momentary test switch

• POC retaining angles

• OCI (Open closed indication switches)

• Sealed transitions and sleeves

• Security bars

• Smoke detectors

• Transitions: R, C, O

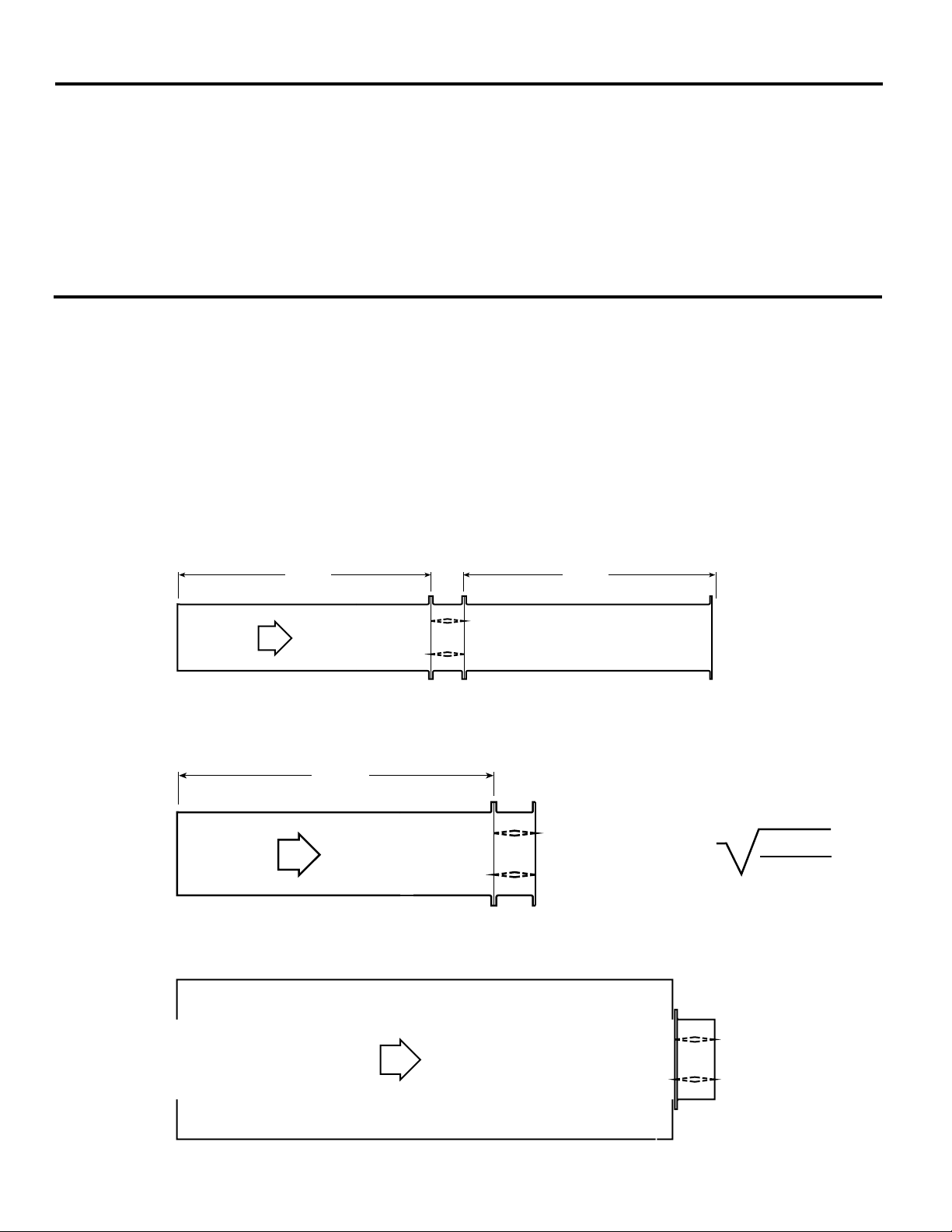

Pressure Drop Data

This pressure drop testing was conducted in accordance with AMCA Standard 500-D using the three configurations shown. All

data has been corrected to represent standard air at a density of .075 lb/ft

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop information along with an

analysis of other system influences should be used to estimate actual pressure losses for a damper installed in a given HVAC

system.

AMCA Test Figures

Figure 5.3 Illustrates a fully ducted damper. This configuration has the lowest pressure drop of the three test configurations

because entrance and exit losses are minimized by straight duct runs upstream and downstream of the damper.

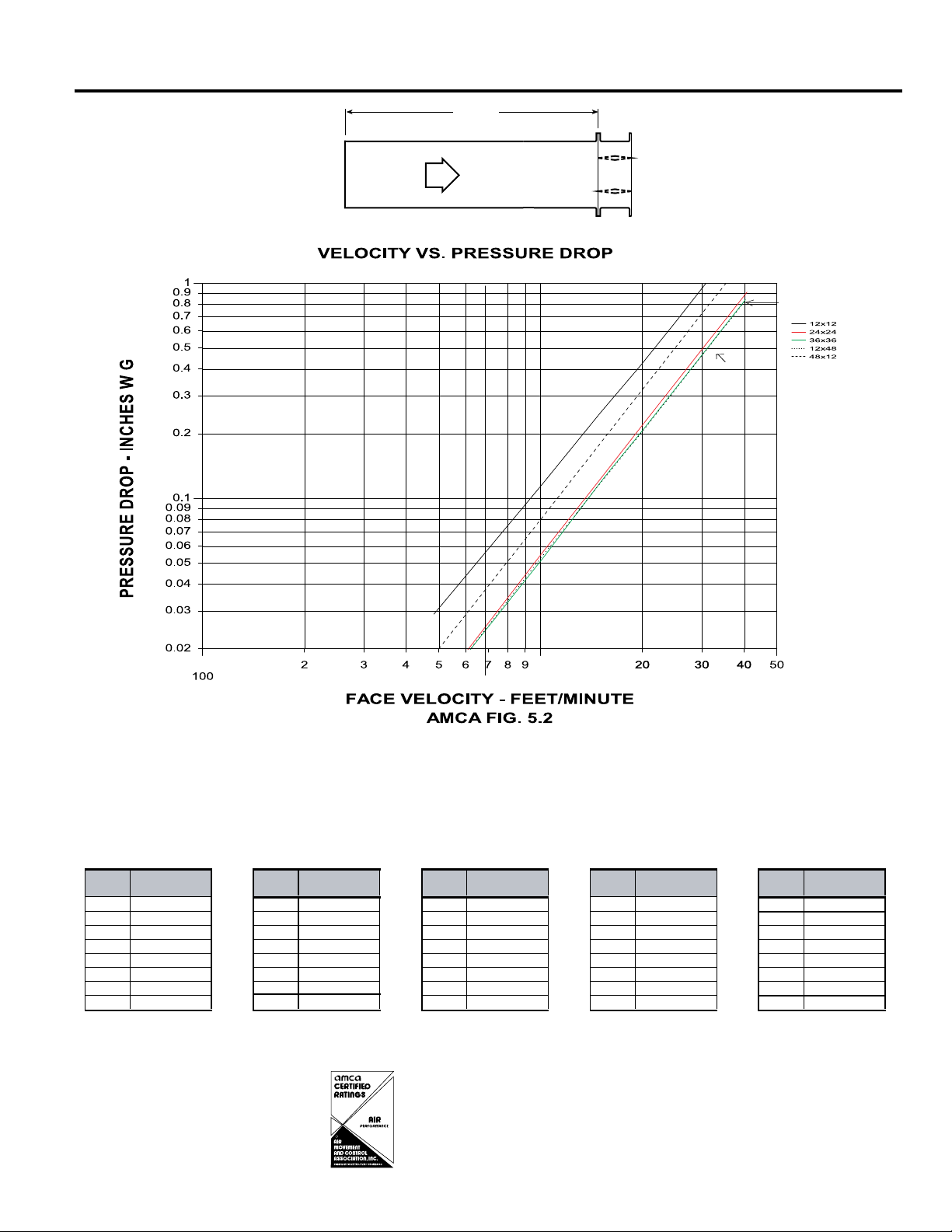

Figure 5.2 Illustrates a ducted damper exhausting air into an open area. This configuration has a lower pressure drop than

Figure 5.5 because entrance losses are minimized by a straight duct run upstream of the damper.

Figure 5.5 Illustrates a plenum mounted damper. This configuration has the highest pressure drop because of extremely high

entrance and exit losses due to the sudden changes of area in the system.

3

(1.201 kg/m

3

).

5D 6D

Figure 5.3

5D

Figure 5.2

D

4 (W) (H

3.14

)

Figure 5.5

12x12

48x12

24x24

36x36

12x48

AMCA 5.2 Pressure Drop SMD-302

5D 6D

D

4 (W) (H)

3.14

Velocity

(fpm)

Pressure Drop

(in. wg)

Velocity

(fpm)

Pressure Drop

(in. wg)

Velocity

(fpm)

Pressure Drop

(in. wg)

Velocity

(fpm)

Pressure Drop

(in. wg)

Velocity

(fpm)

Pressure Drop

(in. wg)

500 0.03 500 0.01 500 0.01 500 0.01 500 0.02

1000 0.12 1000 0.06 1000 0.061000 0.051000 0.08

1500 0.26 1500 0.12 1500 0.121500 0.12 1500 0.18

2000 0.46 2000 0.22 2000 0.222000 0.21 2000 0.33

2500 0.72 2500 0.34 2500 0.342500 0.332500 0.51

3000 1.04 3000 0.49 3000 0.493000 0.483000 0.74

3500 1.41 3500 0.67 3500 0.673500 0.653500 1.00

4000 1.84 4000 0.87 4000 0.884000 0.854000 1.31

12in. X 48 in.

(

305mm x 1219mm) 48 in. x 12 in. (1219mm x 305mm) 24 in. x 24 in. (610mm x 610mm) 36in. x 36 in. (914mm x 914mm) 12 in. x 12 in. (305mm x 305mm)

5D

* Sizes are in inches.

R

Greenheck Fan Corporation certifies that the

model SMD-302 shown herein is licensed to bear

the AMCA Seal. The ratings shown are based on

tests and procedures performed in accordance

with AMCA Publication 511 and comply with

the requirements of the AMCA Certified Ratings

Programs. The AMCA Certified Ratings Seal

applies to air performance ratings only.

Loading...

Loading...