Greenheck SEVCD-23 Installation Manual

Blade Seal Replacement

Note: Wipe down blade with Isopropyl Alcohol before seals are

applied to blades.

Note:

- Blade and closure strip must be cleaned with Isopropyl Alcohol to remove oil prior to application of seal to ensure complete adhesion.

- Apply seal to blade and closure with moderate pressure with a roller.

Blade seal

Instructions

for HCD, VCD, SMD, FSD, series

Greenheck offers three different blade styles and

uses four different attachment methods for control

damper blade seals. These instructions address either

replacement or initial installation.

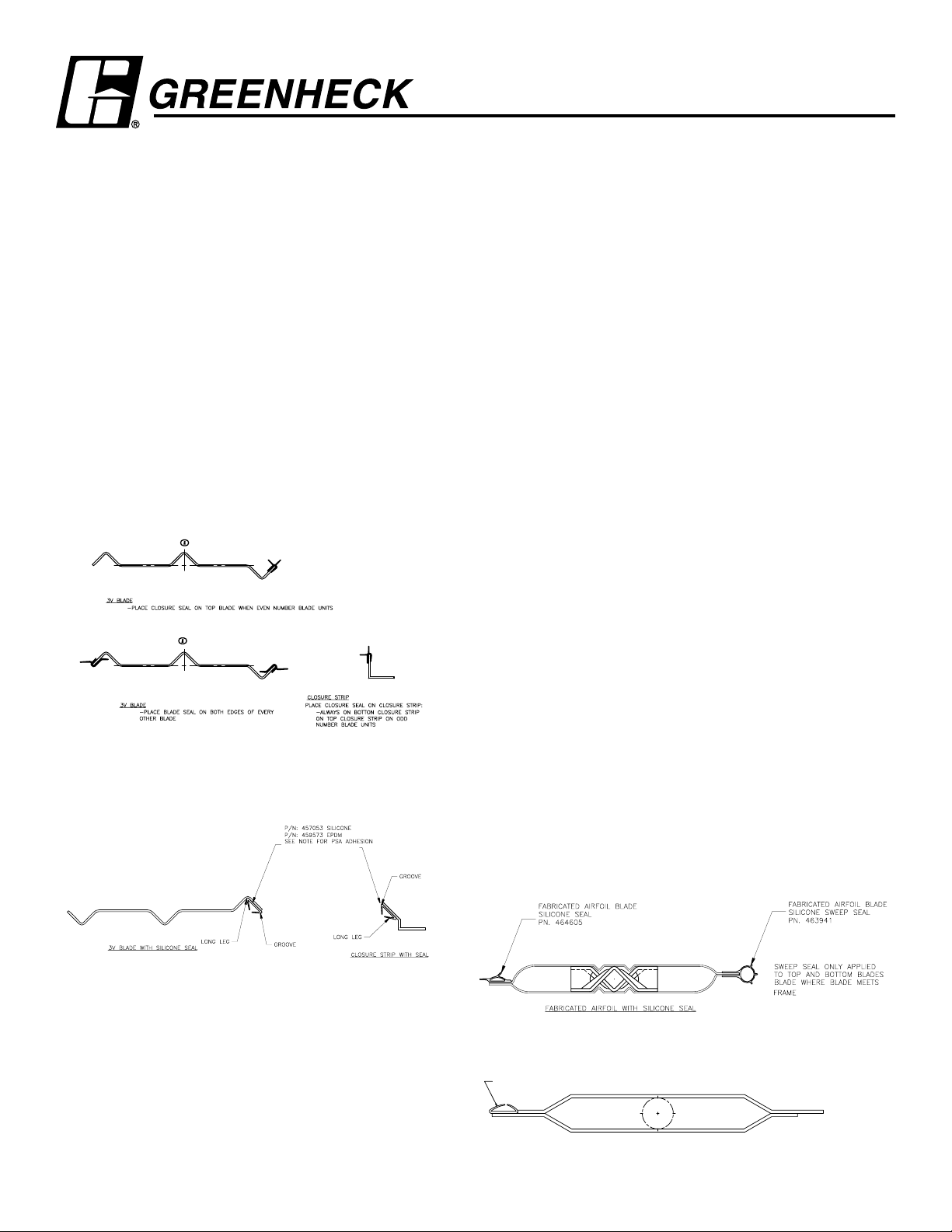

3-V Blade Style

Applicable to Models: VCD-18, VCD-23, SEVCD-23,

SMD-201, SMD-202, FSD-211, FSD-212,FSD-231,

CFSD-211, CFSD-212, OFSD-211, OFSD-212,

SSFSD-211,SEFSD-211, HCD-120, HCD-220

Clip-On

The vinyl seal, also known as dual-durometer, pushes

onto the blade edge and is held by the friction between

the blade material and directional projections inside

the rigid plastic clip. Seal material is cut-to-length

before installing. Seal is normally installed to the

drive blade and to every blade tip on the same side of

damper.

Stainless Steel/Silicone Composite

Silicone rubber seal has a stainless steel clip to

mechanically fasten seal to the blade edge. Installation

is the same as the vinyl seal.

• Install when blade surface is above 70°F or above.

• Cut seal material slightly longer than blade with release

paper still on seal material.

• Start at one end of blade. Peel off 1-2 feet of release

paper at a time and place seal rmly onto blade surface.

Do NOT touch the adhesive. Use nger or roller to press

seal to blade. Do NOT stretch seal as it will pop off in

time.

• Trim seal material at blade end as required. Excess seal

is prone to pulling from blade surface and will force jamb

seal away, increasing leakage.

Silicone Seal with Silicone Adhesive

Tremco Spectrem 1 adhesive is used to adhere silicone

seal to painted surfaces, as PSA adhesives will not bond

to most powder painted surfaces.

• Open blades. Use scraper to remove any existing seal

or adhesive.

• Cut seal to approximate length with release material still

on seal.

• Clean blade in the same manner as above. Temperature

limits also apply.

• Apply thin 1/8 in. bead of Tremco Spectrem 1 to blade

surface. Spread adhesive using a putty knife or scraper

to approximately ½ in. (13 mm) wide.

• Install seal to blade edge, starting at one end and removing release paper as one moves down blade. Do

NOT stretch seal.

• Press seal rmly into place. If seal was stretched, length

will shrink.

• Allow adhesive material to cure 15 minutes. Trim seal to

length.

Fabricated Airfoil Blades

Applicable to models: VCD-33, VCD-34, SEVCD-33,

SMD-301,SMD-302, FSD-311, FSD-312, FSD-311V,

CFSD-311, CFSD-312, HCD-130, HCD-135, HCD-230,

HCD-330, HCD-430, HCD-530

Silicone or EPDM Seal with Pressure Sensitive

Adhesive (PSA)

• Open blades. Use scraper to remove any existing

seal or adhesive.

• Surface must be free from dust, dirt, oil and moisture.

Clean blade edge with alcohol or similar solvents.

Do not use mineral spirits or other petroleum based

solvents that leave a residue.

HCD Fabricated Airfoil with Silicone Seal

Silicone or EPDM Seal with Pressure Sensitive

Blade Seal

Blade Seal

Adhesive (PSA)

• Open blades. Use scraper to remove any existing seal or

adhesive.

• Surface must be free from dust, dirt, oil and moisture.

Clean blade edge with alcohol or similar solvents. Do

not use mineral spirits or other petroleum based solvents

that leave a residue.

• Install when blade surface is above 70°F or above.

• Cut seal material slightly longer than blade with release

paper still on seal material.

• Start at one end of blade. Peel off 1-2 feet of release

paper at a time and place seal rmly onto blade surface.

Do NOT touch the adhesive. Use nger or roller to press

seal to blade. Do NOT stretch seal as it will pop off in

time.

• Trim seal material at blade end as required. Excess seal

is prone to pulling from blade surface and will force jamb

seal away, increasing leakage.

Silicone Seal with Silicone Adhesive

Tremco Spectrem 1 adhesive is used to adhere silicone

seal to painted surfaces, as PSA adhesives will not bond to

most powder painted surfaces.

• Open blades. Use scraper to remove any existing seal or

adhesive.

• Cut seal to approximate length with release material still

on seal.

• Clean blade in the same manner as above. Temperature

limits also apply.

• Apply thin 1/8 in. bead of Tremco Spectrem 1 to blade

surface. Spread adhesive using a putty knife or scraper

to approximately ½ in. (13 mm) wide.

• Install seal to blade edge, starting at one end and

removing release paper as one moves down blade. Do

NOT stretch seal.

• Press seal rmly into place. If seal was stretched,

length will shrink.

• Allow adhesive material to cure 15 minutes. Trim seal

to length.

SS/Silicone Composite

Silicone rubber seal has a stainless steel clip to

mechanically fasten seal to the blade edge. Seal

material is cut-to-length before installing. Seal is

normally installed to the drive blade and to every blade

tip on the same side of damper.

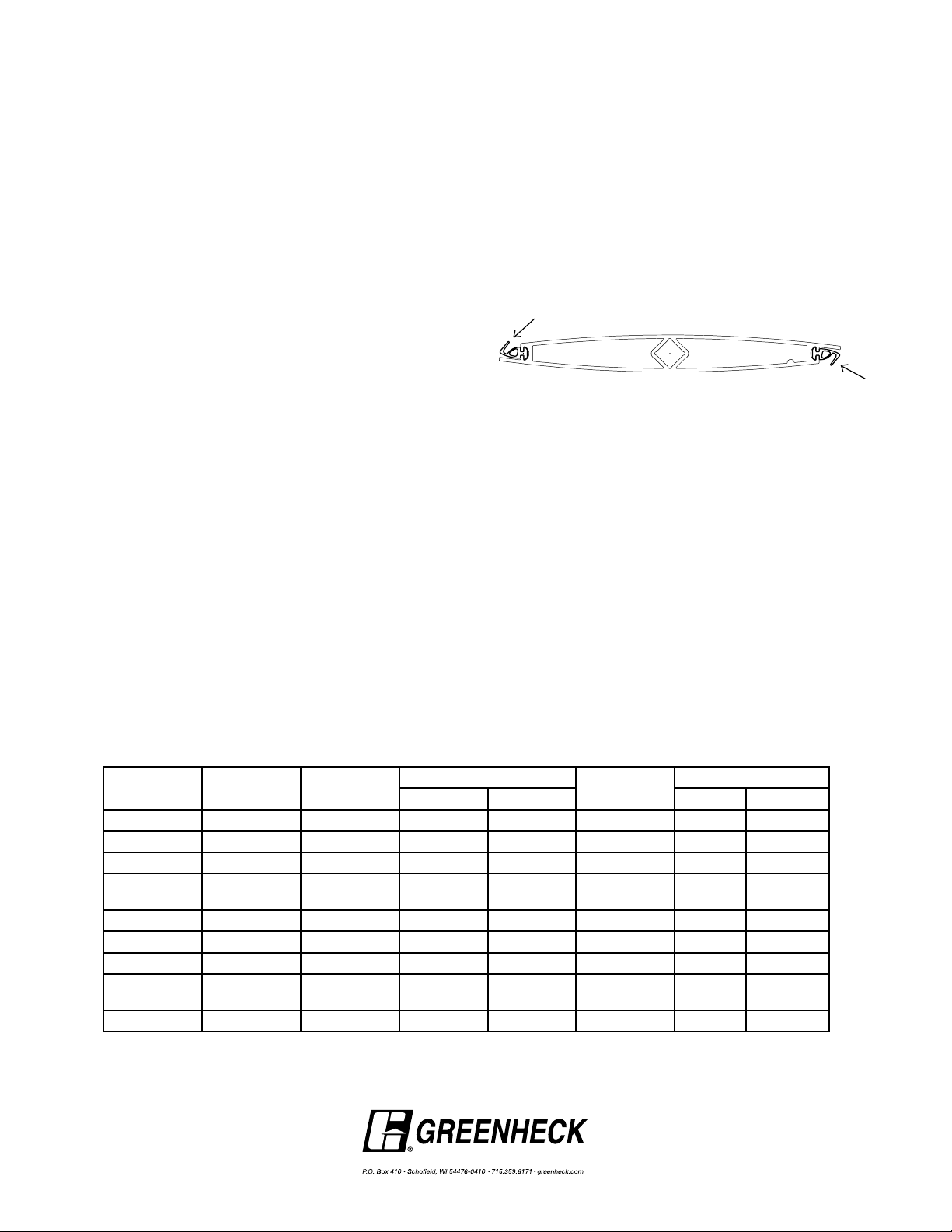

Aluminum Airfoil Blades

Applicable to models: VCD-40, VCD-42, VCD-43,

SMD-401, ICD-45, HCD-140, HCD-240, HSD-401

Extruded aluminum blades have a groove at both blade

edges to hold seal. Blade ends are crimped to prevent

seal from sliding out.

• Open blades. Remove existing seal. It is usually

easiest to pull seal from blade end rather than pulling

it out of groove along blade edge.

• Cut seal slightly longer than blade length. Do NOT

stretch, as seal will creep back to original length.

• Start at one blade end. The non-attached seal

lip is installed away from the blade surface. Seal

can usually be stretched sufciently to pass under

existing blade end crimp. Needle nose pliers works

well in grasping seal end.

• Use a center punch to re-crimp blade end if

necessary.

• Trim seal to length.

Blade Type

3-V Vinyl Clip-on 16 ga. 14 ga. 455501 -20 180

Fabricated

Airfoil

Aluminum

Airfoil

Elastomer

Material

Silicone Adhesive All All 457053 -60 400

SS/Silicone Clip-on 16 ga. 12 ga. 220108 -60 400

Silicone PSA All All 464605 -60 350

Silicone Adhesive All All 457053 -60 400

EPDM PSA All All 468644 -20 250

SS/Silicone Clip-on 16 ga. 12 ga. 220108 -60 400

Silicone Groove n/a n/a 461254 -60 400

EPDM Groove n/a n/a 460115 -20 250

Blade

Attachment

Blade Thickness Greenheck

Minimum Maximum Minimum Maximum

Part number

Copyright © 2008 Greenheck Fan Corporation

Temperature °F (°C)

Blade Seal Replacement Instructions

Rev. 2 Nov 2008