Page 1

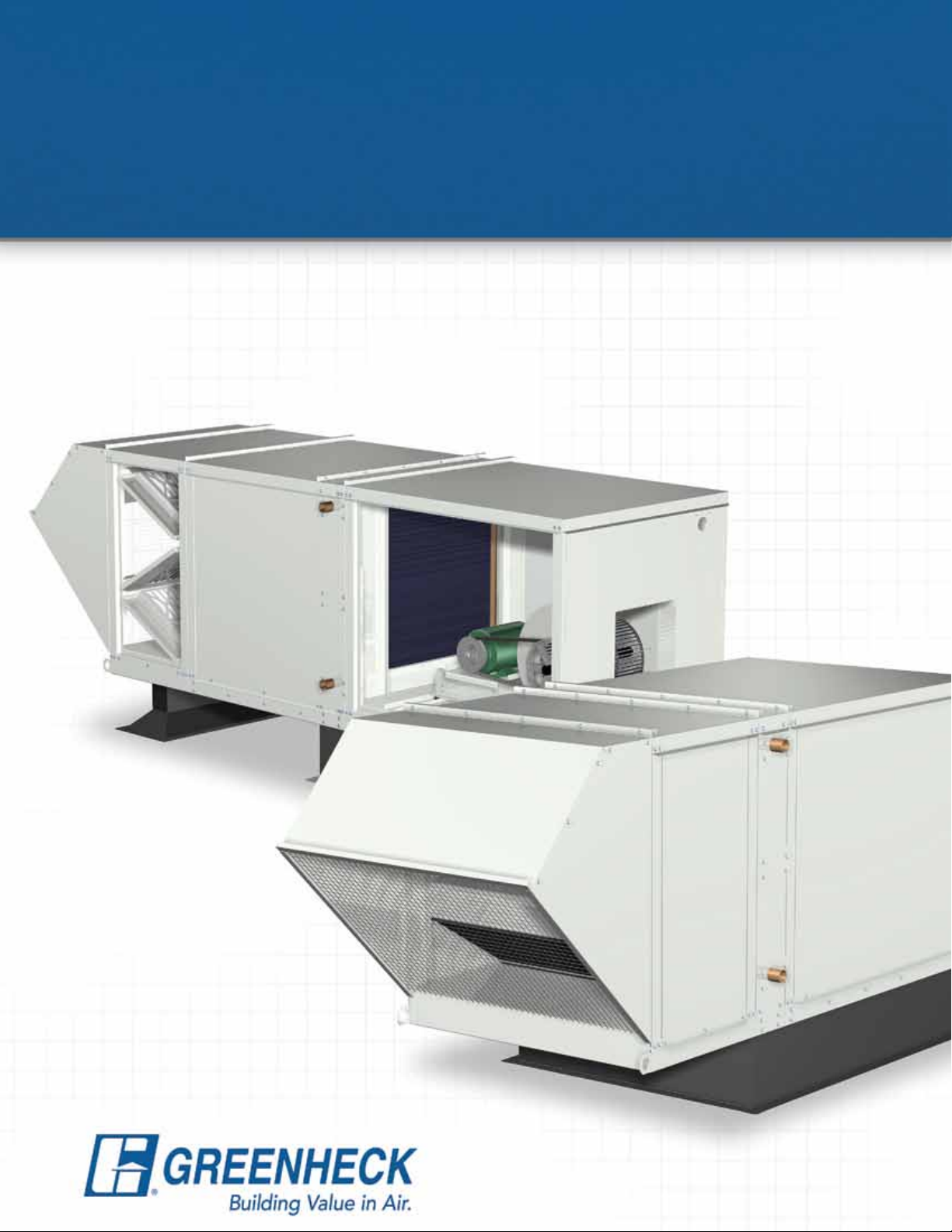

Modular Supply Make-Up Air Unit

Model MSX

• Flexible Design • Factory Assembled

Heating Options

• Hot Water

• Steam

• Electric

Cooling Options

• Evaporative

• Direct Expansion

• Chilled Water

November

2009

Page 2

Product Features

Model MSX

Modular Supply Unit

The Greenheck model MSX is an

ideal make-up air unit where gas-fired

heating is not desired. Coil heating

and/or cooling tempering options are

available with airflow volumes up to

48,000 cfm. The MSX may also be

used for untempered applications.

A flexible design concept enables

each product to be customized

for its application. Units are

factory assembled and wired to

minimize field installation labor.

The result is a semi-custom

product at an attractive cost.

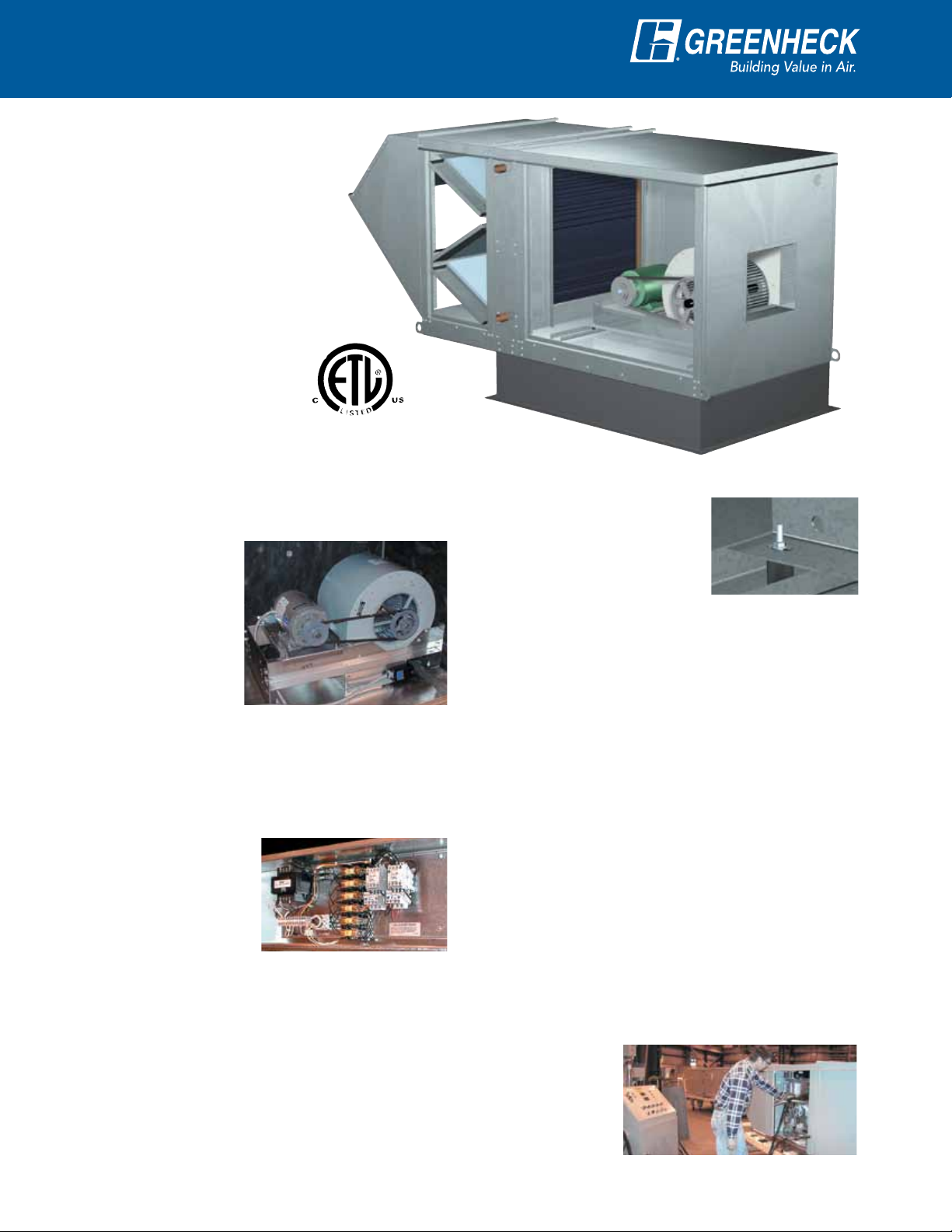

Reliable Fan Performance

Air performance ratings from Greenheck’s AMCA

registered test chamber ensure accurate data.

Double-width,

double inlet forward

curved wheels for

high efficiency and

low sound levels are

constructed of heavy

gauge steel. Wheels

are balanced to ensure

vibration free operation.

MSX shown with optional filter section,

hot water coil and horizontal discharge.

Vibration Isolators

The entire fan and motor

assembly is mounted on

vibration isolators to minimize

noise transmission to the

building. Spring isolators are

available in lieu of neoprene isolators.

Durable Construction

Designed for maximum weather resistance, MSX

housings are constructed of heavy gauge G90

galvanized steel. Lifting lugs are standard.

Control Center (Optional)

The control center includes the following standard

components:

•Magneticmotorstarterwithsolidstateoverload

protection

•Controltransformerwith

fusing

•Disconnectswitch

•Individualmotorfusing

•Distributionterminal

strip

Premium grade control components are selected for

reliable operation. All electrical components are UL

Listed, recognized or classified and factory prewired

for single point power connection.

2

Shafts

Shafts are precision turned, ground and polished steel

sized so that the first critical speed is at least 25%

over the maximum operating speed.

Bearings

Shafts rotate in permanently lubricated, heavy duty

ball bearings. Bearings are selected for a minimum

average (L10) life in excess of 100,000 hours at

maximum operation speeds.

Access Panels

Large access panels are provided for easy inspection

and maintenance of motors, drives, fan wheels, filters,

and heater controls.

Factory Wired and Tested

All units are tested

prior to shipment.

Units are checked

for proper fan and

controls operation.

Page 3

Tempering Options

Heating Coils

Hot water, steam and electric heating is available with the model MSX. The heating section consists of the

heating coil factory installed in a pre-engineered coil housing. Water and steam coil connections are stubbed

through the wall for convenience.

For proper coil sizing, use Greenheck CAPS selection software or contact your local representative. All heating

options are available with airflow capacity up to 48,000 cfm.

The heating coil section is installed upstream of the fan section for a draw through arrangement and provide a

streamlined transition to adjacent MSX sections.

Hot Water and Steam

Hot water and steam

coils are available in

either a 100% thru-coil

airflow or face and bypass arrangement. Coils

have copper tubes with

permanently expanded

aluminum fins and are

tested and rated in

accordancewithAHRI410.

Evaporative Cooling

Electric Heat

Electric heaters are

UL Listed and feature

open coil heating

elements. Heater

control cabinets are

installed completely

within the heating

section, are factory

wired up to 200 kW and

meet all requirements

of the National Electric Code.

The evaporative cooling section includes a galvanized steel housing with

a louvered intake, 2-inch aluminum mesh filters and a stainless steel

evaporative cooling module. The evaporative cooling media is Munters

CELdek or GLASdek and has a depth of 12 inches for 90% cooling

effectiveness.

The entire section mounts directly to the front of the MSX unit,

eliminating transition or ductwork by others. Drain and overflow are

conveniently tapped through the side of the cooling section. The supply

line connection is field located where convenient. Freeze protection and

automatic drain & fill options are also available.

Cooling Coils

Airflow capacity for evaporative cooling is up to 48,000 cfm. The

evaporative cooling section for the housing size 32 through 42 ships

separately.

Chilled water or direct expansion (DX) cooling is available with the model

MSX. The cooling section includes the cooling coil, sloped stainless

steel drain pan and insulated double wall construction. Drain and coil

connections are stubbed through the wall for convenience.

For proper coil sizing, use Greenheck CAPS selection software or contact

your local representative. Four row and six row chilled water or DX coils

are available with airflow capacity up to 30,000 cfm.

Cooling coil sections are installed upstream of the fan section for a draw

through arrangement and provide a streamlined transition to adjacent

MSX sections. DX coils require remote condensing units.

3

Page 4

Options

Mixing Box

The mixing box option expands the make-up air application capabilities of the MSX. This section includes low

leakage control dampers for outdoor and return air and an actuator in

a face and bypass configuration. Either 2 inch pleated 30% filters or

2 inch aluminum mesh filters available within the mixing box section.

Double wall construction is available.

Greenheck offers three standard airflow control options with the MSX.

• Building Pressure Control: Outdoor air and return air dampers

modulate to maintain desired building pressure. Furnace control

is based on discharge temperature. A remote control panel with

photohelic gauge is required with this option.

• Potentiometer Control: Enables manual control of the outdoor air

and return air damper positions. A remote control panel is required

with this option.

• External Signal: Outdoor air and return air dampers modulate based

on an external 2-10 VDC or 4-20 mA signal.

Weatherhoods for MSX units with a mixing box include a mist eliminator to prevent moisture from entering the

mixing box section.

Arrangements

Downblast, Horizontal or Upblast Discharge

Model MSX is available in either downblast (Arrangement DB),

horizontal (Arrangement HZ), or upblast (Arrangement UB)

discharge.

Kitchen Combination Package

The Greenheck combination package simplifies

installation and reduces field labor costs for kitchen

ventilation systems. The pre-engineered design

ensures that the supply fan, exhaust fan, curb

and combination extension components interface

properly.

Equally important, Greenheck combination packages

are specifically designed to comply with NFPA 96.

NFPA 96 states:

• Exhaustductmustterminateatleast24inches

(610 mm) above the roof deck

• Fandischargemustbeatleast40inches

(1016 mm) above the roof deck

• Airintakeshallhaveahorizontalseparationof

10 feet (3.048 m) from the exhaust discharge

4

See Greenheck’s Series C catalog for complete

details on the model CUBE exhaust fan.

Note: Consult local codes and the authority having

jurisdiction if there are questions concerning

the use of this product.

Page 5

Accessories

Remote Control Panels

Industrialtyperemotecontrol

panels feature a variety of switches

and indicator lights mounted on a

Permatector™ coated galvaneal steel

box.Ifroomoverrideisspecified,

the override thermostat is factory

mounted on the remote panel as

shown at right.

Additional Accessories

Air Filter Gauge

The air filter gauge indicates when filters become

dirty. An indicator light may be wall/beam mounted or

provided with a remote control panel.

Motorized Dampers

Intakeordischargedampersareavailabletoprevent

backdraftswhenthefanisnotinoperation.Intake

dampers are factory mounted and wired.

Spring Vibration Isolation

Spring vibration isolators are available in lieu of

neoprene isolators.

Exhaust Fan Starter(s)

Exhaust fan starters may be added to the control

center.

Kitchen style remote

panels feature toggle

switches and a stainless

steel face plate for flush

mounting to a wall. The

junction box is also

included.

Freezestat

An on/off type discharge duct stat (with a timer)

prevents the discharge of cold air into the building

when the unit is not providing adequate tempering.

Equipment Supports

Factory provided equipment supports may be required

in addition to a roof curb, depending on the specified

unit configuration. Standard construction is G90

galvanized steel.

Special Coatings

Greenheck’s Permatector™ powder paint is available

if a painted look is desired. Decorative baked enamel

paints are also available in a variety of colors to match

existing building fixtures. Consult your Greenheck

representative for paint selections.

Inlet Air Sensor

An on/off type duct stat automatically de-energizes

the gas system and interrupts the flow of gas to the

burners when the inlet air temperature is above the

desired setting.

115 Volt GFCI Service Receptacle

A115voltGFCIoutletismountedexternallyina

NEMA-3R box for the convenience of field service

personnel. A separate 115 volt power source is

required.

Roof Curbs

Factory provided roof curbs are available to ensure

compatibility between make-up air unit and roof curb.

Standard construction is G90 galvanized steel.

2-Speed Motor

A 1⁄3 reduction 2-speed motor is available. Consult the

factory for 1⁄2 reduction 2-speed motor availability.

Smoke Detector

Photoelectric smoke detector is available for duct

mounting.

Fiberglass Insulation

Fiberglass insulation is used to line the housing to

prevent the formation of condensation and to form

anacousticalbarrier.Insulationisincludedforunits

specified with mixing box option.

Weatherhood

A galvanized steel weatherhood with birdscreen is

available. A mist eliminator is an optional weatherhood

accessory.

Duct Adapter

Duct adapter is available with factory supplied curbs

and allows an easy method for connecting ductwork to

curb.

Double Wall Construction

An interior metal liner is available to isolate insulation

from the airstream. One inch thick insulation is

included with this option.

Discharge Diffuser

Diffusers are available as either 3-way for horizontal

discharge or 4-way for downblast discharge.

5

Page 6

Air Performance

Housing Size 12

Blower

Size

108

109

110

Housing Size 22

Blower

Size

112

115

CFM

800

1,200

1,500

2,500

2,500

3,500

CFM

2,600

3,500

4,400

5,000

6,000

7,000

RPM 993 1109 1216 1311 1399 - -

BHP 0.21 0.26 0.31 0.35 0.40 - -

RPM 1238 1347 1445 1530 - - -

BHP 0.51 0.59 0.68 0.75 - - -

RPM 880 1014 1140 1255 1361 1460 -

BHP 0.36 0.45 0.54 0.63 0.73 0.84 -

RPM 1154 1244 1329 1419 1503 1587 -

BHP 1.1 1.2 1.4 1.6 1.7 1.9 -

RPM 906 995 1082 1166 1247 1325 1402

BHP 0.79 0.93 1.1 1.2 1.4 1.5 1.7

RPM 1131 1202 1275 1340 1401 1464 -

BHP 1.8 2.0 2.2 2.4 2.6 2.8 -

RPM 662 761 853 934 1009 - -

BHP .58 .72 .86 1.0 1.2 - -

RPM 756 839 920 993 1065 1133 1195

BHP 1.0 1.3 1.5 1.7 1.9 2.1 2.3

RPM 871 939 1006 1073 1137 1197 1254

BHP 1.8 2.1 2.4 2.6 2.9 3.1 3.3

RPM 671 741 808 871 931 986 1038

BHP 1.7 2.0 2.3 2.6 2.9 3.2 3.5

RPM 749 812 870 929 982 1035 1086

BHP 2.6 2.9 3.3 3.7 4.0 4.4 4.8

RPM 833 889 943 994 1044 1093 -

BHP 3.7 4.2 4.6 5.0 5.5 5.9 -

Total Pressure in inches wg

0.50 0.75 1.00 1.25 1.50 1.75 2.00

Total Pressure in inches wg

0.50 0.75 1.00 1.25 1.50 1.75 2.00

Housing Size 32

Blower

Size

118

120

Note: The air performance data shown does not include internal static pressure losses due to items such as filters, dampers and coils.

For exact air performance data based on specific unit configuration, use the Greenheck CAPS selection program.

6

CFM

7,000

8,500

10,000

10,000

12,500

15,000

0.50 0.75 1.00 1.25 1.50 1.75 2.00

RPM 566 627 685 738 790 839 885

BHP 2.1 2.5 2.8 3.2 3.6 4.0 4.4

RPM 636 690 740 790 836 880 923

BHP 3.3 3.8 4.2 4.7 5.1 5.6 6.1

RPM 712 759 805 849 891 933 -

BHP 5.0 5.5 6.1 6.6 7.1 7.7 -

RPM 542 590 634 678 723 765 803

BHP 3.6 4.0 4.5 5.0 5.6 6.1 6.6

RPM 633 672 711 748 784 820 855

BHP 6.3 6.9 7.5 8.1 8.7 9.3 10.0

RPM 731 763 795 829 861 892 -

BHP 10.2 10.9 11.6 12.3 13.1 13.8 -

Total Pressure in inches wg

Page 7

Air Performance

Housing Size 35

Blower

Size

122

125

CFM

15,000

17,000

19,000

19,000

21,000

23,000

Housing Size 38

Blower

Size

127

130

CFM

24,000

30,000

26,000

34,000

Total Pressure in inches wg

0.50 0.75 1.00 1.25 1.50 1.75 2.00

RPM 573 605 637 667 698 727 755

BHP 7.5 8.3 8.9 9.6 10.4 11.1 11.9

RPM 634 662 690 718 745 772 799

BHP 10.6 11.4 12.2 12.9 13.6 14.4 15.3

RPM 697 720 746 771 796 821 -

BHP 14.5 15.2 16.1 17.0 17.8 18.6 -

RPM 530 563 594 625 655 683 711

BHP 8.9 9.8 10.7 11.7 12.8 13.8 14.8

RPM 573 603 631 660 688 715 741

BHP 11.6 12.6 13.5 14.6 15.7 16.9 18.0

RPM 616 643 671 697 723 748 -

BHP 14.9 15.9 16.9 18.0 19.2 20.4 -

Total Pressure in inches wg

0.50 0.75 1.00 1.25 1.50 1.75 2.00

RPM 422 451 478 504 530 554 578

BHP 10.1 11.6 13.0 14.3 15.8 17.2 18.6

RPM 501 525 548 571 593 613 -

BHP 18.1 19.6 21.4 23.2 24.9 26.6 -

RPM 355 384 412 440 467 494 520

BHP 9.9 11.2 12.5 13.9 15.2 16.8 18.3

RPM 430 454 477 499 519 542 564

BHP 19.9 21.5 23.1 24.8 26.4 28.3 30.1

Housing Size 42

Blower

Size

133

136

Note: The air performance data shown does not include internal static pressure losses due to items such as filters, dampers and coils.

For exact air performance data based on specific unit configuration, use the Greenheck CAPS selection program.

CFM

0.50 0.75 1.00 1.25 1.50 1.75 2.00

RPM 343 371 397 422 446 467 488

32,000

BHP 14.0 15.7 17.5 19.2 21.0 22.6 24.3

RPM 401 426 448 470 491 512 531

40,000

BHP 25.0 27.1 29.1 31.5 33.7 35.8 37.9

RPM 385 405 426 445 464 482 499

42,000

BHP 25.6 27.7 29.8 32.0 34.1 36.3 38.5

RPM 429 447 465 483 500 517 -

48,000

BHP 36.7 39.0 41.5 44.0 46.4 48.9 -

Total Pressure in inches wg

7

Page 8

Specifications

General: Make-up air unit shall be as manufactured by

Greenheck Fan Corporation or approved equal provided

all specifications are met. Greenheck Model MSX is used

as the basis of design. Performance shall be as scheduled

on plans. All untempered and coil units shall be listed to

UL 1995.

Hot Water or Steam Coil: Coil shall be factory tested and

ratedinaccordancewithAHRI410.Coilsshallhavecopper

tubes with permanently expanded aluminum fins, 12 fpi or

less. Coil connections shall be stubbed out through the

make-up air unit housing wall.

Electric Heat: Electric heaters shall be UL Listed and

feature open coil heating elements. Heater control cabinets

shall be installed completely within the heating section and

be factory wired up to 200 kW and meet all requirements of

the National Electric Code. A separate power source shall

be provided for the electric heater.

Unit Casing and Frames: Unit shall be of internal frame

type construction of galvanized steel. All frames and

panels shall be G90 galvanized steel. Where top panels are

joined, there shall be a standing seam to insure positive

weather protection. All metal-to-metal surfaces exposed

to the weather shall be sealed, requiring no caulking at

jobsite. All components shall be easily accessible through

removable doors.

Insulation: Models provided with a mixing box shall be

insulated from the return section to the supply discharge.

Insulation shall be in accordance with NFPA 90A and

tested to meet UL 181 erosion requirements. Double wall

shall be provided if specified.

Fan Section: Centrifugal fans shall be double width,

double inlet. Fan and motor shall be mounted on a common

base and shall be internally isolated. All blower wheels

shall be balanced. Ground and polished steel fan shafts

shall be mounted in permanently lubricated ball bearings

(up to size 118) or ball bearing pillow blocks (size 120 and

larger). Bearings shall be selected for a minimum (L

in excess of 100,000 hours at maximum cataloged speeds.

Motors and Drives: Motors shall be energy efficient,

complying with EPACT standards, for single speed ODP

and TE enclosures. Motors shall be permanently lubricated,

heavy duty type, matched to the fan load and furnished at

the specified voltage, phase and enclosure. Drives shall be

sized for a minimum of 150% of driven horsepower. Pulleys

shall be cast and have machined surfaces, 10 horsepower

and less shall be supplied with an adjustable drive pulley.

Electrical: All internal electrical components shall be

prewired for single point power connection, excluding

electric heaters. All electrical components shall be

10

) life

UL Listed, recognized or classified

where applicable and wired in

compliance with the National Electrical

Code. Control center shall include

motor starter, control circuit fusing,

control transformer for 120 VAC

circuit, integral disconnect switch with

separate motor fusing and terminal

strip. Contactors, Class 20 adjustable

overload protection and single phase

protection shall be standard.

Filter Section: Filters shall be

mounted in a V-bank arrangement

such that velocities across the filters

do not exceed 550 feet per minute.

Filters shall be easily accessible

through a removable access panel.

Weatherhood: Weatherhood shall be

constructed of G90 galvanized steel

with birdscreen mounted at the intake.

Recirculation (optional): Recirculation airflow shall be

controlledbyadjustmentofreturndamperposition.Input

signal for return damper shall be from building pressure

sensors, potentiometer, external signal, or manual switch.

Recirculated air shall not be permitted to pass across the

burner. Return air shall be filtered.

Variable Volume (optional): Volume shall be varied

by either a 2-speed motor or variable frequency drive.

Inputsignalforfanspeedshallbefrombuilding pressure

sensors, potentiometer, external signal, or manual switch.

Cooling Coil: Direct expansion (DX) or chilled water

coil shall be factory tested and rated in accordance with

AHRI410.Coilsshallhavecoppertubeswithpermanently

expanded aluminum fins, 12 fpi or less. DX coils shall be

equipped with distributors to receive expansion valves at

the liquid connections. Drain pans shall extend at least

12 inches downstream of coil and be sloped to drain

connection.

Evaporative Cooling Section: Evaporative cooling

section shall include a galvanized steel housing with

louvered intake, 2-inch aluminum mesh filters and a

stainless steel evaporative cooling module all provided

by the make-up air unit manufacturer. The louver shall

be stationary type with drainable blades, designed to

withstand wind loads of 25 PSF. Evaporative cooling

media shall be Munters CELdek with a depth of 12 inches

for a cooling effectiveness of 90%. Drain and overflow

connections shall be piped through the side of the

evaporative cooling section.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of

one year from the shipment date. Any units or parts which prove defective during the warranty period will

be replaced at our option when returned to our factory, transportation prepaid. Motors are warranted by the

motor manufacturer for a period of one year. Should motors furnished by Greenheck prove defective during

this period, they should be returned to the nearest authorized motor service station. Greenheck will not be

responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Greenheck P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2009 Greenheck Fan Corporation • MSX Rev. 2 November 2009 RG

Prepared to Support

Green Building Efforts

Loading...

Loading...