Greenheck MS4120 Installation Manual

Part number 473696

!

MS Series Actuators

Mounted Internally

Models MS4120, MS8120, MS4620, MS7510, MS7520 and MS8110

INSTALLATION INSTRUCTIONS

These instructions apply to the internal field replacement of the Honeywell, FATPA Series, actuators on Greenheck models

VCD control dampers. when they are duct mounted or sleeved.

ACTUATOR PART #

MS4120F1006 115V 382823

MS8120F1002 24V 382824

MS4620F1005 230V 382825

MS4120F1204 115V 383024

MS8120F1200 24V 383255

MS4620F1203 230V 383254

MS7510A2008 383739

MS7510A2206 383213

MS8110A1206 383818

MS7520A2015 383785

MS7520A2213 383784

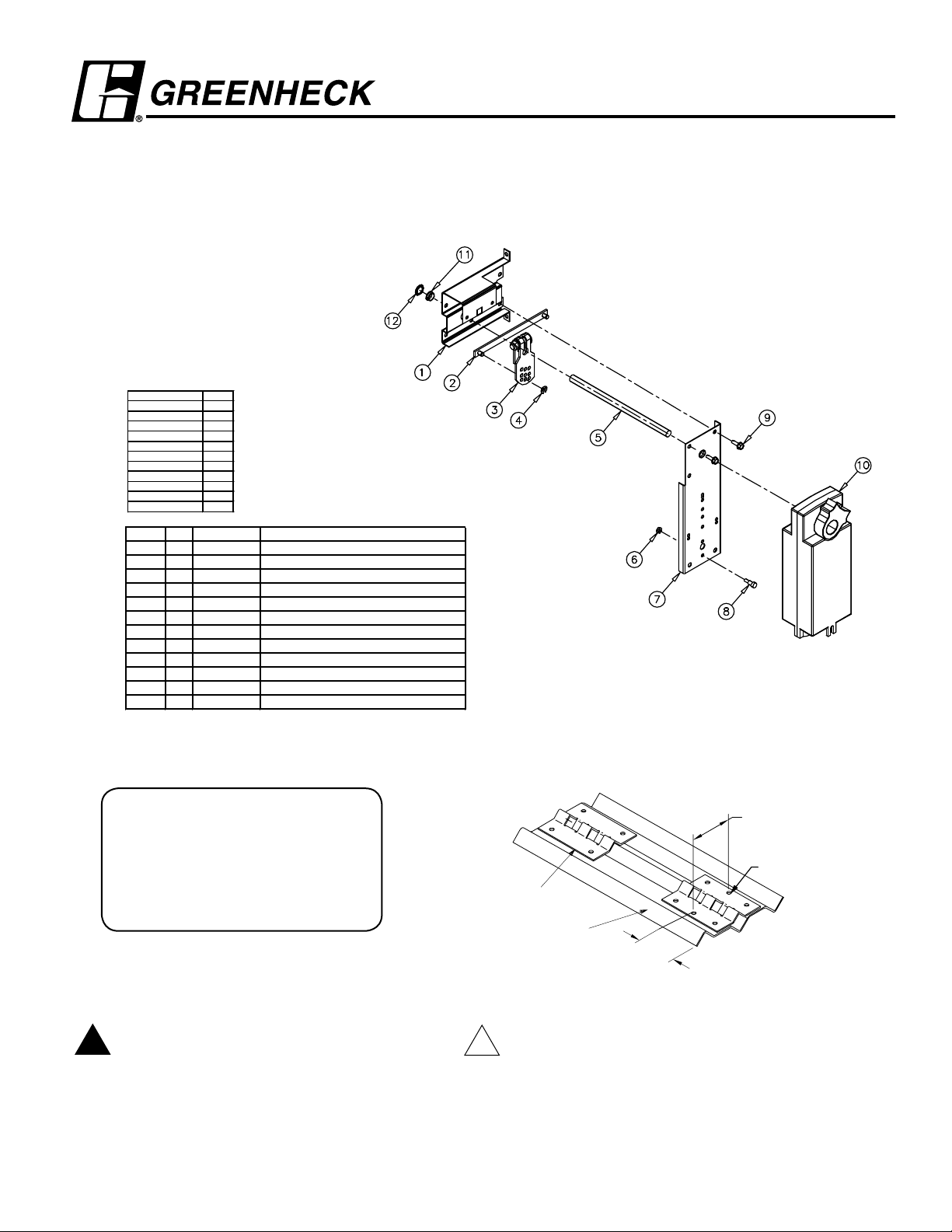

ITEM # QTY PART # DESCRIPTION

1 1 723981 INTERNAL ACTUATOR BRKT

2 1 839475 DRIVE LINK ASSEM BLY

3 1 829206 1/ 2" CRANK ARM A SS EMB LY

4 1 451588 1/ 4" E -RING

5 1 593831 6. 5" JACK SHAFT, 1/2" DIA.

6 1 415934 10-24 NY LOC NUT

7 1 846545 1/ 2" A NTI-ROTATION BRKT. ASM

8 1 416048 10-24X.375 SHOULDER BOLT

9 2 415264 1/ 4-20x1/2 TCS

10 1 SEE CHART ACTUATOR

11 1 370159 1/ 2" S NAP IN BEA RING

12 1 416179 RE TAINING RING 1/2"

Tools Required:

Wrenches: (1) 7⁄16 in., (1) 3⁄8 in., (1) 9⁄16 in.

(1) Ratchet with

(1) 1⁄8 in. Allen wrench,

(1) Drill with 3⁄8 in. nut driver,

3

⁄8, 7⁄16, 9⁄16 in. deepwell

socket

(1) .203 dia. drill bit

Figure 1: Honeywell Series internal mount (exploded view).

Blade Axle Bracket

Damper Blade

1.563 in.

(39mm)

1.75 in. (44mm)

Blade Lever Hole

Location

.203 in. (5.2mm) Diameter.

(2)

Detail A

!

Equipment Damage or Electrical Power Hazard.

WARNING

Line voltage can cause death or serious injury

and short equipment circuitry. Disconnect power

supply before installation.

!

Device Malfunction Hazard. Improper set screw

tightening causes device malfunction. Tighten

set screws with proper torque to prevent damper

shaft slippage.

CAUTION

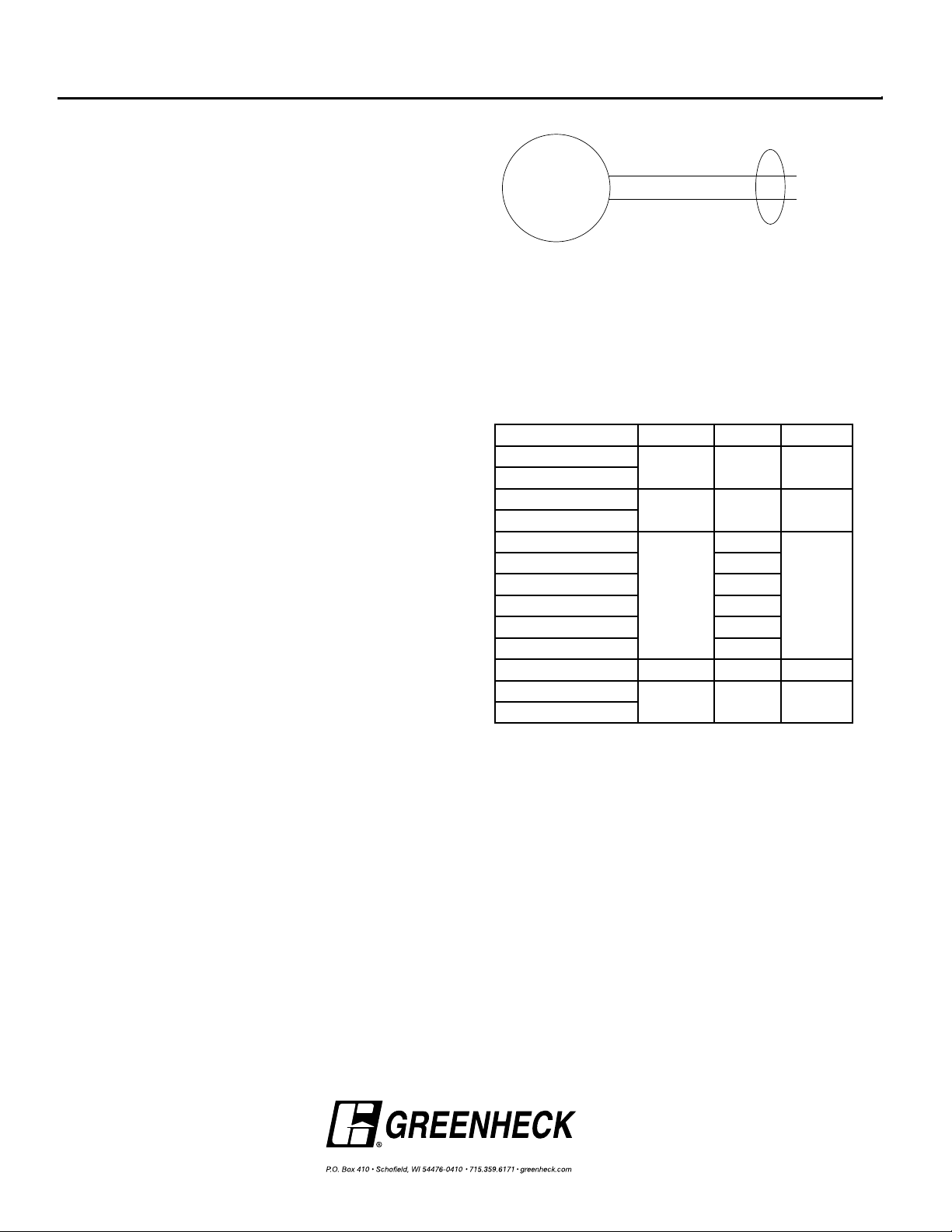

INSTRUCTIONS MS DIRECT DRIVE SERIES

Black

White

120 Volt o

r

24 volt

M

These installation instructions assume a damper is

already mounted in a duct or sleeve. Have damper

blades in the fail position.

1. Drill [2] .203 inch holes in the third blade from

bottom, at location shown in detail "A".

2. Attach blade drive lever to blade using [2] ¼ in.

- 20 x ½ in. thread cutting screws, self drilling

screws or ¼ -20 x 1¼ in. bolts.

3. Fasten actuator bracket (item 1) to the left

jamb of damper frame using [2] thread cutting

screws. Note: the 0.563 in. hole in the bracket

(item 1) that the 6 1/2 in. jackshaft (item 5) goes

through must be centered with the centerline of

the blade. Snap bearing (item 11) into internal

actuator bracket (item 1).

4. Snap bearing (item 11) into anti-rotation bracket

(item 7) and attach the anti-rotation bracket

assembly (item 7) to the internal mount bracket

(item #1) using [2] thread cutting screws (item 9).

5. Slide ½ in. diameter rod (item 5) slightly through

the anti rotation bracket (item 7). Install crankarm

(item 3) and drive link (item 2) onto the ½ in.

diameter rod (item 5) and install retaining clip

(item 12) to lock drive link onto the crankarm.

6. Install 10-24 x .375 shoulder bolt (item 8) to the

anti rotation bracket (item 7) using #10 Nylock

nut (item 6).

7. Attach actuator (item 10) to anti-rotation bracket

assembly (item 6). Tighten actuator onto shaft.

8. Connect drive link to blade drive lever using

e-clip. With blades closed and the actuator in its

fail position, position blades in their fail position

and tighten the crankarm to the 1/2 in. shaft.

9. Connect all electrical leads to the actuator.

Apply power to the actuator. The damper blades

should power position and return to the fail

position when power is disconnected.

Important

A break in power of less than one second can cause the

actuator to spring-return 5 degrees or less and remain in

place until a break in power of longer duration.

MS4120F1006

MS4120F1204

MS4620F1005

MS4620F1203

MS7510A2008

MS7510A2206 14W

MS7520A2007 16W

MS7520A2015 22W

MS7520A2205 16W

MS7520A2213 22W

MS8110A1206 24 VAC/VDC 30W 8W

MS8120F1002

MS8120F1200

Wiring Illustration

Model Volts Running Holding

120 VAC 35W 10W

230 VAC 35W 10W

14W

24 VAC/VDC

24 VAC 45W 10W

5W

Copyright © 2010 Greenheck Fan Corporation

473696 Internal lg MS IOM Rev. 1 May 2010

Loading...

Loading...