Greenheck MS4104 Installation Manual

Document Number 477252

!

®

MSXX04 & MSXX09 Series Actuators

INSTALLATION INSTRUCTIONS

These instructions apply to the external field installation of the Honeywell actuators on Greenheck models VCD Control

Dampers when they are duct mounted or sleeved.

These models are direct drive actuators that rotate to their energized position when power is applied, and spring return

to their fail position when power is disconnected.

Tools Required:

Wrenches: (1) 7⁄16 in., (1) 3⁄8 in.

(1) Ratchet with 3⁄8 in. deepwell socket

1

⁄8 in. Allen wrench

(1)

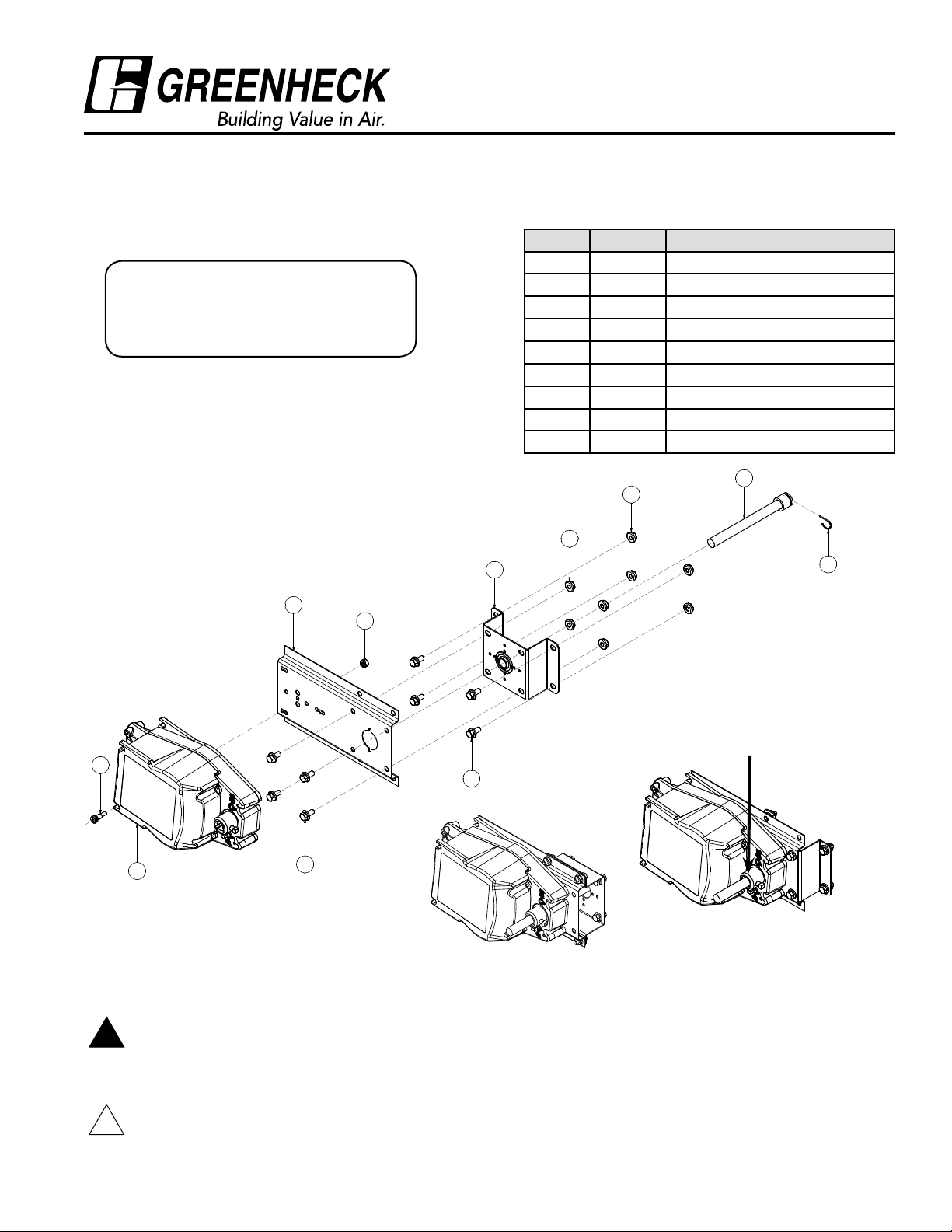

Part No. Quantitiy Description

1 1 External Mounting Bracket

2 1 #10-24 x .375 Shoulder Bolt

3 1 #10-24 Nut

4 8 1/4 - 20 x 1/2 Spinlock Bolt

5 8 1/4-20 Spinlock Nut

6 1 Actuator

7 1 Standoff Bracket

8 1 Extension Pin - 5 3/4 in. long

9 1 Retaining Clip - 1/2 in. dia.

Figure 1: Honeywell MSXX04 & MSXX09 Series external mount (exploded view).

5

5

7

1

3

2

6

Actuator can be flipped

aroung to reverse rotation.

Note: Bracket (7) is not used when damper model is VCDR or VCDRM series. On VCDR and VCDRM models, the

bracket (1) is bolted directly to the damper shaft upport bracket.

4

4

With Jackshaft

Without Jackshaft

8

9

Note:

Actuator shaft collar

accepts 1/2 in. (13mm)

diameter shaft.

WARNING

!

Equipment Damage or Electrical Power Hazard. Line voltage can cause death or serious injury and short equipment

circuitry. Disconnect power supply before installation.

CAUTION

!

Device Malfunction Hazard. Improper set screw tightening causes device malfunction. Tighten set screws with

proper torque to prevent damper shaft slippage.

FATPA DIRECT DRIVE SERIESINSTRUCTIONS

These installation instructions assume the damper is

already mounted in a duct or sleeve with the damper

shaft extending beyond the duct or sleeve 6 inches

(152mm).

1. Install the stand-off bracket

Dampers with a jackshaft

1a. Remove the 1/2 in. (13mm) ball bearing from the

standoff bracket. Mount the stand-off bracket (item

#7) with [4] ¼-20 x ½ in. (M6 x 12mm) spinlock

bolts and nuts (item #4 and 5). Orient the stand-off

bracket (item #7) so the hole is centered on the

jackshaft (see Figure 1, With Jackshaft).

Dampers without a jackshaft (Shaft Extension)

1b. Mount the stand-off bracket (item #7) spanning

across the damper frame flanges. Fasten to the

damper frame with [4] ¼-20 x ½ in. (M6 x 12mm)

spinlock bolts and nuts (item #4 and 5). Be sure not

to run the screws into the damper linkage, which is

between the flanges.

2. Mount actuator bracket

Fasten the actuator bracket (item #1) (See Figure

1) to the standoff bracket (item #7) using [4] ¼-20 x

½ in. (M6 X 20mm) spinlock bolts and nuts (item #4

and 5). Use outer four holes of the actuator bracket

(item #2).

3. Fail Position

If fail position is closed, make sure damper

blades are fully close and ensure blade seals are

compressed prior to tightening the actuator clamp

to the damper extension pin or jackshaft.

4. Install the actuator

Install the actuator (item #6) over the damper drive

shaft and tight against the actuator bracket (item

#1). Install [1] #10-24 x .375 shoulder bolts (item #2)

through lugs on actuator and through the holes in

back of the actuator bracket (item #1). Secure with

[2] #10-24 nuts (Item #5) (See Figure 1).

5. Secure actuator (Item #6) to drive shaft by

tightening the set screws on actuator collar.

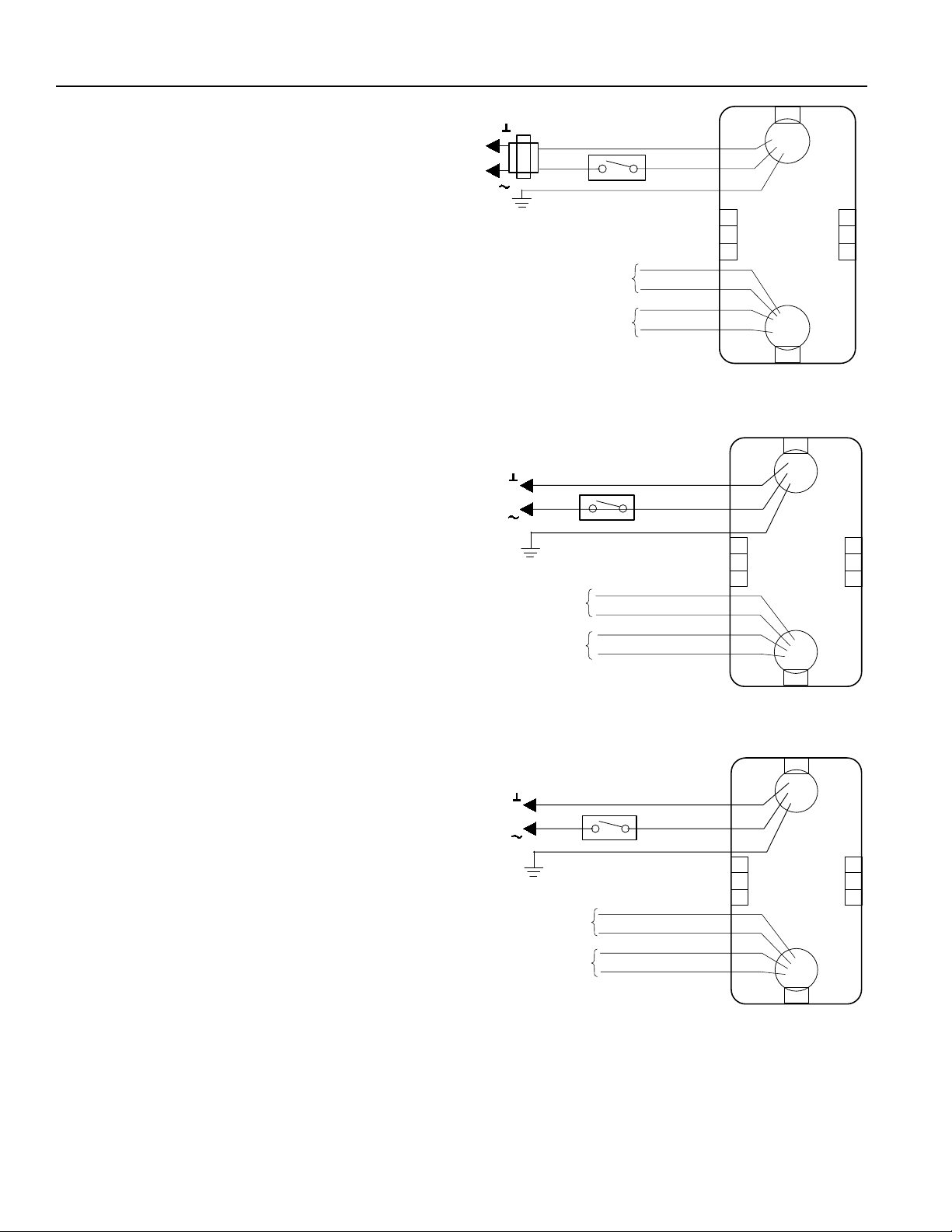

6. The wiring illustration identifies actuator electrical

requirements and connections (See Figure 2).

Wiring must comply with all applicable electrical

codes.

7. Apply power to the actuator. The damper blades

should fully open or close and return to the fail

position when power is disconnected.

( )

L2

( )

L1

( )

L2

120 VAC

( )

L1

7° AUXILIARY

85° AUXILIARY

( )

L2

230 VAC

( )

L1

7° AUXILIARY

85° AUXILIARY

24 VAC

7° AUXILIARY

SWITCH

85° AUXILIARY

SWITCH

24 VAC wiring diagram

SWITCH

SWITCH

120 VAC wiring diagram

SWITCH

SWITCH

BLACK

RED

GREEN

BLUE

BLUE

YELLOW

YELLOW

M34624

WHITE

BLACK

GREEN

BLUE

BLUE

YELLOW

YELLOW

M34625

BLUE

BROWN

GREEN

BLUE

BLUE

YELLOW

YELLOW

230 VAC wiring diagram

M34626

Figure 2: MS Series wiring illustration.

2

Loading...

Loading...