Page 1

Tools Required:

(1)

3

/8" and (2)1/2" wrenches

(1)

5

/32" Allen wrench

These instructions apply to the external field installation of Multi Products actuators on Greenheck models VCD Control

Dampers.

Multi Products actuators are impedance protected, and stall type. They rotate to their stall position when power is applied and

spring return to their fail position when power is interrupted.

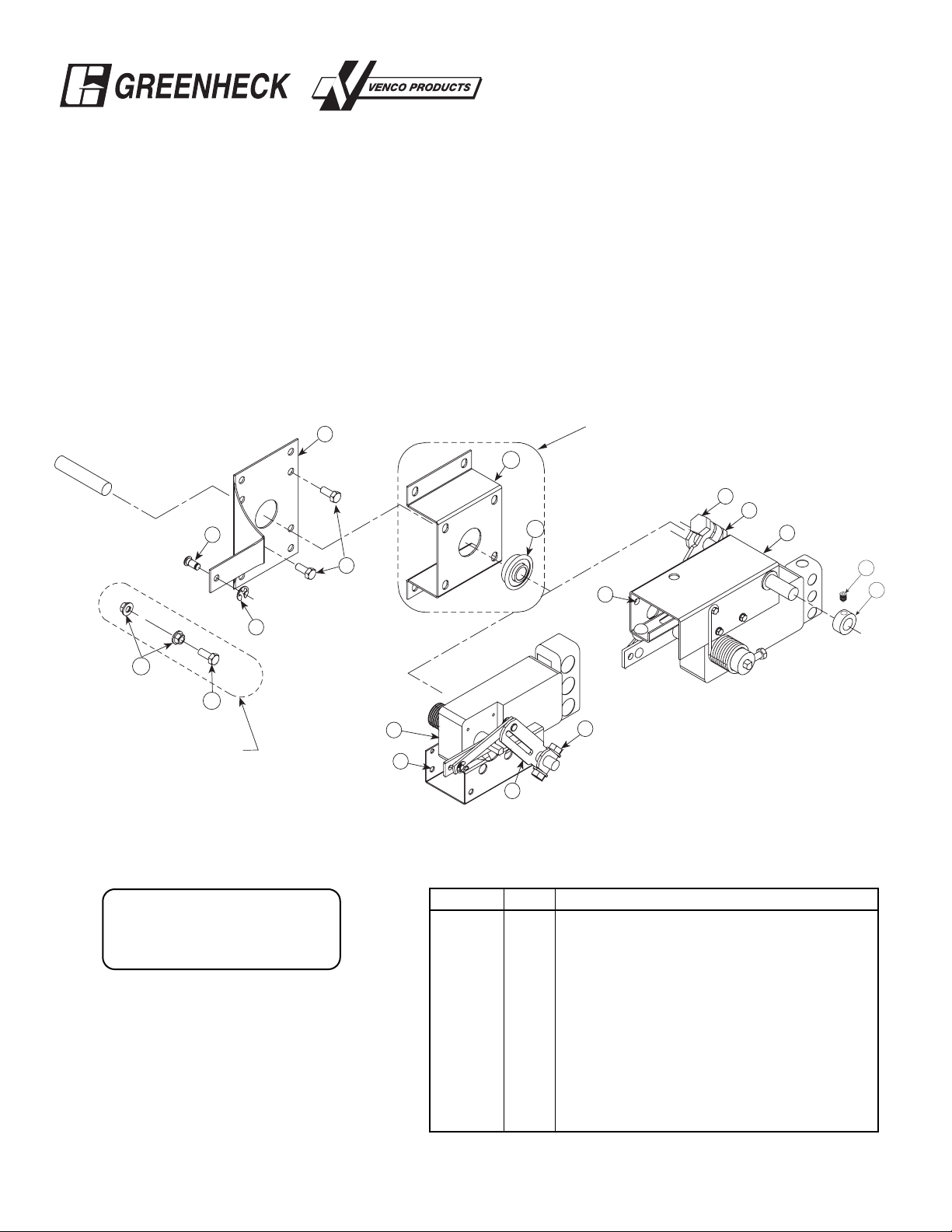

Part No. Qty. Description

1 1 Anchor Bracket

24

1

/4"-20 x 1/2" Thread Cutting Screws

31

5

/

16" Bolt with Nut

4 1 Linkage

5 1 Actuator Assembly

6 1 Set Screw

7 1 Shaft Collar

8 1 E-Ring

9 1 Knurl Pin

10 1 Stand Off Bracket (Used with Shaft Extension)

11 1 Ball Bearing (Used with Shaft Extension)

12 2

1

/

4"-20 Spinlock Nut

13 1

1

/4"-20 x 11/4" Bolt

Field Installation Instructions for

Multi Products Actuators

Models MP-3560, MP-3754, MP-3755 &

MP-3756

UL Listed Electric Actuators with Spring Return

Part no. 463549

DAMPERS AND LOUVERS

®

Used on VCD with control

shaft extension only.

(supplied with damper)

3

4

5

Damper Shaft

1

10

9

11

12

13

Required for counter

clockwise fail rotation

with a control shaft

extension.

2

A

8

Orientation of Actuator

Assembly for Clockwise

5

A

4

Orientation of Actuator Assembly for

Counter-Clockwise Fail Rotation

3

Fail Rotation

6

7

Page 2

Instructions:

These installation instructions assume the damper is already

mounted in a duct or sleeve with the damper shaft extending

beyond the sleeve or duct 6".

1. Install the anchor bracket.

Dampers with a jackshaft

1a. Mount the anchor bracket, #1, onto the jackshaft bracket

with four

1

/4"-20 X 1/2" thread cutting screws. Orient the

anchor bracket perpendicular to the damper on the duct or

sleeve so that the bracket's shaft hole is centered on the

jackshaft.

Dampers without a jackshaft (shaft extension)

1b. Mount the anchor bracket, #1, spanning across the damper

frame flanges. Orient the anchor bracket perpendicular to

the damper on the duct or sleeve so that the bracket's shaft

hole is centered on the shaft extension. Fasten to the

damper frame with four #14 Tek screws or equal, supplied

by others. Be sure not to run the screws into the damper

linkage, which is between the flanges.

2. Note the damper shaft rotation for fail direction and orient

the actuator appropriately. The actuator assembly, #5, can

be mounted with linkage towards or away from the damper

to provide correct rotation. Make sure the linkage is as

shown in the appropriate illustration.

Note: Inspect the damper blades and the damper shaft to

determine the proper damper shaft rotation for the desired

blade fail position.

3. Insert the damper shaft through the crankarm and the nylon

bearings in the actuator assembly.

4. Hole A in the mounting bracket mates with the

1

/4" pin

of the anchor bracket, #9, which is installed by the

factory. Secure the bracket with an E-ring, #8.

Note: For clockwise fail rotation with a control shaft

extension use part #12 and #13 in place of part #8 and

#9 to fasten the actuator assembly to the anchor

bracket.

5. Position the damper blades in the fail position,

either open or closed.

6. Tighten the

5

/16" bolt, #3, in the crank arm, #4.

7. On dampers with jackshafts, if the linkage is facing the

damper, install the shaft collar, #7, with the set screw,

#6, onto the damper shaft to hold the actuator on the

shaft, otherwise the shaft collar is not needed.

8. The above wiring illustration identifies actuator

electrical connections. Wiring should be per an

approved project or job wiring diagram and must

comply with all applicable electrical codes.

9. Apply power to the actuator.

The damper blades should fully open or close and

return to the fail position when power is disconnected,

if they do not, adjustments can be made by:

-Resetting the crankarm position on the damper shaft.

-or-

-Loosening the set screw in the

5

/16" shaft collar on

the motor shaft to increase or decrease return spring

tension.

Wiring Diagram

IOM MP3754 & MP3756 Motor Pack FS

Rev. 1 July 2003

Copyright © 2003 Greenheck Fan Corp.

Red

Brown

Black

White

Green

110/115/120 Volt

Actuator

Dual Voltage Actuators

Red

Black

Brown

White

Green

208/220/230/240 Volt

Actuator

Black

Black

Green

Single Voltage Actuator

Actuator

GREENHECK

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410

PH. 715-359-6171

www.greenheck.com

Loading...

Loading...