Page 1

Field Installation Instructions

Motor Pack Contents

1. Actuator

2. Actuator Bracket

3. Actuator Arm Assembly

4. Connecting Links

5. Actuator Spring

All hardware included

4

Part Number 463547

Multi Products

MP-310 Motor Pack

UL Listed Electric Actuators With Spring Return

For Use With WD-300 Series Dampers

1

1

1

5

1. MP-310 motor packs

are designed for use on

model WD-300 series

backdraft dampers

only.

2. For single panel damper, insert tab of Actuator Bracket into

the slot on the side of the frame. For dampers with center

bars, the tab of the Actuator Bracket should be inserted into

the slot on the bottom of the center bearing rail. Position

bracket over the two holes on the bottom of the frame and

secure with the #10 hardware provided.

3. Position the Connecting Link(s) on the second blade pivot

from the bottom of the damper. Slip the Connecting Link

over the bushing and with a needle nose pliers bend the tab

over to the position shown in detail "A". This will hold the

Connecting Link in place on the pivot.

4. To adjust the Actuator Linkage Assembly, pull back on the

Actuator Arm Assembly until a slight amount of tension

has been applied to the Actuator Spring. Tighten the

fasteners between the Connecting Link and the Actuator

Arm Assembly. Fasteners should be placed as far apart as

possible. This provides greater stability to the linkage. To

increase spring tension, raise the spring up on the bracket.

To decrease spring tension, lower the spring.

NOTE: It is important to avoid too much spring tension; use

just enough tension to help close the damper. Too

much tension could impair opening of the damper.

5. Actuators are supplied with junction boxes and covers.

When wiring, make sure the voltage is correct. On dual

voltage motor packs, be sure to connect the proper motor

leads for the correct voltage and insulate any unused wire.

The voltage of each specific model is stamped into the

actuator housing or on a label that is affixed to the actuator

(see page 2 for typical wiring diagrams).

2

Single Panel Multiple Panel

5

3

2

Note: When two panels or more, use the multiple panel method

for all actuators.

6. If the damper fails to open properly, check for one of

the following causes:

A. Motor pack fails to open the damper completely.

• Check for an ‘out of square’ or racked damper.

• Spring tension too great.

• Excessive voltage drop.

B. Motor pack fails to function.

• Check for correct voltage.

• Check for proper wiring.

Motor Pack Quantity

One or two motor packs may be required depending on

damper size. Single panel dampers have one column

of blades and one actuator is installed as shown in the

Single panel view above. Double panel dampers have

two columns of blades and on actuator is installed

as shown in the Multiple panel view above. Triple

panel dampers have three columns of blades and two

actuators are installed as shown in the Multiple panel

view above.

Actuator Specifications

MP-310 motor packs use single phase 60hz (50hz

optional) shaded pole stall type impedance protected

electric actuators and are supplied in various

voltages(see chart below). For 277, 575 or 600 volt

operation a transformer and 115 volt motor pack is

required.

3

Motor packs 24V (60 Hz) 440V (60 Hz) 120V (50/60 Hz) 208V (50/60 Hz) 220V (50/60 Hz) 24V (50 Hz) 380V (50 Hz)

Stall Amps .740 .047 .110 .050 .062 .100 .098

Spec ID# 3753 3752 3751 3751 3751 2651-A 2663-C

Page 2

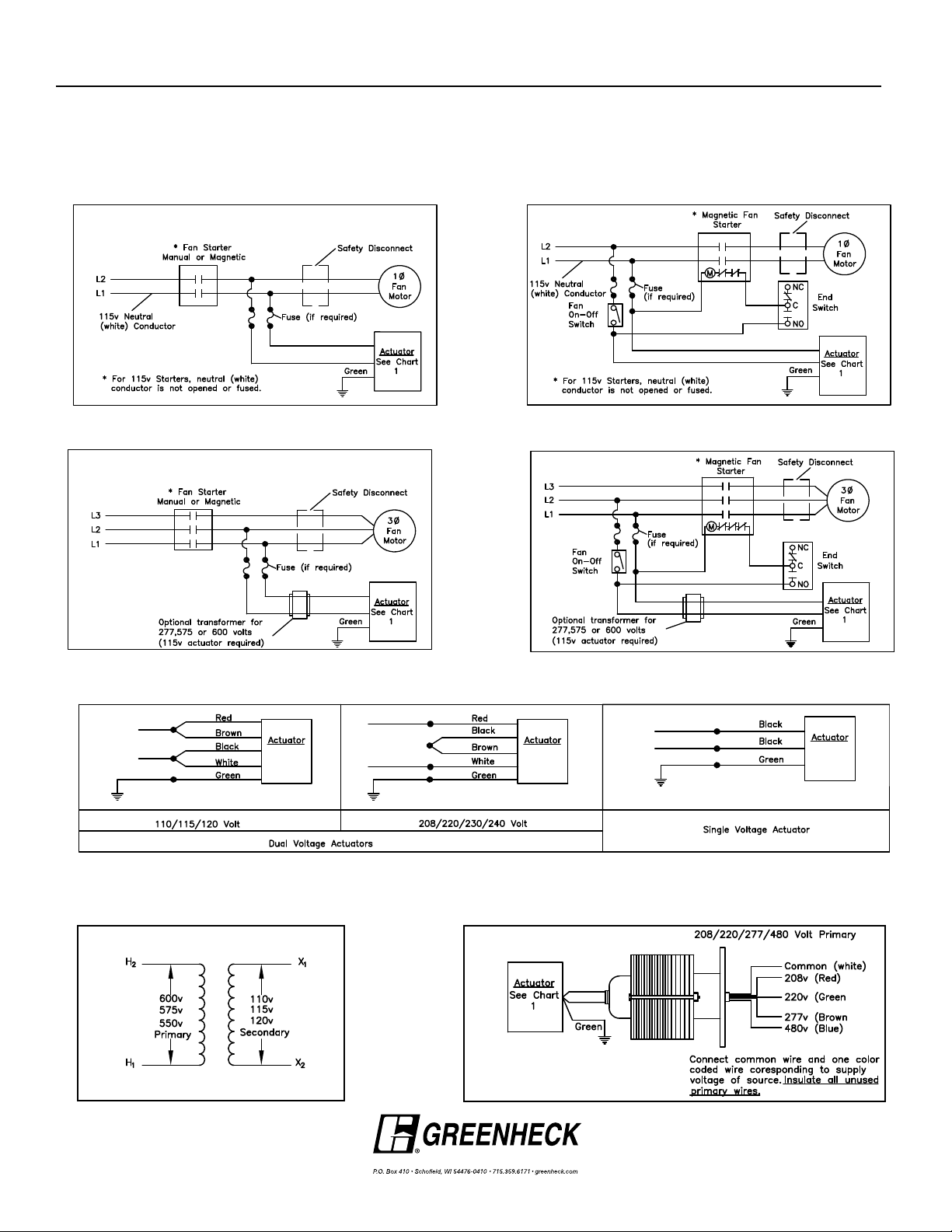

TYPICAL WIRING DIAGRAMS MP-310

Wiring diagrams are shown for motor packs and dampers installed with power ventilator fan equipment with single speed

motor. The damper will open when the fan is on and close when the fan is off. For connection to 2-speed fan motors or for

other control sequences consult the factory. The wiring diagrams shown with end switches are for applications where it is

desirable to have the damper fully open before fan start-up.

Single Phase

Three Phase

575/600 Volt Transformer Model B050WZ13

Chart 1

Transformers

208/220/277/460 Volt Transformer

Copyright © 2009 Greenheck Fan Corporation

463547 MP310 rev 4 Dec 2009

Loading...

Loading...