Page 1

®

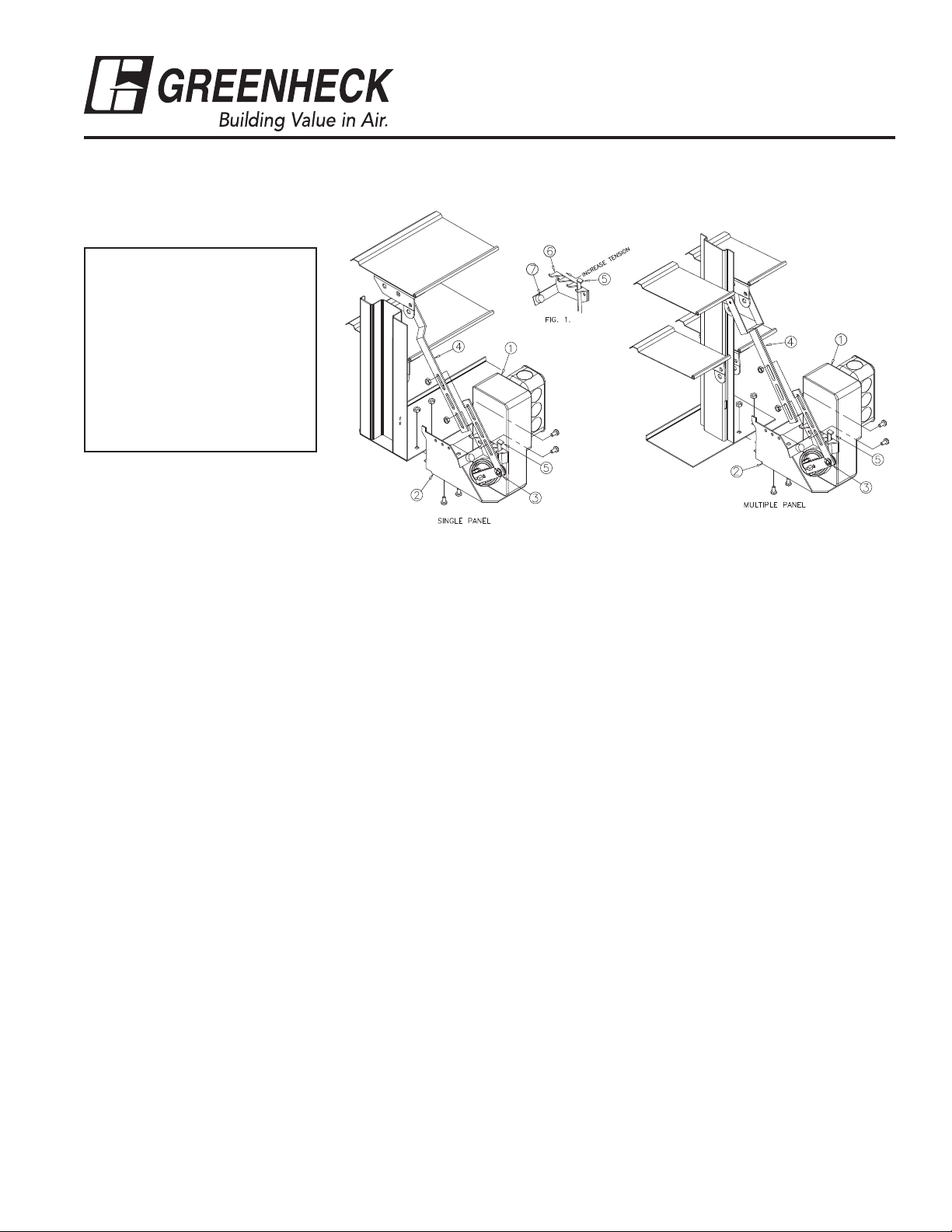

Field Installation Instructions

Motor Pack Contents

1. Actuator

2. Actuator Bracket

3. Actuator Arm Assembly

4. Connecting Links

5. Actuator Spring

All necessary hardware included

Document Number 463544

MP-220A Motor Pack

UL Listed Electric Actuators with Spring Return

for use with WD-200 Series Dampers

1. The MP-220A motor pack is designed for

installation on model WD-200 series backdraft

dampers only.

2. For single panel damper, insert tab of motor bracket

into the slot on the side of the frame. For dampers

with center bars, the tab of the motor bracket should

be inserted into the slot on the bottom of the center

bearing rail. Position bracket over the two holes on the

bottom of the frame and secure with the #10 hardware

provided.

3. Loosely connect the actuator arm assembly to

the connecting link using the provided hardware.

Fasteners should be placed as far apart as possible to

provide greater stability to the linkage. The connecting

links may need to be modified or shortened on some

dampers sizes. To make the adjustment easier, release

the spring from the spring adjustment bracket.

Note: The connecting link(s) have been

installed on the damper at the factory.

4. To adjust the actuator linkage, position the actuator

arm approximately 1/8” away from the rubber bumper.

While holding the damper blades closed, tighten the

fasteners between the connecting link and actuator

arm assembly. Place the spring onto the first hook

of the adjustment bracket (see Fig. 1). Operate the

damper manually. Verify that the linkage and fasteners

do not interfere with any components of the assembly

and that the damper blades close completely when

released. To increase spring tension, move the spring

to the next hook as shown in Fig 1.

Note: It is important to avoid too much

spring tension; use just enough tension to

close the damper. Too much tension could

impair opening of the damper or cause

damage to the components as the crankarm

impacts the rubber bumper.

5. Actuators are supplied with junction box and

covers. When wiring, make sure the supply voltage

agrees with the actuator voltage. On dual voltage

motor packs, be sure to connect the proper motor

leads for the correct voltage and insulate any unused

wire. The voltage of each specific model is indicated

on a label that is affixed to the actuator (see page 2

and 3 for typical wiring diagrams).

6. If the damper fails to open properly, check for one

of the following causes:

• Check for an ‘out of square’ or racked

damper

• Check for mounting screws interfering with

the blade and linkage rotation

• Spring tension too great

• Excessive voltage drop

• Excessive negative pressure in the building

If actuator fails to function:

• Check for correct voltage

• Check for proper wiring

Page 2

Motor Pack Quantity

More than one motor pack may be required depending

on damper size. On single panel dampers, the

actuator is installed as shown on page 1 in the Single

Panel view. On double panel dampers, the actuator

is installed as shown on page 1 in the multiple panel

view. On triple panel dampers, two actuators are

installed as shown in the multiple panel view.

Chart 1

Motor Packs 24V (50/60 Hz)

Stall Amps .66 .15 .07 .041

Spec ID# G24 G110-240 G-110-240 G460

110 thru 120V

(50/60Hz)

Actuator Specifications

MP-220A motor pack uses a single phase shaded

pole stall type impedance protected electric actuators

and are supplied in various voltages (see chart). For

277, 380, 575 or 600 volt operation, a transformer and

a 120V motor pack is required.

208 thru 240V

(50/60 Hz)

460V (60Hz)

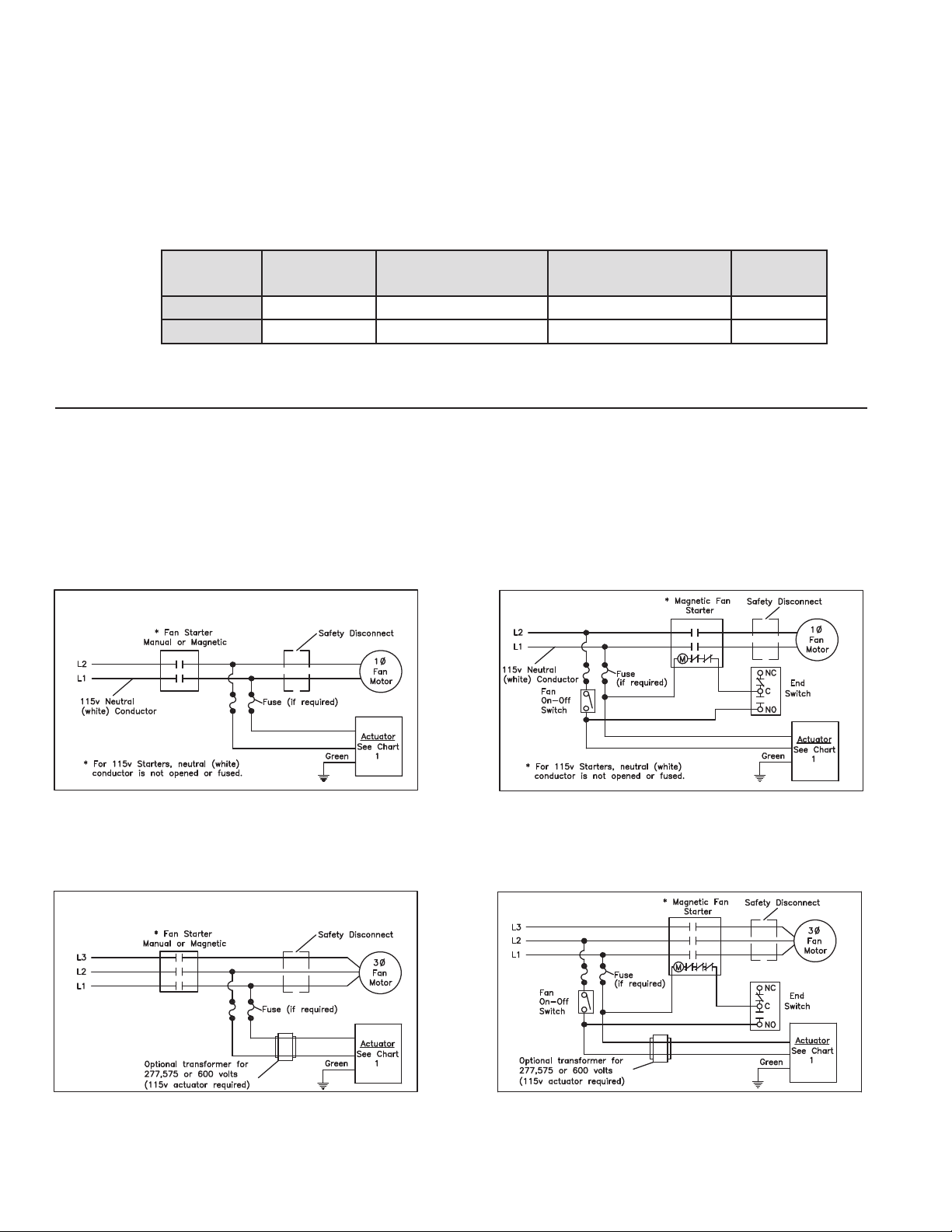

Typical Wiring Diagrams

Wiring diagrams are shown for motor packs and dampers installed with power ventilator fan equipment with

single speed motor. The damper will open when the fan is on and close when the fan is off. For connection to

2-speed fan motors or for other control sequences consult the factory. The wiring diagrams shown with end

switches are for applications where it is desirable to have the damper fully open before fan start-up.

Single Phase

Three Phase

Page 3

Typical Wiring Diagrams MP-220A

Optional transformer for

277, 380, 575 or 600 volts

(120V actuator required)

Optional transformer for

277, 380, 575 or 600 volts

(120V actuator required)

Optional transformer for

277, 380, 575 or 600 volts

(120V actuator required)

Optional transformer for

277, 380, 575 or 600 volts

(120V actuator required)

Blue

110/115/120V Dual Voltage Actuators

Blue

208/220/230/240V Dual Voltage Actuators

Actuator Wiring Diagrams

Blue

110/115/120V Dual Voltage Actuators

White

24V Single Voltage Actuator

575/600 Volt Transformer Model B050WZ13 208/220/277/460 Volt Transformer

Transformers

208/220/230/240V Dual Voltage Actuators

460V Single Voltage Actuator

Blue

Brown

Brown

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in

the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

463544• MP220A Series Rev. 4, October 2014 Copyright 2014 © Greenheck Fan Corporation

3

Loading...

Loading...