Page 1

DOCUMENT NUMBER 479869

®

MOUNTING KIT FOR ACTUATORS

Belimo and Honeywell models

Installation, Operation, and Maintenance Instructions

These instructions apply to the internal or external field replacement of mounting hardware for direct drive

actuators (Belimo and Honeywell [except MS7505 and MS8105 series] ) on Greenheck control dampers when

they are duct mounted or sleeved.

WARNING

!

Equipment Damage or Electrical Power Hazard.

Line voltage can cause death or serious injury

and short circuit equipment. Disconnect power

supply before installation.

Wrenches: (1)

(1) Ratchet with

(1) Drill with 3⁄8 in. and 9/32 in. nut driver,

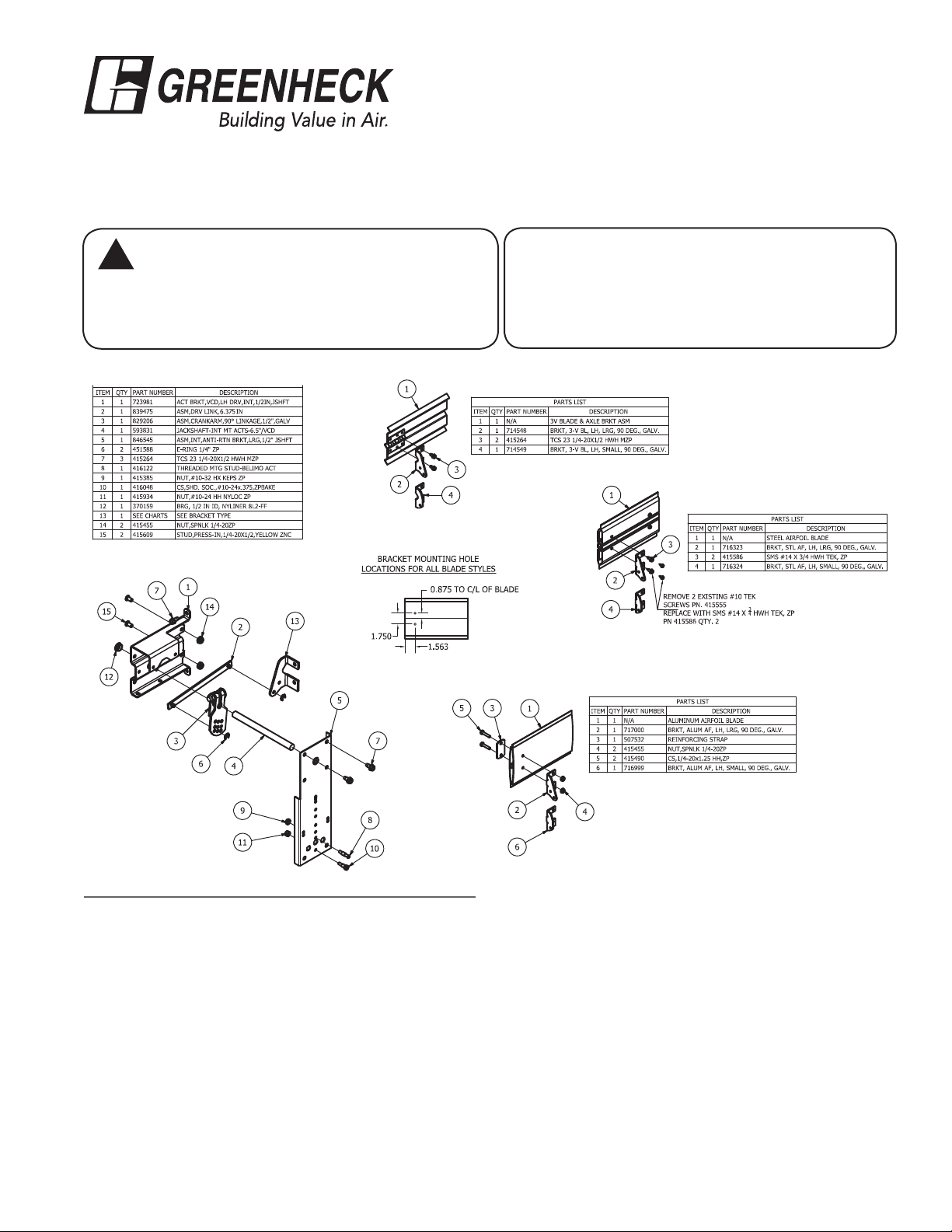

PART NO. 872700: INTERNAL MOUNT - 1/2 IN. PIN OR JACKSHAFT

3-V Blade

Tools Required:

7

⁄16 in., (1) 3⁄8 in., (1) 9⁄16 in.

3

⁄8, 7⁄16, 9⁄16 in. deepwell socket

(1) 1⁄8 in. Allen wrench,

(1) .203 dia. drill bit

Steel Airfoil Blade

Instructions

1. Have damper in desired fail position.

2. Drill (2) 0.203 inch holes in the first blade (when one

or two blade damper) or third blade (more than a two

blade damper) at a location as shown above for the

blade type you have.

3. Attach blade drive lever (item #13) using two fasteners

(see list above based on blade type). Note: Shaft (item

#4) needs to be centered with the centerline of the

blade.

4. Fasten actuator bracket (item #1) to the left jamb of

damper frame using (1) thread cutting screw in top tab

of bracket (0.203 in. hole is required). Note bottom tab

does not get a fastener. Install (2) 1/4 -20 x 1/2 studs

(item #15) and nuts (item #14) through holes in damper

Aluminum Airfoil Blade

frame. Snap bearing (item #12) into internal actuator

bracket.

5. Slide 1/2 in. diameter shaft (item #4) slightly through

the anti-rotation bracket (item #5). Install crankarm

(item #3) and drive link (item #2) onto the 1/2 in.

diameter shaft (item #4) and install e-clip (item #6) to

lock drive link (item #2) on the crankarm (item #3).After

the crankarm is installed, slide 1/2 in. shaft through the

bearing (Item #12).

6. Install shoulder bolt (items #8 or 10) to the anti-rotation

bracket (item #5) using nut (item #9 or 11). Bolt

location will vary depending on the actuator model.

7. Slide the anti-rotation bracket (item #5) over the 1/2

in. shaft. Fasten to actuator bracket (item #1) using

thread cutting screws (item #7). Attach actuator to

Page 2

PART NO. 872700 INSTRUCTIONS CONT...

anti-rotation bracket assembly (item #5). Tighten the

actuator onto the shaft (item #4).

8. Connect drive link (item #2) to blade drive lever (item

#13) using e-clip (item #6). For fail close, position the

blades in the closed position and the actuator in its fail

position. For fail open, position the blades in the open

position and the actuator in its fail position. Tighten

the crankarm to the 1/2 in. shaft.

9. Connect all electrical leads to the actuator. Apply

power to the actuator. The damper blades should

rotate to the power position and return to the fail

position when power is disconnected.

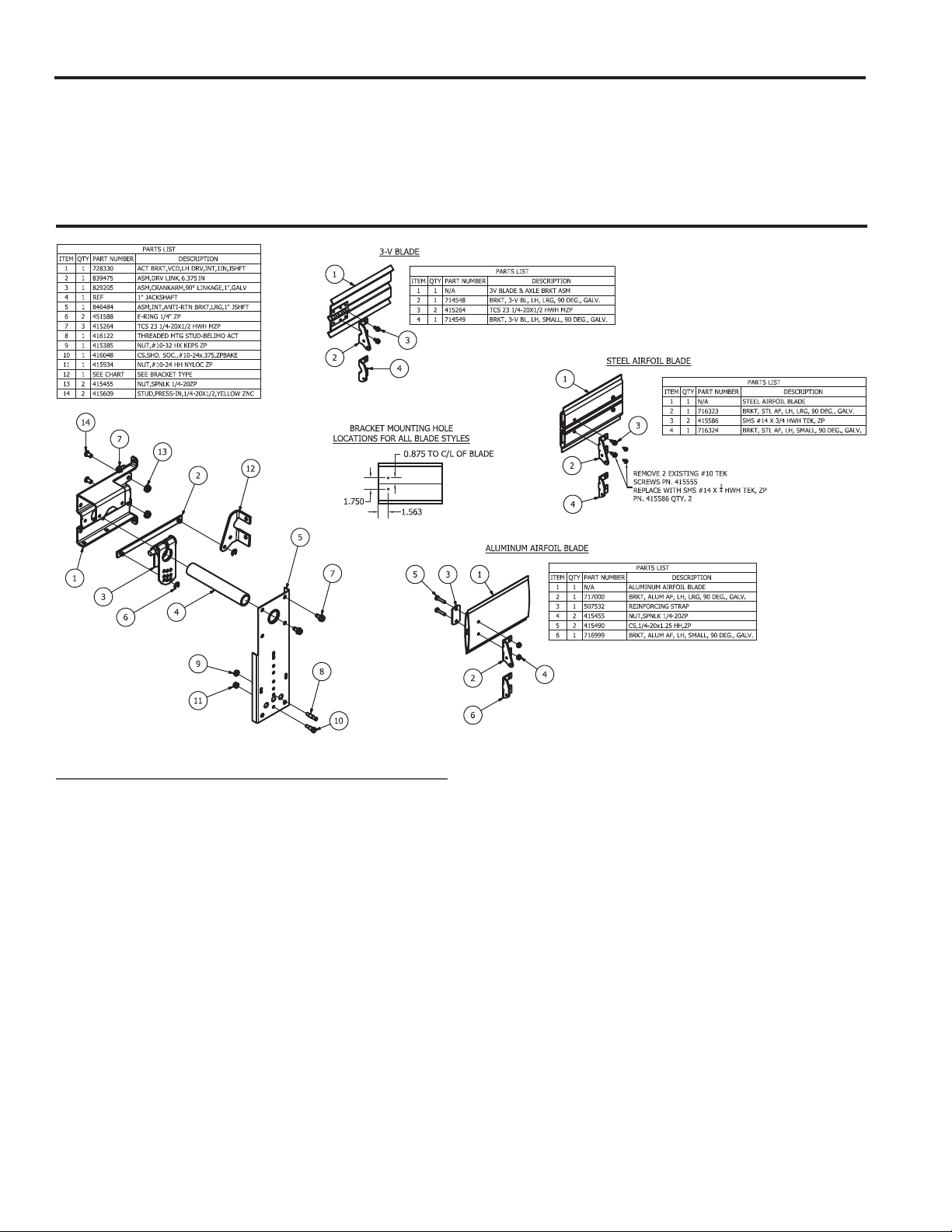

PART NO. 872701: INTERNAL MOUNT FOR 1 IN. JACKSHAFT

Instructions

1. Have damper in desired fail position.

2. Drill (2) 0.203 inch holes in the first blade (when one

or two blade damper) or third blade (more than a two

blade damper) at a location as shown above for the

blade type you have.

3. Attach blade drive lever (item #12) using two fasteners

(see list above based on blade type). Note: Shaft

needs to be centered with the centerline of the blade.

4. Fasten actuator bracket (item #1) to the left jamb of

damper frame using (1) thread cutting screw in top tab

of bracket (0.203 in. hole is required). Note: bottom tab

does not get a fastener. Install (2) 1/4 x 20 x 1/2 stud

bolts (item #14) and nuts (items 13) through the frame.

5. Slide 1 in. diameter shaft (item #4) slightly through the

anti-rotation bracket (item #5). Install crankarm (item

#3)and drive link (item #2) onto the 1 in. diameter shaft

(item #4) and install e-clip (item #6) to lock drive link

(item #2) on the crankarm.

2

6. Install shoulder bolt (item #8 or 10) to the anti-rotation

bracket (item #5) using nut (item #9 or 11). Bolt

location will vary depending on the actuator model.

7. Install anti-rotation bracket (item #5) to actuator

bracket (item #1) using thread cutting screws (item #7).

Attach actuator to anti-rotation bracket assembly (item

#5). Tighten the actuator onto the shaft.

8. Connect drive link (item #2) to blade drive lever (item

#12) using e-clip (item #6). For fail close, position the

blades in the closed position and the actuator in its fail

position. For fail open, position the blades in the open

position and the actuator in its fail position. Tighten

the crankarm to the 1/2 in. shaft (item #4).

9. Connect all electrical leads to the actuator. Apply

power to the actuator. The damper blades should

rotate to the power position and return to the fail

position when power is disconnected.

Page 3

PART NO. 872907: EXTERNAL MOUNT DIRECT DRIVE

Instructions

1. Have damper in desired fail position.

2. Install clip (item #4) into extension pin (item #1). Push

extension pin onto drive blade (bottom blade for

dampers with one or two blades) or third blade (when

damper has more than two blades).

3. Mount the stand-off bracket (item #2) over the

extension pin (item #1) spanning across the damper

frame. Fasten to the damper frame with bolts and nuts

(items 5 & 6).

4. Fasten the actuator bracket (item #3) to the standoff

bracket using bolts and nuts (items #5 & 6).

5. Install shoulder bolt (item #7 or 8) to the anti-rotation

bracket (item #3) using nut (item #9 or 10). Bolt

location will vary depending on the actuator model.

6. For fail close, position the blades in the closed

position and the actuator in its fail position. For fail

open, position the blades in the open position and the

actuator in its fail position. Tighten the actuator clamp

to the damper pin (item #1).

7. Attach actuator to anti-rotation bracket assembly (item

#3). Tighten the actuator onto the shaft (item #1).

8. Connect all electrical leads to the actuator. Apply

power to the actuator. The damper blades should

rotate to the power position and return to the fail

position when power is disconnected.

3

Page 4

PART NO. 872908: EXTERNAL MOUNT JACKSHAFTED

Instructions

1. Have damper in desired fail position.

2. Jackshaft supplied is 1 in. (25mm) diameter or 1/2 in.

(13mm) diameter. Mount the stand-off bracket (item #3)

with thread cutting screws (item #5). Orient the standoff bracket (item #3) so the hole is centered on the

jackshaft.

3. Fasten the actuator bracket (item #4) to the standoff

bracket using thread cutting screws (item 5). Use outer

four holes of the actuator bracket.

5. Install shoulder bolt (item #6 or 7) to the anti-rotation

bracket (item #3) using nut (item #8 or 9). Bolt location

will vary depending on the actuator model.

4. For fail close, position the blades in the closed

position and the actuator in its fail position. For fail

open, position the blades in the open position and the

actuator in its fail position. Tighten the actuator clamp

to the jackshaft (item #1).

5. Attach actuator to anti-rotation bracket assembly

(item #4). Tighten the actuator onto the shaft (item #1).

6. Connect all electrical leads to the actuator. Apply

power to the actuator. The damper blades should

rotate to the power position and return to the fail

position when power is disconnected.

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in

the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

479869• Mounting Kits for Actuators Rev. 1, January 2015 Copyright 2015 © Greenheck Fan Corporation

4

Loading...

Loading...