Greenheck ML4XXX Installation Manual

®

Part number 458403

! !

FATPA Series Actuators

Models ML4XXX, ML8XXX, MS4209,MS4309, MS8209, and MS8309

INSTALLATION INSTRUCTIONS

These instructions apply to the external field installation of the Honeywell, FATPA Series, actuators on Greenheck models VCD

Control Dampers when they are duct mounted or sleeved.

These models are direct drive actuators that rotate to their energized position when power is applied, and spring return to

their fail position when power is disconnected.

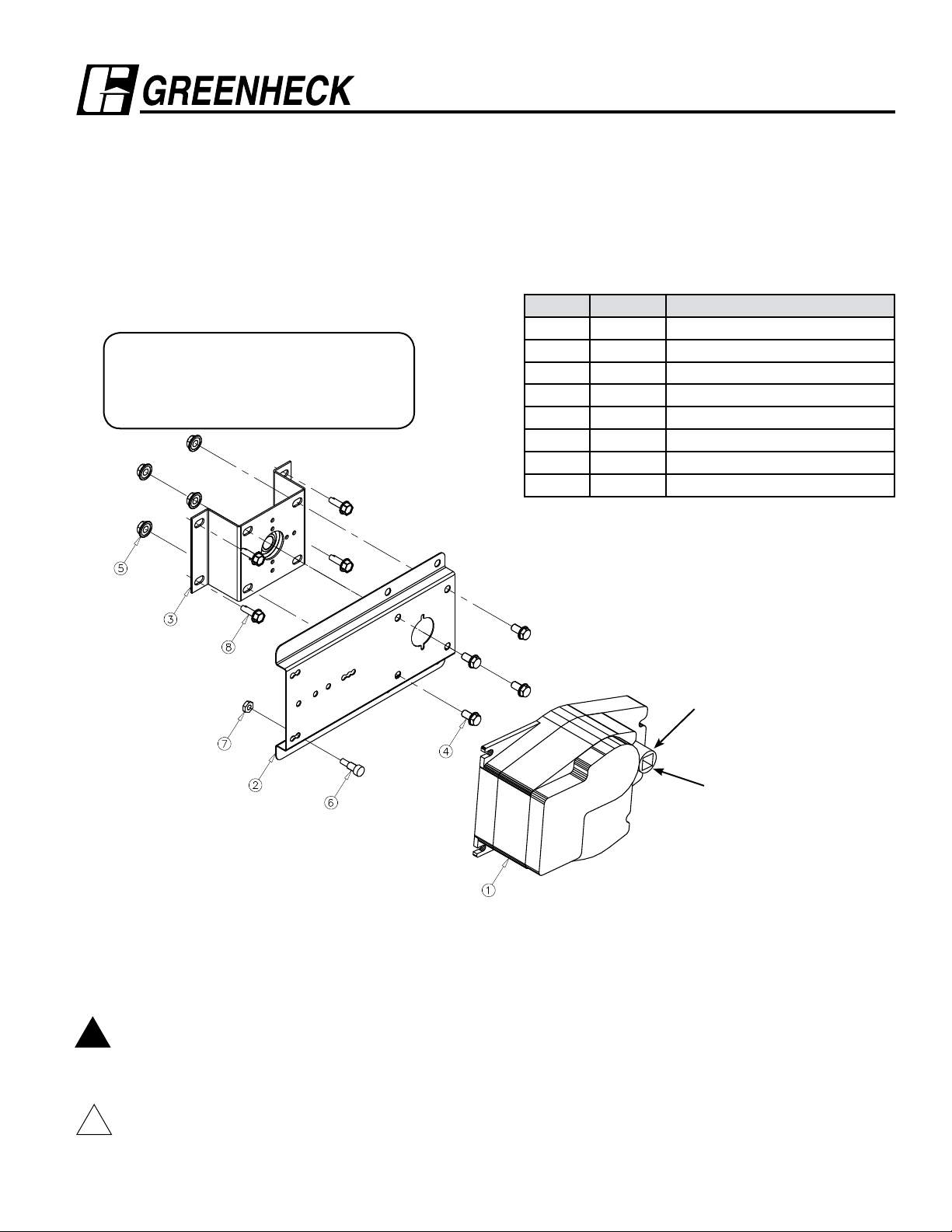

Part No. Quantitiy Description

1 1 Actuator, Honeywell FATPA Series

Tools Required:

Wrenches: (1) 7⁄16 in., (1) 3⁄8 in.

(1) Ratchet with

(1)

3

⁄8 in. deepwell socket

1

⁄8 in. Allen wrench

2 1 Anti Rotation Bracket

3 1 Standoff Bracket

4 4 1/4 - 20 x 1/2 Spinlock Bolt

5 4 1/4-20 Spinlock Nut

6 1 1/4 x 3/8 Shoulder Bolt

7 1 #10 - 24 Nyloc Nut

8 4 #14 x 3/4 Tek Screws

Figure 1: Honeywell FATPA Series external mount (exploded view).

WARNING

Equipment Damage or Electrical Power Hazard. Line voltage can cause death or serious injury and short equipment

circuitry. Disconnect power supply before installation.

Note:

Actuator shaft collar

accepts 1/2 in. (13mm)

diameter shaft. Shaft

rotation designated from

this side of actuator.

Torque Set Screws to

50-55 in. lbs. (5.6-6.2 Nm)

CAUTION

Device Malfunction Hazard. Improper set screw tightening causes device malfunction. Tighten set screws with

proper torque to prevent damper shaft slippage.

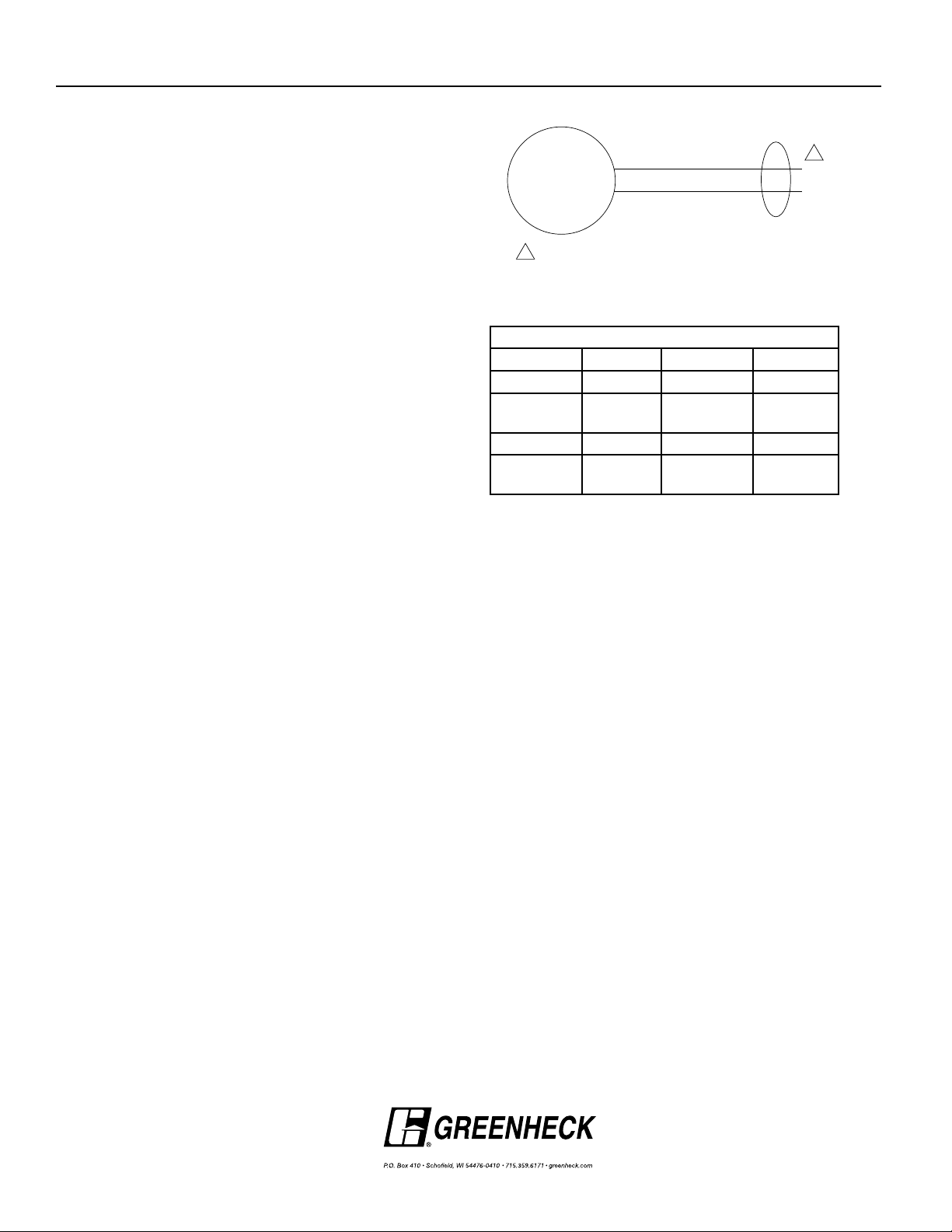

Black

White (120 Vac)

L

1

(Hot)

M

L

2

Red (24 Vac)

Power supply . Provide disconnect and means of overload protection.

1

1

These installation instructions assume the damper is already

mounted in a duct or sleeve with the damper shaft extending

beyond the duct or sleeve 6 inches (152mm).

1. Install the stand-off bracket

Dampers with a jackshaft

1a. Jackshaft supplied is typically 1 in. (25 mm) diameter.

Mount the stand-off bracket (item #2) with [4] ¼-20 x ½

in. (M6 x 12mm) self drilling screws (item #3). Orient the

stand-off bracket (item #2) so the hole is centered on the

jackshaft (See Figure 1).

Dampers without a jackshaft (Shaft Extension)

1b. Mount the stand-off bracket (item #2) spanning across

the damper frame flanges. Fasten to the damper frame

with [4] ¼-20 x ½ in. (M6 x 12mm) self drilling screws

(item #3). Be sure not to run the screws into the damper

linkage, which is between the flanges.

2. Mount actuator bracket

Fasten the actuator bracket (item #6) (See Figure 1) to

the standoff bracket (item #2) using [4] ¼-20 x ½ in. (M6 X

20mm) thread studs (item #4) and [4] ¼-20 (M6) nuts (item

#5). Use outer four holes of the actuator bracket (item #6)

(See Figure 2).

3. Fail Position

If fail position is closed, make sure damper blades are

fully close and ensure blade seals are compressed prior to

tightening the actuator clamp to the damper extension pin

or jackshaft.

4. Install the actuator

Install the actuator (item #1) over the damper drive shaft

and tight against the actuator bracket (item #6). Install [2]

¼-20 x ½ in. (M6 x 20mm) shoulder bolts (item #4) through

lugs on actuator and through the holes in back of the

actuator bracket (item #6). Secure with [2] ¼-20 M6 nuts

(Item #5) (See Figure 1).

5. Secure actuator (Item #1) to drive shaft by tightening the

set screws on actuator collar to 50-55 in. lbs. (5.6 - 6.2

Nm).

6. The wiring illustration identifies actuator electrical

requirements and connections (See Figure 3). Wiring must

comply with all applicable electrical codes.

7. Apply power to the actuator. The damper blades should

fully open or close and return to the fail position when

power is disconnected.

IMPORTANT

For actuators with a product date code before 0527m

a power break of less than two seconds can cause the

actuator to spring-return 5 degrees or less and remain

in place until a power break of longer duration. For

actuators with a product date code of 0527 or after, a

power break of any duration will cause the actuator to

spring-return and be able to drive immediately when

power is reapplied.

FATPA DIRECT DRIVE SERIESINSTRUCTIONS

Figure 3: FATPA Series wiring illustration.

Power Consumption

Model Volts Running Holding

ML4XXX 120 18W 9W

MS4209

MS4309

ML8XXX 24 16W 8W

MS8209

MS8309

Actuator Weight

5 lb (2.3 kg).

Noise Rating

Driving Open: Maximum 65 dBA at 1m.

Holding: Maximum 20 dBA at 1m (no audible noise).

Temperature Ratings

Ambient: 0°F to 130°F (-18°C to 55°C)

Shipping and Storage: -40°F to 140°F (-40°C to 60°C)

Humidity Ratings

5% to 95% RH non-condensing.

Environmental Protection Ratings

NEMA 1

IP42

Approvals

Underwriters Laboratories Inc. UL 873 plenum rating,

and cUL: File #E4436: Guide #XAPX.

Direction of Spring Return

Counterclockwise (see Figure 1, see note)

MS4309, ML4302

MS8309, ML8302

Clockwise (see Figure 1, see note)

MS4209, ML4202

MS8209, ML8202

Actuator Timing (Under Load)

Drive Open: 15 seconds.

Spring Close: 15 seconds.

120 23W 7W

24 23W 7W

Copyright ©2009 Greenheck Fan Corporation

458403 IOM - FATPA Rev 7 June 2009

Loading...

Loading...