Page 1

Document Number 459011

!

FATPA Series Actuators

Mounted Internally

Models ML4XXX, ML8XXX, MS4209, MS4309, MS8209 and MS8309

INSTALLATION INSTRUCTIONS

These instructions apply to the internal field replacement of the Honeywell, FATPA Series, actuators on Greenheck models

VCD control dampers. when they are duct mounted or sleeved.

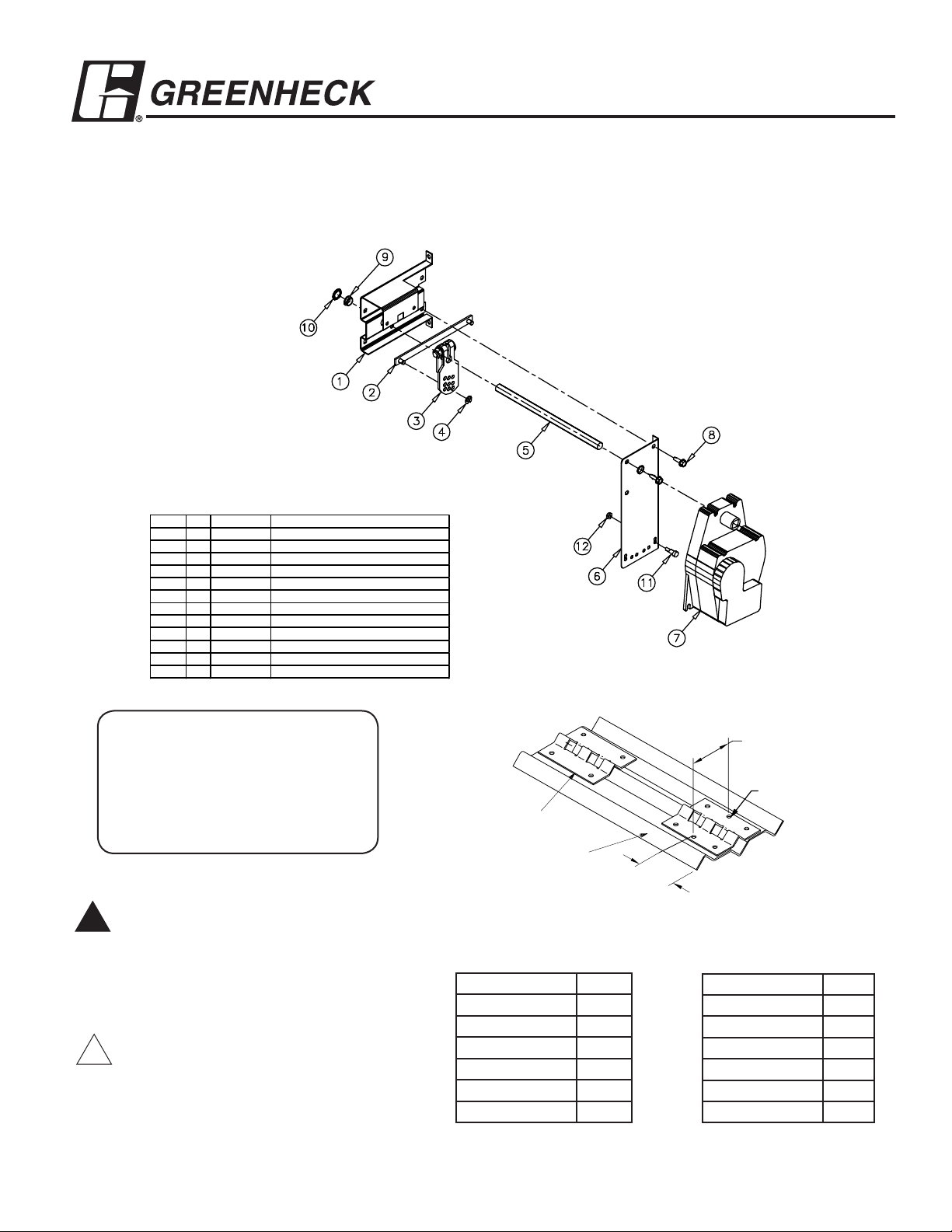

ITE M # QTY PART # DESCRIPTION

1 1 723981 INTERNAL ACTUA TOR BRKT

2 1 839475 DRIVE LINK A SSEMB LY

3 1 829206 1/ 2" CRANKARM A SSE MBLY

4 1 451588 1/ 4" E-RING

5 1 593831 6. 5" JACKSHAFT, 1/ 2" DIA.

6 1 846591 A NTI-ROTATION B RACKET ASM

7 1 SEE CHART A CTUATOR

8 2 415264 1/ 4-20x1/2 TCS

9 1 370159 1/ 2" SNAP IN BEARING

10 1 416179 RETAINING RING 1/2"

11 1 416048 10-24X.375 SHOULDER BOLT

12 1 415934 10-24 NYLOC NUT

Figure 1: Honeywell FATPA Series internal mount (exploded view).

Tools Required:

Wrenches: (1) 7⁄16 in., (1) 3⁄8 in., (1) 9⁄16 in.

(1) Ratchet with 3⁄8, 7⁄16, 9⁄16 in. deepwell

socket

(1) 1⁄8 in. Allen wrench,

(1) Drill with 3⁄8 in. nut driver,

(1) .203 dia. drill bit

!

Equipment Damage or Electrical Power Hazard.

Line voltage can cause death or serious injury

and short equipment circuitry. Disconnect power

supply before installation.

!

Device Malfunction Hazard. Improper set screw

tightening causes device malfunction. Tighten

set screws with proper torque to prevent damper

shaft slippage.

WARNING

CAUTION

Blade Axle Bracket

Damper Blade

Fail Close Dampers Part #

ML4202F1000 120V 383260

ML8202F1006 24V 383264

MS8209F1003 24V 382733

MS4209F1007 120V 382731

ML4702F1009 230V 383262

MS4709F1014 230V 382735

1.563 in.

(39mm)

1.75 in. (44mm)

Blade Lever Hole

Location

.203 in. (5.2mm) Diameter.

(2)

Detail A

Fail Open Dampers Part #

ML4302F1008 120V 383261

ML8302F1004 24V 383265

MS8309F1001 24V 382734

MS4309F1005 120V 382732

ML4802F1007 230V 383263

MS4809F1012 230V 382736

Page 2

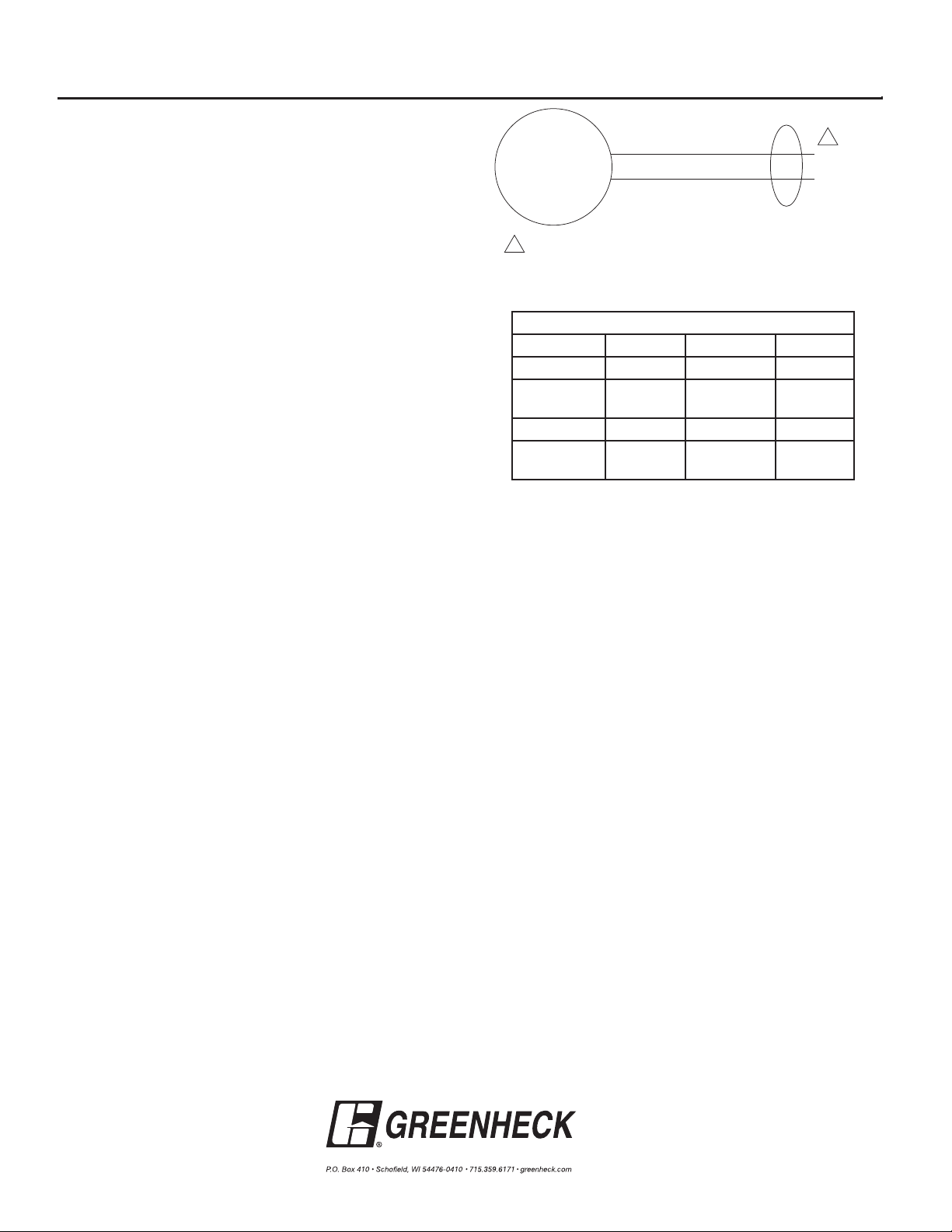

Black

White (120 Vac)

L

1

(Hot)

M

L

2

Red (24 Vac)

Power supply. Provide disconnect and means of overload protection.

1

1

INSTRUCTIONS FATPA DIRECT DRIVE SERIES

These installation instructions assume a damper is already

mounted in a duct or sleeve. Have damper blades in the fail

position.

1. Drill [2] .203 inch holes in the third blade from bottom,

at location shown in detail "A".

2. Attach blade drive lever to blade using [2] ¼ in. - 20 x

½ in. thread cutting screws, self drilling screws or ¼

-20 x 1¼ in. bolts.

3. Fasten actuator bracket (item 1) to the left jamb of

damper frame using [2] thread cutting screws. Note:

the 0.563 in. hole in the bracket (item 1) that the 6 1/2

in. jackshaft (item 5) goes through must be centered

with the centerline of the blade. Snap bearing (item 9)

into internal actuator bracket (item 1).

4. Snap bearing (item 9) into anti-rotation bracket (item 6)

and attach the anti-rotation bracket assembly (item 6)

to the internal mount bracket (item #1) using [2] thread

cutting screws (item 8).

5. Slide ½ in. diameter rod (item 5) slightly through the

anti rotation bracket (item 6). Install crankarm (item 3)

and drive link (item 2) onto the ½ in. diameter rod (item

5) and install retaining clip (item 10) to lock drive link

onto the crankarm.

6. Install 10-24 x .375 shoulder bolt (item 11) to the anti

rotation bracket (item #6) using #10 Nylock nut (item

12).

7. Attach actuator (item #7) to anti-rotation bracket

assembly (item 6). Tighten the actuator onto the shaft.

8. Connect drive link to blade drive lever using e-clip.

With blades closed and the actuator in its fail position,

position the blades in their fail position and tighten the

crankarm to the 1/2 in. shaft.

9. Connect all electrical leads to the actuator. Apply

power to the actuator. The damper blades should

power position and return to the fail position when

power is disconnected.

IMPORTANT

For actuators with a product date code before 0527 a

power break of less than two seconds can cause the

actuator to spring-return 5 degrees or less and remain

in place until a power break of longer duration. For

actuators with a product date code of 0527 or after, a

power break of any duration will cause the actuator to

spring-return and be able to drive immediately when

power is reapplied.

Figure 2: FATPA series wiring illustration.

Power Consumption

Model Volts Running Holding

ML4XXX 120 18W 9W

MS4209

MS4309

ML8XXX 24 16W 8W

MS8209

MS8309

120 23W 7W

24 23W 7W

Actuator Weight

5 lb. (2.3 kg).

Noise Rating

Driving Open: Maximum 65 dBA at 1m.

Holding: Maximum 20 dBA at 1m (no audible noise).

Temperature Ratings

Ambient: 0°F to 130°F (-18°C to 55°C)

Shipping and Storage: -40°F to 140°F (-40°C to 60°C)

Humidity Ratings

5% to 95% RH non-condensing.

Environmental Protection Ratings

NEMA 1

IP42

Approvals

Underwriters Laboratories Inc. UL 873 plenum rating,

and cUL: File #E4436: Guide #XAPX.

Direction of Spring Return

Counterclockwise (see Figure 1, Note 3)

MS4309, ML4302

MS8309, ML8302

Clockwise (see Figure 1, Note 3)

MS4209, ML4202

MS8209, ML8202

Actuator Timing (Under Load)

Drive Open: 15 seconds.

Spring Close: 15 seconds.

Copyright © 2013 Greenheck Fan Corporation

459011 Internal FATPA Rev. 9 April 2013

Loading...

Loading...