Page 1

Document 475595

Microprocessor Controller for

®

Tempered Air Products

Reference Guide for the Microprocessor Controller

Please read and save these instructions. Read carefully before attempting to operate or maintain the product

described. Protect yourself and others by observing all safety practices. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

TAP v2.10

Version Date: 4/1/14

Introduction

Program Features

The microprocessor controller offers improved control

through easy monitoring and adjustment of unit

parameters by way of a lighted graphical display and a

push-button keypad.

Pre-Programmed Operating Sequences

The controller has been pre-programmed to offer

multiple control sequences to provide tempered

air. Factory default settings allow for easy setup

and commissioning. The sequence parameters are

fully adjustable. Refer to the Sequence of Operation

beginning on page 2 for details.

BMS Communication

With the addition of an optional BMS Communication

card, the user can remotely adjust set points, view

unit status points and alarms. The microprocessor

controller is capable of communicating over several

protocols:

• BACnet® MSTP • LonWork®

• BACnet® IP/Ethernet • Modbus

See Points List on pages 36 and 37 for a complete list

of BMS points.

Internal Time Clock

The controller has an internal programmable time

clock, allowing the user to add up to seven different

occupancy schedules. The user may also add Holidays

for additional energy savings. The time clock option

also has morning warm-up capability for optional

comfort at the time of occupancy.

Alarm Management

The microprocessor controller will monitor the unit

conditions for alarm conditions. Upon detecting an

alarm, the controller will record the alarm description,

time, date, available temperatures, and unit status for

user review. A digital output is reserved for remote

alarm indication. Alarms are also communicated via

BMS (if equipped).

Occupancy Modes

The microprocessor controller offers three modes of

determining occupancy: a dry contact, the internal time

clock or the BMS. If in the Unoccupied mode the unit

will either be shut down, or will cycle on to maintain

adjustable unoccupied room temperature and humidity

set points.

Remote Display Panel (Optional)

A touchpad display panel allows for remote monitoring

and adjustment of parameters, allowing ease of control

access without going outdoors.

WARNING

Electrical shock hazard. Can cause personal injury

or equipment damage. Service must be performed

only by personnel that are knowledgeable in the

operation of the equipment being controlled.

®

DDC Controller for Tempered Air Products

1

Page 2

Table of Contents Sequence of Operation

Sequence of Operation . . . . . . . . . . . . . . . 2

General Operation. . . . . . . . . . . . . . . . 2-3

Set Point Control. . . . . . . . . . . . . . . . . . 3

Heating. . . . . . . . . . . . . . . . . . . . . . . 3

Cooling. . . . . . . . . . . . . . . . . . . . . . . 3

Economizer . . . . . . . . . . . . . . . . . . . . 4

Dehumidification. . . . . . . . . . . . . . . . . . 4

Reheat . . . . . . . . . . . . . . . . . . . . . . . 4

Supply Fan VFD . . . . . . . . . . . . . . . . . . 4

Exhaust Fan VFD . . . . . . . . . . . . . . . . . 5

Outdoor Air and Recirculated (Recirc) Air . . . . . 5

Energy Recovery Wheel Sequence . . . . . . . . 5

Alarms . . . . . . . . . . . . . . . . . . . . . . . 5

Controller Overview . . . . . . . . . . . . . . . . 6-7

Display Use . . . . . . . . . . . . . . . . . . . . . 8

Example of Parameter Adjustment . . . . . . . . . 8

Example of Alarms. . . . . . . . . . . . . . . . . . 9

Menu Overview . . . . . . . . . . . . . . . . . 10-11

Main Menu Overview . . . . . . . . . . . . . . 12-14

Menus

A.

On/Off Unit . . . . . . . . . . . . . . . . . 14

B.

Setpoint . . . . . . . . . . . . . . . . 15-21

C.

Clock/Scheduler . . . . . . . . . . . . . .22

D.

Input/Output . . . . . . . . . . . . . . . .22

E.

Data Logger . . . . . . . . . . . . . . . . 22

F.

Board Switch. . . . . . . . . . . . . . . .23

G.

Service

a. Information. . . . . . . . . . . . . . . . .23

b. Overrides . . . . . . . . . . . . . . . 23-25

c. BMS Config . . . . . . . . . . . . . . 26-27

d. Service Settings

a. Working hour set . . . . . . . . . . . . 27

b. Probe adjustment. . . . . . . . . . . .27

c. Password/Defaults . . . . . . . . . . . 27

H.

Manufacturer

a. Configuration . . . . . . . . . . . . . . . 28

b. I/O Configuration . . . . . . . . . . . . . 28

c. Factory Settings . . . . . . . . . . . . 29-34

d. Initialization . . . . . . . . . . . . . . . . 35

Remote Display . . . . . . . . . . . . . . . . . . . 35

Points List

LonWorks® . . . . . . . . . . . . . . . . . . . .36

ModBus/BACnet®. . . . . . . . . . . . . . . . .37

Expansion I/O (pCOe) . . . . . . . . . . . . . . . .38

Troubleshooting . . . . . . . . . . . . . . . . . . . 39

NTC Temperature Sensor Chart. . . . . . . . . . .39

BACnet® MSTP Quick Start. . . . . . . . . . . . .40

BACnet® IP/Eth Quick Start. . . . . . . . . . . . .41

Economizer Commissioning Tool . . . . . . . . . .42

Maintenance Log . . . . . . . . . . . . . . . . . . 43

Our Commitment. . . . . . . . . . . . . . Backcover

The microprocessor controller can be configured for air

handler, energy recovery, dedicated outdoor air system

and make-up air applications. Each application utilizes

similar technologies for heating and cooling: chilled

water, hot water, indirect gas, electric heat, packaged

DX cooling, and packaged DX cooling with digital

scrolls. All set points, lockouts and delays are user

adjustable via the keypad display.

General Operation

UNIT START COMMAND: The microprocessor

controller requires a digital input to enable operation.

The unit can then be commanded on or off by this

digital input, the BMS or internal time clock.

• Initial delay

• Factory mounted and wired dampers are powered, if

equipped. (Outdoor air, exhaust air, and recirculation

air dampers).

• Exhaust fan and energy recovery wheel start after a

10 second delay, if equipped.

• Supply fan starts 15 seconds after the exhaust fan.

• Tempering operation begins (see modes below).

UNIT STOP COMMAND (OR DE-ENERGIZED):

• Supply fan, exhaust fan, tempering, and wheel are

de-energized.

• Outdoor air and Exhaust air dampers are closed after

a 10 second delay. Recirculation air dampers spring

open.

OCCUPIED/UNOCCUPIED MODES: The

microprocessor controller offers three modes of

determining occupancy: a dry contact, the internal time

clock or the BMS. When in the unoccupied mode, the

unit can be configured to shut down, or cycle on to

maintain the unoccupied room set points. The unit can

be temporarily overridden to the occupied mode via a

digital input or the keypad display.

The internal time clock can be configured with morning

warm-up to bring the space to the occupied set point

prior to occupancy.

• Occupied Mode:

- Exhaust fan on, if equipped

- Supply fan on

- Heating (refer to Heating section)

- Cooling (refer to Cooling section)

- Energy Recovery Wheel control (refer to

Energy Recover Wheel section), if equipped.

- Damper control (refer to Outdoor Air and

Recirculated Air section), if equipped.

• Unoccupied Mode (Unit Off): Unit remains off when

in unoccupied mode.

• Unoccupied Mode (Cycle on Room): Optional

unoccupied mode when there is an unoccupied

recirculation damper and room temperature and/

or humidity sensor(s) connected to the controller.

The unit will cycle on to maintain unoccupied room

set points if there is a call for unoccupied heating,

cooling or dehumidification.

DDC Controller for Tempered Air Products

2

®

Page 3

Sequence of Operation

- Exhaust fan off, if equipped.

- Supply fan off.

- Recirculation air damper open.

- OA damper closed.

- Tempering operations begin (see modes below)

Set Point Control (Occupied)

Supply air temperature set point can be configured

as constant, or can be reset by either outside air

temperature, or room temperature set point. If equipped

with BMS communications, the user can also directly

command the supply temperature set point, or room

temperature set point (if equipped with a room temp

sensor).

• Outdoor Air Temperature Reset Function: The

controller will default to supply temperature reset

based on outdoor air temperature. The controller will

monitor the OA temperature and reset the supply

temperature set point based upon the outdoor air

reset function.

• Room Temperature Reset (optional): With a

room temperature sensor, the controller will adjust

the supply air temperature set point between the

minimum (55°F) and maximum (90°F), to satisfy the

desired room temperature.

Set Point Control (Unoccupied)

When equipped with an unoccupied recirculation

damper and optional room temperature and/or

humidity sensors, the unit will cycle on to maintain the

unoccupied room set points.

• Unoccupied Heating: If equipped with heating,

the unit is enabled when the room temperature is

less than the unoccupied heating set point minus

differential (65°F-5°F). The supply air temperature

set point will be set to the supply maximum reset

limit (90°F). The unit cycles off when the room

temperature reaches the unoccupied heating set

point.

• Unoccupied Cooling: If equipped with cooling,

the unit is enabled when the room temperature is

greater than the unoccupied cooling set point plus

differential (80°F+5°F). The supply air temperature

set point will be set to the supply minimum reset

limit (55°F). The unit cycles off when the room

temperature reaches the unoccupied cooling set

point.

• Unoccupied Dehumidification: If equipped with

cooling, the unit is enabled when the room relative

humidity exceeds the unoccupied room relative

humidity set point plus differential (50%+5%), or

when dehumidistat contact indicates excessive

humidity. The supply air temperature set point will be

set to the equivalent occupied supply set point.

• Morning Warm-Up: The unit uses an algorithm

involving space temperature and the heating /cooling

rate of the previous day to determine the time

required to efficiently temper the space to occupied

set point prior to occupancy.

Heating

The heating is controlled to maintain the supply

temperature set point. The heating will be locked out

when the outside air temperature is above the heating

lockout (70°F).

• Indirect Gas Furnace: Microprocessor controller

will modulate the indirect gas furnace to maintain the

supply temperature set point.

• Hot Water Coil: Microprocessor controller will

modulate a hot water valve (provided by others)

to maintain the supply temperature set point. Coil

freeze protection must be provided by others in

the field!

• Electric Heater: Microprocessor controller will

modulate an electric heater to maintain the supply

temperature set point.

• Heat Pump: Microprocessor controller will stage

compressor(s) to maintain the supply air set point.

This signal will come wired to the factory provided

heat pump module. All external water valves and

valve controls are provided, wired and mounted

by others in the field, including freeze protection.

Cooling

The cooling is controlled to maintain the supply

temperature set point. The mechanical cooling will be

locked out when the outside air temperature is below

the cooling lockout (55°F).

• Chilled Water: Microprocessor controller will

modulate a chilled water valve (provided by others) to

maintain supply air set point. Coil Freeze protection

must be provided by others in the field!

• Packaged DX Cooling (Standard Scroll):

Microprocessor controller will control stages of

cooling to maintain the supply air set point.

• Packaged DX Cooling (Digital Scroll):

Microprocessor controller will modulate the digital

scroll to maintain the supply air temperature set

point.

• Heat Pump: Microprocessor controller will power

the reversing valve within the heat pump module

to direct the refrigerant flow for airside cooling.

The cooling is controlled to maintain the supply

temperature set point. All external water valves and

valve controls are provided, wired and mounted

by others in the field, including freeze protection.

®

DDC Controller for Tempered Air Products

3

Page 4

Economizer

If the application requires cooling, and the outdoor

air conditions are suitable for free cooling, the

controller may enter the economizer state. If the unit is

economizing and the discharge temperature set point is

not being met, the controller may bring on mechanical

cooling. If equipped with a modulating outdoor air and

recirculated air damper, the dampers will modulate

between the minimum OA and maximum positions to

maintain the supply temperature set point. If equipped

with an energy wheel, see Energy Recovery Wheel

Sequence.

• Temperature: The economizer will be locked out

when:

- The outside air is less than the economizer low

lockout (40°F).

- The outside air is greater than the economizer

high lockout (65°F).

- The unit is operating in dehumidification mode.

- There is a call for heating.

• Temperature/Dew Point: The economizer will be

locked out when:

- The outside air is less than the economizer low

lockout (40°F dry-bulb).

- The outside air is greater than the economizer

high lockout (75°F dry-bulb).

- The outside air is greater than the economizer

high dew point lockout (55°F dew point)

- The unit is operating in dehumidification mode.

- There is a call for heating.

Dehumidification

The cooling is controlled to maintain the cold coil set

point. The dehumidification sequence will be locked out

when the OA is less than the dehumidification lockout

(10°F) above the cold coil set point. If equipped with

BMS communications, the user can also directly set the

cold coil leaving air set point.

• Optional Room Dehumidistat: The room

dehumidistat is a field mounted sensor that monitors

the relative humidity (RH) of the room. If the RH

exceeds set point, the dehumidistat will reset the

cold coil set point to the minimum (50°F). Once the

room dehumidistat is satisfied, the cold coil set point

will return to the maximum (55°F).

• Optional Room Relative Humidity Sensor: The

controller will adjust the cold coil leaving air

temperature set point between the minimum (50°F)

and maximum (55°F) set points, to satisfy the desired

room relative humidity set point.

Reheat

While the unit is in dehumidification mode, the supply

air can be reheated via Primary Heating Source, On/Off

Hot Gas Reheat or Modulating Hot Gas Reheat.

• Primary Heating Source: The main heating source

is enabled to reheat the air to meet the supply

temperature set point. (Except heat pump). The

DDC Controller for Tempered Air Products

4

primary heat source may also be configured to act as

secondary reheat.

• Modulating Hot Gas Reheat (bypass damper): The

microprocessor controller will open the On/Off hot

gas reheat valve, and modulate the Hot Gas Reheat

bypass damper to maintain the supply temperature

set point.

• Modulating Hot Gas Reheat (valve): The

microprocessor controller will modulate the hot gas

reheat valve to maintain the supply temperature set

point.

• On/Off Hot Gas Reheat: The microprocessor

controller will open the On/Off hot gas reheat valve to

maintain the supply temperature set point.

Supply Fan VFD Sequence

If the factory has installed a VFD and wired it to the

controller, it is intended to operate at a constant speed

during operation. This speed needs to be set during

test and balance of the unit. If equipped with BMS

communications, the user can also directly command

the supply fan speed.

• Optional Room CO2 Sensor: The controller will

modulate the supply fan based upon a comparison

of the CO2 set point to the actual CO2 levels

reported from the sensor. Mechanical high static

protection cutoffs must be installed by others

to protect the system and equipment from

over-pressurization.

• Optional Duct Static Pressure Sensor: The

controller will modulate the supply fan based upon a

comparison of the duct static pressure set point to

the actual duct static pressure level reported from

the sensor. Mechanical high static protection

cutoffs must be installed by others to protect

the system and equipment from overpressurization. The manufacturer does not

assume responsibility for this.

• Optional Building Static Pressure Sensor: The

controller will modulate the supply fan based upon a

comparison of the building static pressure set point

to the actual building static pressure level reported

from the sensor.

• Optional Single Zone VAV (SZ): The controller will

control the supply air temperature and supply fan

speed to maintain the room temperature set point.

This sequence requires a room temperature sensor.

Heating - When the room requires heating, the

controller will reset the supply air temperature set

point up to the maximum (90°F) while increasing the

supply fan speed up to its maximum heating speed.

Cooling - When the room requires cooling, the

controller will first reset the supply air temperature

set point down to the minimum (55°F) while the

supply fan remains at the minimum cooling speed.

After a time delay, the supply fan speed will increase

up to its maximum cooling speed to maintain the

room temperature set point.

®

Page 5

Exhaust Fan VFD Sequence

If the factory has installed a VFD and wired it to the

controller, it is intended to operate at a constant speed

during operation. This speed needs to be set during

test and balance of the unit. If equipped with BMS

communications, the user can also directly command

the exhaust fan speed.

• Optional Building Static Pressure Sensor: The

controller will modulate the exhaust fan based upon

a comparison of the building static pressure set point

to the actual building static pressure level reported

from the sensor.

• Optional Supply Fan Tracking: The controller will

proportionally modulate the exhaust fan based upon

the supply fan speed.

• Optional Outdoor Air Damper Tracking: The

controller will proportionally modulate the exhaust fan

based upon the outdoor air damper position.

Outdoor Air and Recirculated (Recirc) Air

Damper Control

If equipped with a modulating outdoor air and

recirculated air damper, the recirculated air damper will

operate inverse of the outdoor air damper. The outdoor

air damper will open to a Minimum Outdoor Air Position

(Min OA) when in occupied mode. If the controller

is configured to modulate the supply fan speed, the

minimum and maximum OA positions can be reset

based on supply fan speed. If equipped with BMS

communications, the user can also directly reset the

damper position up to the maximum OA position.

• Optional Room CO2 Sensor: The controller will

proportionally modulate the OA/RA dampers based

upon a comparison of the CO2 set point to the actual

CO2 level reported from the sensor. As the CO2 level

rises, the controller will proportionally modulate the

outdoor air damper open, between the minimum and

maximum OA position.

• Optional Building Pressure: The OA/RA dampers

will modulate based upon the signal from a building

static pressure sensor. The controller will modulate

the dampers, between the minimum and maximum

OA positions, based upon a comparison of the

building static pressure set point to the actual

building static pressure level reported from the

sensor.

Energy Recovery Wheel Sequences

Economizer (optional): If the unit is equipped with an

energy recovery wheel, the economizer will modulate/

stop the energy wheel to achieve free cooling.

• Stop Wheel: When economizer mode is enabled

and there is a signal for cooling, the wheel will stop

rotating to allow free cooling.

• Modulate Wheel: When economizer mode is

enabled and there is a signal for cooling, the

®

controller modulates wheel speed to maintain the

supply temperature set point.

• Energy Wheel Bypass Dampers (optional): During

normal operation, the dampers shall remain closed

to allow full operation of the energy wheel. During

economizer sequences, the dampers will be open to

bypass the energy wheel.

Frost Control (optional): The microprocessor

controller will activate the frost control method when

the outdoor air temperature is less than the defrost set

point (5°F) and the wheel pressure switch is closed, due

to a high wheel pressure drop. Once either the pressure

drop decreases below the pressure switch point, or the

outdoor air temperature increases, the unit will resume

normal operation.

• Electric Preheater: When frosting is occurring, the

preheater is energized to defrost the wheel.

• Modulate Wheel: When frosting is occurring, the

wheel slows to allow defrosting to occur.

• Cycle Wheel: When frosting is occurring, the

energy wheel is cycled off for a defrost cycle time

(2 minutes). After the defrost cycle time, the wheel

is re-energized to continue normal operation. The

controller will not allow another defrost cycle for a

minimum normal operating cycle time (5 minutes).

• Timed Exhaust: When frosting is occurring, the

supply fan is cycled off along with the tempering for

a defrost cycle time (5 minutes). The exhaust fan

will continue to run, allowing the warm exhaust air

to defrost the wheel. After the defrost cycle time,

the supply fan and tempering are re-energized to

continue normal operation. The controller will not

allow another defrost cycle for a minimum normal

operating cycle time (30 minutes).

Alarms

The microprocessor controller includes a digital output

for remote indication of an alarm condition. Possible

alarms include:

• Dirty Filter Alarm: If the outside air or return air

filter differential pressure rises above the differential

pressure switch set point, the microprocessor

controller will activate an alarm.

• Supply and Exhaust Air Proving Alarm:

Microprocessor controller monitors proving switch on

each blower and displays an alarm in case of blower

failure.

• Sensor Alarm: Microprocessor controller will send

an alarm if a failed sensor is detected (temperature,

pressure, relative humidity).

• Supply Air Low Limit: If the supply air temperature

drops below the supply air low limit (35°F), the

microprocessor controller will de-energize the unit

and activate the alarm output after a preset time

delay (300s).

• Other Alarms: Wheel Rotation, High Wheel

Pressure, High/Low Refrigerant Pressure.

DDC Controller for Tempered Air Products

5

Page 6

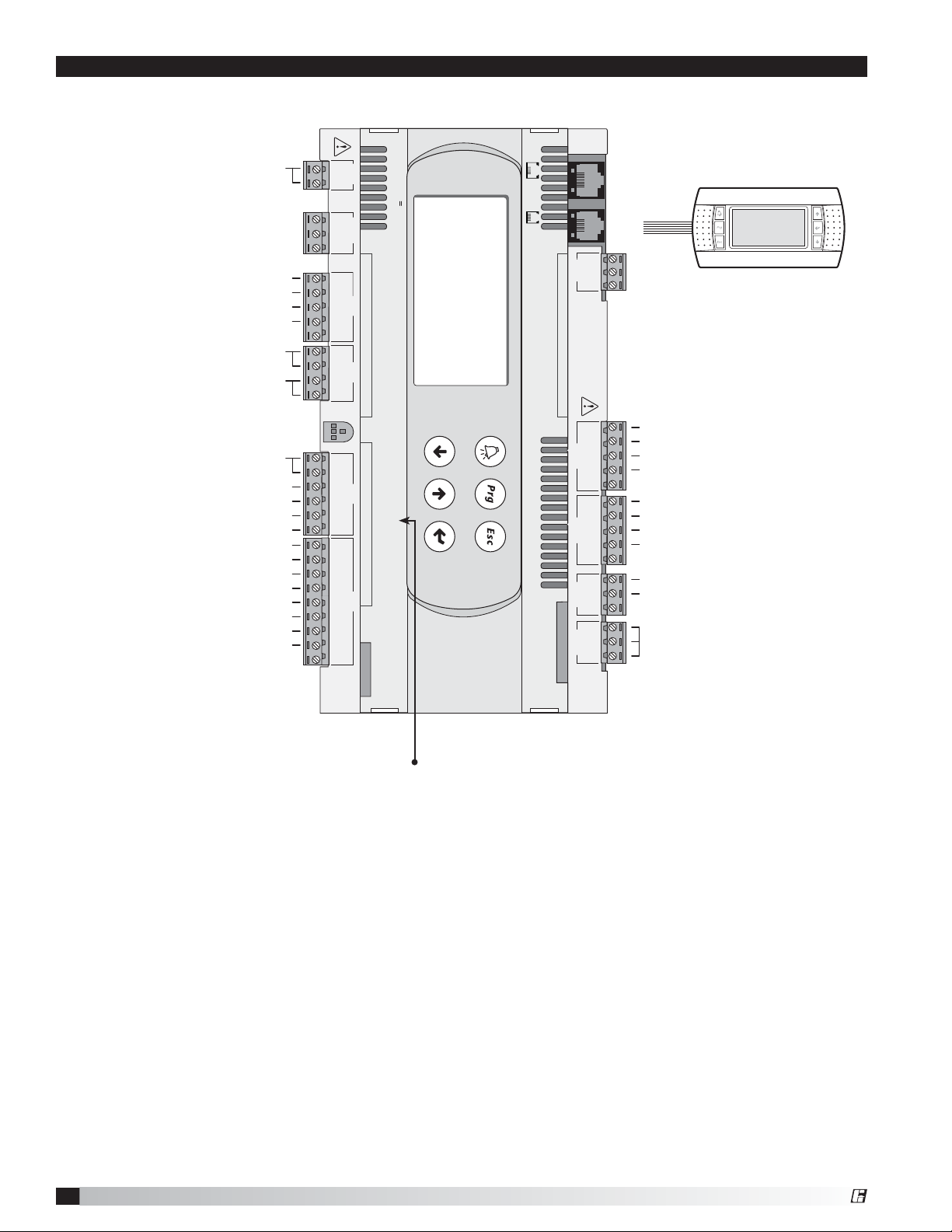

24 VAC to Controller

Small Controller Overview

input: 24V~/ V ; 50 to 60 Hz

max. power: 40 VA/15W

J1J1 J24J24

G

G0

Room RH or Dehumidistat

Room Temperature Sensor

After Cold Coil Temperature Sensor

Sensor B1, B2, B3 Commons

Supply Discharge Temperature Sensor

Outdoor Air Temperature Sensor

24 VAC for Analog Outputs

Energy Wheel Analog Output

Heating Analog Output

Cooling Analog Output

Hot Gas Reheat Analog Output

Supply Fan Proving

Wheel Pressure

Wheel Rotation Alarm

Unit On/Off

Exhaust Fan Proving

Occupied/Unoccupied Input

Dirty Filter

Compressor Limit

+Vterm

GND

+5 VREF

B1

B2

B3

GND

+VDC

B4

BC4

B5

BC5

VG

VG0

Y1

Y2

Y3

Y4

ID1

ID2

ID3

ID4

ID5

ID6

ID7

ID8

IDC1

J10J9

Rx-/Tx-

J11J11

Rx+/Tx+

J2J2 J5J5J4J4J3J3

field card serial card

GND

service card

J12J12 J13J13

J14J14

J15J15

C1

NO1

NO2

NO3

C1

C4

NO4

NO5

NO6

C4

C7

NO7

C7

NO8

C8

NC8

24 VAC When Unit On

Frost Control Enable

Output to Supply Fan

Output to Exhaust Fan

24 VAC from Supply Fan Proving

Heating Enable/Reversing Valve

Compressor Output 1

Compressor Output 2

24 VAC

Output to Dampers

Alarm Dry Contact

Remote Display

(six conductor RJ25 cable)

DDC Controller for Tempered Air Products

6

Optional BACnet, LonWorks and

Modbus cards are located in

Serial Card port

®

Page 7

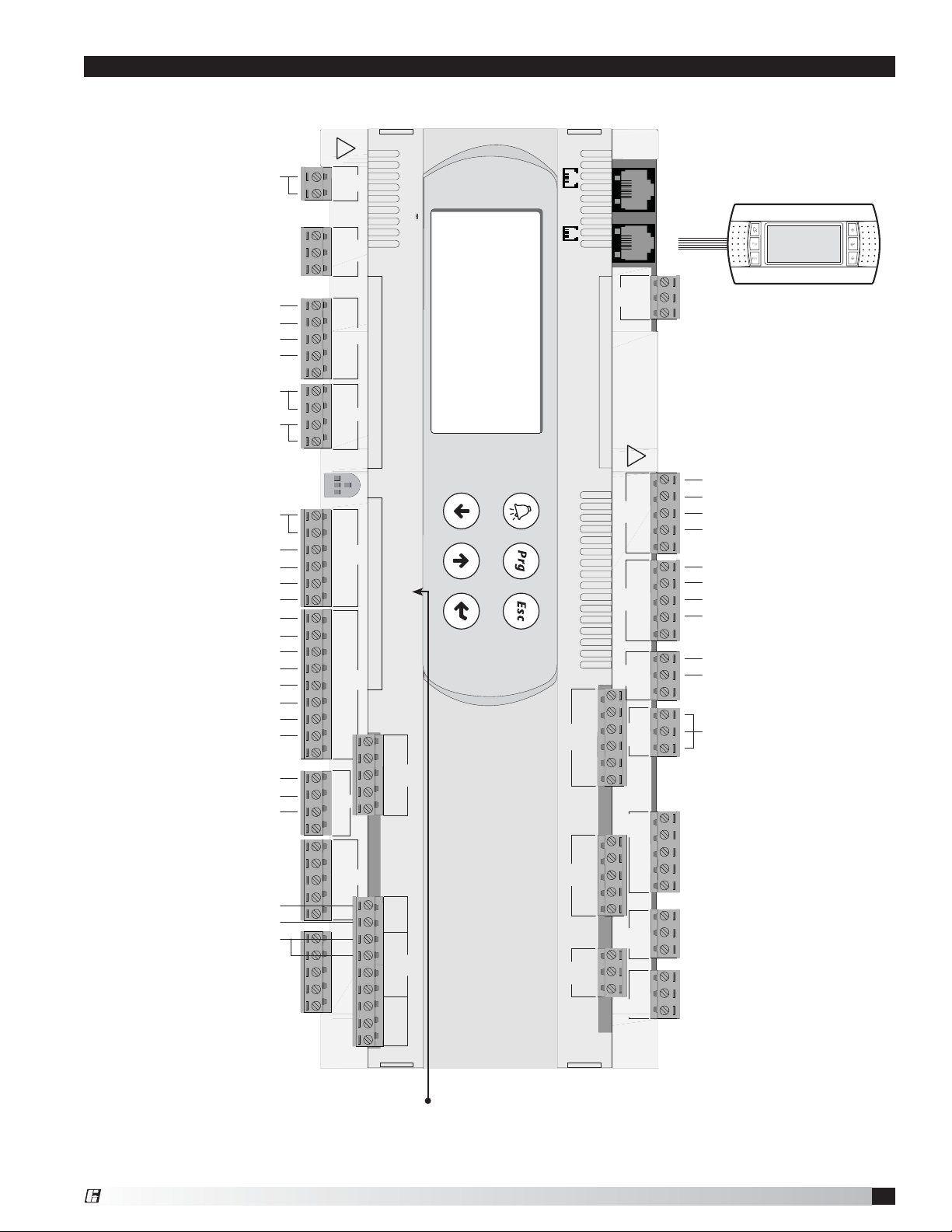

Large Controller Overview

24VAC to Controller

Room RH or Dehumidistat

CO2 Sensor

After Cold Coil Temperature Sensor

Sensor B1, B2, B3 Commons

Supply Discharge Temperature Sensor

Outdoor Air Temperature Sensor

24VAC for Analog Outputs

Outdoor Air Damper Analog Output

Heating Analog Output

Cooling Analog Output

Hot Gas Reheat Analog Output

Supply Fan Proving

Wheel Pressure Limit

Wheel Rotation Alarm

Unit On/Off Input

Exhaust Fan Proving

Occupied/Unoccupied Input

Dirty Filter Input

Compressor Limit

Outdoor Relative Humidity Sensor

Building Pressure Sensor

Duct Pressure Sensor

Supply Fan VFD Output

Exhaust Fan VFD Output

Room Temperature Sensor

G

G0

+V

GND

+5 V

B1

B2

B3

GND

+VDC

B4

BC4

B5

BC5

VG

VG0

Y1

Y2

Y3

Y4

ID1

ID2

ID3

ID4

ID5

ID6

ID7

ID8

IDC1

B6

B7

B8

GND

ID9

ID10

ID11

ID12

IDC9

ID13H

ID13

IDC13

ID14

ID14H

J8

!

max. power: 40 VA/15W

input: 24V~/ V ; 50 to 60 Hz

J1 J24 J2 J3

term

REF

field card serial card

J10J9

Rx-/Tx-

J11

Rx+/Tx+

GND

Remote Display

(six conductor RJ25 cable)

service card

!

J6

J7

J4 J5

ID15H

ID15

IDC15

ID16

ID16H

Y5

Y6

B9

BC9

B10

BC10

ID17

ID18

IDC17

J19

J20

J21

J22

J23

NO14

C14

NC14

NO15

C15

NC15

C16

NO16

NO17

NO18

C16

GND

C1

NO1

J12

NO2

NO3

C1

C4

NO4

J13

NO5

NO6

C4

C7

J14

NO7

C7

NO8

J15

C8

NC8

J16 J17

C9

NO9

NO10

NO11

C9

NO12

C12

NC12

E-

E+

NO13

C13

J18

NC13

24 VAC When Unit On

Wheel Frost Mode

Supply Fan Enable

Exhaust Fan Enable

24 VAC from Supply Fan Proving

Heating Enable/Reversing Valve

Staged Compressor 1

Staged Compressor 2

24 VAC

Economizer Mode/Output to Dampers

Alarm Dry Contact

Optional BACnet, LonWorks and Modbus

cards are located in

Serial Card port

®

DDC Controller for Tempered Air Products

7

Page 8

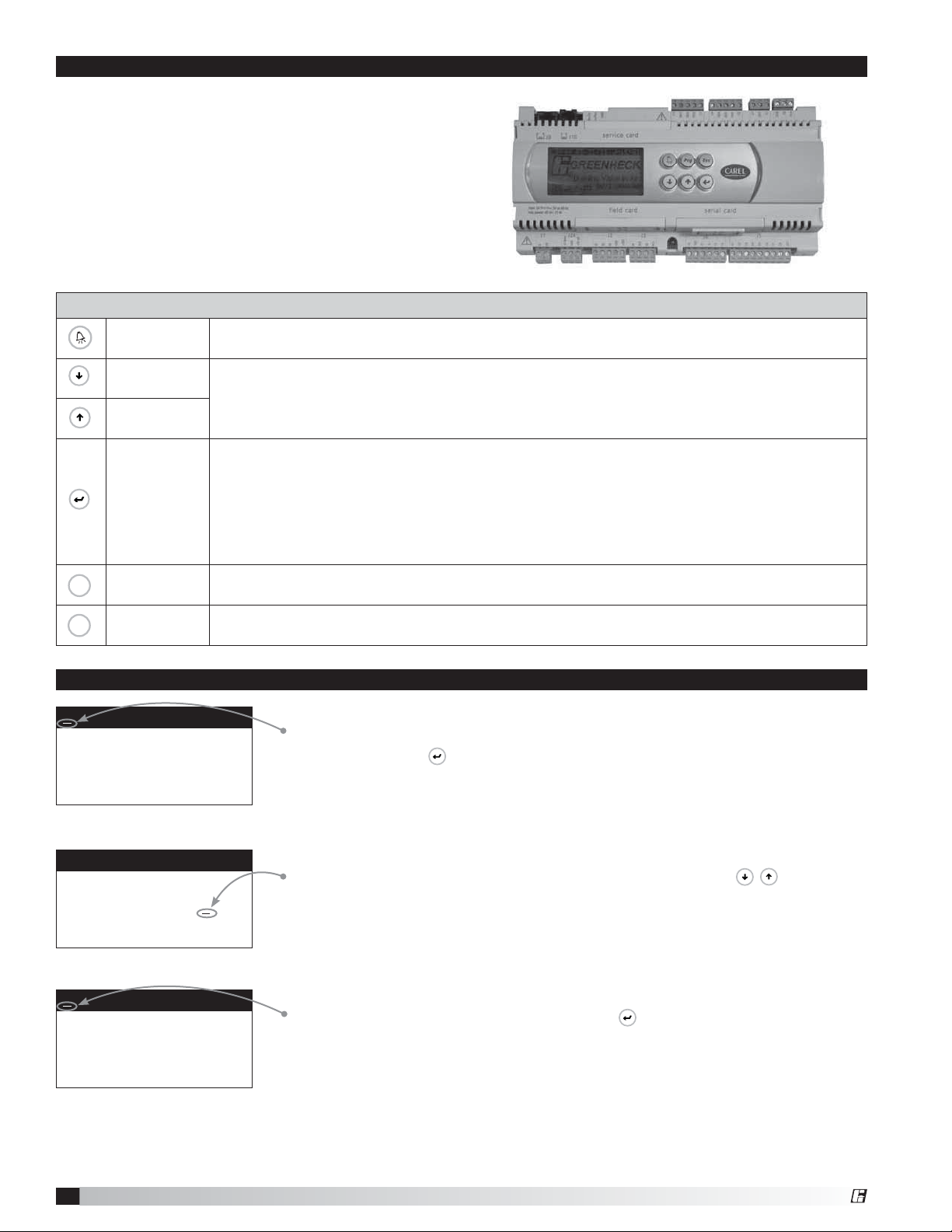

Display Use

The microprocessor controller is located in the unit

control panel. The face of the controller has six keys,

allowing the user to view unit conditions and alter

parameters. The microprocessor controller is preprogrammed with easy to use menus.

To change the display contrast, hold the Enter and

Escape button while pressing the up and down arrows.

A remote mounted display is also available, which

connects via the J10 port. A six wire patch cable is

needed.

Keypad Description

Alarm

Down Arrow

Up Arrow

Enter

Button will blink red, indicating an alarm condition. Press to review current alarms. To review

previous alarms, access the DATA LOGGER through the main menu.

The arrow keys allow the user to scroll through different screens and adjust parameters.

A. In screens with adjustable parameters, pressing the Enter key moves the cursor from

the upper left corner of the screen to the parameter. The arrow keys can then be used to

adjust the parameter.

B. To move to the next parameter on the same screen, press the Enter button.

C. To save the change, press the Enter button until the cursor moves back to the upper left

corner of the screen.

Esc

Escape Allows the user to exit the current menu, jumping to the Main Menu.

Prg

Program

Supply air low limit

Alarm when supply is

below: 35.0º F

Alarm delay: 300s

Supply air low limit

Alarm when supply is

below: 32.0º F

Alarm delay: 300s

Supply air low limit

Alarm when supply is

below: 32.0º F

Alarm delay: 300s

Pressing the Prg (Program) button allows the user to enter the Main Program Menu. Refer to

pages 10 and 11 for Main Program Menu description.

Example of Parameter Adjustment

The cursor always begins in the upper left corner of the display and will be

blinking. Press the

Once the cursor has reached the desired parameter, press the

adjust the value.

When satisfied with the adjustment, press the

When finished, make certain the cursor is in the upper left corner. If the cursor is

not in the upper left corner, the changes will not be saved. The cursor must be in

the upper left corner to enable screen advancement.

key to move the cursor down for parameter adjustment.

key to save the parameter.

keys to

DDC Controller for Tempered Air Products

8

®

Page 9

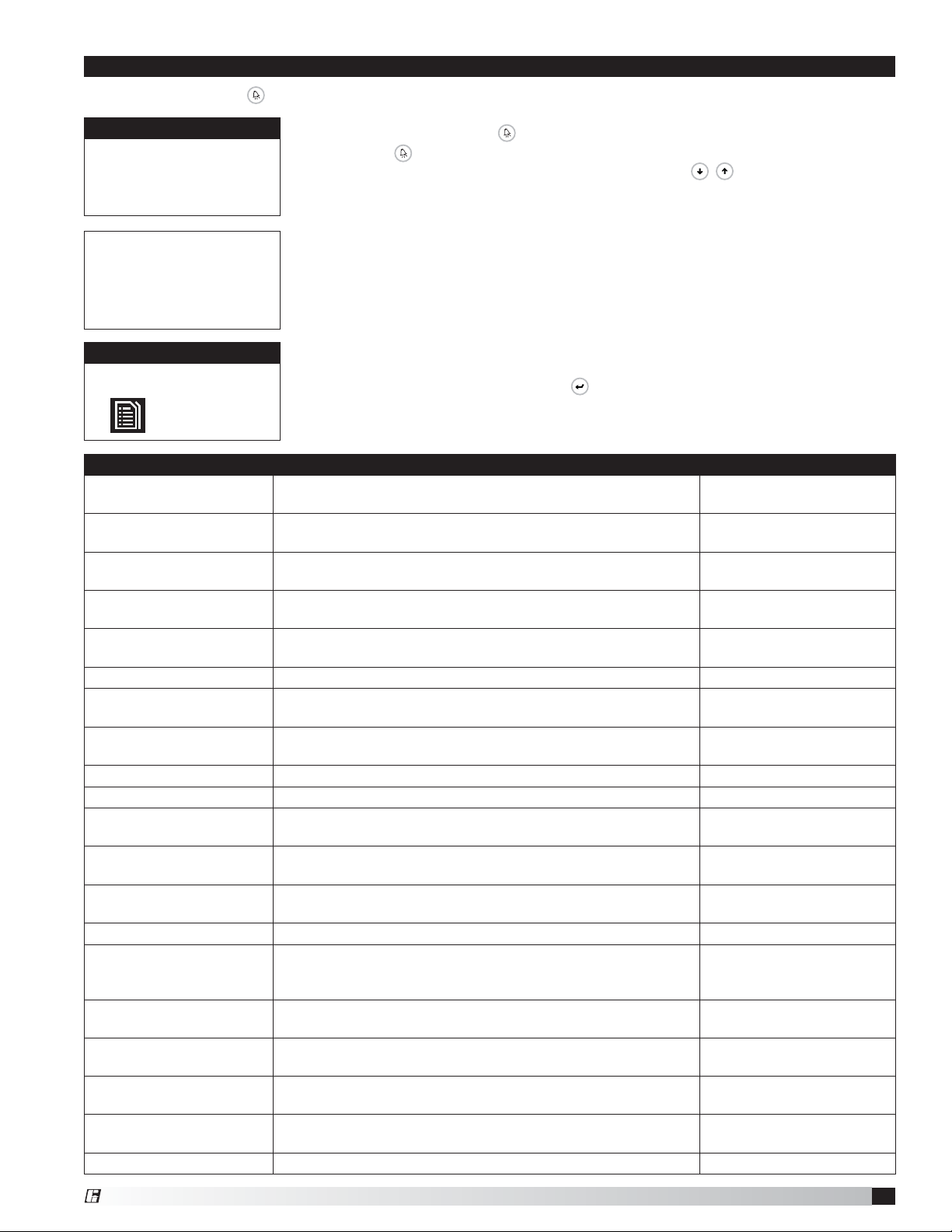

Examples of Alarms

If an alarm occurs, the

Alarms

Press DOWN to review

current alarm(s).

Press ESC to exit.

Press ALARM to reset.

button will glow red on the controller and the remote display (if installed).

To view alarm, press the button once. This will display the most recent alarm.

Press the

button again to reset the alarm. If the alarm cannot be cleared,

the cause of the alarm has not been fixed. Press the

additional occurring alarms.

buttons to view any

This is an example of an outdoor air sensor failure.

Outside Air Temperature

Sensor B01 Failure

Alarms

No active alarm

Press ENTER

to DATA LOGGER

This screen appears if there are no active alarms.

To view all saved alarms, press the

button to enter the DATA LOGGER. For

more information, see the Data Logger menu.

Examples of Alarms

Outdoor Air Temperature

Sensor Failure

Supply Air Temperature

Sensor Failure

Cold Coil Temperature

Sensor Failure

Room Temperature

Sensor Failure

System has exceeded the

set number of run hours

Supply airflow Indicates a loss of airflow in the supply fan. Alarm & Shutdown

Wheel Pressure

- Dirty Wheel/High CFM

Energy recovery wheel

rotation. Check wheel.

Exhaust Airflow Indicates a loss of airflow in the exhaust fan. Alarm & Shutdown

Filter Alarm Indicates a buildup of pressure across the filters. Alarm only

A compressor limit

switch has tripped

Supply temperature low

limit alarm

Cold Coil Low Limit Indicates a cold coil temperature lower than the cold coil low limit

pCOe Offline Indicates communication with pCOe auxiliary I/O has failed. Alarm only

pCOe - Analog input

probe on channel #

disconnected or broken

Building Pressure Sensor

Failure

Duct Pressure Sensor

Failure

Room Humidity Sensor

Failure

Outdoor Air Humidity

Sensor Failure

CO2 Sensor Failure Failure of CO2 sensor Alarm & minimum fan speed

Failure of outside air temperature sensor. Alarm only

Failure of supply air temperature sensor. Alarm & Shutdown

Failure of after cooling coil air temperature sensor. Alarm only

Failure of room temperature sensor.

(If Unoccupied - Cycle On Room is enabled)

The unit has been operating for a period longer than the

maintenance set point.

Indicates a buildup of pressure across the energy wheel. Alarm only

Indicates a wheel rotation failure. Alarm only

Indicates a high or low refrigerant pressure switch has tripped. Alarm only

Indicates a supply air temperature lower than the supply low limit

set point.

Indicates an analog probe failure on the pCOe. Check integrity of

auxiliary I/O analog probes.

Failure of building pressure sensor Alarm & minimum fan speed

Failure of duct pressure sensor Alarm & minimum fan speed

Failure of room RH sensor Alarm only

Failure of outdoor air humidity sensor Alarm only

Alarm only

Alarm only

Alarm & Shutdown

Alarm & discharge air sensor

lockout

Alarm only

®

DDC Controller for Tempered Air Products

9

Page 10

Press

Prg

to enter menus.

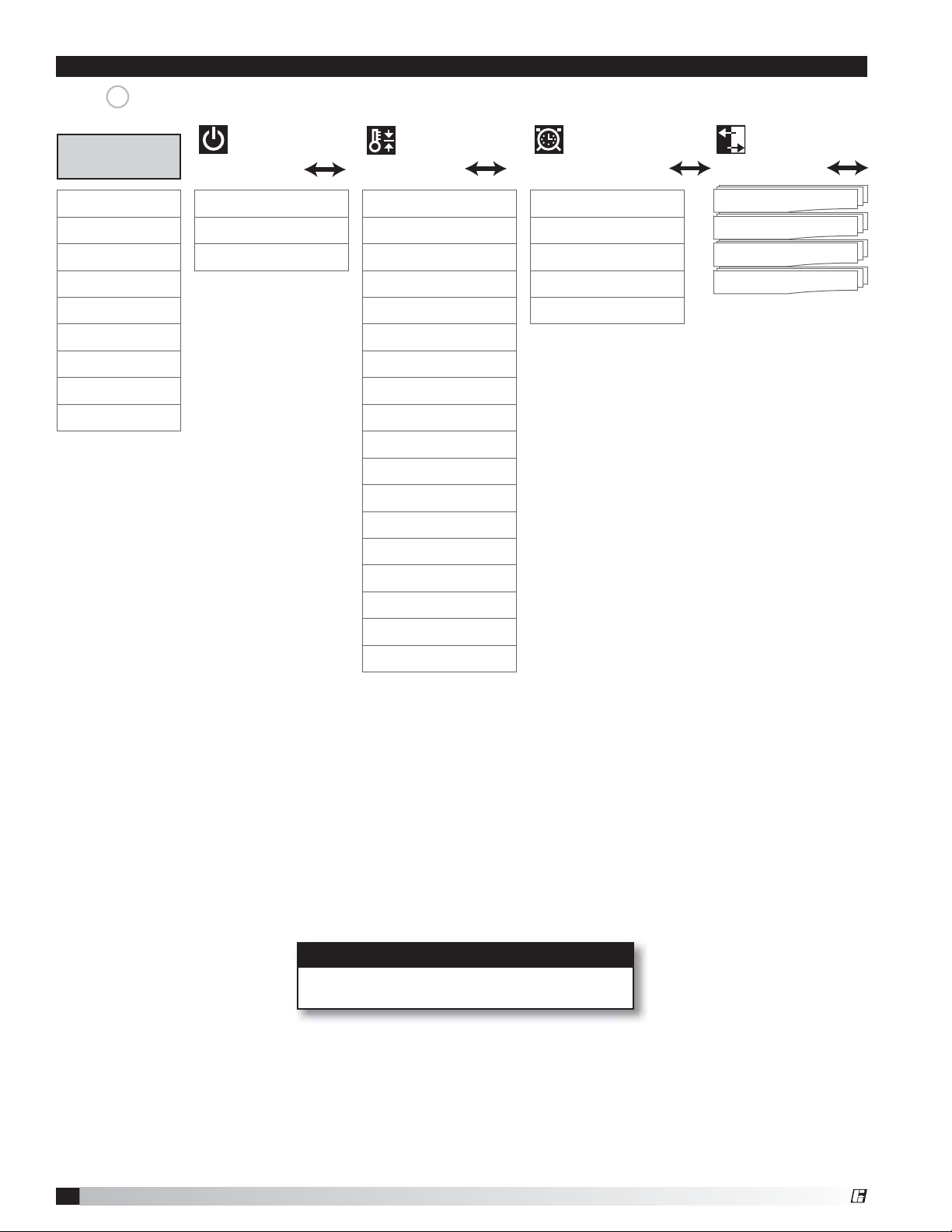

Menu Overview

Main Menu

Main Status Unit On/Off Supply Temp Set Pt Clock Analog Inputs

¬¬¬¬ ¬

Temp Status Unit On/Off Control Room Temp Scheduler Enable Digital Inputs

¬

Occ Override Occupancy Control Cold Coil Set Pt Morning Warm-up Digital Outputs

¬¬ ¬ ¬ ¬

Supply Fan Room Humidity Schedule(s) Analog Outputs

¬¬¬¬

Exhaust Fan Heat Lockout Holiday(s)

¬¬¬

Energy Wheel Cool Lockout

¬¬

Cooling Dehumid Lockout

¬¬

Heating Econ Lockout

¬¬

OA Damper Supply Low Limit

¬¬

On/Off Menu

¬

Setpoint

Clock/Scheduler Input/Output

¬¬ ¬

Defrost

¬

Unoccupied Cycle

¬

Supply Fan VFD

¬

Duct Pressure

¬

Single Zone VAV

¬

Exhaust Fan VFD

¬

Building Pressure

¬

CO2 Set Point

¬

OA Damper Set Point

¬

DDC Controller for Tempered Air Products

10

NOTE

Your controller may not show all menus

depending on unit configuration.

®

Page 11

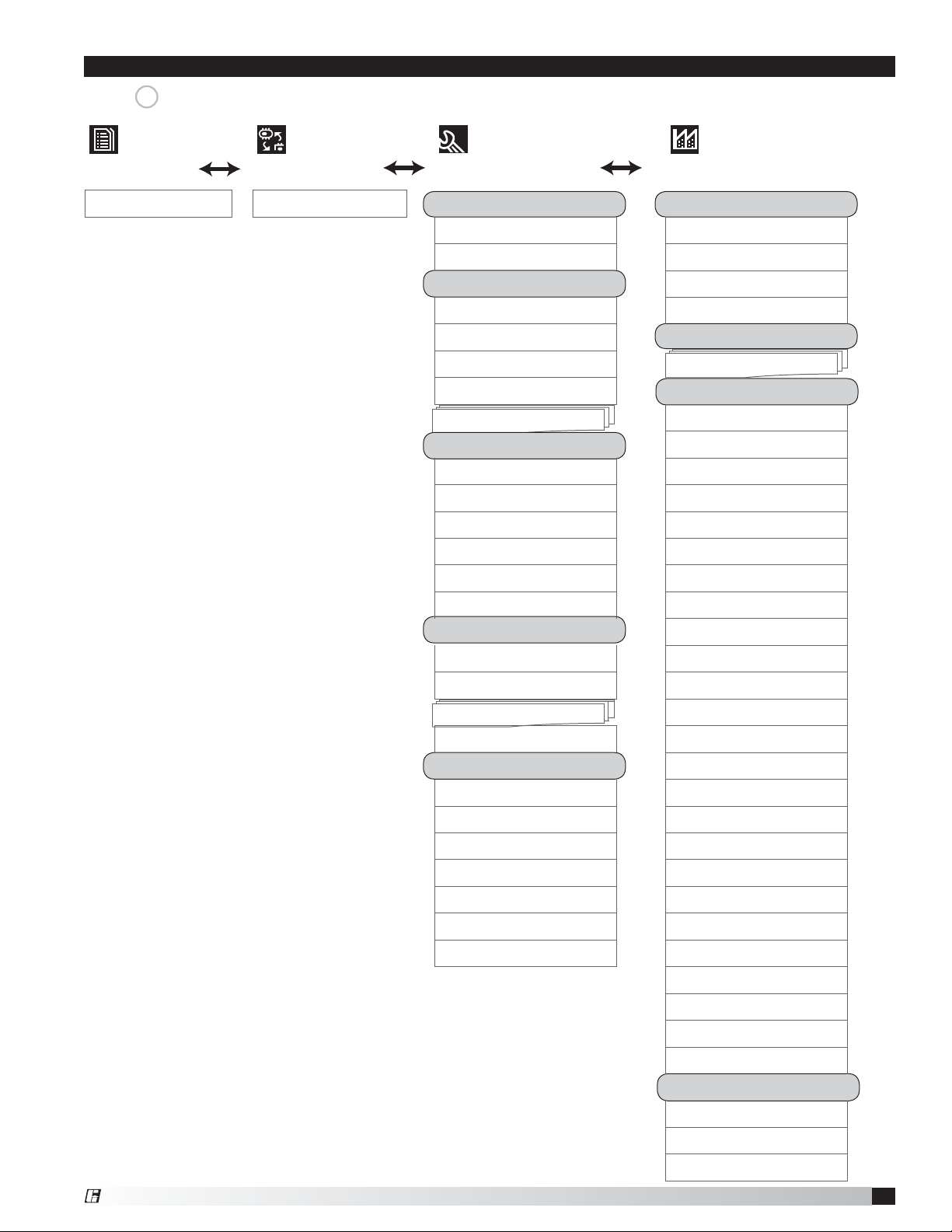

Menu Overview

Press

Data Logger Board Switch Service Manufacturer

¬¬

Prg

to enter menus.

Alarms Board Switch Set Information Configuration

Information Unit Code

¬¬

Information2 Expansion I/O

¬¬

Overrides pLAN Comm

Analog Inputs Field Card Comm

¬¬

Analog Outputs I/O Config

¬

Digital Inputs Inputs/Outputs

¬¬

Digital Outputs Factory Settings

¬

Components Economizer

¬¬

BMS Config Defrost Cycle

Protocol Cooling Control

¬¬

Modbus Comp Rotation

¬¬

BACnet MSTP Digital Scroll

¬¬

BACnet TCP/IP Comp Timers

¬¬

BACnet TCP/IP Comp Staging

¬¬

BACnet R/W Heat Control

¬¬

Service Settings Heater Reheat

Working Hours Heater Reheat 2

Maintenance Hours Hot Gas Control

¬¬

Probe Adjustment Hot Gas Timers

Analog Inputs Hot Gas Setup

¬¬

Password/Default SA Reset Control

Service Password Heat/Cool Delay

¬¬

Service Restore Damper Delay

¬¬

Prg Menu Lock Unocc Setup

¬¬

¬

¬

¬

¬

¬

¬

Damper Delay

¬

Air Proving

¬

Fan Delay

¬

Rotation Delay

¬

CO2 Control

¬

Duct Pressure

¬

Building Pressure

¬

Units / Display

¬

Initialization

Manf Restore

¬

Manf Password

¬

Factory Restore

¬

®

DDC Controller for Tempered Air Products

11

Page 12

Main Menu Overview

The microprocessor controller will revert to a default main menu loop. This loop includes several screens to view the

operating conditions of the unit. Scroll through the menu screens by using the

line border are dependent upon an optional accessory and may not always appear.

keys. Screens with a dashed

TIME DATE UNIT##

®

TAP v2.10 GWY1X000XXXX

STATUS LINE

TIME DATE UNIT##

Supply Air: 000.0°F

Outside Air: 000.0°F

OA Humidity 00.0%

Cold Coil: 000.0°F

Room Temp: 000.0°F

Room Humidity: 00.0%

STATUS LINE

Occupancy Override

Clock Override: OFF

Override Time: 1 hr

THE INITIAL MENU SCREEN DISPLAYS THE PROGRAM VERSION, UNIT CODE AND STATUS

LINE. THE STATUS LINE DISPLAYS WHICH MODE THE UNIT IS IN.

Possible modes include:

• Initial Delay

• Opening Dampers

• Exhaust Fan Starting

• Supply Fan Starting

• System On

• Defrost Mode Active

• Sys On - Econ+Cooling

• Sys On - Economizer

• Sys On - Heating

• Sys On - Cooling

• Sys On - Dehumidifying

• Sys On - Dehumid & Reheat

• Unoccupied - Unit On

• Unoccupied - Unit Off

• Unoccupied - Dehumid

• Unoccupied - Dehumid & Reheat

• Unoccupied - Heating

• Unoccupied - Cooling

• Manual Override

• Remote Off

• Press Alarm Button!!!

• Temp Occupied

THE SENSOR STATUS SCREEN DISPLAYS REAL TIME CONDITIONS FROM THE SENSORS

LOCATED IN THE UNIT AND THE ROOM (IF INSTALLED).

OCCUPANCY OVERRIDE (IF UNOCCUPIED)

If the unit is currently unoccupied, the occupancy can be temporarily overridden

for a period of Override Time. The Override Time parameter can be set from one

to three hours.

Supply Fan Status

Supply Fan Ramp: 0%

(0%=Min Speed by VFD)

Duct Ps Control

Duct Pressure: 0.00”wc

STATUS LINE

Exhaust Fan Status

Exhaust Fan Ramp: 0%

(0%=Min Speed by VFD)

Building Ps Control

Building Ps: +.000”wc

STATUS LINE

Energy Recovery

Wheel: 100% Speed

Wheel Differential

Pressure Is: Normal

Preheater: OFF

STATUS LINE

SUPPLY FAN STATUS. (IF EQUIPPED WITH VFD)

If equipped with a supply fan VFD, this screen will display the supply fan ramp

being sent from the controller to the VFD. The minimum and maximum speeds are

set in the VFD (See unit Installation and Operation Manual for VFD programming).

The controller can modulate the fan between the min and max speeds via an

analog output. This screen also displays the method of fan control and the

parameter it is controlling.

Possible methods include: Constant Speed, Duct Pressure Control, Building

Pressure Control, CO2 Control, and Single Zone VAV.

EXHAUST FAN STATUS. (IF EQUIPPED WITH VFD)

If equipped with an exhaust fan VFD, this screen will display the exhaust fan ramp

being sent from the controller to the VFD. The minimum and maximum speeds are

set in the VFD (See unit Installation and Operation Manual for VFD programming).

The controller can modulate the fan between the min and max speeds via an

analog output. This screen also displays the method of fan control and the

parameter it is controlling.

Possible methods include: Constant Speed, Building Pressure Control, Outdoor

Air Damper Tracking, and Supply Fan Tracking.

ENERGY RECOVERY WHEEL STATUS. (IF EQUIPPED)

If selected with a preheater, the status will also be displayed.

DDC Controller for Tempered Air Products

12

®

Page 13

Cooling Status

Cooling Control: 000%

Compressor D 1 2

STATUS LINE

COOLING STATUS IS DISPLAYED, ALONG WITH COMPRESSOR OPERATION. (IF EQUIPPED)

This screen appears if a cooling option is provided.

Chilled Water: The Cooling Control % is directly proportional to the 0-10 VDC

output signal.

0% Cooling = 0 VDC

100% Cooling = 10 VDC

The cooling control output can be configured to DIRECT / REVERSE acting,

along with the minimum and maximum output voltages by entering the

MANUFACTURER menu.

Packaged DX Cooling: The Cooling Control displays internal cooling ramp as a

percent. Compressor operation is displayed when engaged.

• D = Digital Scroll Compressor Operation

• 1 = First Staged Compressor Operation

• 2 = Second Staged Compressor Operation

Heat Pump Cooling: The Cooling Control displays internal cooling ramp as a

percent. Compressor operation is displayed when engaged.

• 1 = First Staged Compressor Operation

• 2 = Second Staged Compressor Operation

Heating Status

Heater Control: 000%

Hot Gas Reheat: 000%

Staged reheat is: ON

Compressor: 1 2

STATUS LINE

HEAT AND REHEAT OPERATION IS DISPLAYED. (IF EQUIPPED)

Heater Control displays the proportional percentage of the heater analog output.

Electric Heater: The Heater Control % is proportional to the 0-10 VDC signal

being sent to the SCR controller, located in the electric heater control center.

0% Heating = 0 VDC - 0 kW output

100% Heating = 10 VDC - Max kW output

Hot Water: The Heater Control % is proportional to the 0-10 VDC signal being

sent to the heating control valve (BY OTHERS). The heating control output can be

configured to DIRECT / REVERSE acting, along with the minimum and maximum

output voltages by entering the MANUFACTURER menu.

0% Heating = 0 VDC

100% Heating = 10 VDC

Indirect Gas: The Heater Control % is proportional to the 0-10 VDC signal being

sent to the indirect gas furnace controller, located in the indirect gas control

center. The first stage is on at 1% Heater Control. The furnace will then modulate

proportionally from minimum to maximum capacity.

0% = 0 VDC – OFF

1% = 0 VDC – MINIMUM TURNDOWN ENABLED

1 - 100% = 0 - 10 VDC = FURNACE MODULATION

Heat Pump Heating: The Heater Control % displays internal heating ramp as a

percent. Compressor operation is displayed when engaged.

• 1 = First Staged Compressor Operation

• 2 = Second Staged Compressor Operation

Hot Gas Reheat:

If hot gas reheat is staged control:

“Staged reheat is: ON/OFF” will indicate operation.

If hot gas reheat is modulating bypass damper control:

0% = OFF

1% - 100% = 4 - 10 VDC = AIRFLOW DAMPER MODULATION

If hot gas reheat is modulating valve control:

0% = OFF

1% - 100% = 0 - 10 VDC = HOT GAS REHEAT VALVE MODULATION

®

DDC Controller for Tempered Air Products

13

Page 14

Outdoor Damper Status

Damper Position: 50%

Active on Minimum OA%

CO2 Level: 0

STATUS LINE

PPM

OUTDOOR AIR DAMPER STATUS . (IF EQUIPPED WITH MODULATING OUTDOOR AND

RECIRCULATED AIR DAMPERS)

This screen will display the outdoor air damper position commanded by the

controller and which method the damper position is actively utilizing.

Possible methods include: Active on Minimum OA%, Active on Economizer, Active

on CO2 and Active on BMS.

Menus

The controller is equipped with several menus to help guide users with altering program parameters. The following

menus can be accessed by pressing the

A. On/Off Unit

Unit On/Off

The On/Off Unit menu allows the user to view the detailed On/Off status of the

controller.

The unit ships from the factory in a disabled state. To allow the unit to operate,

Prg

key. To enter the desired menu, press the key.

the controller must receive a run command from digital input ID4. Jumper unit

Actual state:

Off by DIG INPUT (ID4)

Change to: SWITCH ON

*Power ID4 to start…

terminals R - G to allow the unit to operate.

Actual State: The controller may be in following On/Off states:

a. Unit On - Unit is ON, functioning normally.

b. Off by ALARM - Unit is OFF due to an alarm. View alarms by pressing

ALARM button.

c. Off by PLAN - Unit is OFF by pLAN network.

d. Off by BMS - Unit is OFF by BMS command

e. Off by UNOCCUPIED - Unit is OFF by unoccupied command.

f. Off by DIGITAL INPUT (ID4) - Unit is OFF by digital input 4 (ID4).

g. Off by KEYPAD - Unit is commanded OFF by this screen.

Change to (Switch Off/Switch On): Enables user manually turn unit On/Off via

display. Unit terminal G must have 24 VAC power to enable the unit.

Unit ON/OFF Control

Enable unit OnOff

By digit input: Yes

By BMS: No

Occupancy Control

Type: Unit OFF

Source: Input ID6

DDC Controller for Tempered Air Products

14

THIS SCREEN ALLOWS THE USER TO ADJUST WHICH SYSTEM CONTROLS THE UNIT

ON/OFF STATE.

Digital Input: Default to YES. Unit terminal G must have 24 VAC power to enable

the unit.

The user can also use the BMS or internal time clock to command the unit

On/Off state. If scheduling is desired, go to the Clock/Scheduler menu to set

a schedule.

BMS: YES allows BMS to control unit On/Off state.

THIS SCREEN DISPLAYS WHAT THE UNIT WILL DO IN UNOCCUPIED MODE.

This screen allows the user to select the source of determining occupancy. The

factory default is terminal ID6 on the controller.

Input ID6: Typically used with a remote time clock, motion sensor or switch

(default).

BMS: BMS control (see Points List). BMS can be overridden with ID6.

Time Clock: Internal time clock (Scheduler). See Clock/Scheduler menu for

more information. The Scheduler can be overridden with digital

input ID6.

®

Page 15

B. Setpoint

The Setpoint menu allows the user to view and adjust temperature related

parameters.

Supply Temp Set Point

Active: 70.0°F

Source: Local 70.0°F

Max: 90.0°F

Min: 55.0°F

Supply Temp Set Point

Active: 72.0°F

Source: BMS 72.0°F

Max: 90.0°F

Min: 55.0°F

Supply Temp Set Point

Active: 55.0°F

Source: OA Reset

Outside Supply

55.0°F 70.0°F

65.0°F 55.0°F

THIS SCREEN DISPLAYS THE SUPPLY AIR TEMPERATURE SET POINT SCREEN

PARAMETERS.

When operating, the unit will control the heating and cooling to maintain the active

supply temperature set point. The active set point will be determined by the set

point source selection.

Possible Set Point Sources:

Local – The supply set point will be constant set from screen. (exp. 72°F).

BMS – The BMS can directly control the supply air temperature set point (requires

BMS communication option).

OA-Reset -The controller monitors the outdoor air temperature and adjusts the

desired supply temperature set point accordingly. For example, when the outdoor

air is below 55°F, the controller will change the supply set point to 70°F. If the

outdoor air is above 65°F, the controller will change the supply set point to 55°F.

If the outdoor air temperature is between 55°F and 65°F, the supply set point

changes according to the outdoor air reset function. A visual representation of the

outdoor air reset function is shown below.

Outdoor Air Reset Function

75°

70°

65°

Supply Temp Set Point

Active: 72.0°F

Source: Room Reset

Max: 90.0°F

Min: 55.0°F

Room Temp Set Point

Active: 72.0°F

Source: Local 72.0°F

Room Temp Set Point

Active: 72.0°F

Source: BMS 72.0°F

60°

55°

50°

Supply Air Set Point (°F)

45°

50° 55° 60° 65° 70°

Outside Air Temperature (°F)

Room-Reset – The controller will reset the supply air temperature set point to

maintain the room temperature set point (requires room temp sensor). See the

Room Temp Set Point screen in this menu for more information.

THIS SCREEN DISPLAYS THE ROOM TEMP SET POINT.

This screen only appears if Room Reset is selected as the supply set point source,

and a room temperature sensor is wired into the controller.

The unit will reset the supply air temperature set point to maintain the room temp

set point.

Possible Set Point Sources:

Local – The room set point will be constant set from screen (exp. 72°F).

BMS – The BMS can directly control the room temperature set point (requires

BMS communication option).

®

DDC Controller for Tempered Air Products

15

Page 16

Cold Coil Set Point

Active: 55.0°F

Source: Local 55.0°F

Max: 55.0°F

Min: 50.0°F

Cold Coil Set Point

Active: 55.0°F

Source: BMS 55.0°F

Max: 55.0°F

Min: 50.0°F

Cold Coil Set Point

Active: 55.0°F

Source: Room RH 55.0°F

Max: 55.0°F

Min: 50.0°F

Cold Coil Set Point

Active: 55.0°F

Source: Room DewPt 55.0°F

Max: 55.0°F

Min: 50.0°F

THIS SCREEN DISPLAYS THE TEMPERATURE SET POINTS FOR THE COOLING COIL.

This screen only appears if the unit is equipped with cooling.

When in dehumidification mode, the controller will maintain the active cold coil set

point. The active set point will be determined by the set point source selection.

Possible Set Point Sources:

Local – The supply set point will be constant set from screen (exp. 55°F). If a

dehumidistat was provided with the unit, the active set point will be reset to the

minimum set point.

BMS – The cold coil leaving air temperature set point can be adjusted over the

BMS via the Dehumidification Set Point (see Points List).

Room RH – The controller will reset the cold coil temperature set point to

maintain the room relative humidity set point (requires room relative humidity

sensor). See the Room RH Set Point screen in this menu for more information.

Room Dew Point – The controller will reset the cold coil temperature set point to

maintain the room dew point set point (requires room temperature and relative

humidity sensors). See the Room Dew Point Set Point screen in this menu for

more information.

Room Humidity SetPoint

Active: 55.0%

Source: Local 55.0%

Room Humidity: 50.0%

Room DewPt Set Point

Active: 55.0°F

Source: Local 55.0°F

Room Dew Point: 46.0°F

THIS SCREEN DISPLAYS THE ROOM RELATIVE HUMIDITY SET POINT.

This screen only appears if Room RH is selected as the cold coil set point source,

and a room relative humidity sensor is wired into the controller.

The unit will reset the cold coil temperature set point to maintain the room relative

humidity set point.

Possible Set Point Sources:

Local – The room set point will be constant set from screen (exp. 55% RH).

BMS – The cold coil leaving air temperature set point can be adjusted over the

BMS via the Dehumidification Set Point (see Points List).

THIS SCREEN DISPLAYS THE ROOM DEW POINT SET POINT.

This screen only appears if Room Dew Point is selected as the cold coil set point

source, and a room relative humidity sensor and room temperature sensor are

wired into the controller.

The unit will reset the cold coil temperature set point to maintain the room dew

point set point.

Possible Set Point Sources:

Local – The room set point will be constant set from screen (exp. 55°F)

BMS – The cold coil leaving air temperature set point can be adjusted over the

BMS via the Dehumidification Set Point (see Points List).

DDC Controller for Tempered Air Products

16

®

Page 17

Heating Lockout

Lockout heating when outside

above: 70.0°F

Differential: 2.0°F

THIS SCREEN DISPLAYS THE HEATING LOCKOUT.

This screen only appears if the unit the unit is equipped with heating.

There is a built in hysteresis of 2°F which prevents the heating from short cycling.

The hysteresis is similar to a dead-band above and below the lockout set point.

(Example: If Lockout = 70°F, heating is locked out above 72°F and enabled below

68°F outside air temperature.)

Cooling Lockout

Lockout cooling when outside

below: 55.0°F

Differential: 2.0°F

Dehumidification lock

Lockout dehumidification until

outside air is 10.0°F above

cold coil set point.

Economizer Lockout

Type: DryBulb+DewPoint

Below: 40.0°F (Dry Bulb)

Above: 75.0°F (Dry Bulb)

Above: 55.0°F (Dew PT)

Differential: 2.0°F

THIS SCREEN DISPLAYS THE COOLING LOCKOUT.

This screen only appears if the unit is equipped with cooling.

There is a built in hysteresis of 2°F which prevents the cooling from short cycling.

The hysteresis is similar to a dead-band above and below the lockout set point.

(Example: If Lockout = 55°F, cooling is locked out below 53°F and enabled above

57°F outside air temperature.)

THIS SCREEN DISPLAYS THE TEMPERATURE DIFFERENCE AT WHICH THE

DEHUMIDIFICATION MODE IS LOCKED OUT. (FACTORY DEFAULT = 10°F)

This screen only appears if the unit is equipped with cooling.

This setting prevents the unit from operating in dehumidification mode when the

outdoor air conditions are relatively cool. Example: If the cold coil set point is 55°F,

dehumidification mode cannot operate until the outdoor air is at least 65°F.

THIS SCREEN DISPLAYS THE ECONOMIZER LOCKOUTS.

This screen only appears if economizer functionality was provided with the unit.

The lockouts determine when economizer is available, based on the outdoor

air temperature or outdoor air temperature and humidity. The low temperature

lockout prevents outdoor air from entering the unit at too cold of a temperature

that could freeze coils. There is a built in differential that is similar to a deadband,

above and below the lockout set point.

If an outdoor relative humidity sensor was provided with the unit, the user can

change the economizer lockout control type.

Possible Control Types:

DryBulb – The economizer will be locked out based on the outdoor dry-bulb

temperature.

DryBulb+DewPoint (preferred) – The economizer will be locked out based on the

outdoor dry-bulb temperature and a calculated outdoor air dew point.

DryBulb+Enthalpy – The economizer will be locked out based on the outdoor

dry-bulb temperature and a calculated outdoor enthalpy.

DryBulb+WetBulb – The economizer will be locked out based on the outdoor drybulb temperature and a calculated outdoor air wet-bulb temperature.

Supply air low limit

Alarm when supply is

below: 35.0°F

Alarm delay: 300s

®

THIS SCREEN DISPLAYS THE LOW SUPPLY AIR TEMPERATURE LIMIT.

If the unit supply air temperature falls below Supply Air Low Limit for a period of

Alarm Delay, the unit will shut down and an alarm will be signaled. The purpose of

the supply low limit is to protect the building and contents from cold supply air. It

is NOT designed to protect the air-handling unit.

If the unit does not have chilled water (CW) or hot water (HW) coils, it should not

need additional protection from freezing. If the unit does have CW or HW coils,

field provided coil freeze protection may be necessary.

DDC Controller for Tempered Air Products

17

Page 18

Defrost

Allow wheel defrost

mode when outside

is below: 05.0°F

THIS SCREEN DISPLAYS THE TEMPERATURE AT WHICH THE UNIT WILL ENABLE FROST

CONTROL MODE IF NECESSARY. (FACTORY DEFAULT = 5°F)

This screen only appears if the unit has an energy recovery wheel and a frost

control method was provided with the unit.

Upon sensing a high differential pressure across the energy wheel, the unit will go

into defrost if the outside air temperature is below this temperature setting.

UnOcc Fan Cycle Setup

UnOcc Room Set Points:

Heating: 65.0°F

Cooling: 80.0°F

Room RH: 50.0%

Temp Diff: 5.0°F

Dehumid Diff: 5.0%

THIS SCREEN DISPLAYS THE ROOM SET POINTS DURING THE UNOCCUPIED MODE.

This screen only appears if an unoccupied recirculation damper was provided with

the unit. Room sensor(s) must be wired to the controller.

In the unoccupied mode, the unit will monitor the room temperature and humidity

sensors. The unit will cycle on to maintain the unoccupied room set points by

tempering recirculated air. The differential prevents short cycling. For example, in

heating, the unit cycles on at 60°F and turns off at 65°F.

Supply Fan Speed SetPt

Active: 100%

THIS SCREEN DISPLAYS THE SUPPLY FAN SPEED SET POINTS.

This screen only appears if equipped with a supply fan VFD controlled by

microprocessor.

Source: Local 100%

UnOccupied Cycle 100%

(0%=Min Speed by VFD)

The Speed Set Point is the proportional percentage of the analog output from the

controller to the VFD.

0% Speed = Min Speed (determined by VFD)

100% Speed = Max Speed (determined by VFD)

UnOccupied Cycle - The supply fan speed when the unit is on during unoccupied

cycle times.

Possible Set Point Sources:

Local – The fan speed will be constant set from screen (exp. 100%).

BMS – The BMS can directly control the fan speed (requires BMS communication

option).

Duct Pressure – Fan speed is determined by duct pressure control loop.

Building Pressure - Fan speed is determined by building pressure control loop.

CO2 - Fan speed is determined by CO2 control loop.

DDC Controller for Tempered Air Products

18

®

Page 19

ExhaustFan Speed SetPt

Active: 100%

THIS SCREEN DISPLAYS THE EXHAUST FAN SPEED SET POINTS.

This screen only appears if equipped with an exhaust fan VFD controlled by

microprocessor.

Source: Local 100%

(0%=Min Speed by VFD)

The Speed Set Point is the proportional percentage of the analog output from the

controller to the VFD.

0% Speed = Min Speed (determined by VFD)

100% Speed = Max Speed (determined by VFD)

Possible Set Point Sources:

Local – The fan speed will be constant set from screen (exp. 100%).

BMS – The BMS can directly control the fan speed (requires BMS communication

option).

Building Pressure - Fan speed is determined by building pressure control loop.

Supply Fan Tracking – Exhaust speed proportionally tracks supply speed.

ExhaustFan Speed SetPt

Active: 0%

Source: OA Damper Trk

OA Damper EF Speed

Min OA 0%

Max CO2 50%

Max Econ 100%

ExhaustFan Speed SetPt

Active: 0%

Source: OA Damper Trk

OA Damper EF Speed

30% 0%

Max BMS 50%

Max Econ 100%

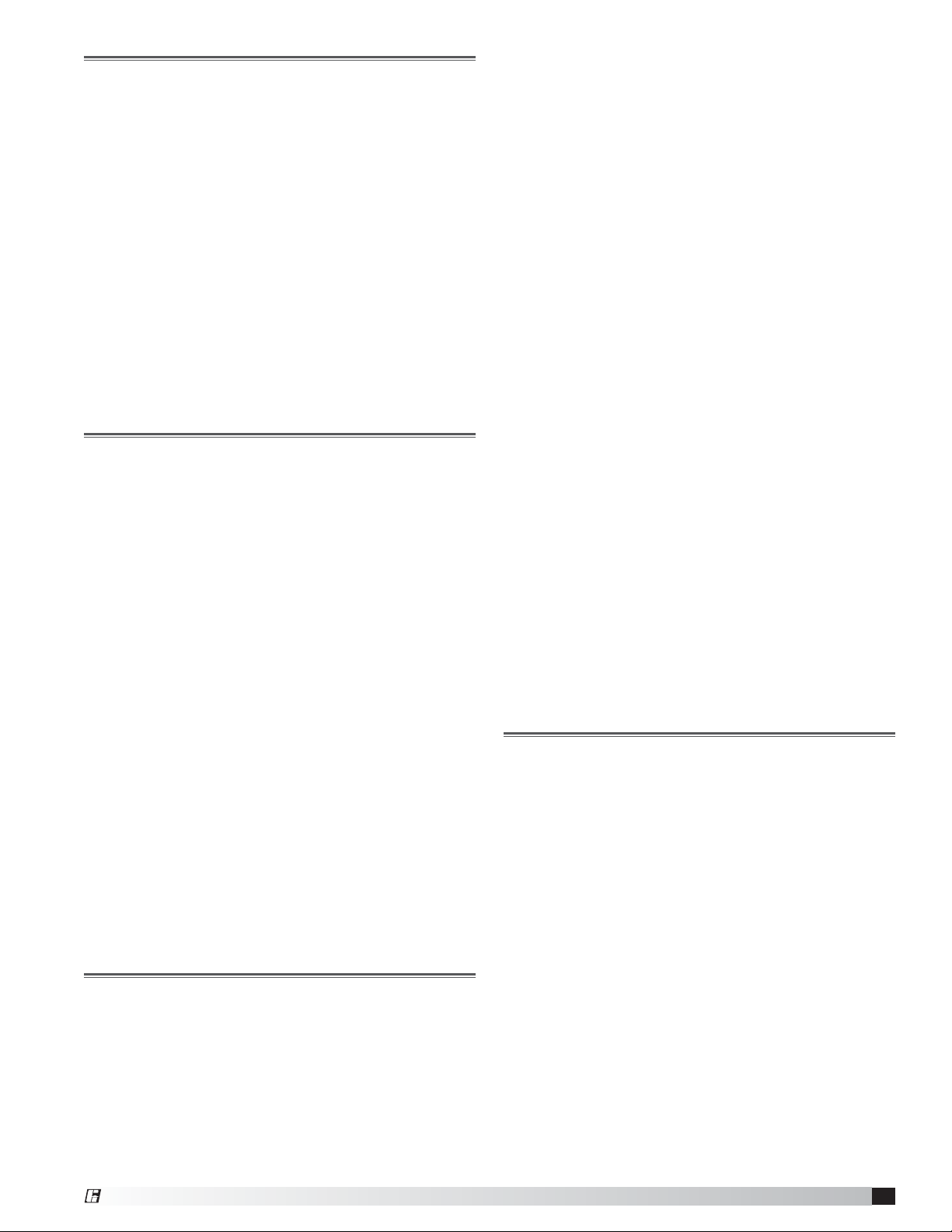

Outdoor Air Damper Tracking – The exhaust fan will proportionally track the

outdoor air damper, between a minimum and maximum position.

Normal Operation: During non-economizer operation, the exhaust fan will track

the outdoor air damper between the minimum outdoor air position (Min OA) and

the maximum sequence position (Max CO2 or Max BMS). *Note that if the OA

Damper Set Point is controlled by the BMS, the exhaust fan tracking algorithm

references an adjustable minimum position on the display. In this case, the

outdoor air damper must open above this position before the exhaust fan begins

increasing speed.

Economizer Operation: During economizer operation, the exhaust fan will track

the outdoor air damper between the minimum outdoor air position and the

maximum economizer position (Max Econ).

džŚĂƵƐƚ&ĂŶdƌĂĐŬŝŶŐŽĨKĂŵƉĞƌWŽƐŝƟŽŶ

100%

50%

džŚĂƵƐƚ&ĂŶ^ƉĞĞĚ

0%

0% (MiŶ Speed)

ĐŽŶŽŵŝnjĞƌ

KƉĞƌĂƟŽŶ

Normal

KƉĞƌĂƟŽŶ

100% (Max Speed)

KƵƚĚŽŽƌĂŵƉĞƌWŽƐŝƟŽŶ

®

DDC Controller for Tempered Air Products

19

Page 20

Duct Pressure SetPt

Active: 0.25” wc

Source: Local 0.25” wc

THIS SCREEN DISPLAYS THE DUCT PRESSURE SET POINT.

This screen only appears if equipped with a duct pressure sensor.

The unit will modulate the supply fan to maintain the local duct pressure set point.

Set point source must be changed to BMS to allow BMS control.

Duct Ps: 0.18” wc

Single Zone VAV Setup

Supply Fan Speeds

Cooling Heating

Min: 0% 0%

Max: 100% 100%

Cooling Fan Delay: 180s

CO2 Set Point

Active: 1000PPM

Source: Local 1000PPM

CO2 Level: 66PPM

THIS SCREEN DISPLAYS THE SINGLE ZONE FANS SPEED PAR AMETERS.

This screen only appears if the supply fan VFD control is configured as Single

Zone VAV. A room temperature sensor is required.

When the unit is configured for Single Zone VAV, the heating, cooling and

economizer are controlled to maintain the active supply air temperature set point,

which is reset based on room temperature reset. The supply fan is modulated in

addition to the supply air temperature to satisfy the room temperature set point.

The minimum and maximum supply fan speed limits can be set during space

cooling and heating.

Space Cooling: When the room requires cooling (the room is warmer than room

temperature set point), the supply air temperature set point will reset as low as the

minimum supply temperature set point (see Supply Temp Set Point screen) to try

to cool the space. If further cooling is required, after the Cooling Fan Delay, the

supply fan will increase in speed to deliver more cooling to the space.

Space Heating: When the room requires heating (the room is cooler than the room

temperature set point), the supply air temperature set point will reset as high as

the maximum supply temperature set point (see Supply Temp Set Point screen)

and the supply fan will increase in speed to deliver more heating to the space.

THIS SCREEN DISPLAYS THE CO2 SET POINT.

This screen only appears if equipped with a CO2 sensor.

Depending on unit configuration, the unit will either modulate the supply fan or

outdoor air damper to maintain the CO2 set point.

Set point source must be changed to BMS to allow BMS control.

Building Press SetPt

Active: +0.010” wc

Source: Local +0.010” wc

Building Ps: +0.010” wc

DDC Controller for Tempered Air Products

20

THIS SCREEN DISPLAYS THE BUILDING PRESSURE SET POINT.

This screen only appears if equipped with a building pressure sensor.

Depending on unit configuration, the unit will either modulate the exhaust or

supply fan to maintain the local building pressure set point.

Set point source must be changed to BMS to allow BMS control.

®

Page 21

OA Damper Set Point

Active: 40%

Source: Local 40%

Max Econ: 100%

OA Damper Set Point

Active: 50%

Source: SF RESET

SupplyFan: 0% 100%

Min OA: 50% 40%

Max Econ: 100%

OA Damper Set Point

Active: 30%

Source: DCV CO2

SupplyFan: 0% 100%

Min OA: 30% 20%

Max CO2: 50% 40%

Max Econ: 100%

OA Damper Set Point

Active: 25%

Source: BMS 25%

Max BMS: 50%

Max Econ: 100%

THIS SCREEN DISPLAYS THE OUTDOOR AIR DAMPER SET POINT.

This screen only appears if equipped with a modulating outdoor air and

recirculating damper.

The set point is the proportional percentage of the outdoor air damper being

open.

0% = Full recirculation air

100% = Full outdoor air

Minimum Position – When in the occupied mode, the Active set point will be equal

to a local minimum OA set point, which may be constant or reset by fan speed

if equipped with a modulating supply fan. The OA damper set point can then

be further adjusted between the minimum OA and maximum OA settings with

sequences such as DCV CO2, Building Pressure and Economizer.

Maximum Position – Each sequence that can adjust the OA damper set point

contains a maximum position to prevent excess OA. The Active set point will be

determined based on the greatest demand of the configured sequences. For

example, if a unit is equipped with a DCV CO2 and an economizer sequence,

the OA damper set point will react to an economizer demand even if the CO2 set

point is satisfied. Likewise, if economizer is not available but CO2 is above set

point, the OA damper will open to satisfy the CO2 set point.

Supply F an Reset of OA Damper PosiƟon

100%

Max Econ

50%

Max CO2

Min OA

OA Damper PosiƟon Open %

0%

0% (Min Speed)

100% (Max Speed)

Supply F an S peed %

Economizer – The Active set point will be reset based on Economizer demand,

between the minimum and maximum positions.

Possible Set Point Sources:

Local – The minimum outdoor air percentage is constant, set by the controller.

SF Reset – The min and max positions are reset by the supply fan speed.

BMS – The BMS can directly control the OA damper position up to the Max BMS

position.

Building Pressure – Damper position is reset by a building pressure control loop.

DCV CO2 – Damper position is reset by a demand-controlled ventilation control

loop based on room CO2 levels.

®

DDC Controller for Tempered Air Products

21

Page 22

C. Clock/Scheduler

The Clock/Scheduler menu allows the user to view and alter the time and date.

The user can also add up to seven schedules for occupancy requirements.

Set Date & Time

Day: Monday

Date: MM/DD/YY

Hour: 15:30

Scheduler

Number of schedules: 0

Holidays

Holiday = unoccupied mode

for 24 hours.

Number of Holidays: 0

Morning Warm-up

Morning Warmup Off

Temperature Diff: 2.0°F

THE CLOCK SCREEN ALLOWS THE USER TO ADJUST THE TIME AND DATE.

THIS SCREEN ALLOWS THE USER TO ADD THE NUMBER OF UNOCCUPIED SCHEDULES

AND HOLIDAYS.

The Number of Schedules corresponds to the number of unoccupied periods the

user wishes to add. By setting the number of schedules to a value greater than

zero, the unoccupied mode will automatically be set to time clock.

A holiday is a single occurrence in which you would like the unit to be unoccupied

for 24 hours. A maximum of 15 holidays can be set. Holidays must be

reconfigured each year.

THIS SCREEN ALLOWS THE USER TO ENABLE THE MORNING WARM-UP SEQUENCE AND

THE DIFFERENTIAL REQUIRED TO ALLOW THE SEQUENCE TO OCCUR.

This screen only appears if Unoccupied Tempering is available.

The morning warm-up sequence calculates the time required to temper the space

to the occupied set point prior to occupancy. This sequence is limited between 10

to 60 minutes. The controller will re-evaluate the heating and cooling rate daily to

continually adjust to the changing climate.

Scheduler

Schedule #: #

Time On: 07:00

Time Off: 05:00

Days Enabled: MTWTFSS

Holiday #1

Month: MM

Day: DD

Unoccupied for 24 hrs

D. Input/Output

Analog Input

Outside Temperature

Input B01: 75.0°F

E. Data Logger

THIS SCREEN ALLOWS THE USER TO ADJUST SCHEDULES.

This screen only appears if a Schedule was added in the screen above.

The program supports up to seven separate schedules. Each schedule will

require the user to enter a Time On, Time Off and which days the schedule is

applicable for.

THIS SCREEN ALLOWS THE USER TO SET HOLIDAY DATES (IF ENABLED).

This screen only appears if Holidays are enabled.

The internal time clock will go into unoccupied mode as long as the date is equal

to the holiday date (always a 24 hour period).

The Input/Output menu allows the user to quickly view the status of the controller

inputs and outputs.

To manually control I/O values, go to the Service menu > Overrides.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize all equipped of the inputs and outputs

shown. See unit wiring diagram for your specific configuration.

The Data Logger menu allows the user to view up to 100 past alarms.

13:21:04 MM/DD/ YY

OA TEMP SENSOR

Outside Air T: -623.3

Discharge T: 52.8

Cold Coil T: 55.9

Room T: 72.5

SYS ON-HEATING

DDC Controller for Tempered Air Products

22

THIS SCREEN IS AN EXAMPLE OF A RECORDED ALARM.

The unit conditions are displayed for past alarm events. The date, time,

temperatures and unit status are recorded.

To clear recorded alarms, press

Prg

and

Esc

simultaneously.

®

Page 23

F. Board Switch

The Board Switch menu allows the user to jump between different controllers with

a remote display. This requires a remote display, along with additional controllers,

set-up in a pLAN network. A pLAN can consist of up to 32 devices, in different

combinations, but a maximum of 31 controllers.

Board Switch

Unit Address: 1

Switch to unit: 1

1. . . . . . . . . . 16

17 . . . . . . . . . 32

The Service menu allows the user to access several sub-menus regarding controller

information, controller overrides, operating hours, BMS configuration, I/O manual

G. Service

management and Probe Adjustment. The user can also change the default Service

Password (1000) by accessing the Service Settings sub-menu. By accessing the

BMS Config sub-menu, the user can adjust BMS protocol settings. (BACnet®,

LonWorks®, Modbus®)

G. Service

a. Information

Information

Greenheck Fan

Code: GWY1X000XXXX

Ver.2.10 4/1/14

Manual: 475595

Bios: 5.18 11/17/10

Boot: 4.03 07/03/06

WHEN VIEWING THIS SCREEN FROM A REMOTE DISPLAY, THE USER IS ABLE TO CHANGE

WHICH CONTROLLER’S MENU SHOULD BE DISPLAYED.

Unit Address: The pLAN address of the controller the display is currently

accessing.

Switch to unit: The pLAN address of the controller the display would like to

access.

ENTERING THE INFORMATION SUB-MENU WILL DISPLAY INFORMATION ABOUT THE

CONTROLLER AND THE PROGRAM LOADED ON THE CONTROLLER.

Code: Controller setup code determines functionality of program. When

contacting the factory, please reference this code.

Ver: Displays the current program version and data code of the current program.

Manual: The manufacturer part number for the corresponding Installation,

Operation and Maintenance (IOM) Manual.

G. Service

b. Overrides

a. Analog Inputs

b. Digital Inputs

c. Relay Outputs

d. Analog Outputs

e. Control Loops

Analog Input

Outside Temperature

Manual Control B005: OFF

Manual Position 0.0

Value 73.5

Control Loop Overrides

Unit must be ON.

To resume normal operation,

cycle unit power.

Energy Wheel Override

Wheel Control: Auto

Wheel: OFF

The Overrides menu is for start-up, commissioning and troubleshooting. This

menu allows the user to override the control loops and specific inputs and

outputs. To access the Overrides sub-menus, enter the service password

(Default=1000). Caution: overriding components and I/O can be dangerous to the

equipment. Always cycle power to the unit when finished with the override.

THIS SCREEN IS AN EXAMPLE OF A MANUALLY MANAGED TEMPERATURE ANALOG INPUT.

To manually control an analog input, change Manual Control to ON. Move cursor

to Manual position and alter value. The altered value will be displayed below.

Similar screens exist for the remaining I/O. To resume normal operation, simply

cycle power to the unit. Contact the factory for more details.

To manually override a control loop, the unit must be ON. In each respective

screen, change the control from AUTO to MANUAL.

To resume normal operation after overriding the controller, simply cycle power to

the unit.

THIS SCREEN ALLOWS THE USER TO OVERRIDE THE ENERGY WHEEL OPERATION.

This screen only appears if the unit is equipped with a non-VFD operated energy

wheel.

When the Wheel Control is in the MANUAL mode, use the arrow buttons to turn

the wheel ON or OFF.

®

DDC Controller for Tempered Air Products

23

Page 24

Energy Wheel Override

Wheel Control: Auto

Wheel: 100%

THIS SCREEN ALLOWS THE USER TO OVERRIDE THE ENERGY WHEEL OPERATION.

This screen only appears if the unit is equipped with a VFD operated energy wheel.

When the Wheel Control is in the MANUAL mode, use the arrow buttons to alter

the wheel %. This is directly proportional to a 0 - 10 VDC signal being sent to the

energy wheel VFD.

Wheel Preheat Override

Energy Recovery Wheel

Preheat Control: Auto

Preheater: OFF

Cooling Override

Cooling Control: Auto

Cooling: 100%

THIS SCREEN ALLOWS THE USER TO OVERRIDE THE ENERGY RECOVERY WHEEL

PREHEATER.

This screen only appears if an electric preheat frost control was provided with the

unit.

THIS SCREEN ALLOWS THE USER TO OVERRIDE THE COOLING OPERATION.

This screen only appears if a cooling operation was provided with the unit.

When the Cooling Control is in the MANUAL mode, use the arrow buttons to vary

the cooling output.

Chilled Water: The Cooling % is directly proportional to the 0 - 10 VDC output

signal.

0% Cooling = 0 VDC; 100% Cooling = 10 VDC

Packaged Cooling and Heat Pump: The Cooling % displays compressor

engagement as a percent. The compressors are subject to the minimum

On/Off times and Heating/Cooling Lockouts. Compressors engage in sequence

as described in the Compressor Staging screen in the

Manufacturer > Factory Settings menu.

Heating Override

Heating Control: Auto

Heating: 100%

THIS SCREEN ALLOWS THE USER TO OVERRIDE THE HEATING OPERATION.

This screen only appears if a heating operation was provided with the unit.

When the Heating Control is in the MANUAL mode, use the arrow buttons to vary

the heating output.

Electric Heater: The Heater Control % is proportional to the 0-10 VDC signal

being sent to the SCR controller, located in the electric heater control center.

0% Heating = 0 VDC - 0 kW output

100% Heating = 10 VDC - Max kW output

Hot Water: The Heater Control % is proportional to the 0-10 VDC signal being

sent to the heating control valve (BY OTHERS).

0% Heating = 0 VDC

100% Heating = 10 VDC

Indirect Gas: The Heater Control % is proportional to the 0-10 VDC signal being

sent to the indirect gas furnace controller, located in the indirect gas control

center. The first stage is on at 1% Heater Control. The furnace will then modulate

proportionally from minimum to maximum capacity. The furnace is subject to

minimum On/Off times and Heating Lockouts.

0% = 0 VDC – OFF

1% = 0 VDC – MINIMUM TURNDOWN ENABLED

1 - 100% = 0 - 10 VDC = FURNACE MODULATION

Heat Pump: The Heating % displays compressor engagement as a percent. The