Great Planes GPMA1543 User Manual

Wingspan: 41 in [1035mm]

Wing Area: 337 in2 [21.8dm2]

Weight: 27 – 31 oz [765 – 880g]

Wing Loading: 11.5 – 13.2 oz/ft2 [35 – 40g/dm2]

Length: 40 in [1015mm]

Required (not included):

Radio: 4-channel with four micro servos, two 6"

[152mm] servo extensions, two 16" [406mm]

servo extensions one Y-harness

Motor: RimFire™ 35-30-1250kV brushless out-runner

(GPMG4595) or Ammo™ 24-45-3790kV

brushless in-runner (GPMG0505) brushless out-runner

Gear-Drive: 24mm gear-drive with 4.5:1 gear ratio

ESC: 35A Brushless

Battery: 3-cell 1250 to 2100mAh LiPo battery & LiPo

compatible charger

INSTRUCTION MANUAL

Great Planes

®

Model Manufacturing Co. guarantees this kit to be free from def ects in both material and workmanship at the date of purchase.

This warranty does not cover an y component parts damaged by use or modifi cation. In no case shall Great Planes’ liability exceed the

original cost of the purchased kit. Further, Great Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the fi nal assembly or material used for fi nal assembly, no liability shall be assumed nor accepted

for any damage resulting from the use by the user of the fi nal user-assembled product. By the act of using the user-assembled product,

the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the b uy er is advised to return th is kit

immediately in new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822 USA

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax

number, e-mail address), a detailed description of the problem and a photocopy of the purchase receipt. Upon receipt of the package

the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE

STARTING CONSTRUCTION. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS

WARRANTY

CONCERNING THE ASSEMBLY AND USE OF

THIS MODEL.

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

Entire Contents © Copyright 2007 GPMZ1543 for GPMA1543 V1.0

TABLE OF CONTENTS

INTRODUCTION

INTRODUCTION ...............................................................2

AMA ..................................................................................2

SAFETY PRECAUTIONS .................................................2

LITHIUM BATTERY HANDLING & USAGE .....................3

DECISIONS YOU MUST MAKE ........................................3

Radio Equipment ..........................................................3

Motor Recommendations .............................................3

Propeller .......................................................................4

ESC (electronic speed control) ....................................4

Battery Pack .................................................................4

Charger ........................................................................4

Required Adhesive & Building Supplies .......................4

Optional Supplies & Tools ............................................4

IMPORTANT BUILDING NOTES ......................................5

ORDERING REPLACEMENT PARTS ..............................5

COMMON ABBREVIATIONS ...........................................5

METRIC CONVERSIONS .................................................5

KIT INSPECTION ..............................................................6

KIT CONTENTS ................................................................6

PREPARATIONS ...............................................................7

ASSEMBLE THE WING PANELS .....................................7

INST ALL THE WING PANELS ..........................................9

ASSEMBLE THE T AIL SECTION ...................................11

INSTALL THE TAIL SERVOS & PUSHRODS .................13

INSTALL THE LANDING GEAR .....................................13

MOUNT THE MOTOR .....................................................15

In-runner Brushless Motor with 24mm Gear Drive ........15

Out-runner Brushless Motor .......................................16

INSTALL THE RADIO & ESC .........................................17

INSTALL THE COWL, CANOPY & SPINNER ................18

APPL Y THE DECALS .....................................................20

GET THE MODEL READY TO FL Y .................................20

Check the Control Directions .....................................20

Set the Control Throws ...............................................20

Balance the Model (C.G.) ...........................................21

Balance the Model Laterally .......................................21

PREFLIGHT ....................................................................21

Identify Your Model .....................................................21

Charge the Batteries ..................................................21

Balance the Propellers ...............................................22

Range Check .............................................................22

MOTOR SAFETY PRECAUTIONS .................................22

AMA SAFETY CODE (excerpts) ....................................22

CHECK LIST ...................................................................23

FLYING ............................................................................23

Takeoff ........................................................................23

Flight ..........................................................................24

Landing ......................................................................24

3D FLYING ......................................................................24

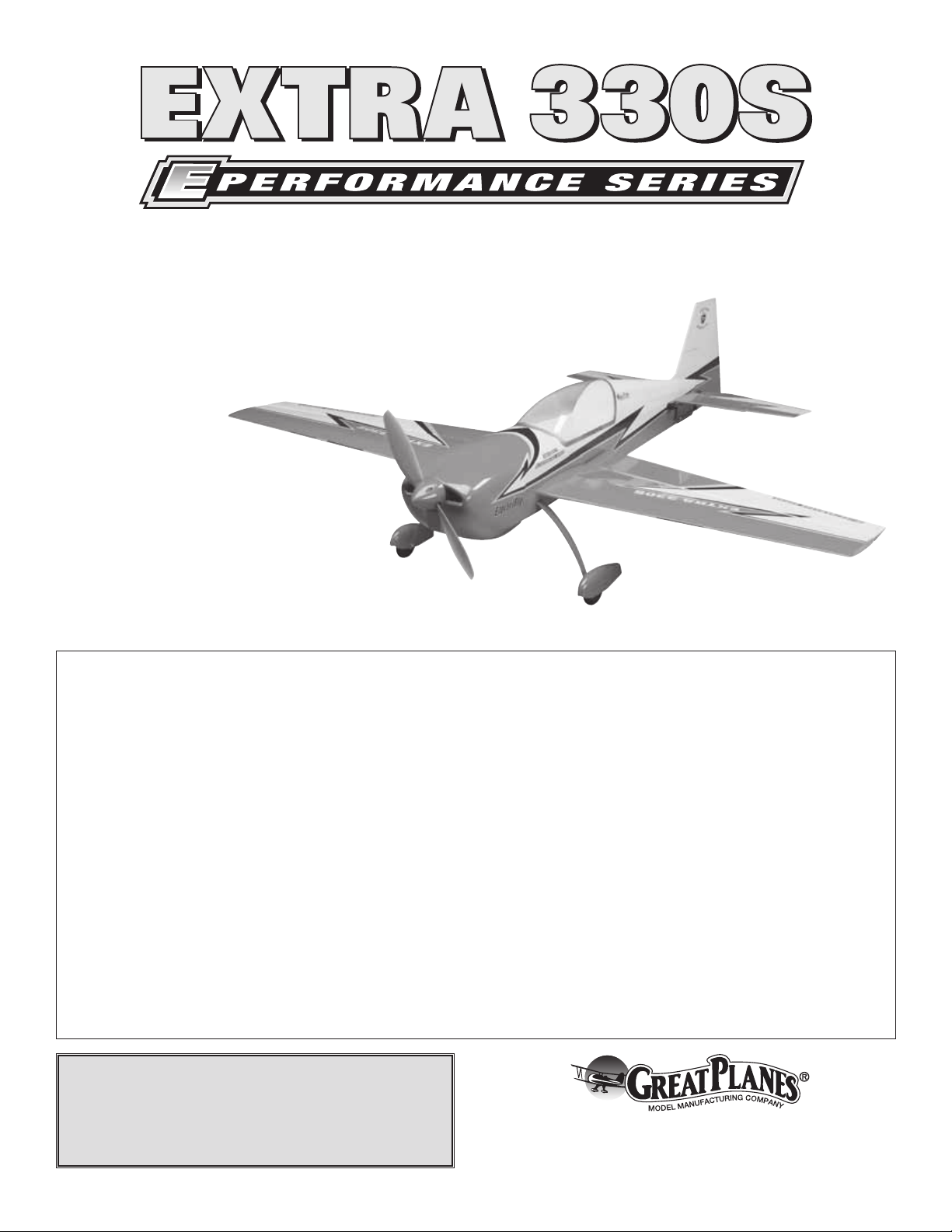

The Extra 330S EP ARF is another great release in a line of

electric built-up, all out performance 3D planes. You can fl y

incredible 3D maneuvers with the Extra 330S EP ARF just lik e

larger scale, expensiv e gas models . In addition, high capacity

LiPo battery packs and a brushless motor will allow you the

convenience of electric fl ying within a reasonable b udget.

For the latest technical updates or manual corrections to

the Extra 330S EP ARF, visit the Great Planes web site at

www.greatplanes.com. Open the “Airplanes” link, then

select the Extra 330S EP ARF. If there is new technical

information or changes to this model a “tech notice” box will

appear in the upper left corner of the page.

AMA

We urge you to join the AMA (Academy of Model Aeronautics)

and a local R/C club. The AMA is the governing body of model

aviation and membership is required to fl y at AMA clubs.

Though joining the AMA provides many benefi ts, one of the

primary reasons to join is liability protection. Coverage is not

limited to fl ying at contests or on the club fi eld. It e ven applies

to fl ying at public demonstrations and air shows. Failure to

comply with the Safety Code (excerpts printed in the back of

the manual) may endanger insurance cov erage . Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. There are over

2,500 AMA chartered clubs across the countr y. Contact the

AMA at the address or toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can do

to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

PROTECT Y OUR MODEL, YOURSELF

& OTHERS....FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

1. Your Extra 330S EP ARF should not be considered a toy,

but rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Extra 330S EP ARF, if not assembled and

operated correctly, could possibly cause injury to yourself or

spectators and damage to property.

2

2. Y ou must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in an

unsafe or unfl yable model. In a f ew cases the instructions may

differ slightly from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in fi rst-class

condition, and a correctly sized engine and components

(fuel tank, wheels, etc.) throughout the building process.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

6. You must check the operation of the model before every

fl ight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not an experienced pilot or have not fl own

this type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

your fi rst fl ights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area whose

membership includes experienced pilots.

8. While this kit has been fl ight tested to exceed normal use,

if the plane will be used for extremely high-stress fl ying, such

as racing, or if a motor larger than one in the recommended

range is used, the modeler is responsible for taking steps to

reinforce the high-stress points and/or substituting hardware

more suitable for the increased stress.

We, as the kit manuf acturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

• NEVER charge at currents greater than 1C.

• ALWAYS set the charger’s output volts to match the

battery volts.

• ALWAYS charge in a fi reproof location.

• NEVER trickle charge.

• NEVER allow the battery temperature to exceed

150° F [65° C].

• NEVER disassemble or modify pack wiring in any way or

puncture cells.

• NEVER discharge below 2.5V per cell.

• NEVER place on combustible materials or leave

unattended during charge or discharge.

• ALWAYS KEEP OUT OF REACH OF CHILDREN.

DECISIONS YOU MUST MAKE

This is a partial list of items required to fi nish the Extra 330S

EP ARF that may require planning or decision making before

starting to build. Order numbers are provided in parentheses.

Radio Equipment

A 4-channel radio system with four micro servos and a micro

receiver are required for this model. The servos and receiver

shown in the manual are Futaba® S3114 micro servos and

the Futaba R114F micro receiver. Two 6" [150mm] servo

extensions, two 16" [400mm] servo extensions, and a

Y-harness are also required. Order numbers for these items

are provided.

❏ (4) Futaba S3114 Micro High Torque Servo

7.7g (FUTM0414)

❏ Futaba R114F FM Micro Receiver (Low Band – FUTL0442,

High Band – FUTL0443)

❏ Futaba FM Single Conversion Short Crystal

(Low Band – FUTL62**, High Band – FUTL63**)

❏ (2) Futaba C-25 Extension Slim Wire 150mm (FUTM4506)

❏ (2) Futaba “J” 16" [400mm] Servo Extension (FUTM3955)

❏ Futaba “J” 6" Dual Servo Extension (FUTM4130)

Remember: T ake your time and f ollow the instructions to

end up with a well-built model that is straight and true.

LITHIUM BATTERY HANDLING & USAGE

WARNING!! Read the entire instruction sheet included with

this battery. Failure to follow all instructions could cause

permanent damage to the battery and its surroundings and

cause bodily harm!

• ONLY use a LiPo approved charger. NEVER use a NiCd/

NiMH peak charger!

• NEVER charge in excess of 4.20V per cell.

• ONLY charge through the “charge” lead. NEVER charge

through the “discharge” lead.

Motor Recommendations

The Extra 330S EP ARF comes with two mounting box es that will

accommodate either a brushless in-runner motor with gear drive

or a brushless out-runner motor. For all-out 3D performance,

we suggest the out-runner motor. For sport fl ying, either motor

choice is acceptable. The motors that have been tested and

perform well in this plane are listed below. If using the in-runner

motor with gear drive, be sure to install the 11T pinion that is

included with the gear drive to achieve a gear r atio of 4.5:1.

❏ Great Planes RimFire

out-runner motor (GPMG4595)

❏ Great Planes Ammo™ 24-45-3790kV brushless in-runner

motor (GPMG5185)

™

35-30-1250kV brushless

❏ Great Planes Gear Drive 24mm motors (GPMG0505)

3

Note: Motors from other manufacturers may work with the

Extra 330S EP ARF. However, the included fi rewall pieces

are designed to work specifi cally with the Great Planes

motors listed.

Propeller

If using the Ammo brushless in-runner motor with 4.5:1 gearbox

or the RimFire brushless out-runner motor, we recommend a

10" x 7" E Slo-Flyer electric propeller (GPMQ4123).

™

Triton2

is capable of charging NiCd, NiMH, LiPo, and lead acid

batteries. Order numbers for both are provided as follows:

charger will only charge one pack at a time, but

❏ Great Planes PolyCharge4 DC Only 4 Output LiPo

Charger (GPMM3015)

or

❏ Great Planes ElectriFly Triton2 DC Comp Peak

Charger (GPMM3153)

Required Adhesive & Building Supplies

ESC (electronic speed control)

A brushless ESC (electronic speed control) is required for

this plane. We recommend using the Great Planes Silver

Series 35A Brushless ESC 5V/2A BEC (GPMM1830).

Battery Pack

The Extra 330S EP ARF has been tested with 11.1V LiPo

packs ranging from 1250mAh to 2100mAh. Order numbers

are provided for packs of this siz e. The lighter 1250mAh pac k

is suggested for maximum performance.

❏ Great Planes LiPo 1250mAh 11.1V 20C Discharge

w/Balance (GPMP0609)

❏ Great Planes LiPo 1500mAh 11.1V 20C Discharge

w/Balance (GPMP0613)

❏ Great Planes LiPo 2100mAh 11.1V 15C w/Balance

BP2100 (GPMP0721)

Note: Do not use Great Planes LiPo 1500mAh 11.1V

3S 8C Discharge (GPMP0831). This battery pack is not

capable of supporting the current draw of the recommended

power systems.

Also, if using a 1250mAh battery pack combined with the

brushless out-runner motor, avoid prolonged full throttle

fl ying since the current draw of the motor exceeds the

continuous maximum current draw rating of the battery pack.

The 1250mAh battery pack is capable of supporting shorter,

full throttle maneuvers.

Charger

This is the list of adhesive and building supplies required to

fi nish the Extra 330S EP ARF. Order numbers are provided

in parentheses.

❏ 1/2 oz. [15g] Thin Pro

™

CA (GPMR6001)

❏ 1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❏ Pro 30-minute epoxy (GPMR6047)

❏ Denatured alcohol

❏ Drill bits: 1/8" [3mm]

❏ #1 Hobby knife (HCAR0105)

❏ #11 blades (5-pack, HCAR0211)

❏ Hobbico Steel T-pins 1" (100) (HCAR5100)

❏ Great Planes Pro Threadlocker (GPMR6060)

❏ CA applicator tips (HCAR3780)

❏ Small spring clamps

❏ 220-grit Sandpaper

Optional Supplies & Tools

Here is a list of optional tools mentioned in the manual that

will help you build the Extra 330S EP ARF.

❏ 21st Century

®

sealing iron (COVR2700)

❏ 21st Century iron cover (COVR2702)

❏ 2 oz. [57g] Spray CA activator (GPMR6035)

❏ 4 oz. [113g] Aerosol CA activator (GPMR6034)

❏ CA debonder (GPMR6039)

❏ Epoxy brushes (6, GPMR8060)

❏ Mixing sticks (50, GPMR8055)

❏ Mixing cups (GPMR8056)

❏ Hobbico Duster

™

can of compressed air (HCAR5500)

❏ Panel Line pen (TOPQ2510)

❏ Rotary tool such as Dremel

®

❏ Hobbico fl exible 18" ruler stainless steel (HCAR0460)

Note: A cell balancer is required for the LiPo battery packs

listed above.

❏ Great Planes ElectriFly

(GPMM3160)

A suitable charger is also required. The Great Planes

PolyCharge4™ is designed for LiPo packs only, but is able

to charge four LiPo packs simultaneously. The Great Planes

™

Equinox LiP o 1 to 5 Cell Balancer

4

IMPORTANT BUILDING NOTES

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment is by credit card or

personal check only; no C.O.D.

• When you see the term test fi t in the instructions, it

means that you should fi rst position the part on the assembly

without using any glue, and then slightly modify or custom

fi t the part as necessary for the best fi t.

• Whenever the term glue is written you should rely upon

your experience to decide what type of glue to use. When

a specifi c type of adhesive works best for that step, the

instructions will make a recommendation.

• Whenever just epoxy is specifi ed you may use either

30-minute (or 45-minute) epoxy or 6-minute epoxy. When

30-minute epoxy is specifi ed it is highly recommended that

you use only 30-minute (or 45-minute) epoxy, because you

will need the working time and/or the additional strength.

• Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following steps

to get another view of the same parts.

• The stabilizer and wing incidences and engine thrust

angles have been factory-built into this model. However,

some technically-minded modelers may wish to check these

measurements anyway. To view this inf ormation visit the web

site at www.greatplanes.com and click on “Technical Data.”

Due to manufacturing tolerances which will have little or no

effect on the way your model will fl y, please expect slight

deviations between your model and the published values.

ORDERING REPLACEMENT PARTS

If additional assistance is required for any reason contact Product

Support by e-mail at productsupport@greatplanes.com,

or by telephone at (217) 398-8970.

Replacement Parts List

GPMA3040 Wing Set

GPMA3041 Fuse

GPMA3042 Tail Surfaces

GPMA3043 Landing Gear

GPMA3044 Wheel Pants

GPMA3045 Cowl

GPMA3046 Canopy

GPMA3047 Battery Hatch

GPMA3048 Decals

GPMA2981 Spinner

GPMA2982 Hardware Set

COMMON ABBREVIATIONS

Fuse = Fuselage

Stab = Horizontal Stabilizer

Fin = Vertical Fin

LE = Leading Edge

TE = Trailing Edge

LG = Landing Gear

Ply = Plywood

" = Inches

mm = Millimeters

ESC = Electronic Speed Control

METRIC CONVERSIONS

Replacement parts for the Great Planes Extra 330S EP ARF

are available using the order numbers in the Replacement

Parts List that follows. The fastest, most economical service

can be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Hobbico web site at

www.hobbico.com. Choose “Where to Buy” at the

bottom of the menu on the left side of the page. Follow the

instructions provided on the page to locate a U.S., Canadian

or International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721,

but full retail prices and shipping and handling charges will

apply. Illinois and Nevada residents will also be charged

sales tax. If ordering via fax, include a Visa® or MasterCard®

number and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

1" = 25.4mm (conversion factor)

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4.0mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

5

3/4" = 19.0mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762.0mm

36" = 914.4mm

KIT INSPECTION

KIT INSPECTION

KIT CONTENTS

Before starting to build, take an inventory of this kit to make sure it is complete and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or missing parts, use the part names exactly as they are written in

the Kit Contents list.

Great Planes Product Support:

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

KIT CONTENTS

1

5

6

8

7

9

10

15

3

2

4

11

12

8

10

16

17

16

13

14

Kit Contents

1 Cowl

2 Fuse

3 Canopy

4 Tail Skid

5 Spinner

6 Out-Runner Motor Mounting Box (8 pcs.)

7 In-Runner Motor Mounting Box (6 pcs.)

8 Landing Gear (2 pcs.)

9 Wheel Pants (L&R)

10 Wheels (2 pcs.)

11 Cowl Ring

12 Wing Alignment Jig (6 pcs.)

13 Vertical Fin & Rudder

14 Horizontal Stabilizer & Elevators

15 Right Wing Panel & Aileron

16 Spar Doublers (2 pcs.)

17 Left Wing Panel & Aileron

6

PREPARATIONS

❏ 1. If you have not done so already, remove the major parts

of the kit from the box and inspect for damage. If any par ts

are damaged or missing, contact Product Support at the

address or telephone number listed in the “Kit Inspection”

section on page 6.

❏ 2. Carefully remove the tape and separate all the control

surfaces. Use a co v ering iron with a covering sock on medium

heat to tighten the covering if necessary. Apply pressure over

sheeted areas to thoroughly bond the cov ering to the wood.

❏ 2. Insert the CA hinges halfway into the slots in the wing

panels. Push small T-pins through the middle of the hinges to

keep them centered. Insert the ailerons onto the other ends

of the hinges. Align the outer tips of the ailerons fl ush with the

wing tips. Pull the ailerons away from the panels far enough

to confi r m that the hinges remained perpendicular with the

hinge line. If not, use a hobby knife or small screwdr iver to

nudge them straight.

ASSEMBLE THE WING P ANELS

❏ 1. Use a sharp hobby knife to trim open the hinge slots in

the wing panels and ailerons. Test fi t the pre-cut CA hinges

into the slots. If any are diffi cult to install, enlarge the slots

with your knife.

❏ 3. When satisfi ed, carefully remove the T-pins from the

hinges. Adjust the ailerons so there is a small gap between

the LE of the aileron and the wing. The gap should be small,

just enough to see light through the gap or slip a piece of

paper through. Use thin CA glue to secure the ailerons by

applying 6 to 7 drops onto both sides of each hinge.

❏ 4. Attach a 6" [152mm] servo extension to each aileron

servo and wrap the connection with transparent tape or heatshrink tubing.

7

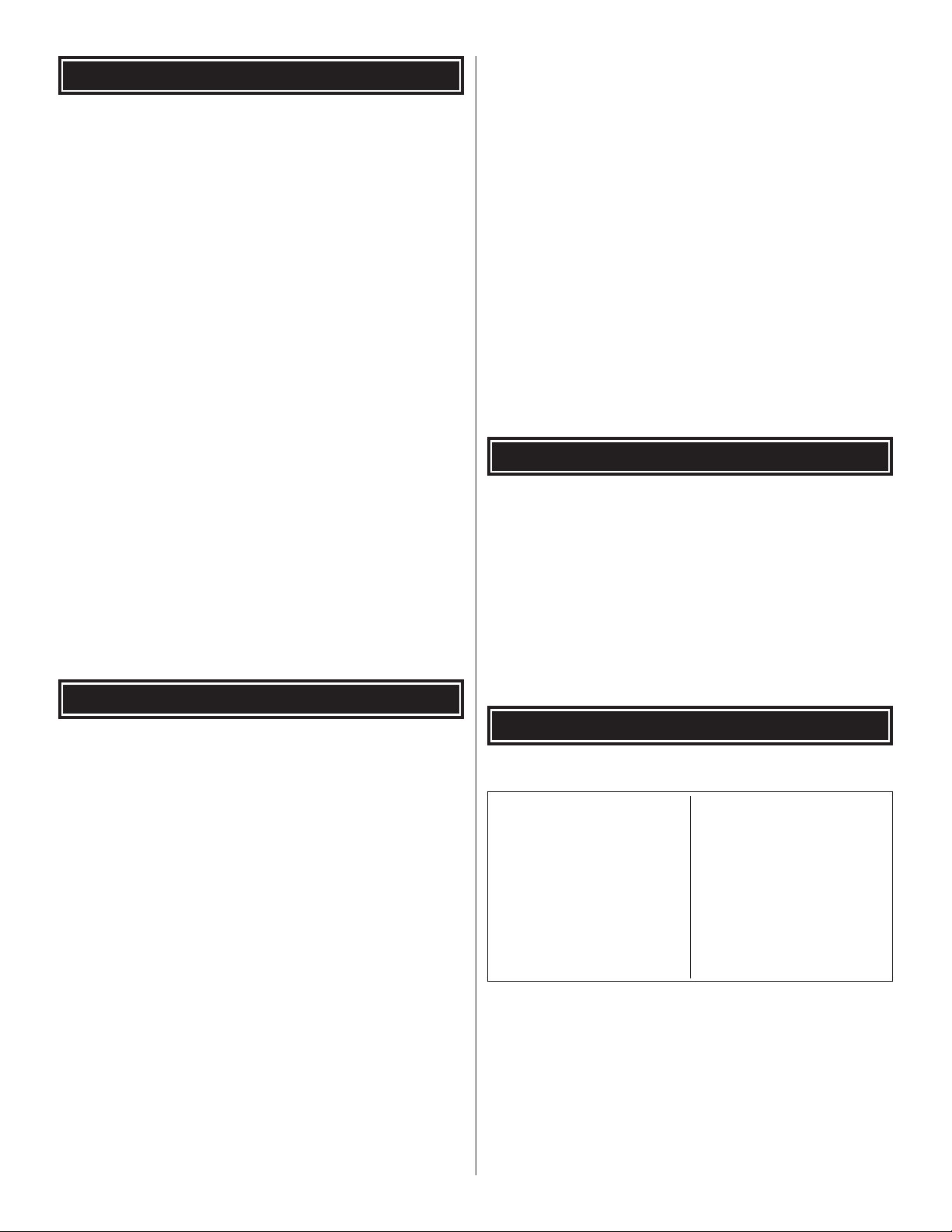

❏ 5. Trim the covering from the aileron servo bays on the

undersides of the wing panels.

❏ 6. Insert the servo leads into the servo bays and pull them

through the wing ribs. The servos can be installed using

the hardware included with the servos or they can be glued

in place. If gluing the servos in place, slit or puncture the

covering just beneath the servo mounting tabs where they

will contact the wing. This will ensure that the servo will be

glued to the plywood servo bay, not just the covering. Glue

the aileron servos into the servo bays using epoxy or CA glue

with the servo splines facing the LE of the wings. After the

glue has cured, confi rm that the servos are properly secured

to the wings and reinforce with extra glue if necessary.

❏ 8. Temporarily connect your aileron servos and battery

pack to your radio and center the servos and trim levers on

the transmitter. Test fi t the double-sided servo arms parallel

to the aileron hinge line. If the servo arm does not fi t onto

the servo spline parallel to the hinge line, remove it from the

servo and rotate it 180°. Decide which way fi ts best (closest

to parallel) and cut off the arm that isn’t used. Be sure to

make a left and right servo arm.

❏ 7. Locate two double-sided servo arms that fi t the output

splines of your aileron servos and four adjustable clevises.

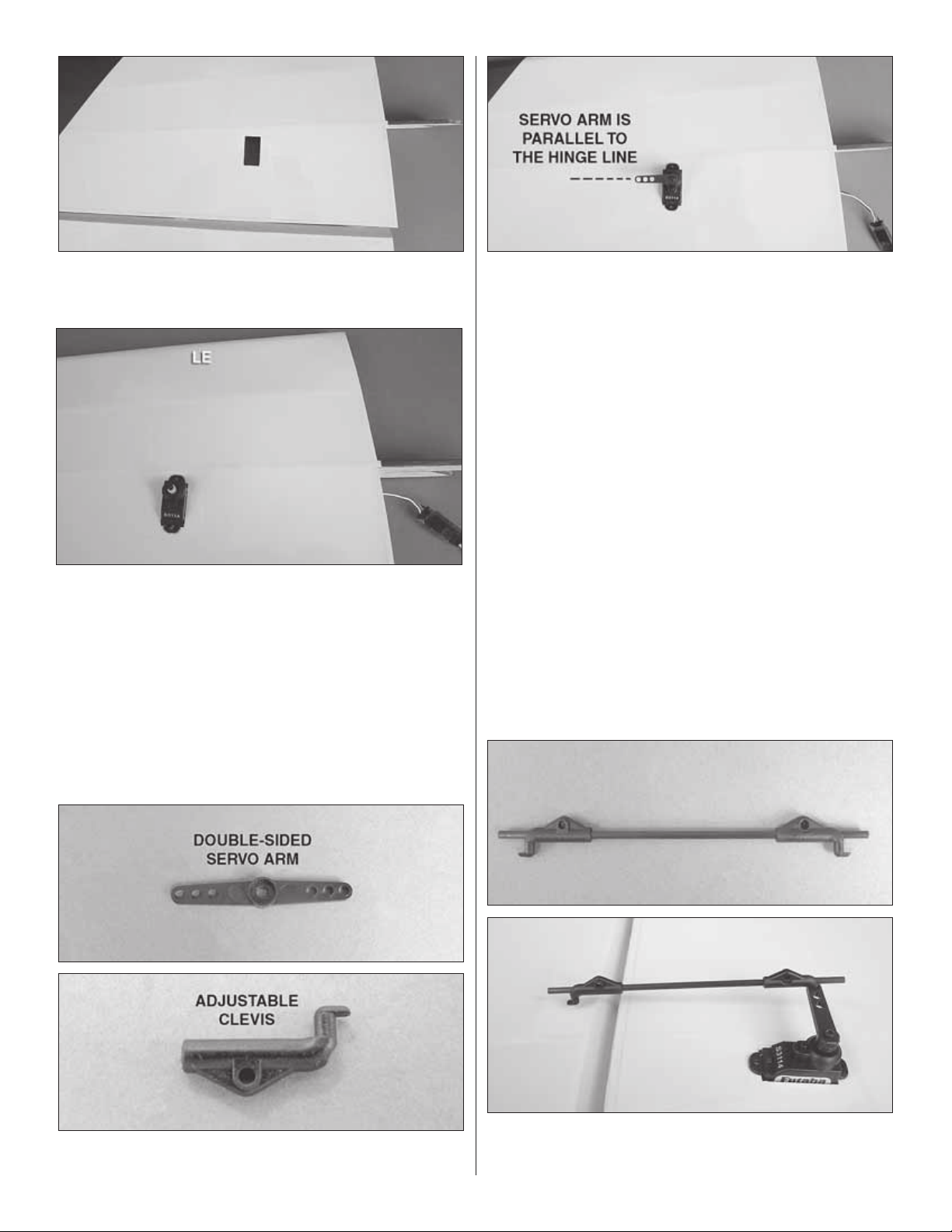

❏ 9. Fit two adjustable clevises onto both 2mm x 90mm

aileron pushrods. Push one of the clevises from each

pushrod into the outer holes of the servo arms.

8

❏ 10. Locate the aileron double rib that has a rectangular

mounting block at the LE. Using the position of the pushrods

as a guide, cut a slot 3/8" [9.5mm] long perpendicular to the

hinge line just behind the bevel of the LE of aileron for each

control horn in the center of the mounting block. The slot

only needs to be wide enough to accommodate the thickness

of the control horn tab on the control horn (approximately

1/16" [1.6mm] thick). Do not cut all the way through the

ailerons! 3/16" to 1/4" [5mm to 6mm] deep is suffi cient. Trim

the control horn backplate tabs shorter so that the control

horns sit fl at in the slots you made.

❏ 12. Use the position of the control horn to adjust the length

of the pushrods as needed. Remove the servo arms from

the aileron servos. Connect the other adjustable clevises on

the aileron pushrods to the control horns and reattach the

servo arms. Fine tune the length of the pushrods inside the

clevises so that the ailerons are in the neutral position. Lock

the clevises onto the pushrods by threading a 2mm x 4mm

screw into each clevis scre w hole . The screw head should fi t

into the recessed hole in the adjustable clevises as shown

(installing the screws in the wrong direction may not properly

tighten the clevises onto the pushrods). The e xcess rod ends

can be cut away.

INST ALL THE WING P ANELS

❏ 11. Confi rm that the holes in the control horn are centered

over the hinge line. When satisfi ed, coat the backplate tabs

with medium CA and press them into the slots.

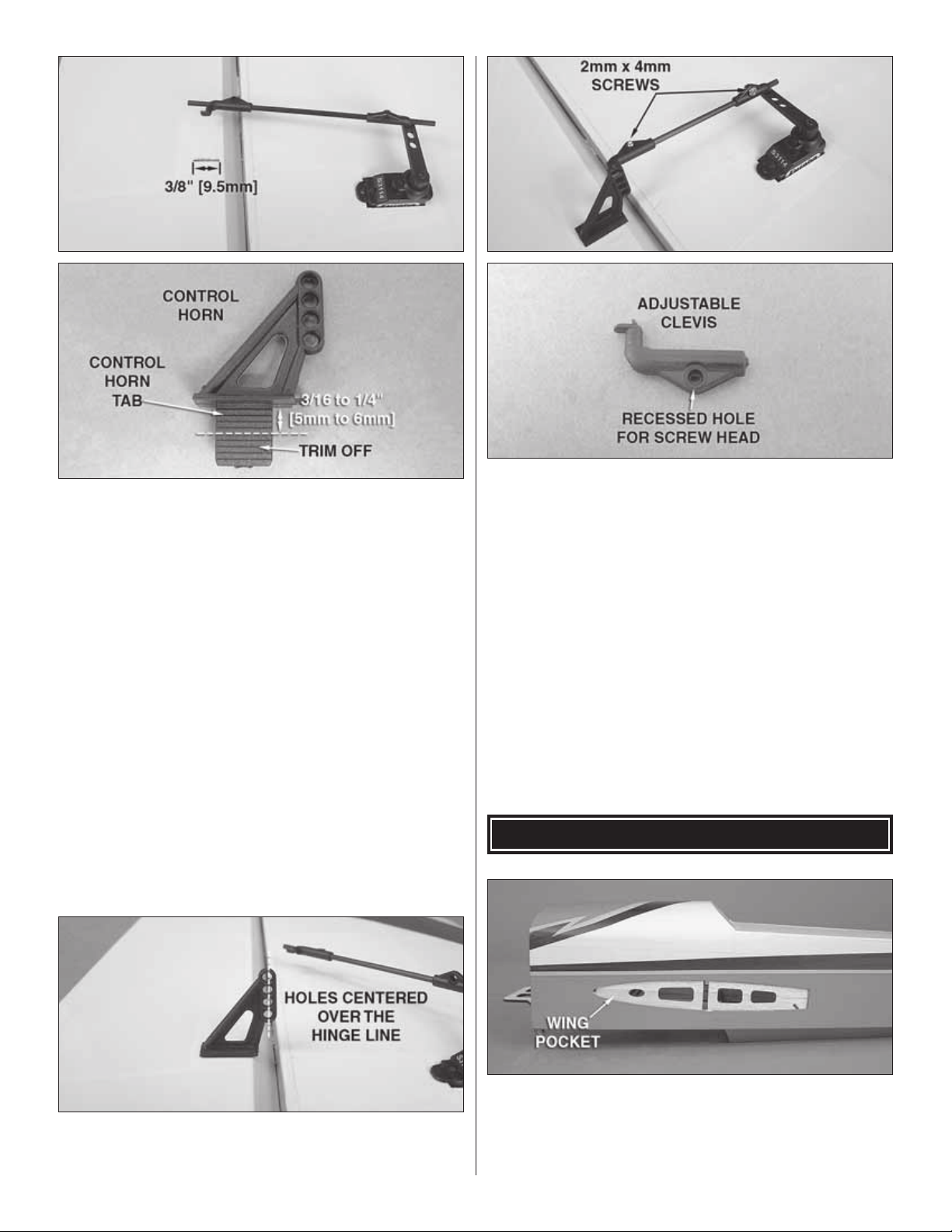

❏ 1. Trim the covering from the wing pockets in the fuse.

For the best results, work slowly and use a new hobby knife

blade for this step . Be careful not to cut into the fuse sides. On

the wing panels, trim the covering that overlaps onto the wing

panel root ribs.

9

Loading...

Loading...