Page 1

EP ARF

INSTRUCTION

MANUAL

®

Length: 41.5 i n

[1055mm]

SPECIFICATIONS

Wingspan:

Wing Area:

52.5 in

[1335mm]

441 in

[28.4 dm2]

Radio:

Weight:

2

Wing

Loading:

5.25– 5.75 lb

[2380– 2610 g]

27– 30 oz/ft

[82– 92 g/dm2]

2

Motor/ESC/Prop: RimFire

4-5 Channel with

4 micro servos (w/o flaps) or

6 micro servos (with flaps)

ElectriFly SS-45

APC-E 12x8

WARRANTY

Great Planes® Model Manufacturing Co. guarantees this kit to

be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component

parts damaged by use or modification. In no case shall Great

Planes’ liability exceed the original cost of the purchased kit.

Further, Great Planes reserves the right to change or modify this

warranty without notice.

In that Great Planes has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

™

.32 (42-50-800)

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

© 2011 Hobbico®, Inc. GPMA1485 Mnl

Page 2

TABLE OF CONTENTS

AMA

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

AMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

ITEMS REQUIRED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Motor, ESC, & Propeller Recommendations . . . . . . . .3

Battery & Charger Recommendations . . . . . . . . . . . . .3

Required Adhesive & Building Supplies. . . . . . . . . . . .4

Optional Supplies & Tools . . . . . . . . . . . . . . . . . . . . . .4

IMPORTANT BUILDING NOTES. . . . . . . . . . . . . . . . . . . .4

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . .5

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

BEFORE YOU BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

WING ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Aileron Servo Installation . . . . . . . . . . . . . . . . . . . . . . .6

Fixed Flap Option 1 . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fixed Flap Option 2 . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Servo Operated Flap Option 3 . . . . . . . . . . . . . . . . . .11

FUSELAGE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . .13

Main Landing Gear Installation . . . . . . . . . . . . . . . . .13

Tail Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Tailwheel & Rudder Installation . . . . . . . . . . . . . . . . .15

Servo Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

MOTOR, ESC & RADIO INSTALLATION . . . . . . . . . . . .18

COWL & PROPELLER INSTALLATION . . . . . . . . . . . . .20

FINAL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Pilot Installation (Optional) . . . . . . . . . . . . . . . . . . . . .23

Apply the Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . . .23

Center the Controls & Check the Control Directions .23

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . .24

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . .25

Balance the Model Laterally. . . . . . . . . . . . . . . . . . . .25

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Identify Your Model. . . . . . . . . . . . . . . . . . . . . . . . . . .26

Balance Propellers. . . . . . . . . . . . . . . . . . . . . . . . . . .26

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

MOTOR SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . .26

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

CHECKLIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Academy of Model Aeronautics:If you are not already a

member of the AMA, please join! The AMA is the governing

body of model aviation and membership provides liability

insurance coverage, protects modelers’ rights and interests

and is required to fly at most R/C sites.

Academy of Model

Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

www.modelaircraft.org

IMPORTANT!!!

Two of the most important things you can do to preserve the

radio controlled aircraft hobby are to avoid flying near fullscale aircraft and avoid flying near or over groups of people.

SCALE COMPETITION

Though the Great Planes Mister Mulligan EP is an ARF and

may not have the same level of detail as an “all-out” scratchbuilt competition model, it is a scale model nonetheless

and is therefore eligible to compete in the Fun Scale class

in AMA competition (we receive many favorable reports of

Great Planes ARF’s in scale competition!). In Fun Scale, the

“builder of the model” rule does not apply. To receive the five

points for scale documentation, the only proof required that a

full size aircraft of this type in this paint/markings scheme did

exist is a single sheet such as a kit box cover from a plastic

model, a photo, or a profile painting, etc. If the photo is in

black and white other written documentation of color must

be provided. Contact the AMA for a rule book with full details.

If you would like photos of the full-size Mister Mulligan for

scale documentation, or if you would like to study the photos

to add more scale details, photo packs are available from:

Bob’s Aircraft Documentation

3114 Yukon Ave

Costa Mesa, CA 92626

Phone: (714) 979-8058

Fax: (714) 979-7279

www.bobsairdoc.com

PROTECT YOUR MODEL, YOURSELF

& OTHERS… FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

INTRODUCTION

For the latest technical updates or manual corrections to the

Mister Mulligan EP visit the Great Planes web site at www.

greatplanes.com. Open the “Airplanes” link, then select the

Mister Mulligan EP ARF. If there is new technical information

or changes to this model a “tech notice” box will appear in

the upper left corner of the page.

1. Your Mister Mulligan EP should not be considered a toy,

but rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Mister Mulligan EP, if not assembled and

operated correctly, could possibly cause injury to yourself or

spectators and damage to property.

2. You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in an

unsafe or unflyable model. In a few cases the instructions may

2

Page 3

differ slightly from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in good condition,

a correctly sized engine, and other components as specified

in this instruction manual. All components must be correctly

installed so that the model operates correctly on the ground

and in the air. You must check the operation of the model and

all components before every flight.

5. If you are not an experienced pilot or have not flown

this type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

your first flights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area whose

membership includes experienced pilots.

6. While this kit has been flight tested to exceed normal use,

if the plane will be used for extremely high stress flying, such

as racing, or if a motor larger than one in the recommended

range is used, the modeler is responsible for taking steps to

reinforce the high stress points and/or substituting hardware

more suitable for the increased stress.

7. WARNING: The cowl, wheel pants, and some fairings are

made of fiberglass, the fibers of which may cause eye, skin

and respiratory tract irritation. Never blow into or on a part

to remove fiberglass dust, as the dust will blow back into

your eyes. Always wear safety goggles, a particle mask and

rubber gloves when grinding, drilling and sanding fiberglass

parts. Vacuum the parts and the work area thoroughly after

working with fiberglass parts.

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

ITEMS REQUIRED

Radio Equipment

A 4-channel minimum radio system is required to fly this

model. We recommend using a 6-channel radio so that wing

flaps can be used.

Futaba

❏

OR

Futaba R114F FM Micro Receiver

❏

(Low Band – FUTL0442, High Band – FUTL0443)

Futaba FM Single Conversion Short Crystal

❏

(Low Band – FUTL62**, High Band – FUTL63**)

®

R617FS 7-channel 2.4GHz Receiver

No Flaps Option

(1) Y-harness (FUTM4130)

❏

(4) Futaba 3115 Micro Precision Servo (FUTM0415)

❏

OR

(4) minimum 39 oz-in (2.8 kg-cm) Micro Servos

❏

Operable Flaps Option

(2) Y-harness (FUTM4130)

❏

(2) 6" [150mm] servo extension (HCAM2701 for Futaba)

❏

(6) Futaba 3115 Micro Precision Servo (FUTM0415)

❏

OR

(6) minimum 39 oz-in (2.8 kg-cm) Micro Servos

❏

Motor, ESC and Propeller

Great Planes RimFire .32 (42-50-800kV) Brushless

❏

Outrunner Motor (GPMG4700)

Great Planes Silver Series 45A Brushless ESC

❏

(GPMM1840)

APC 12x8 Electric Propeller (APCQ4133)

❏

Battery and Charger

Other battery packs will also work in this model, but please

be sure to always use a 4S LiPo pack that can supply at least

45A continuous.

FlightPower

❏

(FPWP6576)

Great Planes ElectriFly Triton

❏

(GPMM3155)

Read the entire instruction sheet included with the battery.

Failure to follow all instructions could cause permanent

damage to the battery and its surroundings, and cause

bodily harm!

• ONLY use a LiPo approved charger.

• NEVER charge in excess of 4.20V per cell.

• ONLY charge through the “charge” lead. NEVER charge

through the “discharge” lead.

• NEVER charge at currents greater than 1C.

• ALWAYS set charger’s output volts to match battery

volts.

• ALWAYS charge in a fi reproof location.

• NEVER trickle charge.

• NEVER allow battery temperature to exceed 150° F (65° C).

• NEVER disassemble or modify pack wiring in any way

or puncture cells.

• NEVER discharge below 3.0V per cell

• NEVER place on combustible materials or leave

unattended during charge or discharge.

• ALWAYS KEEP OUT OF REACH OF CHILDREN.

®

EON-X™ 4350mAh 14.8V 30C LiPo

™

EQ AC/DC Charger

LIPO WARNING!!

(2) 12" [300mm] servo extension

❏

(HCAM2711 for Futaba)

3

Page 4

Required Adhesives

and Building Supplies

To finish this airplane you will need the following items.

1 oz. [30g] Thin Pro™ CA (GPMR6002)

❏

1 oz. [30g] Medium Pro CA+ (GPMR6008)

❏

2 oz. [60g] Foam Safe CA Activator (GPMR6035)

❏

Pro 6-minute epoxy (GPMR6045)

❏

R/C-56 canopy glue 4oz (JOZR5007)

❏

#11 Hobby knife w/ 5 blades (EXLR9018)

❏

3/32" Long Ball-Driver (GPMR8002)

❏

Drill bits: 1/16" [1.6mm], 5/64" [2mm], 3/32" [2.4mm]

❏

Builder’s Triangle Set (HCAR0480)

❏

18" flexible steel rule (HCAR0460)

❏

Hobbico Heavy Duty Diagonal Cutter 7" (HCAR0627)

❏

Pliers with wire cutter (HCAR0625)

❏

Panel Line Pen (TOPQ2510)

❏

Medium T-pins (100, HCAR5150)

❏

Epoxy brushes (6, GPMR8060)

❏

Mixing sticks (50, GPMR8055)

❏

Mixing cups (GPMR8056)

❏

Threadlocker™ thread locking cement (GPMR6060)

❏

Denatured alcohol (for epoxy clean up)

❏

Light machine oil

❏

Flat metal file

❏

Masking tape

❏

Optional Supplies and Tools

IMPORTANT BUILDING NOTES

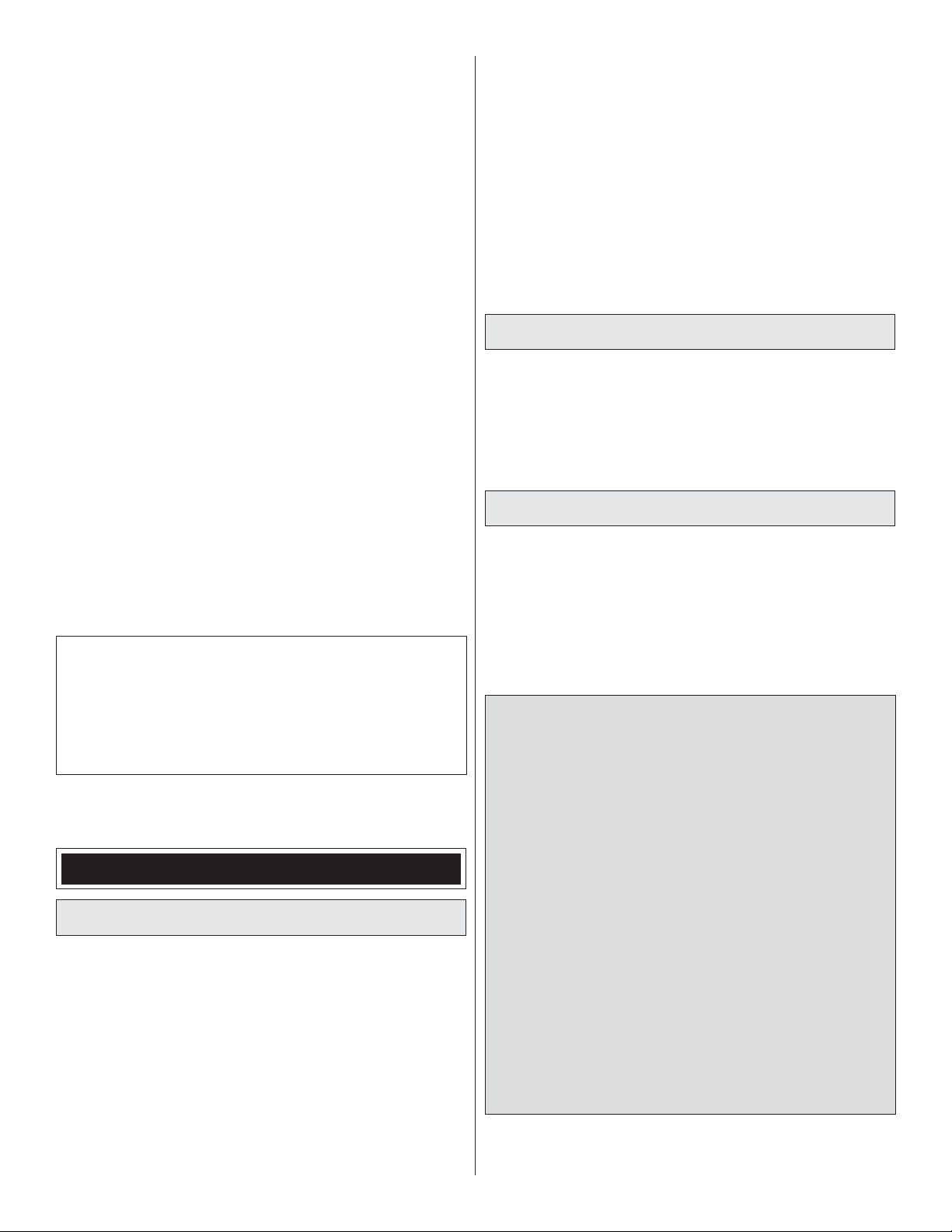

• There are three types of screws used in this kit:

Sheet metal screws are designated by

a number and a length. For example,

#6 x 3/4" [19mm]

Machine screws are designated by a

number, threads per inch, and a length.

For example 4-40 x 3/4" [19mm]

Socket Head Cap Screws (SHCS) are

designated by a number, threads per

inch, and a length. For example 4-40 x

3/4" [19mm]

• When you see the term test fit in the instructions, it means

that you should first position the part on the assembly

without using any glue, and then slightly modify or custom

fit the part as necessary for the best fit.

• Whenever the term glue is written you should rely upon

your experience to decide what type of glue to use. When

a specific type of adhesive works best for that step, the

instructions will make a recommendation.

• Whenever just epoxy is specified you may use either

30-minute (or 45-minute) epoxy or 6-minute epoxy. When

30-minute epoxy is specified it is highly recommended that

you use only 30-minute (or 45-minute) epoxy, because you

will need the working time and/or the additional strength.

Pro 30-minute epoxy (GPMR6047)

❏

3/8" [9.5mm] heat-shrink tubing (DUBM2180)

❏

21st Century® sealing iron (COVR2700)

❏

21st Century iron cover (COVR2702)

❏

Rotary tool such as Dremel

❏

Rotary tool reinforced cut-off wheel (GPMR8200)

❏

CA applicator tips (HCAR3780)

❏

CA debonder (GPMR6039)

❏

Dremel Drum Sander, Coarse 3/8” (DRER0968)

❏

Great Planes Easy-Touch™ Hand Sander 5.5”

❏

(GPMR6169)

Great Planes Easy-Touch Sandpaper 150 Grit

❏

(GPMR6183)

Great Planes 1/5th Scale Sport Pilot – Red

❏

(GPMQ9015)

Great Planes 1/5th Scale Sport Pilot – Blue

❏

(GPMQ9016)

Great Planes 1/5th Scale Sport Pilot – Yellow

❏

(GPMQ9017)

Revell® Razor Saw (RMXR6960)

❏

®

• Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following steps

to get another view of the same parts.

• The Mister Mulligan EP is factory-covered with Jet White

Top Flite

ever be required, MonoKote can be patched with additional

MonoKote purchased separately. MonoKote is packaged in

six-foot rolls, but some hobby shops also sell it by the foot. If

only a small piece of MonoKote is needed for a minor patch,

perhaps a fellow modeler would give you some. MonoKote

is applied with a model airplane covering iron, but in an

emergency a regular iron could be used. A roll of MonoKote

includes full instructions for application.

®

MonoKote® film (TOPQ0204). Should repairs

4

Page 5

G

1

©

yg

KIT INSPECTION

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of

acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or

missing parts, use the part names exactly as they are written

in the Kit Contents list.

Great Planes Product Support:

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

ORDERING REPLACEMENT PARTS

Replacement parts for the Mister Mulligan EP are available

using the order numbers shown below. The fastest, most

economical service can be provided by your hobby dealer or

mail-order company.

To locate a hobby dealer, visit the Great Planes web site

at www.greatplanes.com. Choose “Where to Buy” at the

bottom of the menu on the left side of the page. Follow the

instructions provided on the page to locate a U.S., Canadian

or International dealer.

Parts may also be ordered directly from Hobby Services

by calling (217) 398-0007, or fax at (217) 398-7721, but full

retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax.

®

If ordering via fax, include a Visa

or MasterCard® number

and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason, contact

Product Support by telephone at (217) 398-8970, or by

e-mail at productsupport@greatplanes.com.

Hatch

Dummy

Engine

Wing Tube

GPMA4126

Cowl

GPMA4124

Cowl & Dummy Engine

GPMA4125

Dummy Engine Only

GPMA4131

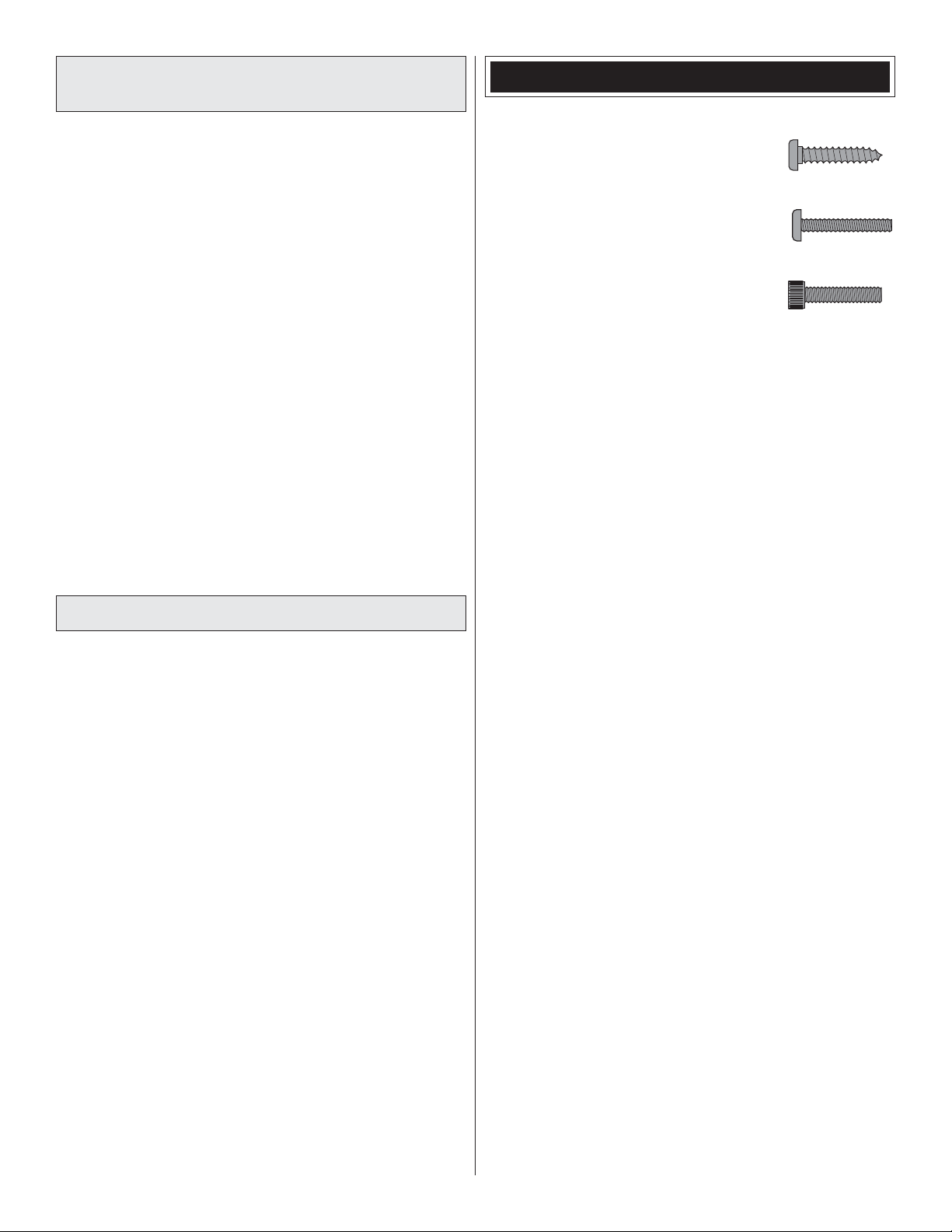

KIT CONTENTS

Wing Halves

Fuselage

GPMA4120

GPMA4121

Vertical

Stabilizer

GPMA4123

Horizontal

Stabilizer

GPMA4122

Landing

Gear

GPMA4127

Wheel

Wing Struts

Pants

GPMA4128

GPMA4129

GPMA1485 D01 ©2010 Great Planes

PMA1485 D0

2010 Great Planes

GPMA4130

NOTE

Full-size plans are not available. You can download a copy of this manual at greatplanes.com.

5

Page 6

BEFORE YOU BEGIN

Before you begin assembling your model, inspect it for

wrinkled covering and areas where the covering should be

tacked down to the wood like the openings for the servo

bays. Use Low heat (about 250° F [121° C]) to tack down the

edges. Raise the temperature and iron over wrinkles with

light pressure. Be careful not to contact the edges that you

tacked down while shrinking.

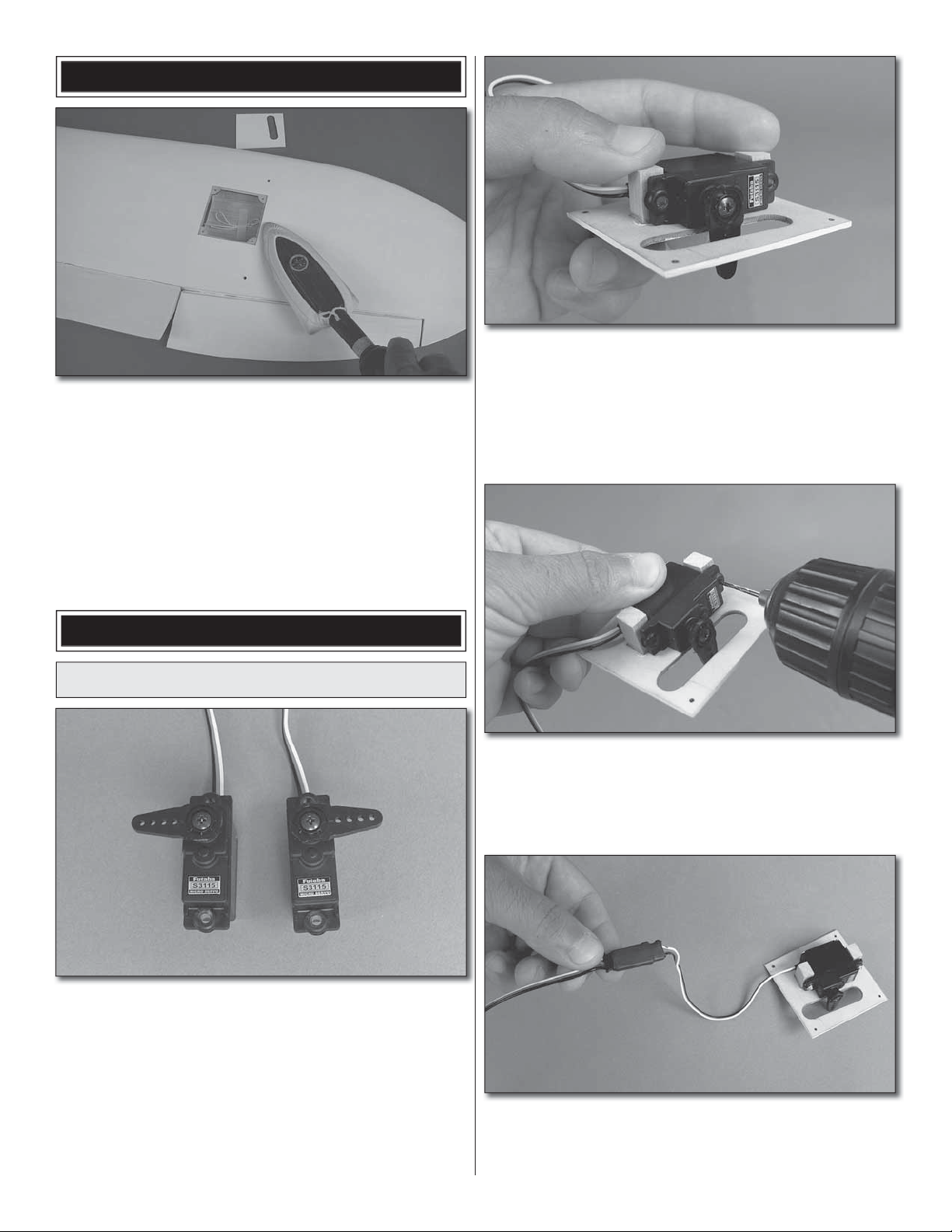

2. Working with the left wing, remove the aileron servo

❏ ❏

bay cover. Center the servo arm in the opening with the arm

pointing out as shown. With the servo in this position, glue

two 7mm x 10mm x 14mm hardwood blocks under the servo

mounting tabs. If you are using the recommended Futaba

S3115 servos, you may simply use epoxy to glue the blocks

in the positions marked inside the cover.

Note: Save the plastic bag that the fuselage came in. It will

be used later in the assembly.

WING ASSEMBLY

Aileron Servo Installation

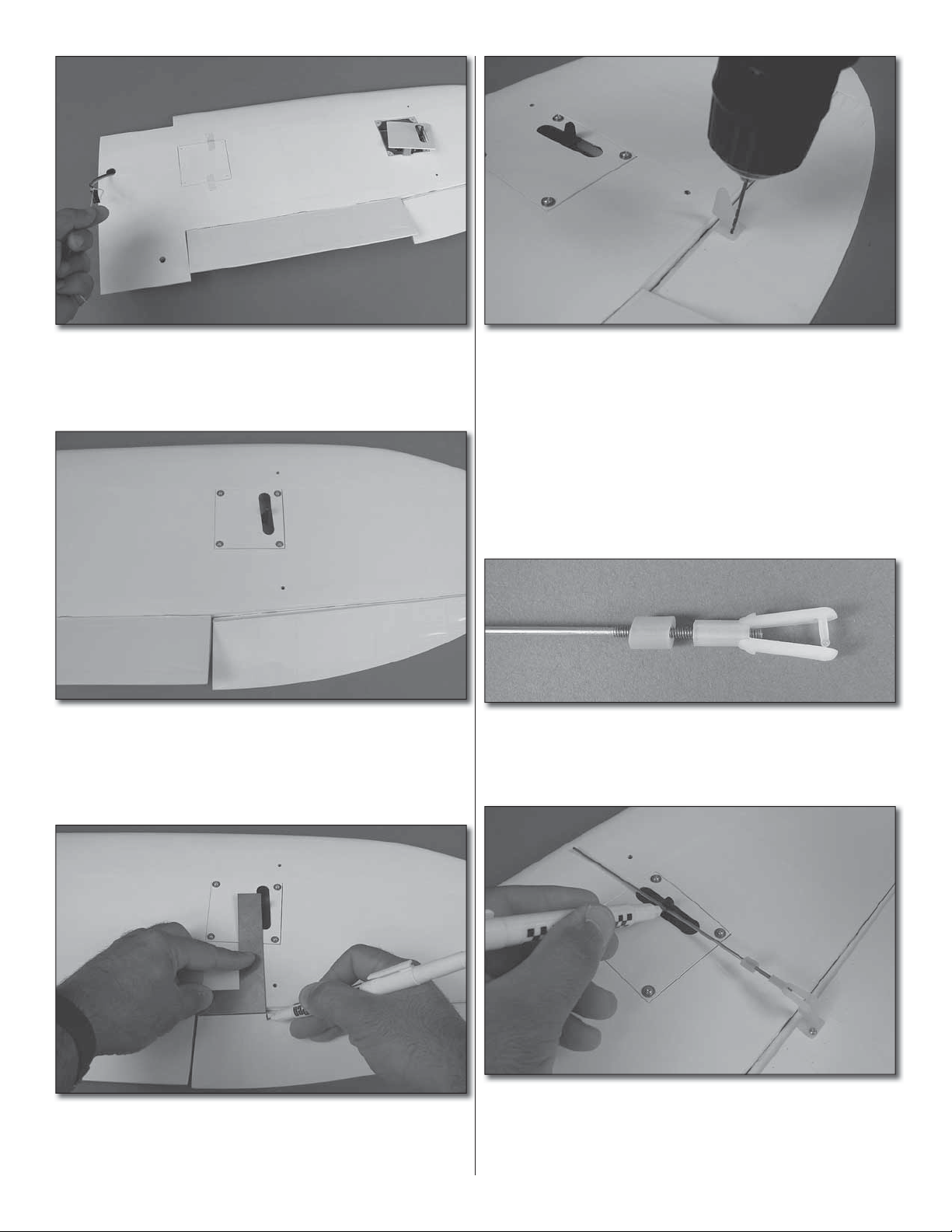

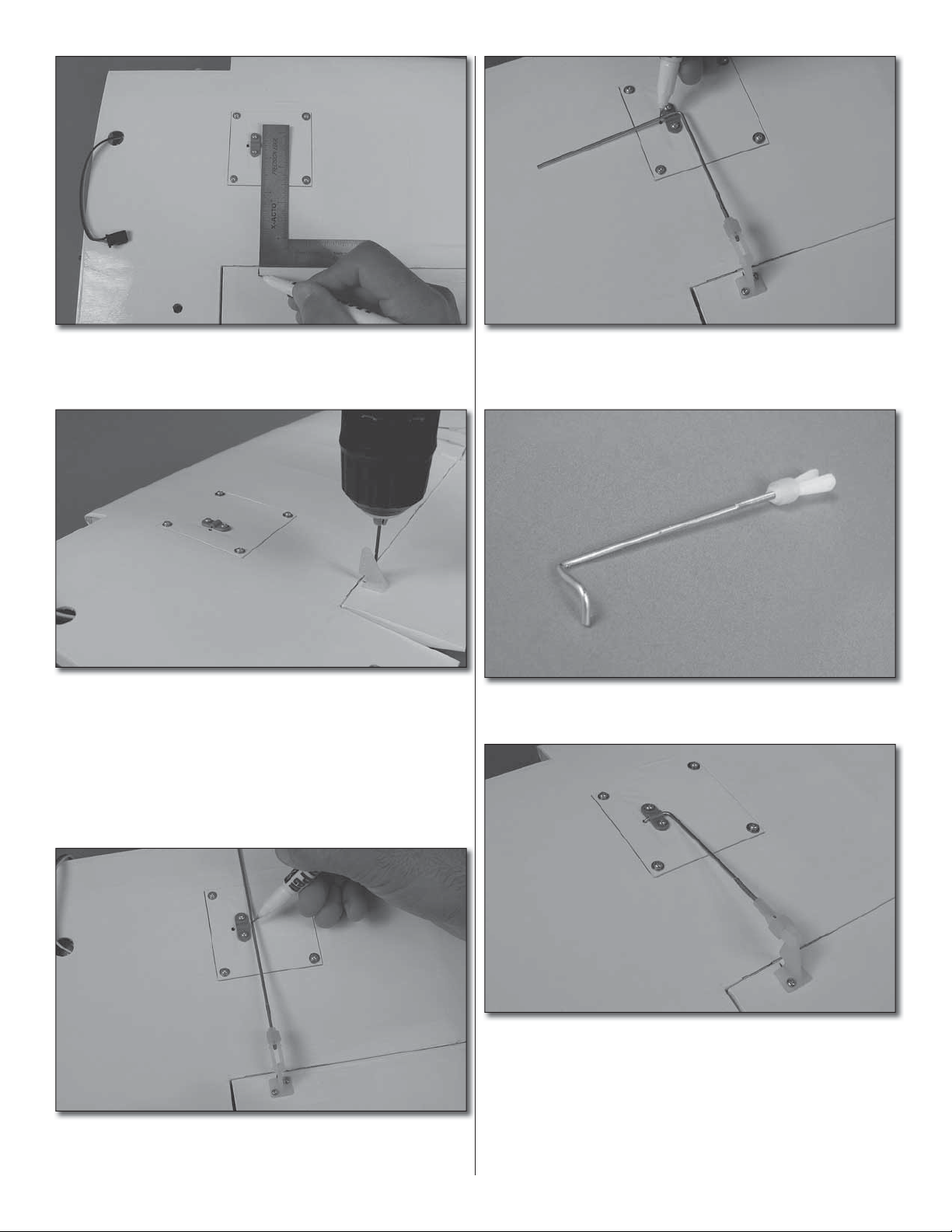

3. Drill mounting holes for the servo using a 1/16"

❏ ❏

[1.6mm] drill. Install the two servo screws that came with your

servo. Remove the screws and the servo and wick a drop of

thin CA into the screw threads that you just tapped in the

hardwood blocks. After the CA cures, re-install the screws.

1. Prepare a left and a right servo using your radio system

❏

to center the servos. Remove the servo arm retaining screws

and the servo arms. Install the standard size servo arms that

came with your servos. Rotate the arm on the splined servo

shaft and choose the arm that is 90° to the side of the servo

case when the servo is centered. Clip off the unused servo

arms so that your aileron servos appear as shown. Fit any

servo grommets now (if equipped).

4. Attach a 12" [305mm] servo lead extension to the

❏ ❏

aileron servo. Secure the connection with a piece of 3/8"

[9.5mm] diameter heat shrink tubing (not supplied) or wrap

the connection with electrical tape.

6

Page 7

5. Tie the guide string to the end of the servo lead and

❏ ❏

carefully route the servo lead through the wing and out of the

hole in the sheeting near the root rib of the wing.

6. Orient the servo bay cover as shown and install it

❏ ❏

using four #2 x 3/8" [9.5mm] sheetmetal screws with four

#2 flat washers. Remove the screws, washers and the cover

and harden the screw holes in the wing with thin CA. Then,

re-install the cover and screws.

8. Clip off and discard the backing plate from a small

❏ ❏

control horn. Align the horn over the mark you made and

slide it forward until the pushrod holes in the horn are directly

over the hinge line. Drill two 3/8" [9.5mm] deep holes using a

1/16" [1.6mm] drill. Be careful not to drill completely through

the aileron.

9. Install the control horn using two #2 x 3/8" [9.5mm]

❏ ❏

sheetmetal screws. Remove the screws and the horn and

wick about 4-5 drops of thin CA into the screw holes you

tapped. Allow the CA to dry and reinstall the control horn.

10. Screw a clevis onto a 6" [152mm] threaded pushrod

❏ ❏

so that at least 1/8" [3.2mm] of thread protrudes past the

barrel of the clevis. Loosely fit a silicone clevis retainer to the

pushrod.

7. Using a 90° builder’s square or a builder’s triangle,

❏ ❏

make a mark on the aileron directly behind the aileron servo

arm. Align the flat base of the square with the aileron hinge

line. Then slide the square into position and make your mark.

11. Fit the clevis to the outermost hole in the aileron

❏ ❏

control horn. Extend the pushrod forward and align it with

the hole you drilled in the servo arm. With the servo arm

centered and the aileron at neutral, make a mark at the hole

in the servo arm.

7

Page 8

12. Bend the pushrod 90° at the mark that you made.

❏ ❏

Fit the pushrod to the servo arm and fasten it with a FasLink

pushrod retainer. Cut off the remaining pushrod so that at

least 1/4" [6.4mm] of pushrod remains.

16. Glue the 3mm x 20mm wing alignment dowel into the

❏

left wing as shown so that at least 10mm is protruding.

Fixed Wing Flap (Option 1)

13. Repeat steps 2 through 12 to prepare the right wing.

❏

14. Glue a 6mm x 25mm wing dowel into the leading edge

❏

of each wing so that the dowel protrudes out 1/4" [6.4mm]

as shown.

On this model, you can set up the flaps one of three ways.

You can purchase two additional servos and use flaps for

landings. If you never intend to use flaps, you may glue the

flaps in the fully retracted position. If you want the option to

add flaps later you can install the control horns and fix them

in place using the supplied flap pushrod.

1. To permanently fix the flaps in the retracted position,

❏

glue the wing flap servo bay covers in place.

15. Sand the surface of the wing alignment dowel to

❏

prepare it for glue.

2. Trim the covering from the leading edge of each flap.

❏

Remove the covering from the trailing edge of the wing in

front of each flap. Trim the covering about 1/16" [1.6mm]

inside of the edge.

8

Page 9

3. Mix up a batch of 6-minute epoxy. Brush epoxy on the

❏

leading edge of each flap and the corresponding trailing

edge of each wing. Glue each flap in the retracted position.

Before the epoxy cures, wipe off the excess with a paper

towel dampened with denatured alcohol.

Fixed Wing Flap (Option 2)

With this option, you can easily add operable flaps later.

6-minute epoxy, you can heat up the glue joint later and

easily remove the fixed flap retainers to convert to operable

flaps.

3. Trim away the covering from the three small holes.

❏

Install a nylon strap across the two longitudinal holes using

two of the sheetmetal screws included with the straps. Don’t

forget to harden the screw holes with thin CA. Prepare both

servo bay covers.

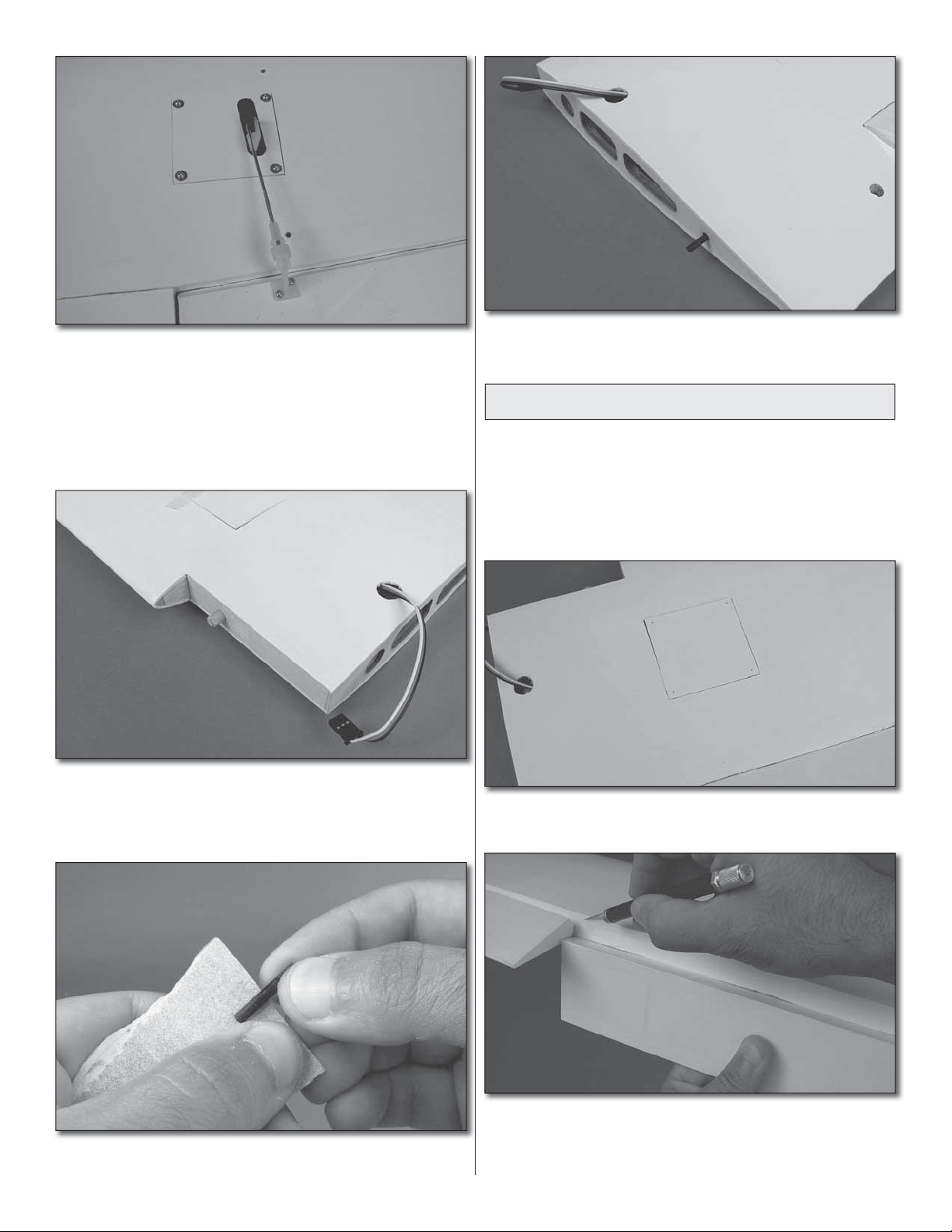

1. Identify the four wooden fixed flap retainers shown

❏

here. Rotate the small oval piece until the three holes in that

piece align with the three holes in the larger piece. Glue the

small oval piece to the larger piece. Use the laser-etched

outline and the holes to center the small oval piece. Allow the

glue to dry. Note: The pair that you create will not be mirror

images because both flap servo arms must operate in the

same direction as they exit the wing.

2. Glue the pieces into the flap servo bay covers using

❏

6-minute epoxy. Do not remove the covering. By using

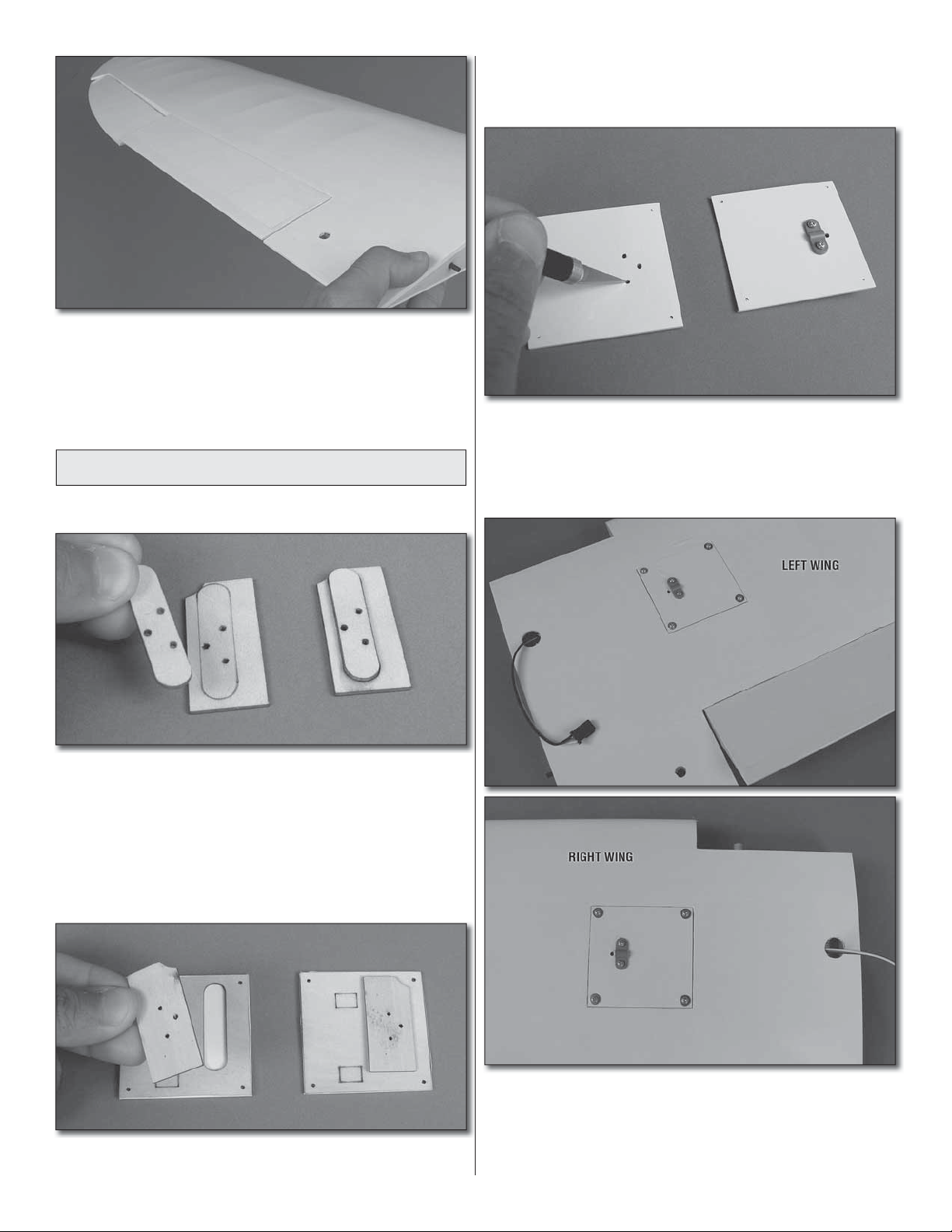

4. Install the covers onto the wings. Be careful to orient

❏

the covers properly as shown.

9

Page 10

5. Working with the left wing first, make a mark on the

❏ ❏

flap LE directly behind the side opposite the hole in each

servo bay cover. This is the side the pushrod will be on.

6. Hold a small control horn over the mark you made

❏ ❏

with the pushrod holes directly over the hinge line. Drill two

3/8" [9.5mm] deep holes using a 1/16" [1.6mm] drill bit.

7. Install the control horn using two #2 x 3/8" [9.5mm]

❏ ❏

sheetmetal screws.

8. Prepare a 6" [152mm] pushrod the same way you

❏ ❏

prepared the aileron servos using one nylon clevis and a

silicone clevis retainer.

10. Bend the pushrod 90°. Insert the bent portion

❏ ❏

under the hump of the nylon strap. Make a mark at the point

you will make the second 90° bend.

11. Remove the pushrod and make the second 90°

❏ ❏

bend so that it is vertical as shown.

9. Attach the clevis to the outermost hole in the flap

❏ ❏

control horn. Extend the pushrod forward and mark the point

that you will make the first 90° bend.

12. Remove the nylon strap and reinstall the pushrod.

❏ ❏

Make any adjustments to the length of the pushrod by

tightening or loosening the clevis until the flap is set in the

retracted position.

10

Page 11

13. Repeat steps 5 through 12 to finish the right wing.

❏

Remember to orient the servo bay cover properly. Use the

photo above for reference.

14. To add operable flaps later, remove the pushrod from

❏

the servo bay cover. Using a heat gun, heat up the wooden

flap retainer pieces you glued in place until you soften the

epoxy. Use a flat razor blade to separate the glue joint and

remove the retainer pieces from the servo bay covers. Follow

the directions in the next section to install and set up flap

servos. Note: Clip off the last 90° bend from the pushrods

and reuse them to hook up your servos.

Servo Operated Flaps (Option 3)

Because of the relatively small amount of control throw

that is needed for the flaps, we recommend that you use

a radio system that has adjustable end-points. The small

amount of control throw necessary is very difficult to achieve

mechanically. We found that we had to set our end points to

30 – 40%.

2. Establish the rotation direction of your flap servos.

❏ ❏

Lay one flap servo on its side as shown in the sketch. Turn

on your radio and actuate the flap channel. Make sure that

the servo rotates in the proper direction in conjunction with

the movement of the flap dial or slider. If it doesn’t, reverse

the servo operation so that it does.

3. With the radio still switched on, set the flaps on the

❏ ❏

transmitter to the fully retracted position. Using the short arms

that came with your servos, prepare two servos as shown

choosing the servo arm that aligns perpendicular to the servo

centerline. Drill the outermost hole in the short arm or the hole

that is approximately 5/16" [8mm] out from the center of the

output shaft.

1. Trim away the covering from the servo arm hole.

❏ ❏

4. Prepare each flap servo bay cover using two 7mm

❏ ❏

x 10mm x 14mm hardwood blocks. Glue these in place and

drill the holes for the servo screws using a 1/16" [1.6mm]

drill. Install the servos. Both covers should look the same.

11

Page 12

5. Attach a 6" [152mm] servo lead extension to the flap

❏ ❏

servo. Secure the connection using 3/8" [9.5mm] heat shrink

tubing or electrical tape.

6. Route the servo lead through the wing and out

❏ ❏

of the hole in the sheeting as shown. Install the servo bay

cover in the orientation shown using four #2 x 3/8" [9.5mm]

sheetmetal screws and four #2 flat washers. Harden the

threads in the wood with thin CA as instructed before.

8. Hold a small control horn over the mark you made with

❏ ❏

the pushrod holes directly over the hinge line. Drill two 3/8"

[9.5mm] deep holes using a 1/16" [1.6mm] drill bit. Be careful

not to drill completely through the flap. Install the control horn

using two #2x3/8" [9.5mm] sheetmetal screws.

threads in the wood with thin CA.

9. Prepare a 6" [152mm] pushrod the same way you

❏ ❏

prepared the aileron servos using one nylon clevis and a

silicone clevis retainer.

10. Attach the pushrod to the outermost hole in the

❏ ❏

flap control horn. Extend the pushrod forward and line it

up with the outermost hole in the servo arm. With the flap

retracted and the servo in the retracted position as shown,

mark your first bend point on the pushrod. Make a 90° bend

at the mark you made.

Harden the

7. Make a mark on the flap LE directly behind the

❏ ❏

servo arm.

12

11. Attach the pushrod to the servo using a nylon Faslink

❏ ❏

.

Page 13

12. Repeat steps 1 through 11 for the right wing.

❏

13. Insert the wing tube into one wing and join the two

❏

wings. You may use epoxy to glue the wings together if you

wish, but it is not required.

FUSELAGE ASSEMBLY

Main Landing Gear Installation

2. The main landing gear leg fairings are only slightly different.

❏

It is difficult to see the difference by just looking at them. We

recommend test fitting both of the landing gear fairings over

the main landing gear and checking the fit. If they are properly

oriented, they should fit against the fuselage closely. If they do

not, try switching them or rotating them front to back.

3. Glue the fairings to the gear legs using R/C-56 canopy

❏

glue around the flange. Clean up any excess glue with a

damp paper towel. Tape the fairings in place. Remove the

tape after the glue dries.

1. Install the main landing gear to the fuselage using six

❏

4-40 x 1/2" [12.7mm] socket-head cap screws, six #4 lock

washers, and six #4 flat washers. Apply a drop of threadlocker

to the screws before installing.

4. Install an axle onto a landing gear leg using a 5/16-24

❏

lock nut. Using a felt tipped pen, mark the bottom side of

each axle as shown. Make one mark 3/16" [4.8mm] from the

base of the axle and the other mark 1-1/8" [29mm] from the

base of the axle.

13

Page 14

5. Grind one 3/16" [4.8mm] wide flat spot at each mark

❏

you made.

Tail Installation

1. Cut the protective piece of balsa wood out of the TE of

❏

the horizontal stabilizer slot on the fuselage.

2. Fit the wing to the fuselage using two 1/4-20 nylon wing

❏

bolts.

6. Install the main wheel on the axle using a 5/32" [4mm]

❏

wheel collar on either side of the wheel. Use thread locking

compound on the 6-32 set screws and tighten the set screws

against the flat spots. Add a drop of light weight household

machine oil between the axle and the wheel and check that

the wheel spins freely.

Let’s finish assembling the fuselage before putting the wheel

pants on.

3. Test fit the horizontal tail to the fuselage. Align the slot

❏

in the center of the horizontal stab with the slot for the vertical

fin. Test fit the vertical tail.

4. Raise and support the tail of the model and take a few

❏

steps back. Look at the alignment between the horizontal tail

and the wing. If one side of the tail sits higher than the other,

14

Page 15

remove the tail and lightly sand the bottom of the horizontal

stab slot on the high side and the top of the slot on the low

side. Re-fit the horizontal and vertical tail and check the

alignment once again.

5. Using a large builder’s triangle, check the vertical tail to

❏

see that it is square with the horizontal tail.

Tailwheel and Rudder Installation

1. Clean the surface of the plastic tailwheel bushing using

❏

denatured alcohol. Sand the bent portion of the tailwheel

wire. Apply a drop of oil onto the tailwheel wire to prevent the

wire from being glued to the bushing.

6. Pull the vertical fin out of the fuselage. Using a toothpick

❏

apply 30-minute epoxy to the top of the horizontal stabilizer,

through the vertical fin slot. Glue the horizontal and vertical

tail to the fuselage using thin CA. Wick several generous

beads of CA into the tail to fuselage joints. Remember to

apply glue to both sides and the top and bottom of the

horizontal stabilizer.

7. Remove the wing.

❏

2. Insert the tailwheel assembly into the fuselage from

❏

the bottom. Using 6-minute epoxy, glue the tailwheel bushing

into the fuselage. Don’t get epoxy in the bushing or on the

wire.

15

Page 16

3. Prepare three CA hinges by

❏

poking a T-pin through the center

of the hinge.

4. Test fit the hinges in the slot of the vertical fin. Then,

❏

test fit the rudder onto the hinges. If you are having trouble

fitting the hinges into the fin or the rudder, use the back of a

hobby knife to dig out the hinge slot.

6. Fit the rudder onto the hinges and the tailwheel wire.

❏

Push the rudder forward up against the fin and remove the

T-pins. Slide the rudder up or down until the top of the rudder

is even with the top of the fin. Deflect the rudder left and

right a few times. Hold the rudder to one side and apply 5-7

drops of thin CA to each hinge. Deflect the rudder in the

opposite direction and apply 5-7 drops of CA to the other

side of each hinge. Clean up any excess CA using a paper

towel, dampened with CA debonder.

Servo Installation

5. Using a toothpick, apply some 6-minute epoxy to the hole

❏

in the rudder for the tailwheel wire. Apply a bit of epoxy to the

tip of the tailwheel wire. Proceed immediately to the next step.

1. Prepare two 36" [914mm] pushrods using two nylon

❏

clevises and two silicone clevis retainers. Thread the clevis

onto the pushrod so that at least 1/8" [3.2mm] of thread

protrudes past the barrel of the clevis.

16

Page 17

2. Fit one pushrod into the elevator pushrod guide tube on

❏

the left side of the fuselage.

4. Drill two 3/32" [2.4mm] holes completely through the

❏

elevator.

5. Install the control horn using the backing plate and two

❏

2-56 x 1/2" [12.7mm] machine screws. Fit the clevis to the

outermost hole in the control horn.

3. Cut the backing plate from the large control horn and set

❏

it aside for now. Align the center of the control horn directly

over the arm of the elevator torque rod as shown in the sketch.

Make sure that the horn is also aligned fore and aft so that the

pushrod holes are directly over the hingeline. Using the horn

as a guide, mark the location of the mounting holes.

6. Clip the excess length of pushrod to allow you to work

❏

with the elevator pushrod easily. Prepare a servo using a

standard arm so that the servo arm is 90° to the servo case.

Fit it to the servo tray so that the second hole outboard or

the hole that is 13/32" [10.3mm] outboard of the center of the

servo shaft is lined up with the pushrod. Use a 1/16" [1.6mm]

drill to drill two holes for the servo. Install the servo using

the screws that came with your servo. As before, harded the

threads in the wood with thin CA.

17

Page 18

7. Drill the servo arm at the second hole outboard using

❏

a 5/64 [2mm] drill. Hold the elevators at zero throw and mark

where to bend the elevator pushrod.

and a #6 lock nut to secure the screw. Now screw a nylon

torque rod horn onto the threaded end of the screw so that it

is flush with the end. Connect the clevis.

11. Prepare a servo. Install the rudder servo the same

❏

way you installed the elevator servo. Bend the pushrod 90°

and trim the excess pushrod so that at least 1/4" [6.4mm] of

pushrod remains. Connect the pushrod to the second hole of

the servo arm using a nylon Faslink to secure it.

8. Bend the pushrod 90° and trim the excess pushrod so

❏

that at least 1/4" [6.4mm] of pushrod remains. Connect the

pushrod to the second hole of the servo arm. Use a nylon

Faslink to secure the pushrod.

9. Fit the other pushrod to the rudder guide tube on the

❏

right side of the fuselage.

MOTOR, ESC, & RADIO INSTALLATION

1. Install the

❏

standard X-mount

to the back of the

Rimfire .32 motor

using the screws

supplied with the

motor. Apply a drop

of threadlocker to

the threads before

installing the screws.

10. Assemble the rudder horn as shown in the sketch. Fit

❏

a #6 flat washer under the head of the 6-32 x 2" machine

screw and fit the screw to the rudder so that the head of the

screw is on the left side of the rudder. Use a #6 flat washer

2. Orient the motor wires as shown and attach the motor

❏

to the firewall with four 4-40 x 1/2" socket head cap screws,

four #4 lock washers and four #4 flat washers. Use thread

locking compound on the screw threads for added security.

18

Page 19

3. Mix up some 6-minute epoxy and thin it down with

❏

some denatured alcohol. Brush it onto the ESC tray and the

battery tray to prepare the wood. Allow the epoxy to cure.

4. Cut 5" of non-adhesive backed hook and loop material.

❏

Separate the hook side from the loop side and join the two

pieces so that 1-1/2" [38mm] overlaps in the middle.

6. Cut a 1-1/2" [38mm] piece of adhesive backed hook

❏

and loop material. Stick one side to the back of the ESC and

the other side to the ESC tray. Clean the back side of your

ESC with some denatured alcohol before you stick the hook

and loop material onto it.

7. Glue the ESC tray into the fuselage as shown. Fit the

❏

ESC. Connect the ESC leads to the motor leads.

5. Cut a 1-1/4" [32mm] and a 3/4" [19.1mm] piece of adhesive

❏

backed hook and loop material. Stick the hook side to the battery

tray as shown. Fit the strap you made to the battery tray

.

8. Use the remaining adhesive backed hook and loop

❏

material to attach your receiver to the radio equipment tray.

Connect the elevator and rudder servo leads to the receiver.

Plug a Y-connector into the aileron channel and a Y-connector

into the flap channel (if you are using flaps). Connect the

ESC servo plug to the throttle channel on your receiver.

19

Page 20

9. Test the motor for proper operation. If the motor does

❏

not spin in the correct direction, unplug two of the motor

wires from the ESC and swap the position of the two wires.

Test the motor once again to confirm. Warning: Do not install

the propeller until you have performed this check and have

determined that the motor works properly.

COWL & PROPELLER INSTALLATION

1. Cut out the center of the dummy engine to allow access

❏

for the prop adapter. Use a rotary tool with a sanding drum

to smooth the edges.

10. If you have a 72MHz radio system, route your antenna

❏

through the antenna tube.

11. Route the Y-connector(s) through the cabin floor

❏

panel. Hold the panel in place against the pre-installed rails

and drill six 1/16" [1.6mm] holes into the rails using the holes

in the floor panel as guides. Install the cabin floor using six

#2 x 3/8" sheetmetal screws and six #2 flat washers.

2. Pushrod tubes are provided for you if you choose to

❏

detail the dummy engine. Drill a hole in the bottom of the

rocker cover and a corresponding hole in the crank case using

a 3/32" [2.4mm] drill. To start the hole, use your hobby knife

and poke a small “starter hole” to keep your drill centered.

3. Install the aluminum pushrod tubes from the inside.

❏

Glue them in place.

20

Page 21

4. Use a sharp hobby knife or small sanding drum to

❏

remove the plastic between the dummy engine cylinders.

Leave a 20mm wide ring around the edge of the dummy

engine. Use sand paper to remove the paint from the lip of

the dummy engine. Clean the lip using denatured alcohol.

5. Sand the inside of the cowl near the rear lip and where

❏

the dummy engine will mount. Clean the surfaces you just

sanded using denatured alcohol.

#4 lock washers and four #4 flat washers. Use a 3/32" ball

wrench (GPMR8002) to tighten the screws.

8. Slide the cowl over the cowl ring and center the motor

❏

prop adapter in the dummy engine. Install a propeller to

check that it rotates without rubbing on the cowl or dummy

engine. Make any adjustments to the dummy engine or cowl

so that the propeller spins freely. Note: The cowl ring should

be at the back edge of the cowl when everything is positioned

correctly.

6. Fit the dummy engine inside the cowl. Position it as far

❏

forward as possible, aligning the rocker arm covers with the

blisters on the cowl. Apply epoxy along the seam between

the dummy engine and the cowl.

7. Temporarily attach the plywood cowl ring to the fuselage

❏

with four 4-40 x 1/2" [13mm] socket head cap screws, four

9. Remove the cowl and the cowl ring. Cut the fuselage

❏

bag (you did keep the bag, right?) 12" [305mm] from the

closed end. Slide the bag over the front of the fuselage. A

hole will need to be cut for the motor. Also cut four small

holes for the cowl ring screws. Reinstall the cowl ring with the

4-40 x 1/2" [13mm] socket head screws.

21

Page 22

10. Apply a thin layer of 6-minute epoxy along the inside

❏

edge of the cowl. Slide the cowl over the cowl ring and

position the cowl so that one of the dummy engine cylinders

is straight up and the prop adapter is centered.

FINAL ASSEMBLY

1.

Connect the aileron and flap servo leads to the

❏

Y-connectors. Install the wing using two 1/4-20 nylon wing bolts.

2. Identify the two right wing struts. Use the picture above

❏

to identify the proper orientation of each strut.

11. Once the epoxy has cured, remove the cowl and

❏

plastic bag. To increase the strength of the joint between the

cowl and cowl ring, apply a small fillet of epoxy on the inside

of the cowl ring.

12. Once the epoxy has cured, reinstall the cowl using

❏

the 4-40 x 1/2" [13mm] socket head cap screws, #4 lock

washers and #4 flat washers.

3. Turn the model over and install the wing struts onto

❏

the wing and the fuselage using three 2-56 x 1/2" [12.7mm]

machine screws, three #2 lock washers, and three #2 flat

washers. Add a bit of thread locking compound to the screw

threads for added security. Lay the front strut over the rear

strut at the fuselage attachment point. Then, install the screw.

4. Identify the left wing struts and install them using

❏

three 2-56 x 1/2" [12.7mm] machine screws, three #2 lock

washers, and three #2 flat washers.

13. Install the propeller using the prop washer and nut

❏

that came with the motor. Tighten the prop nut securely.

5. Install the left and right wheel pants using four 4-40 x

❏

1/2" [12.7mm] SHCS, four #4 lock washers, and four #4 flat

washers.

22

Page 23

Pilot Installation (Optional)

Apply the Decals

To install a pilot figure, please use the Great Planes 1/5th

scale sport pilot. This is available in red, yellow, or blue. Please

see the parts list earlier in this manual for these part numbers.

1. Cut the pilot figure down to 3" [76mm] using a razor

❏

saw or your hobby knife. Sand the bottom of the figure flat

using a belt sander or a sanding block.

1. Be certain the model is clean and free from oily fingerprints

and dust. Prepare a dishpan or small bucket with a mixture

of liquid dish soap and warm water—about one teaspoon of

soap per gallon of water. Submerse the decal in the soap

and water and peel off the paper backing. Note: Even though

the decals have a “sticky-back” and are not the water transfer

type, submersing them in soap & water allows accurate

positioning and reduces air bubbles underneath.

2. Position decal on the model where desired. Use the

photos on the box for reference. Holding the decal down,

use a paper towel to wipe most of the water away.

3. Use a piece of soft balsa or something similar to squeegee

remaining water from under the decal. Apply the rest of the

decals the same way.

2. Sand the inside surface of the pilot figure and clean it

❏

with denatured alcohol. Cut and glue a wooden base (not

included) inside the pilot figure using 6-minute epoxy. Let the

epoxy cure.

3. Glue the pilot figure in the cockpit.

❏

4. Install the canopy.

❏

4. We have also included a template for the passenger door.

Turn to the back of this manual and cut this out. Hold it up to

the right hand side of the model and trace the outline of the

door onto the fuselage using a panel line pen.

GET THE MODEL READY TO FLY

Center the Controls and

Check the Control Directions

Warning: Once the battery is connected to the ESC, stay

clear of the propeller!

1. Turn on the transmitter, center the trims, and move the

❏

throttle stick all the way down. Plug your airplane’s battery

into the ESC.

2. Check to see that the controls are centered. If any

❏

control requires adjustment, remove the clevis and tighten

or loosen it to adjust the length of the pushrod. Tighten the

clevis to “shorten” the pushrod or loosen it to “lengthen” the

pushrod. Reinstall the clevis snapping closed the arms, and

fit the silicone retainer over the clevis arms to secure it. If you

have to remove a servo arm to make an adjustment, don’t

forget to reinstall the locking screw.

23

Page 24

4-CHANNEL RADIO SET UP

(STANDARD MODE 2)

RIGHT AILERON

RUDDER

MOVES

RIGHT

FULL

THROTTLE

3. Make certain that the control surfaces and the throttle

❏

respond in the correct direction as shown in the diagram.

If any of the controls respond in the wrong direction, use

the servo reversing in the transmitter to reverse the servos

connected to those controls. Be certain the control surfaces

have remained centered. Adjust if necessary.

MOVES UP

LEFT AILERON

MOVES DOWN

ELEVATOR

MOVES DOWN

1. Use a Great Planes AccuThrow™ gauge, a ruler, or an

❏

inclinometer to accurately measure and set the control throw

of each control surface as indicated in the chart that follows.

If your radio does not have dual rates, we recommend

setting the throws at the LOW rate setting. Under normal

circumstances, and if you have both high and low rates set

up, you will perform takeoffs and landings using high rate

aileron and elevator and then switch to low rates for flight.

With this model, we recommend using high rate rudder only

during taxi on the ground. Switch to low rate rudder before

you initiate your takeoff.

2. When setting up flaps for this model, please use only

❏

the amount that we suggest below. This is the right amount

required to slow the model down without causing it to balloon

up excessively.

Set the Control Throws

To ensure a successful first flight, fly your model set up only

according to the C.G. and control surface throws specified in

this manual. The throws and C.G. are not arbitrary, but have

been determined through extensive testing and accurate

record-keeping. This provides you with the best chance for

success and enjoyable first flights that should be surprisefree. Additionally, the throws and C.G. shown are true, real

data which will allow the model to perform in the manner in

which it was intended when flown by a pilot of the skill level

for which it was intended. DO NOT OVERLOOK THESE

IMPORTANT PROCEDURES. A model that is not properly

setup may be unstable and possibly unflyable.

The building steps earlier in this manual that show the

mechanical setup for the elevator, rudder, and aileron

linkages show you the best way to configure the linkages to

achieve the proper throws using Futaba servos and a Futaba

radio system. If you are using a different radio system or

you cannot achieve the proper control throws using our

suggested linkage configuration, you may have to install the

pushrods in different holes on the servo arms or the control

horns. Keep in mind that changing the throws mechanically

is preferred to changing them using your radio’s end-point

adjustment. End points can be used to “fine-tune” to get the

proper throws.

24

These are the recommended control surface throws:

HIGH RATE LOW RATE

[16 mm]

ELEVATOR

Right

[19 mm]

RUDDERAILERONSFLAPS

[22 mm]

Up

5/8"

12°

3/4"

13°

Up

7/8"

22°

Down

5/8"

[16 mm]

12°

Left

3/4"

[19 mm]

13°

Down

7/8"

[22 mm]

22°

11/16"

[17 mm]

16°

Up

1/2"

[13 mm]

9°

Right

5/8"

[16 mm]

11°

Up

5/8"

[16 mm]

15°

Down

1/2"

[13 mm]

9°

Left

5/8"

[16 mm]

11°

Down

5/8"

[16 mm]

15°

Page 25

Balance the Model (C.G.)

At this stage the model should be in ready-to-fly condition

with all of the systems in place including the motor, prop,

landing gear, radio system, wheel pants, struts, and battery

hatch (canopy).

1. Turn the model over and mark the C.G. location on the

❏

bottom of the wing using a felt-tip pen. The C.G., or balance

point, is located at 2-1/4" [57mm] back from the leading edge

of the wing at the wing root. This is where your plane should

balance and fly for the first few flights. Note: It is permissible

to fly the airplane with the C.G. up to 1/4" [6.4mm] forward or

1/4" [6.4mm] aft of this point. Do not fly outside of the listed

C.G. range!

To ensure a successful first flight, fly your Mr. Mulligan set

up only according to the C.G. and control surface throws

specified in this manual. The throws and C.G. are not

arbitrary, but have been determined through extensive

testing and accurate record-keeping. This provides you

with the best chance for success and enjoyable first flights

that should be surprise-free. Additionally, the throws and

C.G. shown are true, real data which will allow the model to

perform in the manner in which it was intended when flown

by a pilot of the skill level for which it was intended. DO

NOT OVERLOOK THESE IMPORTANT PROCEDURES.

A model that is not properly setup will be dangerous,

unstable, and possibly unflyable.

2. Strap the battery to the battery tray, but do not connect

❏

it. Fit the canopy. Suspend the model upright by placing your

fingers on the marks you made.

3. If the tail drops, the model is “tail heavy” and the battery

❏

pack and/or receiver must be shifted forward or weight must

be added to the nose to balance. If the nose drops, the

model is “nose heavy” and the battery pack and/or receiver

must be shifted aft or weight must be added to the tail to

balance. If possible, relocate the battery pack and receiver

to minimize or eliminate any additional ballast required. If

additional weight is required, nose weight may be easily

added by using a “spinner weight” (GPMQ4645 for the 1 oz.

[28g] weight, or GPMQ4646 for the 2 oz. [57g] weight). If

spinner weight is not practical or is not enough, use Great

Planes (GPMQ4485) “stick-on” lead. A good place to add

stick-on nose weight is to the structure around the firewall

(don’t attach weight to the cowl—it is not intended to support

weight). Begin by placing incrementally increasing amounts

of weight on the bottom of the fuse over the firewall until the

model balances. Once you have determined the amount of

weight required, it can be permanently attached. If required,

tail weight may be added by cutting open the bottom of the

fuse and gluing it permanently inside.

Note: Do not rely upon the adhesive on the back of the lead

weight to permanently hold it in place. Use #2 sheet-metal

screws or epoxy to permanently hold the weight in place.

4. IMPORTANT: If you found it necessary to add any

❏

weight, recheck the C.G. after the weight has been installed.

Balance the Model Laterally

1. With the wings level, have an assistant help you lift

❏

the model by the propeller shaft and the bottom of the fuse

under the TE of the fin. Do this several times.

2. If one wing always drops when you lift the model, it

❏

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been laterally

balanced will track better in loops and other maneuvers.

25

Page 26

PREFLIGHT

MOTOR SAFETY PRECAUTIONS

Identify Your Model

No matter if you fly at an AMA sanctioned R/C club site or

if you fly somewhere on your own, you should always have

your name, address, telephone number and AMA number on

or inside your model. It is required at all AMA R/C club flying

sites and AMA sanctioned flying events. Fill out the included

identification tag on page 29 and place it on or inside your

model.

Balance Propellers

Carefully balance your propeller and spare propellers before

you fly. An unbalanced prop can be the single most significant

cause of vibration that can damage your model. Not only

will motor mounting screws loosen, possibly with disastrous

effect, but vibration may also damage your radio gear.

We use a Top Flite Precision Magnetic Prop Balancer

(TOPQ5700) in the workshop and keep a Great Planes

Fingertip Prop Balancer (GPMQ5000) in our flight box.

Failure to follow these safety precautions may result

in severe injury to yourself and others.

• Get help from an experienced pilot when learning to

operate electric motors.

• Use safety glasses when operating motors.

• Do not operate the motor in an area of loose gravel or sand;

the propeller may throw such material in your face or eyes.

• Keep your face and body as well as all spectators away

from the plane of rotation of the propeller as you operate

the motor.

• Keep these items away from the prop: loose clothing, shirt

sleeves, sweater strings, ties, scarves, long hair or loose

objects such as pencils or screwdrivers that may fall out of

shirt or jacket pockets into the prop.

• Always keep your radio on when plugging the motor

batteries into the ESC.

• Stay clear of the propeller at all times: Some ESC units do

not have safety arming features, so any movement of the

throttle stick may cause the propeller to turn.

• Always use a charger designed to charge LiPo batteries for

charging the LiPo flight battery.

• Never leave the LiPo battery unattended while charging. If

the battery becomes hot, discontinue charging.

AMA SAFETY CODE (EXCERPTS)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model Aviation magazine, the AMA web site or

the Code that came with your AMA license.

Range Check

When you get to your flying site ground check the operational

range of the radio before the first flight of the day. With the

transmitter antenna collapsed or the transmitter in “power

down” mode and the receiver and transmitter on, you should

be able to walk at least 100 feet away from the model and

still have control. Have an assistant stand by your model

and, while you work the controls, tell you what the control

surfaces are doing. Repeat this test with the motor running

at various speeds with an assistant holding the model, using

hand signals to show you what is happening. If the control

surfaces do not respond correctly, do not fly! Find and correct

the problem first. Look for loose servo or battery connections,

damaged wires or a damaged receiver crystal from a previous

crash in another model. One other possible source of radio

“noise” that could cause interference is the arrangement and

relative location of the receiver, receiver antenna and motor

wires. If possible, remount the receiver in a different location

or reroute some of the wires. Then try the range check again.

General

1) I will not fly my model aircraft in sanctioned events, air shows,

or model flying demonstrations until it has been proven to be

airworthy by having been previously, successfully flight tested.

2) I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid flying in the

proximity of full-scale aircraft. Where necessary, an observer

shall be utilized to supervise flying to avoid having models fly

in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

flying site I use, and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

5) I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model. Note: This

does not apply to models while being flown indoors.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

26

Page 27

Radio Control

1) I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of spectators

until I become a qualified flier, unless assisted by an

experienced helper.

3) At all flying sites a straight or curved line(s) must be

established in front of which all flying takes place with the

other side for spectators. Only personnel involved with flying

the aircraft are allowed at or in the front of the flight line.

Intentional flying behind the flight line is prohibited.

4) I will operate my model using only radio control frequencies

currently allowed by the Federal Communications Commission.

5) I will not knowingly operate my model within three

miles of any pre-existing flying site except in accordance

with the frequency sharing agreement listed [in the

complete AMA Safety Code].

9) Under no circumstances may a pilot or other person

touch a powered model in flight; nor should any part of the

model other than the landing gear, intentionally touch

the ground, except while landing.

11. Reinforce holes for wood screws with thin CA where

❏

appropriate (servo mounting screws, etc.).

12. Check that all servo connectors are fully plugged into

❏

their respective channels on the receiver.

13. Make sure any servo extension cords you may have

❏

used do not interfere with other systems (servo arms,

pushrods, etc.).

14. Check the receiver for secure attachment. This must

❏

not be “stuffed into place.”

15. Balance your model laterally as explained in the

❏

instructions.

16. Check the C.G. according to the measurements

❏

provided in the manual.

17. Place your name, address, AMA number and telephone

❏

number on or inside your model.

18. Fully charge your transmitter battery and check the

❏

battery voltage after it is charged.

19. Range-check your radio at the flying field.

❏

20. Confirm that all controls operate in the correct direction

❏

and the throws are set up according to the manual.

21. If you wish to photograph your model, do so before

❏

your first flight.

FLYING

CHECK LIST

During the last few moments of preparation your mind may

be elsewhere anticipating the excitement of the fi rst fl ight.

Because of this, you may be more likely to overlook certain

checks and procedures that should be performed before

the model is fl own. To help avoid this, a check list is provided

to make sure these important areas are not overlooked.

Many are covered in the instruction manual, so where

appropriate, refer to the manual for complete instructions.

Be sure to check the items off as they are completed.

1. Check the motor for secure attachment.

❏

2. Check the cowl for secure attachment.

❏

3. Balance your propeller (and spare propellers).

❏

4. Tighten the propeller nut and check to make sure that a

❏

prop washer is in place.

5. Rotate the propeller a full turn. Check for free rotation

❏

of the prop. Make sure that the dummy engine does not

interfere with rotation.

6. Check the wheels for free rotation, the axles and landing

❏

gear for security, and add a drop of light machine oil to the

axles.

7. Make sure all hinges are securely glued in place.

❏

8. Check the control horns for secure attachment to the

❏

control surfaces.

9. Pull/push on each of the pushrods and check to see that

❏

the adjustable pushrod connectors do not slip.

10. Check the servo arms for secure attachment and make

❏

sure that the arm screws are in place and are tight.

CAUTION (THIS APPLIES TO ALL R/C AIRPLANES): If,

while flying, you notice an alarming or unusual sound such

as a low-pitched “buzz,” this may indicate control surface

flutter. Flutter occurs when a control surface (such as an

aileron or elevator) or a flying surface (such as a wing or

stab) rapidly vibrates up and down (thus causing the noise).

In extreme cases, if not detected immediately, flutter can

actually cause the control surface to detach or the flying

surface to fail, thus causing loss of control followed by

an impending crash. The best thing to do when flutter is

detected is to slow the model immediately by reducing

power, then land as soon as safely possible. Identify which

surface fluttered (so the problem may be resolved) by

checking all the servo grommets for deterioration or signs of

vibration. Make certain all pushrod linkages are secure and

free of play. If it fluttered once, under similar circumstances

it will probably flutter again unless the problem is fixed.

Some things which can cause flutter are; Excessive hinge

gap; Not mounting control horns solidly; Poor fit of clevis

pin in horn; Side-play of wire pushrods caused by large

bends; Excessive free play in servo gears; Insecure servo

mounting; and one of the most prevalent causes of flutter;

Flying an overpowered model at excessive speeds.

Takeoff

The goals of your first flight should be to trim the airplane

Before you get ready to takeoff, see how the model handles

on the ground by doing a few practice runs at low speeds on

the runway. Hold “up” elevator to keep the tail wheel on the

ground. If necessary, adjust the tail wheel so the model will

roll straight down the runway.

27

Page 28

Takeoff directly into the wind. Gradually advance the throttle

while holding a bit of up elevator to keep the tail on the ground

to maintain tail wheel steering. Also start applying right rudder.

If the throttle is advanced too quickly, the plane will want to

turn quickly to the left. As the model gains speed, decrease

up elevator allowing the tail to come off the ground. Gain as

much speed as your runway and flying site will practically

allow before gently applying up elevator, lifting the model into

the air. Be smooth on the elevator stick, allowing the model to

establish a gentle climb to a safe altitude before turning into

the traffic pattern.

Flight

For reassurance and to keep an eye on other traffic, it is a

good idea to have an assistant on the flight line with you. On

the first flight the assistant can help you adjust the trims.

In the air, the Mister Mulligan flies similar to a sport plane.

It can perform the basic aerobatic maneuvers; loops, rolls,

stall turns and wing overs. Be mindful of the flight time. With

electric planes it is best to have a timer set so that the plane

can be landed with power to spare, just in case you have to

abort the landing and go around. A dead stick with an electric

plane is the same as a dead stick with a glow plane. Risky!

Landing

RBefore the battery power drops, make a few passes with

the flaps down to see how the plane slows down. If this is

your first plane equipped with flaps, here are a couple of

notes on how to land with flaps. Only lower the flaps at half

throttle or less. When the flaps are lowered, the plane will

balloon up slightly, then, level off as the speed slows. On final

approach, keep the power on and control the descent with

the throttle. The plane will land slower with flaps than without.

Don’t let the plane get to slow, even with flaps the plane can

tip stall if it gets too slow.

One final note about flying the Mister Mulligan. Have a goal or

flight plan in mind for every flight. This can be learning a new

maneuver(s), improving a maneuver(s) you already know,

or learning how the model behaves in certain conditions

(such as on high or low rates). This is not necessarily to

improve your skills (though it is never a bad idea!), but more

importantly so you do not surprise yourself by impulsively

attempting a maneuver and suddenly finding that you’ve run

out of time, altitude or airspeed. Every maneuver should be

deliberate, not impulsive. For example, if you’re going to do a

loop, check your altitude, mind the wind direction (anticipating

rudder corrections that will be required to maintain heading),

remember to throttle back at the top, and make certain you

are on the desired rates (high/low rates). A flight plan greatly

reduces the chances of crashing your model just because of

poor planning and impulsive moves. Remember to think.

Have a ball!

But always stay in control and fly in a safe manner.

GOOD LUCKAND GREAT FLYING!

28

Page 29

Cut

Align these dashed lines

with the other windows.

DOOR TEMPLATE

Note: Door is only

on RH side.

Cut

29

This model belongs to:

Name

Address

City, State, Zip

Phone Number

AMA Number

Page 30

NOTES

30

Page 31

31

Page 32

Loading...

Loading...